Submitted:

07 November 2023

Posted:

08 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

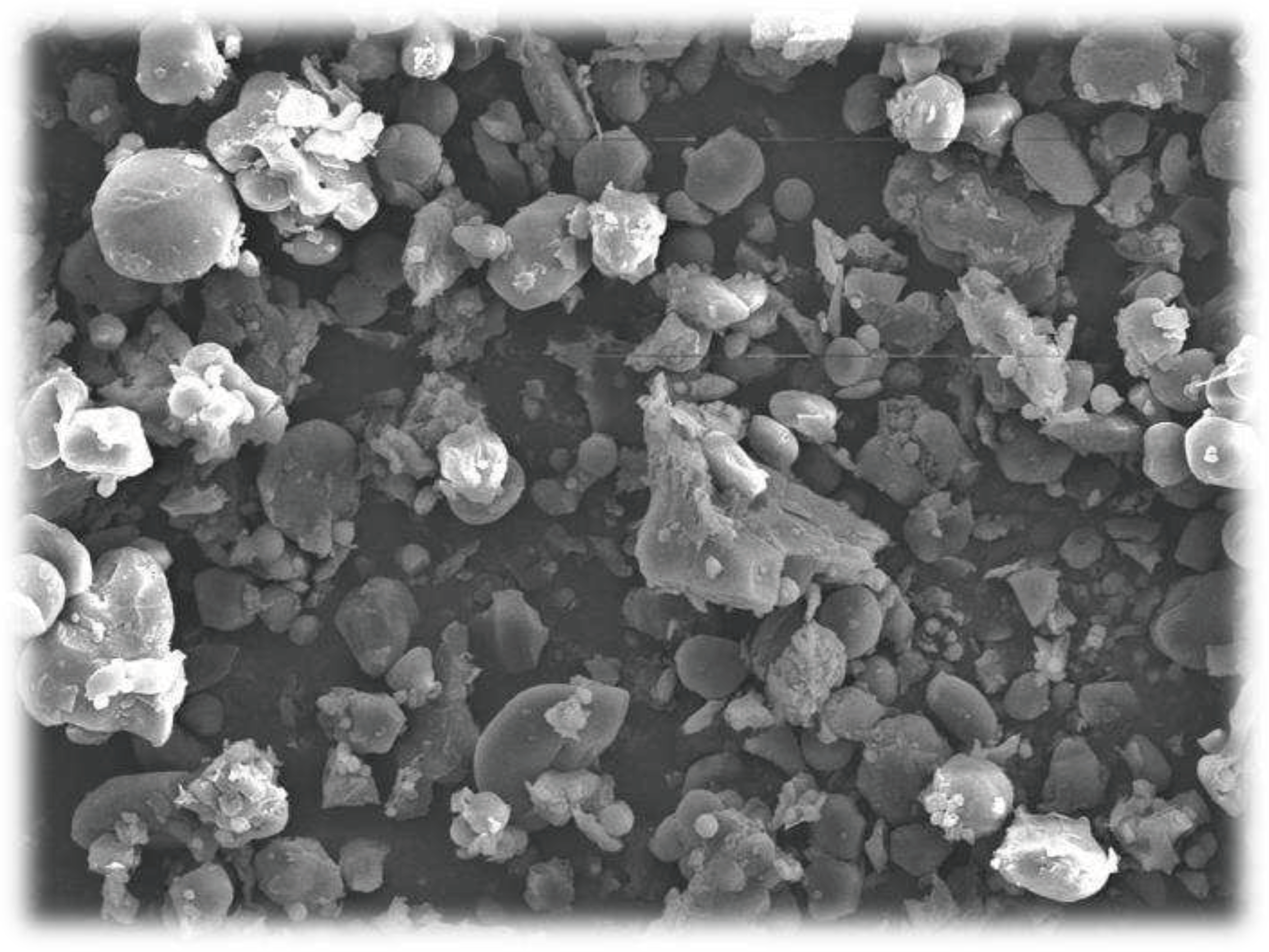

2. Materials and Methods

3. Results and Discussion

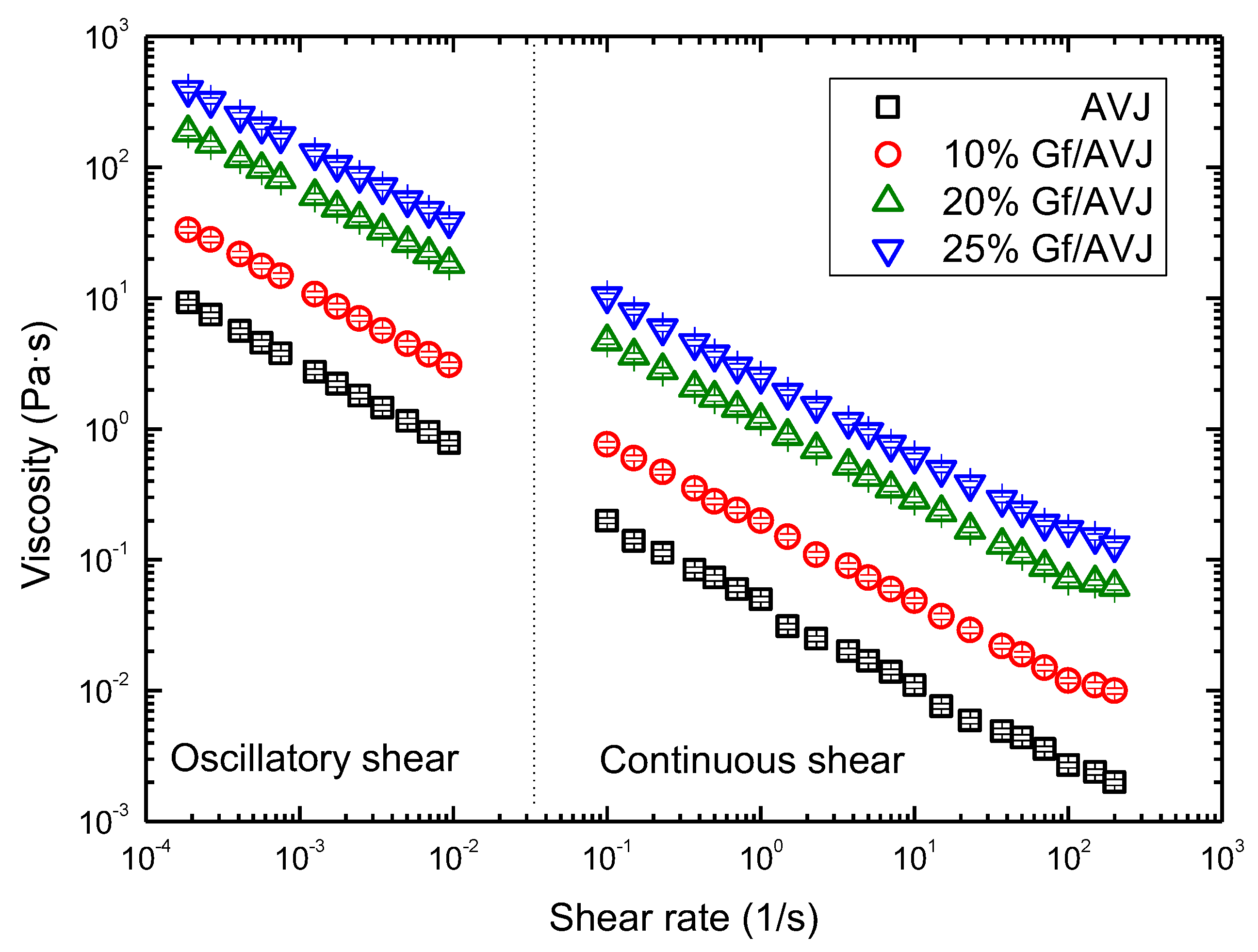

3.1. Steady Viscous Behavior

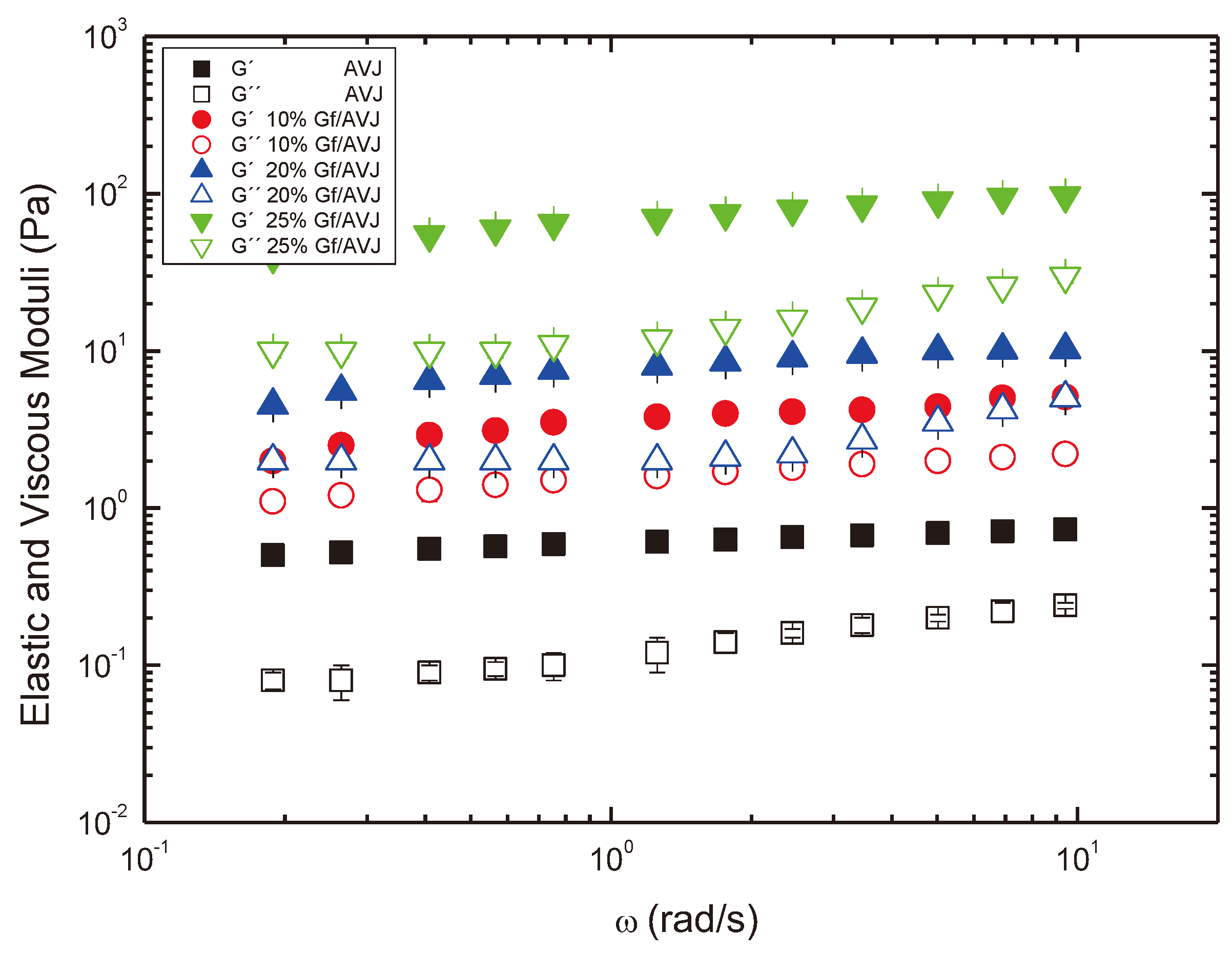

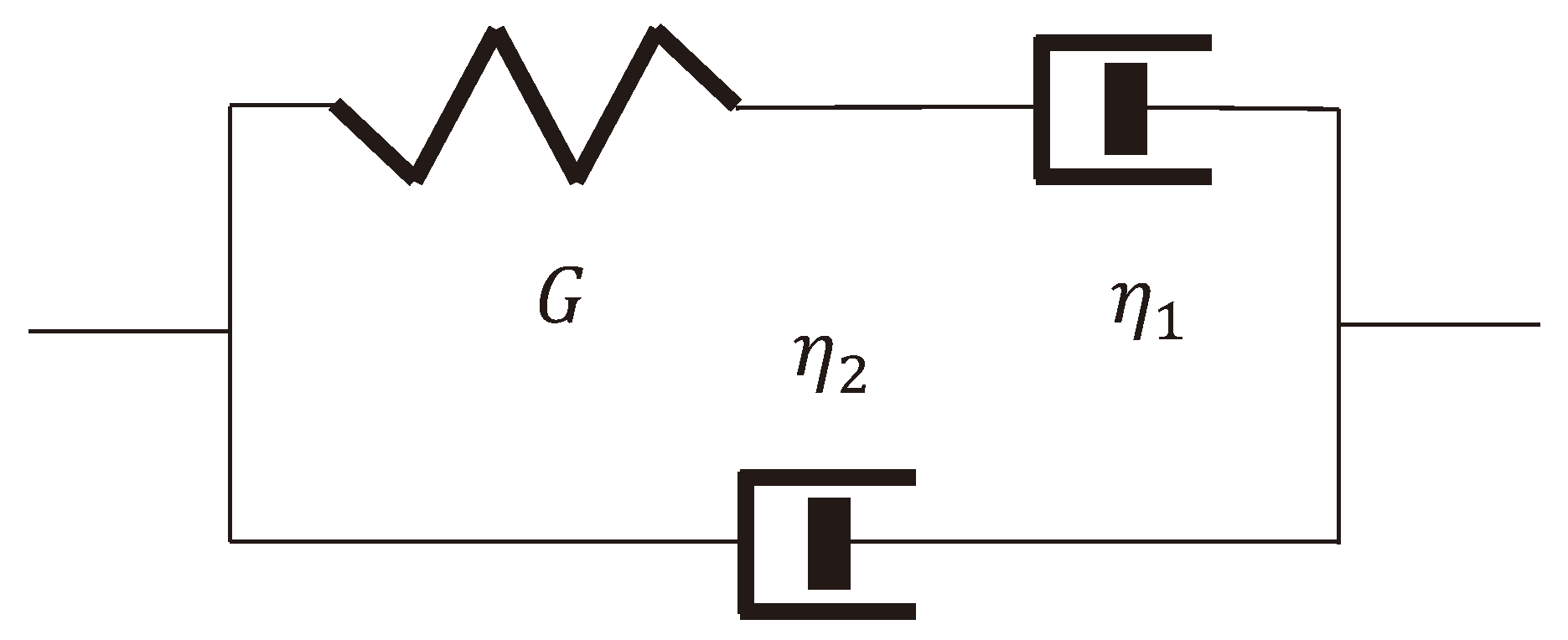

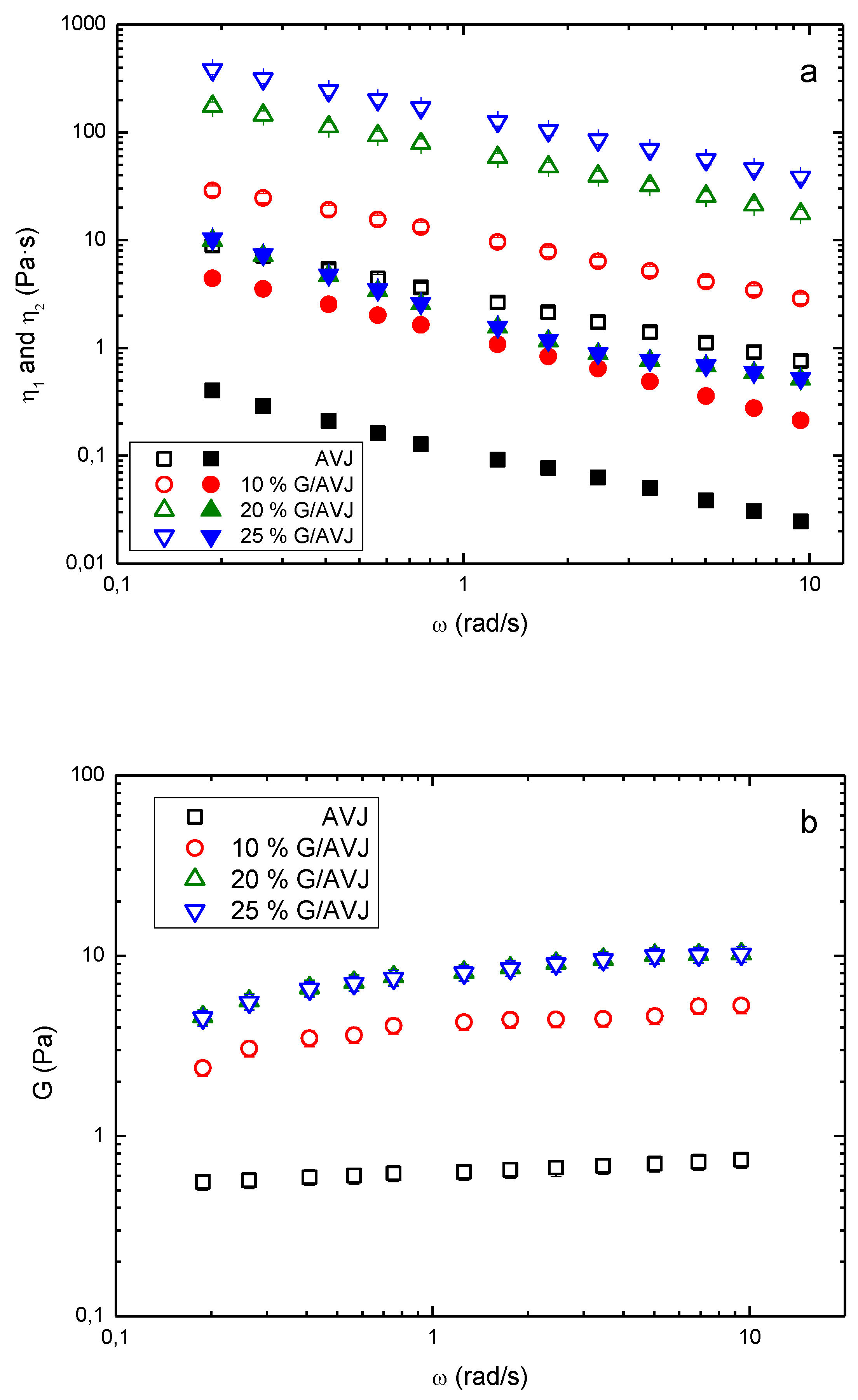

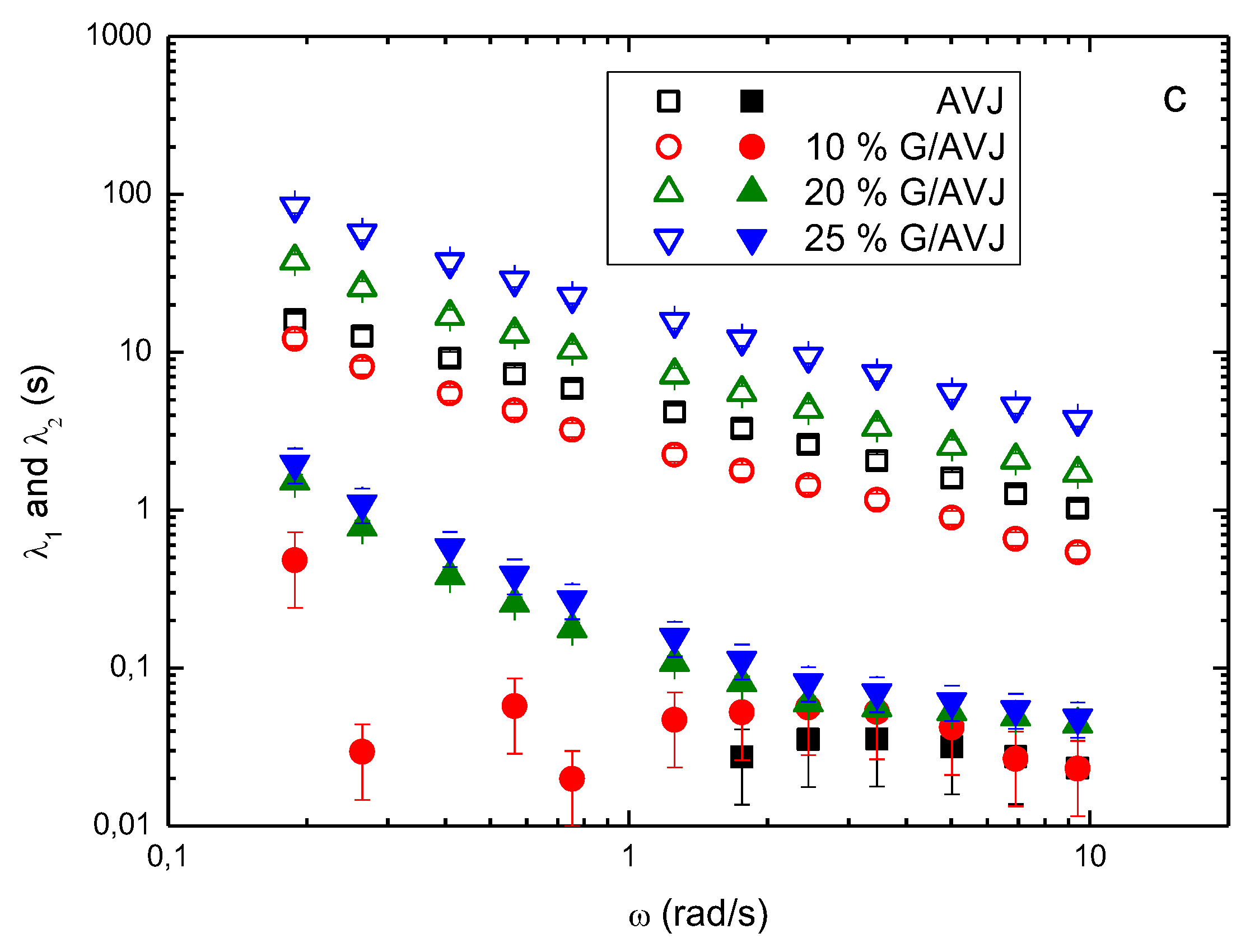

3.2. Viscoelastic Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hes, M.; Dziedzic, K.; Górecka, D.; JedrusekGolinska, A.; Gujska, E. Aloe vera (L.) Webb.: Natural Sources of Antioxidants-A Review. Plant Foods Hum. Nutr. 2019, 74, 255–265. [Google Scholar] [CrossRef] [PubMed]

- Chhikara, N.; Kaur, A.; Mann, S.; Garg, M.K.; Sofi, S.A.; Panghal, A. Bioactive compounds, associated health benefits and safety considerations of Moringa oleifera L.: an updated review. Nutr. Food Sci. 2020, 51, 255–277. [Google Scholar] [CrossRef]

- Domínguez-Fernández, R.N.; Arzate-Vázquez, I.; Chanona-Pérez, J.J.; Welti-Chanes, J.S.; Alvarado-González, J.S.; Calderón-Domínguez, G.; Garibay-Febles, V.; Gutiérrez-López, G.F. Aloe vera gel: structure, chemical composition, processing, biological activity, and importance in pharmaceutical and food industry. Rev. Mex. Ing. Quim. 2012, 11, 23–43. [Google Scholar]

- Sonowane, S.K.; Gokhale, J.S.; Mulla, M.Z.; Kandu, V.R.; Patil, S. A comprehensive overview of functional and rheological properties of aloe vera and its applications in foods. J. Food Sci. Technol. 2021, 58, 1217–1226. [Google Scholar] [CrossRef] [PubMed]

- Matabura, V.V.; Rweyemamu, L.M.P. Effects of Xanthan gum on rheological properties of Aloe-vera-Moringa leaf juice blends. Tanzan. J. Sci. 2021, 47, 583–596. [Google Scholar] [CrossRef]

- Diario Oficial de la Unión Europea (DOUE). Reglamento de Ejecución (U.E.) nº 128/2014.

- Caballero-Mesa, J.M. Estudio toxicológico, higiénico-sanitario y nutricional del gofio canario. PhD Thesis, Universidad de La Laguna, Canary Island, Spain, 2010. [Google Scholar]

- Hu, Y.; Xu, J.; Hu, Q. Evaluation of antioxidant potential of aloe vera (aloe vera barbadensis Miller) extracts. J. Agric. Food Chem. 2003, 51, 7788–7791. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Liu, C.; Kojo, E.; Tian, Z. Quality and safety assurance in the processing of aloe vera gel juice. Food Control 2005, 16, 95–104. [Google Scholar] [CrossRef]

- Hulle, N.R.S.; Patruni, K.; Rao, P.S. Rheological properties of aloe vera (aloe barbadensis Miller) juice concentrates. J. Food Process Eng. 2014, 37, 375–386. [Google Scholar] [CrossRef]

- Prieto-Méndez, J.; Rubio-Hinojosa, C.U.; Román-Gutiérrez, A.D.; Méndez-Marzo, M.A.; González-Ramírez, A.; Prieto-García, F. Degradación física del almidón de cebada (hordeum sativun Jess). Correlación entre la gelatinización y el tamaño de gránulos. Multiciencias 2009, 9, 115–125. [Google Scholar]

- Masoero, E.; Delgado, E.; Pellenq, R.M.; Ulm, F.J.; Yip, S. Nanostructure and nanomechanics of cement: Polydisperse colloidal packing. Phys. Rev. Lett. 2012, 109, 155503. [Google Scholar] [CrossRef] [PubMed]

- Rao, M.A. Rheology of fluid and semisolid foods. Principles and applications; Springer: New York, U.S.A., 2007. [Google Scholar]

- Dak, M.; Verma, R.C.; Sharma, G.P. Flow characteristics of juice of “Totapuri” mangoes. J. Food Eng. 2006, 76, 557–561. [Google Scholar] [CrossRef]

- Sesmero, R.; Mitchell, J.; Mercado, J.; Quesada, M. Rheological characterization of juices obtained from transgenic pectate lyase-silenced strawberry fruits. Food Chem. 2009, 116, 426–432. [Google Scholar] [CrossRef]

- Rubio-Merino, J.; Rubio-Hernández, F.J. Activation energy for the viscoelastic flow: Analysis of the microstructure-at-rest of (water- and milk-based) fruit beverages. Food Chem. 2019, 293, 486–490. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Hernández, F.J.; Ayúcar-Rubio, M.F.; Velázquez-Navarro, J.F.; Galindo-Rosales, F.J. Intrinsic viscosity of SiO2, Al2O3, and TiO2 aqueous suspensions. J. Colloid Interface Sci. 2006, 298, 967–972. [Google Scholar] [CrossRef] [PubMed]

- Krieger, I.M.; Dougherty, T.J. Concentration dependence of the viscosity of suspensions. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Gómez-Merino, A.I.; Rubio-Hernández, F.J.; Velázquez-Navarro, J.F.; Aguiar, J.; Jiménez-Agredano, C. Study of the aggregation state of anatase-water nanofluids using rheological and DLS methods. Ceram. Int. 2014, 40, 14045–14050. [Google Scholar] [CrossRef]

- Sánchez, A. Colloidal gels of fumed silica: microstructure, surface interactions, and temperature effects. PhD Thesis, North Carolina State University, U.S.A., 2006. [Google Scholar]

- Leite, R.T.; de Souza-Mendes, P.R.; Thompson, R.L. A simple method to analyze materials under quasilinear large amplitude oscillatory shear flow (QL-LAOS). J. Rheol. 2019, 63, 305–317. [Google Scholar] [CrossRef]

| 0 | |||||

| 5 | |||||

| 10 | |||||

| 15 | |||||

| 20 | |||||

| 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).