1. Introduction

Sustainability is vital in a supply chain to acquire great productivity and efficiency in SCM. Sustainable supply chain management (SSCM) signifies actions, including the linkage between the elements and relations in the supply chain that are taken to obtain sustainable development. A completely sustainable SCM guarantees socially responsible business practices in supply chain management. A sustainable supply chain helps improve the continuity of supply and also helps in preventing costly downtime and reputation damage. Using sustainable techniques and resources increases the efficiency of a whole supply chain at a significant cost saving. SSCM is an essential tool that involves proper cooperation between suppliers, recipients, and managers to form a good relationship between these systems. [

1] mentioned that sustainable SCM is an excellent function that helps support the organization and manage the whole supply chain. [

2] predicted that with the help of SSCM, it is possible to get an excellent perspective regarding the product’s entire life. [

3] opined that SSCM is critical as it considers the complete value chain for each cycle at all stages. [

4] observed that sustainable supply chain management also emphasizes a very efficient supply chain system for better productivity. [

5] committed that SSCM helps get an outstanding supply management advantage by lowering costs and building an effective supply chain. There are various importance of sustainability in SCM, such as increasing the visibility of value chains, supporting new business models, increasing the information-sharing capabilities, and supporting the robust intake of resources. Conceptualizing the term sustainability, its broad meaning in healthcare institutions is related to the environment, society, and the economy.

’Industry 4.0’ means the smart factory in which smart digital devices are networked and communicate with raw materials, machine tools, robots, and men. Industry 4.0 includes additive manufacturing, Advanced manufacturing systems, Sensors, CPS, the IOT, BDA, AI, Logistics 4.0, and mass customization [

6]. Industry 4.0 is characterized by flexibility, efficient use of resources, and integration of customers and business partners in the business process. Industry 4.0 has enabled a firm’s advancement in SCM by significantly enhancing productivity and efficiency. Today, the developed Industry 4.0 solution is considered a key enabler for SSCM. Sensors play an important role in collecting appropriate data, and protocol development for data integration is the key factor for sustainability in supply chain management. [

7], observed that blockchains are very significant for regularizing sustainability as they help improve the efficiency of emission trading schemes by reducing fraud in the supply chain. [

8] concluded that big data algorithm has very good access to optimized processes due to their flexibility and access to data. The rising difficulty of sustainable development with the help of Industry 4.0 has gathered a lot of attention in the development of SCM and identifying the key challenges in the supply chain. SSCM practices are now becoming a widespread business trend for sustainable development in the industry. Nowadays, the various applications of Industry 4.0, like IoT, AI BIG-DATA, etc., are used in SCM to gain great efficiency and productivity rate. Industry 4.0 and sustainable practices can be integrated and are capable of bringing contributions to the market through strengthening quality programs. These applications allow competitiveness through the offer of new products and better services.

In recent years, the healthcare industry has been experiencing a significant shift due to the emergence of Industry 4.0, the fourth industrial revolution marked by integrating digital technologies into manufacturing and supply chain operations. This integration has notable implications for the healthcare industry, particularly in sustainable supply chain management. Managing a sustainable healthcare supply chain involves managing information, supply, suppliers, services, providers, internal and external customers, and end users, as outlined by [

9]. The healthcare industry has always been known for its sustainability and social responsibility commitment. Still, in recent times, there has been a growing emphasis on incorporating sustainable supply chain management practices. This focus on sustainability and SCM has been fueled by the realization that it can provide significant benefits, including cost reduction, better patient outcomes, and improved reputation for healthcare organizations. The challenges posed by the COVID-19 pandemic and other viruses have further compounded the difficulties that providers face in acquiring the necessary items for quality care at an affordable price. The advent of Industry 4.0 has prompted firms to explore ways to achieve sustainability by shifting their focus from economic performance to becoming more socially and environmentally conscious. The primary objective of this literature review is to investigate the impact of Industry 4.0 applications on supply chain management (SCM). To achieve this objective, a systematic literature review covering the years 2010 to 2020 was conducted, allowing for a comprehensive understanding of the relevant research on Sustainable Supply Chain Management (SSCM) with Industry 4.0. This study’s research question is: "How does Industry 4.0 contribute to sustainable SSCM?" The review includes an introduction to the importance of SSCM, a basic definition, and a literature review. It also explores Industry 4.0 applications, such as IoT AI, and how Industry 4.0 is linked to SSCM, followed by descriptive analysis and research methodology. Finally, this review concludes by listing some benefits of integrating Industry 4.0 (AI) and SSCM in the healthcare sector.

2. Research Methodology

For in-depth identification of the relationship between Industry 4.0 and sustainable scm, a literature review was analyzed and implemented. At first, the equality between Industry 4.0 and SSCM was investigated. Secondly, the different applications of Industry 4.0, like AI, and IoT, were discussed, and their relation with SSCM was also analyzed. In this part, how the data are gathered, analyzed, and reported is described. At the start, the search criteria were selected. Then, the papers and other documents were classified to consider for the analysis, followed by the document analysis in detail by observing the publication year, methodology, and the contributions of different researchers.

2.1. Search criteria

Specific data were considered for a systematic review and to secure the validity of collected data. The databases that were followed are Elsevier MDPI, which provides very well-reviewed journals. The study considered only formal and informal literature by considering various titles, abstracts, and keywords. The papers that were written in English and published in a complete decade between 2010 and the first months of 2020 were selected and reviewed, and this search was from various papers and editorials.

2.2. Article Search

For getting the articles centering on Sustainable Supply Chain Management with Industry 4.0, the database search began with the article that includes the combination of words "SSCM and Industry 4.0 applications like AI and IoT". Various articles were found from Elsevier MDPI, and the articles ’titles, keywords, and abstracts were examined. The different keywords were: "Sustainable", "supply chain", and "industry 4.0 applications AI, IoT, Machine learning"

2.3. Results

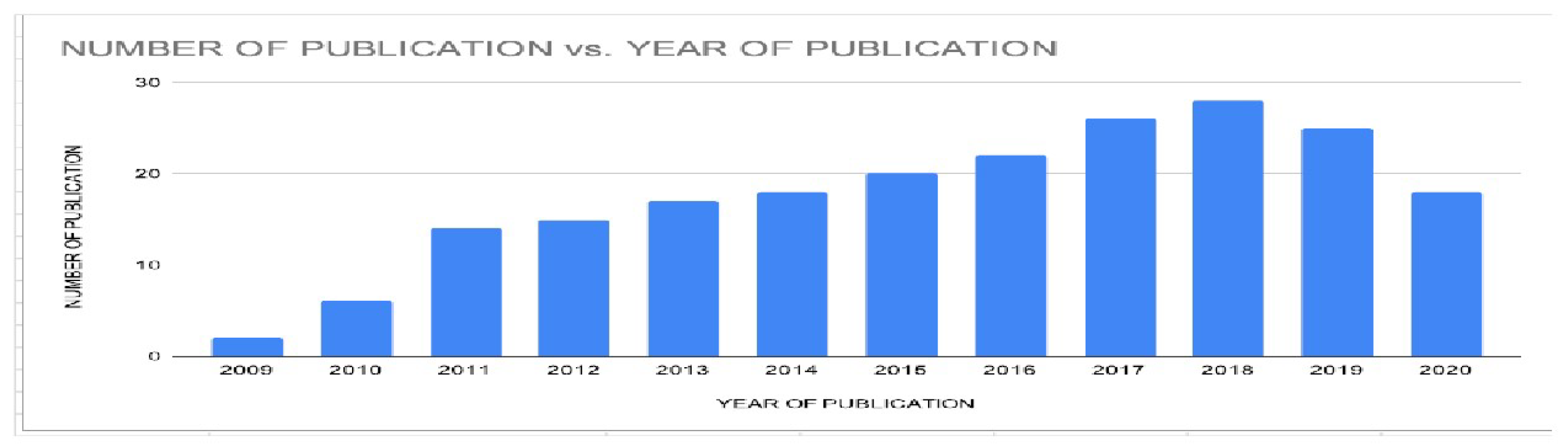

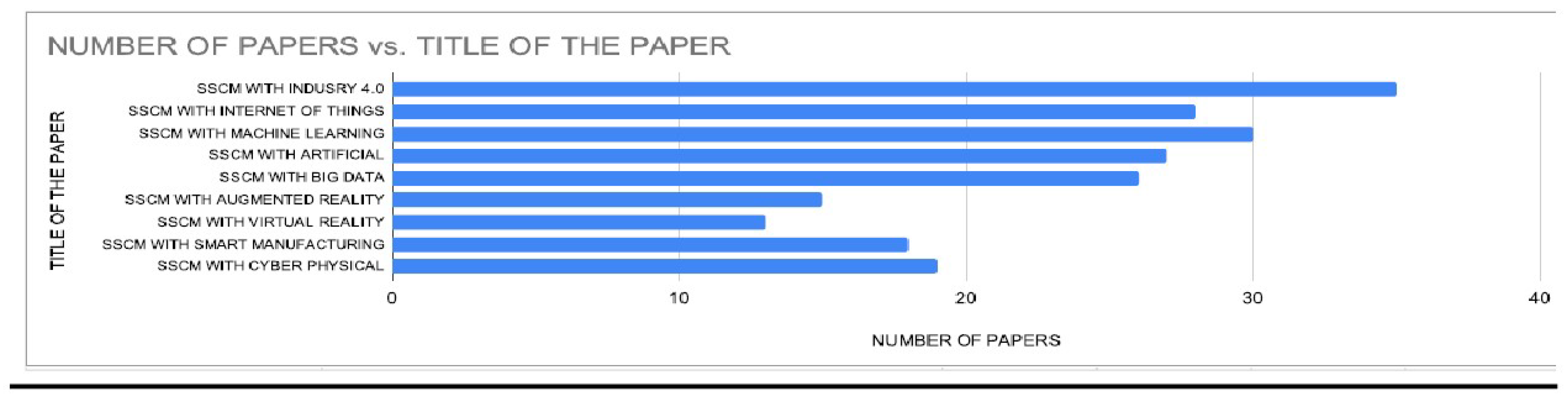

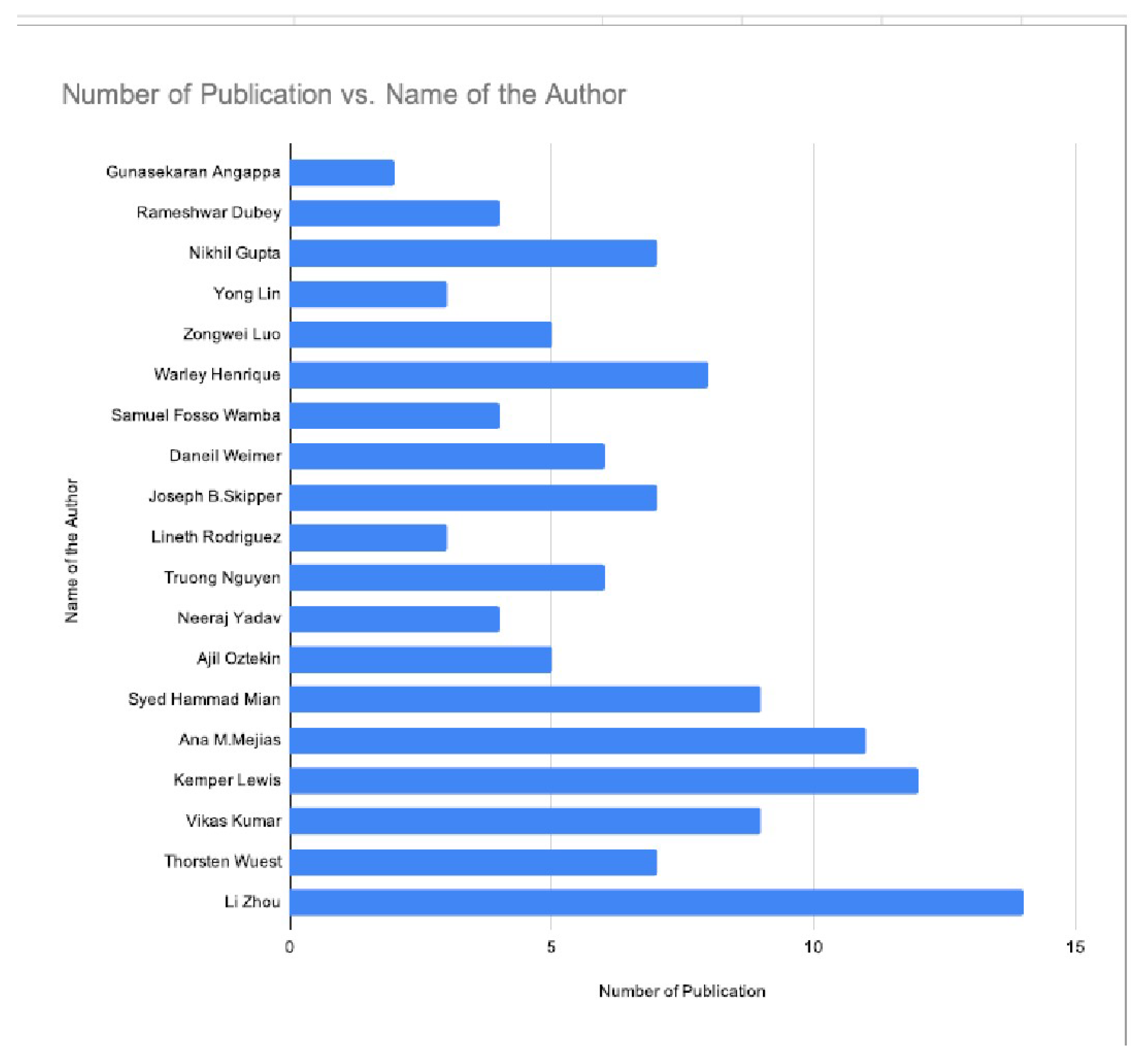

The databases accumulated from different literature reviews were analyzed, and the graphs containing the number of papers published in a particular year, the Titles of the papers and their numbers, the Name of the Author, and the number of publications were drawn in the first part. In addition to this, for each technology, a subset of topics was identified from the different research papers and were discussed with their classification. In the second part, the various applications of Industry 4.0 and their relation with SSCM were discussed and analyzed thoroughly.

Figure 1 The number of published articles has increased between 2009 and 2020, with a maximum number of published articles in 2018. This increasing number of documents shows the interest of the authors and researchers in Industry 4.0 with SSCM.

Figure 2, shows that the various applications of Industry 4.0 have emerged as a very effective tool in SSCM. ML has been identified as a leader in this series. Also, other applications like AI, IoT, CBS, BDA, etc., have often been used for retaining sustainability

Figure 3 hows the number of authors and their publications within the years 2009-2020; many authors have already worked in this area, and still, many of them are working and presenting good knowledge in identifying the technologies that can lead to sustainability in the supply chain.

3. Industry 4. O and SSCM

For a better method, SSCM and Industry 4.0 are classified on the basis of various items. For SSCM, the related classification is MNC, which stands for manufacturing; PRC indicates procurement; DSA implies distribution angle; similarly, INF and COLLAB for information and collaboration. Industry 4.0 related items are IoT, which stands for internet of things, AI artificial intelligence; CPS cyber-physical system; AM additive manufacturing; BDA big data and analytics; MI machine learning; and SMS and BC, which stands for smart manufacturing system and blockchain technology. The role of each industry 4.0 item in SSCM is discussed in the next section

3.1. Artificial intelligence (AI) and SSCM

Artificial intelligence is called the usage of computer systems for reasoning learning. [

10] state that AI makes sustainable supply chain management more efficient because of the optimization process. [

11] explained that AI helps predict data and provides accurate and reliable results in sustainable scm. [

12] found that AI enabled the SSCM system to identify the best possible combination of algorithm sets for the predictions. Silver et al. (2015) AI can be applied to use the data more effectively in sustainable scm. [

13] used various AI techniques to find the best-optimized services in scm and found that with the application of AI, scm can be enhanced easily. [

14] explained that the AM techniques help in getting flexibility towards the development of sustainable scm

3.2. Internet of things (IoT) and SSCM

The IOT is a network of connected device, objects, and sensors that collect and helps in communicating information. There are various advantages of IoT in sustainable scm. [

15] concluded that Development in IT has played a key role in enhancing the planning, controlling, and increasing the efficiency of sscm [

16] explained that through the use of IoT, suppliers can easily ensure safety in SSCM. [

17] found that IoT ensures the convenience of activities and sustains a competitive advantage in scm. Mehl et al., (2015) observed that IoT offers substantial efficiency gains across all the stages of scm. [

18] explained that IOT coupled with the supply chain helps an organization to make informed decisions. [

19] concluded that IoT helps in building a smart and secure supply chain management. [

20] concluded that IoT positively affects the SCM by its application.

3.3. Additive manufacturing (AM) and SSCM

Additive manufacturing led to various solutions in traditional scm and can help to increase the efficiency of scm. [

21] found that AM designs are completely free from any design constraints which is imposed by the traditional method of supply chain management. [

22] explained the emergence of consumer-centric business in SCM with the advent of AM. [

23] concluded that due to AM, there is increased agility in scmt. [

24] found that total supply chain costs, transport costs, and production sites can be easily improved and increased with the use of AM in scm, and also it was observed that the total cost of transportation can be decreased by 50% after conducting few experiments in scm. [

25] observed that the use of 3D printing processes could completely replace mass manufacturing in scm [

26] found that AM is a disruptive technology that will radically change supply chain management. [

27] found that the use of AM supply chain can be made more attractive and effective. [

28] concluded that AM-enabled system in supply chains helps in reducing transportation, upgrading the products, reducing the material consumption, and reducing the time in scm. [

29] found that AM is truly innovative, helps in endless product design, and enhances scm.

3.4. Cyber-physical system (CPS) and SSCM

The growing technologies in the world of CPS promise a new solution to the problem in manufacturing and supply chain management. [

30] explained that for proper implementation of CPS in the supply chain, sensors form a very effective integral part. [

31] analyzed that the cyber aspect is an important part that combines with CPS in managing the supply chain. [

32] observed that with the help of CPS, a new dimension for full transparency of supply chain material flow can be enabled. [

33] concluded that the synchronization of supply chains with the support of CPS embodies a relevant opportunity for enhancing performance in scm. [

34] found that applications of CPS have grown in all areas, supporting managers in decision-making and enabling a better understanding of processes in complex systems in scm. [

35] explained that CPS promises a new problem solution in manufacturing in supply chain management. [

36] concluded that CPS integrates the obtained data into the virtual world of information by mastering complex data structures and helps in supply chain management. [

37] observed that with the use of CPS in SCM, flexibility, productivity, and modularity could be increased easily.

3.5. Machine learning (ML) and SSCM

ML has become one of the best technologies that has revolutionized supply chain management by improving its processes. [

38] found that the models in machine learning can react to new, unknown data and help in predictions in scm. [

39] explained that machine learning techniques enhance data-driven decisions in scm. [

40] concluded that machine learning applications support and lead to sustainability in SCM. [

41] observed that machine learning deals with computer-aided modeling which helps in improving performance or in making concrete predictions in SCM. [

42] analyzed that the machine learning technique helps to simplify the findings of new possible partners in SCM. Pat et al., (2011) concluded that machine learning could bring actual value for supply chain management. [

43] explained that machine learning algorithms combined with sensors to provide end-to-end visibility across the SCM. [

44] concluded that with the help of ML, manufacturers can reduce SCM latency for components and parts used in products. [

45] observed that the machine learning algorithms can yield the lead-time prediction in production with a shorter response time in scm.

3.6. Smart manufacturing (SM) and SSCM

Smart manufacturing, today is attracting much interest in scm. [

46] found that smart manufacturing helps mass customization of products and allows the companies to meet consumers’ demand in scm. [

47] concluded that smart manufacturing helps develop and will improve the workers’ safety to enhance manufacturing in supply chain management. [

48] explained that smart manufacturing provides flexibility to increase productivity and efficiency in SCM. [

49] said that SM aims towards a fully integrated sequence of planning and production solutions to create a more visible manufacturing process in supply chain management. Jsoo et al., (2019) concluded that SM helps in response-efficient tactical supply planning model with flexibility in scm. [

48] explained that the production systems aim to process multiple products in scm in a smart manufacturing unit. [

50] found that smart manufacturing is the mode of product design, manufacturing in scm, and even how products are sold.. [

51] concluded that smart manufacturing is an implementation of a wide variety of digital technologies that help increase the efficiency of SSCM.

3.7. Big data (BD) and SSCM

Big data is a way to investigate information from data sets that are large or complex to be dealt with by traditional methods that are used in supply chain management. Big data has been applied in SCM for procurement, sourcing cost improvement, and production planning and control. [

52] concluded that big data and its applications have revolutionized supply chain management. [

53] found that big data is significant because it can transform the entire business process in supply chain management. [

54] analyzed the various dimensions of big data and concluded that they have all the potentials that help capture all the benefits of scm. [

55] found that big data helps maximize productivity, collaboration, speed, and visibility in supply chain management, avoiding losses in the supply chain. [

56] found that big data enables real-time analysis and supports manufacturing optimization, which helps increase the efficiency of scm.

3.8. Blockchain technology (BCT) and SSCM

Blockchain technology today helps enable more transparent and accurate end-to-end tracking in supply chain management. [

57] found that blockchain technology helps maintain sustainability in the supply chain. [

58] explain that blockchain integration in the supply chain can lead to a more reliable, authentic, and secure system. [

59] concluded that blockchain technology is a recommended tool for sustainability in the manufacturing industry because of the benefit of real-time transparency. [

60] found the various advantages of blockchain technology, like accessibility, data management, data safety and decentralization, and quality control in supply chain management. [

61] concluded that blockchain technology is an enabler of real-time, verifiable, and transparency and also improves auditing practices, reducing trading costs, reducing fraud risk, enhancing the audibility of transactions and increasing the effectiveness of monitoring in an SCM.

4. Framework

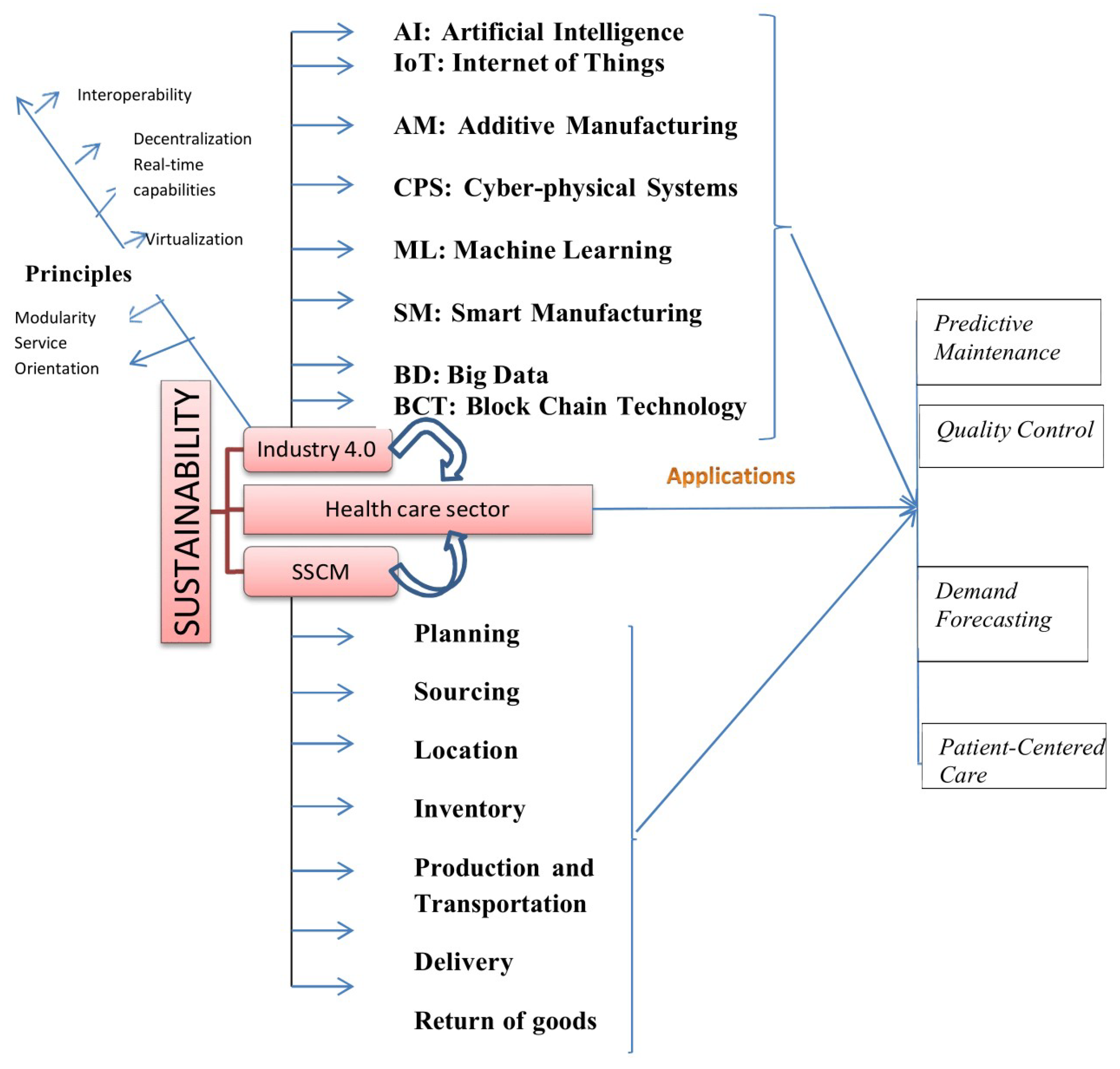

Figure 4 depicts a framework of present trends in healthcare utilizing I4.0 and SSCM components to provide a sustainable evolution of I4.0 technologies immersing into the healthcare sector. Technologies like artificial intelligence, the Internet of things, additive manufacturing, cyber-physical systems, machine learning, smart manufacturing, big data, and blockchain technology have been harnessed to bring fruitful evolution in the modern healthcare sector. Moreover, I4.0 is growing sporadically worldwide rapidly, and its powers to transform and impact lives are gaining broad visibility.

Sustainable supply chain management (SSCM) components, which already exist in their traditional forms, are getting into the transition phases of evolving into digitized versions. This would facilitate more coherent and synchronized supply chain systems with faster and easier supply with enhanced transparency and flow of materials for utility in healthcare corridors. I4.0 technologies and digitized SSCM components have started immersing into healthcare to enrich sustainability paradigms. Predictive maintenance, quality control, demand forecasting, and patient-centered care are successfully witnessing the diffusion of I4.0 and SSCM components.

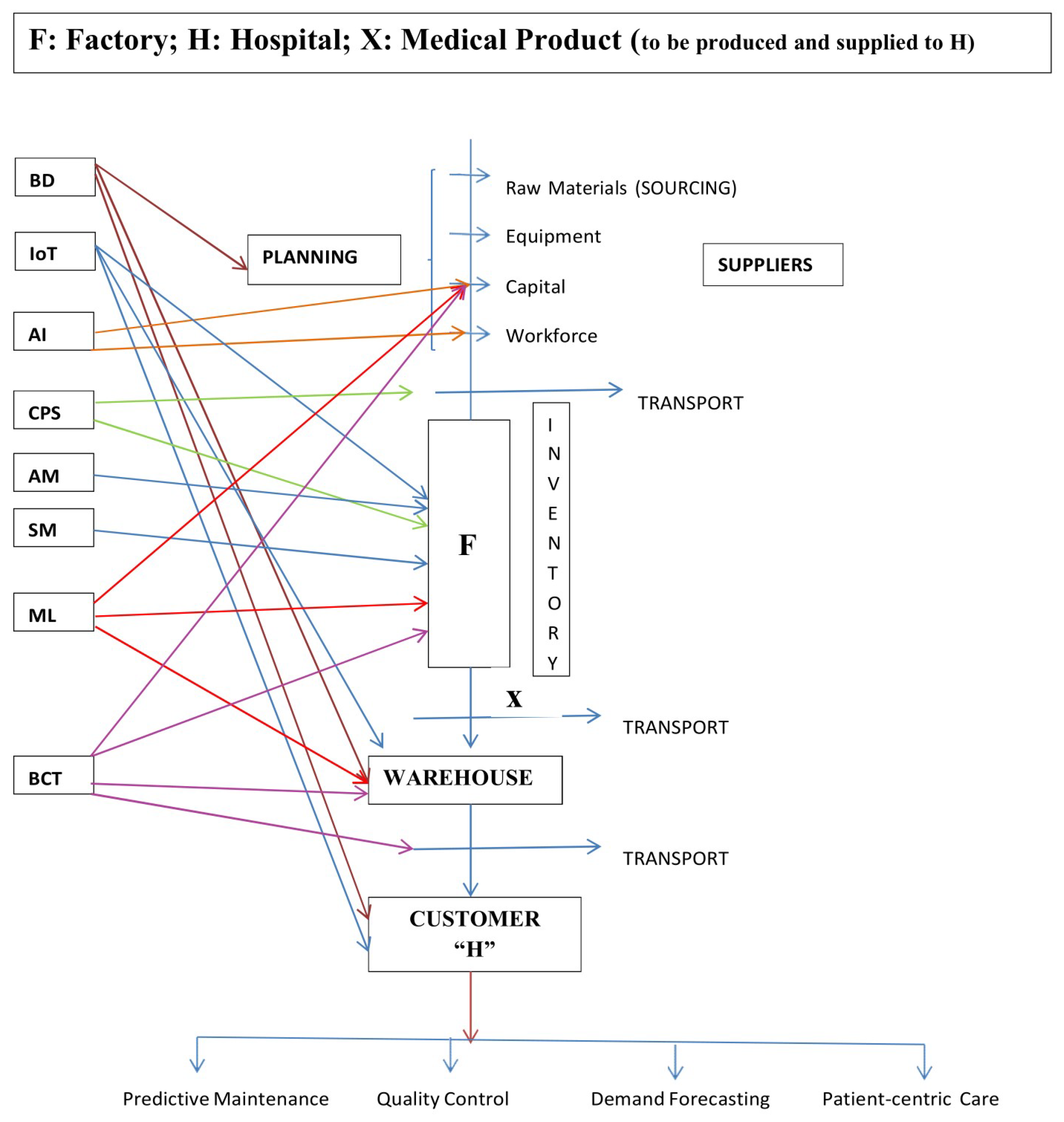

Figure 5 showcases a typical example of a hospital [H] receiving a medical product produced in a factory and supplied to a customer [H]. Along the course of procuring raw materials from suppliers to a factory, conversion of raw material into finished products inside the factory [F], and then supply chains to transport the product to the customer, the various I4.0 technologies have varied degrees of influence on multiple sections of the core SSCM process. This is depicted as an example that aids in improving the multiple facets of the healthcare sector, such as predictive maintenance, quality control, demand forecasting, and patient-centered care.

Figure 4.

A framework of I4.o and SSCM towards application in healthcare: Present trends.

Figure 4.

A framework of I4.o and SSCM towards application in healthcare: Present trends.

Figure 5.

An Example of a medical product being produced and supplied using I4.0 and SSCM.

Figure 5.

An Example of a medical product being produced and supplied using I4.0 and SSCM.

5. Healthcare system:Industry 4.0(AI) and SSCM

The advent of Industry 4.0, specifically the utilization of Artificial Intelligence (AI), has presented new possibilities for advancing supply chain management (SCM) in the healthcare sector

Figure 4. AI can be employed for various purposes, including predictive maintenance, quality control, demand forecasting, and patient-centric care

Figure 5. Furthermore, AI has the potential to enhance supply chain operations and promote sustainability.

5.1. Predictive Maintenance

Recent studies have highlighted the importance of predictive maintenance in the healthcare industry, where equipment upkeep is essential for maintaining the optimal functioning of machines. Predictive maintenance can prevent unplanned downtime and save costs by utilizing Artificial Intelligence (AI) algorithms and Internet of Things (IoT) sensors. Furthermore, it can help healthcare providers optimize inventory management, reduce waste, and improve the overall efficiency of the supply chain (Schweitzer & Wang, 2021). This approach is essential in the current healthcare climate, where the COVID-19 pandemic has pressured healthcare systems to maximize their resources [

62].

5.2. Quality control

Quality control is vital in ensuring patients receive optimal care in the healthcare industry. AI technology can help identify defects and potential failures in medical products and devices, allowing manufacturers to take prompt corrective action. By leveraging AI-based quality control techniques, healthcare providers can reduce the risk of medical errors, improve patient outcomes, and decrease the likelihood of adverse events [

63].

5.3. Demand Forecasting

The healthcare industry experiences significant fluctuations in demand, especially during public health crises. AI algorithms can analyze vast data to forecast the need for medical products and services, empowering healthcare providers to optimize their inventory levels and minimize costs. This technology can play a crucial role in streamlining supply chain management in the healthcare industry [

64].

5.4. Patient-Centered Care

AI technology is becoming increasingly important as healthcare providers shift towards a more personalized approach to patient care. AI can help develop individualized treatment plans and care pathways by analyzing patient data, improving patient outcomes, greater patient satisfaction, and reducing healthcare costs. (Kostkova, P. 2020).

5.5. Sustainability

The healthcare industry is one of the most significant contributors to greenhouse gas emissions and waste generation, making sustainable supply chain management crucial. Adopting Industry 4.0 technologies, such as AI and IoT sensors, can help healthcare providers optimize their supply chain operations, minimize waste, and improve environmental sustainability. Implementing closed-loop supply chains, promoting the reuse of materials, and adopting green supply chain practices are some measures that can be taken to achieve sustainable SCM in the healthcare industry. (World Health Organization. (2021), (Healthcare Supply Chain Association. (2017) and (E&Y., 2020).

6. Discussion

From the sustainability perspective, the focus was on industry 4.0 technologies, and it is easier than what industry 4.0 technology better fits with sustainable supply chain management. Industry 4.0 brings a revolution in the supply chain through smart manufacturing. AM, BDA, and IOT are the most frequently used industry 4.0 applications regarding manufacturing and distribution angle.AM leads to product optimization, and with AM, innovative solutions can be applied, leading to sustainability. Big Data enhances the sustainability and effectiveness of supply chains by collaboration. Many organizations operating with industrial IoT solutions saw improvement in the sustainability of the supply chain. CPS helps manage big data, forming pillars for sustainability in the supply chain. SM, which includes a system like GPS and sensors, leads to excellent efficiency and helps in achieving sustainability in the supply chain. AI can help organizations make a positive change, ensuring sustainability in the SCM. Some dark side of Industry 4.0 affects the sustainability of the supply chain, including challenges like management, technical barriers, and political challenges. [

65] concluded that other challenges are faced by industry 4.0 applications, such as insufficient research and development, poor quality data, and lack of infrastructure. Therefore, comprehensive strategies and applications of framework are required to realize the applications of industry 4.0 technologies in maintaining sustainability in the SCM.

From the healthcare perspective, along with Industry 4.0, the integration of AI in healthcare SCM, within the context of Industry 4.0, has been a focus in healthcare to enhance efficiency, cut costs, improve patient outcomes, and promote sustainability. One notable advantage of AI in healthcare SCM is predictive maintenance, which relies on AI algorithms and IoT sensors to detect problems before they become critical, avoiding unplanned downtime and reducing expenses. Additionally, AI can aid in demand forecasting, crucial for managing demand fluctuations in the healthcare industry. AI can also boost patient safety by ensuring that medications are dispensed accurately to the intended patients at the correct time. With the help of AI, healthcare providers can track medication movements throughout the supply chain and ensure that they are appropriately labelled, stored, and distributed.

7. Conclusions

Through a well-ordered literature analysis, this paper offers a very good idea about the relationship between industry 4.0 applications and sustainable supply chain management. This entire study forms a very good work for maintaining SSCM. Considering how industry 4.0 applications influence the supply chain, it is possible to confirm that industry 4.0 applications are essential in SSCM. In the second part, depending on each industry 4.0 application, other topics were discussed. AI, IoT, and ML help in developing information technology that increases efficiency and maintains sustainability in the supply chain. CPS supports the development of innovative services like maintenance applications. Considering different industries, 4.0 technologies help identify technology corresponding to the particular area in maintaining sustainability in the supply chain. Finally, with the practical implementation of different industry 4.0 technologies, SSCM requires continuous monitoring and control such that sustainability can be easily ensured in the supply chain, which will ultimately add to the efficiency of the supply chain. Applications of Industry 4.0 need very good attention as various works have been done in this area. Still, there are various challenges these technologies face for which continuous monitoring is required so that the use of these technologies can be increased, leading to the enhancement of sustainability in the supply chain. This study provides a good allusion for future work and investigations.

Author Contributions

Conceptualization, K.S., and B.M.; methodology, B.M.; software, K.S., and B.M.; validation, H.-C.K., S.T.; formal analysis, K.S.; investigation, K.S., and B.S.; resources, K.S.; data curation, B.S.; writing—original draft preparation, K.S.; writing—review and editing, K.S., and B.S.; visualization, M.H., and D.S.; supervision, H.-C.K., and S.T.; project administration, K.S., B.M., H.-C.K., S.T., M.H. and D.S.; funding acquisition, H.-C.K. and S.T. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

Review of secondary literature.

Acknowledgments

This research was supported by the MSIT(Ministry of Science ICT), Korea, under the National Program for Excellence in SW, supervised by the IITP(Institute of Information & Communications Technology Planning & Evaluation) in 2022 (2022-0-01091, 1711175863).

Conflicts of Interest

“The authors declare no conflict of interest.”

References

- Haseeb, M.; Hussain, H.I.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A solution towards technology challenges of sustainable business performance. Social Sciences 2019, 8, 154.

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and supply chain management–an introduction to the special issue, 2008. [CrossRef]

- Gupta, S.; Palsule-Desai, O.D. Sustainable supply chain management: Review and research opportunities. IIMB Management review 2011, 23, 234–245. [CrossRef]

- Marull, J.; Font, C.; Boix, R. Modelling urban networks at mega-regional scale: Are increasingly complex urban systems sustainable? Land Use Policy 2015, 43, 15–27.

- Xia, Y.; Tang, T. Sustainability in supply chain management: Suggestions for the auto industry. Management Decision 2011, 49, 495–512. [CrossRef]

- Bagheri, B.; Yang, S.; Kao, H.A.; Lee, J. Cyber-physical systems architecture for self-aware machines in industry 4.0 environment. IFAC-PapersOnLine 2015, 48, 1622–1627. [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research 2019, 57, 2117–2135. [CrossRef]

- Hess, T.; Matt, C.; Benlian, A.; Wiesböck, F. Options for formulating a digital transformation strategy. Mis quarterly executive 2016, 15.

- Scavarda, A.; Daú, G.L.; Scavarda, L.F.; Korzenowski, A.L. A proposed healthcare supply chain management framework in the emerging economies with the sustainable lenses: The theory, the practice, and the policy. Resources, Conservation and Recycling 2019, 141, 418–430. [CrossRef]

- Gevorgyan, T. Adoption and inclusion of Artificial Intelligence in digitalization strategies of organizations. PhD thesis, 2019. [CrossRef]

- Yao, X.; Yu, M.; Chen, Y.; Xiang, Z.C. Connotation, architecture and key technologies of Internet of manufacturing things. Jisuanji Jicheng Zhizao Xitong/Computer Integrated Manufacturing Systems, CIMS 2014, 20, 1–10. [CrossRef]

- Hall, W.; Pesenti, J. Growing the artificial intelligence industry in the UK. 2017.

- Shakya, S.; Chin, C.; Owusu, G. An AI-based system for pricing diverse products and services. Knowledge-Based Systems 2010, 23, 357–362. Artificial Intelligence 2009. [CrossRef]

- Melnyk, S.A.; Narasimhan, R.; DeCampos, H.A. Supply chain design: issues, challenges, frameworks and solutions, 2014. [CrossRef]

- Bhandari, R.R. Impact of Technology on Logistics and Supply Chain Management. 2014.

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Computer Networks 2010, 54, 2787–2805. [CrossRef]

- Borgia, E. The Internet of Things vision: Key features, applications and open issues. Computer Communications 2014, 54, 1–31. [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Computers & Industrial Engineering 2019, 127, 925–953. [CrossRef]

- Abdel-Basset, M.; Manogaran, G.; Mohamed, M. RETRACTED: Internet of Things (IoT) and its impact on supply chain: A framework for building smart, secure and efficient systems. Future Generation Computer Systems 2018, 86, 614–628. [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J.; others. The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australasian Journal of Information Systems 2018, 22. [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. The International Journal of Advanced Manufacturing Technology 2012, 62. [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technological Forecasting and Social Change 2015, 102. [CrossRef]

- Roberta Pereira, C.; Christopher, M.; Lago Da Silva, A. Achieving supply chain resilience: the role of procurement. Supply Chain Management: an international journal 2014, 19, 626–642. [CrossRef]

- Barz, A.; Buer, T.; Haasis, H.D. A Study on the Effects of Additive Manufacturing on the Structure of Supply Networks. IFAC-PapersOnLine 2016, 49, 72–77. 7th IFAC Conference on Management and Control of Production and Logistics MCPL 2016. [CrossRef]

- Mefford, R. The Economic Value of a Sustainable Supply Chain. Business and Society Review 2011, 116. [CrossRef]

- Lipson, H.; Kurman, M. Fabricated: The new world of 3D printing; John Wiley & Sons, 2013.

- King, W.; Anderson, A.; Ferencz, R.; Hodge, N.; Kamath, C.; Khairallah, S.; Rubenchik, A. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Applied Physics Reviews 2015, 2, 041304. [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.; Flanagan, W.; Lifset, R.; Duflou, J. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications: Environmental Dimensions of Additive Manufacturing. Journal of Industrial Ecology 2017, 21. [CrossRef]

- Attaran, M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum: An International Journal 2020, 21. [CrossRef]

- Morosini Frazzon, E.; Lima Dutra, M.; Barbosa Vianna, W. BIG DATA APPLIED TO CYBER-PHYSICAL LOGISTIC SYSTEMS: CONCEPTUAL MODEL AND PERSPECTIVES. Brazilian Journal of Operations & Production Management 2015, 12. [CrossRef]

- Rajkumar, R. A cyber-physical future. Proceedings of the IEEE 2012, 100, 1309–1312.

- Gürdür, D.; El-Khoury, J.; Seceleanu, T.; Lednicki, L. Making interoperability visible: Data visualization of cyber-physical systems development tool chains. Journal of Industrial Information Integration 2016, 4, 26–34. [CrossRef]

- Waller, M.; Fawcett, S. Click Here for a Data Scientist: Big Data, Predictive Analytics, and Theory Development in the Era of a Maker Movement Supply Chain. Journal of Business Logistics 2013, 34. [CrossRef]

- Sakurada, L.; Barbosa, J.; Leitão, P.; Alves, G.; Borges, A.P.; Botelho, P. Development of Agent-Based CPS for Smart Parking Systems. IECON 2019 - 45th Annual Conference of the IEEE Industrial Electronics Society, 2019, Vol. 1, pp. 2964–2969. [CrossRef]

- Di Ciccio, C.; van der Aa, H.; Cabanillas, C.; Mendling, J.; Prescher, J. Detecting flight trajectory anomalies and predicting diversions in freight transportation. Decision Support Systems 2016, 88, 1–17. [CrossRef]

- Alexandru, A.M.; De Mauro, A.; Fiasché, M.; Sisca, F.G.; Taisch, M.; Fasanotti, L.; Grasseni, P. A smart web-based maintenance system for a smart manufacturing environment. 2015 IEEE 1st International Forum on Research and Technologies for Society and Industry Leveraging a better tomorrow (RTSI). IEEE, 2015, pp. 579–584.

- Colledani, M.; Tolio, T.; Fischer, A.; Iung, B.; Lanza, G.; Schmitt, R.; Váncza, J. Design and management of manufacturing systems for production quality. CIRP Annals - Manufacturing Technology 2014, 63. [CrossRef]

- Data, F.A.B. Zukunftsmarkt Künstliche Intelligenz–Potenziale und Anwendungen, 2018.

- Sharma, R.; Kamble, S.S.; Gunasekaran, A.; Kumar, V.; Kumar, A. A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Computers & Operations Research 2020, 119, 104926. [CrossRef]

- Mishra, D.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J. Big Data and supply chain management: a review and bibliometric analysis. Annals of Operations Research 2018, 270, 313–336. [CrossRef]

- Schmid, V.; Doerner, K.F.; Laporte, G. Rich routing problems arising in supply chain management. European Journal of Operational Research 2013, 224, 435–448. [CrossRef]

- Machine learning approach for finding business partners and building reciprocal relationships. Expert Systems with Applications 2012, 39, 10402–10407.

- Estelles-Lopez, L.; Ropodi, A.; Pavlidis, D.; Fotopoulou, J.; Gkousari, C.; Peyrodie, A.; Panagou, E.; Nychas, G.J.; Mohareb, F. An automated ranking platform for machine learning regression models for meat spoilage prediction using multi-spectral imaging and metabolic profiling. Food Research International 2017, 99. [CrossRef]

- Samvedi, A.; Chan, F.; Chung, S.H. Fuzzy time series forecasting for supply chain disruptions. Industrial Management & Data Systems 2015, 115, 419–435. [CrossRef]

- Juez-Gil, M.; Erdakov, I.N.; Bustillo, A.; Pimenov, D.Y. A regression-tree multilayer-perceptron hybrid strategy for the prediction of ore crushing-plate lifetimes. Journal of Advanced Research 2019, 18, 173–184. [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. International Journal of Distributed Sensor Networks 2016, 12, 3159805. [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 2016, 52, 161–166.

- Gaub, H. Customization of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinforced Plastics 2016, 60, 401–404. [CrossRef]

- Fu, W.; Chien, C.F. UNISON data-driven intermittent demand forecast framework to empower supply chain resilience and an empirical study in electronics distribution. Computers & Industrial Engineering 2019, 135, 940–949. [CrossRef]

- Tjahjono, B.; Esplugues, C.; Enrique, A.; Peláez-Lourido, G. What does Industry 4.0 mean to Supply Chain? Procedia Manufacturing 2017, 13, 1175–1182. [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. procedia CIRP 2016, 40, 536–541. [CrossRef]

- Fosso Wamba, S.; Gunasekaran, A.; Akter, S.; Ren, S.; Dubey, R.; Childe, S. Big data analytics and firm performance: Effect of dynamic capabilities. Journal of Business Research 2016, 70. [CrossRef]

- Manyika, J. Big data: The next frontier for innovation, competition, and productivity. 2011.

- Wang, G.; Gunasekaran, A.; Ngai, E.W.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. International Journal of Production Economics 2016, 176, 98–110. [CrossRef]

- Sundarakani, B.; Kamran, R.; Piyush.; Jain, V. Designing a Hybrid Cloud for a Supply Chain Network of Industry 4.0: A Theoretical Framework. Benchmarking An International Journal 2019, xx, xx. [CrossRef]

- Zuo, Y.; Kajikawa, Y.; Mori, J. Extraction of business relationships in supply networks using statistical learning theory. Heliyon 2016, 2, e00123. [CrossRef]

- Bumblauskas, D.; Mann, A.; Dugan, B.; Rittmer, J. A blockchain use case in food distribution: Do you know where your food has been? International Journal of Information Management 2020, 52, 102008. [CrossRef]

- Azzi, R.; Chamoun, R.K.; Sokhn, M. The power of a blockchain-based supply chain. Computers & Industrial Engineering 2019, 135, 582–592. [CrossRef]

- Ko, T.; Lee, J.; Ryu, D. Blockchain Technology and Manufacturing Industry: Real-Time Transparency and Cost Savings. Sustainability 2018, 10. [CrossRef]

- Yadav, S.; Prakash Singh, S. Modelling procurement problems in the environment of blockchain technology. Computers & Industrial Engineering 2022, 172, 108546. [CrossRef]

- Dai, J.; Vasarhelyi, M. Toward Blockchain-Based Accounting and Assurance. Journal of Information Systems 2017, 31. [CrossRef]

- Bause, M.; Esfahani, B.K.; Forbes, H.; Schaefer, D. Design for health 4.0: Exploration of a new area 2019. 1, 887–896.

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and supply chain performance: A systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Industrial Marketing Management 2022, 105, 268–293. [CrossRef]

- Tekkeşin, A.İ.; others. Artificial intelligence in healthcare: past, present and future. Anatol J Cardiol 2019, 22, 8–9.

- Zhu, Y.; Xie, C.; Wang, G.J.; Yan, X.G. Predicting China’s SME Credit Risk in Supply Chain Finance Based on Machine Learning Methods. Entropy 2016, 18. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).