Submitted:

24 November 2023

Posted:

28 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- 1)

- The direct growth technique uses a material specific design for generating nanoscale surface roughness patterns for CNT nucleation and growth, and providing a CNT base with primary bonds with the host surface. In other words, the CNT forest is inherently linked with strong anchorage to the SS surface;

- 2)

- No external catalyst, or dye solution, or slurry or other deposition technique being required, it is the stainless-steel substrate itself that is acting as the CNT growth and anchoring site;

- 3)

- the simple catalyst-free RR2R technique continuously generates reliably very long CNT-covered wires able to generate the very large collecting surfaces required, together with a CNT forest oriented in a direction perpendicular to the surface;

- 4)

- the CNT-covered wires intrinsically provide a much larger surface area for atmospheric suspended micro-droplet collection compared to bare wires. More importantly, both of the required local hydrophilic/hydrophobic properties needed for water capture and drainage are generated.

- 5)

- Finally, in a view of possibly extending the RR2R technique to other applications requiring large surfaces and various geometries, it is to be noted that the direct-growth technique based on a relatively simple metallurgical surface transformation allows the possibility of various surface shapes and sizes, as demonstrated by growth generated on particles, flat surfaces, and grids.

2. Fog harvester basics and requirements

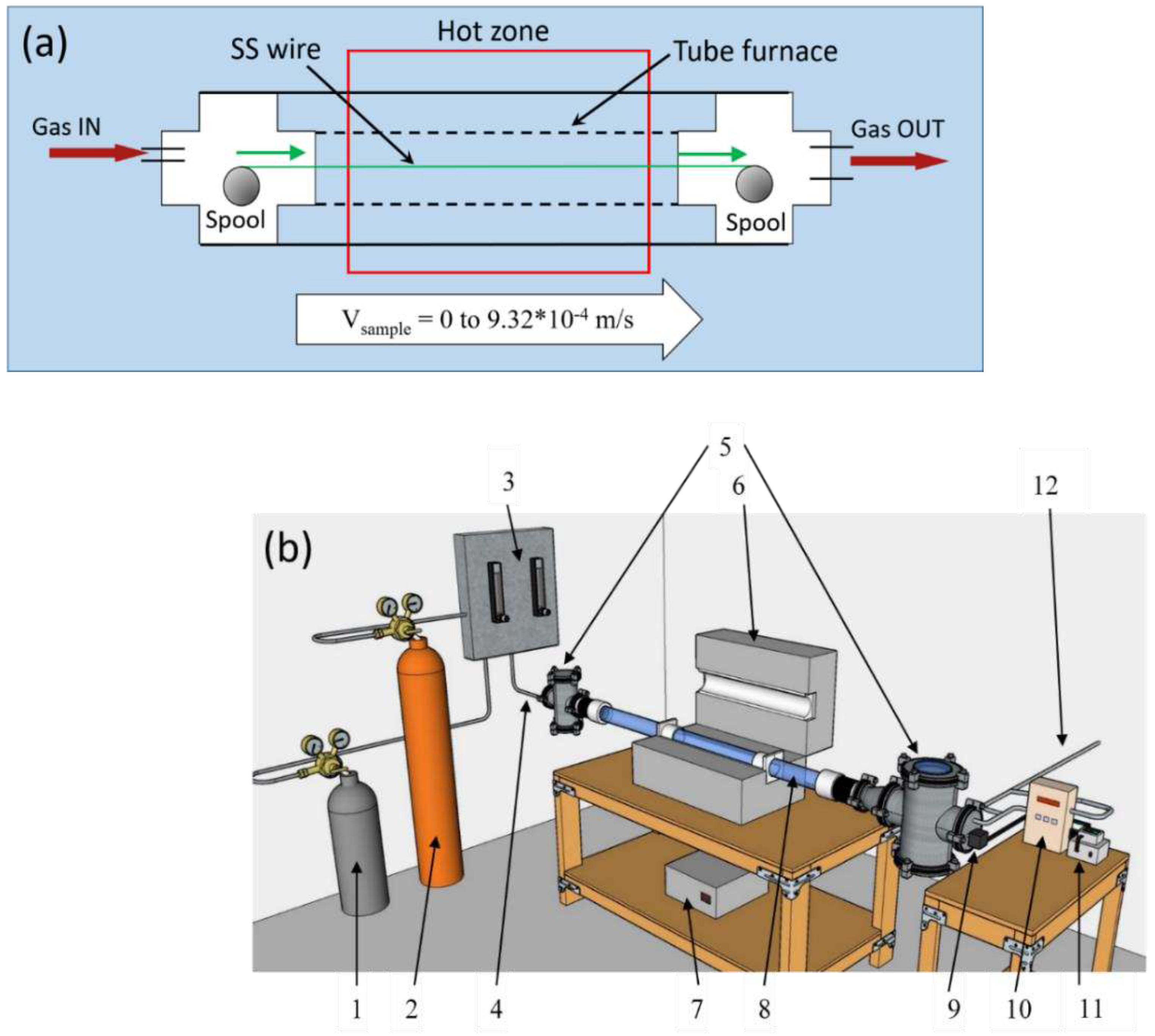

3. Generation of a CNT-on-SS wire structure in a continuous RR2R process

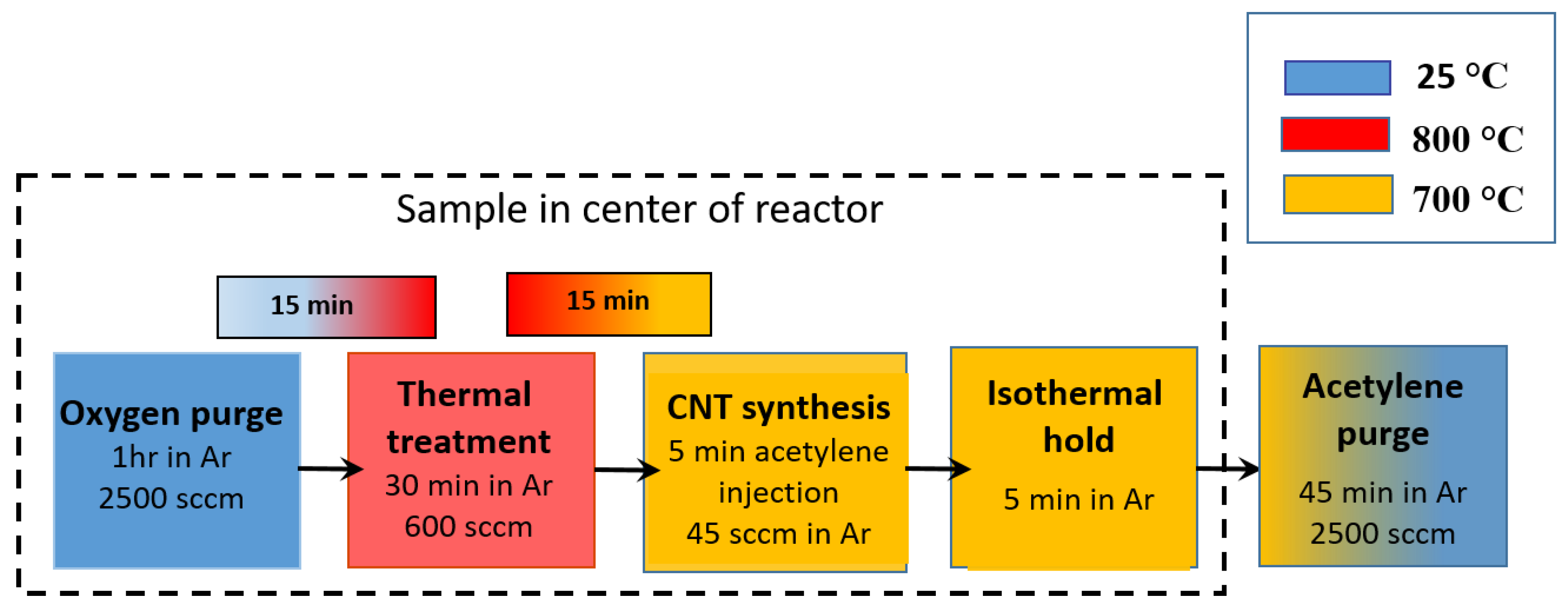

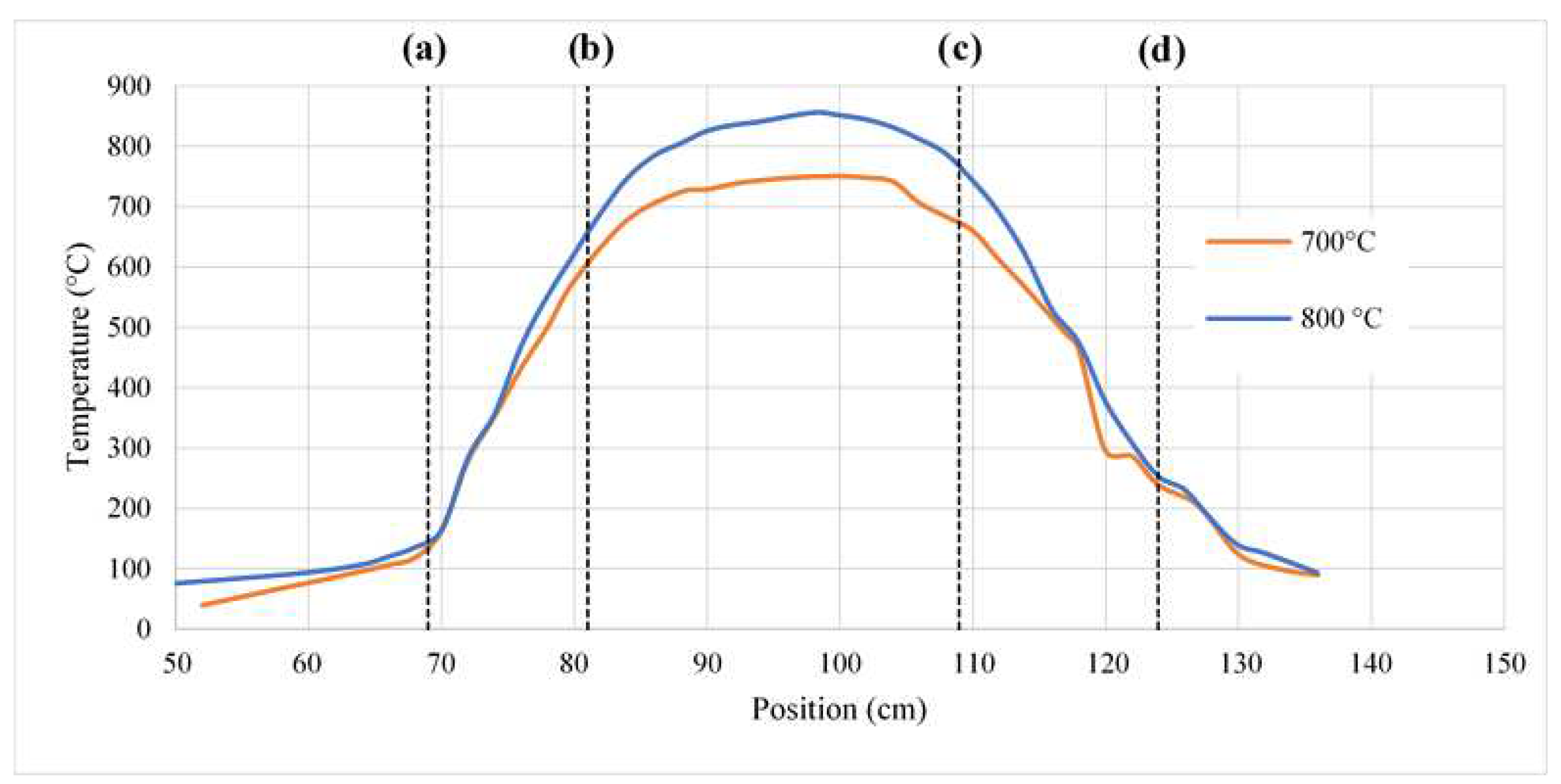

3.1. Methodology for dynamic RR2R MWCNT growth

4. Experimental results

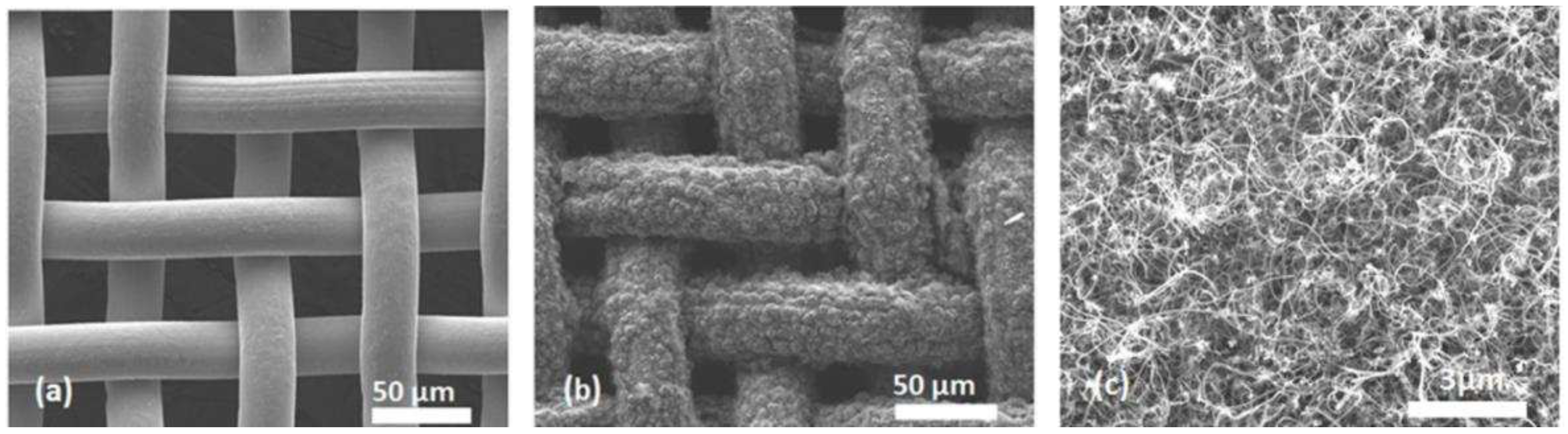

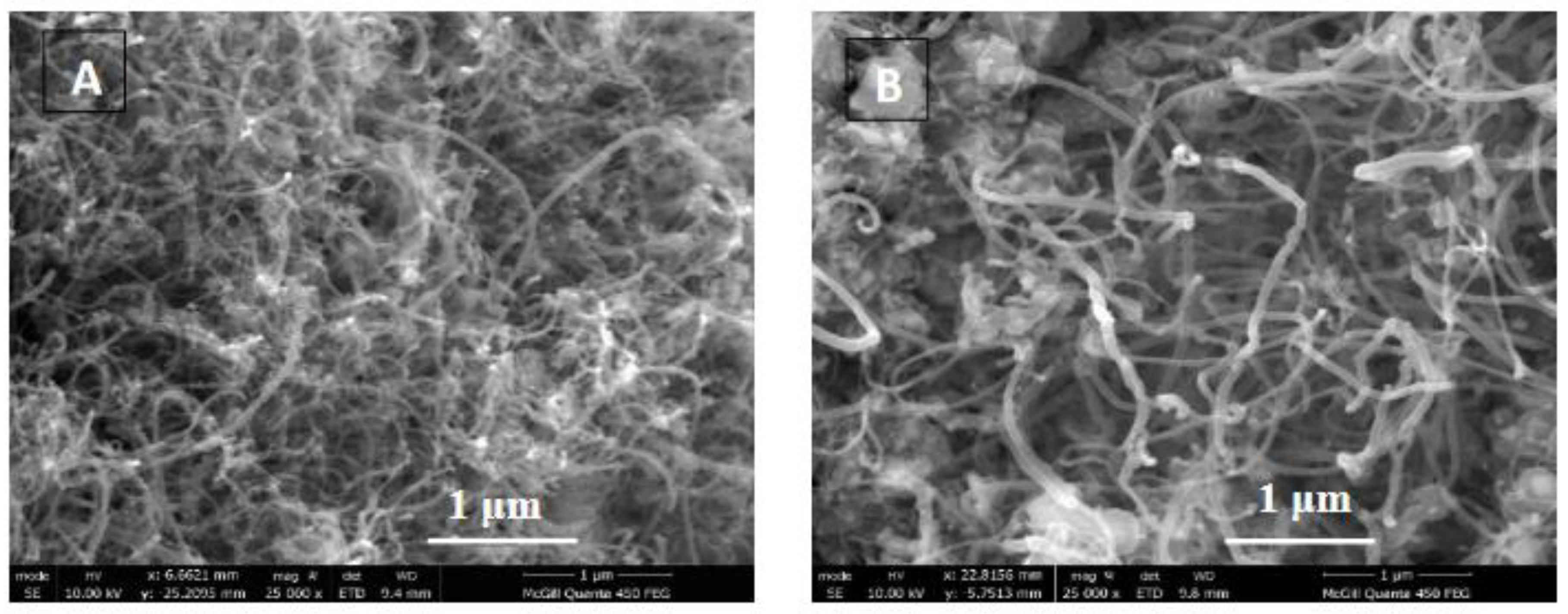

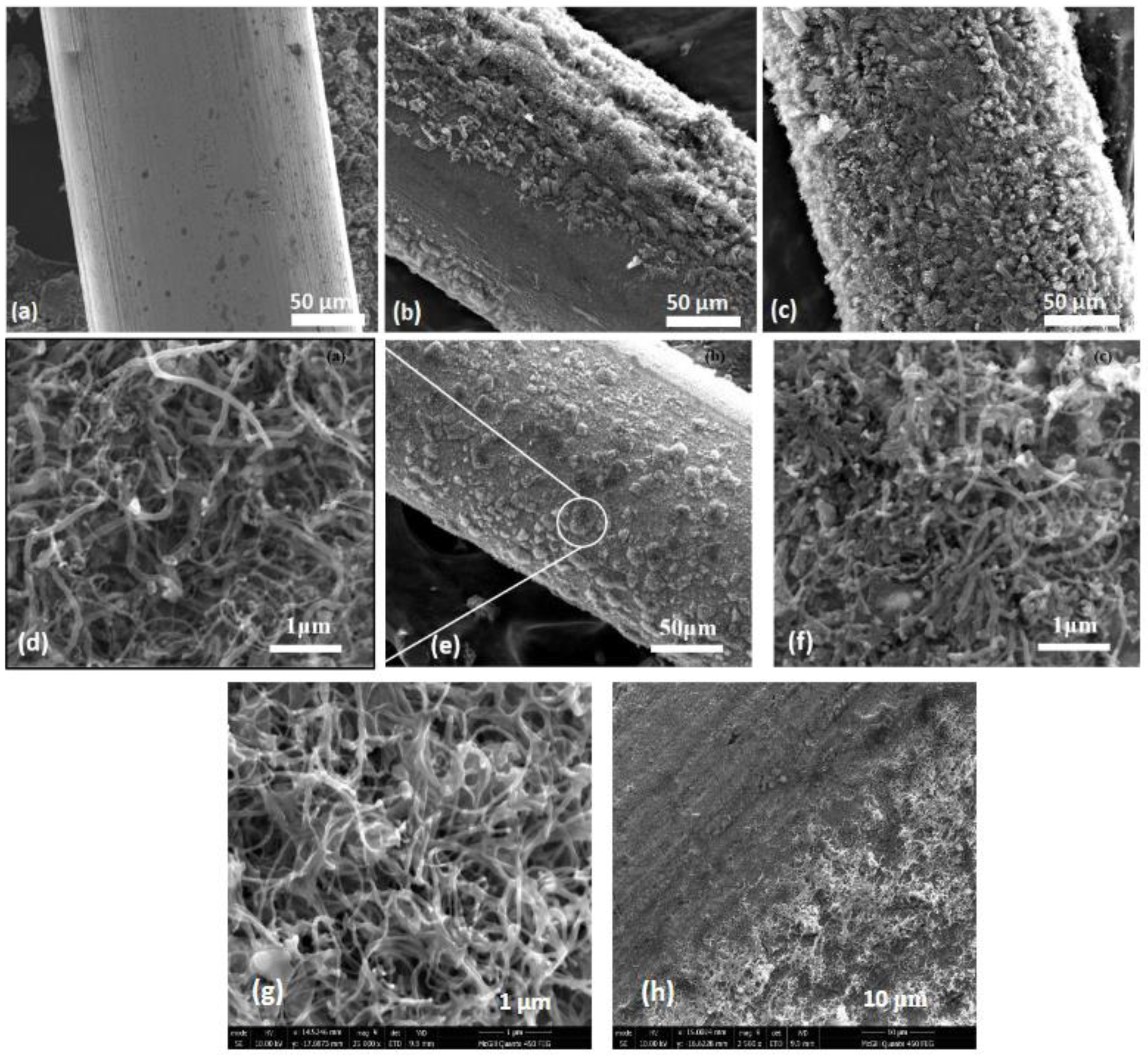

4.1 CNT static growth on SS wires

4.2. CNT static growth on SS grids

4.3. Transition from static to moving wire

5. Fog harvesting experiments

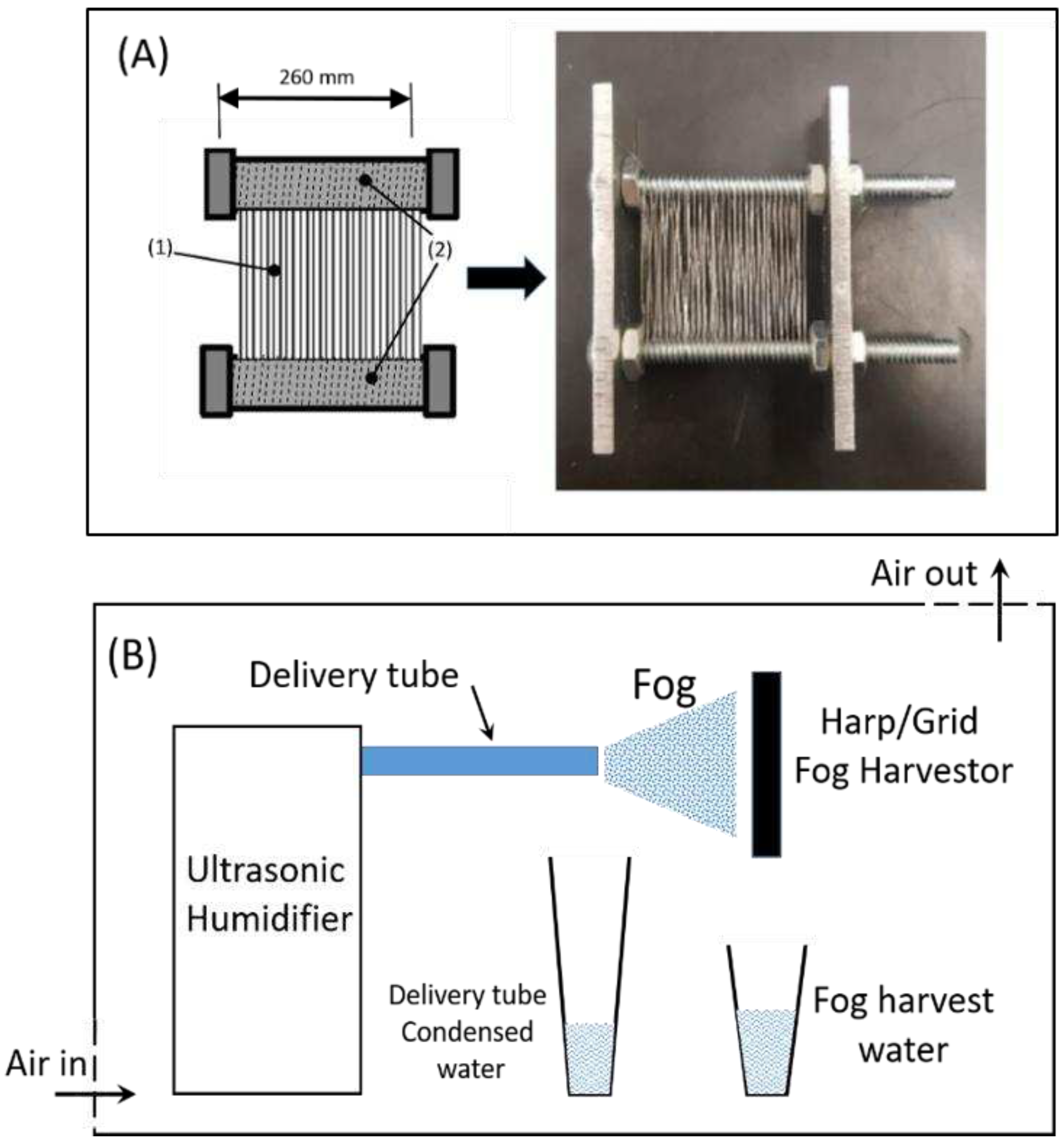

5.1. Fog harvesting setup

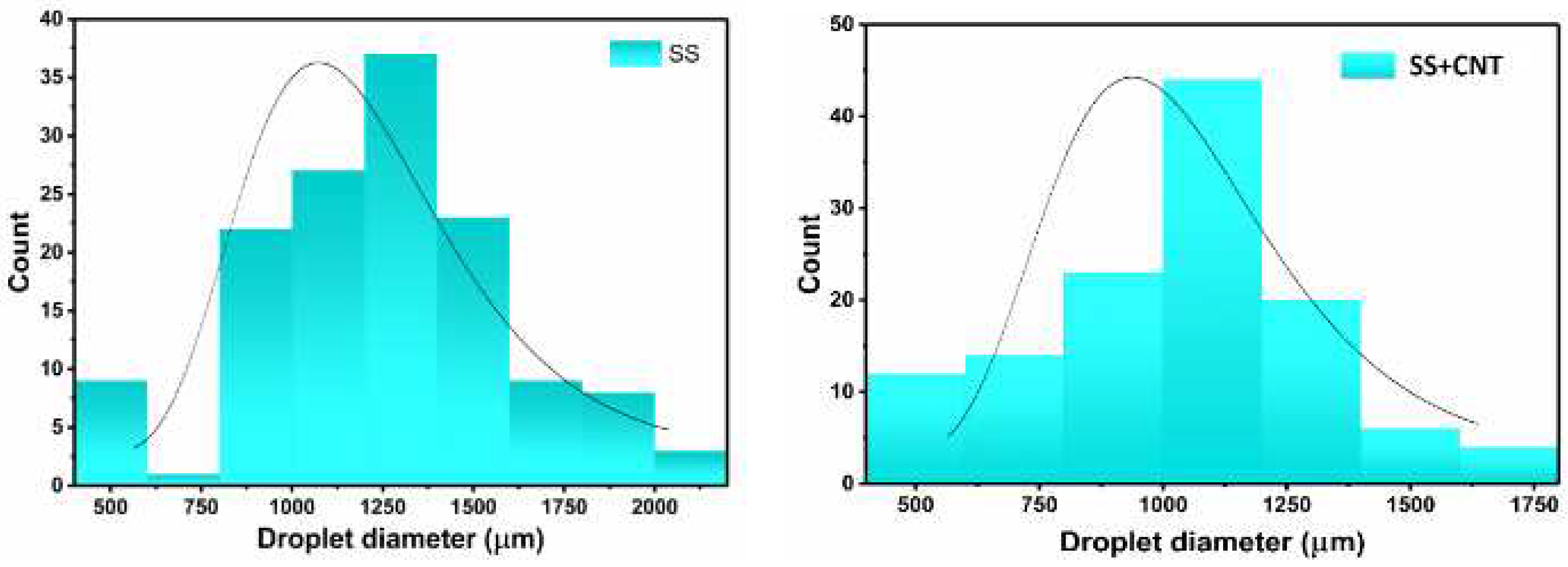

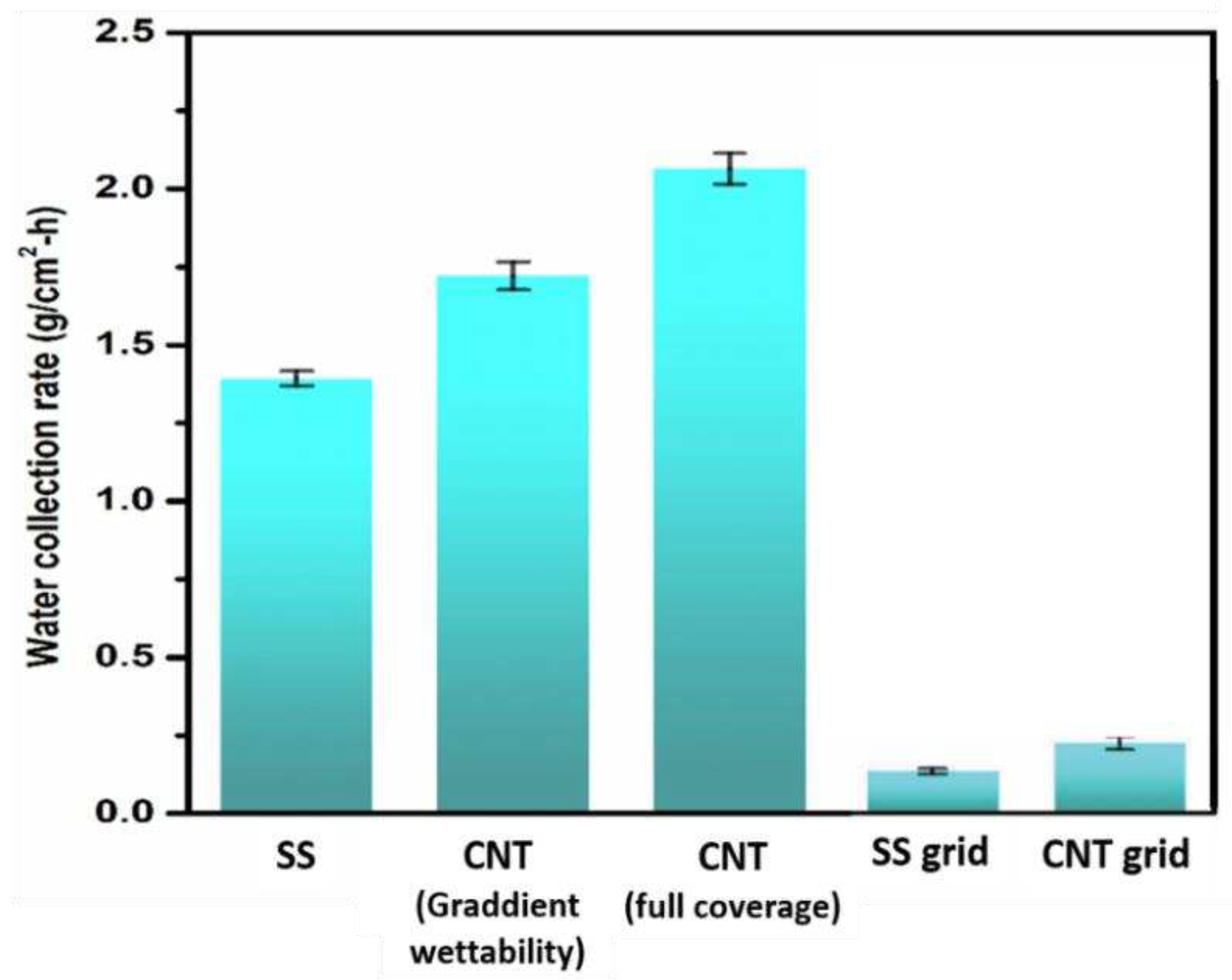

5.2. Fog harvesting results

6. Discussion

7. Conclusion

Acknowledgments

References

- S. Abdul-Wahab and V. Lea, "Reviewing fog water collection worldwide and in Oman," International Journal of Environmental Studies, vol. 65, no. 3, pp. 487-500, 01 06 2008.

- R. Schemenauer, H. Fuenzalida and P. Cereceda, "A Neglected Water Resource: The Camanchaca of South America," Bulletin of the American Meteorological Society, vol. 69, no. 2, pp. 138-147, 01 02 1988.

- R. Jarimi, R. Powel and S. Riffat, "Review of sustainable methods for atmospheric water harvesting," International Journal of Low-Carbon Technologies, Vol. 15, No. 2, pp. 253-276, 2020.

- O. Klemm, R. S. Schemenauer, A. Lummerich, P. Cereceda, V. Marzol, D. Corell, J. Van Heerden, D. Reinhard, T. Gherezghiher, J. Olivier, P. Osses, J. Sarsour, E. Frost, M. Estrela, J. A. Valiente and G. M. Fessehaye, "Fog as a Fresh-Water Ressource: Overview and Perspectives," AMBIO, Vol. 41, No. 3, pp. 221-234, 2012.

- M. Qadir, B. R. Sharma, R. Bruggeman, R. Choukr-Allah and F. Karajeh, ""Non-conventional water resources and opportunities for water augmentation to achieve food security in water scarce countries," Agricultural Water Management, vol. 87, no. 1, pp. 2-22, 10 01 2007.

- R. S. Schemenauer and P. Cereceda, "Fog-Water Collection in Arid Coastal Locations," Ambio, vol. 20, no. 7, pp. 303-308, 1991.

- United Nation University - Institute for Water Environment and Health (UNU - INWEH), "Uncover Resources: Alleviating global water scarcity through unconventional water resources and technologies," 2019.

- B. Pangarkar, M. Sane and M. Guddad, "Reverse Osmosis and Membrane Distillation for Desalination of Groundwater: A Review,," ISRN Materials Science,, p. 523124, 2011.

- K. Zotalis, E. Dialynas, N. Mamassis and A. Angelakis, "Desalination technologies: Hellenic experience," Water (Switzerland), vol. 6, no. 5, pp. 1134-1150, 2014.

- E. Jones, M. Qadir, M. Van Vliet, V. Smakhtin and S. Kang, "The state of desalination and brine production: A global outlook," Science of The Total Environment, vol. 657, pp. 1343-1356, 20 03 2019.

- V. Gude, "Energy consumption and recovery in reverse osmosis," Desalination and Water Treatment, vol. 36, no. 1-3, pp. 239-260, 01 12 2011.

- A. Al-Karaghouli and L. Kazmerski, "Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes," Renewable and Sustainable Energy Reviews, vol. 24, pp. 343-356, 01 08 2013.

- L. Greenlee, D. Lawler, B. Freeman, B. Marrot and P. Moulin, "Reverse osmosis desalination: Water sources, technology, and today's challenges," Water Research, vol. 43, no. 9, pp. 2317-2348, 01 05 2009.

- J. Beltran and S. Koo-Oshima, "Water desalinisation for agricultural applications," Food and Agriculture Organization of the United Nations, Rome 2006, 2006.

- WHO, "Technical notes on drinking-water, sanitation and hygiene in emergencies," URL: https://www.who.int/water_sanitation_health/publications/2011/WHO_TN_09_How_much_water_is_needed.pdf?ua=1., 2013.

- P. H. Gleick, "Water in crisis - A guide to the World's Fresh Water Resources," Oxford University Press, pp. 13-24, 26 August 1993.

- U. Legrand, D. Klassen, S. Watson, A. Aufoujal, B. Nisol, R. Boudreault, K. Waters, J. L. Meunier, P. L. Girard-Lauriault, M. Wertheimer and J. R. Tavares, "Nanoporous sponges as carbon-based sorbents for atmospheric water generation.," Industrial & Engineering Chemistry Research, vol. 60, no. 35, pp. 12923-12933, 2021.

- U. Legrand, P. L. Girard-Lauriault, J. L. Meunier, R. Boudreault and J. R. Tavares, "Experimental and theoretical assessment of water sorbent kinetics," Langmuir, 2022.

- Y. Zhang and S. Tan, "Best practices for solar water production technologies," Nat Sustain, vol. 5, pp. 554-556, 2022.

- U. Legrand, J. Castillo Sanchez, R. Boudreault, J. L. Meunier, P. L. Girard-Lauriault and J. R. Tavares, "Fundamental thermodynamic properties of sorbents for atmospheric water capture,," Chemical Engineering Journal, vol. 431, p. 134058, 2022.

- H. Bai, L. Wang, J. Ju, R. Sun, Y. Zheng and L. Jiang, "Efficient Water Collection on Integrative Bioinspired Surfaces with Star-Shaped Wettability Patterns," Advanced Materials, vol. 26, no. 29, pp. 5025-5030, 01 08 2014.

- Shang L., "Bioinspired Multifunctional Spindle-Knotted Microfibers from Microfluidics," Small, vol. 14, no. 4, p. 1600286, 01 01 2017.

- Z. Yu, F. F. Yun, Y. Wang, L. Yao, S. Dou, K. Liu, L. Jiang and X. Wang, "Desert Beetle-Inspired Superwettable Patterned Surfaces for Water Harvesting," Small, vol. 13, no. 36, 2017.

- W. Shi, L. H. De Koninck, B. J. Hart, N. G. Kowalski, A. P. Fugaro, T. Van der Sloot, R. S. Ott, B. S. Kenedy and J. B. Boreyko, "Harps under Heavy Fog Conditions: Superior to Meshes but Prone to Tangling," ACS Applied Materials & Interfaces, vol. 12, no. 42, pp. 48124-48132, 21 10 2020.

- J. Lei and Z. Guo, "A fog-collecting surface mimicking the Namib beetle: its water collection efficiency and influencing factors," Nanoscale, vol. 12, no. 13, pp. 6921-6936, 2020.

- C. Wen, H. Guo, H. Bai, T. Xu, M. Liu, J. Yang, Y. Zhu, W. Zhao, J. Zhang and L. Zhang, "Beetle-Inspired Hierarchical Antibacterial Interface for Reliable Fog Harvesting," ACS Applied Materials & Interfaces, vol. 11, no. 37, pp. 34330-34337, 18 09 2019.

- D. Seo, J. Lee, C. Lee and Y. Nam, "The effects of surface wettability on the fog and dew moisture harvesting performance on tubular surfaces," Scientific Reports, vol. 6, no. 1, p. 24276, 11 04 2016.

- M. Azad, D. Ellerbrok, W. Barthlott and K. koch, "Fog collecting biomimetic surfaces: Influence of microstructure and wettability," Bioinspir Biomim, vol. 10, no. 1, p. 016004, 19 01 2015.

- W. Shi, T. Van der Slot, B. Hart, B. Kennedy and J. Boreyko, "Harps Enable Water Harvesting under Light Fog Conditions," Advanced Sustainable Systems, vol. 4, no. 6, p. 2000040, 01 06 2020.

- K. Park, S. Chhatre, S. Srinivasan, R. Cohen and G. Mckinley, "Optimal Design of Permeable Fiber Network Structures for Fog Harvesting," Langmuir, vol. 29, no. 43, pp. 13269-13277, 29 10 2013.

- C. Regalado and A. Ritter, "The design of an optimal fog water collector: A theoretical analysis," Atmospheric Research, Vols. 178-179, pp. 45-54, 01 09 2016.

- J. de Dios Rivera, "Aerodynamic collection efficiency of fog water collectors," Atmospheric Research, vol. 102, no. 3, pp. 335-342, 1 11 2011.

- W. Shi, M. Anderson, J. Tulkoff, B. Kennedy and J. Boreyko, "Fog Harvesting with Harps," ACS Applied Materials & Interfaces, vol. 10, no. 14, pp. 11979-11986, 11 04 2018.

- N. Hordy, S. Coulombe and J. L. Meunier, "Plasma functionalizationof carbon nanotubes for the synthesis of stable aqueous nanofluids and poly(vinyl alcohol) nanocomposites," Plasma Processes and Polymers, vol. 10, no. 2, pp. 110-118, 2013.

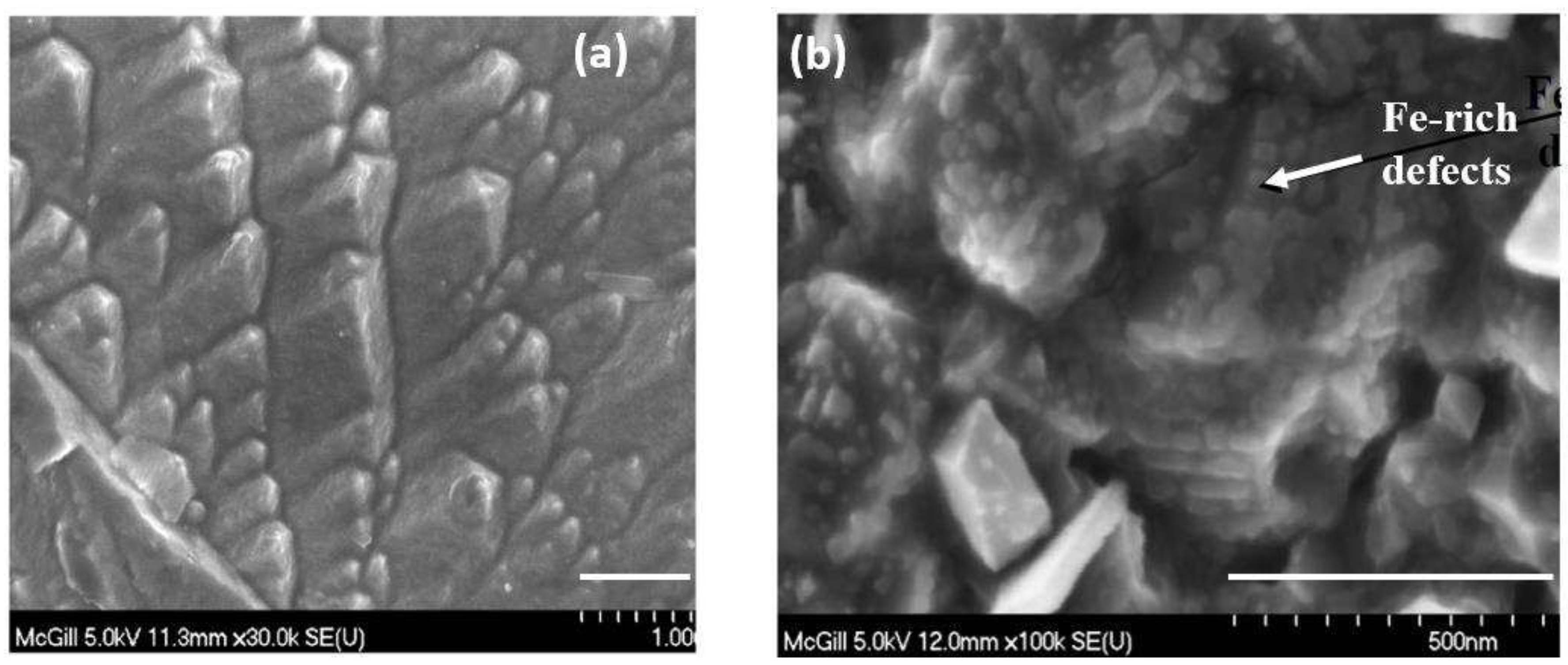

- C. E. Baddour, F. Fadlallah, D. Nasuhoglu, R. Mitra, L. Vandsburger and J. L. Meunier, "A simple thermal CVD method for carbon nanotube synthesis on stainless steel 304 without the addition of an external catalyst," Carbon, vol. 47, no. 1, pp. 313-318, 2009.

- M. R. Arcila-Velez, J. Zhu, A. Childress, M. Karakaya, R. Podila, A. M. Rao and M. E. Roberts, "Roll-to-roll synthesis of vertically aligned carbon nanotube electrodes for electrical double layer capacitors," Nano Energy, vol. 8, pp. 9-16, 01 09 2014.

- T. Rashid, H.-L. Liang, M. Taimur, N. Chiodarelli, H. A. Khawaja, K. Edvardsen and M. de Volder, "Roll to roll coating of carbon nanotube films for electro thermal heating," Cold Regions Science and Technology, vol. 182, no. 103210, 2021.

- S. Zhang, B. E. Leonhardt, N. Nguyen, A. Oluwalowo, C. Jolowsky, A. Hao, R. Liang and J. G. Park, "Roll-to-roll continuous carbon nanotube sheets with high electrical conductivity," RSC Advances, vol. 8, pp. 12692-12700, 2018.

- P. Li, X. Lim, Y. Zhu, T. Yu, C. K. Ong, Z. Shen, A. T.-S. Wee and C. H. Sow, "Tailoring Wettability Change on Aligned and Patterned Carbon Nanotube Films for Selective Assembly," The Journal of Physical Chemistry B, vol. 111, no. 7, pp. 1672-1678, 01 02 2007.

- A. Aufoujal, "PHYSICAL AND CHEMICAL APPROACHES FOR WATER MICRO-DROPLET CAPTURE," Masters thesis - Département de génie chimique, Polytechnique Montreal, Montreal, 2020.

- N. Hordy, D. Rabilloud, J. Meunier and S. Coulombe, "High temperature and long term stability of carbon nanotube nanofluids for direct absorption solar thermal collectors," Solar Energy, vol. 105, pp. 82-90, 01 07 2014.

- N. Hordy, S. Coulombe and J. L. Meunier, "Plasma Functionalization of Carbon Nanotubes for the Synthesis of Stable Aqueous Nanofluids and Poly(vinyl alcohol) Nanocomposites10(2), 110-118. Plasma Processes and Polymers, vol. 10, no. 012, pp. 110-118, 2013. [CrossRef]

- C. Rodes, T. Smith, R. Crouse and G. Ramachandran, "Measurements of the Size Distribution of Aerosols Produced by Ultrasonic Humidification," Aerosol Science and Technology, vol. 13, no. 2, pp. 220-229, 1990.

- A. Yule and Y. Al-Suleimani, "On droplet formationfrom capilary waves on a vibrating surface," Proc. of the Royal Soc. of London, Series AMathematical, Physical and Engineering Sciences, vol. 456, no. 1997, pp. 1069-1085, 08 05 2000.

- S. Kooij, A. Astefanei, G. Corthals and D. Bonn, "Size distributions of droplets produced by ultrasonic nebulizers," Scientific Reports, vol. 9, no. 1, p. 6128, 16 04 2019.

- A. Ritter, C. Guerra and J. Water, "Quantification of Fog Water Collection in Three Locations of Tenerife (Canary Islands)," Water, vol. 7, pp. 3306-3319, 2015.

- J. L. Pérez-Diaz, O. Ivanov, Z. Peshev, M. A. Alvarez-Valuenzuela, I. Valiente-Blanco, T. Evgenieva, T. Dreischuh, O. Gueorguiev, P. V. Todorov and A. Vaseashta, "Fogs: Physical Basis, Characteristic Properties, and Impacts on the Environment and Human Health," Water, vol. 9, p. 807, 2017.

- Y. Tu, R. Wang, Y. Zhang and J. Wang, "Progress and Expectation of Atmospheric Water Harvesting," Joule, vol. 2, no. 8, pp. 1452-1475, 15 08 2018.

- C. Luo and X. Wang, "Conditions for Barrel and Clam-Shell Liquid Drops to Move on Bio-inspired Conical Wires," Scientific Reports, vol. 7, no. 1, p. 9717, 29 08 2017.

- A. Aufoujal, U. Legrand, J. L. Meunier and J. R. Tavares, "Suppression of Hydrophobic Recovery in Photo-Initiated Chemical Vapor Deposition," Catalysts, vol. 10, no. 5, p. 534, 2020.

- R. Schemenauer and P. Joe, "The collection efficiency of a massive fog collector," Atmospheric Research, vol. 24, no. 1, pp. 53-69, 01 12 1989.

- E. Pajootan, S. Amin, S. Omanovic and S. Coulombe, "Radiofrenquency plasma-assisted pulsed laser deposited Pt/TiOxNy coatings on multiwalled carbon nanotubes as gas diffusion electrodes for the oxygen reduction reaction," Advanced Materials Technologies, vol. 2200196, 2022.

- N. Hordy, D. Rabilloud, S. Coulombe and J. L. Meunier, "A stable carbon nanotube nanofluid for latent heat-driven volumetric absorption solar heating applications.," Journal of Nanomaterials, vol. 2015, no. ID850217, pp. 1-6, 2015.

- L. Rao, N. Reddy, S. Coulombe, J. Meunier and R. Munz, "Carbon nanotubes as nanoparticle collector," Journal of Nanoparticle Research, vol. 9, no. 4, pp. 689-695, 2007.

- D. Sridhar, J. L. Meunier and S. Omanovic, "Directly grown carbon nano-fibers on nickel foam as binder-free long lasting supercapacitor electrodes," Materials Chemistry and Physics, pp. 434-440, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).