In this study, the authors present a novel procedure to develop and validate an efficient computational model that can be analysed and employed to optimise multi-MW electrical generator rotor supporting structures using only the variables affecting the most. With the use of this model and following the proposed methodology, one can reduce the amount of material needed to withstand the demanding loading conditions, which include not only the typically considered inherent generator operation loads but also the external conditions. The manufacturing, labour, installation and transportation time as well as the associated resources can be diminished with the consequent reduction in CO2 and methane emissions, water usage and costs. The effect of those modifications can be quantified by looking at the changes in the structure’s natural frequencies and the impact in the generator operating range and turbine energy harvesting capability.

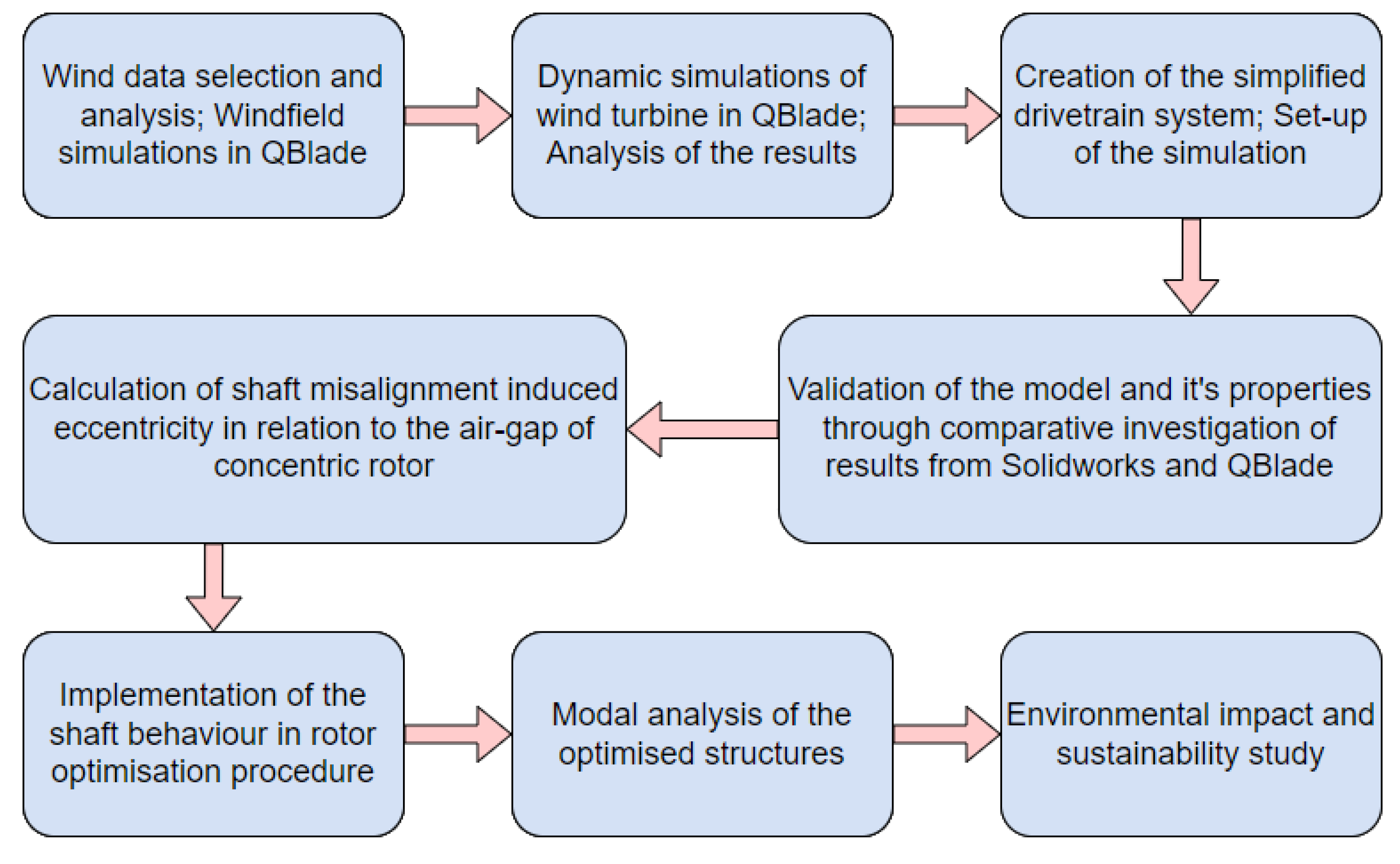

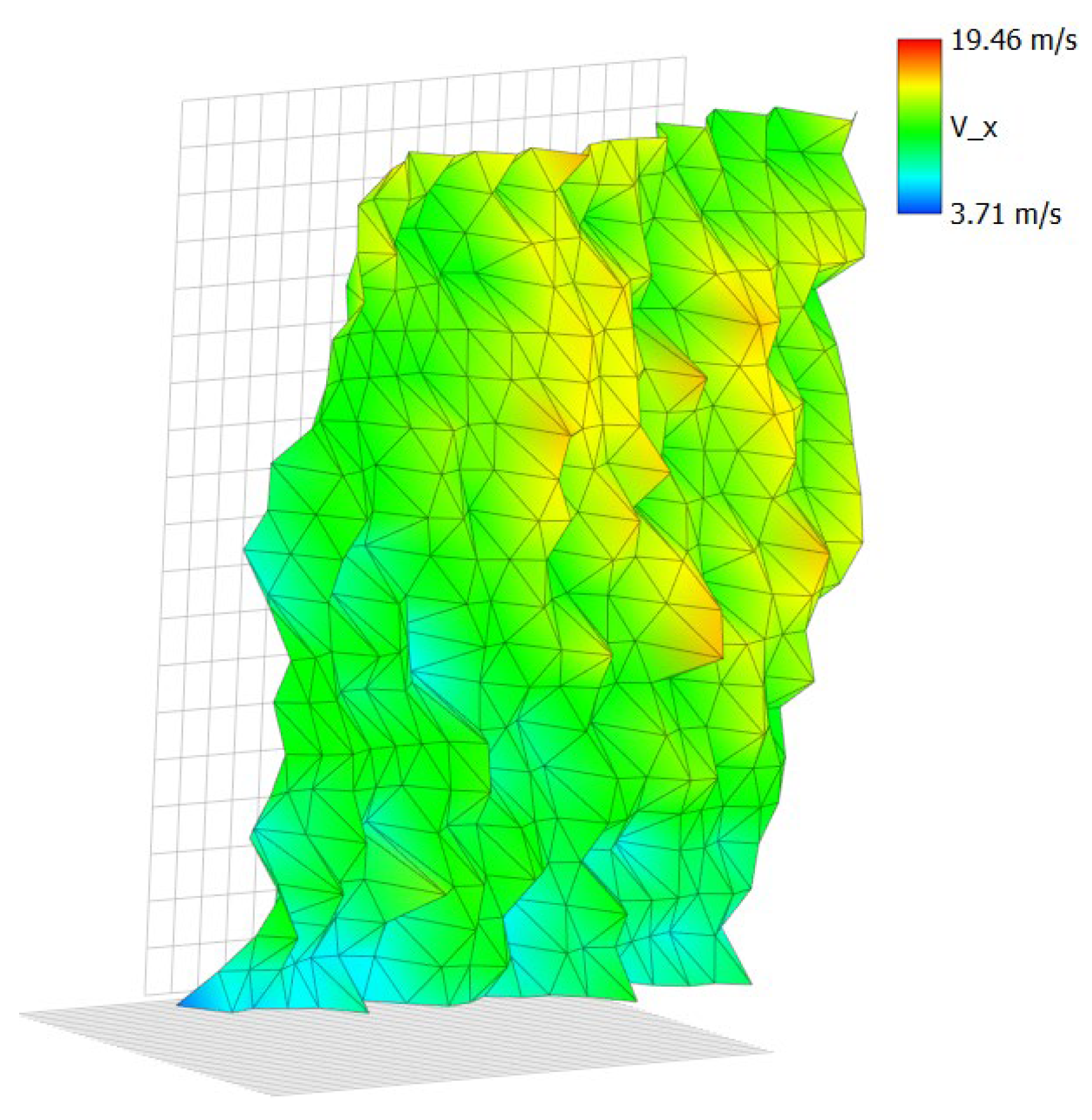

The methodology of the conducted research can be found in

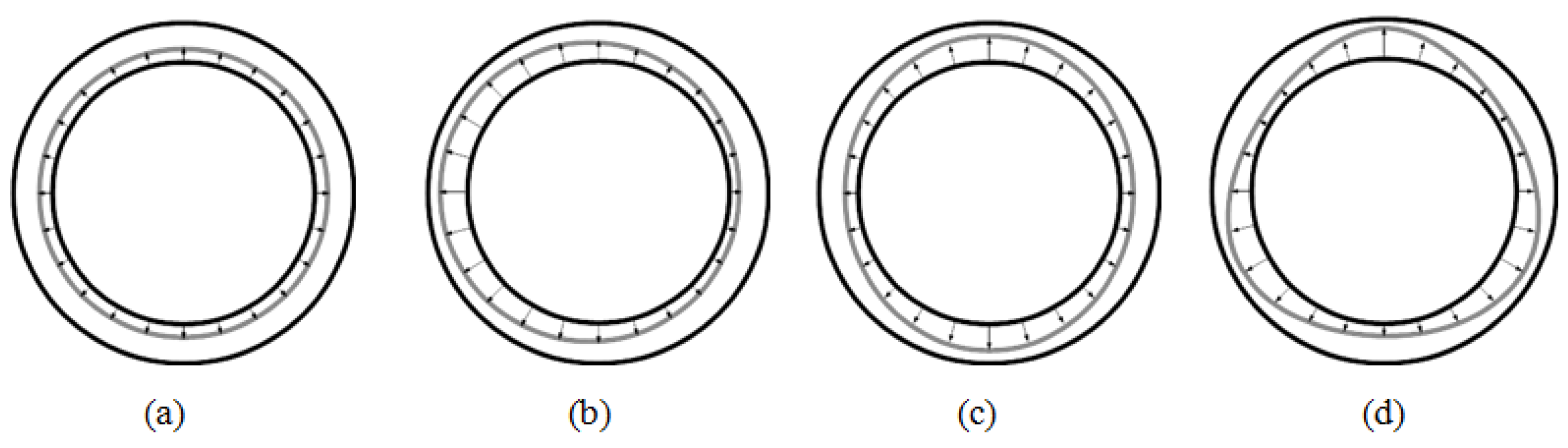

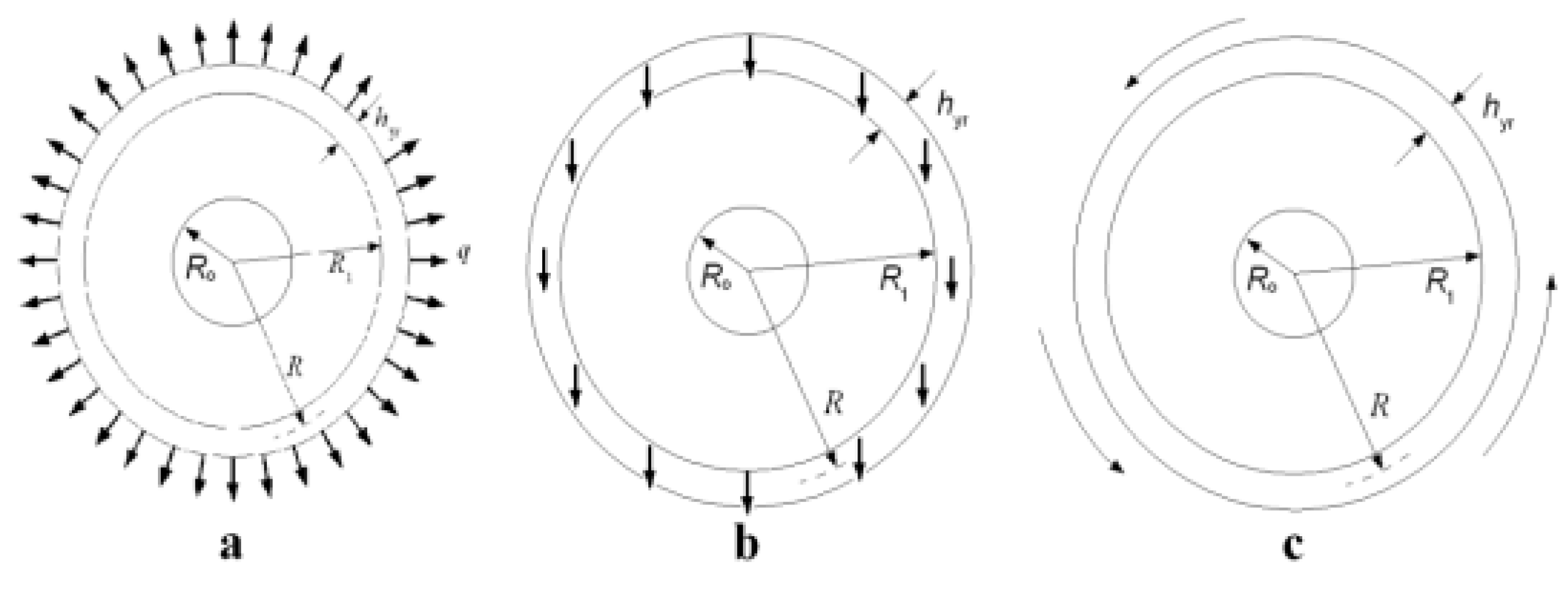

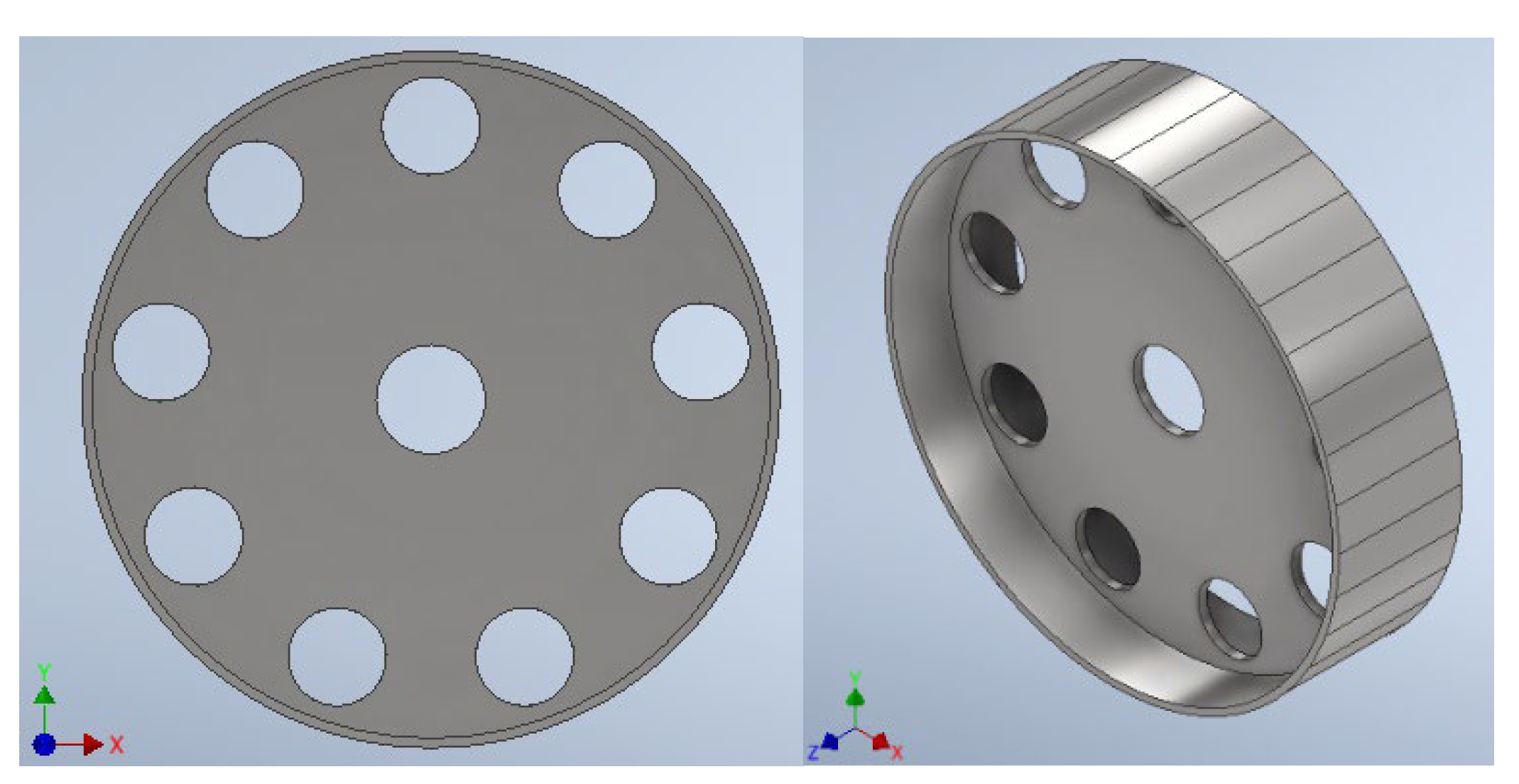

Figure 6. Firstly, real-world wind data sets were obtained and selected after careful investigation and appraisal of the corresponding wind farms. The chosen data package was then further analysed and edited. This resulted in the creation of 3 aerodynamic settings corresponding to the considered wind speeds: Low, Rated and High. Moreover, the wind patterns at the chosen site were specified. The obtained data was validated through a correlation study of wind speeds and corresponding altitudes. To translate the real-world wind behaviour to software aided analysis, windfield simulations in QBlade were conducted. The obtained results were compared against the real-world data. Subsequently, the validated windfield data was used in dynamic, structural simulations on a 5 MW wind turbine in QBlade, thus output values for normal stresses on the blades were acquired. Following the analysis of the wind turbine in QBlade, a simplified drivetrain system was created. Finite element analysis of the system was conducted after the simulation set-up procedure in Solidworks, which consisted of material properties specification, application of fixtures and mesh independence study. The results were then validated through comparative investigation between the gathered data from QBlade and Solidworks. Furthermore, the shaft misalignment induced eccentricity in relation to the air-gap of concentric rotor was calculated for the Rated and High aerodynamic settings. The resultant shaft deflections were included in the rotor optimisation procedure, which consisted of rotor structural configuration selection, static FE analysis, topology optimisation, parametric table optimisation and modal analysis of the optimised structures. Lastly, the environmental impact and sustainability of the proposed designs and procedures were studied.

2.1. Wind Data Analysis

The total of 3 different wind data sets from wind farm sites: Penmanshiel, Anholt, and Westermost Rough were found and taken into account. Penmanshiel wind farm data set was obtained from online repository Zenodo [

11] and released by Cubico Sustainable Investments Ltd. [

12], whereas Anholt and Westermost Rough wind farm data sets were supplied by Ørsted [

13]. The chosen data sets for this study came from Anholt wind farm located in eastern Denmark. They were found suitable, as they cover the measurement height requirement for further studies and come with already transposed values e.g., wind direction, thus reducing the workload during the analysis. The technical data and location for Anholt site is provided in

Table 1.

The overall wind turbine power is smaller than the investigated structure in this study. However, the data provided from this site covers a range of altitudes for even the biggest commercially used structures at the time (up to 315.6 m above lowest astronomical tide). Therefore, the wind data is only dependent on the environmental conditions present at the site. The data sets from the Anholt wind farm were found to be suitable for further analysis and validation. The obtained data package consists of various signals produced by continuous measurements in 10-minute intervals taken at the site for over 726 days, which sums up to approximately 2 years and ultimately produces over 100,000 data rows and 150 columns. The columns specify the type of measurement taken over the period and consist of wind speed values, wind directions and 12 different corresponding altitudes. The first 10 altitudes (65.6 m – 315.6 m) were taken into consideration, as those heights would cover the operational area of the studied wind turbine.

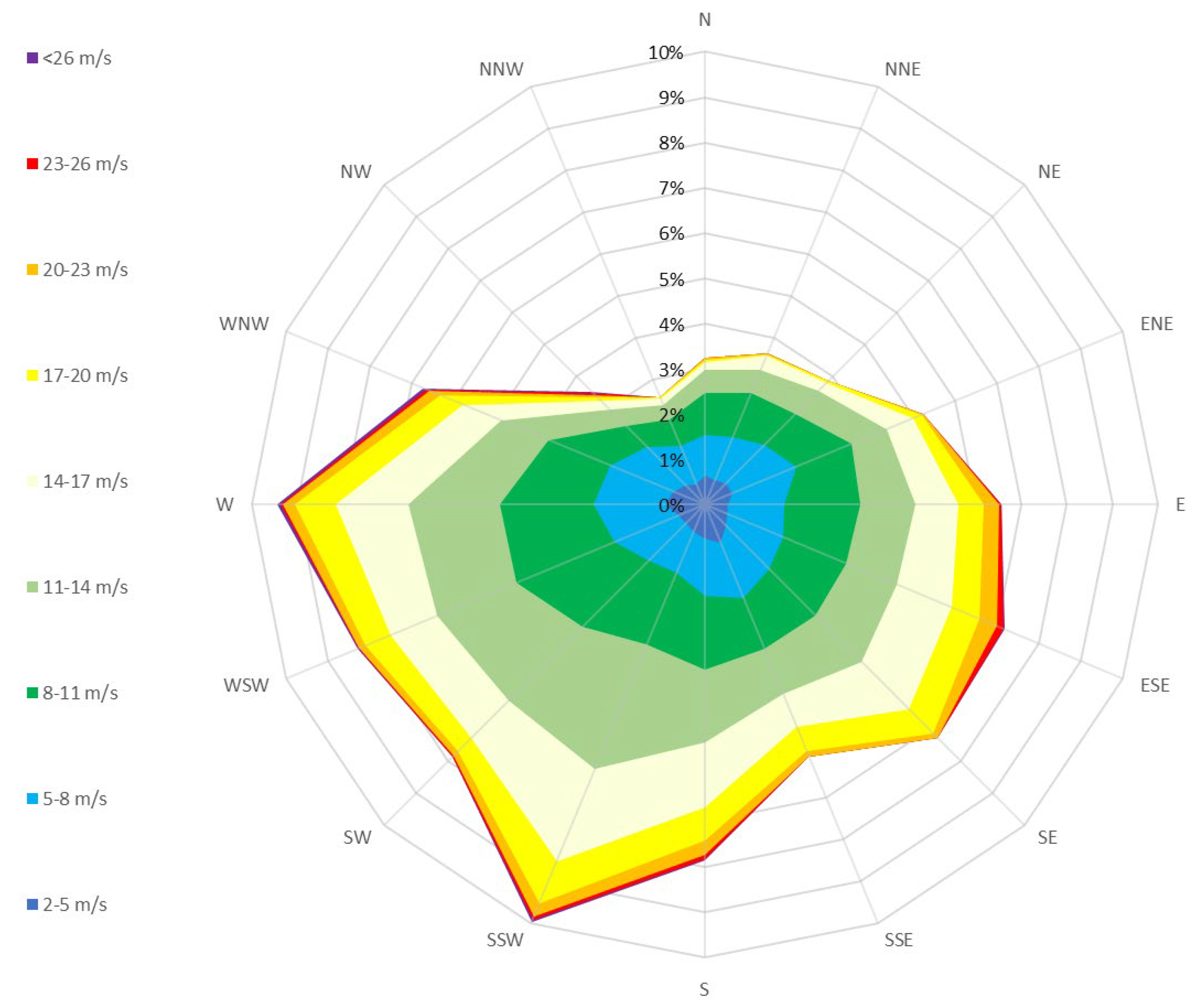

Having a significant amount of data measured over 2 years period, wind direction probability can be identified in order to analyse the working environment of wind turbine while operating. Firstly, the wind data for wind directions and wind speeds was limited to only one column set corresponding to closest hub-height altitude of 5MW wind turbine – altitude 2. The chosen data was then sorted by the wind directions with 22.5° increments, ultimately resulting in a specified data set with identified 16 cardinal directions. The wind speeds were then divided into 9 categories corresponding to the chosen values, sorted and then counted in excel in order to produce a clear probability table that refers to the wind speed and wind direction values over the measurement period – 2 years. The data can be presented as a wind rose (

Figure 7) for better presentation of the results.

The chosen wind speeds were colour coded. The graphed areas correspond to the wind direction, as well as probability of occurrence at Anholt wind farm. The highest probability of 10% occurs at SSW direction for 4 wind speed categories with values over 17 . The overall probability of the wind speed being over 5 is 89.55% and 69% for speeds over 8 . Moreover, a recommended annual wind speed average for utility-scale wind turbines is at least 5.8 . The average wind speed at Anholt wind farm is 10.83 , which validates the site’s operational requirements.

In order to conduct further analysis, 3 wind speed scenarios were created: low, rated and high which respectively correspond to: lowest possible operational wind speed of (cut-in speed), rated wind speed of and highest possible operational wind speed (cut-off speed) for 5MW wind turbine. For the purpose of data filtering, the 3 settings were given a range of wind speed values of . For low and high settings lowest and highest possible operational wind speeds (cut-in/cut-off) was one of the boundaries. Whereas, for rated wind speed of the boundaries were set to . This results in higher data count that is centralised about the specified value for each of the settings. As previously mentioned, the data was filtered against the closest altitude to the hub height (90m) of the 5 MW WT.

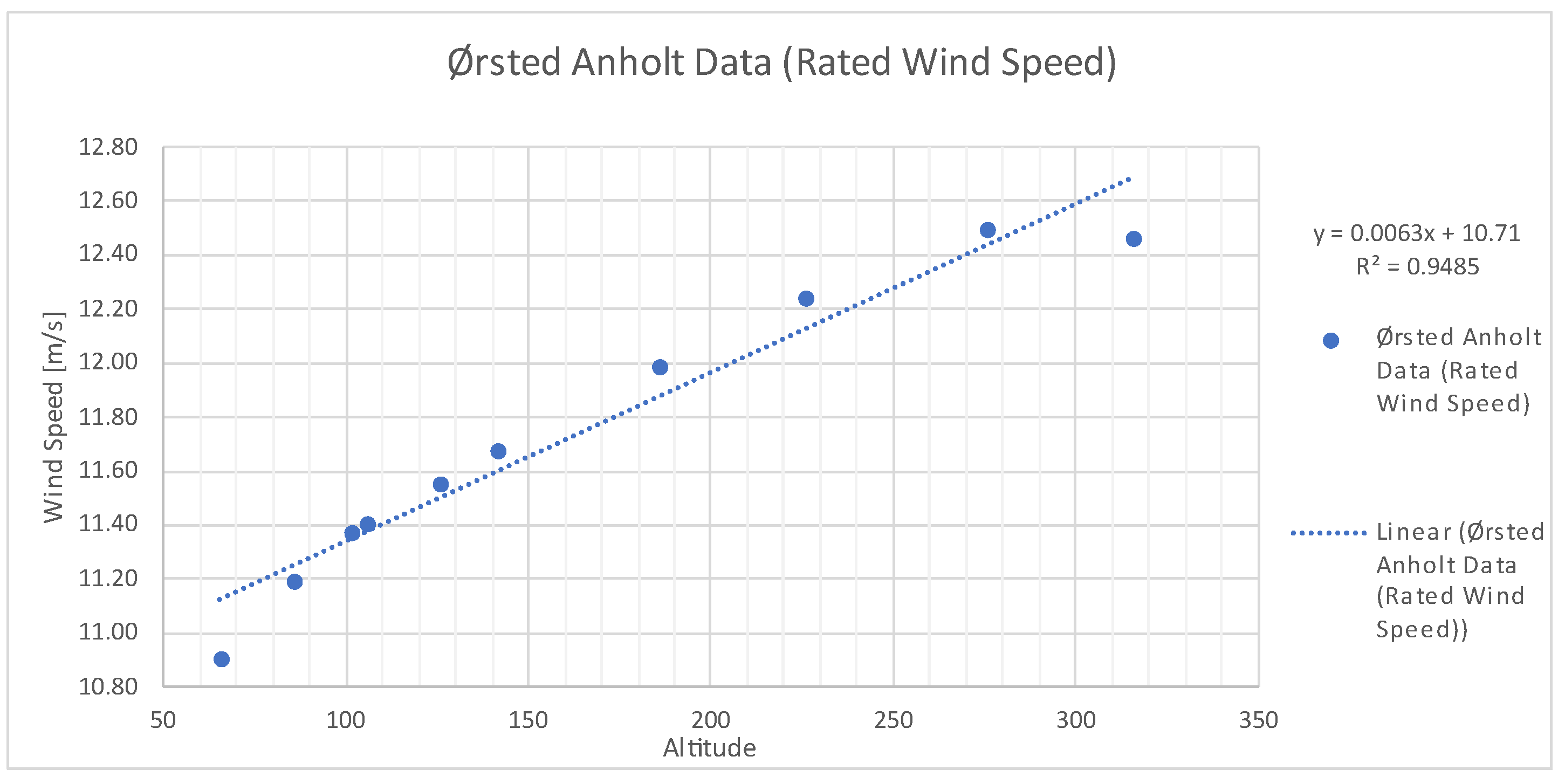

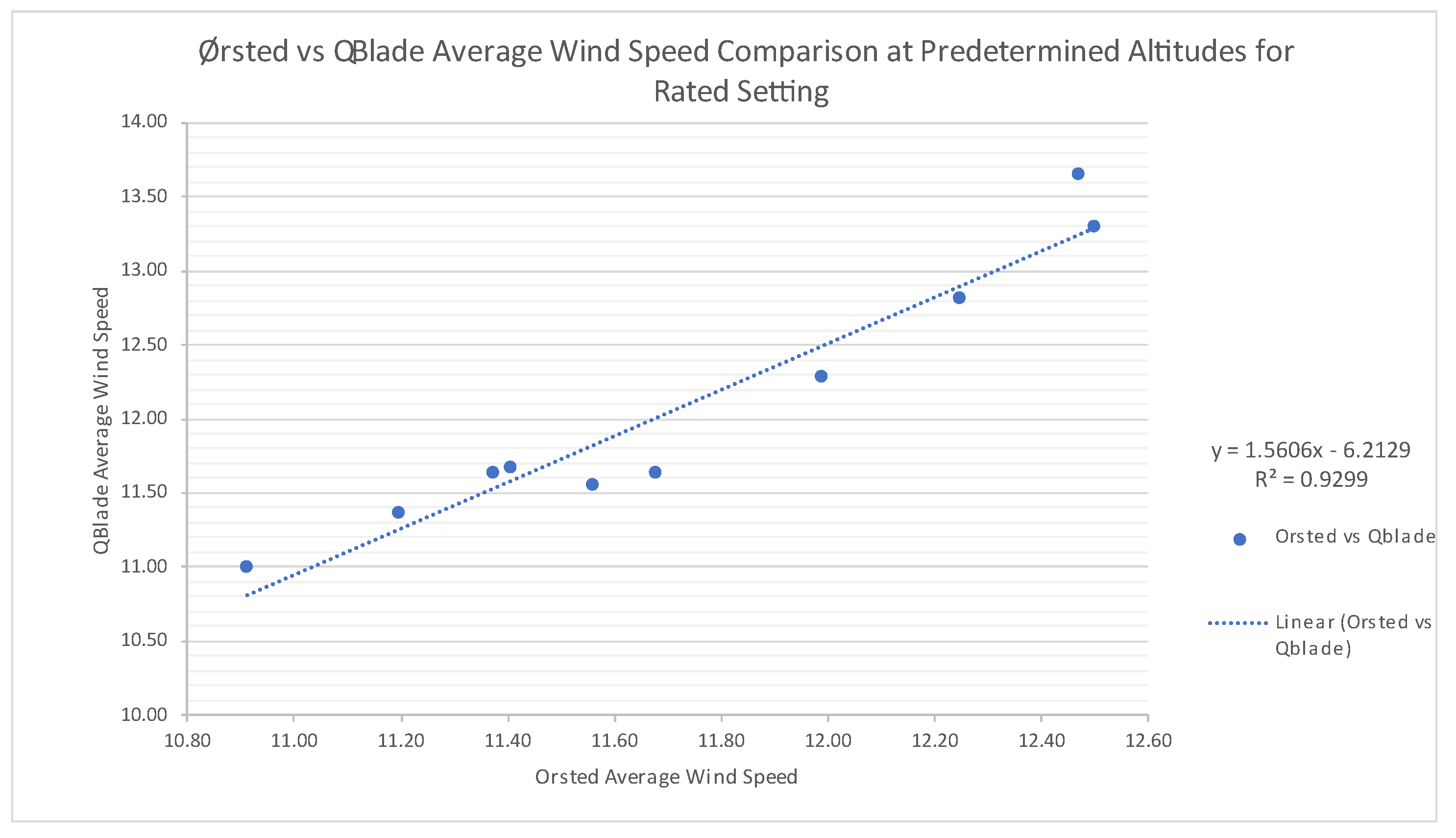

The average wind speeds were then calculated for each of the 3 settings for 10 predetermined altitudes. The obtained results followed a normalised pattern with coefficient of determination R

2 of over 0.94, which shows a good correlation of the data and minimum impact of the irregularities. The exemplary correlation graph for Rated Wind Speed can be seen in

Figure 8.

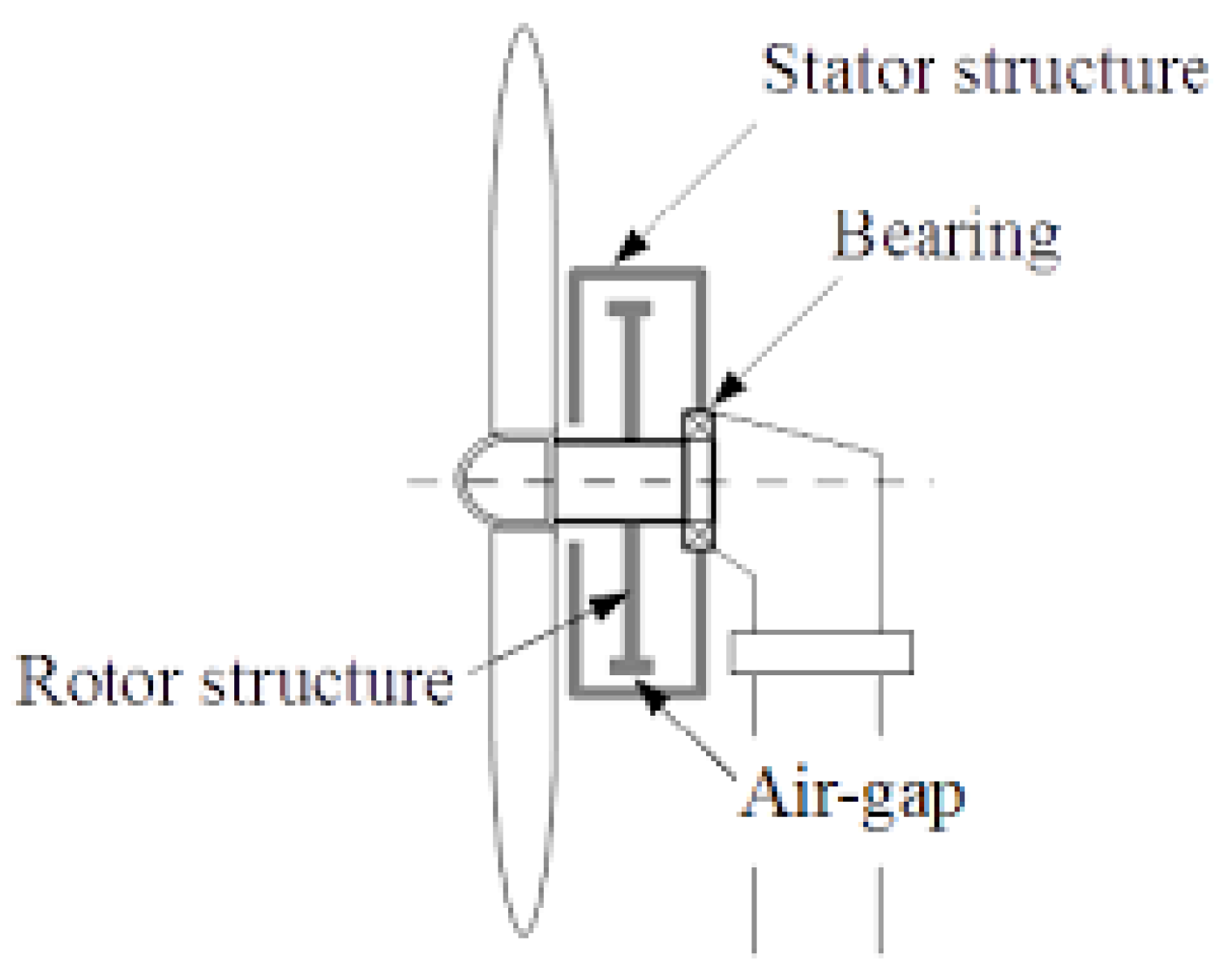

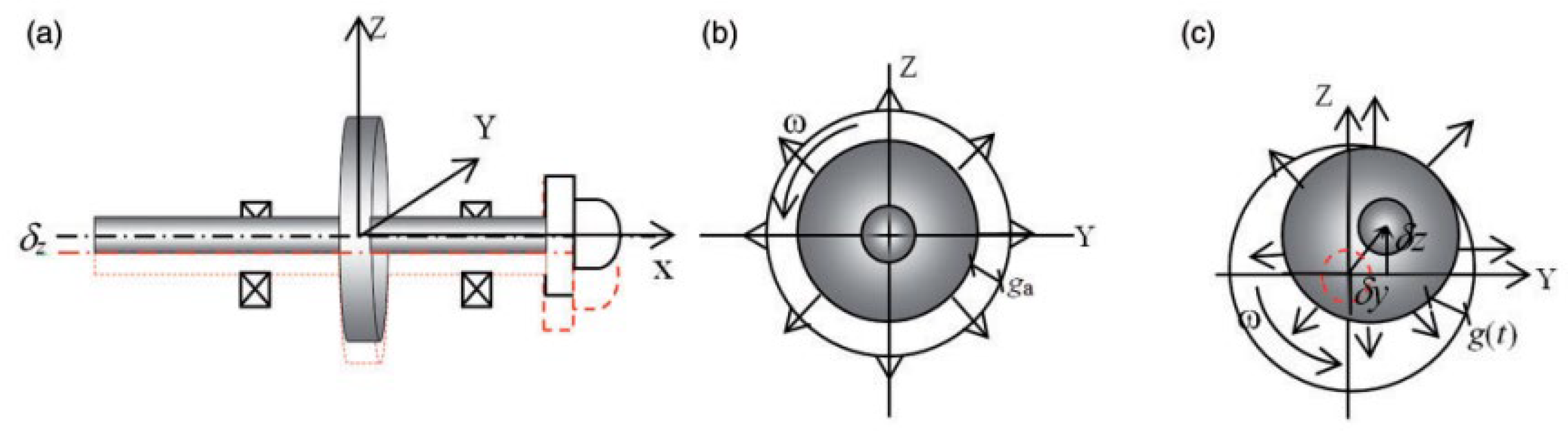

2.3. Structural Analysis of the Wind Turbine Structure

The main goal of this investigation was to produce a simplified and validated process for direct drive system analysis of 5MW wind turbine. For that, the structural analysis of the wind turbine structure was conducted in 2 software programmes: QBlade and Solidworks through built-in features, as well as finite element analysis. The process started by using the validated windfield data as an input towards development of aerodynamic loading on blade’s structure in QBlade and resulted in calculation of the shaft eccentricity in relation to the air-gap of concentric rotor. The displacement of the shaft was found through finite element analysis in Solidworks after conducting necessary validation techniques, since QBlade does not offer drivetrain component-based results.

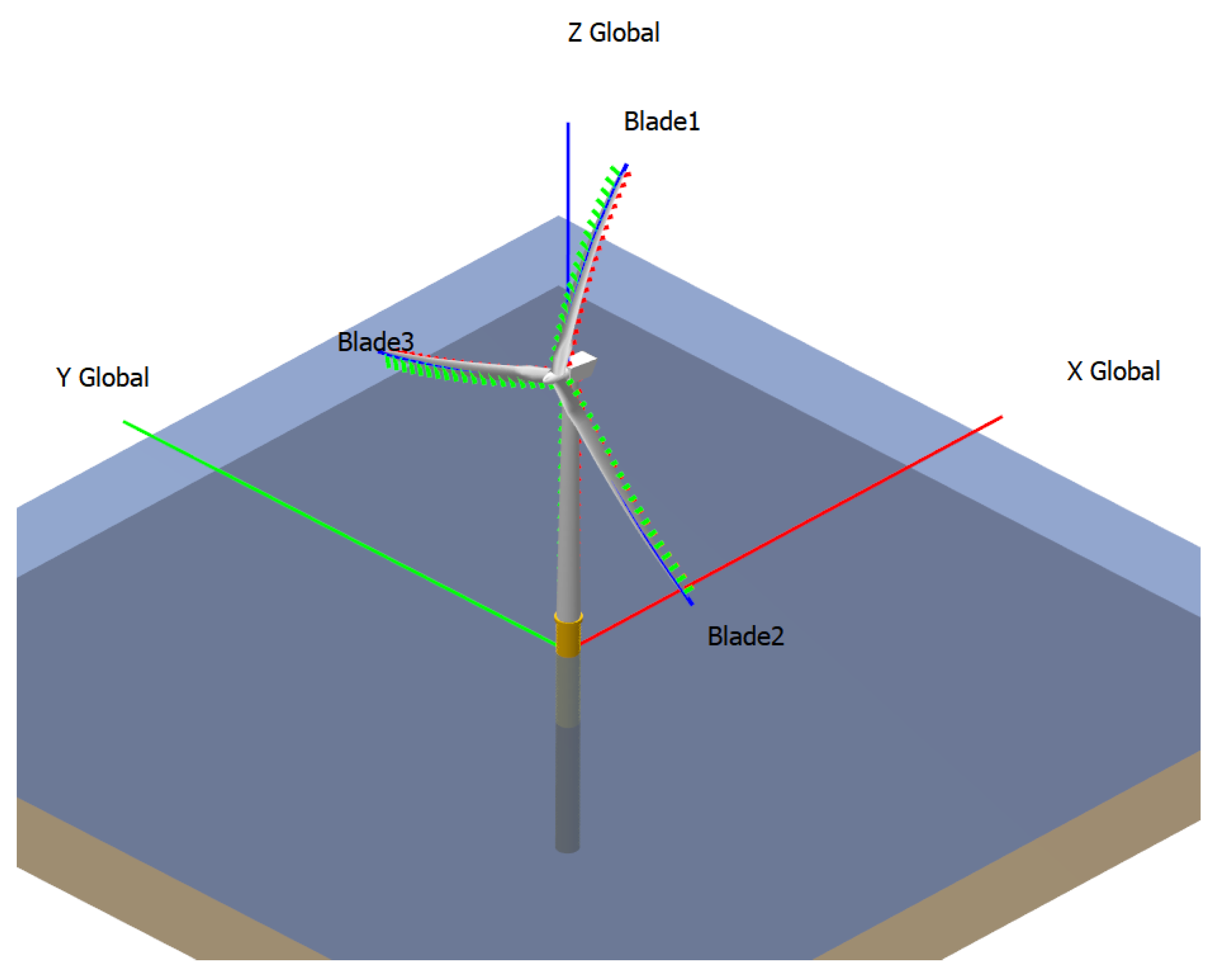

For the purpose of conducting the study, a computationally designed 5MW monopile wind turbine structure was needed. QBlade offers advanced capabilities of modelling and designing such equipment without necessary CAD models. The structure investigated in this study was taken from an official online repository website owned by QBlade [

15], which shares the same technical parameters as described in the technical reports from NREL. In order to find the loads on the blades exerted by the wind conditions, the verified windfields were introduced to the system along with the 5MW NREL monopile wind turbine model. The schematic model of the system is shown in

Figure 11.

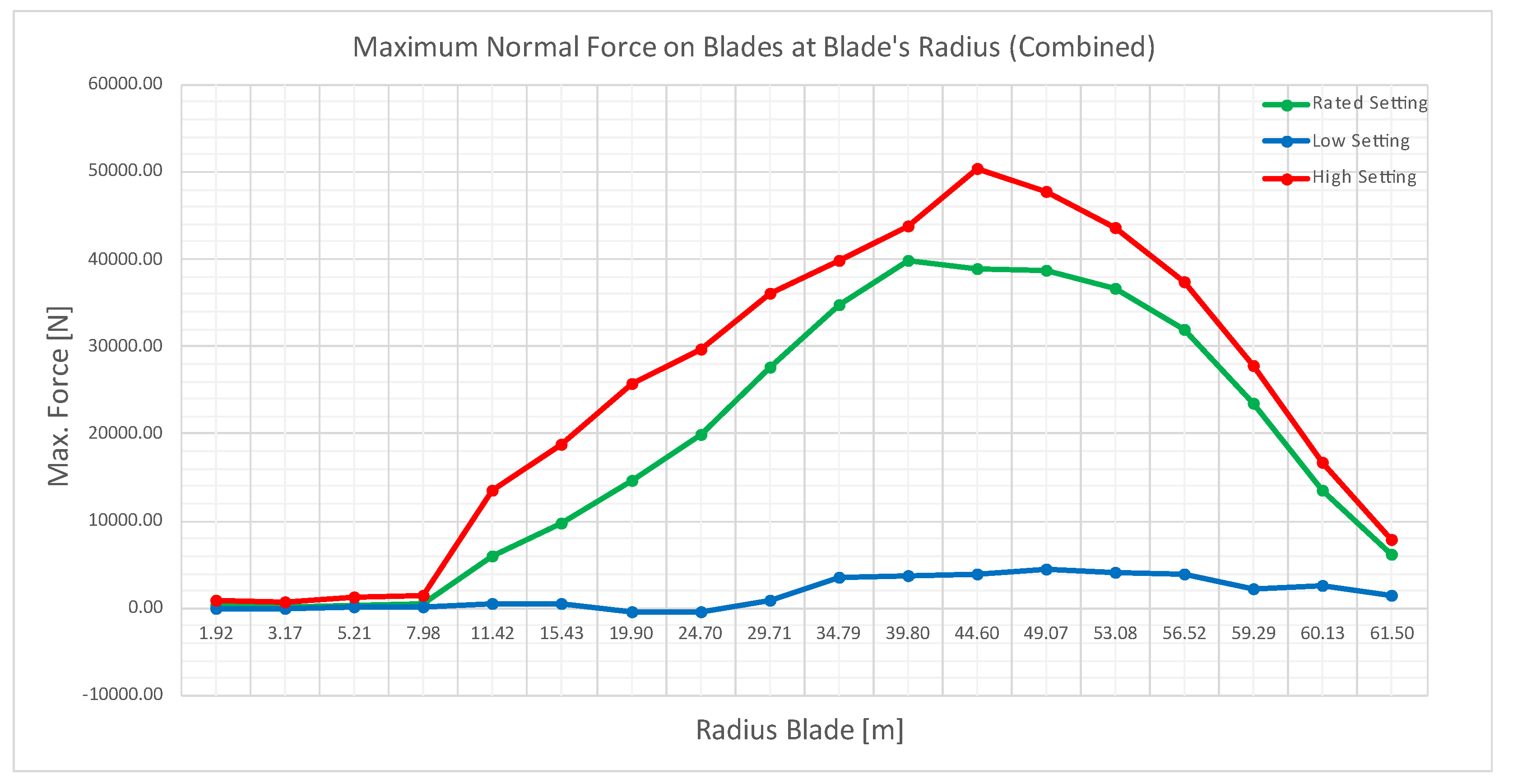

The dynamic simulation of the wind turbine model comprised of 1,000 timesteps, during which the data was gathered. Moreover, at the beginning of the simulation study the wind turbine was given an independent ramp-up time of 20 seconds (ramp-up of rotational speed up to predetermined rated rpm of 12.126). The main outputs for these simulations are normal forces on blades for 3 different settings. The results are presented as numerical values per section of the blade. This means that the blade was divided into 18 sections and corresponding forces specified in

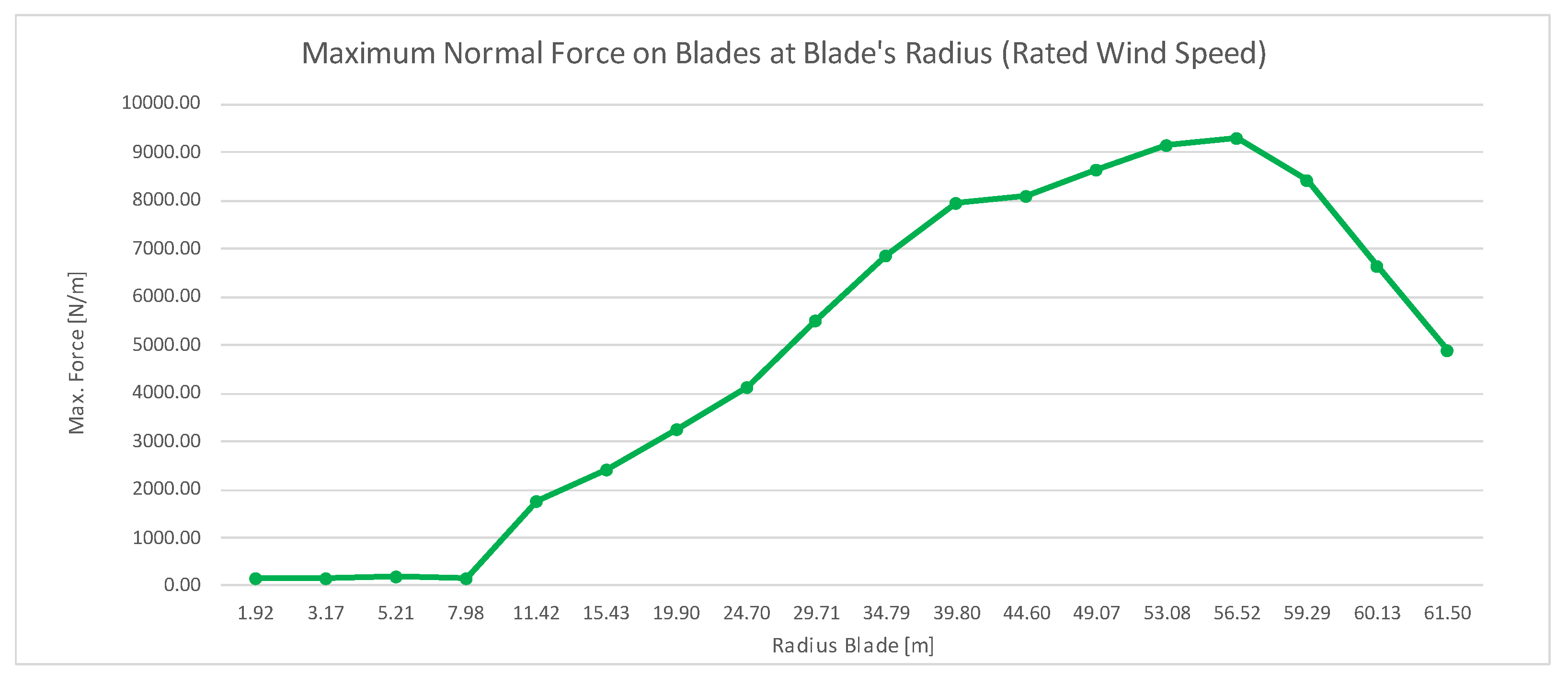

. The exemplary results for Rated setting and its maximum normal forces are presented in

Figure 12.

Results for High and Rated settings followed a pattern, which can be seen by the shape of the sketched curve. Low setting results are mainly inconclusive due to the obtained values. The shown pattern of normal forces acting on the blade does not follow a normal distribution due to extremely low wind speed with a set of negative values for the blade section between 11.42 m and 34.79 m and maximum stress at the tip of the blades. Therefore, this setting will not be analysed in further simulations, due to the indeterminate results.

Rated and High settings have the highest normal forces at sections between 49.07m to 56.52 m. Moreover, they show low values at roots of the blades and decreasing values at the tips.

To validate the next simulations in Solidworks in relation with QBlade results, steady boundary element method (BEM) analysis was conducted. This feature is used to run simulations on rotor performance (rotor simulation) with accurate preliminary results. It was used in this investigation to produce a simulated set of data for evaluation of the blade stresses and maximum loads present at the blades in quadratic finite element method (QFEM) – structural blade design and analysis feature. For this purpose, wind speed, tip speed ratio range from 1 to 12 and wind variables were specified. Subsequently, the loading conditions were imported to QFEM – static blade design and analysis feature through the carried-out BEM simulation, along with the specified tip speed ratio value taken from previous wind turbine simulation study properties.

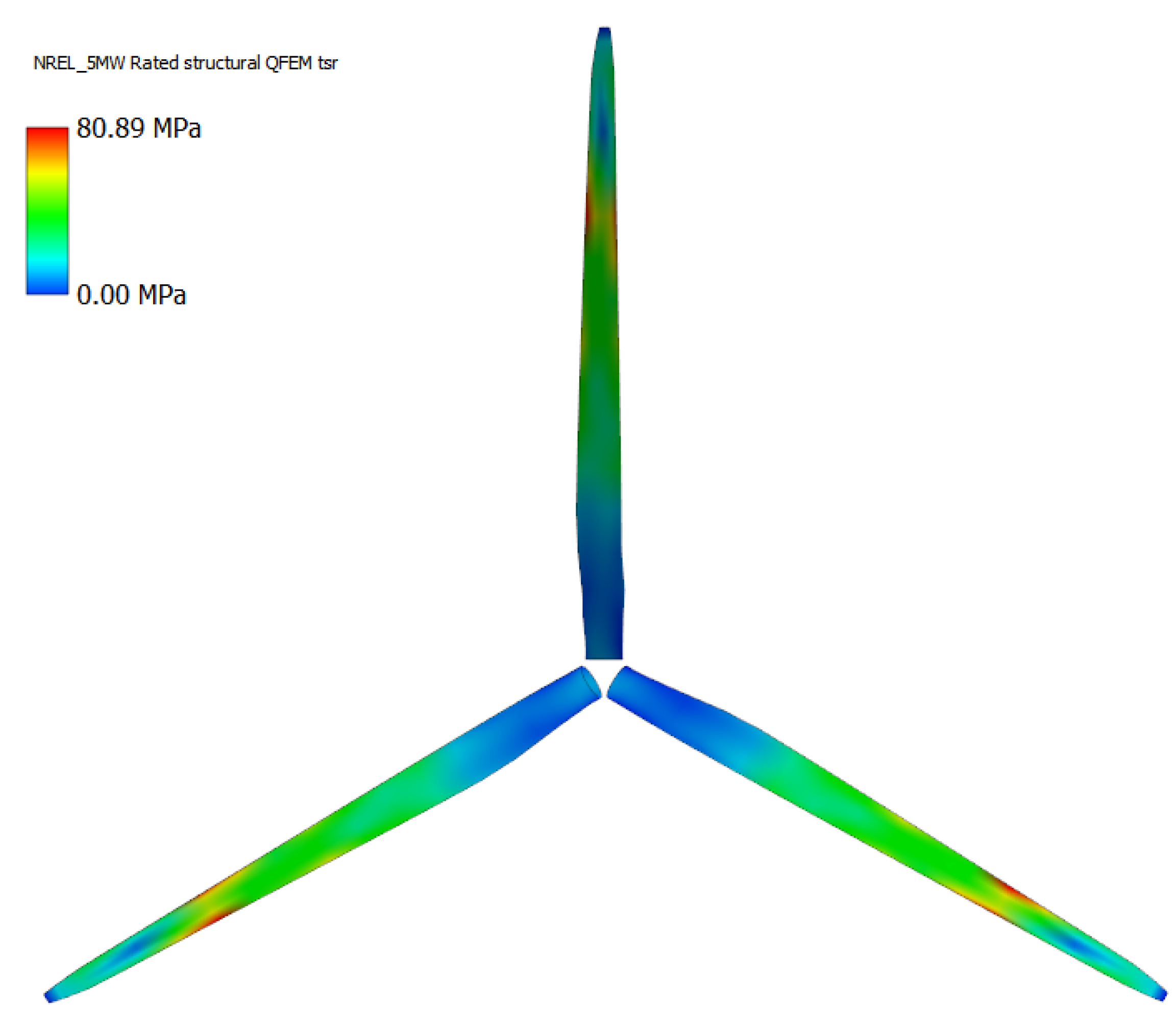

After specifying the rotor blade file, structural model developed in blade design and blade static loading conditions, the maximum blade stress of 80.89 MPa for Rated setting was obtained. This value will be used to compare the output values on the rotor structure from Solidworks and validate the simulation. The graphical and numerical solution for this simulation can be seen in

Figure 13.

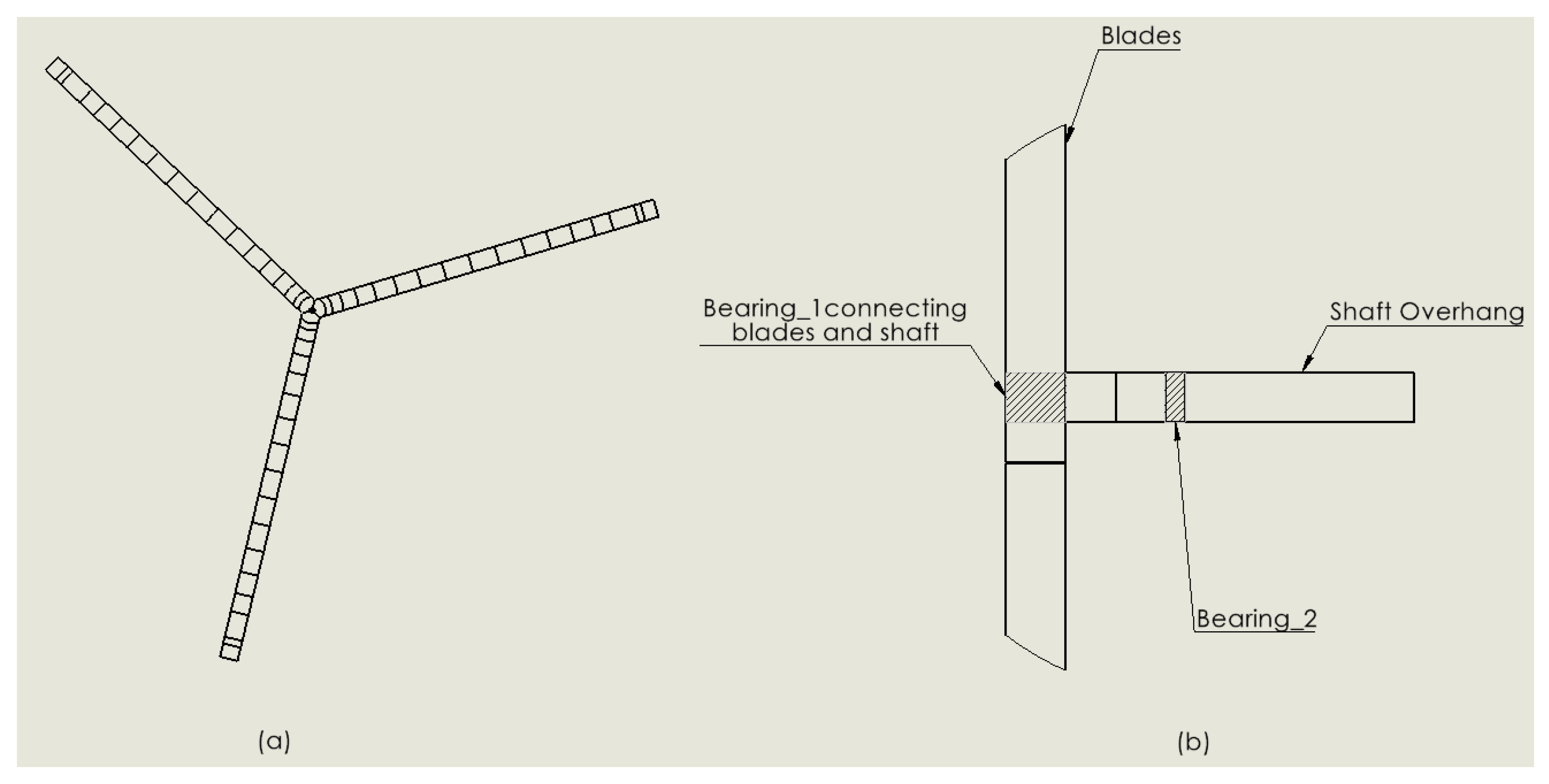

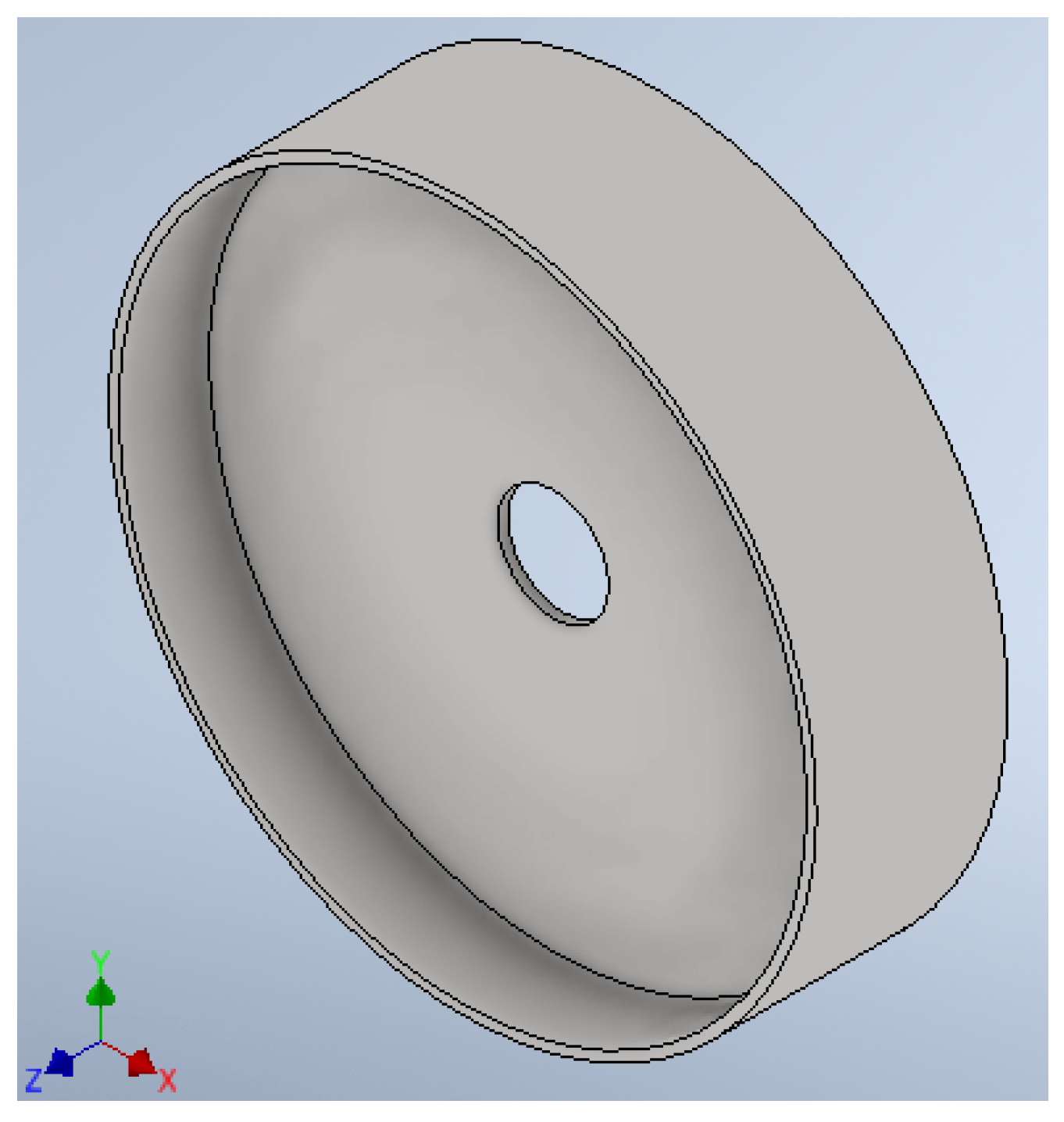

With the aim of performing structural analysis through finite element analysis in Solidworks, CAD models of the assembly containing blades, bearings and shaft had to be developed. Considering the computational expense and solution time of the structural study a more efficient and validated model was generated.

Since the blades would act as a load bearing structure for transferring the stresses to the drive system, it was decided to simplify the model to a rectangular beam. The length of the developed beam would correspond to the blade length. Thickness and breadth of the beam would be taken as an average value from the blade CAD file and 5MW NREL wind turbine technical report [

10]. The blade has also been divided into 18 sections of the identical length to the ones proposed by QBlade software as referenced in

Figure 12. Structural dimensions of the blades are given in

Table 2.

Shaft dimensions and properties are referenced from [

8]. The dimensions of the shaft, as well as locations of 2 concentric bearing supports are presented in

Table 3.

The bearings were located at:

The connection area between the blades and shaft. Therefore, the breadth of the Bearing_1 was set to 1,200 mm (equal to simplified blade thickness), in order to cover the whole connection area.

3,200 mm from the front face of the shaft. This results in creation of 2,000 mm long section of unsupported shaft, which corresponds to identified and investigated generator area.

Bearings were not modelled in Solidworks. Instead, the bearing fixture feature was used, which would resulted in ideal connections between blades and shaft. Moreover, it fixed the shaft about X and Y axis and allowed for rotational movement. The shaft structure was given an overhang section of 4,600 mm after bearing_2. This resulted in a transposed end face of the shaft, which was fixed along the Z axis, and limited the impact of the fixture on the studied shaft section – generator area. This was done in accordance with the St. Venant’s principle, which states that the strain produced by forces applied at one end of a long cylinder are much larger near the loaded end than at points at a larger distance [

15] [

16]. As a result, the deformation at the corresponding generator area was not affected by introducing the additional constraint. When applying the bearing fixtures, the shaft has been divided into 4 sections using the split line feature in Solidworks. Lengths of the sections were dependent on the structural properties of: Bearing_1 breadth, Bearing_2 breadth, Shaft overhang and Shaft length between Bearing_1 and Bearing_2 (generator area), as it can be seen in

Figure 14. Two types of bearing fixtures were considered: rigid and flexible, where flexible fixtures had a combined radial stiffness of 3.81E+10

[

7]. Rigid fixtures were taken into consideration and later compared to the flexible fixtures, although it was assumed that flexible bearing fixtures will better portray the behaviour of the system under loading conditions. For the purpose of constraining the model and calculating the radial stiffness for individual bearings, the parallel spring theory was used by using Equation (1),

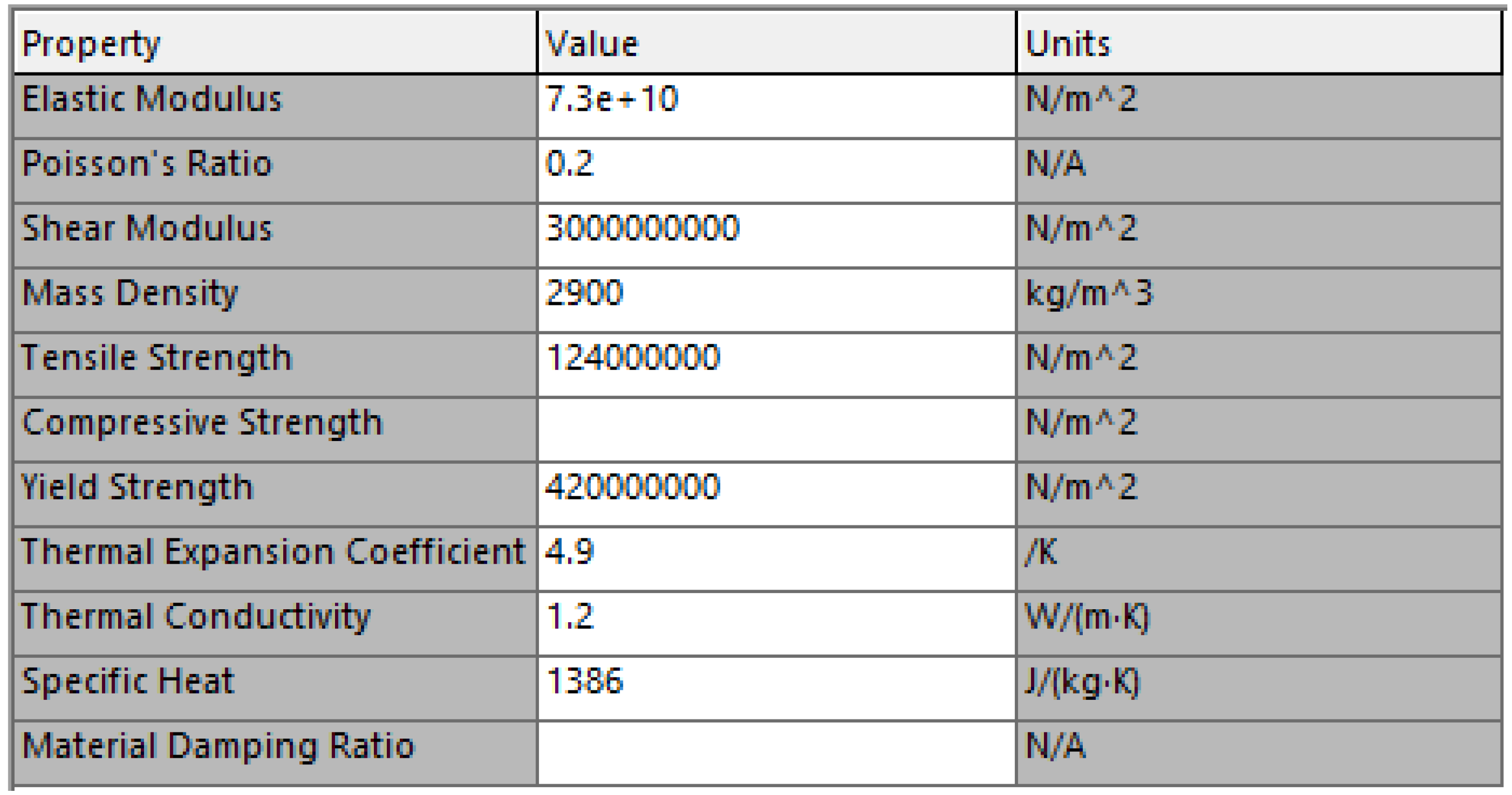

It was necessary to specify the material properties of the created CAD models to produce accurate simulations. Since the analysis of the system in Solidworks was preceded by QBlade simulations, elastic modulus and density, as well as isotropic characteristic of the blade material were taken from the QFEM - static blade design and analysis feature. Any values not specified in QBlade simulations were researched and obtained from MatWeb [

17] and referenced paper [

18]. The blade material was assumed to be made out of E-Glass composite. QBlade finite element package does not consider orthotropic materials. Therefore, the authors used the same approach. The corresponding material properties of the blade are shown in

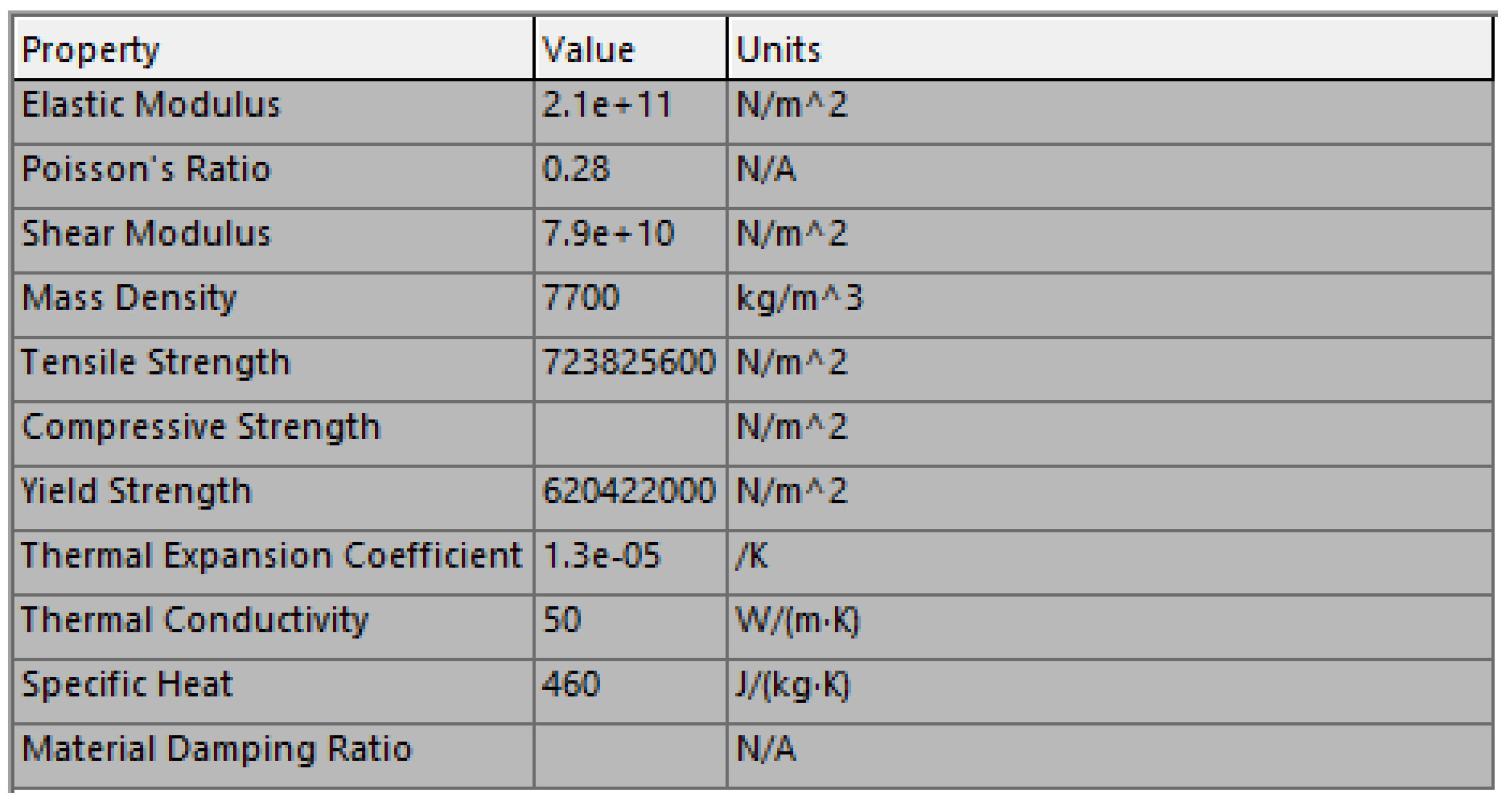

Figure 15. The assumed shaft material properties, shown in

Figure 16, are similar to those of an alloy steel.

The loading conditions have been applied on the blade structure after calculating the corresponding normal forces for Rated and High settings taken from QBlade for all 18 blade sections for each blade condition according to the wind field previously generated. Since the forces from QBlade were specified in

, the obtained values were multiplied by the section length on which the normal forces were acting upon. In total 54 different forces (per setting) were applied on the 3 blades in assembly. The comparison between the calculated normal forces for 3 different settings for one blade were presented in

Figure 17. The results for Low setting were included in the figure, in order to present the minimal influence of the wind speed on the normal forces present.

Due to the significant size of the assembly, blended curvature-based meshing feature was used. Ultimately, two different mesh sizes were used for the model. A coarser mesh was chosen for the blades, whereas by using local mesh control on the shaft, smaller sized mesh was introduced. Once the general characteristics of the meshing technique were examined, a mesh independence study was conducted. Mesh for the blades had a maximum element size of 100 mm and a minimum element size of 10 mm, whereas the shaft had maximum and minimum element sizes of 62 mm and 55.8 mm, respectively. This resulted in 7,816,261 total number of nodes and 5,543,022 total number of tetrahedral elements.