Submitted:

27 November 2023

Posted:

29 November 2023

You are already at the latest version

Abstract

Keywords:

Introduction

A Summary ISO 29903

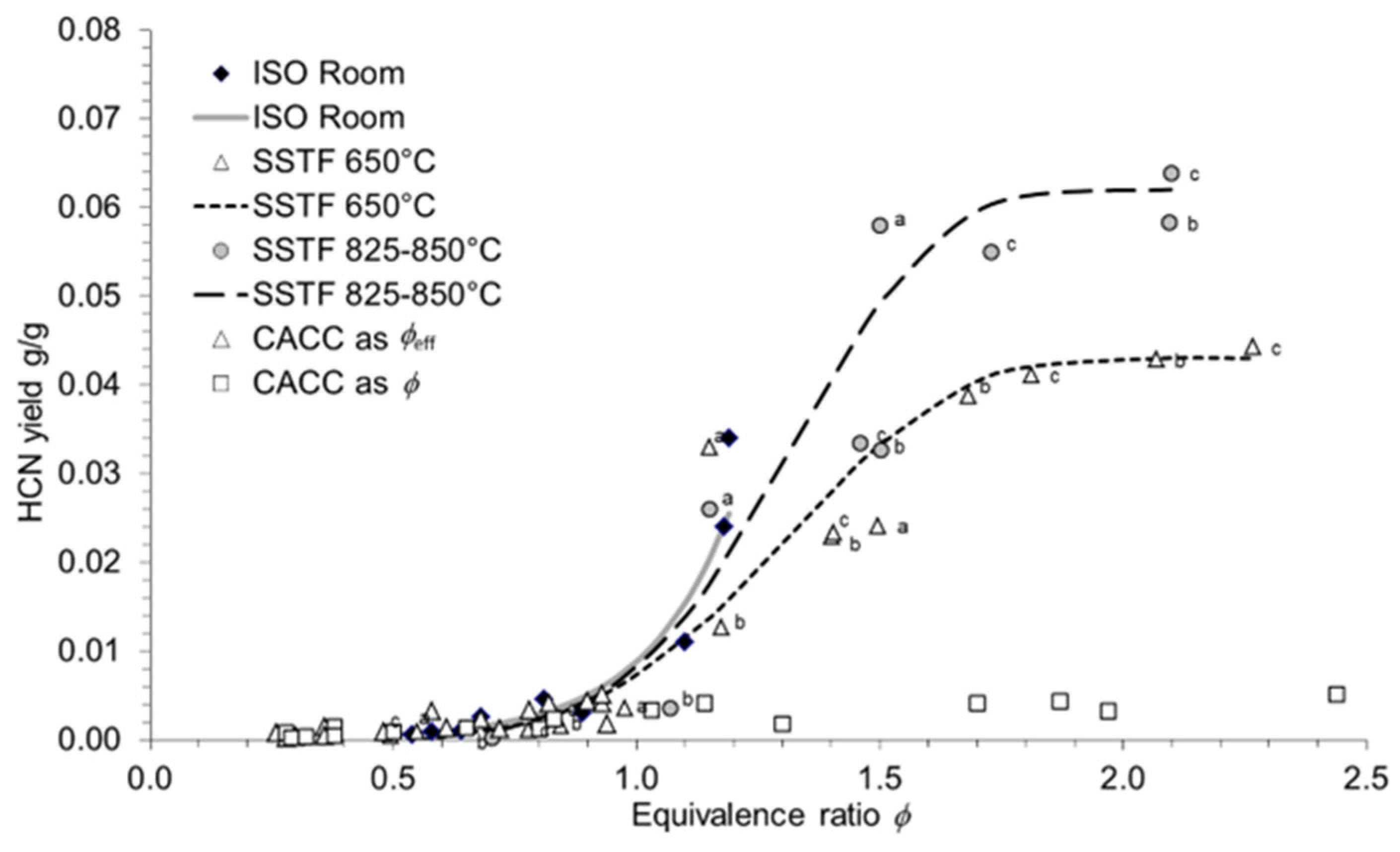

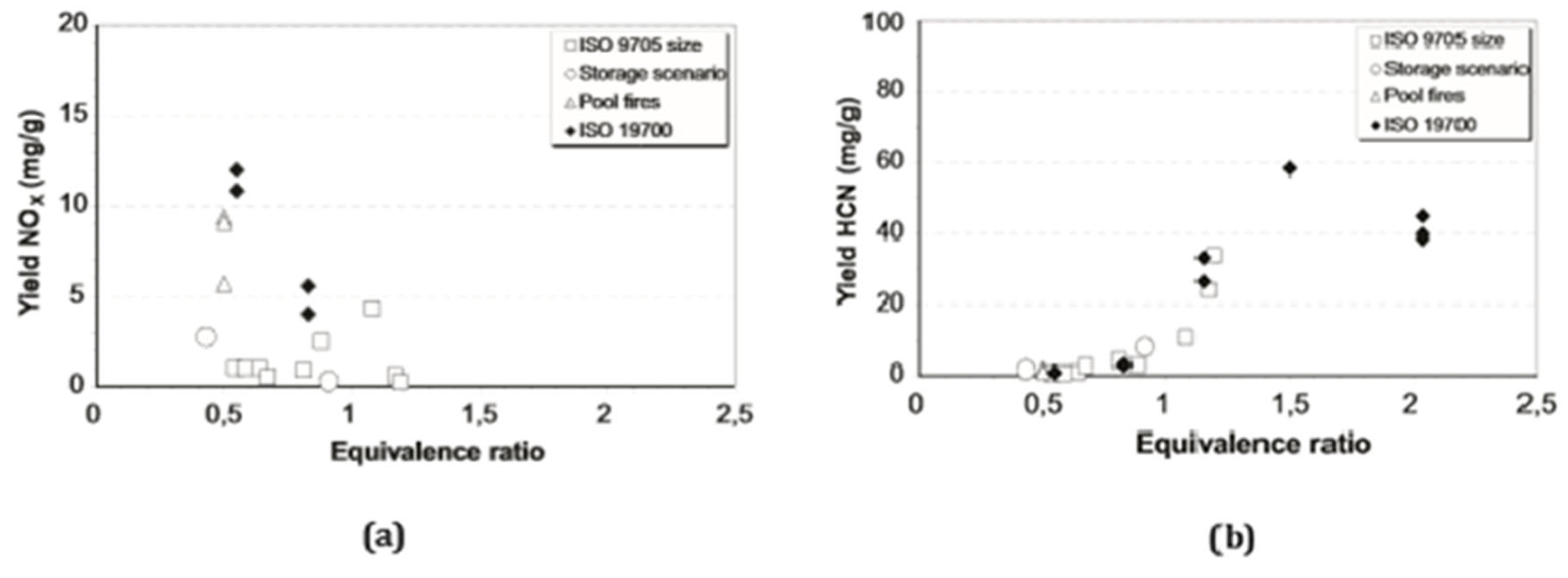

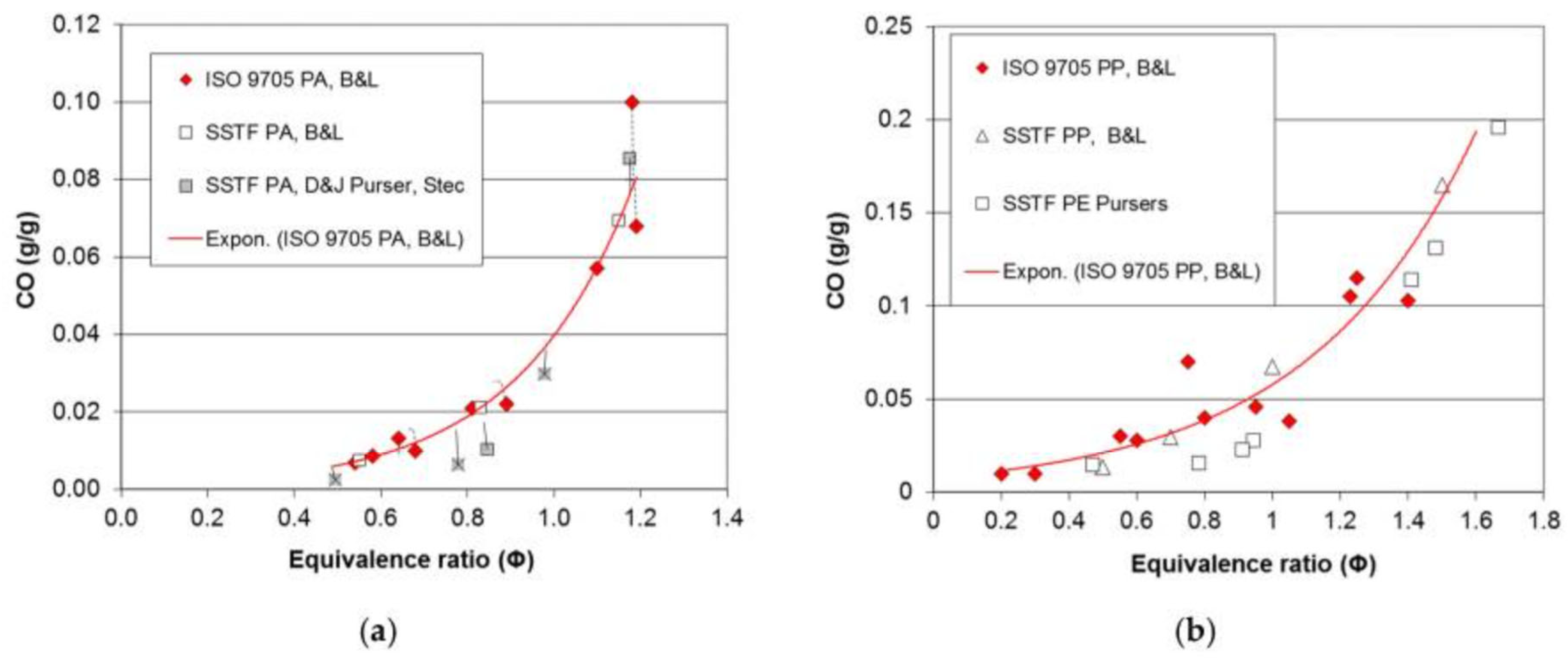

Review of existing bench-to-large scale comparisons

Conclusions

References

- International Standard Organisation (ISO). ISO 29903-1: Guidance for comparison of toxic gas data between different physical fire models and scales (2012).

- BS ISO 29903:2012. Guidance for comparison of toxic gas data between different physical fire models and scales.

- European Commission. Guidance Paper G: The European Classification System for the Reaction to Fire Performance of Construction Products (2003), European Commission enterprise directorate-general.

- ISO 16312-1:2016 Guidance for assessing the validity of physical fire models for obtaining fire effluent toxicity data for fire hazard and risk assessment.

- Liu. X., Hao. J., Gaan. S. Recent studies on the decomposition and strategies of smoke and toxicity suppression of polyurethane based materials (2016), Royal Society of Chemistry Advances (22), pp. 74742-74756. [CrossRef]

- Hull. T. R., Paul. K. T., Stec. A. A. Hydrogen chloride in fires (2008). Fire Safety Science- Proceedings of the ninth international symposium, pp. 665-676. [CrossRef]

- Marsh. N. D., Gann. R. G. NIST Technical note 1760: Smoke Component Yields from Bench-scale Fire Tests: 1. NFPA 269/ ASTM EN 1678 (2013), NIST Fire Research Division Engineering Laboratory, pp 1-57.

- Marsh. N. D., Gann. R. G. NIST Technical note 1761: Smoke component yields from bench-scale fire tests: 2. ISO 19700 Controlled Equivalence ratio tube furnace (2013), NIST Fire Research Division Engineering Laboratory, pp. 1-45.

- Marsh. N. D., Gann. R. G. NIST Technical note 1762: Smoke Component yields from bench-scale fire tests: 3. ISO 5660-1 /ASTM E 1354 with Enclosure and variable oxygen concentration (2013), NIST Fire Research Division Engineering Laboratory, pp. 1-37.

- Marsh. N. D., Gann. R. G. NIST Technical note 1763: Smoke Component yields from bench-scale fire tests: 4. Comparison with room fire results (2013), NIST Fire Research Division Engineering Laboratory, pp. 1-35.

- Blomqvist. P., Sandinge. A. Experimental evaluation of fire toxicity test methods (2018), Research Institute of Sweden, Safety and transport fire research, pp. 1-134.

- Blomqvist. P., Lonnermark. A., Mansson. M., Persson. J. TOXFIRE- Fire characteristics and smoke gas analysis in under-ventilated large-scale combustion experiments (1996), SP Swedish National Testing and Research institute, SP report 1996;45.

- Babrauskas. V., Parker. W. J., Mulholand. G., Twilley. W. H., The phi meter: A simple, fuel-dependant instrument for monitoring combustion equivalence ratio (1994), Review of Scientific Instruments (65), 7, pp. 2367-2375. [CrossRef]

- Hull. T. R., Purser. D. A., Stec. A. A. Fire toxicity assessment: Comparison of asphyxiant yields from laboratory and large-scale flaming fires (2014), Fire Safety Science (11). [CrossRef]

- Blomqvist, P., Hertzberg, T. and Tuovinen, H. A small-scale controlled equivalence ratio tube furnace method – Experience of the method and link to large-scale fires (2007), Proceedings of the 11th International Interflam Conference, Interscience Communications Ltd., London, pp. 391-402.

- Stec, A. A., Hull, T. R., Lebek, K., Purser, J. A., and Purser, D. A. The effect of temperature and ventilation condition on the toxic product yields from burning polymers (2008), Fire and Materials (32), pp. 49-60. [CrossRef]

- Blomqvist. P., Sandinge. A. Experimental evaluation of fire toxicity test methods (2018), Research Institute of Sweden, Safety and transport fire research, pp. 1-134.

- Purser. D. A. Toxic combustion product yields as a function of equivalence ratio and flame retardants in under-ventilated fires: Bench-Larg-Scale comparisons (2016), Polymers (Basel) 8 (9), pp. 330. [CrossRef]

- Purser J.A., Purser D.A., Stec A.A., Moffat C., Hull T.R., Su J.Z., Bijloos M., Blomqvist P. Repeatability and reproducibility of the ISO/TS 19700 steady state tube furnace. Fire Saf. J. 2013;55:22–34. [CrossRef]

- Stec A.A., Hull T.R., Lebeck K., Purser J.A., Purser D.A. The effect of temperature and ventilation condition on the toxic product yields from burning polymers. Fire Mater. 2008;32:49–60. [CrossRef]

- Purser D.A., Purser J.A. HCN yields and fate of fuel nitrogen for materials under different combustion conditions in the ISO 19700 tube furnace. In: Karlsson B., editor. Fire Safety Science, Proceedings of the Ninth International Symposium; Karlsruhe, Germany. 21–26 September 2008; Greenwich, UK: International Association for Fire Safety Science; 2008. pp. 1117–1128.

- Purser D.A., Purser J.A. The Potential for Including Fire Chemistry and Toxicity in Fire Safety Engineering. Building Research Establishment Ltd.; Watford, UK: Mar 23, 2003. Project Report 202804.

- Murthy. D.P., Xie. M. and Jiang. R. Weibull models (2004), John Wiley & Sons.

- Luko. S.N. A review of the Weibull distribution and selected engineering applications (1999), SAE transactions, pp.398-412. [CrossRef]

- Gorgoso-Varela. J.J. and Rojo-Alboreca. A. Use of Gumbel and Weibull functions to model extreme values of diameter distributions in forest stands (2014), Annals of forest science, 71(7), pp.741-750. [CrossRef]

- Purser. J. A., Purser. D. A., et al. Repeatability and reproducibility of the ISO/TS 19700 steady state tube furnace (2013), Fire Safety Journal (55), pp. 22-34. [CrossRef]

| Material | Condition | CO2 yield g/g | CO yield g/g | HCL yield g/g | HCN yield g/g |

|---|---|---|---|---|---|

| Bookcase | 50 kWm- [2] unpiloted ignition | 0.2 | 7.3 x10- [2] | <5x10- [4] | <6x10- [4] |

| 50 kWm- [2] piloted ignition | 1.06 | <4 x10- [4] | <5x10- [4] | <6x10- [4] | |

| 25 kWm- [2] piloted ignition | No data reported | ||||

| Sofa | 50 kWm- [2] unpiloted ignition | 1.65 | 1.9 x10- [2] | < 3 x10- [3] | < 4 x10- [3] |

| 50 kWm- [2] piloted ignition | 1.33 | 6.6 x10- [3] | < 3 x10- [3] | < 4 x10- [3] | |

| 25 kWm- [2] piloted ignition | 1.76 | 4.3 x10- [3]- | < 4 x10- [3] | < 6 x10- [3] | |

| Cables | 50 kWm- [2] unpiloted ignition | 1.12 | 3.0 x10- [2] | 0.18 | < 2 x10- [3] |

| 50 kWm- [2] piloted ignition | 1.18 | 2.8 x10- [2]- | 0.05 | < 2 x10- [3] | |

| 25 kWm- [2] piloted ignition | 0.77 | 1.2 x10- [2] | 0.10 | < 3 x10- [3] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).