1. Introduction

At present, many world manufacturing powers, such as “Made in China 2025” in China, “Industrial Internet” in the United States and “Industry 4.0” in Germany, have implemented the development strategy of “intelligent manufacturing” at the national level. Although China’s industrial capacity and export scale have been at the world’s leading level, and its industrial added value as the world’s largest manufacturing country accounts for about 30% of the world’s total, China is the only country with all industrial categories (41 major categories, 207 medium categories, and 666 subcategories) in the United Nations Industrial Classification, and has been leading other manufacturing economies in the world for many consecutive years. However, even though China has such a huge industrial scale, it is still facing “industrial software”, which cannot be bypassed by “intelligent manufacturing” so far [

1]. In 2021, at the General Assembly of the China Association for Science and Technology and the General Assembly of the academician of the Chinese Academy of Sciences and the Chinese Academy of Engineering, China’s scientific and technological breakthroughs should be based on the urgent needs of current and long-term development, and focus on breakthroughs in core technologies in high-end chip fields and industrial software. Industrial software is considered to be the most urgent problem to be solved today, which is related to the country’s current economic development needs and highlights the important strategic value of industrial software [

2]. In 2021, industrial software was included in the “National Key Research and Development Plan -- the first batch of key special research plan” of the Ministry of Science and Technology for the first time, which represents that it has become the highest level of strategic deployment in the domestic science and technology field, and also marks that China’s domestic industrial software will step into a new stage of vigorous development. Academite Ni Guangnan (2019) pointed out that China is facing the transformation from a “manufacturing power” to a “manufacturing power”, and vigorously developing industrial software is the key support for “intelligent manufacturing” and an important foundation for realizing high-quality development of manufacturing [

3]. Promoting the development of China’s “intelligent manufacturing” to industrial “intelligent digitalization” can not only give priority to the layout of the transformation and upgrading of “manufacturing power”, but also achieve the purpose of rapidly occupying the middle and high-end global market [

4].

According to the statistics of the White Paper on China’s industrial software Industry (2020), the market size of China’s industrial software in 2020 was 197.4 billion yuan, accounting for only 6% of the global industrial software market size, with a year-on-year growth rate of up to 15% (see

Figure 1). In 2020, for example, China’s industrial added value exceeded 31.3 trillion yuan, accounting for nearly 30% of the world’s total. Although the scale of industrial added value industry is huge, the proportion of China’s industrial software market in the world is too low, resulting in a very strong domestic demand for industrial software [

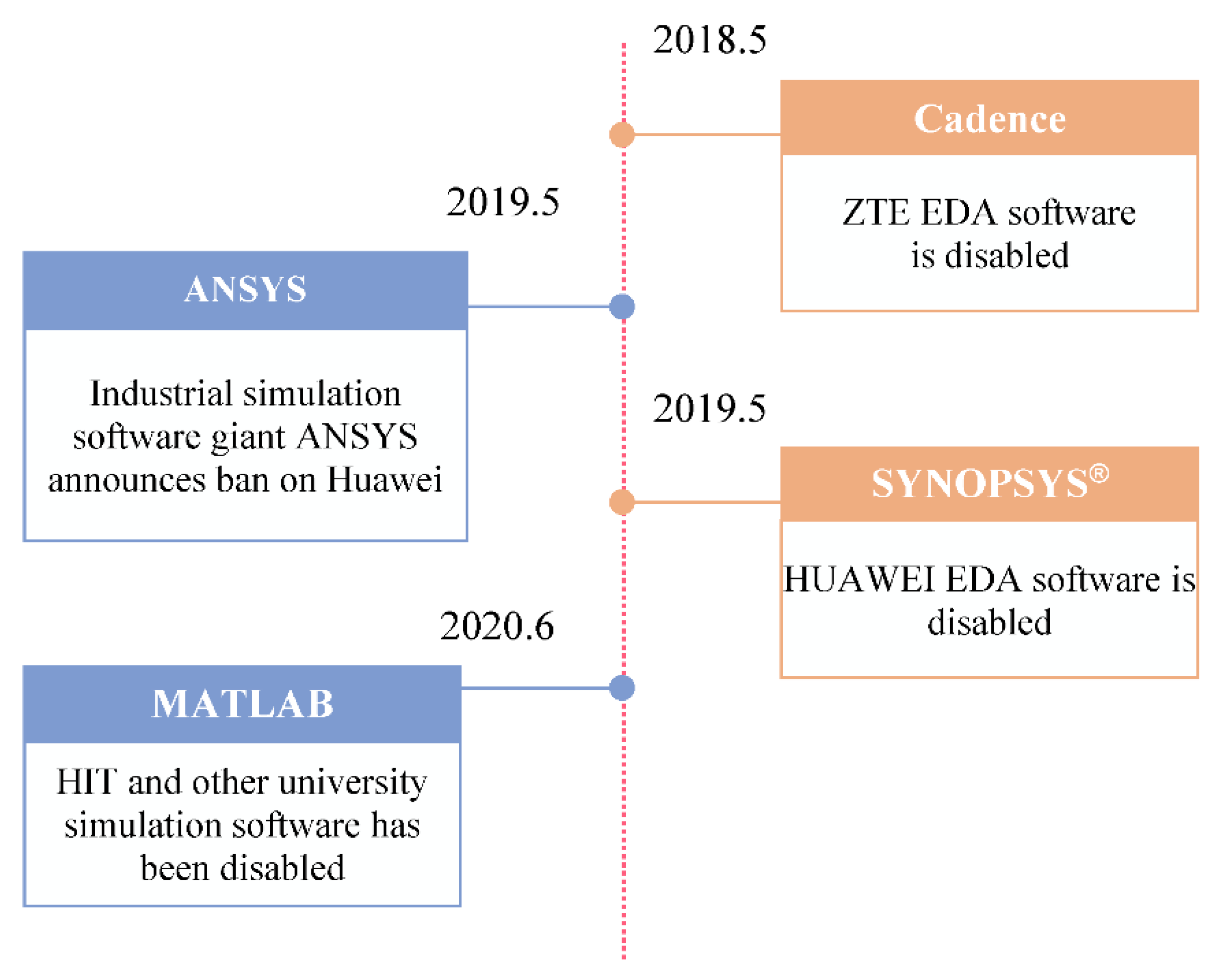

5,

6]. Since 2020, with the continuous spread of COVID-19 worldwide and the increased risk of anti-globalization in the international situation, China’s economic development environment has undergone great changes, and the policy of “new pattern of internal circulation” has become the main line of our future economic and social development. In the process of high-quality development to a “manufacturing power”, China is also facing a series of problems from the “bottleneck” of industrial software in Europe and the United States. As shown in

Figure 2, such as: The United States banned ZTE and Huawei from using industrial software related to chip design of integrated circuit Electronic Design Automation (EDA), and then prohibited some domestic universities from using MATLAB software in course teaching [

7]. Based on the above research background, we find that the state attaches special importance to the development of the industrial software industry and has formulated promotion policies through relevant departments, which also shows that the government recognizes the important role of industrial software in promoting the growth of industrial economy.

Why study total factor productivity (TFP) and improvement paths in the industrial software industry? First, China’s industrial software affects the high-quality development of intelligent manufacturing. The way to achieve high-quality development of the industrial software industry is to optimize the allocation efficiency of the industry. Therefore, improving the total factor productivity (TFP) of the industrial software industry is an effective means to achieve the development of the industrial software industry. The total factor productivity (TFP) of the industrial software industry is a measure of the high-quality development of the industrial software industry. Second, when analyzing the influencing factors of the industrial software industry, capital, technology, environment and human factors cannot fully explain the impact on the industrial software industry. Therefore, it is necessary to study the path to improve the total factor productivity (TFP) of the software industry from the configuration and combination of production factors. Finally, in the process of China’s intelligent manufacturing transformation, a considerable number of industrial enterprises have low efficiency due to low intelligence and informatization, and the industrial software industry directly affects the transformation and upgrading of the manufacturing industry. Therefore, it is necessary to study whether China’s industrial software industry can develop with high quality. The high-quality development of the industrial software industry is measured by the total factor productivity (TFP) of the industrial software industry. The improvement of the total factor productivity (TFP) of China’s industrial software industry depends to a large extent on the R&D investment of domestic industrial software companies, government support and corporate R&D personnel investment. How to improve the total factor productivity (TFP) of the industry has become an extremely realistic issue.

In summary, this paper starts from the total factor productivity (TFP) of the industrial software industry, studies and defines industrial software and industrial software classification, quantitatively measures the total factor productivity of my country’s industrial software industry, analyzes the influencing factors of the total factor productivity of the industrial software industry, and uses the fsQCA method to study its improvement. path. From the perspective of overall analysis, we explore the best path for different factors to improve the total factor productivity of the industrial software industry [

8]; from the perspective of segmentation, we analyze the key factors and path configurations for improving the productivity of different types of industrial software industries. Specifically, which production factors are necessary for enterprises in the industrial software industry, are there substitutability and complementarity between various factors, and how can the industrial software industry without high total factor productivity be improved? How many configuration combinations and paths exist for high total factor productivity configurations in different types of industrial software industries? What is the substitutability and complementarity between various production factors in different types of industrial software industries?

The main contributions of this study are reflected in the following aspects [

9]. First of all, this is the first study on using fsQCA to improve TFP in China’s software industry. Therefore, this article has enriched the literature and efficiency methods of China’s software industry, especially the specific paths to improve TFP [

10]. Secondly, the relationship between factors and outcome is analyzed from a systematic perspective, and the fsQCA considers that there can be multiple different path configuration combinations to achieve the outcome. In this way, our research outcome is not only more consistent with what logic might imply, but also more instructive for improving the China’s software industry [

11]. Thirdly, fsQCA focuses on the asymmetric causal relationship between causes and effects, which breaks through the limitations of the symmetric thinking based on correlation coefficient in traditional quantitative research [

12,

13,

14].

The rest of the paper is structured as follows. This article continues with

Section 2, which presents the relevant on theoretical basis and analytical framework. In

Section 3, we discuss the materials and methods.

Section 4 exhibits the empirical analysis on the TFP of Chinese industrial software industry, also conducts a fsQCA to explore the configurations of TFP improvement. Conclusions and discussion are presented in

Section 5.

2. Theoretical Basis and Analytical Framework

Taken together, existing research has conducted preliminary and useful explorations on the topic of industrial software industry development, which has laid a certain foundation for subsequent related research. However, there is still room for improvement in existing research. On the one hand, existing research still lacks direct empirical evidence to explore the relationship between relevant industry factors and industrial software industrialization. Compared with traditional industries, the industrial software industry is a strategic emerging industry. The differences in industrial attributes may lead to certain differences in the elements of its industrialization. Therefore, it is very necessary to summarize the supporting factors related to the industrial software industry with the help of theory. On the other hand, existing industrialization research is mostly one-dimensional and prefers to explore the single impact of industrial factors on the level of industrialization. However, the industrialization of industrial software itself is a highly complex phenomenon. During the development process, there will definitely be the joint action of multiple factors and the coordinated interaction of multiple factors. At the same time, there may also be situations where the combination of factors is equivalent. In this context, multi-dimensional research is more in line with the reality of high-quality development of industrial software. In addition, there are certain limitations and mismatches in the methods adopted by existing studies. First, quantitative methods based on regression ideas can only explain linear relationships or net effects, but cannot well reveal the nonlinear relationship between industrial factors and the level of industrial software industrialization and the underlying mechanism. Second, the application of qualitative methods represented by case analysis has always faced doubts about the representativeness of the sample and the validity of the generalization of the results. In view of this, this article attempts to creatively introduce the production factor theory of “capital-technology-environment-manpower” into the field of industrial development, and combines the configuration perspective to build an integrated analysis framework. It uses the fuzzy set qualitative comparative analysis method to analyze China’s typical Industrial software companies are used as case samples to empirically analyze the influencing factors and implementation mechanisms of industrial software industrialization. Therefore, on the basis of this theory, this paper introduces the configuration perspective for modification, and finally forms an integrated analysis framework including six influencing factors at the four levels of technology, capital, human resources and environment (as shown in

Figure 3).

2.1. In Terms of Capital Factors

The development of the industrial software industry requires a large amount of capital investment, and capital investment plays an important role in the production process of the industrial software industry. Capital investment is the support for the stable development of the industrial software industry, which is conducive to improving the development environment of the industrial software industry and improving the infrastructure level of the industrial software industry. The intensity of fixed asset investment can reflect the development of the industrial software industry, so the amount of fixed asset investment is also closely related to the total factor productivity of the industrial software industry. When Bai Wen studied the factors affecting the efficiency of my country’s provincial software industry, through Tobit model regression analysis, he found that increasing fixed asset investment is conducive to improving industrial efficiency [

15]. He Xiong used empirical analysis of soft packaging industry data from 28 provinces in China and found that industry scale, human input level, capital investment level, etc. are the main factors affecting total factor productivity, and believed that the level of capital investment can improve soft packaging Industrial efficiency [

16]. Based on the availability data of China’s software industry from 2000 to 2015, Guo Rengui and Qiao Yongzhong believe that the software industry is affected by factors such as the intensity of copyright protection, income quota, fixed asset investment, number of employees, export quota, etc. The intensity of copyright protection A significant negative impact occurs, fixed asset investment has a significant negative impact, and other remaining influencing factors are not significant [

17].

2.2. In Terms of Technical Factors

Li Xu analyzed the relationship between technological innovation of software companies and the performance of listed companies. The use of R&D funds and personnel investment levels can reflect technological innovation capabilities. The higher the level of R&D investment, the higher the technological innovation capabilities and corporate performance levels [

18]. Shao Jinju and Wang Pei measured the input and output efficiency of China’s domestic software service industry. The key influencing factor, R&D investment, is significantly positively correlated with the efficiency of the software service industry [

19]. Jiao Yunxia [

20] used the SFA method to analyze the factors that affect the efficiency of China’s software industry. The influencing factors include the level of informatization (represented by the informatization development index), the level of specialization (represented by the proportion of R&D personnel), and the level of R&D investment (represented by the proportion of R&D funds). (represented by ratio), government support level (represented by the proportion of government funding), and enterprise size (represented by the ratio of total business income to the number of regional enterprises). Among them, investment in R&D personnel can improve the efficiency level of the software industry, but the level of R&D investment has a negative impact on the efficiency of the software industry. impact. Chen Guanju (2015) used the SFA method to study relevant data from 31 national-level software industry bases from 2008 to 2012. The results showed that science and technology funding can promote efficiency improvement, and science and technology funding is a key factor affecting innovation efficiency [

21]. Jiao Yunxia [

22] used the SFA method to analyze the factors that affect the efficiency of the software industry. The influencing factors include the level of specialization (represented by the proportion of R&D personnel), the level of R&D investment (represented by the proportion of R&D funds), and the degree of industrial trade openness (represented by the proportion of export revenue). (represented by ratio), enterprise size (represented by the ratio of total business revenue to the number of regional enterprises); and these factors have a very significant impact. Among them, the level of R&D personnel investment can improve the efficiency of the software industry, and the level of R&D investment has a negative impact on the efficiency of the software industry. Du Qiaoqiao (2019) analyzed the dimensions of production factors (indicating human capital and innovation capabilities), industry dimension (indicating the development of related industries), urban dimension (indicating city scale), and institutional dimension (indicating government support) that affect the agglomeration level of the information service industry. Five dimensional factors including intensity (indicating intensity) and international dimension (indicating the level of opening up to the outside world) [

23]. Ye Hongyun (2020) obtained two main factors that affect the performance of the industrial software industry through literature review: technological innovation capability factors and resource integration factors. The study also found that technological innovation has a significant positive impact on the performance of enterprises, and resource integration also has a positive impact on performance. produce significant positive effects [

24]. When Guo Chaoxian, Miao Yufei et al. (2022) analyzed the current competitiveness level of China’s industrial software industry, the study believed that increasing R&D investment can improve the development level of the industrial software industry [

25]. Dai Xiaolong (2022) believes that industrial software technology innovation and R&D investment are the key to the development of industrial software companies and are the key factors that promote the high-quality development of industrial software companies [

26].

2.3. In Terms of Environmental Factors

When Chen Na (2013) analyzed the operating performance of China’s listed software companies, she found that the company’s performance was positively correlated with the proportion of the top five shareholders’ shareholdings to the company’s total shares [

27]. When Zhiguang Li (2020) analyzed industrial ownership concentration, he believed that there is a negative relationship between company performance and the shareholding ratio of the company’s largest shareholder [

28]. When Liao Mingyan et al. (2018) studied the efficiency of software industry clusters, they used the four-stage DEA method to measure the decomposition of TFP. Their study found that environmental factors are the key influencing factors that limit the improvement of cluster efficiency [

29]. Yan Xiaochang and Huang Guitian (2019) used the software industry base as a research data sample and used a panel regression model to measure the influencing factors on the development of the software industry. The results concluded that enterprises and central government funds, tax incentives, and land incentives And the preferential policies available to talents are significantly positive. Therefore, they believe that government support policies are the main influencing factor [

30]. Tao Zhuo and Huang Weidong (2021) sorted out a series of relevant policies at the national level and major provinces and cities regarding the domestic industrial software industry, analyzed the specific current situation of the industrial chain, R&D chain, and market chain, and distinguished between foreign and domestic representative provinces (Jiangsu, Guangdong) industry development trend, it is proposed to improve the government support environment (policies, tax incentives) [

31]. Long Yuntao, Huang Tingting and others (2021) analyzed the root causes of bottlenecks that restrict the development of domestic industrial software in China, and proposed that improving the innovation ecological environment (intellectual property protection, government tax exemptions) can improve the development of industrial software [

32]. When Zhou Yong, Zhao Dan et al. (2022) analyzed the development of China’s industrial software industry, they believed that preferential tax policies, support for software trade and other forms can enhance the development of China’s industrial software [

33]. When Guo Chaoxian, Miao Yufei and others (2022) analyzed the current competitiveness level of China’s industrial software industry; they proposed ways to increase government loan support, insurance subsidy support, application reward and subsidy support, and intellectual property protection to improve industrial software Industrial development level [

25].

2.4. In Terms of Human Factors

Shao Jinju and Wang Pei (2013) used the SFA method to measure the input and output efficiency of China’s domestic software service industry, and used the Tobit model to empirically test the key factors affecting the efficiency of the software service industry. The key influencing factors include scientific and technological innovation capabilities (represented by R&D investment), urbanization level (represented by the proportion of the tertiary industry to GDP, the proportion of non-agricultural population), and human resource levels (represented by the cost of employees with college or above and labor costs), infrastructure level (represented by the number of Internet accounts), and industrial accumulation degree (represented by location entropy). However, the results found that human capital has a positive but not significant impact on efficiency [

19]. Wu Lei et al. (2013) studied 12 software industry cities in China. They believed that factors such as the number of high-tech talents, R&D investment, and government support policies are important influencing factors. Among them, the number of high-tech talents as a human capital factor can Improve efficiency levels [

34]. Chen Guanju (2015) used the SFA method to study relevant data from 31 national-level software industry bases from 2008 to 2012. The results showed that human capital stock can promote efficiency improvement; human capital structure is a key factor affecting innovation efficiency [

21]. Tao Zhuo and Huang Weidong (2021) sorted out a series of relevant policies at the national level and major provinces and cities (Beijing, Guangdong, Shanghai, Jiangsu) about the domestic industrial software industry, and analyzed the specific status of the industrial chain, R&D chain, and market chain, The development trend of the industry in foreign and domestic representative provinces (Jiangsu and Guangdong) was analyzed, and it was pointed out that the talent structure of industrial software practitioners is a key factor affecting the development of the industrial software industry [

31]. When Zhou Yong, Zhao Dan et al. (2022) analyzed the breakthrough path of industrial software development, based on the development situation of China’s industrial software industry, they believed that supporting the training of industrial software talents can improve the development of China’s industrial software [

33]. Guo Chaoxian, Miao Yufei and others (2022) found that the competitiveness level of China’s industrial software industry needs to be improved compared with European and American countries; they believe that paying attention to the talents of industrial software companies can improve the development level of the industrial software industry [

25].

3. Materials and Methods

3.1. Data Collection

After combing through the relevant literature of domestic scholars in China, it was found that there is currently no sample data for the industrial software industry, and no scholars have empirically studied how to obtain it, because there is no statistical yearbook or related database on the industrial software industry in China. Therefore, this paper refers to the data acquisition methods of Ma Hong and Wang Yuanyue, Chu Deyin et al. (2016) [

35], and Ye Hongyun (2020) [

24]. This paper considers the development of listed firms in the industrial software industry or firms that have received IPO GEM acceptance It is relatively good. These typical firms are basically within 100 in the industrial software ranking list, and can represent the current development level of China’s domestic industrial software industry. Therefore, this paper conducts sample screening and analysis from 848 domestic industrial software firms in the “Directory of Chinese Industrial Software and Service Firms”, and collects and compiles available relevant data on industrial software firms.

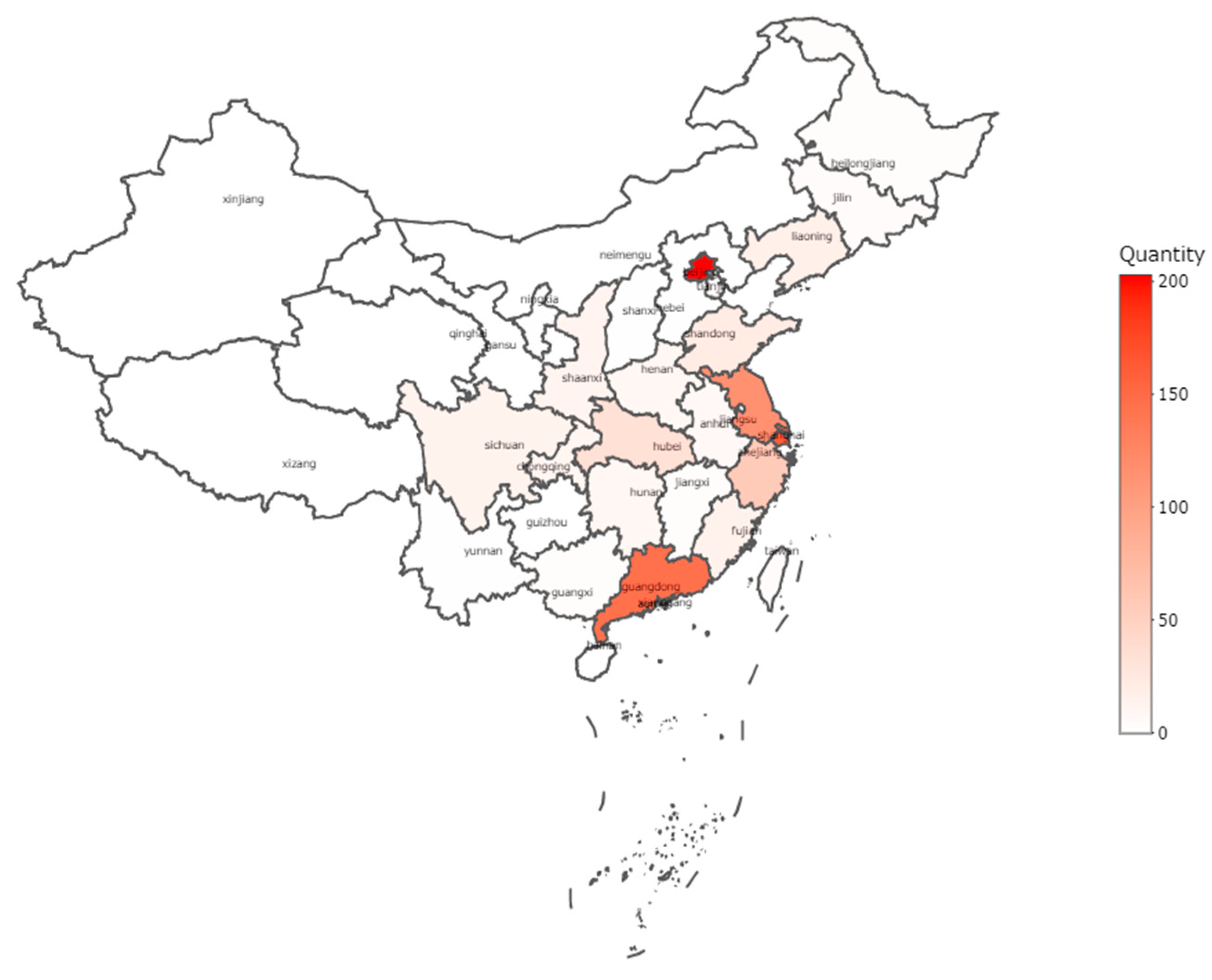

As shown in

Figure 4 above, judging from the distribution of industrial software firms in various provinces in China, the development of China’s industrial software industry is extremely uneven. About 80% of the total number of industrial software firms are concentrated in five provinces, namely Beijing, Shanghai, Guangdong, Jiangsu and Zhejiang. The industry in these provinces is relatively developed, with a relatively large number of firms in the industrial field, and the operating efficiency of industrial firms is relatively good. Compared with other regions, they pay more attention to digital transformation. These regions have a greater demand for industrial software. Therefore, this paper Choose to study the basic situation of typical enterprises in the industrial software industry from the micro level.

This paper collects and collates the relevant data of industrial software firms, and takes the listed firms or IPO firms accepted by GEM among 848 industrial software firms as samples, mainly including R&D and design industrial software firms, operation and management industrial software firms, production control industrial software firms, industrial Internet platform and industrial APP industrial software firms. For the purpose of empirical research, the data of the above firms are processed:

First of all, the input-output data of the DEA model cannot be negative. However, due to the characteristics of some indicators, there may be situations where the original data of some indicators are negative. This requires dimensionless processing of these indicator data so that The processed original data is scaled to be within the positive range.

Secondly, firms with missing enterprise indicator data or input-output indicators of 0 are eliminated. In order to ensure the research sample size, industrial software accounts for the main business firms or a certain Comparable firms in the listed annual reports of category firms are also used as supplementary samples.

Finally, after processing, relevant data of 40 typical industrial software firms from 2018 to 2020 were obtained (because the listing of typical industrial software firms in the R&D and design category or the platform category is relatively Late, even ZW Software will be launched in 2021, resulting in a short time interval for data acquisition, so only data from 2018 to 2020 can be selected in a limited manner).

3.2. Variable Selection: Input-Output

The investment indicators selected by the industrial software industry are in line with Bai Wen (2015) [

15], Wang Zhen et al. (2016) [

36], Wang Zhe et al. (2017) [

37], Wang Huanfang et al. (2020) [

35] for research and analysis in the field, the number of industry personnel at the end of the year is selected to represent the labor input index; in line with the research of Zhou Jing (2011) [

38], Liao Jing (2016) [

39] and others, fixed asset investment is taken as capital investment, fixed assets Investment can indirectly reflect the scale of the firms and its development, etc. It is generally considered to be the material guarantee for innovation and development; it is in line with the views of Ren Yousheng and Qiu Xiaodong (2017) [

40], Wang Huanfang et al. (2020) [

35], etc., choose R&D investment as the capital investment indicator of the industrial software industry.

This paper takes the main business income and net profit of industrial software firms as output indicators. Refer to the research of Li Zhifeng (2018), Yang Ruoxia (2018) [

41], Wang Huanfang et al. (2020) [

35]. Corporate performance can generally be measured by corporate net profit indicators. Obtaining net profits is the purpose of corporate participation in economic activities. Drawing on the research of Bai Wen (2015) [

15], Liao Jing (2016) [

39] and others, they classified each enterprise into Software main operating income is used as an output indicator to measure the efficiency of software firms.

Based on the above analysis, according to the characteristics of the industrial software industry and the common ground of industrial development in related fields, and referring to the empirical research of scholars in related fields, the final selected input indicators are the number of employees at the end of the year, investment in fixed assets, and investment in R&D funds; The output indicators are operating income and net profit of each software business owner (see

Table 1). By processing the relevant data collected and collated, this paper selects the input-output indicators of data, first of all, it fully considers their availability, and second, it also refers to the index selection of other scholars to verify the effectiveness of the index selection of the paper.

3.3. Measurement Methods of TFP in China’s Industrial Software Industry

This paper chooses to use the DEA-Malmquist index method to measure the TFP of typical firms in China’s industrial software industry for the following reasons:

First, this method does not require certain constraints and specific forms for the function. The real development time of China’s industrial software industry is not long, and the specific development situations of each category of industrial software are also different, which makes it difficult to set a consistent production function form suitable for different types of industrial software. In this field, choose Using the DEA-Malmquist index method can avoid measurement deviations caused by setting different functional forms to the greatest extent possible.

Second, the study uses relevant data of typical industrial software firms in China from 2018 to 2020, which can analyze the overall TFP changes of the industrial software industry and the TFP changes of sub-categories from the perspective of time and category.

Third, this method is not affected by the selected input-output data unit, and it can incorporate multiple input and output indicators.

Fourth, the TFP change index obtained by this method is the product of the technical efficiency change index (EFFCH) and the technological progress rate change index (TECHCH), and EFFCH is the change index of pure technical efficiency (PECH) and the scale efficiency change index. (EFFCH) can be used to empirically analyze TFP from the aspects of technological innovation level, capital investment status, R&D funds, and changes in the number of employees in related industries, and explore the sources of dynamic changes in TFP and the internal influencing mechanisms.

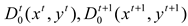

This section discusses methods of measuring total factor productivity (TFP). Malmquist proposed the Malmquist index for analyzing the consumption domain, and then the application of the Malmquist index was extended to the production domain, and combined with the data envelopment method (DEA) to calculate the TFP. At present, the DEA-Malmquist index method based on output constructed by Fare et al. is generally adopted to measure TFP [

42]. Its calculation expression is:

Among them,

respectively represent the production efficiency distance function of period

t with the technology of period

t as a reference and the production efficiency distance function of period

t + 1 with the technology of period

t + 1 as a reference;

epresents the input-output combination of period

t and

t + 1. Formula (1) expresses the change of total factor production efficiency of the input-output combination of the software industry in period

t to the input-output mix of the software industry in period

t + 1. When M

0 < 1, it means that the total factor productivity from period

t to period

t + 1 is decreasing; When M

0 = 1, it means that the TFP from period

t to period

t + 1 remains unchanged; When M

0 > 1, it means that the total factor productivity from period

t to period

t + 1 is increasing [

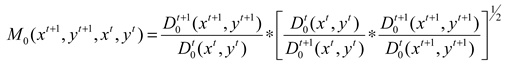

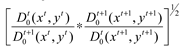

42]. Formula (1) can be further decomposed into:

In formula (2), the first term

on the right side of the equal sign represents the change index of technical efficiency from period

t to period

t + 1, denoted as

EFFCH; The second term

represents the change index of technological progress from period

t to period

t + 1, denoted as

TECHCH.

It can be seen that, under the condition of constant returns to scale, the equation of total factor productivity (TFP) is as follows:

3.4. Methodology: Apply fsQCA to Improvement Paths

This paper uses qualitative comparative analysis (QCA) to analyze the factors and mechanisms that drive total factor productivity in the industrial software industry. There are three main reasons: First, the improvement of TFP of industrial software is a complex issue caused by multiple concurrent causes and effects. QCA can use configuration thinking to test the linkage matching effect of multiple factors, identify multiple equivalent paths that drive the improvement of total factor productivity in the industrial software industry, and explore potential substitute relationships between various factors; secondly, the QCA method can accurately locate The typical enterprise cases covered by each equivalent path help this article to provide an in-depth explanation of the industrial development paths of different types of industrial software enterprises. At the same time, QCA follows the assumption of causality asymmetry, which can help this paper discover the differences and reasons for the combination of conditions that produce high and non-high levels of total factor productivity in the industrial software industry. Third, the variables selected in this study are all continuous variables, and it is more suitable to adopt fuzzy set qualitative comparative analysis (fsQCA) to reflect the changes in the degree and level of variables [

42].

The QCA method set operation logical relationship is expressed in the form of Boolean algebra, stipulating that the ~ symbol represents “not”, the * symbol represents “and”, and the + symbol represents “or”. This method is to obtain different paths with strong explanatory power for the outcome variables by screening and optimizing the consistency value and coverage level of the antecedent condition configuration [

43]. The consistency value represents the similarity between the corresponding sample configuration combination and the original data, and the coverage represents the extent to which the sample result variable can be explained by a specific configuration. The following are formulas representing consistency value and coverage respectively:

Research steps of fsQCA method:

Step 1. Select research case objects. Based on determining the content of the research, delineate a scope according to attributes, such as category or subdivision level, and then select the case objects to be studied based on the standards.

Step 2. Determine the antecedent conditions and outcome variables. The outcome variable of the research content is the core point, and the antecedent condition variables are selected from the influencing factors involved in the previous research by scholars to further construct the antecedent condition variable configuration. In the fsQCA antecedent condition variable selection process, the range of the number of antecedent condition variables is usually relatively small, generally 4-6 are selected. Too many antecedent condition variables will make the case objects “individualized,” which cannot fully explain the regularity and integrity of cross-case objects [

44].

Step 3. Quantify each variable and obtain case data. Based on the clarified variables, combined with available case data, each variable is quantified, and relevant data values are obtained using databases, corporate yearbooks, survey prospectuses, etc.

Step 4. Variable data calibration. Three calibration anchor points are set for each variable to transform the original case data into a membership value between 0 and 1. The membership includes: complete membership (membership value=1), fuzzy intersection point (membership value=0.50), and complete non-membership. (Membership value=0), drawing on the research experience of relevant scholars, 95% is selected as the complete membership point, 5% as the incomplete membership point, and 0.5 as the fuzzy intersection point. The original case data of each variable is calibrated to fuzzy membership values [

45].

Step 5. Test the sufficiency and necessity of a single variable. The adequacy test of fsQCA can tell whether a single factor as an antecedent condition variable is a subset of the outcome variable. If the test is not ideal, it means that improving total factor productivity is the result of the interaction of multiple factors. Multiple different antecedent condition variables are important for improving total factor productivity. There is a complex relationship between factor productivity. fsQCA analysis tests the necessity of a single factor and can know whether the outcome variable is a subset of the antecedent condition variables. The fsQCA method explores the impact of different configurations of antecedent condition variables on outcome variables under non-essential conditions. The antecedent condition variables are selected by eliminating variables that pass the necessity test. According to scholars’ research, if the consistency value exceeds 0.9, it is deemed that the test result is sufficient or necessary [

45].

Step 6. Construct a truth table. The calibrated case sample data is converted into a set membership value, and a 2k row truth table can be generated, where k represents the number of antecedent conditions, and the antecedent condition variable configuration in each row is a path that promotes the outcome variable. Set reasonable case sample frequencies and consistency threshold values, eliminate configurations that do not meet the set conditions, and finally build a truth table. Considering that the sample size of domestic industrial software enterprise cases is relatively small, the frequency threshold is set to 1 and the consistency threshold is 0.85 in this paper, which also satisfies the requirement that the selected configuration samples account for more than 75% of the total case samples [

46].

Step 7. Conditional combination configuration analysis. After calibration and analysis of this method, complex solutions, simple solutions and intermediate solutions can be obtained. The complex solution does not consider the logical remainder, and its analysis is more complicated and cumbersome. The simple solution completely takes into account all the logical remainders, and it is definitely inconsistent with the actual situation. The intermediate solution is to add the consistent part of the logical remainder to the configuration without removing the necessary conditions for the outcome variable. Researchers generally believe that the intermediate solution is better than the other two solutions. The analysis of the paper is an intermediate solution adopted to obtain the consistency value, original coverage and unique coverage values under each configuration. At the same time, this method also needs to judge and analyze the antecedent condition variables. If the antecedent condition variables in the configuration all appear in the configuration of the intermediate and parsimonious solutions, then this variable is considered to be the core variable, which has an important influence on the outcome variable. It has a super strong influence; if the antecedent condition variable only appears in the intermediate plan configuration, then the variable is considered a non-core variable, and its impact on the outcome variable is relatively weak [

47].

4. Results

4.1. Results from Mesurement Model

From the perspective of the industrial software industry as a whole, DEA- Malmquist index analysis was conducted on the relevant data of listed companies or IPO GEM-accepting companies in China’s industrial software industry from 2018 to 2020 to measure the total factor productivity change index and its decomposition of typical companies in the industrial software industry. The summary of results shows (see

Table 2) that the average annual total factor productivity of typical enterprises in China’s industrial software industry is 0.965, and the average annual growth rate is -3.5%. After decomposing the average total factor productivity of typical enterprises in China’s industrial software industry, we get The annual average technical efficiency is 0.793, the annual average growth rate of technical efficiency is -20.7%, the annual average technical progress rate is 1.216, and the annual average growth rate is 21.6%, which shows that the annual average growth rate of typical enterprises in China’s industrial software industry The reason for the decline in total factor productivity comes from the decline in the annual average technical efficiency growth rate. Further decomposing the technical efficiency of typical industrial software enterprises in China, it can be seen that the annual average growth rate of pure technical efficiency and scale efficiency have declined. The annual average growth rate of pure technical efficiency is 0.814, and the average annual growth rate is -18.6%; The annual average value of scale efficiency is 0.975, and the average annual growth rate is -2.5%. From the above analysis, it can be seen that the decline in the annual average growth rate of technical efficiency is due to the decrease in the annual average value of pure technical efficiency and the annual average value of scale efficiency. As a result, the total factor productivity of China’s industrial software industry has declined, resulting in a low-end development trend. This is due to the low level of optimal allocation efficiency of typical industrial software enterprises, that is, the scale of the enterprise is too small, the daily management capabilities of the enterprise are too weak, and the utilization of enterprise resources is too low. Problems such as too low level are the main bottlenecks in improving the total factor productivity of the industrial software industry.

The analysis of the measurement model was done in

Appendix A and quantitative results are summarized in

Table A1 and

Table A2 of annex.

From the index change from 2018 to 2019 (see

Table A1), the technological progress rate index is 1.473, and the technical efficiency, pure technical efficiency and scale efficiency are 0.612, 0.683 and 0.896 respectively, indicating that the decline in TFP of typical enterprises in China’s industrial software industry from 2018 to 2019 is mainly caused by the decline in technical efficiency. Although enterprises have been improved in technology update and iteration, technology introduction and other aspects, the utilization efficiency of production factors of industrial software enterprises has been greatly reduced. From the index change from 2019 to 2020 (see

Table A2), the TFP of typical industrial software enterprises is 1.033, which indicates that the TFP of typical industrial software enterprises has increased by 3.3%, and its technical efficiency, pure technical efficiency, scale efficiency and technological progress rate are 1.029, 0.969, 1.061 and 1.004, respectively. Technical efficiency and technological progress rate have changed significantly. It can be seen that although the technological innovation and technological progress of industrial software enterprises have not improved much from 2019 to 2020, the scale efficiency and daily management level of industrial software enterprises have been greatly improved from 2019 to 2020. This shows that the combined effect of technical efficiency and technological progress rate promotes the positive growth of TFP in the industrial software industry.

4.2. Results from fsQCA

4.2.1. Variable Selection and Descriptive Statistics

Wang and Jiang et al. [

48] pointed out that the sample size of the fsQCA method should be at least greater than or equal to 10. In this paper, the DEA-Malmquist index analysis method is used to measure the TFP of the industrial software industry, and the total factor productivity of the industrial software industry in 2020 is used as the outcome variable of fsQCA analysis. Considering the time lag of the input and output of the industrial software industry, six variables under the four dimensions that affect the total factor productivity of the industrial software industry in 2019 are selected, and the level of government support, fixed asset investment intensity, R&D investment level, R&D personnel investment level, ownership concentration and education level are the antecedents condition variables (see

Table 3).

4.2.2. Calibration of Variables

Unlike traditional variables, the dataset must be calibrated before it can be analyzed by fuzzy set software. In the current version of the fsQCA3.0 software, the calibration is automatic and easy to perform once the three qualitative anchors are defined: full membership, full non-membership, and crossover point. This paper uses fsQCA to analyze the relationship between the causal conditions (namely, the intensity of fixed asset investment, the level of R&D investment, the level of R&D personnel investment, the level of government support and the level of education) and the outcome (TFP of industrial software firms). In this paper, fsQCA is used to set the three qualitative anchors of fuzzy sets of outcome variables and condition variables as full membership (95%), full non-membership (5%) and crossover point (0.50) [

49]. All variable calibration anchors are shown in

Table 4. Through qualitative anchors of outcome variables and condition variables, the original values of all variables are transformed into fuzzy membership scores (values between 0-1) by using the “calibrate” calibration command in fsQCA 3.0 software. However, there is a problem in the calibration that it can produce a fuzzy set membership score of exactly 0.5, which makes it difficult to analyze this situation due to the ambiguity of the case member set. Therefore, the use of an exact membership membership score of 0.5 for causal conditions should be avoided. According to the research practice of previous scholars, this paper adds a constant of 0.01 to the score of all fuzzy set members; Doing so ensures that no cases are removed from the fuzzy set analysis [

50]. Finally, the membership scores of fuzzy sets are obtained.

4.2.3. Analysis of Necessity Conditions

Although the analysis of sufficient condition combinations is the most critical part of the fsQCA study, the necessity of each condition must be tested before constructing the truth table. As suggested by researchers such as Xie, X., Wang, H. (2020) [

49], Ragin, C. C. (2008) [

51], if a single condition variable is required, the consistency and coverage of each condition variable Must be above the recommended threshold of 0.9; otherwise, it is not a requirement. This study analyzes several condition variables of production factors such as FIX, RD, RDP, and GOV, as well as the prerequisites for OC and HE to produce TFP in the industrial software industry. In order to determine whether any of these 6 conditions is required for total factor productivity in the industrial software industry, this paper analyzes whether this antecedent condition variable always exists (does not exist) in all cases where the outcome variable exists (does not exist). The results in

Table 5 show that the necessary consistency of all individual variables is less than 0.9, which is not enough to constitute a necessary condition for TFP in the industrial software industry. No antecedent condition variable can independently improve the TFP of the industrial software industry. One possible reason is that TFP in the industrial software industry is caused by multiple factors, and therefore, no single factor is necessary for high or not-high TFP in the industrial software industry.

4.2.4. Constructing the Truth Table

In order to identify combinations of conditions that are logically sufficient for the existence of an outcome, it is necessary to construct a truth table. The truth table needs to be preliminarily refined according to three criteria of frequency threshold, original consistency and proportional reduction of inconsistency (PRI) consistency before analysis [

49]. Although some recent scholars have shown that the fsQCA method is a very useful tool for analyzing large N (i.e., more than 50 cases) case situations, most previous scholars’ studies using the fsQCA method mostly involve relatively small N case situations (i.e., 10-50 cases) [

52]. Ragin (2008) [

51] and Jin et al.(2020) [

50] suggested that for the case of small N, the frequency cutoff of 1 is the most appropriate; However, for case scenarios with large N, the frequency cutoff should be set higher with the number of cases. This paper studies 40 cases of typical Chinese industrial software companies, which are consistent with the situation of small N. Therefore, the frequency cutoff value is set to 1 in this paper. In addition, the main representative scholar studies of the fsQCA approach suggest [

53] that at least 75-80% of all empirical cases should be included as part of the analysis [

54].

In the study presented in this paper, we rely on both original consistency and PRI consistency. This paper adopts the two rules suggested by Park (2020) [

55] and other scholars on QCA method to determine the critical value of original consistency. Firstly, the raw consistency should be higher than 0.85 for combinations/rows that reliably produce high or non-high TFP [

52]. Second, if there is a breakpoint in which agreement between two rows decreases significantly from the row with a high level of raw consistency to the row with the next level of raw consistency, then the breakpoint can be either high TFP or non-high TFP. For example, in the high TFP of the industrial software industry, there is a significant decrease in consistency from line 29 with consistency of 0.851163 to line 30 with consistency of 0.845343 at the next level (see

Table 6). For the not-high TFP of the industrial software industry, there is a break point between the consistency of 0.852252 in line 27 and 0.846875 in line 28 (see

Table 6); Therefore, we can decide to use 0.85 as the original consistency cutoff. Therefore, the critical value selection to determine the original consistency of the result column values in the truth table ultimately depends on the context, and researchers should consider some decision criteria to determine the critical value cutoff value based on their knowledge of the case and context [

55]. In fsQCA fuzzy set analysis, it is also important to consider PRI consistency scores. PRI consistency scores should be high and ideally not too far from raw consistency scores ((e.g., 0.75), Current best practice further recommends that each solution meet a PRI consistency cutoff at 0.65.

In summary, we excluded from the subsequent analysis the leading combinations that did not satisfy the frequency (1 or above), raw consistency (above 0.85), and PRI consistency (above 0.60) criteria. As a result, the retained truth table contains 31 rows of high TFP and 31 rows of non-high TFP. Tables of truth values are shown in

Appendix B (see

Table B1 and

Table B2).

4.2.5. Path Configuration Analysis

After obtaining the truth table in the previous section, this paper uses Ragin’s truth table algorithm to conduct sufficiency analysis in this step, so as to identify the attribute combination that is always associated with the outcome, and can obtain the Complex Solution, Parsimonious Solution and Intermediate Solution of TFP and~TFP respectively. Generally speaking, most researchers use an intermediate solution that is both general and heuristic. This paper uses the intermediate solution to analyze the specific configuration and combination model to improve the total factor productivity of the industrial software industry, including the configuration of each path, the Raw Coverage, Unique Coverage, Consistency value, as well as the coverage of the overall solution and the consistency value of the overall solution in the configuration mode.

Fiss (2011) defined the antecedent conditions for the overlap between the intermediate solution configuration and the simple solution configuration as core conditions, recorded as “●” or “⊕”; the antecedent conditions and parsimonious solutions that appear in the intermediate solution are excluded the antecedent condition is defined as a peripheral condition, represented by a small “●” or “⊕”, and a blank indicates that the condition variable is insignificant [

45]. Under the conditions of satisfying the consistency and coverage of path configurations, the results show that there are 4 path configurations with core conditions that can be used to evaluate the high TFP (i.e., paths H1-H4) and 4 path configurations with core conditions that can be used to evaluate the not-high TFP (i.e., paths L1-L4). The specific path configuration of TFP in China’s industrial software industry is shown in

Table 6 and

Table 7.

The path configuration of China’s industrial software industry with high TFP as the outcome variable is shown in

Table 6. Through the analysis of intermediate solutions and parsimonious solutions, 4 path configurations with core conditions were obtained to improve the TFP of China’s industrial software industry. The overall solution consistency score of the high TFP improvement path configuration of the industrial software industry is 0.830221. The consistency scores of specific path configurations are 0.9317 (for path configuration H1a), 0.9256 (for path configuration H1b), 0.9029 (for path configuration H1c), 0.9525 (for path configuration H2a), 0.9508 (for path configuration H2b), 0.8760 (For path configuration H3), 0.9459 (for path configuration H4). Therefore, it can be seen that the consistency value of each path configuration exceeds 0.85, and the consistency value of the overall solution exceeds 0.80. This shows that the 4 path configurations have a good explanation for the industrial software industry with high TFP. The TFP of the industrial software industry can be improved through these four paths. The overall solution coverage is 0.723016. Among the four path configurations, path configuration H1 (H1a raw coverage value 0.4032, H1b raw coverage value 0.3800, H1c raw coverage value 0.3849) achieved better performance than other path configurations (H2a raw coverage value 0.2765, H2b raw coverage value 0.2666, H3 raw coverage value 0.3760, H4 raw coverage value 0.2755) higher raw coverage, which indicates a higher relative empirical correlation [

56]. Among them, H1 has a higher coverage, and most industrial software firms with high TFP achieve TFP improvement through H1 path configuration. The above is in line with the qualitative comparative analysis standards proposed by Woodside (2017) [

53].

The detailed analysis of these 4 path configurations is as follows:

The capital path takes high fixed asset investment intensity, low R&D personnel investment and low equity concentration as the main adjustment means. High TFP path configuration H1 includes path H1a (FIX*~RDP*~GOV*~OC*~HE), path H1b (FIX*~RD*~RDP*~OC*~HE), path H1c (FIX*~ RD*~RDP*~GOV*~OC). Paths H1a, H1b, and H1c show that high fixed asset investment intensity, low R&D personnel investment, and low equity concentration are the core conditions for improving the TFP efficiency of the industrial software industry. The auxiliary conditions of path H1a are low government support and low education level. In path H1b, the other two auxiliary conditions are low R&D investment level and low education level. In path H1c, the other two auxiliary conditions are low R&D investment level and low government support. Path H1a describes that when the level of R&D personnel investment is low, the degree of ownership concentration is low, but the fixed asset investment intensity of industrial software companies is high, the TFP of the industrial software industry can be improved even if there is a lack of high government support and good education. Path H1b describes that when the level of R&D personnel investment is low, the degree of ownership concentration is low, but the fixed asset investment intensity of industrial software companies is high, the TFP of the industrial software industry can be improved even if there is a lack of high R&D investment levels and good education levels. Path H1c describes that when the level of R&D personnel investment is low, the degree of equity concentration is low, but the fixed asset investment intensity of industrial software companies is high, the TFP of the industrial software industry can be improved even if there is a lack of high higher R&D investment levels and higher levels of government support.

The capital-human-environment path takes high fixed asset investment intensity, high equity concentration, and high educational attainment as the main adjustment means. The high total factor productivity path configuration H2 includes path H2a (FIX*~RDP*~GOV*OC*HE) and path H2b (FIX*~RD*~RDP*OC*HE). Paths H2a and H2b show that high fixed asset investment intensity, high ownership concentration, and high educational level are the core conditions for improving the total factor productivity efficiency of the industrial software industry. The auxiliary conditions for path H2a are low government support and low R&D personnel investment. In path H2b, the other two auxiliary conditions are low R&D investment level and low R&D personnel investment level. Path H2a describes that when the intensity of fixed asset investment, ownership concentration, and educational level are high, the TFP of the industrial software industry can be improved even if there is a lack of high government support and R&D personnel investment. Path H2b describes that when the intensity of fixed asset investment, ownership concentration, and educational level are all high, the TFP of the industrial software industry can be improved even if there is a lack of higher R&D investment levels and R&D personnel investment levels.

The technology-manpower-environment path is based on high R&D investment levels, high R&D personnel investment levels, high equity concentration and high education levels as the main adjustment means. High TFP path configuration H3 (RD*RDP*GOV*OC*HE). Path H3 shows that high R&D investment levels, high R&D personnel investment levels, high ownership concentration, and high education levels are the core conditions for improving the total factor productivity efficiency of the industrial software industry. The auxiliary condition of path H3 is higher government support. Path H3 describes that when there is a high level of R&D investment, a high level of R&D personnel investment, a high degree of equity concentration, and a high level of education, the TFP of the industrial software industry can be improved even if there is a lack of high government support.

The technology-capital path is based on high fixed asset investment intensity, high R&D investment level and low R&D personnel investment level as the main adjustment means. High TFP path H4 (FAI*RD*~RDP*GOV*OC*~HE). Path H4 shows that high fixed asset investment intensity, high R&D investment level, and low R&D personnel investment level are the core conditions for improving the total factor productivity efficiency of the industrial software industry. The auxiliary conditions of path H4 are higher government support, higher ownership concentration, and lower educational level. Path H4 describes when there is high fixed asset investment intensity, high R&D investment level, and low R&D personnel investment level. Even in the absence of higher government support, higher ownership concentration, and lower education levels, the TFP of the industrial software industry can be improved.

The path configuration of China’s industrial software industry with Not-high TFP as the outcome variable is shown in

Table 7. The overall solution consistency score of not-high TFP path configuration in the industrial software industry is 0.888268. It can be seen that the consistency value of each path configuration exceeds 0.85, and the overall solution solution consistency value exceeds 0.80, which indicates that there are 4 path Configurations has a good explanation for the industrial software industry with low TFP, and the analysis of not-high TFP of the industrial software industry can be realized through these four paths. The overall solution coverage is 0.645358, and most industrial software companies without high TFP are configured for the L1c path.

The detailed analysis of these 4 path configurations is as follows:

External Environmental constrained path. The not-high TFP path configuration L1 includes L1a “FIX*~RD*RDP*~GOV*~HE”, L1b “FIX*~RD*RDP*~GOV*~OC”, and L1c “RD*RDP*~GOV* ~OC*~HE”, L1d “~FIX*RD*RDP*~GOV*~OC”. Paths L1a, L1b, L1c and L1d show that high levels of personnel investment and low levels of government support are core conditions that are not conducive to improving the TFP of the industrial software industry.

Capital-technology constrained path. The not-high TFP path configuration L2 includes path L2a (~FIX*~RD*~GOV*OC*HE), (~FIX*~RD*RDP*OC*HE). Paths L2a and L2b show that low fixed asset investment intensity, low R&D investment level, and high education level are core conditions that are not conducive to improving the TFP of the industrial software industry.

Internal environment-constrained path. Not-high TFP path configuration L3 (RD*RDP*GOV*~OC*HE). Path H3 shows that high R&D investment levels, low ownership concentration, and high education levels are core conditions that are detrimental to the TFP of the industrial software industry.

Environment-human constrained path. Not-high total factor productivity path L4 (~FIX*RD*~RDP*~GOV*OC*~HE). Path L4 shows that high R&D investment levels, low government support, high ownership concentration, and low education levels are core conditions that are unfavorable to the TFP of the industrial software industry.

5. Discussion and Conclusions

There are not so much empirical studies on the TFP of the industrial software industry from the micro level, which provides a new perspective for studying theTFP of the industrial software industry. Apply fsQCA to the analysis of the high-quality development path of industrial software in the field of economics, and obtain the synergistic path of multiple variable factors, providing reference suggestions for industrial software companies to choose a higher TFP path. Scholars’ current research using the fsQCA method is mostly applied in management, sociology and other fields. In recent years, some researchers have begun to extend the application of the fsQCA method to the field of economics. Based on the analysis of the configuration principle and applicability of this method, this paper uses the fsQCA method to obtain the path configuration of each factor to improve the TFP of the industrial software industry.

This study has four findings: first, the necessity test finds that the six factors, including technological innovation, cannot constitute the necessary conditions for promoting the high-quality development of the industrial software industry alone. Secondly, the configuration analysis finds that there are four paths to drive the high-quality development of the industrial software industry, which can be summed up as four driving modes: “technology-human-environment” balanced driving type, “capital-human-environment” balanced driving type, “technology-capital” dual driving type, and “capital” single driving type. These four configurations and four modes reflect the multiple implementation methods of typical enterprises in different industrial software industries. In addition, there are four paths that produce non-high industrialization, and there is an obvious asymmetric relationship between the two types of configurations. Finally, the analysis of potential substitution relationship finds that under specific objective endowment conditions, the combination of technology, capital, human resources and environmental factors can promote the high-quality development of the industrial software industry through equivalent substitution. Among them, the government attaches importance to the significance of more important value.

Based on the above conclusions, this paper makes four suggestions:

Implementing the technological innovation-driven strategy and implementing the classification policy. Increase investment in R&D funds and human capital in the industrial software industry, implement a strategy centered on technological innovation, and improve the utilization of R&D funds and human capital based on technological innovation. In the early stage of technological innovation, a large amount of human capital, R&D funds, etc. are required to be invested. Since the transformation of technological innovation results is extremely slow, a long-term mechanism must be established to ensure the sustainable operation of technological innovation. The government has used the “Industrial Software Total Factor Productivity” special fund to Assist the industrial software industry, focusing on supporting technological innovation of industrial software companies. The formulation of technological innovation policies in the field of industrial software must grasp the differences of different types of industrial software industries, so that human capital, R&D investment, etc. can match different types of industrial software industries.

Increase government support and accurately formulate government support policies. The government and relevant industry participants should follow the development rules of strategic emerging industries, gain insight into the internal correlations and conflicts between various factors that affect industrial development, explore the key factors and paths that restrict industrial development, and use information and intelligent means to Good industry whole-process management.

Coordinate efforts to support the training of industrial software talents through multiple channels. Give full play to the open nature of the open source community, based on national conditions, gather talents from multiple parties, promote the construction of industrial software open source ecosystem, technical community construction, open source project cultivation, open source group standard formulation, open source technology promotion and application, open source talent training, etc., and explore the formation of an Internet environment A new model for open source development of industrial software. Provide policy guidance, intellectual property protection, open source community construction, relevant standard formulation, data asset protection and other services for talent targets at all levels. It is necessary to improve the industrial innovation distribution system and incentive mechanism, improve the development evaluation system that is consistent with the characteristics of various talents, and fully stimulate the motivation of talents to innovate. Respect human input and wisdom output, reasonably ensure personnel treatment, and increase the proportion of personnel costs in project implementation. Promote the “industry-university-research- application” coordination mechanism and encourage industrial software companies to collaborate with universities and scientific research institutions to cultivate the industry. Add industrial software courses in colleges and universities, strengthen the construction of domestic industrial software training systems, and improve the level of human-related industrial software applications.

Classified promotion, cultivate a benign environment for the development of China’s domestic industrial software industry. Promote the combination of effective markets and promising governments around the industrial software development environment, start from the market demand driven by industrial enterprise software products and industrial enterprise application scenarios, implement policies by coordinating and integrating the policy resources of all parties, and rationally allocate taxation and finance in the domestic manufacturing market, financial and other resource support, forming an “internal circulation” and “internal and external dual circulation” pattern for the development of the industrial software industry.

This research had some limitations. This paper only uses the relevant data of 40 listed industrial software enterprises or enterprises accepted by the GEM for IPO. This may cause the accuracy of TFP and its decomposition measures to be less than ideal.

Author Contributions

Conceptualization, X.W., S.W. and L.Z.; Methodology, X.W.; Software, X.W.; Validation, X.W. and L.Z.; Formal analysis, X.W.; Investigation, X.W.; Resources, L.Z.; Data curation, X.W.; Writing—original draft preparation, X.W.; Writing—review and editing, X.W., S.W. and L.Z.; Supervision X.W. and L.Z.; Project administration, X.W., S.W. and L.Z.; Funding acquisition, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Social Science Science Foundation of China (Grant No. 20BJY097).

Data Availability Statement

Survey supporting the study can be obtained by demanding it to any author.

Acknowledgments

Authors acknowledge helpful comments of anonymous reviewers.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

2018-2019 Industrial Software Industry TFP Change Index and Its Decomposition.

Table A1.

2018-2019 Industrial Software Industry TFP Change Index and Its Decomposition.

| Category |

Firm name |

effch |

techch |

pech |

sech |

tfpch |

| R&D and design |

ZWsoft |

0.612 |

1.449 |

0.753 |

0.812 |

0.886 |

| Glodon |

0.476 |

1.557 |

0.231 |

2.055 |

0.741 |

| General electron |

0.056 |

1.687 |

0.507 |

0.110 |

0.094 |

| Gstarsoft |

0.258 |

1.254 |

0.649 |

0.398 |

0.324 |

| Anwise |

0.462 |

1.634 |

0.942 |

0.490 |

0.754 |

| S2C |

0.802 |

1.217 |

1.000 |

0.802 |

0.977 |

| Empyrean |

0.706 |

1.362 |

0.820 |

0.861 |

0.962 |

| Semitronix |

1.289 |

1.634 |

0.933 |

1.381 |

2.106 |

| YJK Building |

1.000 |

1.139 |

1.000 |

1.000 |

1.139 |

| Hollywave |

0.668 |

1.417 |

1.000 |

0.668 |

0.946 |

| Business management |

Yonyou Network |

0.942 |

1.404 |

1.430 |

0.658 |

1.323 |

| Neusoft |

0.568 |

1.581 |

0.384 |

1.478 |

0.898 |

| Dahua Technology |

0.763 |

1.534 |

1.000 |

0.763 |

1.171 |

| BMsoft |

0.675 |

1.307 |

0.499 |

1.351 |

0.882 |

| YGsoft |

0.805 |

1.248 |

0.519 |

1.551 |

1.005 |

| QM information |

1.087 |

1.268 |

1.346 |

0.808 |

1.378 |

| DHC Software |

0.562 |

1.692 |

0.577 |

0.975 |

0.952 |

| HAND Enterprise |

0.168 |

1.615 |

0.081 |

2.072 |

0.272 |

| HopeRun |

0.140 |

1.452 |

0.112 |

1.253 |

0.203 |

| DigiwinSoft |

0.979 |

1.284 |

1.092 |

0.896 |

1.257 |

| Production control |

Baosight |

0.787 |

1.501 |

0.998 |

0.789 |

1.182 |

| Taiji Computer |

0.624 |

1.713 |

0.670 |

0.933 |

1.070 |

| Supcon |

0.834 |

1.239 |

0.865 |

0.964 |

1.034 |

| Friendess Electronic |

1.000 |

1.344 |

1.000 |

1.000 |

1.344 |

| Wiscom System |

0.716 |

1.713 |

0.776 |

0.922 |

1.226 |

| Sifang Automation |

0.564 |

1.703 |

0.498 |

1.132 |

0.961 |

| Integrated Electronic |

0.518 |

1.618 |

0.695 |

0.745 |

0.839 |

| HITE |

0.698 |

1.830 |

0.756 |

0.924 |

1.277 |

| SCIYON |

0.738 |

1.253 |

0.838 |

0.882 |

0.925 |

| HuazhongCNC |

0.599 |

1.861 |

0.779 |

0.769 |

1.115 |

| Industrial Internet and industrial app |

Nancal |

0.800 |

1.486 |

0.874 |

0.916 |

1.189 |

| Yonyou auto |

0.793 |

1.331 |

0.578 |

1.373 |

1.056 |

| QingCloud Tech |

0.585 |

1.861 |

0.860 |

0.680 |

1.089 |

| Thunder Soft |

0.746 |

1.550 |

0.548 |

1.362 |

1.157 |

| Autel |

0.590 |

1.243 |

0.594 |

0.994 |

0.734 |

| Seeyon |

0.833 |

1.468 |

0.879 |

0.947 |

1.222 |

| BONC |

0.595 |

1.248 |

0.553 |

1.076 |

0.743 |

| FII |

0.763 |

1.474 |

1.000 |

0.763 |

1.125 |

| GUOLIAN |

1.000 |

1.581 |

1.000 |

1.000 |

1.581 |

| UNIS |

0.606 |

1.681 |

1.000 |

0.606 |

1.019 |

| |

mean value |

0.612 |

1.473 |

0.683 |

0.896 |

0.901 |

Table A2.

2019-2020 Industrial Software Industry TFP Change Index and Its Decomposition.

Table A2.

2019-2020 Industrial Software Industry TFP Change Index and Its Decomposition.

| category |

Company name |

effch |

techch |

pech |

sech |

tfpch |

| R&D and design |

ZWsoft |

1.219 |

0.828 |

1.12 |

1.089 |

1.01 |

| Glodon |

0.763 |

1.471 |

0.715 |

1.067 |

1.122 |

| General electron |

2.944 |

0.867 |

1.181 |

2.493 |

2.552 |

| Gstarsoft |

2.285 |

0.916 |

1.131 |

2.02 |

2.093 |

| Anwise |

1.175 |

0.492 |

1.714 |

0.686 |

0.578 |

| S2C |

0.179 |

0.76 |

0.835 |

0.215 |

0.136 |

| Empyrean |

1.034 |

1.242 |

0.994 |

1.04 |

1.284 |

| Semitronix |

1.337 |

1.208 |

0.958 |

1.396 |

1.615 |

| YJK Building |

1 |

0.925 |

1 |

1 |

0.925 |

| Hollywave |

0.77 |

1.139 |

1 |

0.77 |

0.877 |

| Business management |

Yonyou Network |

1.061 |

0.963 |

0.926 |

1.146 |

1.021 |

| Neusoft |

0.535 |

1.394 |

0.348 |

1.539 |

0.746 |

| Dahua Technology |

0.784 |

1.263 |

1 |

0.784 |

0.99 |

| BMsoft |

0.897 |

1.077 |

0.684 |

1.312 |

0.966 |

| YGsoft |

1.454 |

0.763 |

1.48 |

0.982 |

1.109 |

| QM information |

0.759 |

1.038 |

0.728 |

1.042 |

0.788 |

| DHC Software |

1.533 |

0.601 |

0.758 |

2.021 |

0.921 |

| HAND Enterprise |

1.947 |

0.491 |

1.761 |

1.106 |

0.956 |

| HopeRun |

2.958 |

1.015 |

1.872 |

1.58 |

3.004 |

| DigiwinSoft |

0.985 |

1.052 |

1.083 |

0.91 |

1.036 |

| Production control |

Baosight |

1.063 |

1.262 |

1.12 |

0.949 |

1.341 |

| Taiji Computer |

0.64 |

1.538 |

0.372 |

1.722 |

0.984 |

| Supcon |

1.19 |

0.828 |

0.75 |

1.587 |

0.986 |

| Friendess Electronic |

1 |

0.954 |

1 |

1 |

0.954 |

| Wiscom System |

0.544 |

1.731 |

0.773 |

0.704 |

0.942 |

| Sifang Automation |

1.131 |

1.455 |

1.129 |

1.002 |

1.646 |

| Integrated Electronic |

0.889 |

1.097 |

1.028 |

0.864 |

0.975 |

| HITE |

1.424 |

1.285 |

1.473 |

0.967 |

1.83 |

| SCIYON |

0.835 |

1.085 |

0.931 |

0.897 |

0.906 |

| HuazhongCNC |

0.754 |

1.952 |

1.053 |

0.717 |

1.472 |

| Industrial Internet and industrial app |

Nancal |

0.805 |

1.358 |

0.94 |

0.856 |

1.094 |

| Yonyou auto |

1.314 |

0.725 |

1.329 |

0.989 |

0.952 |

| QingCloud Tech |

0.491 |

2.073 |

1.166 |

0.421 |

1.019 |

| Thunder Soft |

1.419 |

0.771 |

1.899 |

0.748 |

1.094 |

| Autel |

0.985 |

0.865 |

0.737 |

1.335 |

0.851 |

| Seeyon |

1.383 |

0.736 |

1.341 |

1.032 |

1.018 |

| BONC |

0.748 |

0.788 |

0.278 |

2.691 |

0.59 |

| FII |

1.447 |

0.647 |

1 |

1.447 |

0.936 |

| GUOLIAN |

1 |

0.998 |

1 |

1 |

0.998 |

| UNIS |

1.345 |

0.777 |

1 |

1.345 |

1.045 |

| |

mean value |

1.029 |

1.004 |

0.969 |

1.061 |

1.033 |

Appendix B

Table B1.

Truth table (Outcome = TFP).

Table B1.

Truth table (Outcome = TFP).

| FIX |

RD |

RDP |

GOV |

OC |

HE |

NUMBER |

TFP |

RAW

CONSIST |

PRI

CONSIST |