Submitted:

17 November 2023

Posted:

17 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

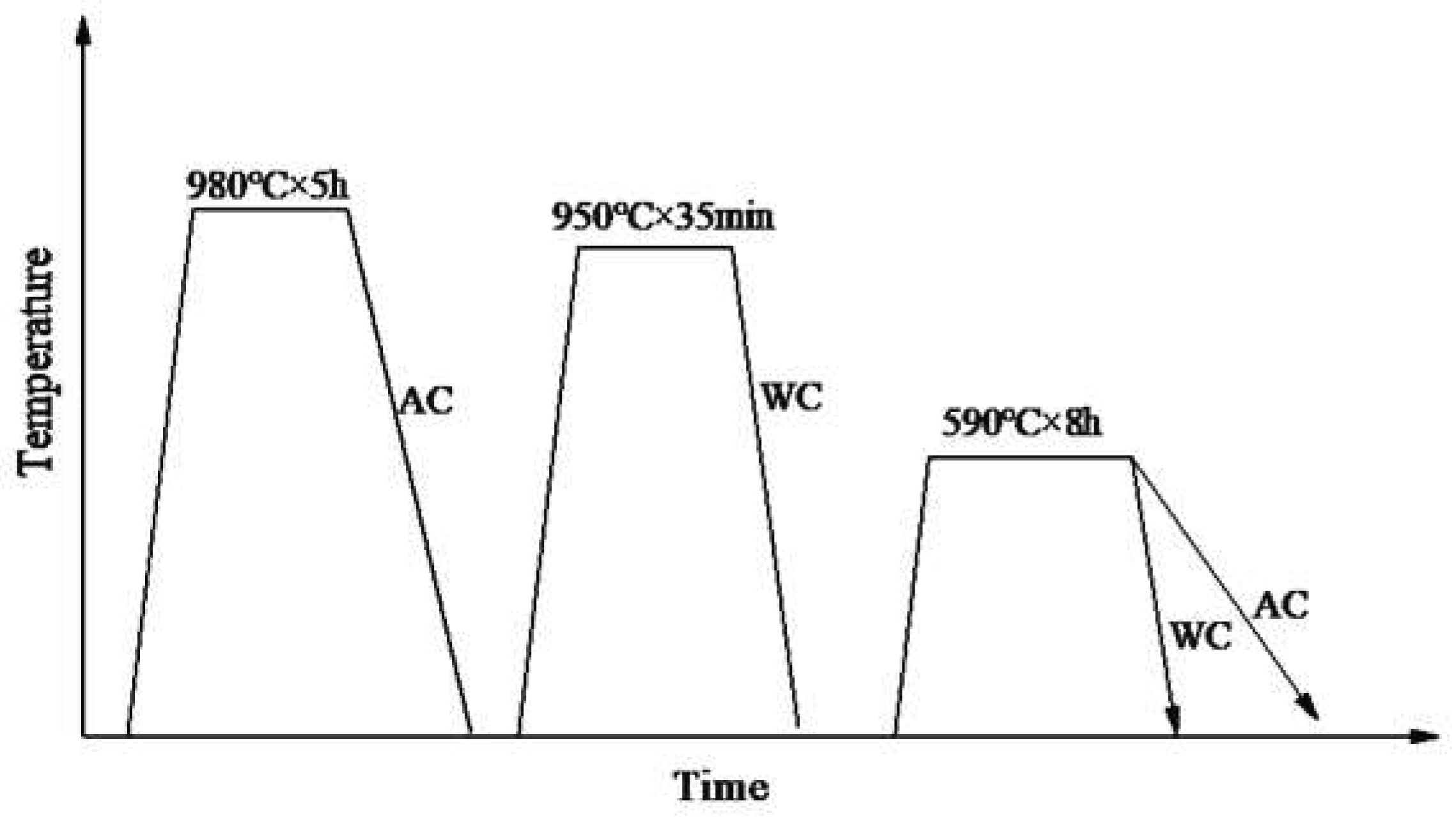

2. Experimental Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties and Microstructure of Tempering Cooling Methods

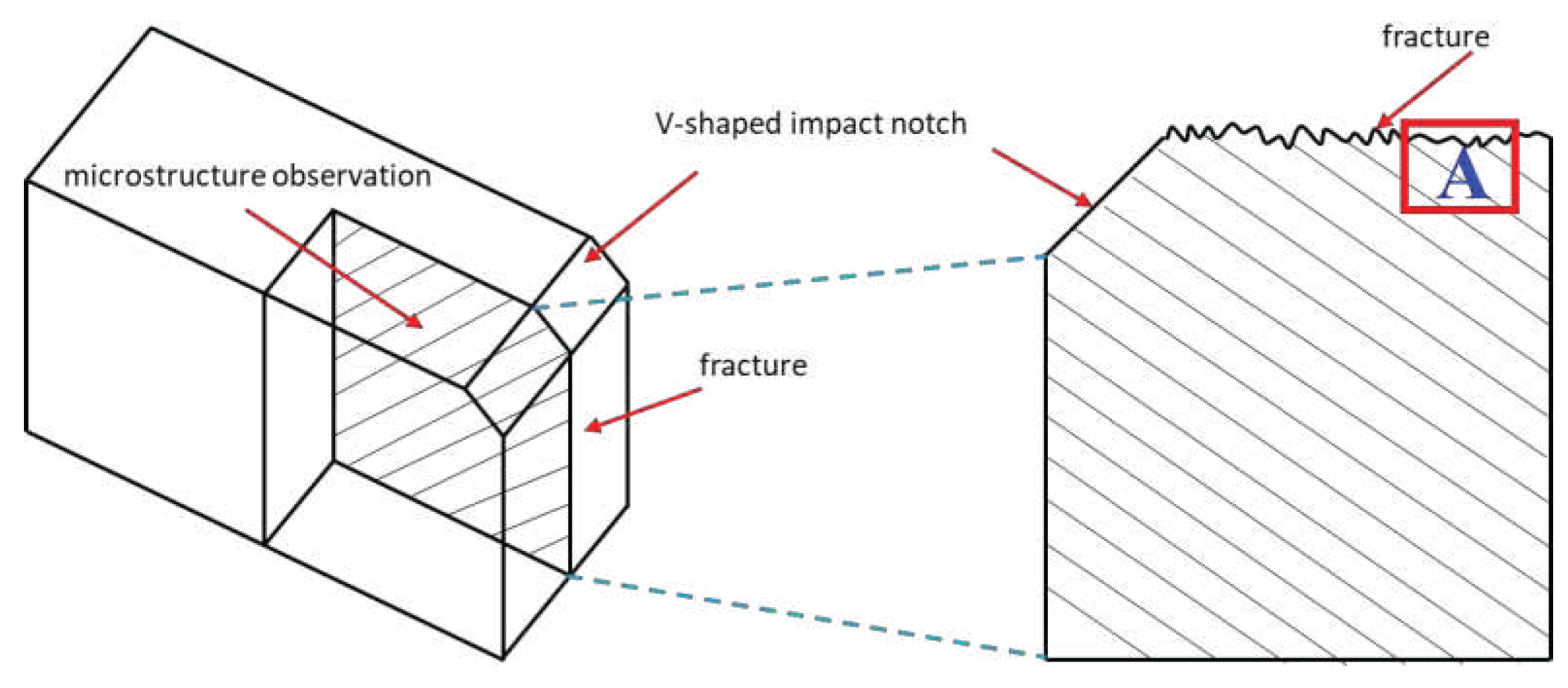

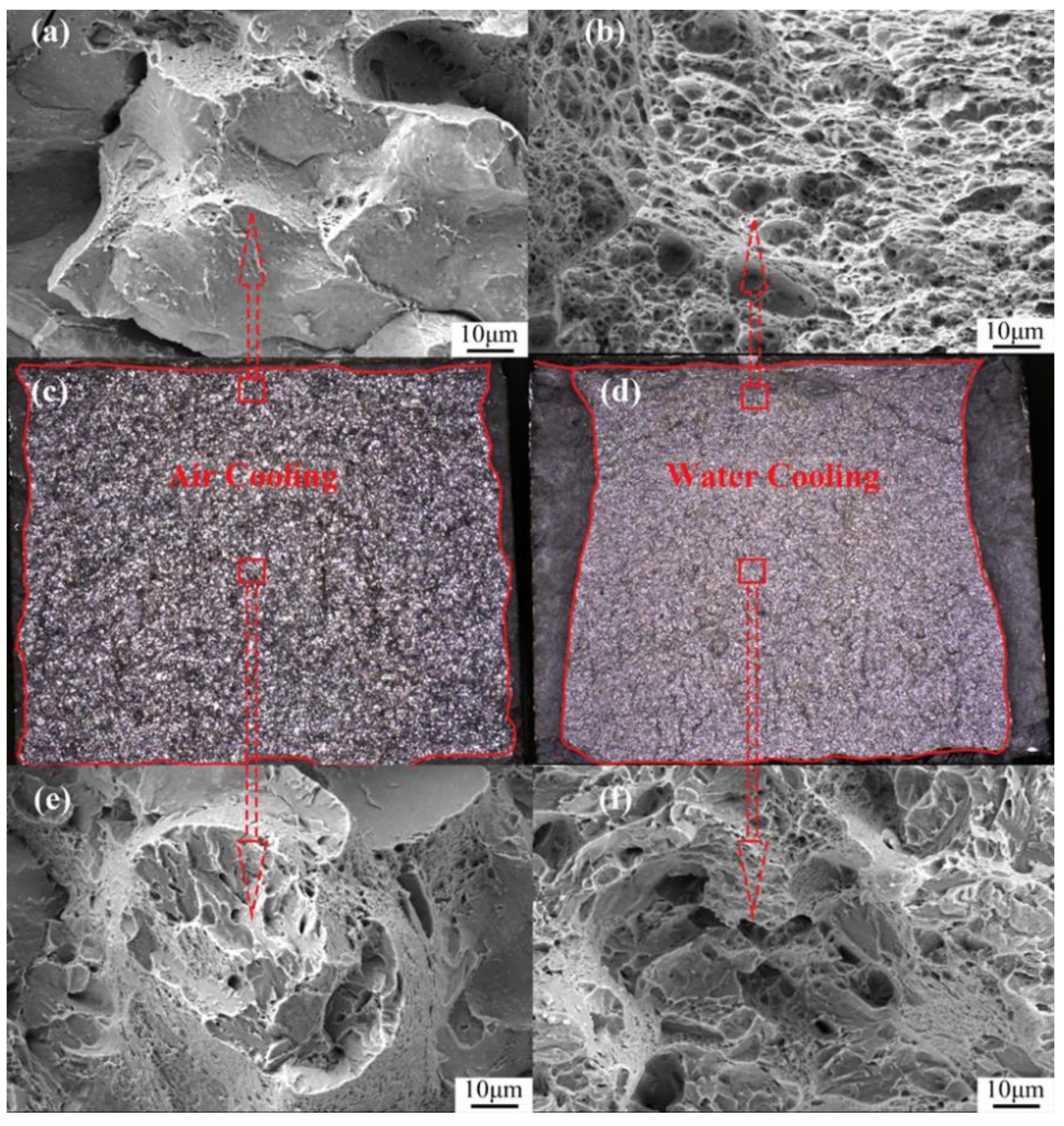

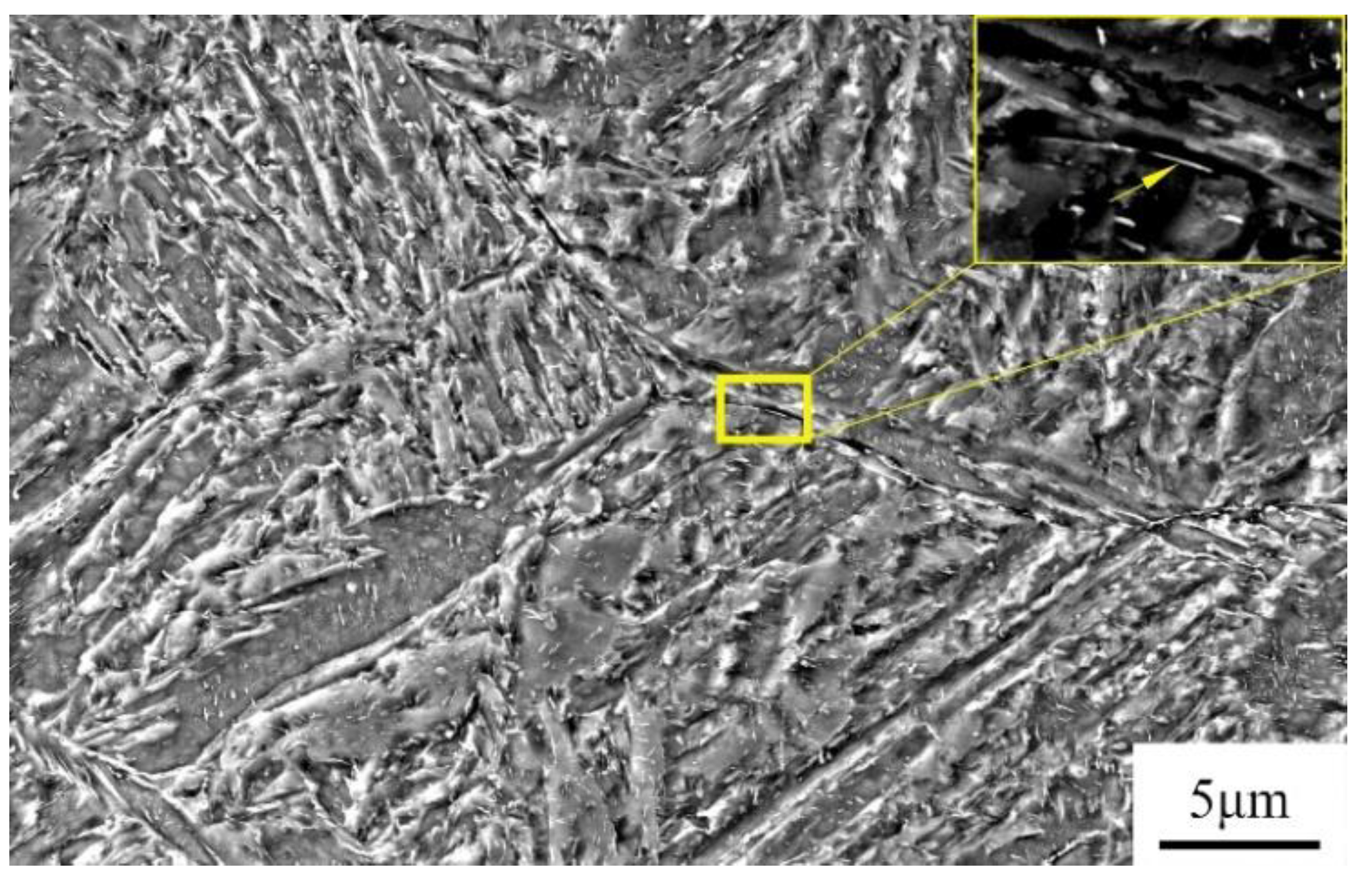

3.2. Impact of Cooling Rate on Crack Propagation

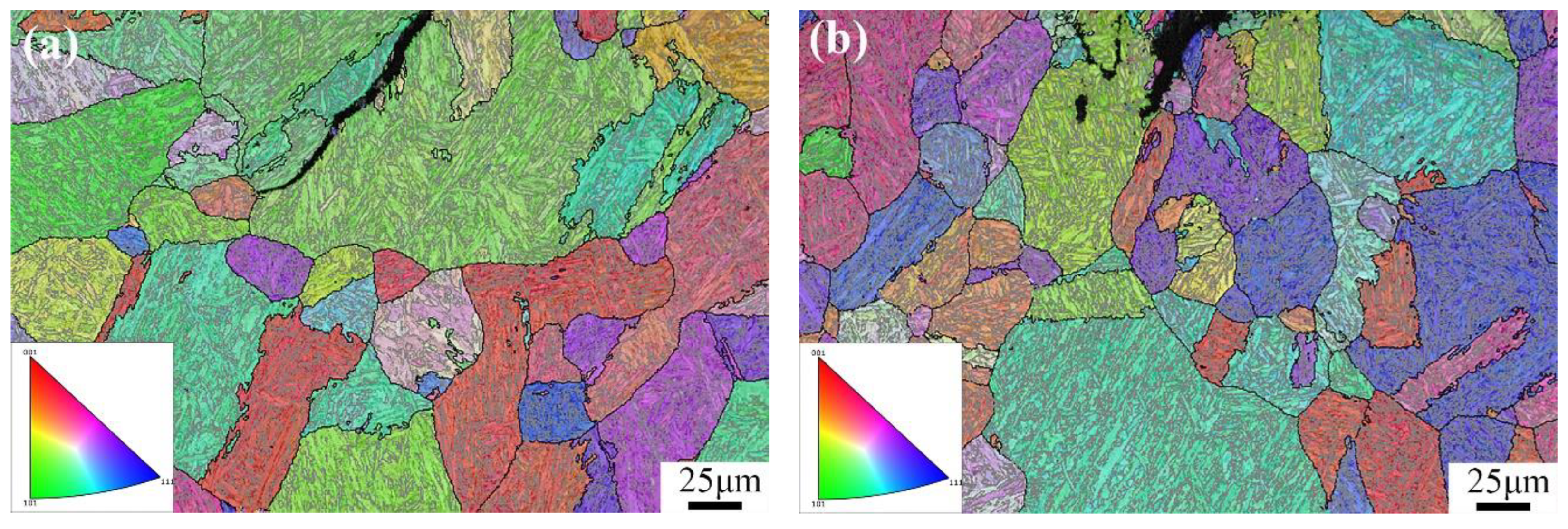

3.3. Influence of Cooling Rate on M/B Microstructure

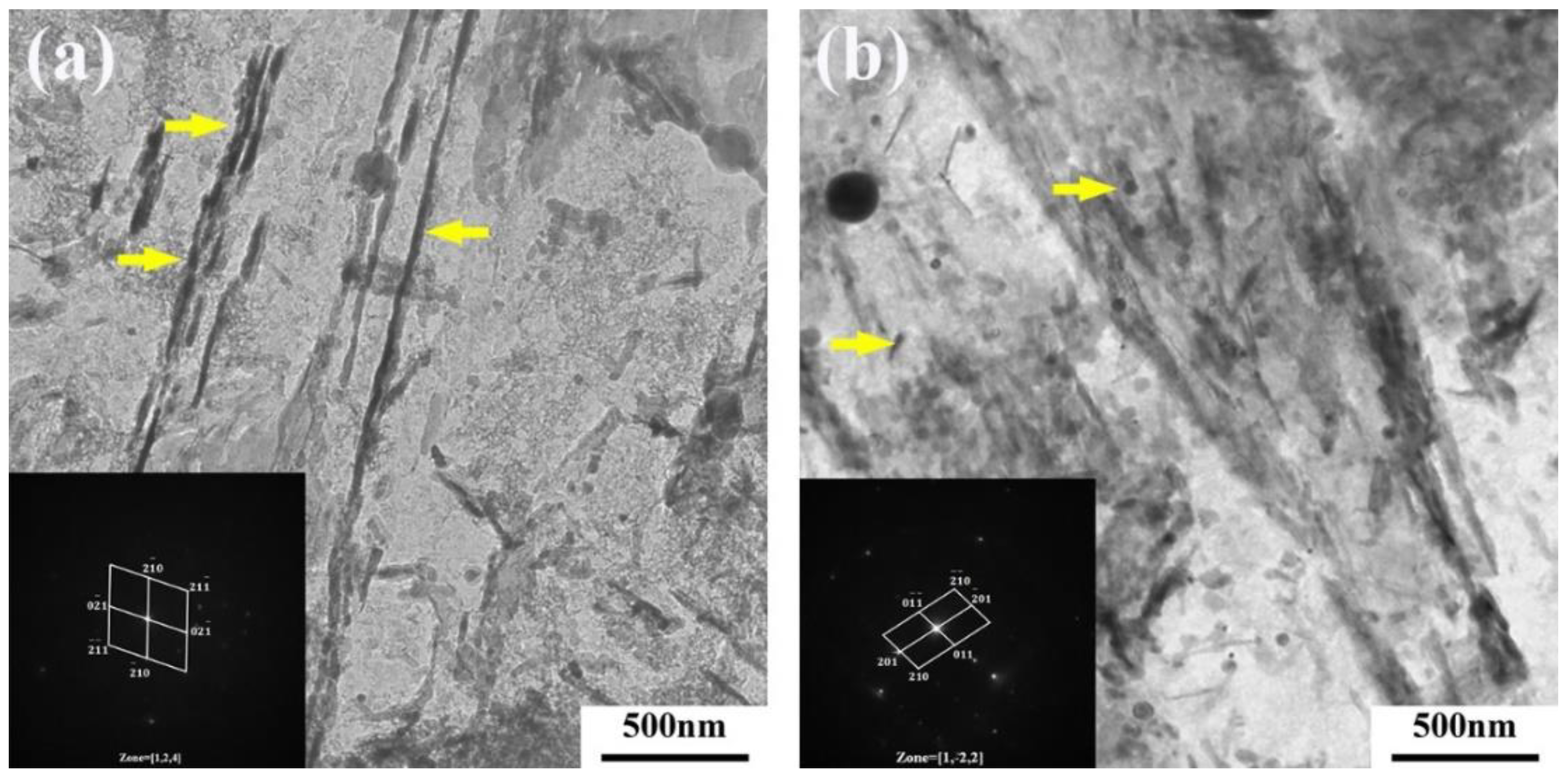

4. Conclusions

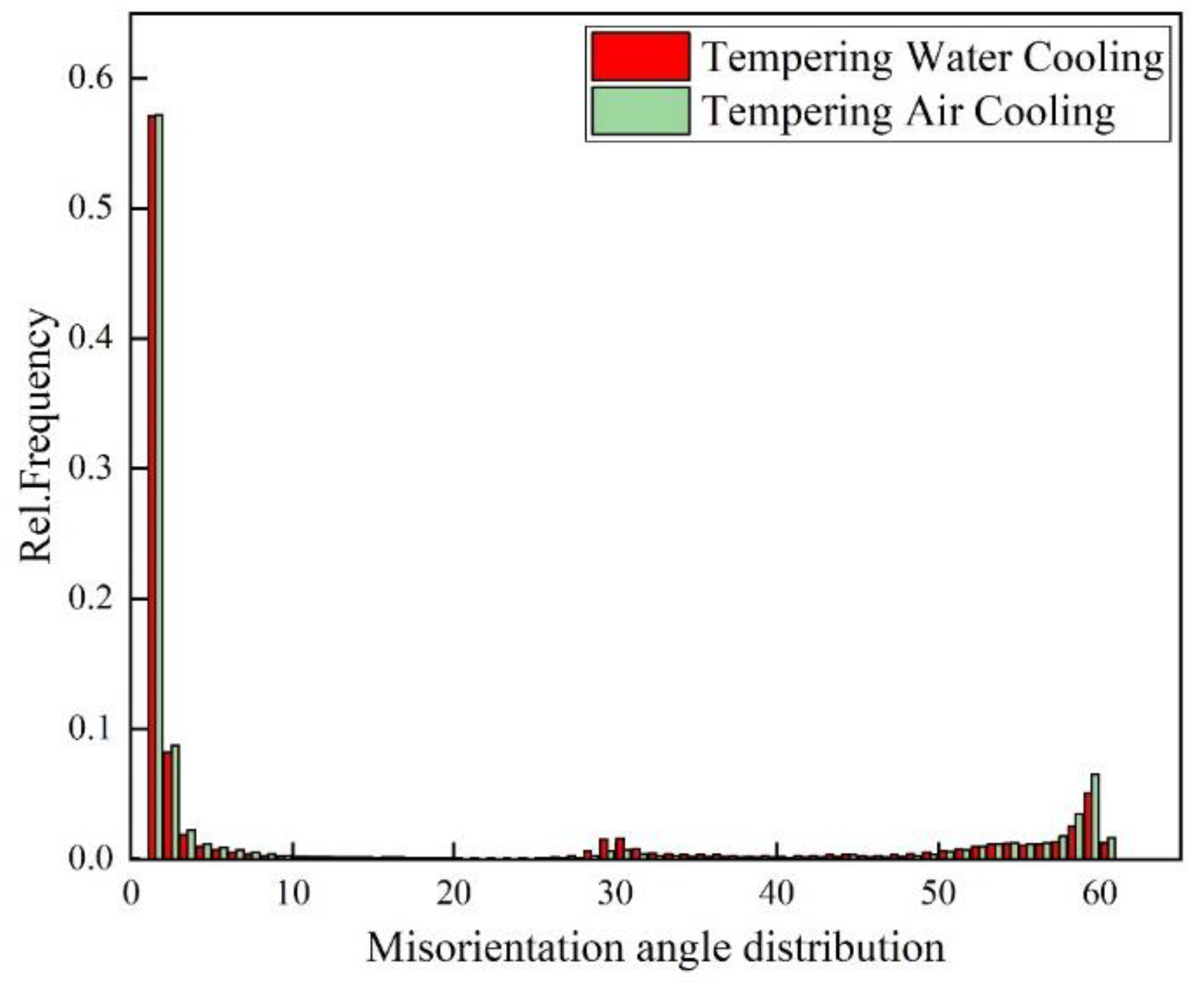

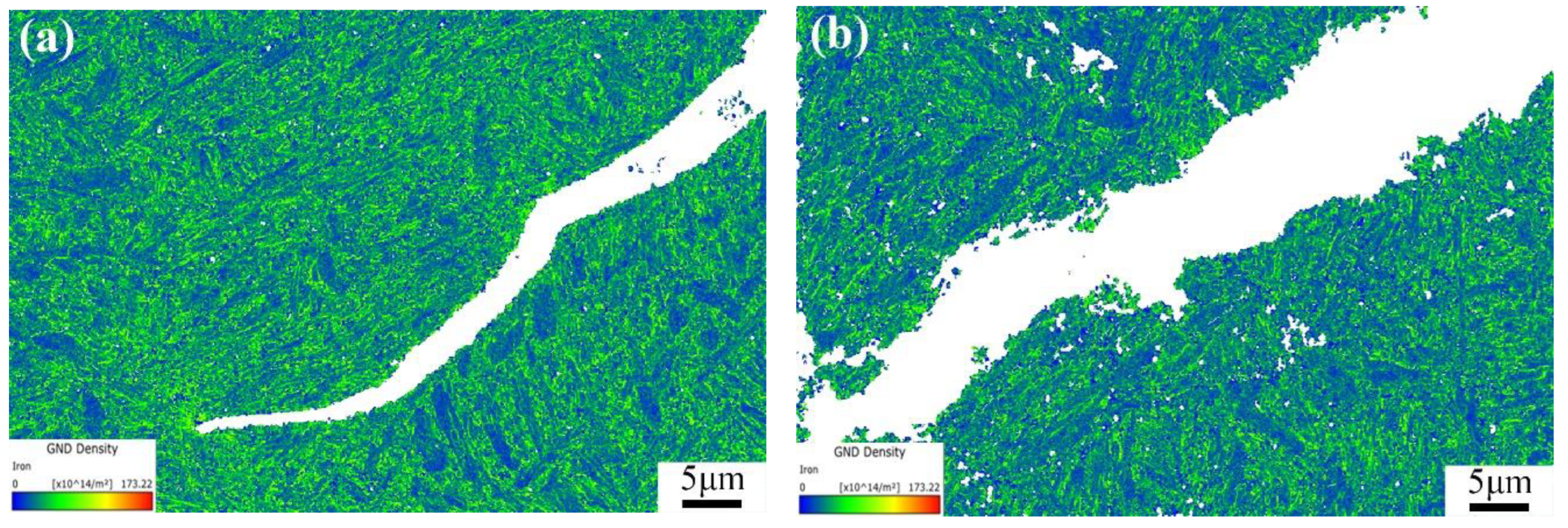

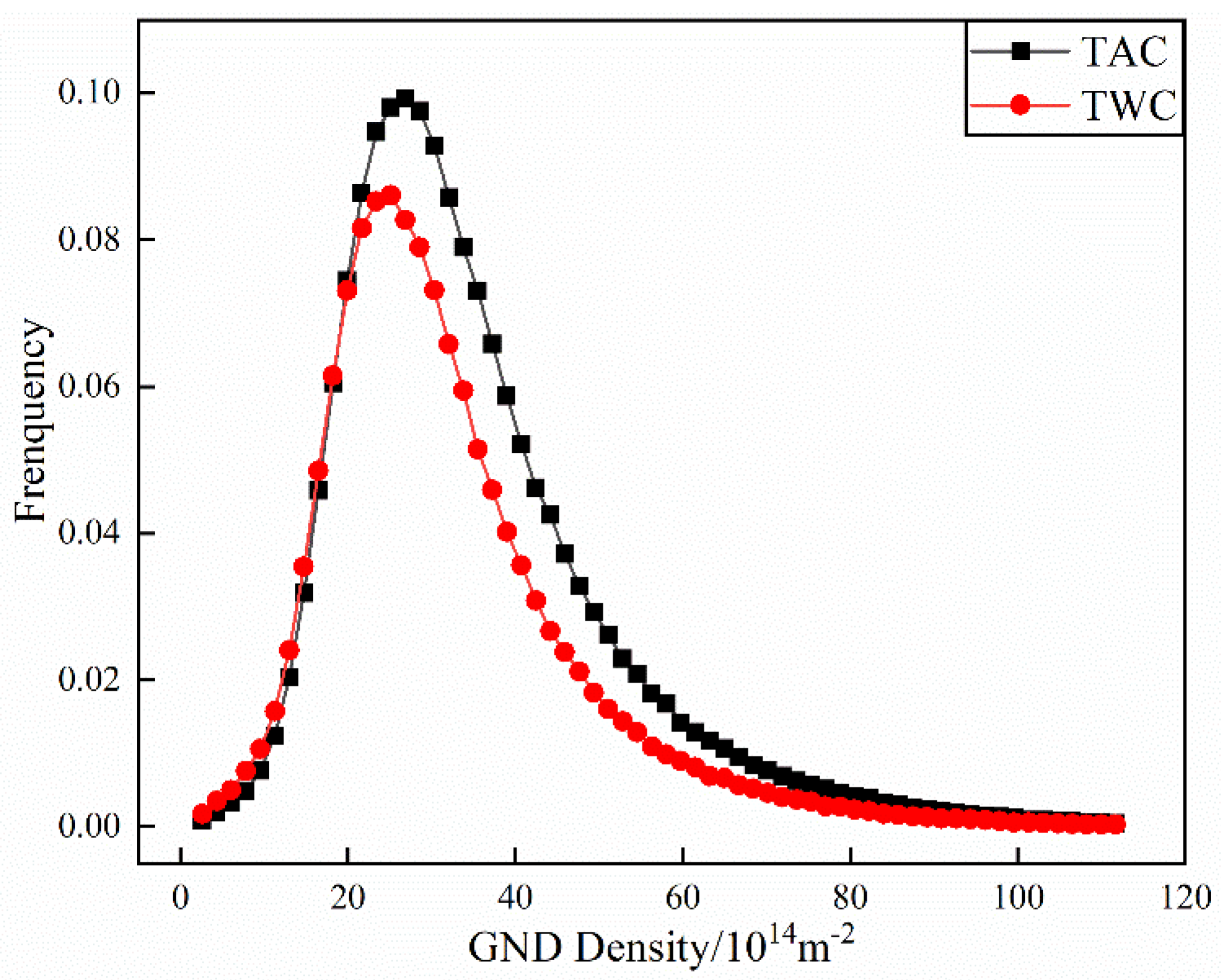

- After air-cooling tempering, the fracture surface is dominated by brittle transgranular fracture, while after tempering and water cooling, quasi-cleavage fracture is predominant. The distribution of high and low-angle grain boundaries shows minimal differences between the two states. However, tempering and water cooling result in lower dislocation density, and the improvement in toughness is related to the decrease in dislocation density.

- The second type of temper embrittlement observed in medium-carbon alloy steel large forgings during high-temperature tempering at 590°C is attributed to the concentration of impurities near the grain boundaries, especially around Fe3C. Tempering and water cooling suppress this segregation, thereby eliminating the already occurring temper embrittlement. At the same time, with an increase in tempering rate, the morphology of Fe3C transforms from elongated rods to granular.

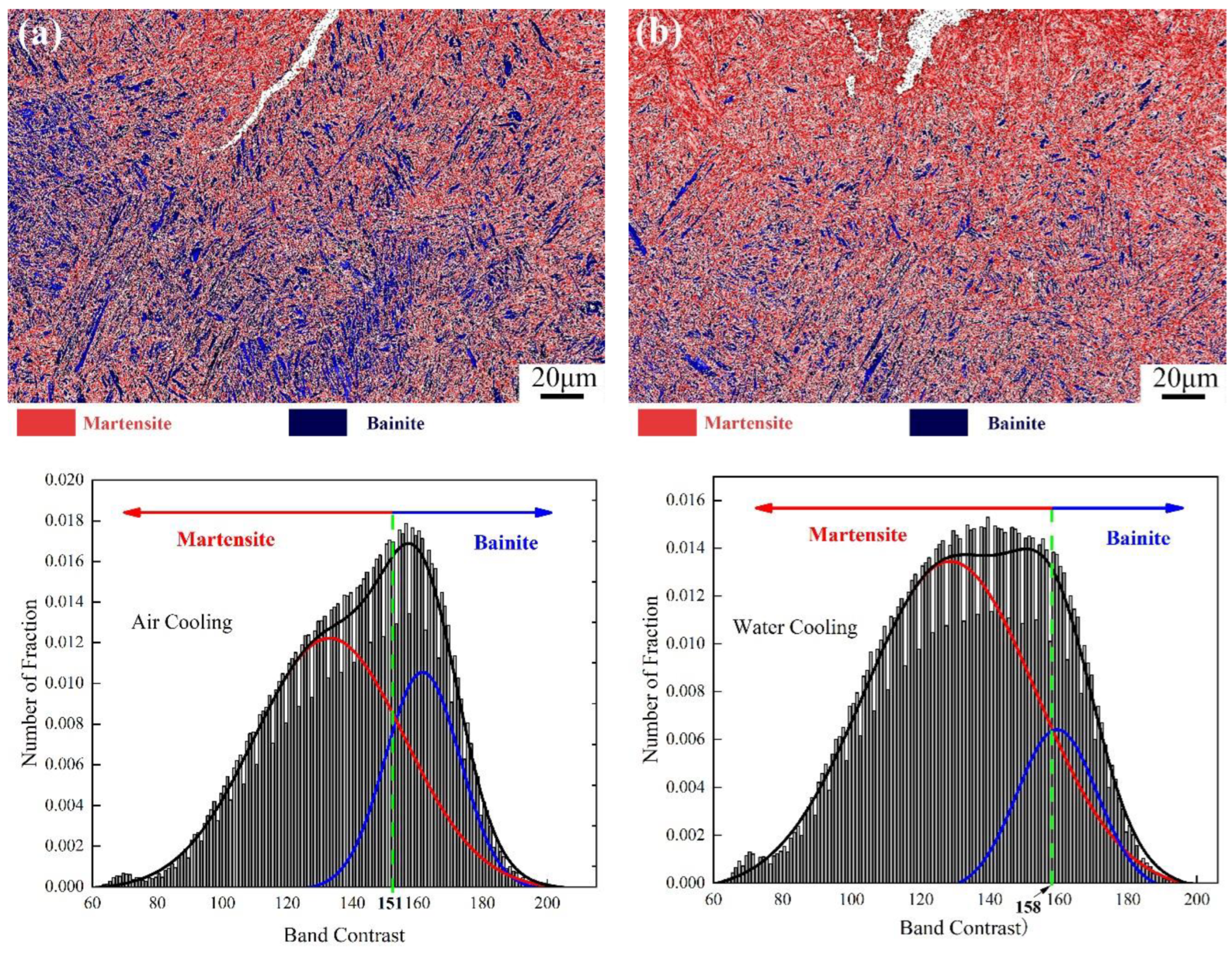

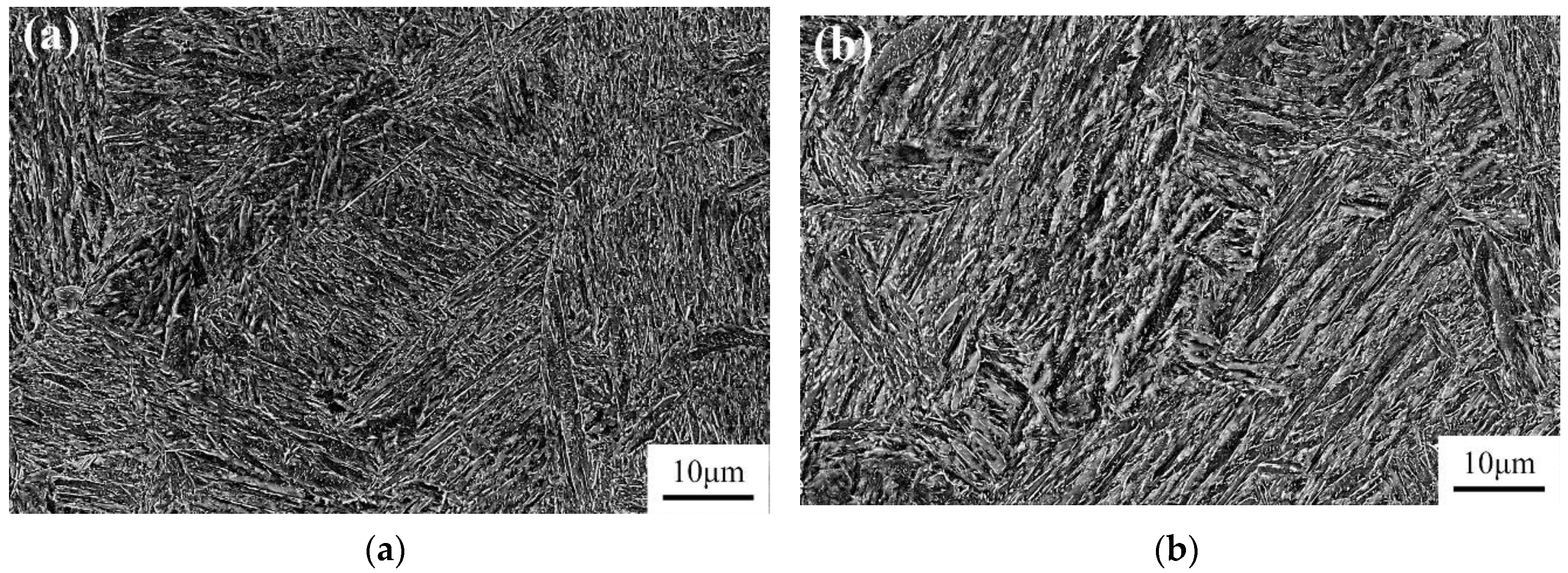

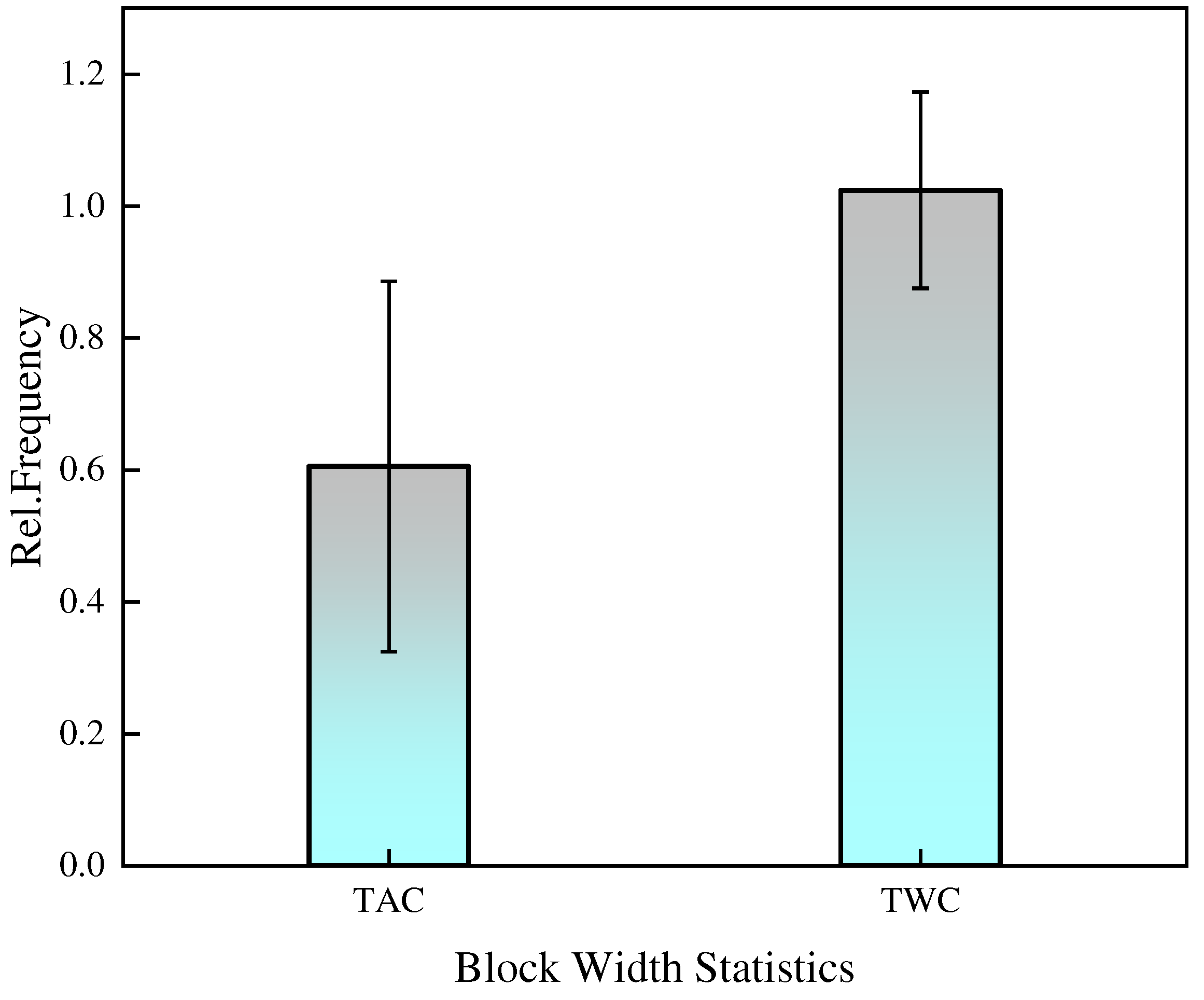

- The impact toughness is higher after tempering and water cooling compared to air-cooling tempering. The microstructure in both states consists of a mixture of martensite and bainite. In the air-cooled state, martensite plates exist in the form of long needles, while in the water-cooled state, the structure consists of uniformly distributed martensite plates. The reduction in bainite content during tempering and water cooling approaches the optimal ratio for martensite-bainite mixed structures, contributing to the enhanced toughness.

References

- Chen, G.H. Temper embrittlement of steels for heavy forging.Specialty Steel. 1995, 16.5, 8-14.

- Bruscato, Robert. High Temperature Embrittlement Phenomena of 2-1/4Cr-1Mo Weldments. ASME, 1971.

- Murakami, Y., T. Nomura, and J. Watanabe. Heavy-Section 21⁄ 4Cr-1Mo Steel for Hydrogenation Reactors. ASTM International. 1982.

- Bandyopadhyay, N., C. L. Briant, and E. L. Hall. Carbide precipitation, grain boundary segregation, and temper embrittlement in NiCrMoV rotor steels. Metallurgical Transactions. 1985,A16, 721-737. [CrossRef]

- Begley, J. A., and P. R. Toolin. Fracture toughness and fatigue crack growth rate properties of a Ni-Cr-Mo-V steel sensitive to temper embrittlement. International Journal of Fracture. 1973, 9, 243-253. [CrossRef]

- Park, Sang-Gyu, et al. Influence of the thermodynamic parameters on the temper embrittlement of SA508 Gr. 4N Ni–Cr–Mo low alloy steel with variation of Ni, Cr and Mn contents. Journal of nuclear materials, 2012, 426, 1-8. [CrossRef]

- Messmer, R.P.; Briant, C.L. The Role of Chemical Bonding in Grain Boundary Embrittlement. Acta Metallurgica 1982, 30, 457–467. [CrossRef]

- Petrov, G. M., and V. V. Tsukanov. Temper brittleness of complex-alloyed structural steels. Metallovedenie i Termicheskaya Obrabotka Metallov.1977, 17-20. [CrossRef]

- Yang, Gang, et al. Embrittlement mechanism due to slow cooling during quenching for M152 martensitic heat resistant steel. Jurnal of iron and steel research international. 2010, 17.6, 60-66. [CrossRef]

- Lei, T., Z. Tang, and M. Su. A Study on High Temperature Temper Brittleness by Internal Friction Measurements. Acta Metall. Sin.(China), 1982, 18.4, 485-492.

- Liang, Yilong, et al. The important role of martensite laths to fracture toughness for the ductile fracture controlled by the strain in EA4T axle steel. Materials Science and Engineering: A, 2017, 695, 154-164. [CrossRef]

- Wang, X. L., et al. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Materials Characterization, 2018, 140, 312-319. [CrossRef]

- Terasaki, Hidenori, et al. Effect of close-packed plane boundaries in a bain zone on the crack path in simulated coarse-grained HAZ of bainitic steel. Metallurgical and Materials Transactions A, 2015, 46, 2035-2039. [CrossRef]

- JW, Morris, and Z. Guo. The nature and consequences of coherent transformations in steel. ISIJ international, 2003, 43.3, 410-419. [CrossRef]

- Chunfang, W. A. N. G., et al. Effect of microstructure refinement on the strength and toughness of low alloy martensitic steel. Journal of Materials Sciences and Technology, 2007, 23.05, 659.

- Chen, Kui, et al. Multiphase microstructure formation and its effect on fracture behavior of medium carbon high silicon high strength steel. Journal of Materials Science & Technology, 2021, 72, 81-92. [CrossRef]

- Baek, Min-Seok, et al. Quantitative phase analysis of martensite-bainite steel using EBSD and its microstructure, tensile and high-cycle fatigue behaviors. Materials Science and Engineering: A, 2020, 785, 139375. [CrossRef]

- Breumier, S., et al. Leveraging EBSD data by deep learning for bainite, ferrite and martensite segmentation. Materials Characterization, 2022,186, 111805. [CrossRef]

| Heat treatment process | Rp0.1/MPa | Rm/MPa | A(%) | Z(%) | KV2@-40℃(J) |

|---|---|---|---|---|---|

| 980℃×5h,AC+950℃×35min,WC+590℃×8h,AC | 1145 | 1422 | 11 | 53 | 19 |

| 980℃×5h,AC+950℃×35min,WC+590℃×8h,WC | 1245 | 1480 | 12 | 54 | 29 |

| Element | Mass fraction/% |

|---|---|

| C | 6.91 |

| Cr | 2.09 |

| Ni | 3.52 |

| Fe | Bal. |

| Tempering cooling method | Martensite | Bainite |

|---|---|---|

| tempering air cooling | 60% | 40% |

| tempering water cooling | 67% | 33% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).