Submitted:

08 November 2023

Posted:

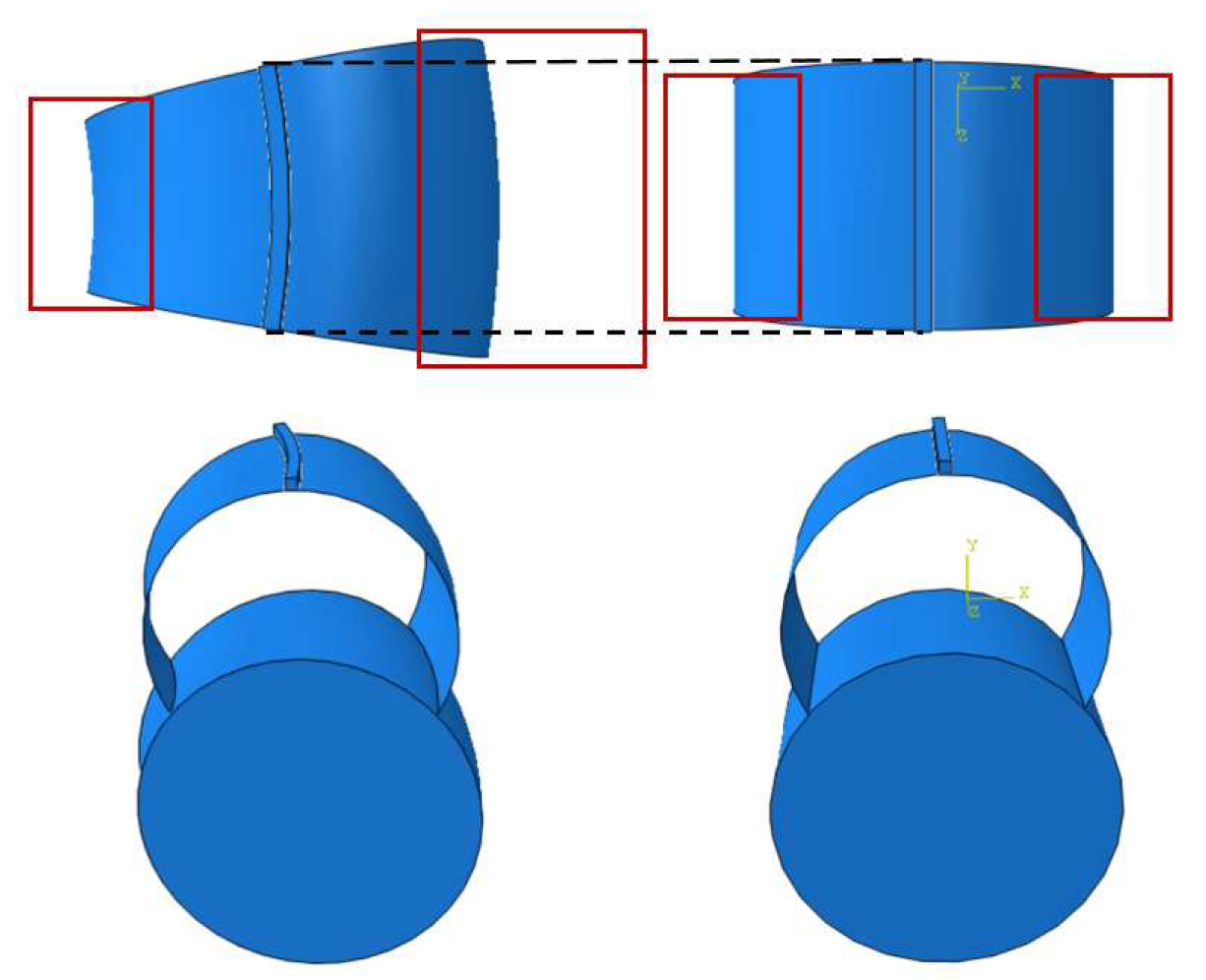

09 November 2023

You are already at the latest version

Abstract

Keywords:

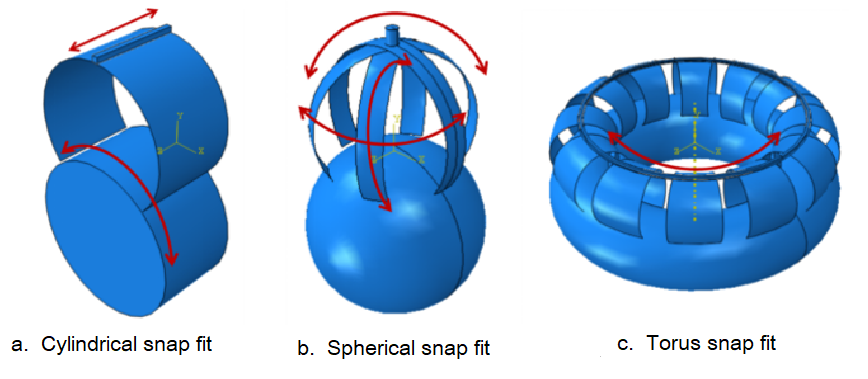

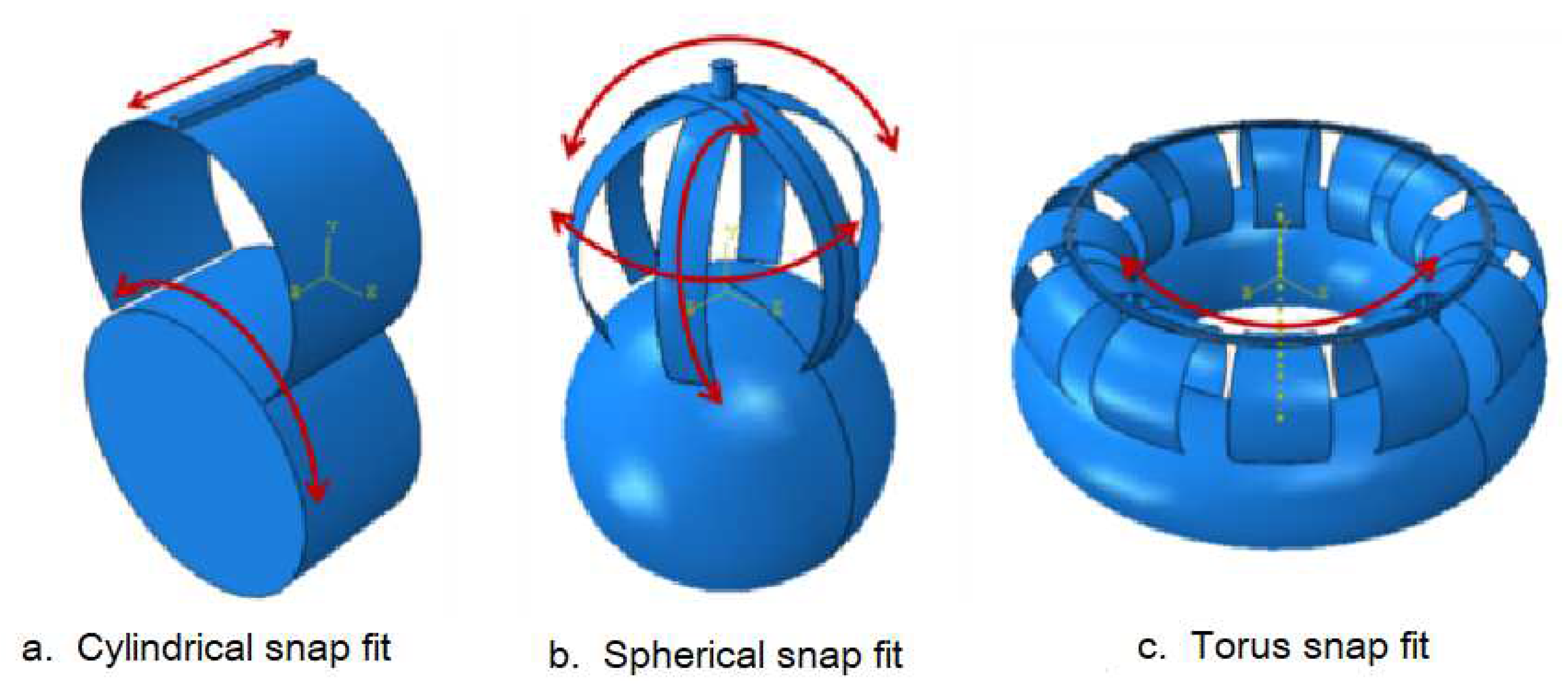

1. Introduction

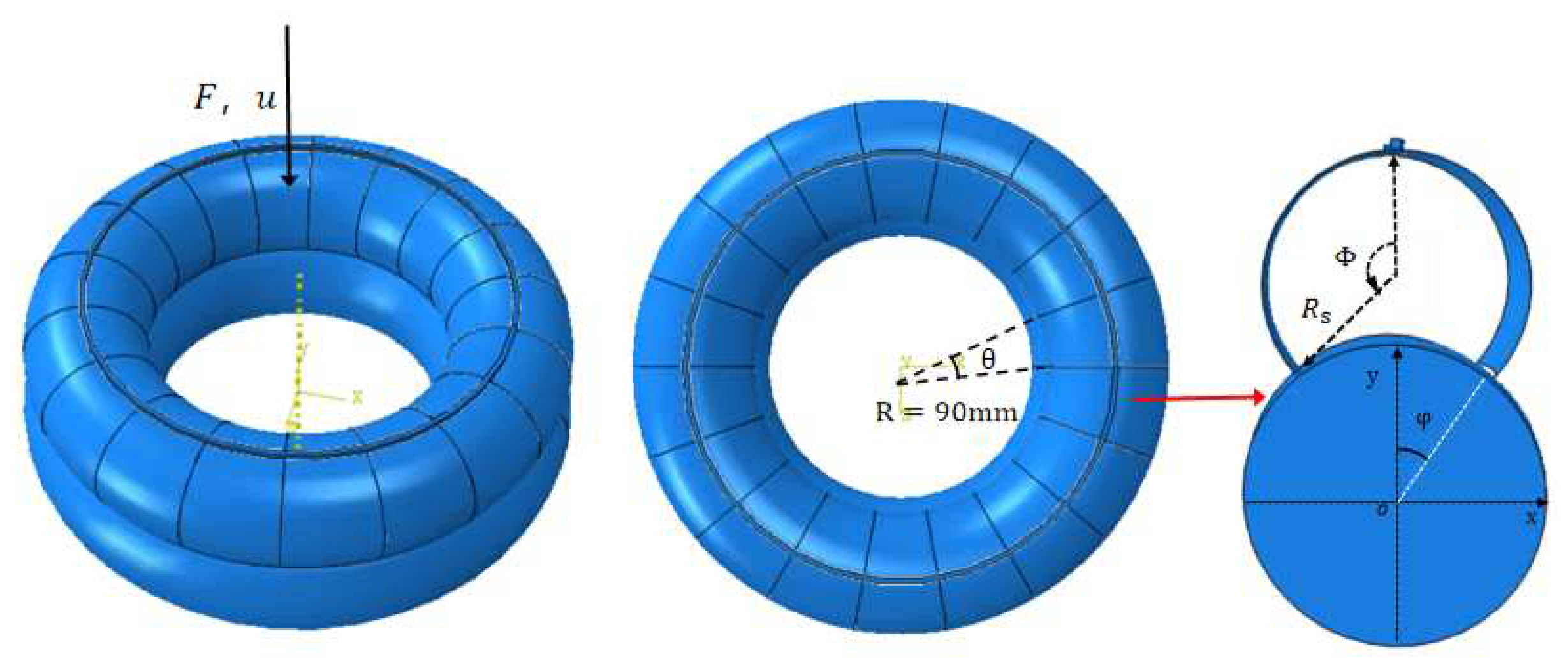

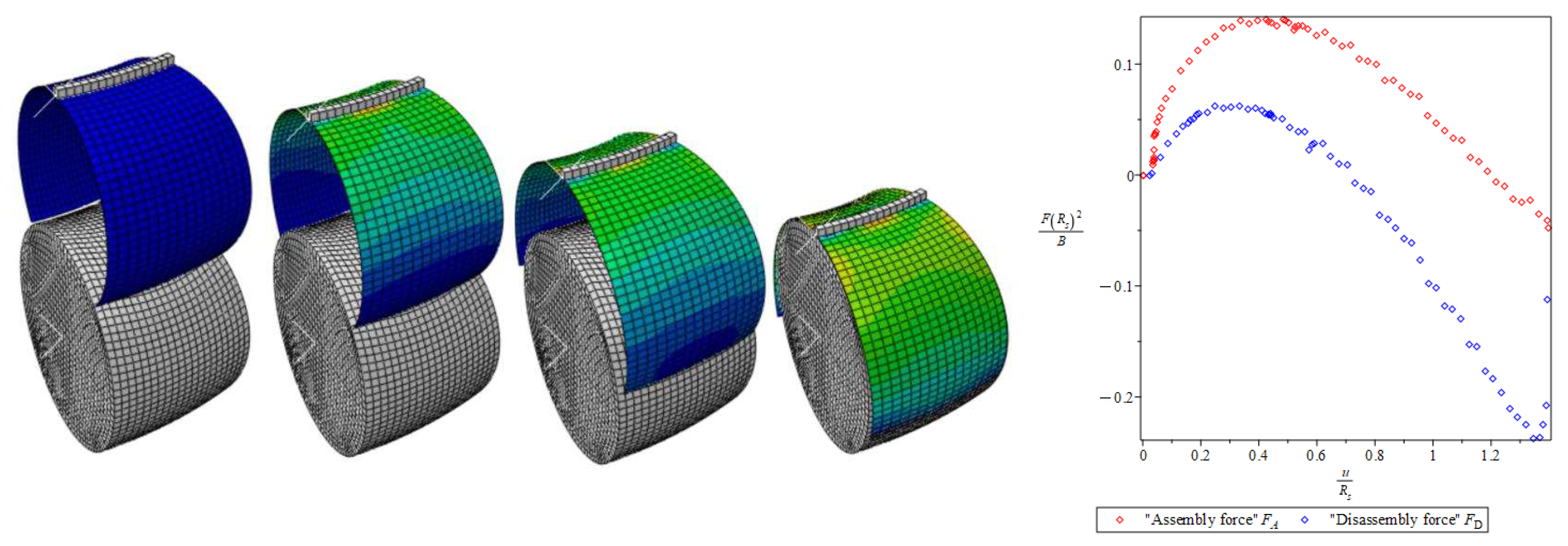

2. Assembly/disassembly force finite element analysis of a single torus snap fit

3. Experimental analysis of a single component torus snap fit

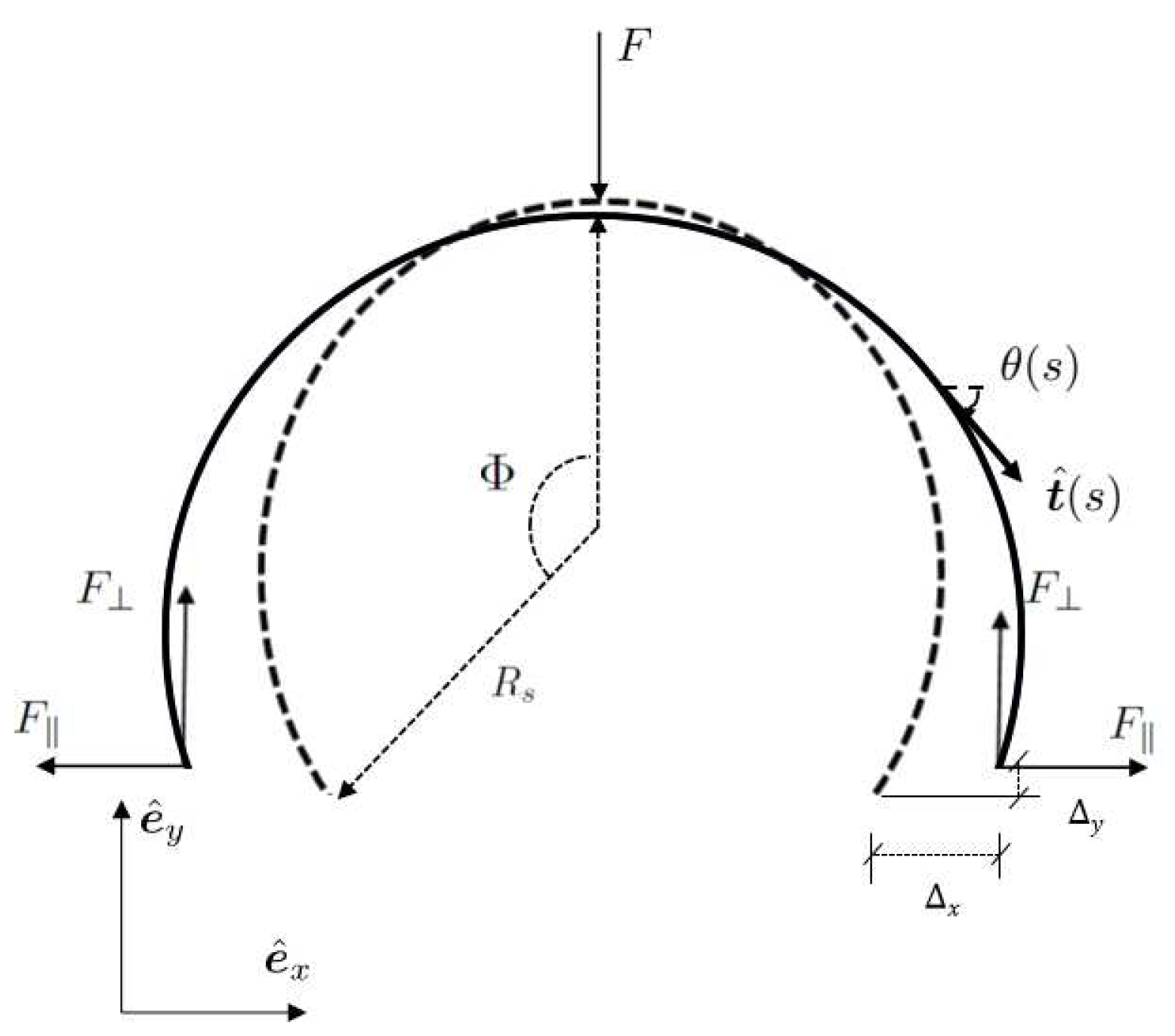

4. Assembly/disassembly force theoretical prediction of a single torus snap fit

5. Conclusions and perspectives

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rivera, J.; Hosseini, M.S.; Restrepo, D.; Murata, S.; Vasile, D.; Parkinson, D.Y.; et al. Toughening mechanisms of the elytra of the diabolical ironclad beetle. Nature 2020, 586, 543–548. [Google Scholar] [CrossRef] [PubMed]

- Wri, J.; Sun, B.H. Bioinspiration: Pull-Out Mechanical Properties of the Jigsaw Connection of Diabolical Ironclad Beetle’s Elytra. Acta Mechanica Solida Sinica 2023. [Google Scholar] [CrossRef]

- Sun, B.H. Closed-form solution of axisymmetric slender elastic toroidal shells. J. of Eng. Mech. 2010, 136, 1281–1288. [Google Scholar] [CrossRef]

- Sun, B.H. Toroidal Shells. (Nova Novinka, New York, 2012).

- Sun, B.H. Exact solution of Qian’s equation of slender toroidal shells (in Chinese). Mech. in Eng. 2018, 38, 567–569. (In Chinese) [Google Scholar]

- Sun, B.H. Small symmetrical deformation of thin torus with circular cross-cection. Thin-Walled Structures 2021, 163, 107680. [Google Scholar] [CrossRef]

- Sun, B.H. Geometry-induced rigidity in elastic torus from circular to oblique elliptic cross-section. Int.J. Non-linear Mech. 2021, 135, 103754. [Google Scholar] [CrossRef]

- Sun, B.H. Gol’denveizer’s problem of elastic torus. Thin-Walled Structures 2022, 171, 108718. [Google Scholar] [CrossRef]

- Sun, B.H. Nonlinear elastic deformation of Mindlin torus. Comm. in Nonlinear Sci. Num Sim. 2022, 114, 106698. [Google Scholar] [CrossRef]

- Song, G.K.; Sun, B.H. Nonlinear investigation of Gol’denveizer’s problem of a circular and elliptic elastic torus. Thin-Walled Structures 2022, 180, 109862. [Google Scholar] [CrossRef]

- Sun, B.H.; Song, G.K. The Mechanics Difference Between the Outer Torus and Inner Torus. J. Appl.Mech. 2023, 90, 071012–1. [Google Scholar] [CrossRef]

- W. Flügge, Stresses in Shells, Springer-Verlag Berlin, 1973.

- Gol’denveizer, A.L. Theory of Elastic thin Shells, Pergamon Press, New York, 1961.

- Audoly, B.; Pomeau, Y. Elasticity and Geometry (Oxford University Press, New York, 2010).

- Zingoni, A.; Enoma, N.; Govender, N. Equatorial bending of an elliptic toroidal shell. Thin-Walled Struct. 2015, 96, 286–294. [Google Scholar] [CrossRef]

- Jiammeepreecha, W.; Chucheepsakul, S. Nonlinear static analysis of an underwater elastic semi-toroidal shell. Thin-Walled Struct. 2017, 116, 12–18. [Google Scholar] [CrossRef]

- Enoma, N.; Zingoni, A. Analytical formulation and numerical modelling for multi-shell toroidal pressure vessels. Computers & Structures 2020, 232, 105811. [Google Scholar]

- Song, G.K.; Sun, B.H. Buckling of ellipsoid grid-shells made of smooth triaxial weaving with naturally in-plane curved ribbons. Thin-Walled Structures 2023, 191, 111060. [Google Scholar] [CrossRef]

- Bayer Corporation. Snap fit Joints for Plastics: A Design Guide (Polymer Division, Pittsburgh, PA, 1996).

- Bonenberger, P.R. The First Snap-Fit Handbook (3rd ed.), Hanser Publishers, Munich (2016).

- Dai, Y.F.; Sun, B.H.; Zhang, Y.; Li, X. Morphological transformation of arched ribbon driven by torsion. Thin-Walled Structures 2022, 170, 108511. [Google Scholar] [CrossRef]

- Xu, R.; He, Y.L.; Li, X.; Lu, M.H.; Chen, Y.F. Snap-fit mechanical metamaterials. Appl. Mat. Today. 2023, 30, 101714. [Google Scholar] [CrossRef]

- Yoshida, K.; Wada, H. Mechanics of a snap fit. Phys. Rev. Lett. 2020, 125, 194301. [Google Scholar] [CrossRef]

- Guo, X.L.; Sun, B.H. Assembly and Disassembly Mechanics of a Cylindrical Snap Fit. Preprints 2022, 2022010076. [Google Scholar] [CrossRef]

- Guo, X.L.; Sun, B.H. Assembly and disassembly mechanics of a spherical snap fit. Theor.Appl. Mech. Lett. 2023, 13, 100403. [Google Scholar] [CrossRef]

- Sun, B.H.; Guo, X.L. Clamping force of a multilayered cylindrical clamper with internal friction. Theor.Appl. Mech. Lett 2022, 12, 100355. [Google Scholar] [CrossRef]

- Moy, V.T.; Florin, E.L.; Gaub, H.E. Intermolecular forces and energies between ligands and receptors. Science 1994, 266, 257. [Google Scholar] [CrossRef]

- Suri, G.; Luscher, A.F. Structural abstraction in snap-fit analysis. J. Mech. Design. 2000, 122, 395. [Google Scholar] [CrossRef]

- Romano, M.; Friedman, D.A.; Shay, T.J. Laboratory experimentation of autonomous spacecraft approach and docking to a collaborative target. J. Spacecr Rockets 2007, 44, 164. [Google Scholar] [CrossRef]

- Benson, R.C. The Deformation of a thin incomplete, elastic ring in a frictional channel. J. Appl. Mech. 1981, 48, 895. [Google Scholar] [CrossRef]

- Benson, R.C. Stick/slip conditions for s thin, incomplete, elastic ring impinging on a frictional barrier. J. Appl. Mech. 1982, 49, 231. [Google Scholar] [CrossRef]

- He, X.Q.; Wang, C.M.; Lam, K.Y. Analytical bending solutions of elastics with one end held while the other end portion slides on a friction support. Arch. Appl. Mech. 1997, 67, 543. [Google Scholar] [CrossRef]

- Rafsanjani, A.; Akbarzadeh, A.; Pasini, D. Snapping mechanical metamaterils under tension. Adv. Mater. 2015, 27, 5931. [Google Scholar] [CrossRef] [PubMed]

- Sano, T.G.; Yamaguchi, T.; Wada, H. Slip morphology of elastic strips on frictional rigid substrates. Phys. Rev. Lett. 2017, 118, 178001. [Google Scholar] [CrossRef]

- Popova, E.; Popov, V. The research works of Coulomb and Amontons and generalized laws of friction. Friction 2015, 3, 183. [Google Scholar] [CrossRef]

- Wu, L.; Xi, X.; Li, B.; Zhou, J. Multi-Stable Mechanical Structural Materials. Adv. Eng. Mater. 2018, 20, 1700599. [Google Scholar] [CrossRef]

- Mose, B.R.; Son, I.-S.; Bae, J.-W.; Ann, H.-G.; Lee, C.Y.; Shin, D.-K. Modified analytical method to calculate the assembly and separation forces of cantilever hook-type snap-fit. J. Mech. Eng. Sci. 2019, 233, 5074. [Google Scholar] [CrossRef]

- Holmes, D.P. Elasticity and Stability of Shape-Shifting Structures. Curr. Opin. Colloid Interface Sci. 2019, 40, 118. [Google Scholar] [CrossRef]

- Sano, T.G.; Hohnadel, E.; Kawata, T.; Metivet, T. Florence Bertails-Descoubes, Randomly stacked open cylindrical shells as functional mechanical energy absorber. Comm. Mat. 2023, 4, 59. [Google Scholar] [CrossRef]

| Radius ratio | Angle | Thickness | Opening angle |

|---|---|---|---|

| t(mm) | (rad) | ||

| 1.14 | 20 | 0.3 | 1.9 |

| 1.14 | 20 | 0.3 | 2.0 |

| 1.14 | 20 | 0.3 | 2.1 |

| 1.14 | 20 | 0.3 | 2.2 |

| 1.14 | 20 | 0.3 | 2.3 |

| 1.14 | 20 | 0.3 | 2.4 |

| 1.14 | 20 | 0.3 | 2.5 |

| 1.14 | 20 | 0.3 | 2.6 |

| 1.14 | 20 | 0.3 | 2.7 |

| 1.14 | 20 | 0.3 | 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).