1. Introduction

Electronic waste (e-waste) is created when electrical equipment becomes unsuitable for use and has been thrown/abandoned. Though most of the parts of the equipment can be refurbished, or recycled; several electronic equipment such as computers, laptops, monitors, TVs, tablets, battery cells, CDs, mobiles, and Xerox machines get converted into e-waste after use, as depicted in

Table 1. E-waste typically consists of metals, plastics, circuit boards, and cables. Due to the innovation of technology and the production of brand-new electronic equipment, it quickly replaces old models/equipment. This is one of the leading causes of the exponential rise in the generation of e-waste.

The usage of electronic equipment has increased in several fields, for example, information technology (IT), pharma, food, chemical, electrical, telecom, business process outsourcing (BPO), and the environment (Iyer, 2018). These latest technologies are beneficial for reducing the time of analysis and other work. As a result, engineers manufacture equipment with the latest technology to provide better outputs. This rapid growth in the production of electrical products has been observed to be directly proportional to the amount of e-waste. Cheaper costs of labor and weak legislation systems are some of the other factors responsible for the fast growth of e-waste generation in developing countries.

E-waste is considered one of the major upcoming global pollution problems (Kiddee et al. 2013). It consists of mainly organic and inorganic compounds. Organic compounds include brominated flame retardants (BFRs), polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), polybrominated biphenyls (PBBs), dechlorane plus (DP), hexabromocyclododecanes (HBCDs), polychlorinated-p-dioxins (PCDDs), polybrominated dibenzo-p-dioxins (PBDDs), polychlorinated dibenzofurans (PCDFs), polybrominated diphenyl ethers (PBDEs), and polybrominated dibenzofurans (PBDFs); while inorganic compounds include lead (Pb), arsenic (As), chromium (Cr), cadmium (Cd), copper (Cu), mercury (Hg), nickel (Ni), selenium (Se), zinc (Zn), cobalt (Co), and tin (Sn).

These hazardous compounds are very toxic in nature and get released into the environment when e-waste is dismantled/processed in an inefficient manner with rudimentary techniques. A study conducted by Panwar and the team on the management of e-waste highlighted that if e-waste is not managed in a sustainable way, then the chances of the release of harmful substances into the environment gets increase (Panwar and Ahmed, 2018). According to a research analysis, harmful substances released due to the dumping of e-waste in open sites are capable of contaminating soil and groundwater (Zhang et al. 2012). These toxic substances eventually enter the food chain through bioaccumulation and cause several diseases (Luo et al. 2011; Alam et al. 2023).

Studies have shown the presence of high levels of contamination of heavy metals in samples of soil and water collected from areas where e-waste units are situated, and unscientific recycling methods are used. A high-level concentration of heavy metals has been studied to negatively affect the microbial population present in soil ecosystems. This has caused an adverse effect on the fertility of the soil (Ahmad et al. 2005). Scientists and researchers have reported the existence of these metals in the blood, placenta, and hair of the citizens residing near the dumping site of e-waste (Monika, 2010). There are many techniques that are available for the removal of these pollutants from the soil and water bodies (Needhidasan et al. 2014). But these techniques are very costly and not effective. So, nowadays researchers are focusing on cost-effective techniques like phytoremediation. This technique appears as a hopeful approach for slightly polluted soils and water. In this technique, plants absorb harmful compounds and convert them into other non-harmful forms.

1.1. Trend of E-Waste Worldwide

Researchers have reported that globally 50 million tonnes of e-waste are produced per year (Bharathi et al. 2022). According to a report from the Basel Convention, 66 % of the world’s population is protected by e-waste regulation. However, despite these e-waste regulations and the Basel Convention, only 20 % of e-waste gets reprocessed each year, which implies that 40 million tonnes of e-waste are either incinerated for retrieval of resources or get unlawfully traded. Even after the enforcement of the convention, unlawful shipment and throwing of e-waste remain to take place in several countries. For example, China has been recognized as one of the major e-waste removal sites in the globe. In China, ~160 million electronic devices are discarded annually, while in the US this amounts to > 100 million annually (Zeng et al. 2013). According to a study, the amount of e-waste produced is 5-10 % globally, and in India, 146,000 tonnes of e-waste are generated each year (Borthakur and Sinha, 2013).

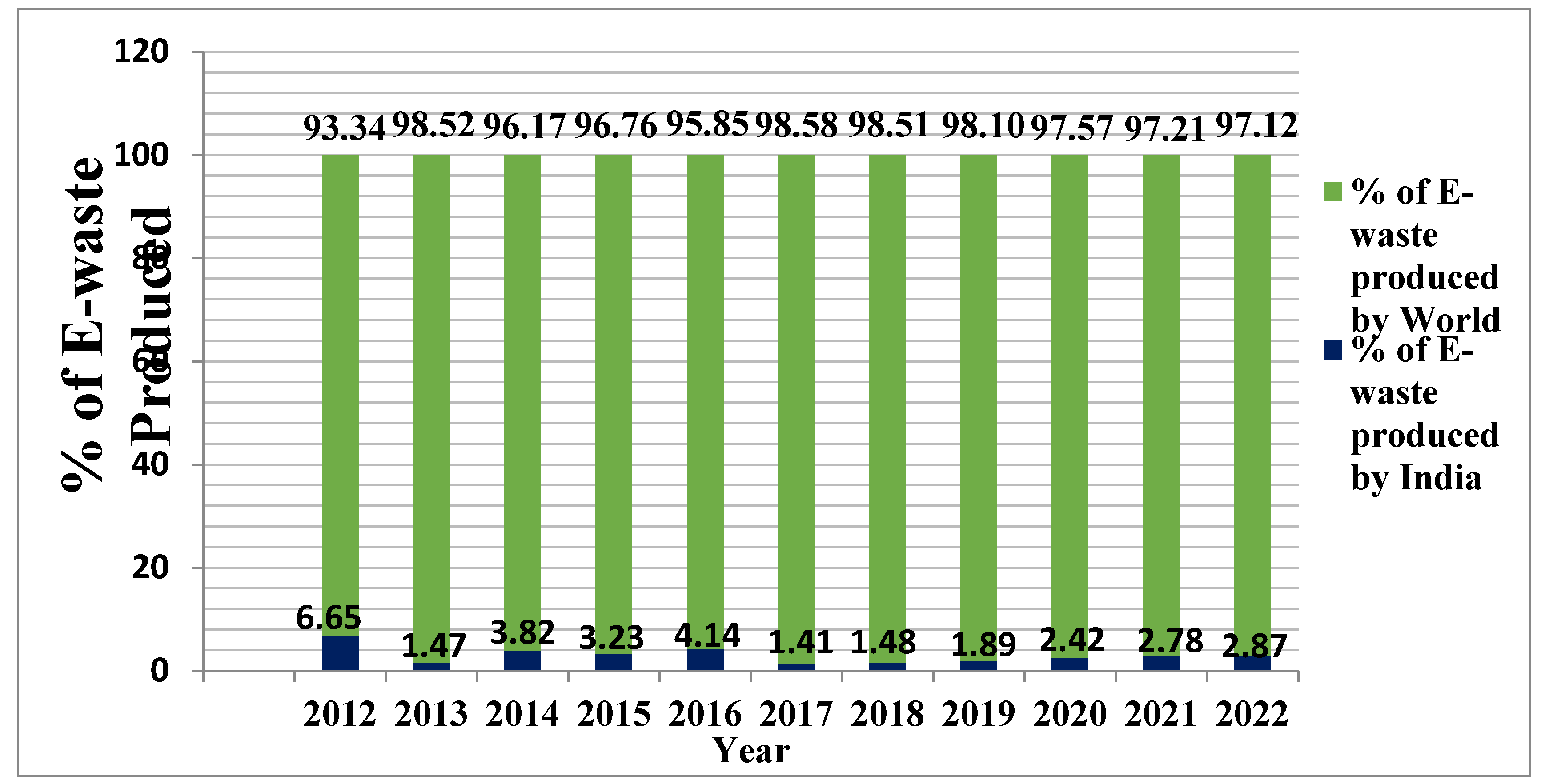

Most of the data that are available nation-wise do not contain e-waste imports (both lawful and unlawful). The European Union (EU) has set a target of 4 kg/capita for the collection, recovery, and reprocessing of e-waste in its member nations (Ibanescu et al. 2018). This target helped to decrease the amount of harmful materials disposed of into landfills and also increased the accessibility of reusable materials. Similarly, Switzerland is the number one country to establish and implement a conventional e-waste management system that has helped to recycle 11 kg/capita of e-waste (Wath et al. 2010). A study has stated that growing nations like India, Peru, China, Pakistan, Ghana, and Nigeria are the greatest recipients of e-waste from industrialized nations (Mmereki et al. 2016). Approximately 70 % of e-waste was collected in 2003 from South Korea under the scheme, Extended Producer Responsibility (EPR). Over the same period, 12 % and 69 % of e-waste were reused and recycled while 19 % of the remaining e-waste was sent to landfill spots or burning plants. The trend of the total e-waste generated worldwide is shown in

Table 2 and

Figure 1.

1.2. Trend of E-Waste in India

As per the report of the World Economic Forum (WEF), India placed 177 amongst 180 nations in the Environmental Performance Index 2018. It stated that India positioned fifth in the world after the USA, China, Japan, and Germany, in terms of top e-waste-producing countries. It generates ~ 2 million tons of e-waste annually while recycling < 2 % (Park, 2019) and also trades in vast quantities of e-waste from other nations. A study by Ahmed and the team stated that in the previous 6 years, e-waste has increased up to 62 % in India (Ahmed and Panwar, 2016). Similarly, Joon and team highlighted the three states in India responsible for producing a significantly high percentage of e-waste Andhra Pradesh, Tamil Nadu, and Maharashtra (Joon et al. 2017). More than 60 % of India’s overall e-waste is produced by 65 Indian cities and Mumbai is the leading e-waste producer followed by Delhi, Bengaluru, Chennai, and Kolkata. Seelampur in Delhi is the major e-waste dismantling place in India.

In India, e-waste recycling has been observed to be one of the major sources of income for many people. The majority of the e-waste collections are, however, managed by an unorganized sector. A recent study has stated that > 95 % of e-waste in India is unlawfully reprocessed by Kabadiwalas or Raddiwalas (Zhongming et al. 2019). These laborers operate separately and in front of any formal company which makes enforcement of e-waste policies difficult to impossible. According to the study by the Associated Chambers of Commerce and Industry of India (ASSOCHAM), e-waste management has identified that e-waste generated by computer devices constitutes 70 %, followed by telecommunications constitutes 12 %, electrical equipment contributes 8 %, while medical equipment 7 %, and household 3 %. It was predicted in a study that India will produce 5.2 million tonnes of e-waste by 2020 (Chatterjee and Kumar, 2009). The government and private sector firms produce nearly 75% of e-waste. As per the study by the Telecom Regulatory Authority of India (TRAI), India had 1.012 billion working mobile connections in January 2018 (Thada et al. 2019). This manuscript discusses the sources, health and environmental impacts, disposal techniques, recycling, and regulation of e-waste contamination in detail.

2. Sources

According to a study conducted in 2021, e-waste has been reported to increase at a rate of ~10 % annually (Chatterjee et al. 2021). Approximately 5.5 million tons of e-waste are produced from the parts of computers, mobile phones, and television sets (Veit and Bernardes, 2015). Both developing and developed nations contribute to the increase in e-waste to such an extent that the exact amount of generation is difficult to estimate. The main sources of e-waste pollution are due to unorganized handling techniques. In 2019, the global production of e-waste had been projected to be 53.6 million tons and this had further increased to ~7-20 % in 2020 (Rene et al. 2021). By rigorous literature analysis, it has been predicted that if this problem is sustained then 622 kilotons of total e-waste might be generated by 2025 (Mairizal et al. 2021).

In India, the main source of e-waste consists of government sectors, public sectors, private/industrial manufacturers, and household contributions (Das, 2013; Biswas et al. 2020). They together generate ~ 1641 kilotons of e-waste annually (Borthakur and Singh, 2020). According to the Comptroller and Auditor General of India (CAG) report, >7.2 million tons of industrial harmful waste and >8 lakh tons of e-waste are generated in India each year (Das, 2013). Iyer and his research team studied the product and e-waste generation and stated that >600 million mobile phones, >60 million PCs, and >43 million TV sets are produced annually, which after a time span, gets converted into e-waste (Iyer, 2018).

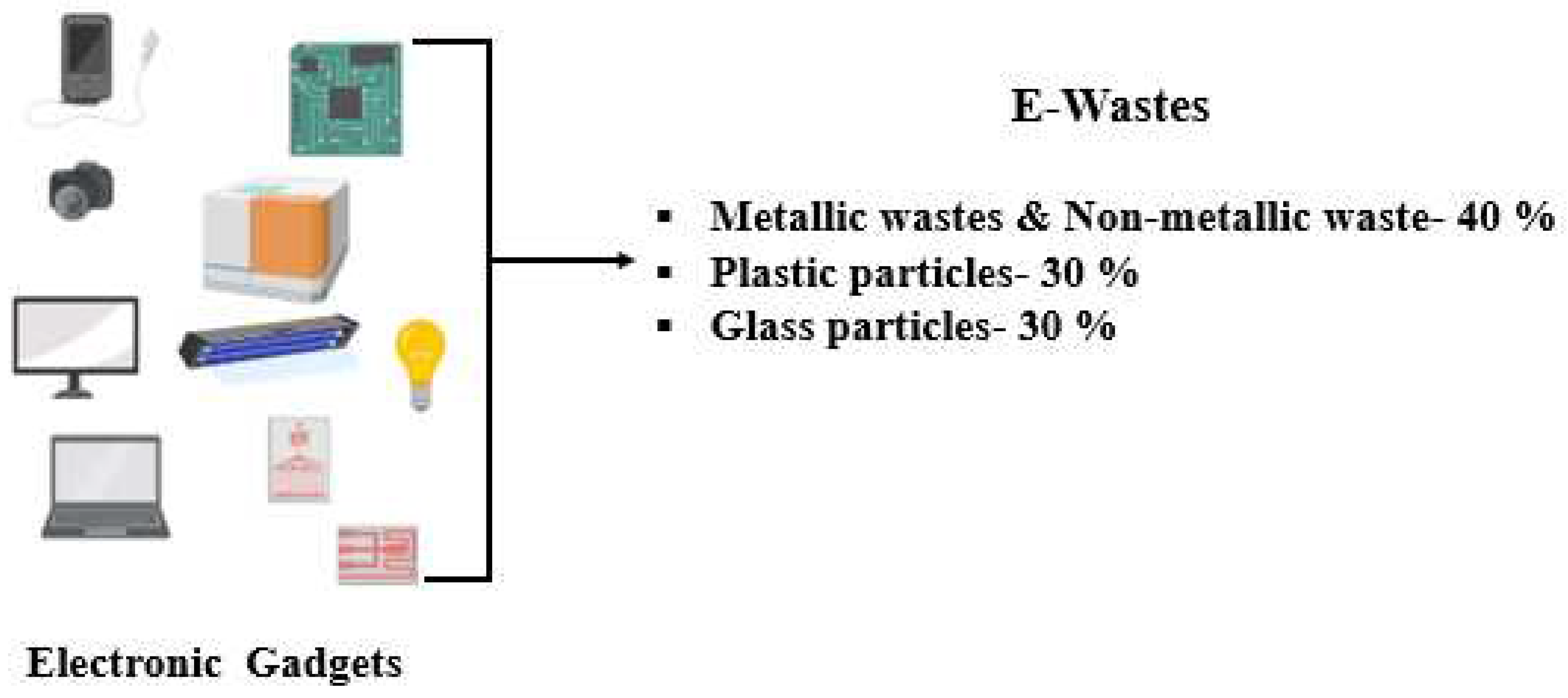

Electronic gadgets such as washing machines, refrigerators, ACs, computers, laptops, mobile phones, chips, etc. contain metals, ferrous and non-ferrous sources (glass, plastics), BFRs, harmful vapors/fumes, biologically active materials, plastic additives, acids, liquid crystals, etc., and become the sources of e-wastes containing toxic materials (

Table 1 and

Figure 2). Such an alarming increase in the amount of e-waste generation has initiated many concerns regarding processing facilities, treatment, metal recovery, etc. There has been a constant need to upgrade the existing technologies to increase the recovery of metal and non-metal contents. It was reported that e-waste contains some useful elements like aluminum (Al), Cu, silver (Ag), gold (Au), platinum (Pt), etc. However, due to the lower costs and easy operations, in growing countries, most e-waste is being treated in backyards or small workshops to recover these elements (Srikant et al. 2021).

3. Health Impacts

E-waste creates a massive risk to the health of animals and humans, and it also affects the environment. Most of the e-waste is generally dealt with open burning or acid baths. As a result, several harmful elements such as dioxins, furans, heavy metals, etc. are issued into the environment that have been studied to affect the health of workers, and residents, who reside near the dumping sites (Bhardwaj et al. 2023). For example, brominated and chlorinated dioxins, which are released into the air from the burning of wires, are carcinogens that are capable of causing cancer in humans. Joon and team stated that e-waste has become an emerging issue for the environment and public health in India (Joon et al. 2017). This is due to the unawareness and low literacy rate of the laborers who are involved in the recycling and handling of e-waste. This has shown adverse effects on their health. It was observed that the workers did not use the personal protective equipment (PPEs) properly and therefore were exposed to contaminants present in the e-waste. It was also studied that ~ 25,000 laborers are engaged in raw e-waste dismantling units in Delhi and they were responsible for dismantling 10,000 to 20,000 tons of e-waste with naked hands (Monika, 2010).

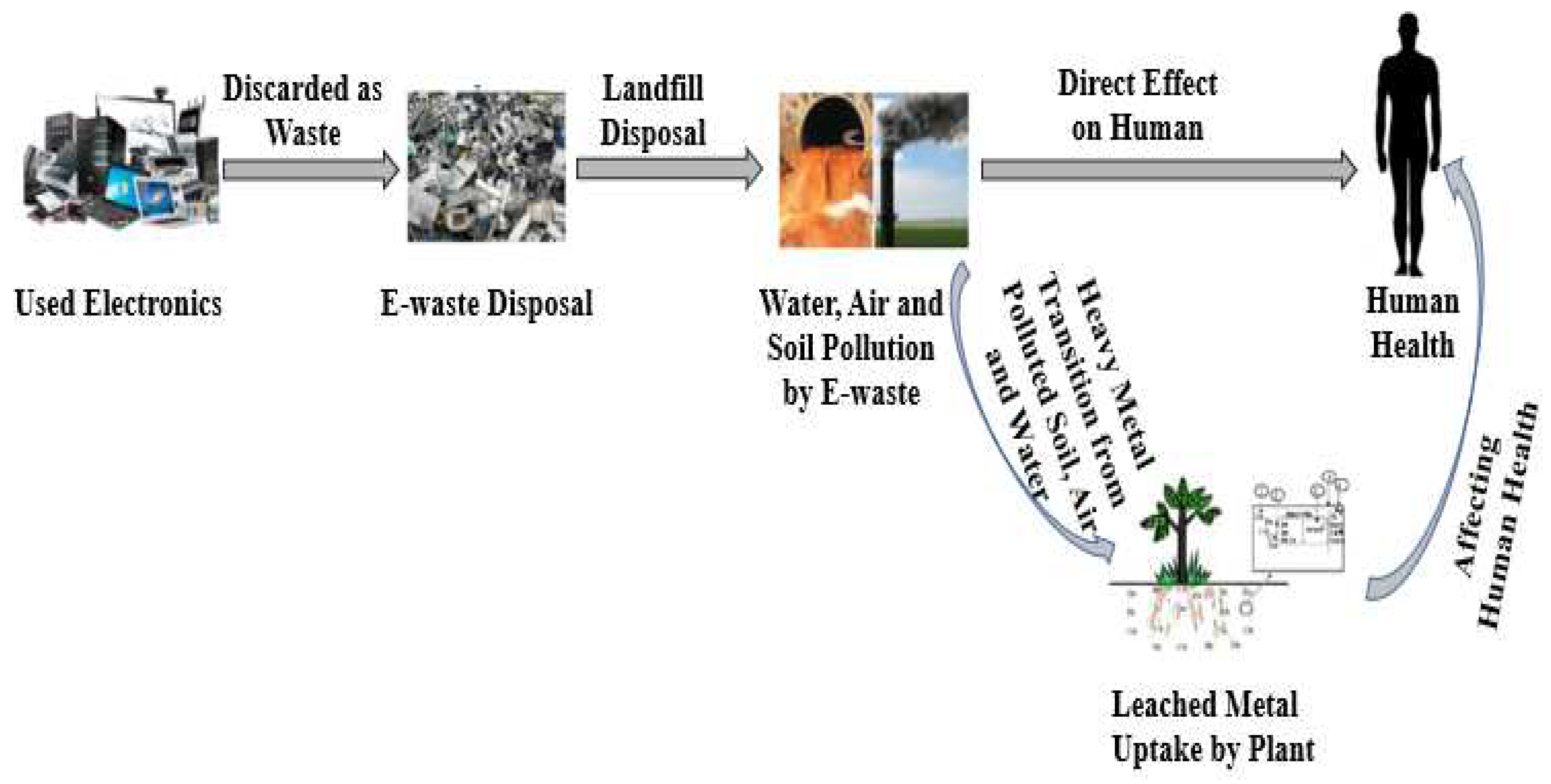

Park and team stated that e-waste is illegally processed outside the formally organized systems by workers and this practice can have serious health consequences (Park and Soni, 2019). Direct or indirect exposure to such harmful toxins and contaminants takes place through skin contact, inhalation, ingestion, etc. Such experience with e-waste can lead to various health concerns including changes in thyroid acts, and poor neonatal results, including unplanned abortions, stillbirths, early births, and reduced child growth (Grant et al. 2013). Other side effects include changes in behaviors, decreased lung function, DNA damage, etc. Children and pregnant women are more susceptible to the health threat of e-waste. A study has shown that the activities of e-waste reprocessing contributed to high blood Pb amounts in children (Brigden, 2005). Abortion, premature birth, and decreased birth weight are linked with exposure to e-waste. Different toxic compounds with their sources and health effects are presented in

Table 3. The flow diagram of e-waste and its impact on human health is shown in

Figure 3.

4. Environmental Impacts

The e-waste items that are not reprocessed are left in landfills or burnt in open spaces. Such methods used for recycling and disposing of e-waste have given rise to many detrimental effects on the environment. As a consequence of such practices, the toxins released have contaminated the water, air, and soil. Researchers studied phthalates in PET bottled water samples and described very well the migration of the pollutant from plastic items to water (Bhardwaj and Sharma, 2021; Bhardwaj, 2022). Developing countries are facing serious environmental challenges, due to illegally imported e-waste from other countries.

4.1. Air

Air pollution is a widespread problem (Bhardwaj and Vikram, 2023a). Dust and large particulates that are released into the surrounding air due to the dismantled and shredded e-waste have been additional causes of air pollution. Fine particles are released into the air after burning of little value e-waste goods like plastics which can move hundreds to thousands of miles. These particles can increase the risk of lung cancer and other chronic diseases. Harmful chemicals and fumes are released into local communities from high-value items such as silver and gold which are obtained from extremely integrated e-waste by desoldering.

Under-regulated or unregulated burning is frequently carried out at low down temperatures and issues dioxins which can damage the health of humans and animals. Research has concluded that e-waste pollution in India is quite high, and nine out of the ten cities of India are polluted (Abi-Habib and Kumar, 2019). The impacts of e-waste on air quality are the worst. The effect can extend to thousands of miles away from the dumping sites. The toxic substances that are released from e-waste have been studied to contaminate the water and soil samples. For example, during the rainy season, these toxic air particulates are washed into the water and soil; thereby easily spreading throughout the environment and ultimately affecting the ecosystem (Bhardwaj and Singh, 2023b).

4.2. Water

Sewage wastes, pesticide runoff, industrial wastes, and e-waste have been studied to contribute to water pollution. Researchers have stated that ~ 80 % of India’s top layer of water is contaminated. E-waste pollutes the water body in two ways.

- (i)

Throwing e-waste into landfills leads to contaminated water bodies. This occurs when poisonous chemicals subsequently leak from the landfills and enter water sources underneath the ante.

- (ii)

Improper recycling produces toxic by-products that contaminate the regional water supply. This further causes contamination by entering the top layer of water like rivers and ponds.

4.3. Soil

The harmful substances such as PCBs, PCDDs, PCDFs, and heavy metals that gradually get released from the e-waste can contaminate the soil near the dumping sites. According to research, a high concentration of PCBs was observed in the soil samples in Chennai, Bengaluru, Delhi, and Mumbai (Needhidasan et al. 2014).

5. Disposal Techniques

Due to improper enforcement of laws and regulations in growing nations, the majority of the e-waste is disposed of in an informal manner by poor people who further utilize it for their economic gain. Such people are not concerned about the threats and health hazards caused to them due to this improper disposal of e-waste. Developed countries generally send much out-of-date electronic items to developing countries which are used until they expire. After that, they are disposed of. There are two sectors formal and informal for the handling of e-waste disposal (Borthakur and Sinha, 2013).

- (i)

Formal Sector: This sector consists of two resources authorized to decompose electronics. These resources primarily collect e-waste from the makers or company manufacturers which follow environmental policies on e-waste disposal. Despite reaching daily capacity, these resources are not sufficient as a conventional method for discarding. The formal sector deals only with the practice of dismantling and segregating components. They physically do not dispose of the e-waste. India has the capacity of 5 tons being disposed of per day.

- (ii)

Informal Sector: This sector handles the e-waste by collection, transportation, processing, and recycling or final disposal. Though it is well-networked but is unregulated. This sector collects used electronic items from product dealers, repair shops, and e-commerce portal vendors and has made it the formal sector to compete. There are some methods such as burning cables and acid baths, etc. which are used for the disposal of e-waste.

6. Recycling of E-Waste

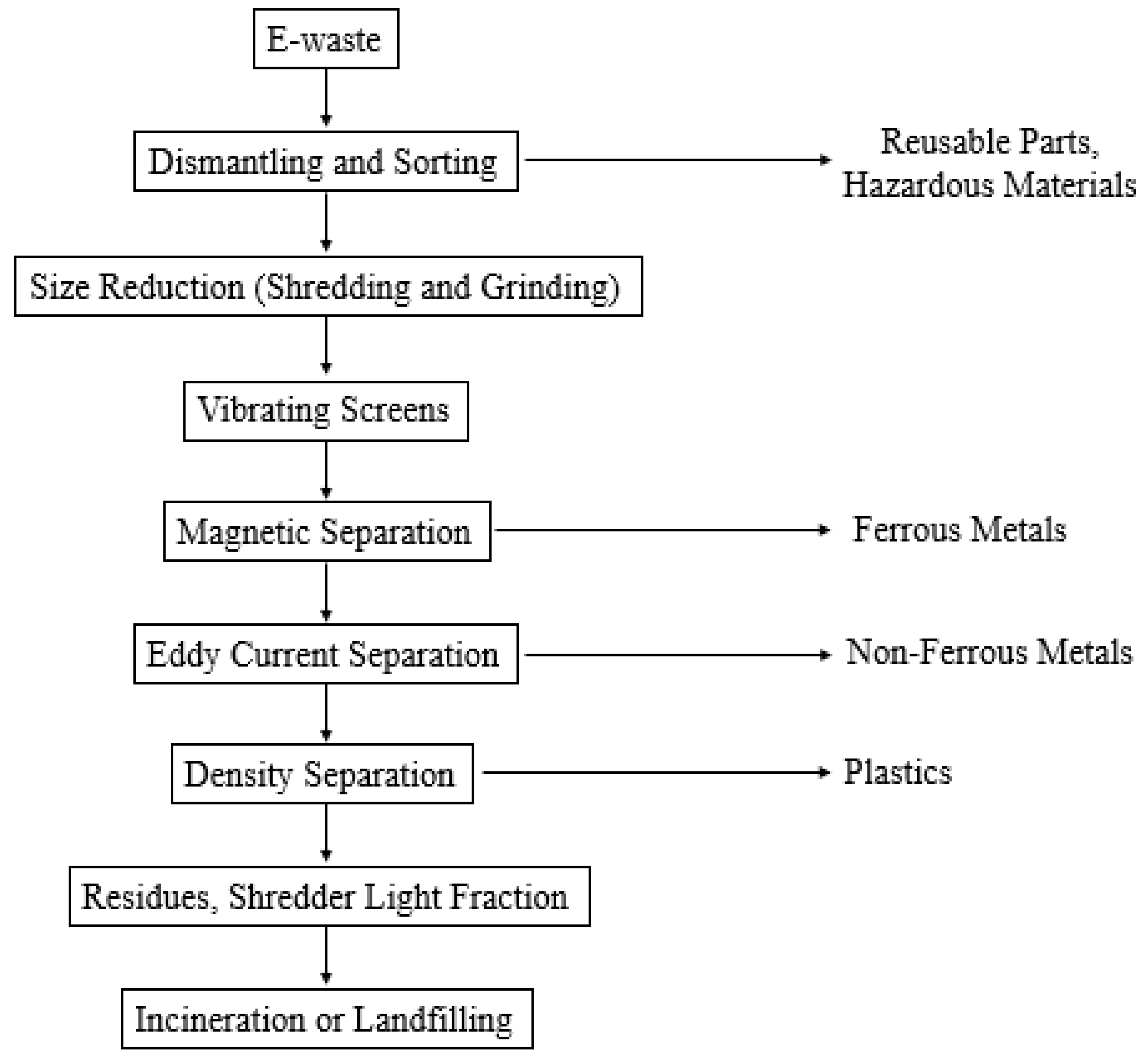

The recycling of e-waste can be carried out under both controlled and uncontrolled conditions. In recycling, e-waste is dismantled and then mechanically processed for the separation and recovery of useful materials as depicted in

Figure 4.

There is a significant economic potential that is associated with the useful recovery techniques of valuable items present in e-waste. This provides an income-generating opportunity at individual and entrepreneur levels. A study has reported that recycling e-waste is a very complex procedure (Ahmed and Panwar, 2014). It has been described that the reprocessing of e-waste by automatic methods has a cause that leads to the loss of precious and valuable metals from the e-waste (Chatterjee and Kumar, 2009). Due to the higher cost of labor and strict environmental legislation, developed countries have consolidated recycling activities, unlike the scenarios in developing countries like India (Gaidajis et al. 2010).

It is estimated that in India, 400,000-500,000 child laborers between the ages of 10-15 years are engaged in e-waste reprocessing activities (Joon et al. 2017). According to a recent study, many people possess expertise in dismantling e-waste. In India, 95 % of e-waste is recycled through informal sectors. There is an entire financial market for e-waste, as their components can be dismantled, and the leftover metals can be reused (Chatterjee et al. 2021). Recycling e-waste is considered a source of revenue for several people in developing countries. Adults as well as children, generally belonging to weaker sections, spend 8–10 hours per day in the extraction of reusable parts and valuable metals like Co, Au, and other various important components from the devices.

E-waste recyclers make use of practices such as open burning and acid-leaching. They often practice rudimentary recycling techniques which ultimately cause the release of poisonous pollutants into the adjacent area. Processing and incineration of wet chemicals are the popular approaches for the discarding of e-waste. There are also some reprocessing techniques that do not follow any type of health or environmental standards.

6.1. Advantages of E-Waste Recycling

E-waste consists of many useful elements like Co, Au, Ag, Pd, Cu, etc. If processed using advanced and proper techniques, these can be recovered by recycling and can be reused.

The application of sorting techniques of e-waste will help in the recovery of the valuable materials which make up a great amount of economic incentive.

E-waste recycling is also essential due to the occurrence of other metals such as Pb, Ni, and plastic components.

Due to the above-stated reasons, management of e-waste is essential from the view of materials and resource recycling.

6.2. Disadvantages of E-Waste Recycling

Several hazardous chemicals are present in the e-waste and get released into the environment during recycling.

After recycling, unused parts are dumped in the open area where they contaminate the soil and water bodies. These hazardous elements then enter the human body affecting their health.

6.3. Impact of Recycling of E-Waste

E-waste contains plastic, glass, and metals and can be recyclable, but due to inappropriate disposal practices these materials cannot be recovered. The toxic substances that get out during the recycling procedure contaminate the ecosystem of water, soil, and air. The poisonous chemicals that have no, or minimum economic importance are thrown during the recycling procedure and then leak into underground aquifers and degrading the quality of groundwater and making it unsuitable for human and agricultural usage. Utilization of such polluted sources allows the entry of these toxic substances into the bloodstream of the individual and can affect the kidney and liver. Due to a lack of knowledge and improper training of workers at the recycling units, personal protective equipment (PPEs) such as face masks and gloves are not used.

It has been reported Pb, Hg, Cd, As, PCBs, and PAHs in the soil samples of the four metro cities (Chennai, Kolkata, New Delhi, and Mumbai) of India, and was observed that such sites were located near the e-wastes units where it gets managed by the informal sectors (Chakraborty et al. 2018; Chakraborty et al. 2019). Persistent organic pollutants (POPs) that are produced or subsequently get released during recycling, are released into the air because of their semi-volatile property. Scientists reported different POPs in the Antarctic regions (Bhardwaj and Jindal, 2020; Bhardwaj et al. 2021; Bhardwaj et al. 2022). As per the study, the release of poisonous chemicals from raw e-waste recycling techniques can have prolonged and irreversible effects (Zhongming et al. 2019).

7. Regulations and E-Waste Management

The e-waste administration system is well established in developed nations and is given high priority. However, due to a lack of funds and techniques in developing countries, this system is not properly managed. In addition, there is a deficiency of adequate infrastructure and appropriate legislation that deals with the management of e-waste. Also, there is an imperfect description of the responsibilities and tasks of stakeholders as well as institutions that play a role in e-waste management, etc. In India, the Ministry of Environment, Forest and Climate Change (MoEFCC) introduced the e-waste administration rules to decrease the production of e-waste and simultaneously increase recycling (MoEFCC, 2018). The targets covered under this rule are monitored by the State Pollution Control Board (SPCB)and the Central Pollution Control Board (CPCB) (CPCB, 2016). Under this rule, extended producer responsibility (EPR) states producers are liable to collect ~30-70% of e-waste in a duration of 7 years. According to these regulations, the e-waste cannot be stored for >180 days from its collection. Under specific circumstances, e-waste can be permitted to be stored for a maximum of 1 year (Awasthi et al. 2018).

The first e-waste management and handling rule was proposed in 2011 and came into effect in 2012. The e-waste management guidelines of October 2016 successfully replaced the e-waste management and handling guidelines of 2011. According to the new rules, the duties of accountable parties were stated. More strict guidelines on the production of e-waste, as well as formulated general definitions of e-waste were enacted. The concept of EPR is documented in these rules. According to the amendments, e-waste was defined as electrical and electronic equipment that are dependent on the electric current or electromagnetic field. The amendment of the e-waste management guidelines of 2018 further relaxed certain aspects associated with the e-waste management guidelines of 2016 and focused more on increasing the e-waste collection goals by 10 % annually, i.e. 10 % during 2017–2018, 20 % during 2018–2019, 30 % during 2019–2020, and so on.

According to these amendments, after 2023 the target has been increased to 70 % of the quantity of waste produced as per the EPR Plan. This amendment also gave the CPCB authority to choose electronic equipment in the market for testing their compliance with rules. According to this, the financial costs related to this testing would be the concern of the government. This concern was earlier given to the producers. Initiatives such as Design for Environment (DfE); EPR; Reduce, Reuse, Recycle (3Rs), and technology platform that links markets working towards a circular economy was proposed aiming to inspire consumers to systematically dispose of their e-waste, while simultaneously increasing reprocessing and reusing rates, and subsequently adopting sustainable habits of consumers.

These rules establish specific responsibilities and some suggestions for each party involved in the manufacture, collection centers, consumer, dismantlers, disposal, recyclers, and the state government. It assigned target goals for convincing industries to decrease their collection of e-waste and also set strict restrictions on the usage of hazardous metals in electronic items. Such rules can help the management of e-waste by generating awareness amongst workers and improving the availability of infrastructure of recycling units as well as implementing prevalent policies. Some of the amended rules include:

Government departments and commercial consumers have to maintain records of their e-waste and produce them in front of state and federal Pollution Control Boards.

The producers will have to ensure minimum usage of hazardous chemicals and metals e.g. PCBs, Pb, Hg, and Cd.

All manufacturers and importers are advised to start e-waste collection centers.

Manufacturing companies that produce electronic items that have the potential of becoming e-waste have to make their consumers aware of the hazardous substances in their products.

The sellers of electronic goods should educate the consumers on how to dispose of the electronic item properly after use. This is because consumers are important to improve the management of e-waste.

Producers of electronic items have to implement EPR so as to make sure that their e-waste is transferred to the recyclers that are authorized by a valid agency.

Competent authorities are also required to establish regulations that help in the implementation of strict regulatory procedures at regular intervals.

A check needs to be maintained on conventional land-filling and open burning of the e-waste.

Better market information should be provided on e-waste.

How Can Governments, City Administration, and Citizens Help?

The ASSOCHAM statement (2017) suggested the government focus on collaboration with industries to draw out conventional/standard operating procedures and formulate phased approaches for reducing e-waste (Manish and Chakraborty, 2019). There is a need for the initiation of start-ups concerned with reprocessing and disposal of e-waste should be supported by providing special allowances. The unorganized sectors are advised to set up a well-established collection network, although the organized sector is capital-intensive. Therefore, the government is advised to strictly ensure the coordination between both sectors so as to collect, organize, handle, and recycle the e-waste in an environmentally friendly and sustainable approach.

The EPR principle is increasingly and successfully implemented for e-waste management in many EU countries. It has been observed that producers play a responsible role in EPR; while the consumers, retailers, municipalities, state governments, local collection agencies, various NGOs, CSOs, as well as Self-Help Groups (SHGs), play a valid role in terms of collection, facilitation, as well as the creation of infrastructure for making a sustainable approach for e-waste management. The citizens play an integral part in e-waste management. Carelessly disposing of small gadgets along with dumped wastes, burning the accumulated waste, etc. have been a cause of concern. During such processes, harmful substances like dioxins and furans are released into the environment and get inhaled and causing health issues. Therefore, to reduce such practices at individual levels, a few of the Resident Welfare Associations (RWAs) have adopted different bins for e-waste collection. Such methods need to be encouraged in other residential societies by creating awareness. Students and Women SHGs can also be prepared to promote such activities in their particular RWAs.

The Basel Action Network (BAN) ensures sustainable and environment-friendly methods for e-waste management. It proposes to protect the earth from poisonous waste trade. In developed countries like the USA, the BAN, Electronics Take-Back Coalition, and Silicon Valley Toxic Coalition, together constitute a well-associated system for environmental advocacy NGOs. The common objective of such organizations is to initiate national-level methods for the management of harmful wastes. A recent approach has been the initiation of e-Stewards, an approach that works for the auditing and certification of recyclers which helps in making consumers aware of the standards of products. In developed countries like Japan and the EU, well-developed projects are set up for e-waste management. However, the lack of enforcement of available regulatory frameworks, less understanding and sensitization, and insufficient knowledge about the occupational security of individuals involved in the processes exacerbate e-waste management issues in growing nations. Therefore, there is a demand to adopt useful strategies to encourage the reuse, refurbishing, and recycling of e-waste in specialized facilities. Also, advanced technologies and planned strategies need to be adopted to prevent environmental pollution and human health threats.

8. Conclusions and Recommendations

Nearly 66 % of the global population is protected under e-waste legislation, however, only 20 % of global e-waste gets recycled annually. Due to the exponential increase in the generation of e-waste, the management of e-waste has become a great task for governments of many growing nations such as India, Bangladesh, Pakistan, etc. For effective collection, segregation, treatment, and disposal of e-waste, as well as systematic channeling of the disposal mechanism from open burning and conventional landfills, it is required to integrate both informal and formal sectors. Competent agencies are required to establish mechanisms to properly handle and sustainably treat e-waste in a sustainable manner.

Increasing campaigns for dissemination of information, capacity building, and awareness among producers, consumers, and waste collectors are critical for promoting environment-friendly management programs for e-waste. Efforts are urgently required to improve current practices related to collection schemes, the construction of more legal e-waste disposal centers, and management practices that would help in reducing the illegal trade of e-waste. Modern waste disposal facilities and appropriate disposal sites for waste should be chosen to avoid injurious effects associated with the indiscriminate disposal of waste. Buildings of residential locations should be situated far away from such areas. We need to focus on the solution formed using a biological combination of plants and microbes to decontaminate highly polluted sites using bioremediation.

Dismantling and processing of e-waste in a crude manner have been the cause of the release of toxic constituents. Hence, adequate knowledge about safety, processing of components, wet chemicals, extraction techniques, etc. is required. In cases that include highly polluted sites, the combination of different remediation techniques is encouraged. In hot spot areas, physical and chemical techniques are required to decrease high levels of pollution. As the local villagers utilize ponds and groundwater for purposes related to irrigation and drinking respectively, the associated potential ecological risk related to heavy metals in the vicinity of abandoned e-waste recycling sites should also be considered.

In India, companies have been made strictly responsible for the proper channeling, collection, as well as disposal of e-waste in compliance with a CPCB-approved EPR Authorization plan. For example, renowned companies like Nokia, GIZ, etc. have been made to develop and adopt an alternative business model guiding informal sector associations towards authorization. Such measures have been shown to have a great effect on the effective execution of e-waste management in India. E-waste collection targets are required to be regularly reviewed as well as renewed to ensure strict compliance across India on e-waste collection.

Proper incentives that would attract stakeholders of e-waste management are encouraged. For e.g. the government must announce incentives, like tax concessions/rebates, to ensure compliance across the electronics industry. Further, the initiation of technology platforms that not only link circular economy and e-waste disposal strategies but also increase the rates of reuse and recycling by adopting sustainable consumer habits are to be encouraged. New entrepreneurs with the necessary financial support and technical guidance should be encouraged. Such practices will be beneficial to solve the growing problem associated with e-waste by putting more emphasis on recycling and better e-waste management.

In some cases, combinatorial remediation techniques should be applied, which simultaneously influence the coexisting contaminants as well as removal approaches of contaminants are required.

In areas of hot spots, a combination of physicochemical techniques is advised to be used to reduce high levels of pollution and prevent subsequent dissemination of pollutants.

We need to focus on the solution in which plants and microbes combine to remediate highly contaminated sites.

The increasing problem of e-waste puts greater highlighting on e-waste recycling and better management.

The government body should promote the new entrepreneurs for the removal of e-waste by delivering essential financial support and technical assistance.

Author Contributions

All authors have equal contributions.

Data Availability Statement

Not applicable

Acknowledgments

The authors are deeply grateful to Amity University, Noida for giving them the platform for doing this study.

Conflicts of Interest

The authors declare that they have no competing interests.

References

- Abi-Habib, M., Kumar, H., 2019. India finally has plan to fight air pollution. Environmentalists are wary. The New York Times.

- Ahmad, I., Hayat, S., Ahmad, A., Inam, A., 2005. Effect of heavy metal on survival of certain groups of indigenous soil microbial population.

- Ahmed, S., Panwar, R.M., 2014. Analysis of barriers of e-waste Management using ISM (interpretive structural modeling) methodology. Innovat. Trends Appl. Phys., Chem., Math. Sci. Emerg. Energy Technol. Sustain. Dev. 93-105.

- Ahmed, S., Panwar, R.M., 2016. Hazardous constituents of e-waste and predictions for India. In Proceedings of the Institution of Civil Engineers-Waste and Resource Management. 169 (2), 83-91. Thomas Telford Ltd.

- Alam, S., Bhardwaj, L.K., Mallick, R., Rai, S., 2023. Estimation of Heavy Metals and Fluoride Ion in Vegetables Grown Nearby the Stretch of River Yamuna, Delhi (NCR), India. Indian Journal of Environmental Protection. 43 (1), 64-73.

- Awasthi, A.K., Wang, M., Wang, Z., Awasthi, M.K., Li, J., 2018. E-waste management in India: A mini-review. Waste Management & Research. 36(5), 408-414. [CrossRef]

- Bharathi, S.D., Dilshani, A., Rishivanthi, S., Khaitan, P., Vamsidhar, A., Jacob, S., 2022. Resource Recycling, Recovery, and Xenobiotic Remediation from E-wastes Through Biofilm Technology: A Review. Applied Biochemistry and Biotechnology. 1-24. [CrossRef]

- Bhardwaj, L., Jindal, T., 2022. Polar Ecotoxicology: Sources and Toxic Effects of Pollutants. New Frontiers in Environmental Toxicology. 9-14.

- Bhardwaj, L.K., 2022. Evaluation of Bis (2-ethylhexyl) Phthalate (DEHP) in the PET Bottled Mineral Water of Different Brands and Impact of Heat by GC–MS/MS. Chemistry Africa. 5(4), 929-942. [CrossRef]

- Bhardwaj, L.K., Jindal, T., 2020. Persistent organic pollutants in lakes of Grovnes Peninsula at Larsemann Hill area, East Antarctica. Earth Systems and Environment. 4, 349-358. [CrossRef]

- Bhardwaj, L.K., Sharma, A., 2021. Estimation of physico-chemical, trace metals, microbiological and phthalate in PET bottled water. Chemistry Africa. 4(4), 981-991. [CrossRef]

- Bhardwaj, L.K., Sharma, S., Jindal, T., 2021. Occurrence of polycyclic aromatic hydrocarbons (PAHs) in the lake water at Grovnes Peninsula Over East Antarctica. Chemistry Africa. 4, 965-980. [CrossRef]

- Bhardwaj, L.K., Sharma, S., Jindal, T., 2023. Estimation of Physico-Chemical and Heavy Metals in the Lakes of Grovnes & Broknes Peninsula, Larsemann Hill, East Antarctica. Chemistry Africa. 1-18. [CrossRef]

- Biswas, A., Singh, S.G., Singh, S.G., 2020. E-waste Management in India: Challenges and Agenda. Centre for Science and Environment.

- Borthakur, A., Singh, P., 2020. Mapping the emergence of research activities on E-waste: A scientometric analysis and an in-depth review. Handbook of Electronic Waste Management. 191-206.

- Borthakur, A., Sinha, K., 2013. Electronic waste management in India: a stakeholder’s perspective. Electronic green journal. 1(36). [CrossRef]

- Brigden, K., 2005. Recycling of electronic wastes in China and India: workplace and environmental contamination. http://www. greenpeace. org/raw/content/china/en/press/reports/recycling-of-electronic-wastes. pdf.

- Chakraborty, P., Sampath, S., Mukhopadhyay, M., Selvaraj, S., Bharat, G.K., Nizzetto, L., 2019. Baseline investigation on plasticizers, bisphenol A, polycyclic aromatic hydrocarbons and heavy metals in the surface soil of the informal electronic waste recycling workshops and nearby open dumpsites in Indian metropolitan cities. Environmental Pollution. 248, 1036-1045. [CrossRef]

- Chakraborty, P., Selvaraj, S., Nakamura, M., Prithiviraj, B., Cincinelli, A., Bang, J.J., 2018. PCBs and PCDD/Fs in soil from informal e-waste recycling sites and open dumpsites in India: levels, congener profiles and health risk assessment. Science of the Total Environment. 621, 930-938. [CrossRef]

- Chatterjee, A., Abraham, J., Abraham, J., 2021. OVERVIEW ON ELECTRONIC WASTE: SOURCES, CURRENT SCENARIO AND THE MANAGEMENT TECHNIQUES. ADVANCES IN ENVIRONMENTAL RESEARCH. 153.

- Chatterjee, S., Kumar, K., 2009. Effective electronic waste management and recycling process involving formal and non-formal sectors. International Journal of Physical Sciences. 4(13), 893-905.

- 22. CPCB Government of India., 2016. E-Waste Rules 2016. https://cpcb.nic.in/displaypdf.php?id=RS1XYXN0ZS9FLVdhc3RlTV9SdWxlc18yMDE2LnBkZg==.

- Das, S., 2013. BIOLEACHING OF ELECTRONIC WASTE AND BIOMINERALIZATION OF GOLD NANOPARTICLES. Education. 2018.

- Gaidajis, G., Angelakoglou, K., Aktsoglou, D., 2010. E-waste: environmental problems and current management. Journal of Engineering Science and Technology Review. 3(1), 193-199. [CrossRef]

- Grant, K., Goldizen, F.C., Sly, P.D., Brune, M.N., Neira, M., van den Berg, M., Norman, R.E., 2013. Health consequences of exposure to e-waste: a systematic review. The lancet global health. 1(6), e350-e361. [CrossRef]

- Ibanescu, D., Cailean, D., Teodosiu, C., Fiore, S., 2018. Assessment of the waste electrical and electronic equipment management systems profile and sustainability in developed and developing European Union countries. Waste management. 73, 39-53. [CrossRef]

- Iyer, L.S., 2018. Knowledge, attitude and behaviour (KAB) of student community towards electronic waste-a case study. Indian Journal of Science and Technology. 11(10). [CrossRef]

- Joon, V., Shahrawat, R., Kapahi, M., 2017. The emerging environmental and public health problem of electronic waste in India. Journal of health and pollution. 7(15), 1-7. [CrossRef]

- Kiddee, P., Naidu, R., Wong, M.H., 2013. Electronic waste management approaches: An overview. Waste management. 33(5), 1237-1250. [CrossRef]

- Luo, C., Liu, C., Wang, Y., Liu, X., Li, F., Zhang, G., Li, X., 2011. Heavy metal contamination in soils and vegetables near an e-waste processing site, south China. Journal of hazardous materials. 186(1), 481-490. [CrossRef]

- Mairizal, A.Q., Sembada, A.Y., Tse, K.M., Rhamdhani, M.A., 2021. Electronic waste generation, economic values, distribution map, and possible recycling system in Indonesia. Journal of Cleaner Production. 293, 126096. [CrossRef]

- Manish, A., Chakraborty, P., 2019. E-waste management in India: challenges and opportunities. TerraGreen. 12, 22-28.

- Mmereki, D., Li, B., Baldwin, A., Hong, L., 2016. The generation, composition, collection, treatment and disposal system, and impact of E-waste. E-waste in Transition-from Pollution to Resource. 65-93.

- MoEFCC Government of India., 2018. E-Waste Management Rules amended for effective management of E-Waste in the country. Union Environment Minister. Retrieved from https://pib.gov.in/newsite/PrintRelease.aspx?relid=177949.

- Monika, J.K., 2010. Best Fiber Laser Cutting Machine| Best Fiber Laser Cutting Machine Factory-MORN LASER. Indian Journal of Community Medicine: Official Publication of Indian Association of Preventive & Social Medicine. 35(3), 382.

- Needhidasan, S., Samuel, M., Chidambaram, R., 2014. Electronic waste–an emerging threat to the environment of urban India. Journal of Environmental Health Science and Engineering. 12, 1-9. [CrossRef]

- Panwar, R.M., Ahmed, S., 2018. Assessment of contamination of soil and groundwater due to e-waste handling. Current Science. 166-173. [CrossRef]

- Park, M., 2019. Electronic waste is recycled in appalling conditions in India. The Conversation. 15.

- Park, M., Soni, L., 2019. India’s two-million-tonne e-waste problem has deadly consequences. Quartz India.

- Rene, E.R., Sethurajan, M., Ponnusamy, V.K., Kumar, G., Dung, T.N.B., Brindhadevi, K., Pugazhendhi, A., 2021. Electronic waste generation, recycling and resource recovery: Technological perspectives and trends. Journal of Hazardous Materials. 416, 125664. [CrossRef]

- Srikant, S.S., Mahapatra, R.P., Rao, R.B., 2021. Extraction of nano-metals with judicious combination of microwave heating and acid leaching process from E-waste. Journal of Microwave Power and Electromagnetic Energy. 55(3), 236-247. [CrossRef]

- Thada, A., Kapur, U.K., Gazali, S., Sachdeva, N., Shridevi, S., 2019. Custom block chain based cyber physical system for solid waste management. Procedia computer science. 165, 41-49. [CrossRef]

- Veit, H.M., Bernardes, A.M., 2015. Electronic waste: generation and management. Electronic waste: Recycling techniques. 3-12.

- Wath, S.B., Vaidya, A.N., Dutt, P.S., Chakrabarti, T., 2010. A roadmap for development of sustainable E-waste management system in India. Science of the Total Environment. 409(1), 19-32. [CrossRef]

- Zeng, X., Li, J., Stevels, A.L.N., Liu, L., 2013. Perspective of electronic waste management in China based on a legislation comparison between China and the EU. Journal of Cleaner Production. 51, 80-87. [CrossRef]

- ZHANG, W.H., Ying-Xin, W.U., Simonnot, M.O., 2012. Soil contamination due to e-waste disposal and recycling activities: a review with special focus on China. Pedosphere. 22(4), 434-455. [CrossRef]

- Zhongming, Z., Linong, L., Xiaona, Y., Wei, L., 2019. Electronic waste is recycled in appalling conditions in India.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).