Submitted:

27 November 2023

Posted:

29 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

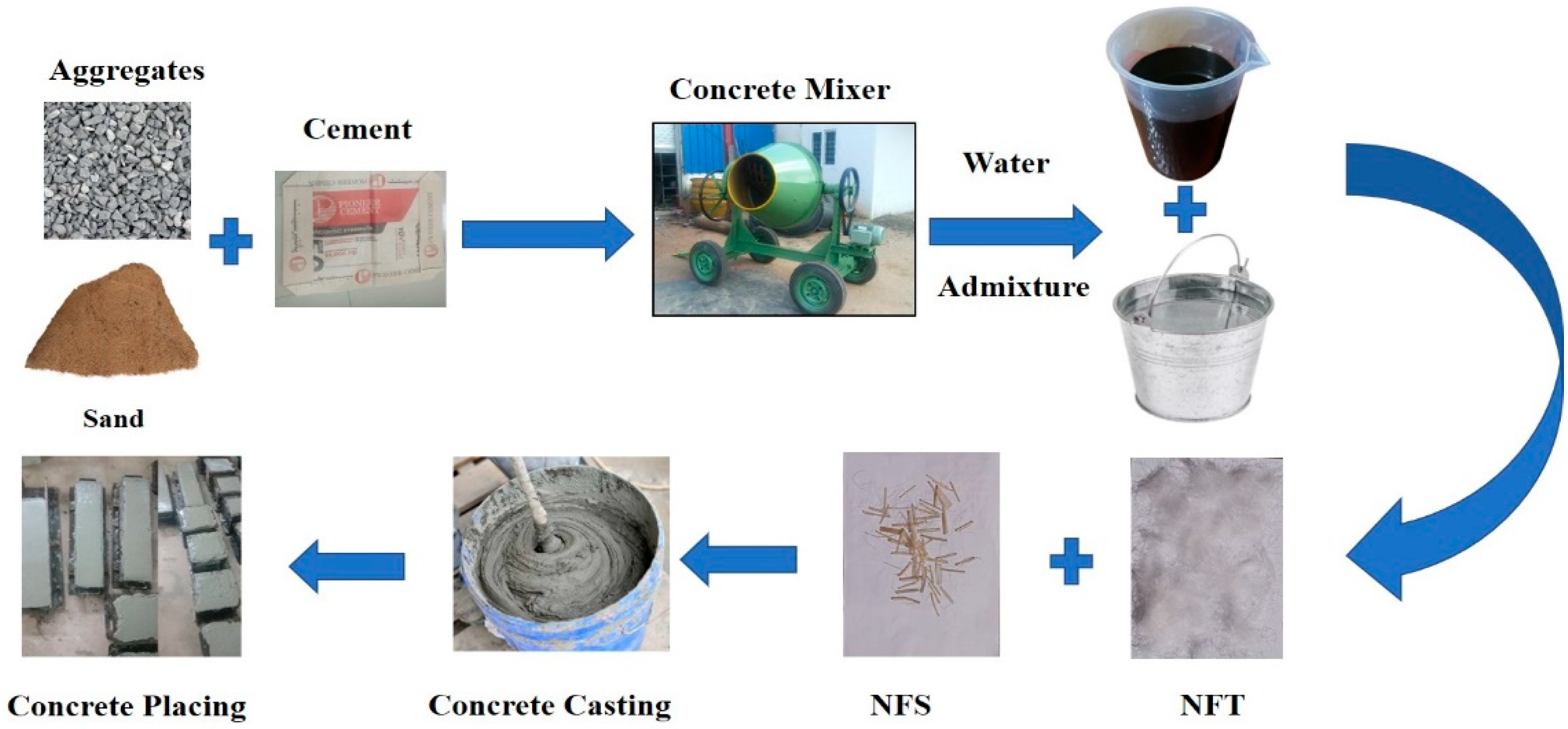

2. Experimental Program

2.1. Materials

2.2. Mix Proportions

2.3. Mixing Procedure

2.4. Preparation of Specimens

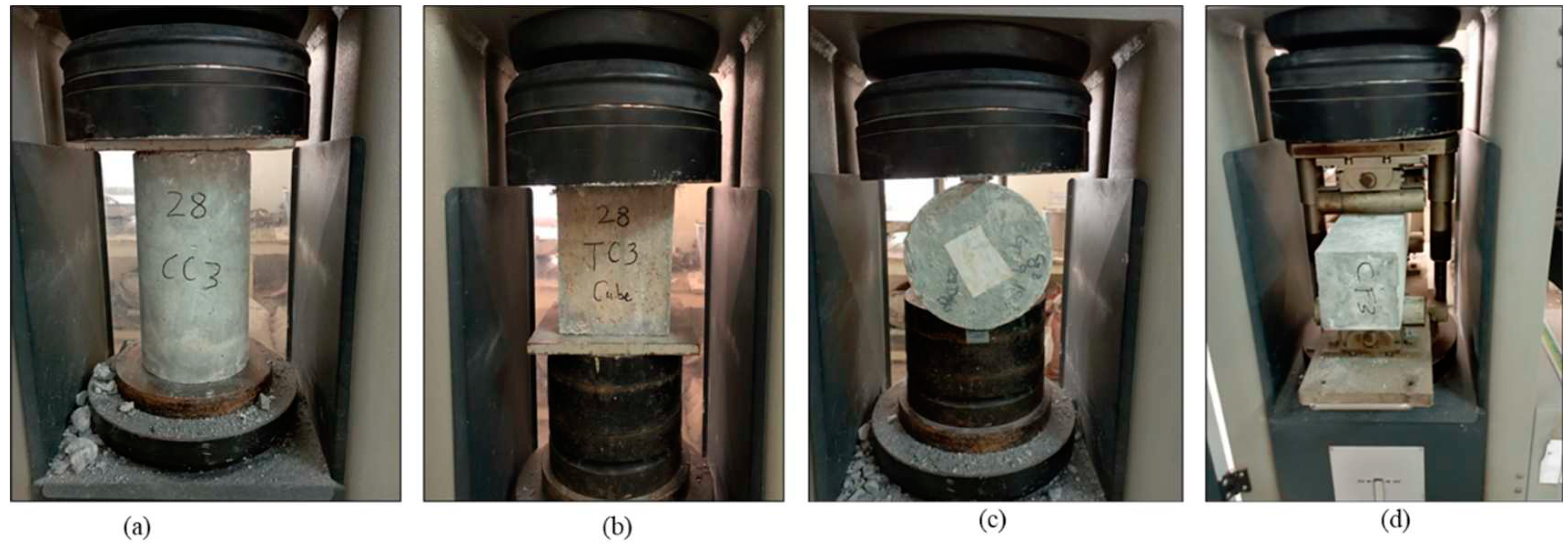

2.5. Methods for Testing

3. Experimental Results and Discussion

3.1. Workability

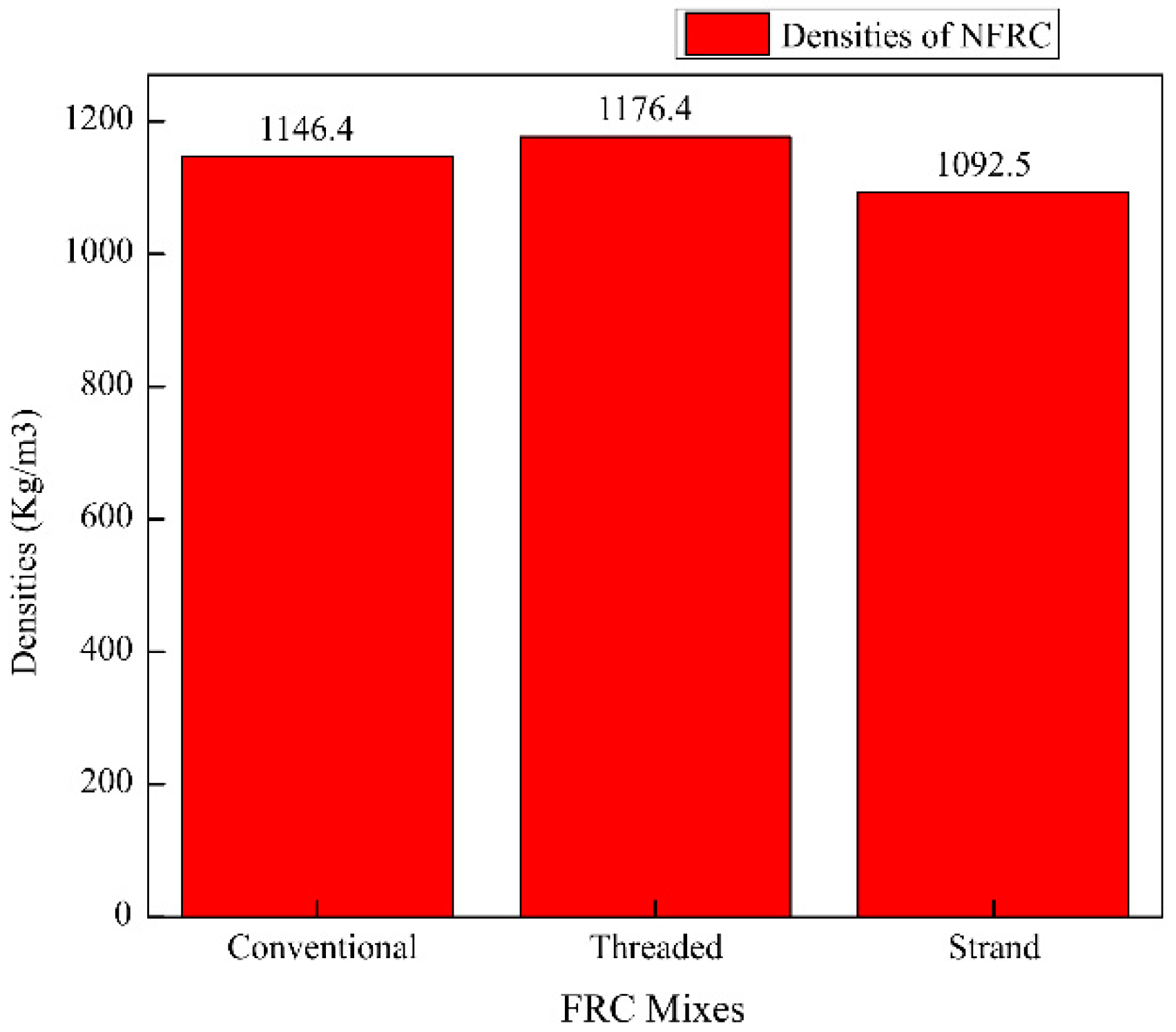

3.2. Density

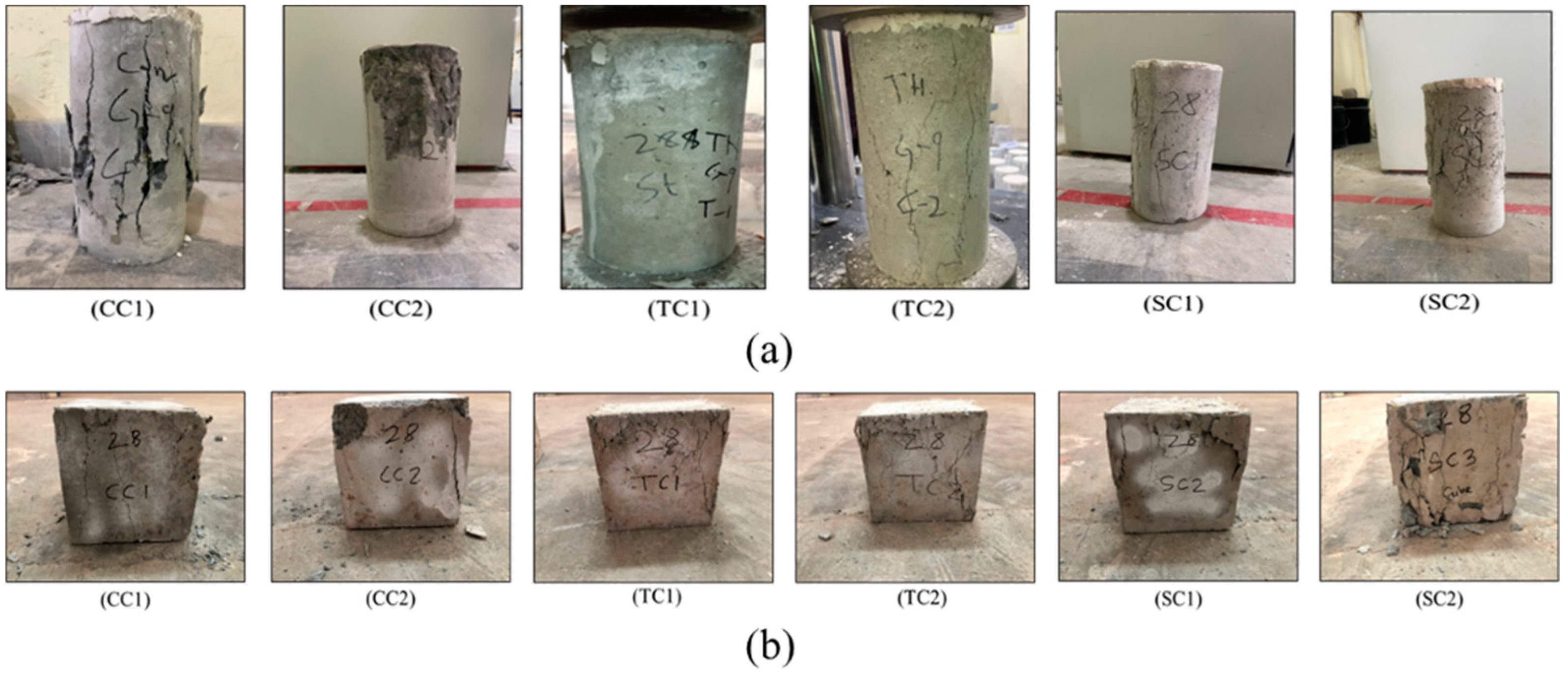

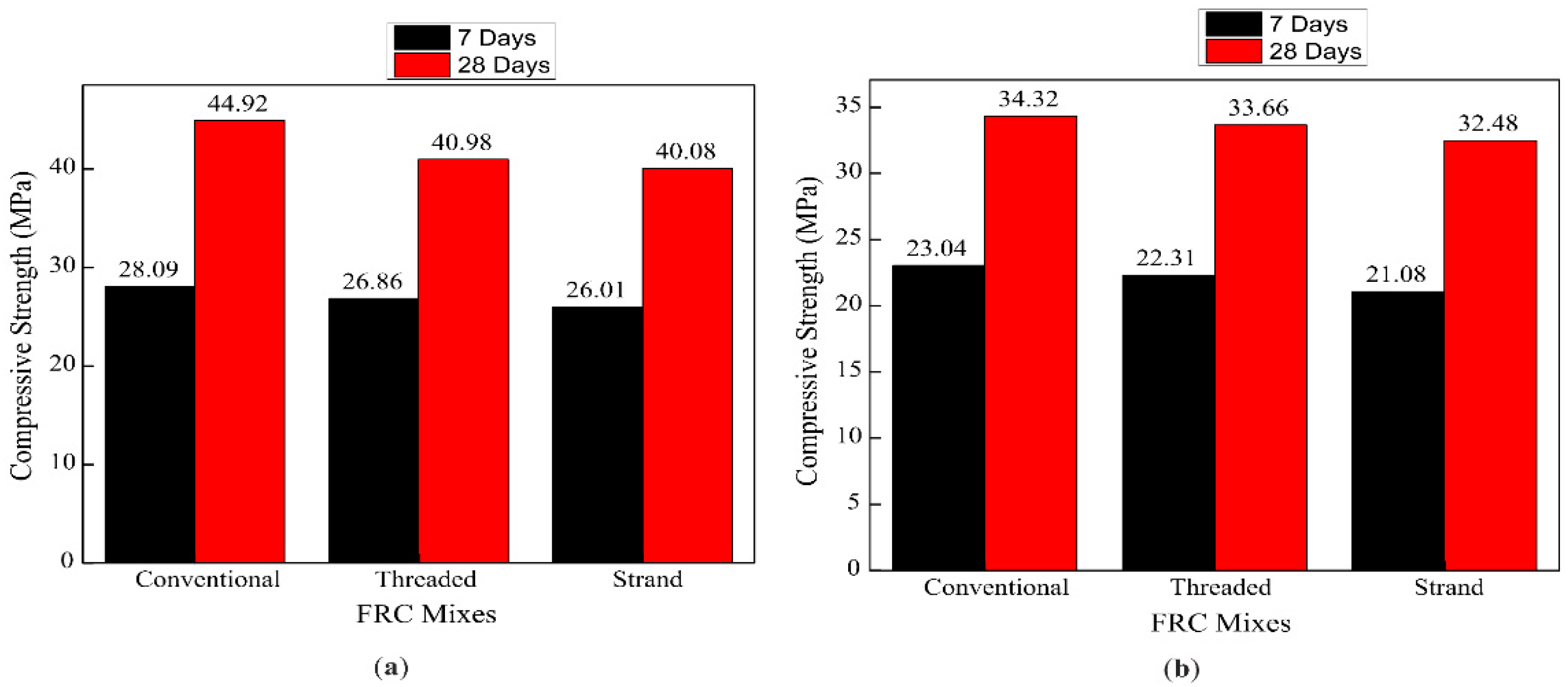

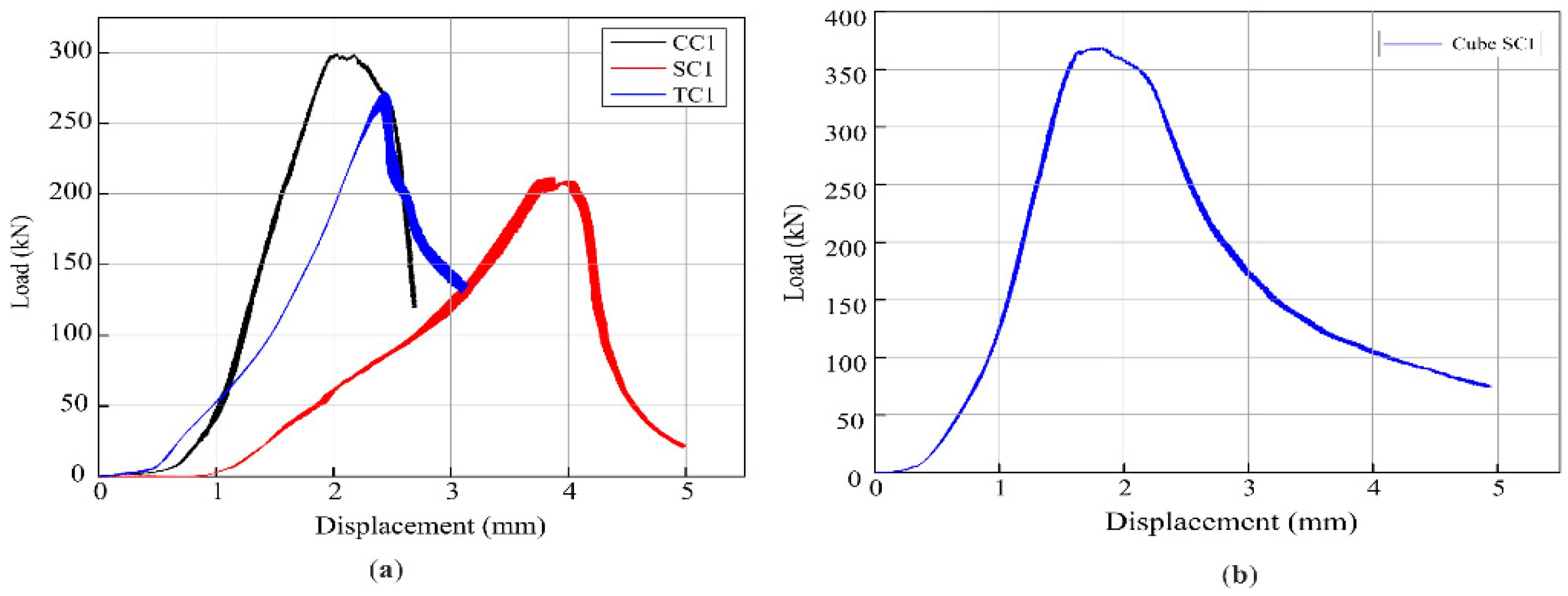

3.3. Compressive Strength (CS)

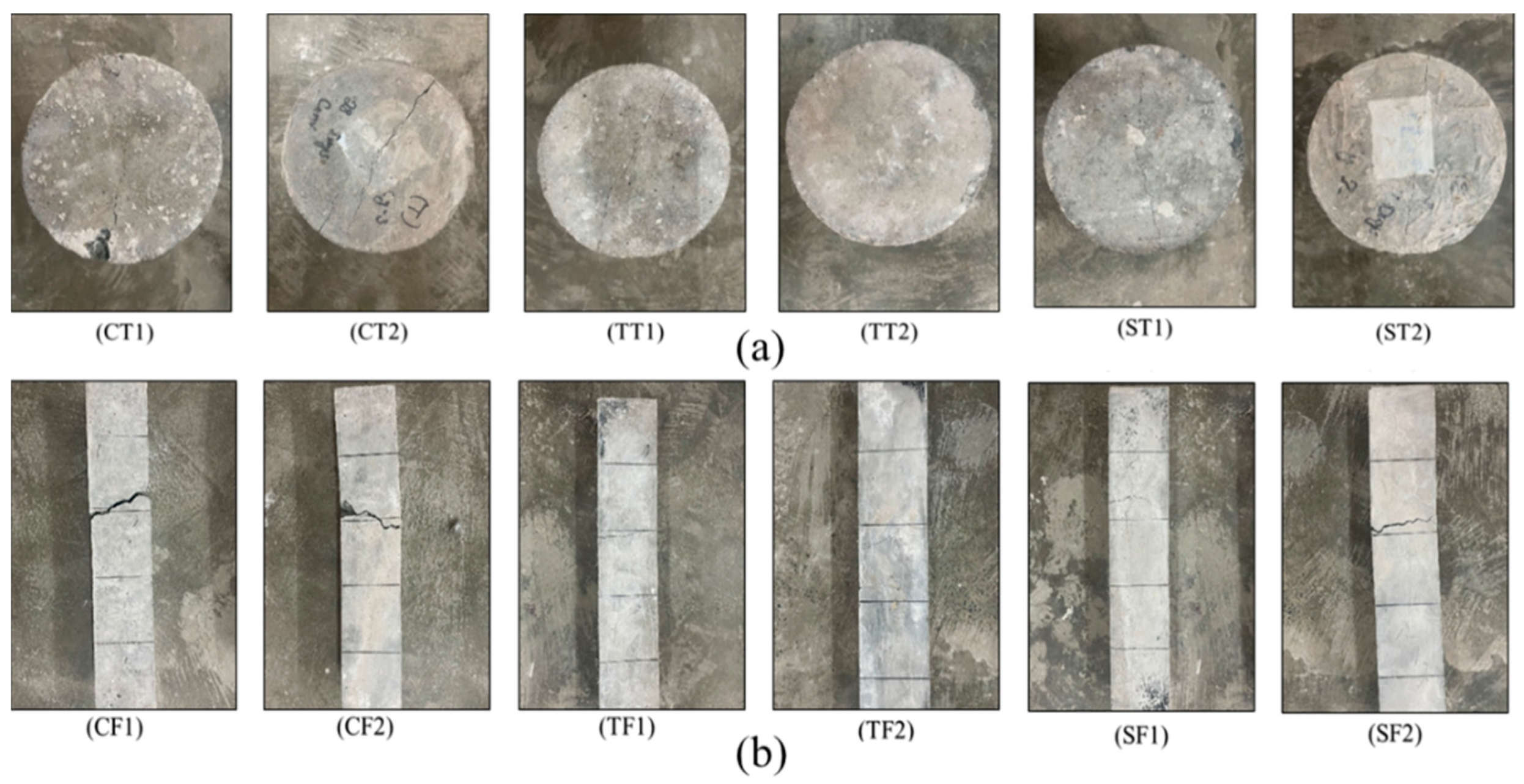

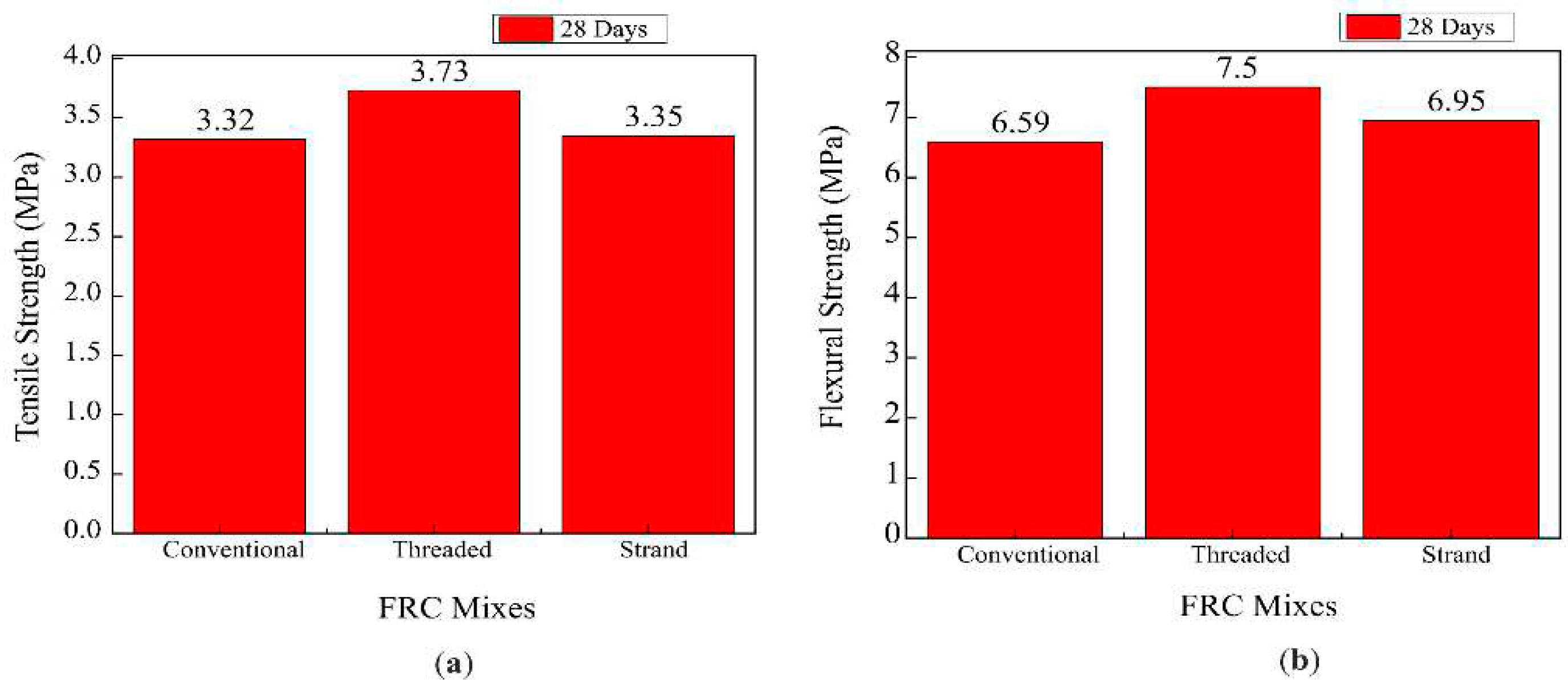

3.4. Splitting Tensile Strength (STS)

3.5. Flexural Strength (FS)

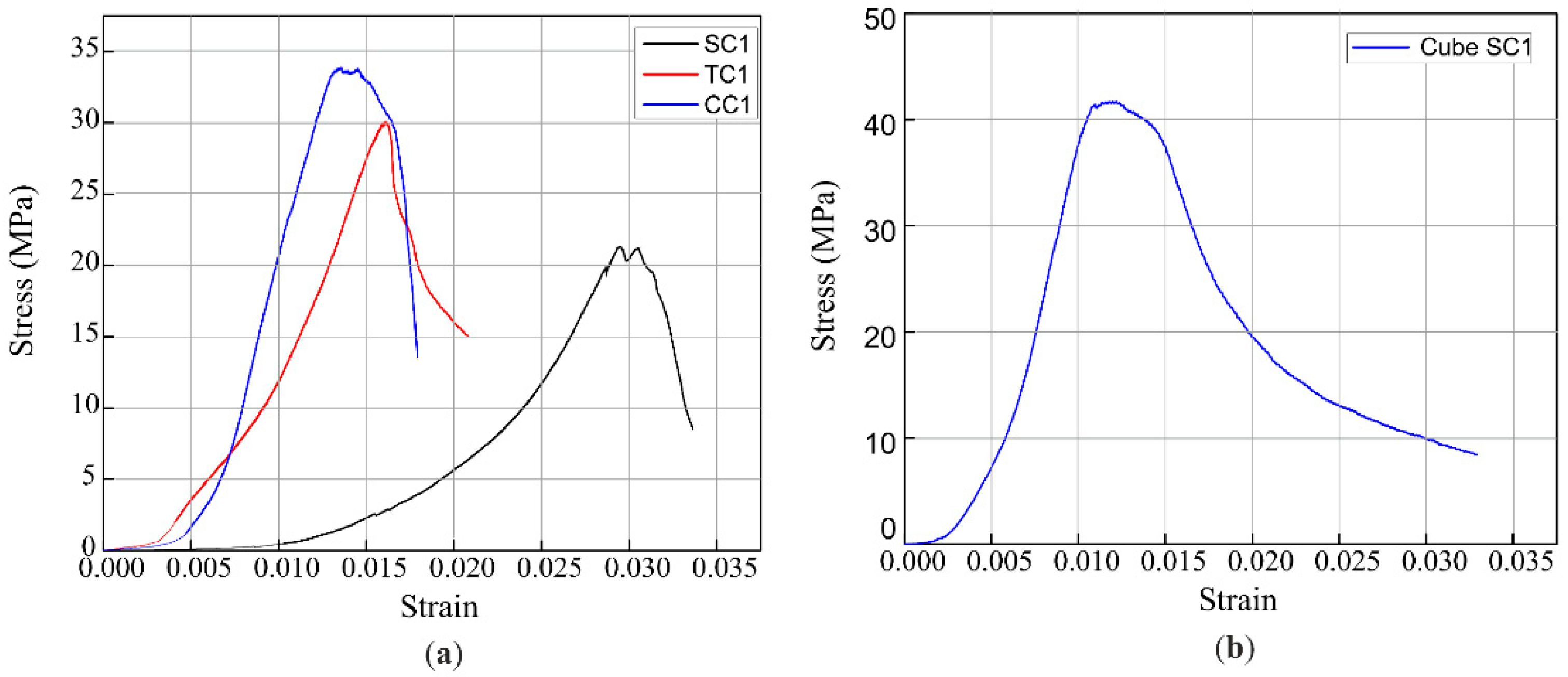

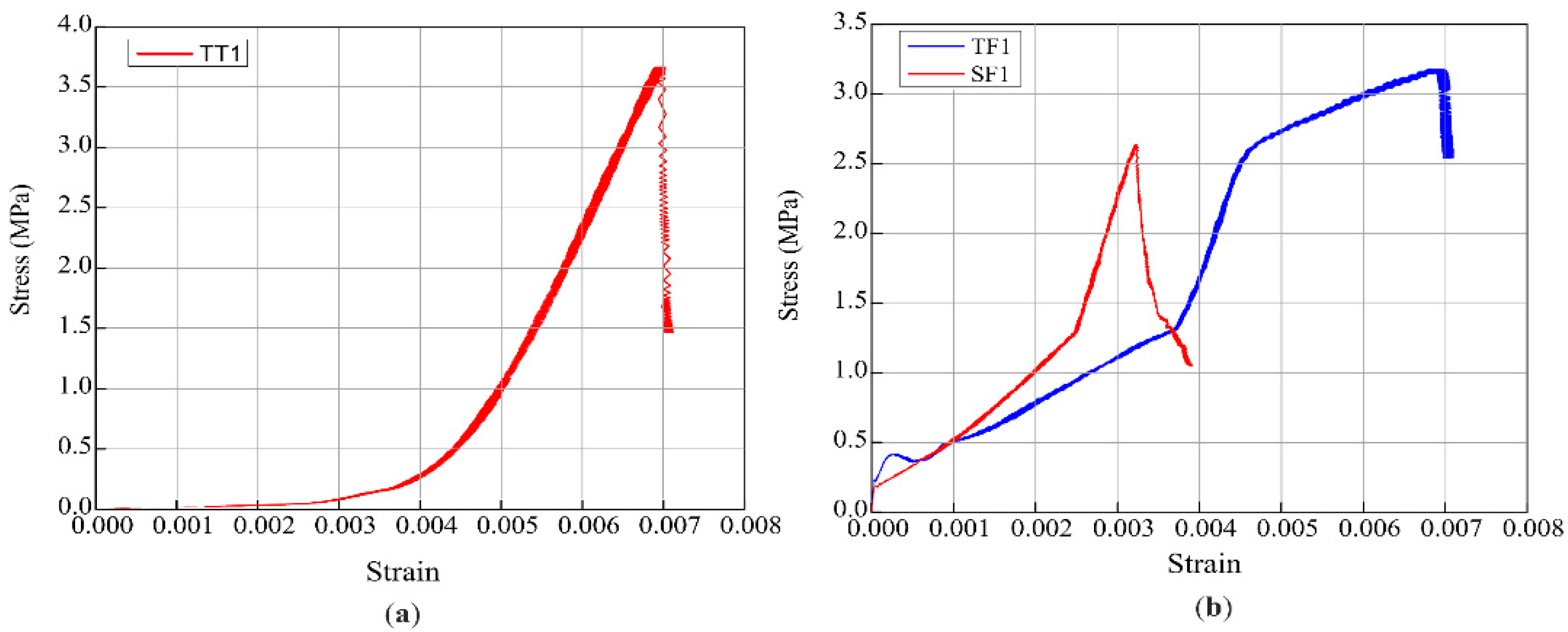

3.6. Stress-Strain () behavior

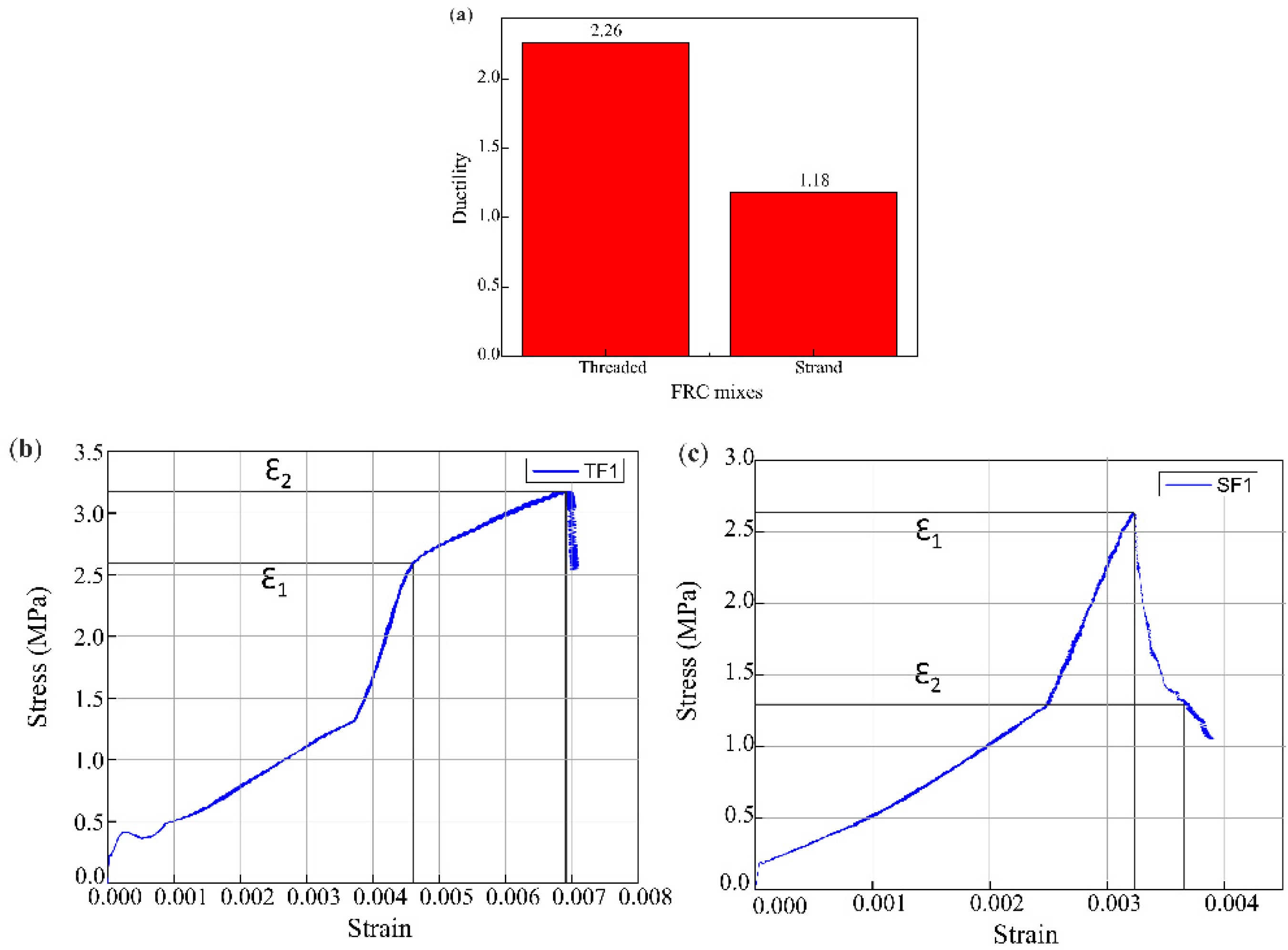

3.7. Ductility

4. Conclusion

- Workability, density, compressive, splitting, and flexural strength tests on NFRC were examined upon adding nylon fiber to PCC. The addition of nylon fiber in PCC enhanced the density of NFT by 0.03%.

- The cracking resistance of PCC was improved up to 12.85% with the addition of nylon fiber and the ductility of NFT was enhanced by 16.8% compared to NFS.

- The incorporation of nylon fibers (2.5%) volume fraction of coarse aggregates in the concrete mix had a 1-6% effect on CS of NFT and NFS. The reduction in CS of NFT and NFS was 1.9% and 5.4%, respectively.

- NFRC specimens cast with 2.5% of NFS and NFT improved STS by 12.3% and 1%, respectively, compared to the PCC with 0% addition of NF.

- Both types of fibers (NFS and NFT) significantly influenced (5-14%) the FS of NFRC. An improvement of 13.8% and 5.5% was observed in the FS of NFT and NFS.

- The experimental results showed that NFT outperform by 13.05% than that of NFS.

Recommendation

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srinivas Allena, Craig M. Newtson, Ultra-High Strength Concrete Mixtures Using Local Materials, J. Civ. Eng. Archit. 5 (2011). [CrossRef]

- K. Kishore, N. Gupta, Application of domestic & industrial waste materials in concrete: A review, Mater. Today Proc. 26 (2020) 2926–2931. [CrossRef]

- J. Ahmad, O. Zaid, C.L.-C. Pérez, R. Martínez-García, F. López-Gayarre, Experimental Research on Mechanical and Permeability Properties of Nylon Fiber Reinforced Recycled Aggregate Concrete with Mineral Admixture, Appl. Sci. 12 (2022) 554. [CrossRef]

- S. Khan, S. Ashraf, S. Ali, K. Khan, Experimental investigations on the mechanical properties and damage detection of carbon nanotubes modified crumb rubber concrete. J. Build. Eng. 75 (2023) 106937. [CrossRef]

- J. Xu, S. Ashraf, S. Khan, X. Chen, A. Akbar, F. Farooq, Micro-cracking pattern recognition of hybrid CNTs/GNPs cement pastes under three-point bending loading using acoustic emission technique. J. Build. Eng. 42 (2021) 102816. [CrossRef]

- Noushini, F. Aslani, A. Castel, R.I. Gilbert, B. Uy, S. Foster, Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete, Cem. Concr. Compos. 73 (2016) 136–146. [CrossRef]

- S. Singh, G.D. Ransinchung, P. Kumar, Effect of mineral admixtures on fresh, mechanical and durability properties of RAP inclusive concrete, Constr. Build. Mater. 156 (2017) 19–27. [CrossRef]

- S. Ashraf, S. Khan, V.K. Oad, Microcracking monitoring and damage detection of graphene nanoplatelets-cement composites based on acoustic emission technology, Case Stud. Constr. Mater. 18 (2023) e01844. [CrossRef]

- E. Ferretti, A discussion of strain-softening in concrete, Int. J. Fract. 126 (2004) L3–L10. [CrossRef]

- E. Ferretti, Shape-effect in the effective laws of plain and rubberized concrete, Comput. Mater. Contin. 30 (2012) 237–284.

- C.A.K.R.P.P.R.& L.S.K. P. Ganesh Prabhu, Study on Utilization of Waste Pet Bottle Fiber in Concrete, IMPACT Int. J. Res. Eng. Technol. (IMPACT IJRET). 2 (2014) 233–240.

- W. Wang, A. Shen, Z. Lyu, Z. He, K.T.Q. Nguyen, Fresh and rheological characteristics of fiber reinforced concrete——A review, Constr. Build. Mater. 296 (2021) 123734. [CrossRef]

- C. Zhao, Z. Wang, Z. Zhu, Q. Guo, X. Wu, R. Zhao, Research on different types of fiber reinforced concrete in recent years: An overview, Constr. Build. Mater. 365 (2023) 130075. [CrossRef]

- S. Hedjazi, D. Castillo, Relationships among compressive strength and UPV of concrete reinforced with different types of fibers, Heliyon. 6 (2020) e03646. [CrossRef]

- D.S. Ozsar, F. Ozalp, H. Dilsad Yilmaz, B. Akcay, Effects of nylon fibre and concrete strength on the shrinkage and fracture behaviour of fibre reinforced concrete, in: Strain-Hardening Cem. Compos. SHCC4 4, Springer, 2018: pp. 188–194.

- K. Cui, L. Xu, T. Tao, L. Huang, J. Li, J. Hong, H. Li, Y. Chi, Mechanical behavior of multiscale hybrid fiber reinforced recycled aggregate concrete subject to uniaxial compression. J. Build. Eng. 71 (2023) 106504. [CrossRef]

- S. Ashraf, M. Rucka, Microcrack monitoring and fracture evolution of polyolefin and steel fibre concrete beams using integrated acoustic emission and digital image correlation techniques, Constr. Build. Mater. 395 (2023) 132306. [CrossRef]

- S. Yin, R. Tuladhar, F. Shi, M. Combe, T. Collister, N. Sivakugan, Use of macro plastic fibres in concrete: A review, Constr. Build. Mater. 93 (2015) 180–188. [CrossRef]

- Y. Choi, R.L. Yuan, Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 35 (2005) 1587–1591. [CrossRef]

- L. Sun, Q. Hao, J. Zhao, D. Wu, F. Yang, Stress strain behavior of hybrid steel-PVA fiber reinforced cementitious composites under uniaxial compression, Constr. Build. Mater. 188 (2018) 349–360. [CrossRef]

- L. Rizzuti, F. Bencardino, Effects of fibre volume fraction on the compressive and flexural experimental behaviour of SFRC, Contemp. Eng. Sci. 7 (2014) 379–390. [CrossRef]

- T. Ayub, S.U. Khan, A. Ayub, Analytical model for the compressive stress–strain behavior of PVA-FRC, Constr. Build. Mater. 214 (2019) 581–593. [CrossRef]

- T. K, S.S. R, V. P, S. V, Study on characteristics of textile fiber reinforced concrete, Int. J. Appl. Sci. 8 (2016) 41–57.

- H. Jahangir Qureshi, J. Ahmad, A. Aljabr, N. Garcia-Troncoso, Review on characteristics of concrete reinforced with nylon fiber, J. Eng. Fiber. Fabr. 18 (2023) 1–15. [CrossRef]

- A. Zia, M. Ali, Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining, Constr. Build. Mater. 155 (2017) 726–739. [CrossRef]

- D. Ra B, K. Zhimo, P. Tigga, C. Bhutia, Y. Bhutia, D. Pradeep, V.P. Darshini, Experimental Study on Concrete Using Zygote Encastment Powder, Crushed Groundnut Shell and Nylon Fiber as a Partial Replacement for Materials, J. Crit. Rev. 7 (2020) 1326–1333. [CrossRef]

- P.S. Song, S. Hwang, B.C. Sheu, Strength properties of nylon- and polypropylene-fiber-reinforced concretes, Cem. Concr. Res. 35 (2005) 1546–1550. [CrossRef]

- M. Najafi, L. Nasri, R. Kotek, High-performance nylon fibers, in: Struct. Prop. High-Performance Fibers, Elsevier, 2017: pp. 199–244. [CrossRef]

| Chemical composition | CaO | SiO2 | MgO | Al2O3 | Fe2O3 | SO3 |

| Percentages (%) | 68.4 | 19.5 | 1.3 | 4.6 | 1.2 | 3.1 |

| Materials | Quantity (Kg/m3) |

| Cement | 540 |

| Sand | 742.44 |

| Coarse aggregates | 849.3 |

| Water | 239.3 |

| Fiber type | NFT Diameter [mm] |

NFS Diameter [mm] |

Fiber Length [mm] |

Specific gravity |

Tensile Strength [MPa] |

Elastic Modulus [MPa] |

Water Absorption [%] |

| Nylon | 0.14 | 2 | 25 | 1.14 | 827.4 | 5300 | 2.8-5.0 |

| Description | Abb** |

Cement (kg/m3) |

Coarse Aggregates(kg/m3) |

Fine Aggregates (kg/m3) |

Nylon Fibers (g) |

SP*(ml) |

| Plain | CC/CT | 3.48 | 5.85 | 5.16 | 0 | 34.8 |

| NFT | TC/TT | 3.48 | 5.76 | 5.16 | 91 | 34.8 |

| NFS | SC/ST | 3.48 | 5.76 | 5.16 | 91 | 34.8 |

| Description | Abb** |

Cement (kg/m3) |

Coarse Aggregates (kg/m3) |

Fine Aggregates (kg/m3) |

Nylon Fiber (g) |

SP* (ml) |

| Plain | CC | 2.53 | 4.23 | 3.75 | 0 | 25.3 |

| NFT | TC | 2.53 | 4.17 | 3.75 | 58 | 25.3 |

| NFS | SC | 2.53 | 4.17 | 3.75 | 58 | 25.3 |

| Description | Abb** | Cement(kg/m3) | CoarseAggregates(kg/m3) | FineAggregates(kg/m3) | Nylon Fiber(g) | SP*(ml) |

| Units | - | (kg/m3) | (kg/m3) | (kg/m3) | (g) | (ml) |

| Plain | CF | 3.08 | 5.17 | 4.57 | 0 | 30.8 |

| NFT | TF | 3.08 | 5.09 | 4.57 | 80 | 30.8 |

| NFS | SF | 3.08 | 5.09 | 4.57 | 80 | 30.8 |

| Concrete type | Water cement ratio | Slump (mm) | Density (kg/m3) |

| PC | 0.4 | collapsed | 1146.4 |

| NFT | 0.4 | zero | 1176.4 |

| NFS | 0.4 | collapsed | 1092.5 |

|

Characteristics Specimen |

size |

Day |

NFRC Mix | ||

| Plain | NFT | NFS | |||

| Compressive strength (MPa) |

150×150×150(mm) | 28 | 44.92 | 40.98 | 40.08 |

| Compressive strength (MPa) |

150×300 (mm) | 28 | 34.32 | 33.66 | 32.48 |

| Splitting tensile strength (MPa) | 150×300 (mm) | 28 | 3.32 | 3.73 | 3.35 |

| Flexural strength (MPa) | 100×100×500 (mm) | 28 | 6.59 | 7.50 | 6.95 |

| Sr. No. | Concrete type | Stress | Strain |

Theoretically (Es) |

Experimentally (Es) |

Units |

| 1 | CC1 | 33.86 | 0.0070 | 27349 | 4837 | (MPa) |

| 2 | TC1 | 30.08 | 0.0079 | 25777 | 3807 | (MPa) |

| 3 | SC1 | 21.31 | 0.014 | 21696 | 1522 | (MPa) |

| Sr. No. | Concrete Type | Ductility | Reduction |

| 1 | TF1 | 2.26 | - |

| 2 | SF1 | 1.88 | 16.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).