Submitted:

03 November 2023

Posted:

06 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

| Highly thermal-conductive graphene-based films | In-plane TC (W m-1 K-1) |

Through-plane TC (W m-1 K-1) |

Thickness (μm) | Density (g cm-3) |

|---|---|---|---|---|

| High TC in single direction | ||||

| Graphene paper [7] | 1434 | - | - | 2.1 |

| Graphene-based hybrid film [8] | 1597 | 2.65 | 7 | - |

| GF [33] | 1940 | - | 10 | 2.03 |

| GF [34] | 1043.5 | - | - | - |

| Ultra-thin GF [35] | 3200 | - | 0.8 | 2.1 |

| GF [36] | 1100 | - | 8.1 | |

| Large-sized GF [37] | 803.1 | 3.98 | 14 | 2.05 |

| Ball-milling exfoliated graphene paper [38] | 1529 | - | 30 | 1.8 |

| Glucose modified GF [39] | 1300 | - | - | - |

| Electrochemically exfoliated graphene paper [40] | 1022.8 | - | - | - |

| Bidirectional high TC | ||||

| Vertical carbon nanotube@SiC-graphene film [14] | 397.9 | 41.7 | 200 | - |

| Graphene/nanocopper film [24] | 234.9 | 5.22 | - | - |

| Graphene-SiO2@C film [26] | 36.54 | 6.65 | - | - |

| Graphene-carbon nantube [27] | 933.37 | 6.27 | 106 | 0.985 |

| Graphene-carbon nanotube-graphite film [28] | 182.6 | 32.96 | 6000 | 1.67 |

| Graphene hybrid paper [30] | 263 | 17.6 | 500 | 0.8 |

| Carbon Nanoring/Graphene Hybrid Paper [31] | 890 | 5.81 | - | - |

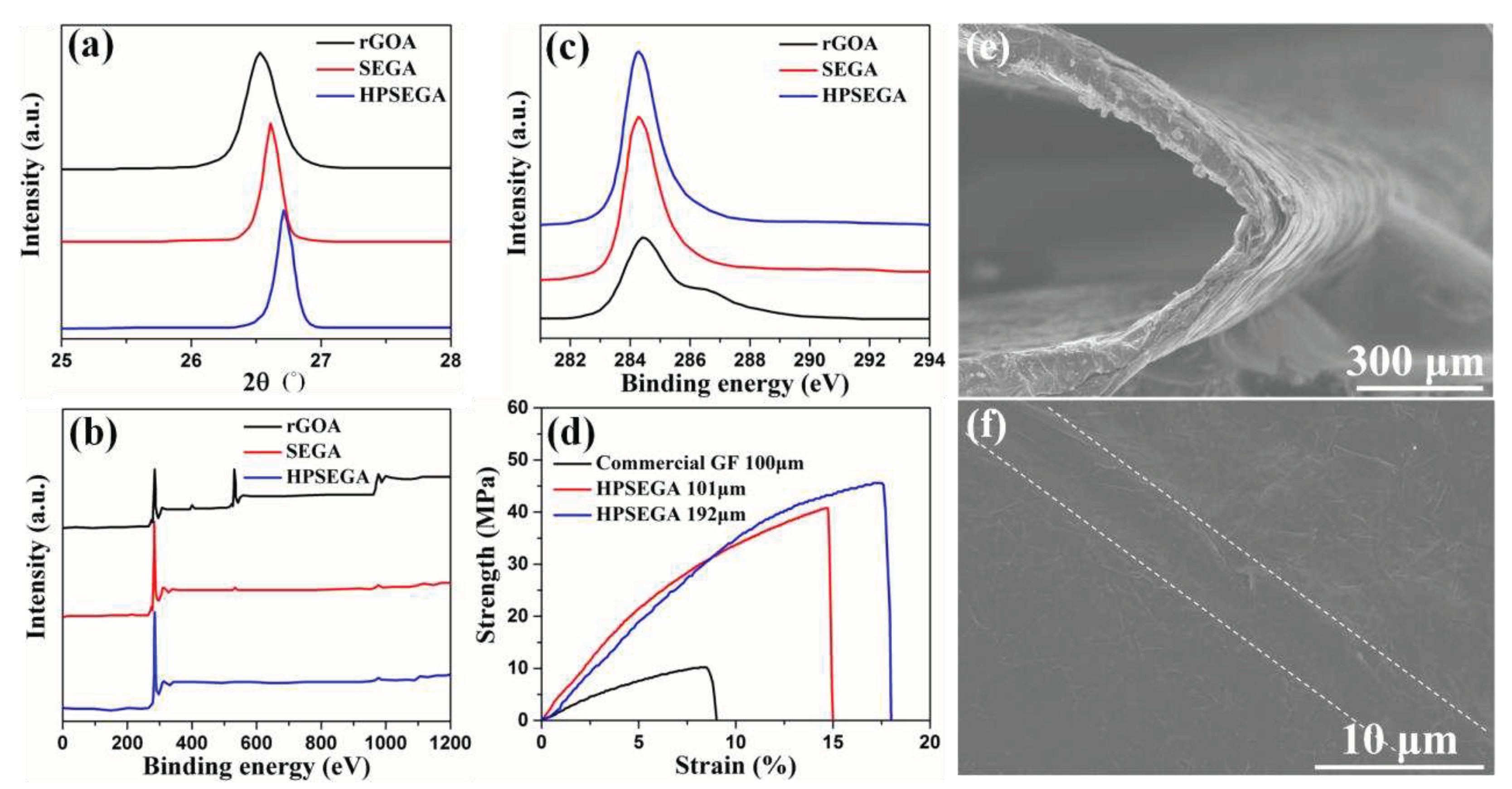

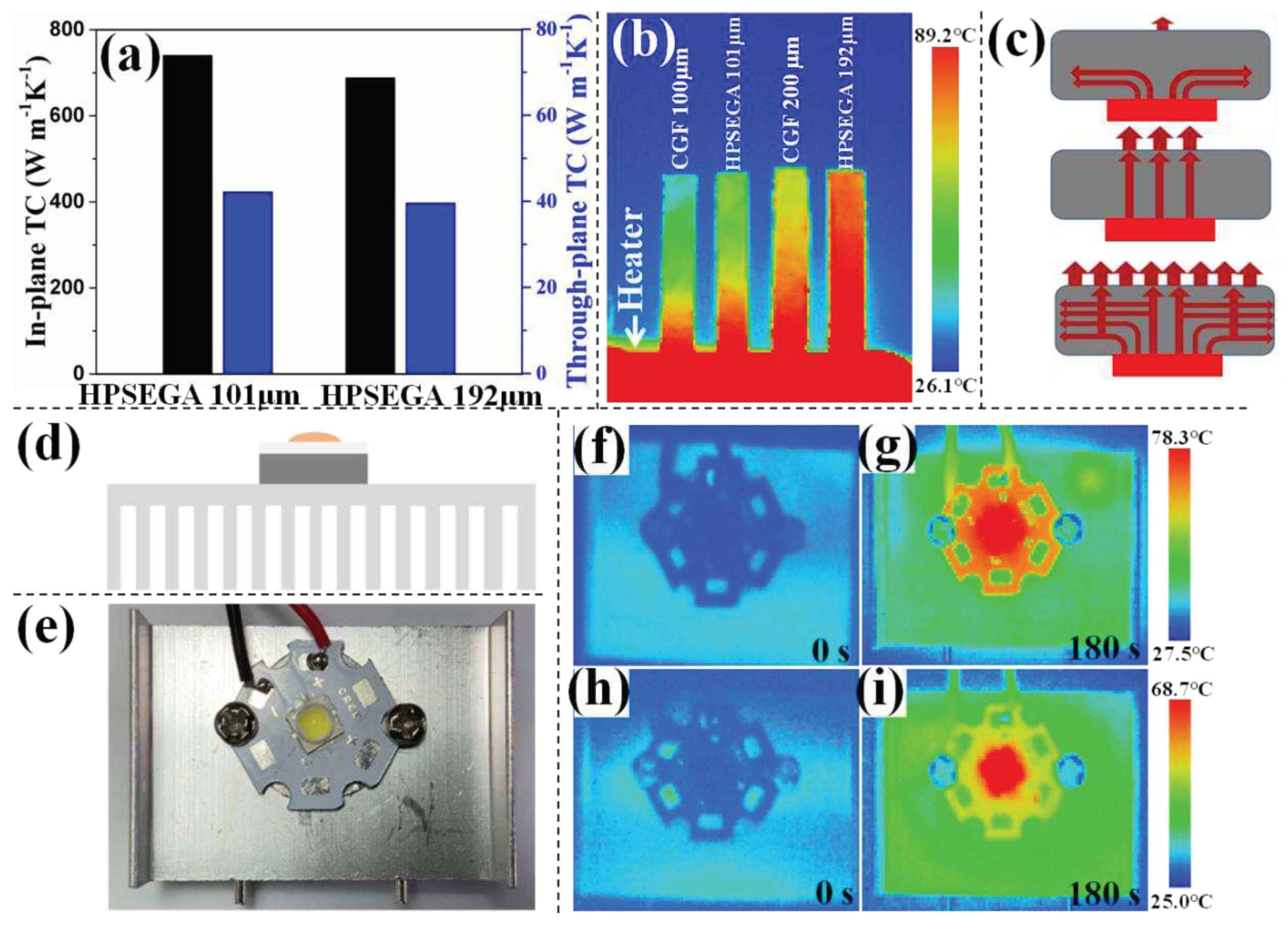

| This work | 740.3 | 42.5 | 101 | 1.35 |

| 688.1 | 39.6 | 192 | 1.57 | |

2. Materials and Methods

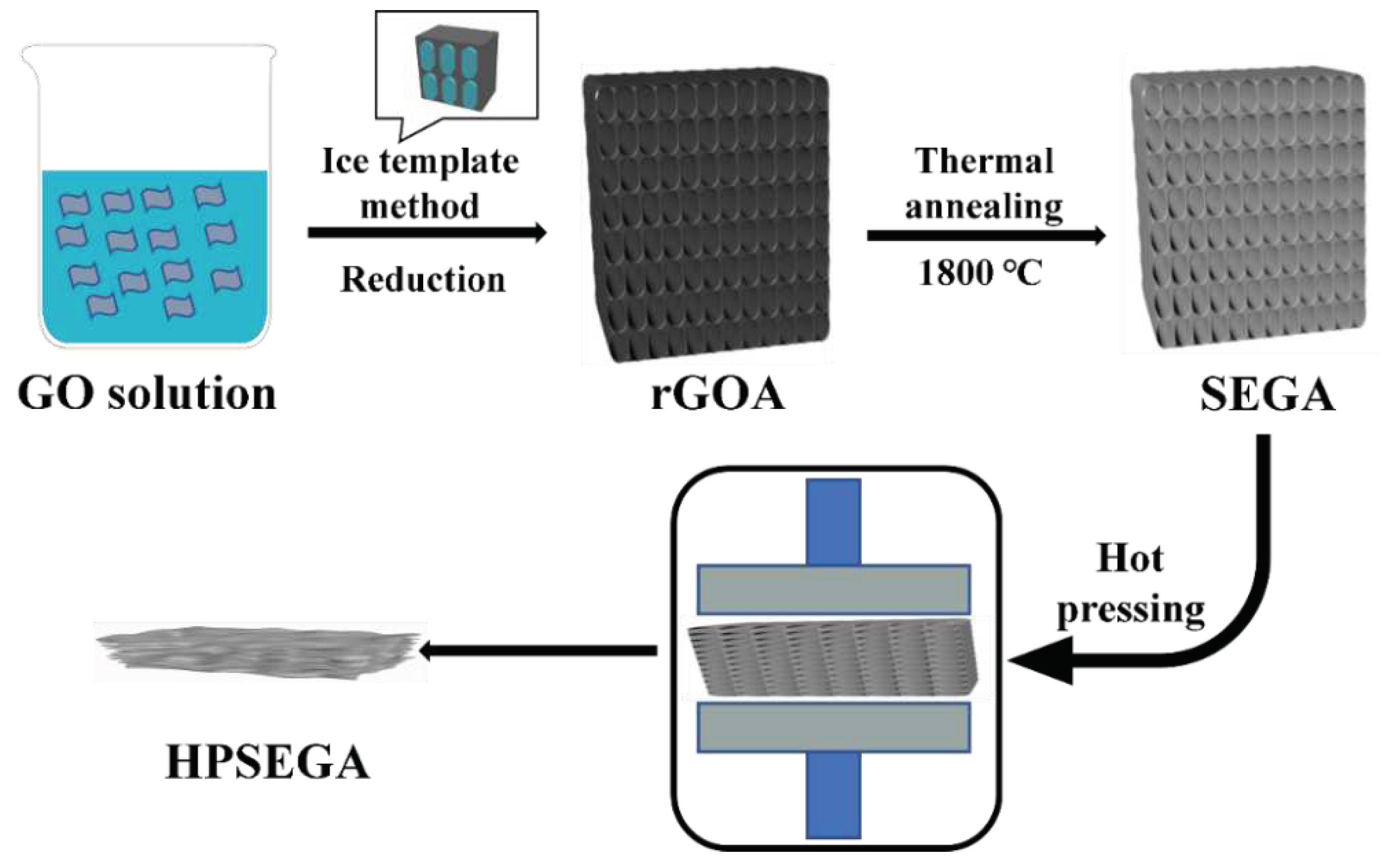

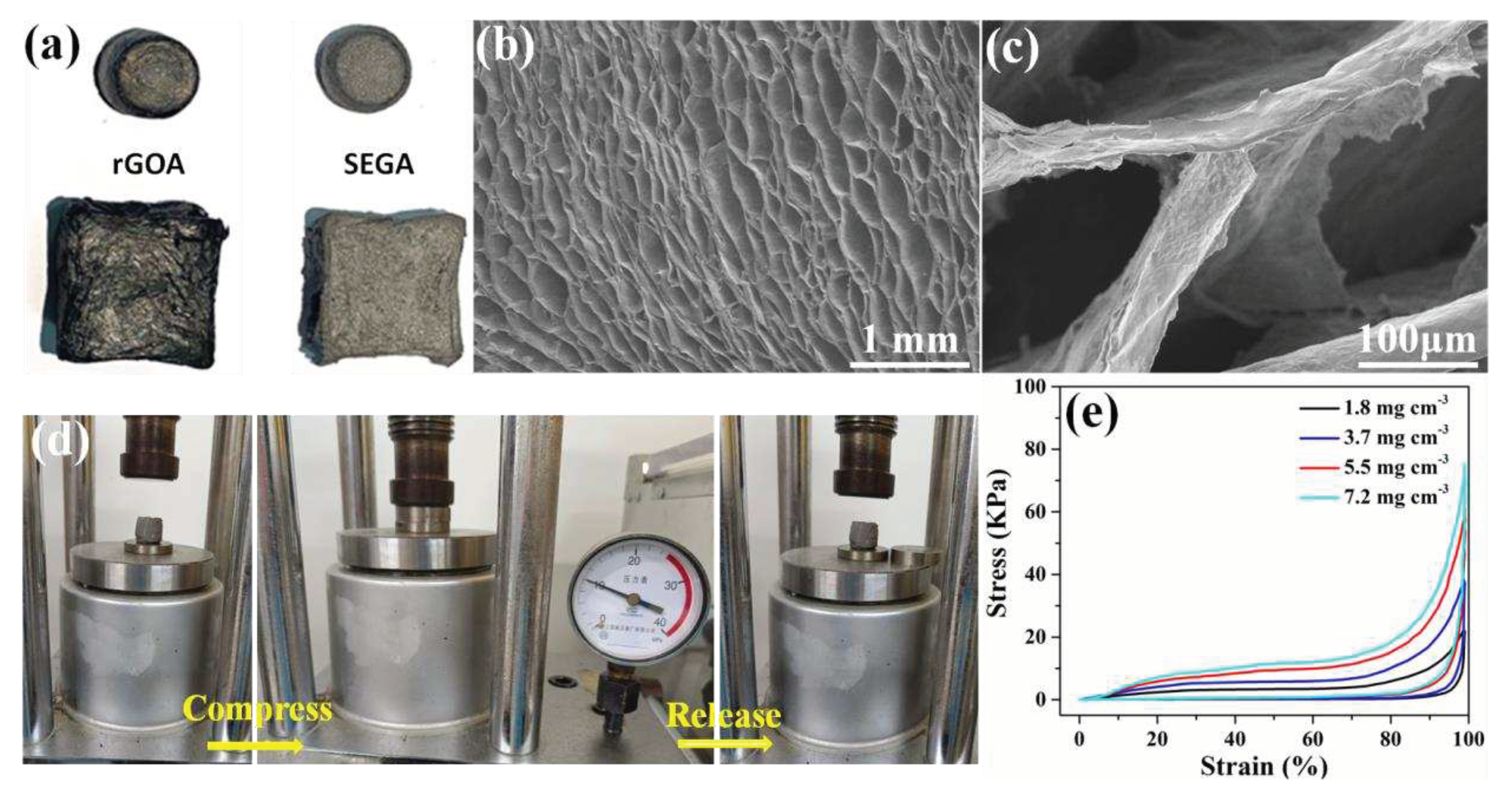

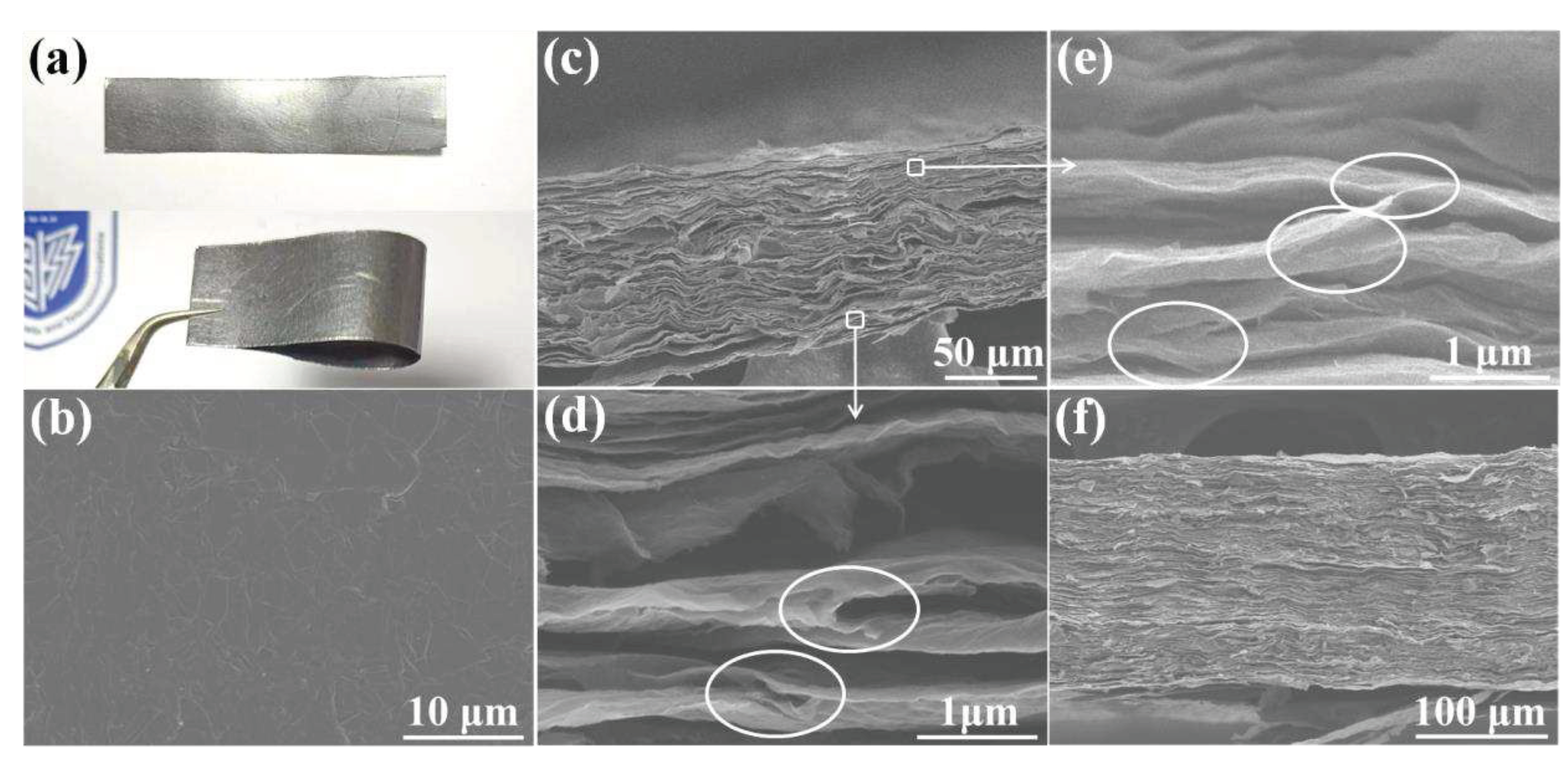

2.1. Preparation of HPSEGA film

2.2. Characterization

3. Results and discussion

4. Conclusions

Supplementary Materials

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, J.; Momin, S. A.; Mariatti, M. A review on advanced carbon-based thermal interface materials for electronic devices. Carbon 2020, 168, 65-112. [CrossRef]

- Zhang, F.; Feng, Y. Y.; Feng, W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Materials Science & Engineering R. 2020, 142, 100580. [CrossRef]

- Lv, L.; Dai, W.; Yu, J. H.; Jiang, N.; Lin, C. T. A mini review: application of graphene paper in thermal interface materials. New Carbon Mater. 2021, 36, 930-938. [CrossRef]

- Zhang, Y.; Heo, Y. J.; Son, Y. R.; In, I.; An, K. H.; Kim, B. J.; Park, S. J. Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials. Carbon 2019, 142, 445-460. [CrossRef]

- Feng, C. P.; Chen, L. B.; Tian, G. L.; Wan, S. S.; Bai, L.; Bao, R. Y.; Liu, Z. Y.; Yang, M. B.; Yang, W. Multifunctional thermal management materials with excellent heat dissipation and generation capability for future electronics. ACS Appl. Mater. Interfaces 2019, 11, 18739-18745. [CrossRef]

- Hou, Z. L.; Song, W. L.; Wang, P.; Meziani, M. J.; Kong, C. Y.; Anderson, A.; Maimaiti, H.; LeCroy, G. E.; Qian, H.; Sun, Y. P. Flexible graphene–graphene composites of superior thermal and electrical transport properties. ACS Appl. Mater. Interfaces 2014, 6, 15026-15032. [CrossRef]

- Xin, G. Q.; Sun, H. T.; Hu, T.; Fard, H. R.; Sun, X.; Koratkar, N.; Borca-Tasciuc, T.; Lian, J. Large-area freestanding graphene paper for superior thermal management. Adv. Mater. 2014, 26, 4521-4526. [CrossRef]

- Zou, R.; Liu, F.; Hu, N.; Ning, H. M.; Gong, Y. K.; Wang, S.; Huang, K. Y.; Jiang, X. P.; Xu, C. H.; Fu, S. Y.; Li, Y. Q.; Yan, C. Graphene/graphitized polydopamine/carbon nanotube all-carbon ternary composite films with improved mechanical properties and through-plane thermal conductivity. ACS Appl. Mater. Interfaces 2020, 12, 57391-57400. [CrossRef]

- Yang, G.; Yi, H. K.; Yao, Y. G.; Li, C. W.; Li, Z. Thermally conductive graphene films for heat dissipation. ACS Appl. Nano Mater. 2020, 3, 2149-2155. [CrossRef]

- Chen, S. J.; Wang, Q. L.; Zhang, M. M.; Huang, R. Z.; Huang, Y. Y.; Tang, J.; Liu, J. H. Scalable production of thick graphene films for next generation thermal management applications. Carbon 2020, 167, 270-277. [CrossRef]

- Malekpour, H.; Chang, K. H.; Chen, J. C.; Lu, C. Y.; Nika, D. L.; Novoselov, K. S.; Balandin, A. A. Thermal conductivity of graphene laminate. Nano Lett. 2014, 14, 5155-5161. [CrossRef]

- Liu, L.; Bian, X. M.; Tang, J.; Xu, H.; Hou, Z. L.; Song, W. L. Exceptional electrical and thermal transport properties in tunable all-graphene papers. RSC Adv. 2015, 5, 75239-75247. [CrossRef]

- Dai, W.; Ma, T. F.; Yan, Q. W.; Gao, J. Y.; Tan, X.; Lv, L.; Hou, H.; Wei, Q. P.; Yu, J. H.; Wu, J. B.; Yao, Y. G.; Du, S. Y.; Sun, R.; Jiang, N.; Wang, Y.; Kong, J.; Wong, C. P.; Maruyama, S.; Lin, C. T. Metal-level thermally conductive yet soft graphene thermal interface materials. ACS Nano 2019, 13, 11561-11571. [CrossRef]

- Peng, L.; Yu, H.; Chen, C.; He, Q.; Zhang, H.; Zhao, F.; Qin, M.; Feng, Y.; Feng, W. Tailoring dense, orientation-tunable, and interleavedly structured carbon-based heat dissipation plates. Adv. Sci. 2023, 10, 2205962. [CrossRef]

- Li, Y. H.; Zhu, Y. F.; Jiang, G. P.; Cano, Z. P.; Yang, J.; Wang, J.; Liu, J. L.; Chen, X. H.; Chen, Z. W. Boosting the heat dissipation performance of graphene/polyimide flexible carbon film via enhanced through-plane conductivity of 3D hybridized structure. Small 2020, 16, 1903315. [CrossRef]

- Zhou, Y.; Wu, S.; Long, Y.; Zhu, P.; Wu, F.; Liu, F.; Murugadoss, V.; Winchester, W.; Nautiyal, A.; Wang, Z.; Guo, Z. Recent advances in thermal interface materials. ES Mater. Manuf. 2020, 7, 4-24. [CrossRef]

- Xu, S. C.; Wang, S. S.; Chen, Z.; Sun, Y. Y.; Gao, Z. F.; Zhang, H.; Zhang, J. Electric-field-assisted growth of vertical graphene arrays and the application in thermal interface materials. Adv. Funct. Mater. 2020, 30, 2003302. [CrossRef]

- Ci, H. N.; Chang, H. L.; Wang, R. Y.; Wei, T. B.; Wang, Y. Y.; Chen, Z. L.; Sun, Y. W.; Dou, Z. P.; Liu, Z. Q.; Li, J. M.; Gao, P.; Liu, Z. F. Enhancement of heat dissipation in ultraviolet light-emitting diodes by a vertically oriented graphene nanowall buffer layer. Adv. Mater. 2019, 31, 1901624. [CrossRef]

- Lian, G.; Tuan, C. C.; Li, L. Y.; Jiao, S. L.; Wang, Q. L.; Moon, K. S.; Cui, D. L.; Wong, C. P. Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading. Chem. Mater. 2016, 28, 6096-6104. [CrossRef]

- An, F.; Li, X. F.; Min, P.; Liu, P. F.; Jiang, Z. G.; Yu, Z. Z. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl. Mater. Interfaces 2018, 10, 17383-17392. [CrossRef]

- Li, X. H.; Liu, P. F.; Li, X. F.; An, F.; Min, P.; Liao, K. N.; Yu, Z. Z. Vertically aligned, ultralight and highly compressive all-graphitized graphene aerogels for highly thermally conductive polymer composites. Carbon 2018, 140, 624-633. [CrossRef]

- Zhang, Y. F.; Han, D.; Zhao, Y. H.; Bai, S. L. High-performance thermal interface materials consisting of vertically aligned graphene film and polymer. Carbon 2016, 109, 552-557. [CrossRef]

- Xu, S. C.; Zhang, J. Vertically aligned graphene for thermal interface materials. Small Strut. 2020, 1, 2000034. [CrossRef]

- Sun, P. J.; Liu, B. W.; You, Z. Y.; Zheng, Y. M.; Wang, Z. S. Graphene/copper nanoparticles as thermal interface materials. ACS Appl. Nano Mater. 2022, 5, 3450-3457. [CrossRef]

- Xiang, J.; Drzal, L. T. Electron and phonon transport in Au nanoparticle decorated graphene nanoplatelet nanostructured paper. ACS Appl. Mater. Interfaces 2011, 3, 1325-1332. [CrossRef]

- Yu, Y.; Zhao, Y.; Zhang, X.; Wang, L.; Liao, B.; Pang, H. Construction of a 3D thermal transport hybrid via the creation of axial thermal conductive pathways between graphene layers. Mater. Lett. 2022, 307, 130949. [CrossRef]

- Jia, H.; Kong, Q. Q.; Yang, X.; Xie, L. J.; Sun, G. H.; Liang, L. L.; Chen, J. P.; Liu, D.; Guo, Q. G.; Chen, C. M. Dual-functional graphene/carbon nanotubes thick film: Bidirectional thermal dissipation and electromagnetic shielding. Carbon 2021, 171, 329-340. [CrossRef]

- Lv, F.; Qin, M. M.; Zhang, F.; Yu, H. T.; Gao, L.; Lv, P.; Wei, W.; Feng, Y. Y.; Feng, W. High cross-plane thermally conductive hierarchical composite using graphene-coated vertically aligned carbon nanotubes/graphite. Carbon 2019, 149, 281-289. [CrossRef]

- Feng, W.; Qin, M. M.; Lv, P.; Li, J. P.; Feng, Y. Y. A three-dimensional nanostructure of graphite intercalated by carbon nanotubes with high cross-plane thermal conductivity and bending strength. Carbon 2014, 77, 1054-1064. [CrossRef]

- Dai, W.; Lv, L.; Lu, J. B.; Hou, H.; Yan, Q. W.; Alam, F. E.; Li, Y. F.; Zeng, X. L.; Yu, J. H.; Wei, Q. P.; Xu, X. F.; Wu, J. B.; Jiang, N.; Du, S. Y.; Sun, R.; Xu, J. B.; Wong, C. P.; Lin, C. T. A paper-like inorganic thermal interface material composed of hierarchically structured graphene/silicon carbide nanorods. ACS Nano 2019, 13, 1547-1554. [CrossRef]

- Zhang, J. W.; Shi, G.; Jiang, C.; Ju, S.; Jiang, D. Z. 3D bridged carbon nanoring/graphene hybrid paper as a high-performance lateral heat spreader. Small 2015, 11, 6197-6204. [CrossRef]

- Zhang, X. D.; Guo, Y.; Liu, Y. J.; Li, Z.; Fang, W. Z.; Peng, L.; Zhou, J.; Xu, Z.; Gao, C. Ultrathick and highly thermally conductive graphene films by self-fusion. Carbon 2020, 167, 249-255. [CrossRef]

- Peng, L.; Xu, Z.; Liu, Z.; Guo, Y.; Li, P.; Gao, C. Ultrahigh thermal conductive yet superflexible graphene films. Adv. Mater. 2017, 29, 1700589. [CrossRef]

- Song, N. J.; Chen, C. M.; Lu, C. X.; Liu, Z.; Kong, Q. Q.; Cai, R. Thermally reduced graphene oxide films as flexible Lateral heat spreaders. J. Mater. Chem. A 2014, 2, 16563-16568. [CrossRef]

- Wang, N.; Samani, M. K.; Li, H.; Dong, L.; Zhang, Z. W.; Su, P.; Chen, S. J.; Chen, J.; Huang, S. R.; Yuan, G. J.; Xu, X. F.; Li, B. W.; Leifer, K.; Ye, L. L.; Liu, J. Tailoring the thermal and mechanical properties of graphene film by structural engineering. Small 2018, 14, 1801346. [CrossRef]

- Shen, B.; Zhai, W. T.; Zheng, W. G. Ultrathin flexible graphene film: an excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 2014, 24, 4542-4548. [CrossRef]

- Lin, S. F.; Ju, S.; Zhang, J. W.; Shi, G.; He, Y. L.; Jiang, D. Z. Ultrathin flexible graphene films with high thermal conductivity and excellent EMI shielding performance using large-sized graphene oxide flakes. RSC Adv. 2019, 9, 1419-1427. [CrossRef]

- Teng, C.; Xie, D.; Wang, J. F.; Yang, Z.; Ren, G. Y.; Zhu, Y. Ultrahigh conductive graphene paper based on ball-milling exfoliated graphene. Adv. Funct. Mater. 2017, 27, 1700240. [CrossRef]

- Li, J.; Chen, X. Y.; Lei, R. B.; Lai, J. F.; Ma, T. M.; Li, Y. Highly thermally conductive graphene film produced using glucose under low-temperature thermal annealing. J. Mater. Sci. 2019, 54, 7553-7562. [CrossRef]

- Kwon, Y. J.; Kwon, Y.; Park, H. S.; Lee, J. U. Mass-produced electrochemically exfoliated graphene for ultrahigh thermally conductive paper using a multimetal electrode system. Adv. Mater. Interfaces 2019, 6. 1900095. [CrossRef]

- Yang, H.; Zhang, T.; Jiang, M.; Duan, Y.; Zhang, J. Ambient pressure dried graphene aerogels with superelasticity and multifunctionality. J. Mater. Chem. 2015, 3 (38), 19268-19272. [CrossRef]

- Chen, X. J.; Deng, X. M.; Kim, N. Y.; Wang, Y.; Huang, Y.; Peng, L.; Huang, M.; Zhang, X.; Chen, X.; Luo, D.; Wang, B.; Wu, X. Z.; Ma, Y. F.; Lee, Z.; Ruoff, R. S. Graphitization of graphene oxide films under pressure. Carbon 2018, 132, 294-303. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).