1. Introduction

For several centuries, cork has proved to be the most effective closure for wine, protecting its qualities and allowing it to develop and improve over time [

1]. Cork is the outer bark of the oak (

Quercus suber L.). Cork oak forests are located in the Mediterranean climate zone of Western Europe as well as in North Africa. Cork is a natural material with unique set of properties. It has attracted the attention of human since antiquity and has been used since then in various applications. Today, cork is widely known as the closure of wine bottles [

2]. The cork sector in the Mediterranean area is important due to the relevance of the wine sector in the EU, where 60% of the world’s wine production is concentrated [

3].

In the wine market there are multiple closures types. However, these stoppers can be classified into three large families: cork or cork-based stoppers, screw caps and plastic-base stoppers. PricewaterhouseCoopers/Ecobilan quantified and compared the environmental impacts of cork stoppers versus aluminum and plastic closures on the UK market of wine [

4]. According to the researchers behind this study, when compared to aluminum and plastic closures, cork stoppers emerge as the most favorable alternative in terms of non-renewable energy consumption, greenhouse gas emissions, impact on atmospheric acidification, contribution to the formation of photochemical oxidants, influence on surface water eutrophication, and overall solid production [

4]. It is clear that cork material plays a crucial role in preserving biodiversity, a key aspect of sustainable development. Additionally, it contributes to lowering greenhouse gas emissions and capturing CO

2. The unique property of cork trees to regenerate after each harvest, where more than 50 percent of the bark is removed, enables them to endure such losses. The use of cork, derived from the living trees' bark, is preferred by policymakers due to its more environmentally friendly nature compared to synthetic alternatives [

3,

5]. Cork is recommended for bottles of reserve wines and wines that need to age in the bottle [

1]. However, cork stopper is not an inert material and its permeability can lead to entry of quantity of oxygen molecules [

6].

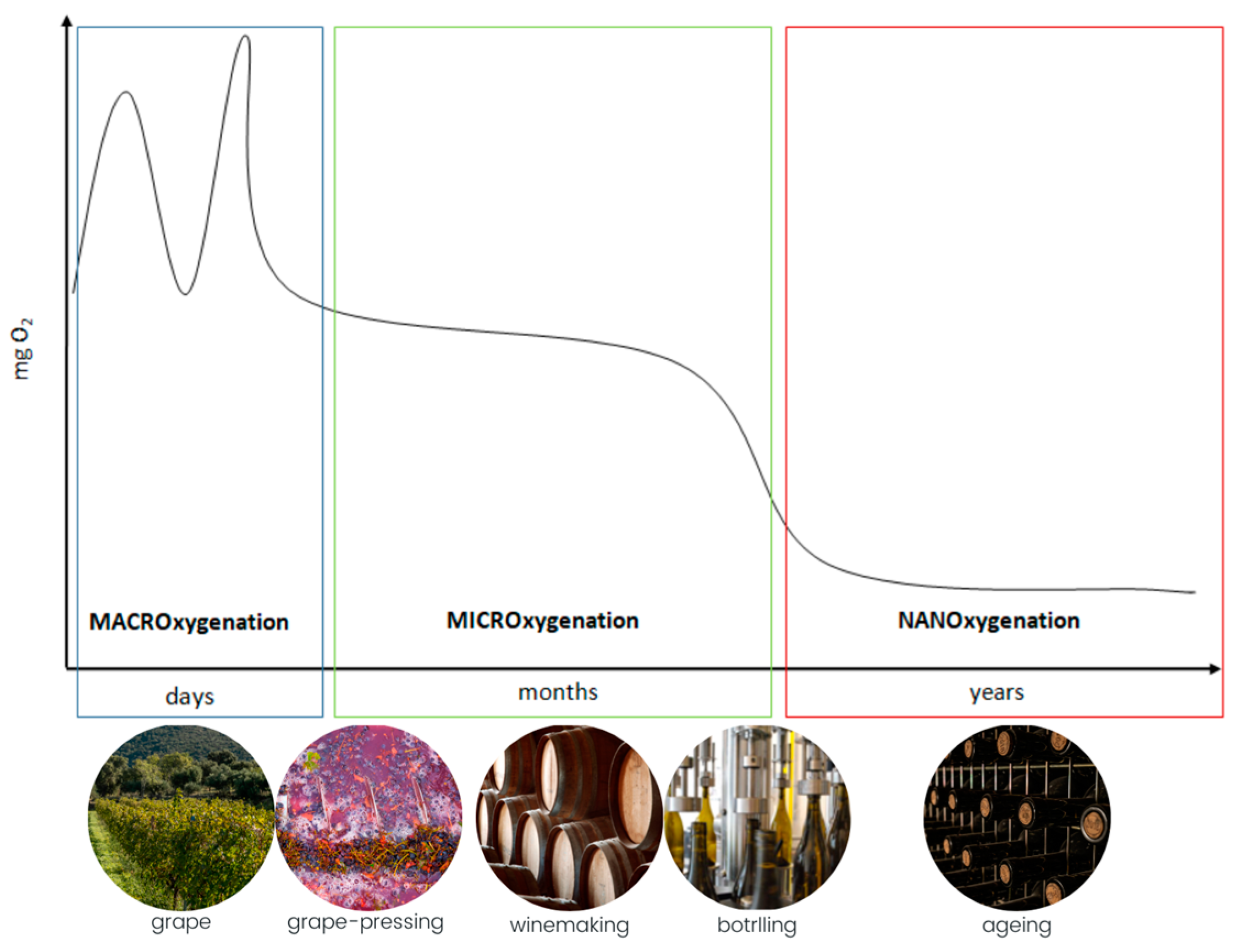

One of the most important aspects to maintain the quality of food products during the manufacturing, packaging and conservation process is the control and measurement of the oxygen permeability. Food oxidation is related to the loss of organoleptic properties and reduced durability. In the case of the wine sector, the evolution of the wine is extremely dependent on the oxygen amount the wine receives. Oxygen is crucially involved in the oenological process, from the collection of the grapes to the opening and consumption of the wine itself [

7]. Oxygen determines the development of the winemaking process and defines the final sensory characteristics of the wine, among other factors Oxygen management and oxidation-reduction reactions are part of the main challenges that winemakers have to face during the production and aging of wine [

8]. Pressing the grapes, the movements of the wine, filtration and bottling contribute to bringing large amounts of oxygen to the wine [

5] (

Figure 1). This study was focused on the final phase of the winemaking process: post-bottling and aging. Due to the extremely low rates of oxygen entry through a closure, this form of oxygen exposure has been called nano-oxygenation.

The main function of a stopper is to secure good seal to avoid any deterioration of the wine during storage and the ageing. Controlling the amount of oxygen is a critical aspect in the winemaking process from the harvest until the aging processing bottle, since oxygen can deteriorate or improve the characteristics of a wine [

9]. Oxygen permeability of wine closures may vary depending on closure type and strongly influence the evolution of wines during bottling aging [

10,

11,

12,

13,

14,

15]. Godden et al. 2005 [

16] described that different final products from the same wine could result with bottling under different closures.

Different authors studied the permeability of different types of stoppers (natural cork stoppers, agglomerated, microagglomerated or synthetic stoppers) [

17,

18,

19,

20] and others the permeability of the natural stoppers of different qualities [

21,

22]. It had been determined most of the oxygen diffuses out of the cork into the bottles during the first 12 and 24 months of storage [

23]. Internal research from ICSURO has also shown that a coated group of natural cork stoppers (flower class) with wax presented more oxygen inlet that the same group of stoppers without covered explaining that the oxygen that is transferred to the bottle comes from the inside of the stopper itself and not from the outside. However, the influences of the finishing operations of the production process of natural cork stoppers have not been studied.

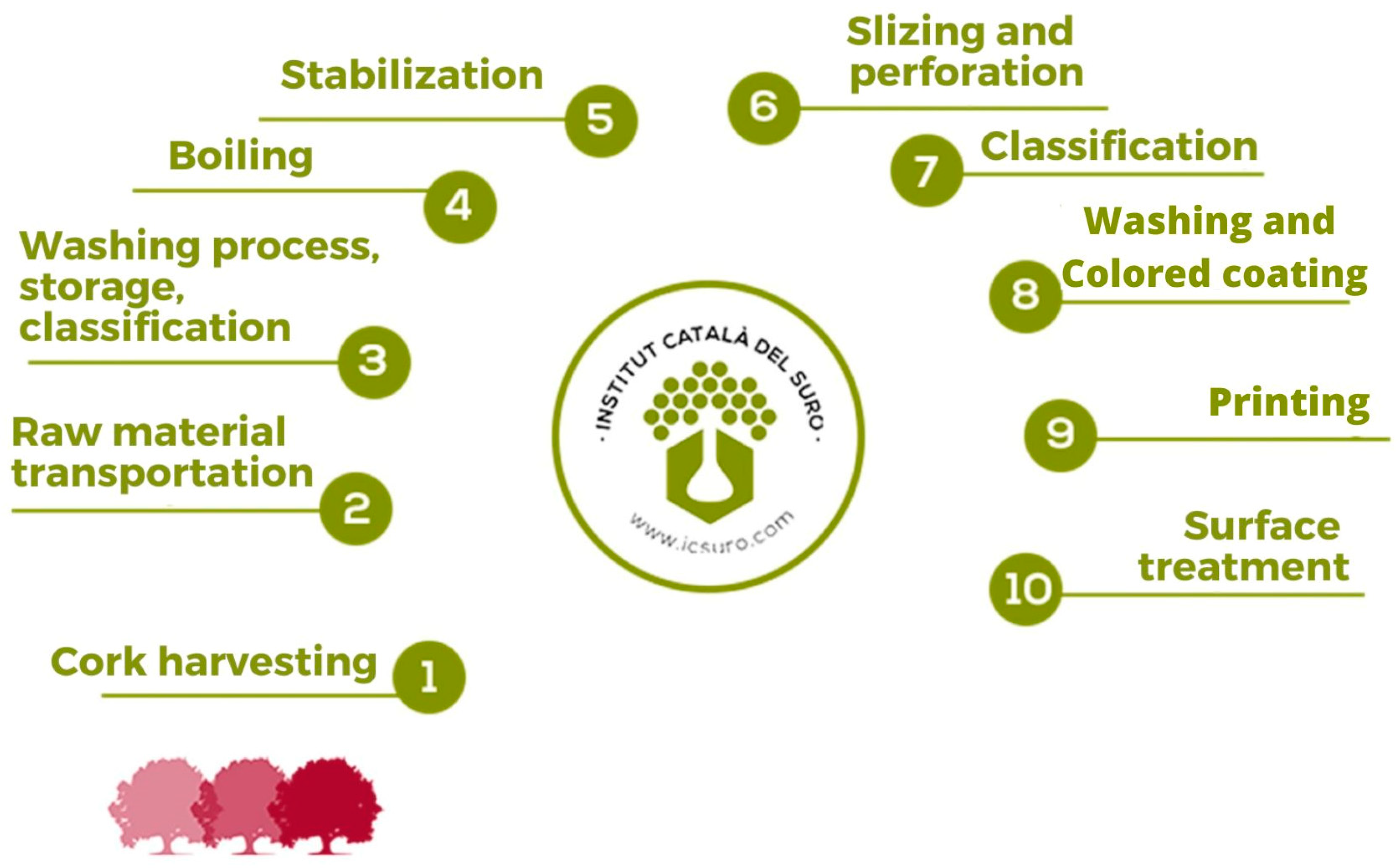

After harvesting, the cork planks are stabilized, boiled, and stabilized again. After this resting period, the stoppers are punched and classified in graded. When the correct dimensions of the stoppers are obtained, the selected stoppers undergo to the finishing operations of the production process. The finishing operation starts with washing and disinfection stage, with a cleaning process of an aqueous solution of hydrogen peroxide most commonly [

1]. Next, the stoppers are dried, and the stoppers may or may not be coloured coating. This process is not always carried out and has the purpose of put of a coloured layer on the stopper to give it a uniform colour [

24]. Finally, the stoppers may be printed, and surface treated with paraffin or/and silicon to obtain the final product [

3] (

Figure 2).

In this paper, the influence on stoppers permeability of different washing processes, different colored coatings, and different surface treatments and how also these affects wine ageing was studied. Synthetic alternatives stoppers can easily identify the OTR of the material and exists some synthetic closures into the market that report their permeability in their technical sheets. However, natural cork stoppers are not as well known as other alternative stoppers and this study aims to provide new data in the study of the permeability of natural cork stoppers that will allow them to be characterized and better understood. As has been said, cork stoppers are a natural material unlike other stoppers and therefore all research related to knowing the material and promoting its use has a direct link in the field of sustainability and the use of natural materials.

2. Materials and Methods

2.1. Cork Stoppers Samples

The stoppers studied were manufactured by the same batch. All of them were visual classified as flower class (the best visual class in range on classification). Seven groups of 150 natural cork stoppers were made by: four washing processes (no wash, peroxide spray washing, peroxide immersion washing and peracetic acid spray washing); two different coloured coatings (not coated, water-based coated stoppers and solvent-based coated stoppers)and twodifferent surface treatments (1 and 2) (

Table 1). The formulations and the method of application of each processwere carried out by the company according to its own production process, therefore it found under the trade secret.

All closures were analysed prior to bottling for dimensions, density, and moisture (ranged from 4% to 6%) according to UNE 56921:2021 methodologies [

25]. A selection of ten stoppers of each group was made according to the most homogeneous values obtained for dimensions, weight, and density.

2.2. Glass Botlles

A set of 375 mL Extra white (colourless) “bordelaise” classic bottles with standardised bottleneck bores, 18.5 mm diameter were used. Bottles were coded to ensure traceability to the specific cork closure tested in each bottle. Bottle internal neck profiles were measured using a PerfiLab® with Kroeplin instrument (Egitron, Portugal). Measures were taken from the rim to 50 mm depth at a 1 mm pace along the bottleneck. All the bottles that were used complied with the internal diameter of the bottle according to UNE standard at 3 and 45mm [

26].

2.3. Corking Operation

A semi-automatic corker Moeller model M500with corking jaws at 16 mm compression, was used for all closures. All bottles were bottled under controlled conditions and were sealed with different closures under a continuous flush of nitrogen (2.5 bar). An initial reading of the sensor was done in other to control degas oxygen process in the empty bottles. All bottles were left upright for 1 h after bottling and then stored horizontally over 12 months.

2.4. Storage Conditions

Bottles were stored horizontally in darkness conditions under constant temperature of 20±2°C and a constant relative humidity of 65±20 % over this period.

2.5. Monitoring Oxygen Ingress

Oxygen measurements were taken using chemiluminescenceby an analyzeroximetric model NOMASenseO2P6000 with Fibox 3 LCD Tace V6fiber andPts6 sensors (Wine Quality Solutions). The system has a transmitter/receiver probe. This flow is directed to a sensor (called spot) previously placed inside a transparent bottle. The spot was placed inside the bottles and left for 24 hours in the dark before starting the test. An initial reading of the sensor was done in other to control the inserting process just after corking the empty bottles. During the first 1 hour, the empty bottles are measured every few minutes to verify that the corking process was done correctly and that there were not leaks. Each bottle has its initial oxygen value. This amount of oxygen was subtracted from the following reading in order to know the amount of incoming oxygen. The measurements were taken daily for the first 90 days and then every 15 days up to 12 months. The device expressed the result as partial pressure of oxygen (PO2). Partial pressure of oxygen inside the empty bottles was converted to milligrams of oxygen by the general law of ideal gases and the molecular mass of oxygen.

2.6. Modelling and Data Analysis

All readings are records in Microsoft Excel and they were transformed from hPa to mg O2 with the same program. Thanks to the Excel functions, the increments were calculated and the modalization over time for each bottle or for a pool was done. Thus, analytical data were obtained with Microsoft Excel. Analysis of variance (ANOVA), Turkey test, Kruskal Wallis and Welch's t-test for two samples were developed by R commander package for Windows of R software (ver. 3.5.3, 2019).

2.7. Red Wine

A young red wine from the DO Empordà was used in the second part of the study. The oenological analysis of the wines was carried out by a wine specific laboratory. The analyses were carried out according to international standards. The Instituto de Ciencias de la Vid y el Vino of the Universidad de la Rioja studied the evolution of the monomeric phenolic compounds of the wines according to their internal protocols.

3. Results

Cork stopper finishing operations include a stage of washing and optionally colored coating with subsequent drying, classification into commercial quality classes and a final impression with the client's brand followed by the final surface treatment, which is normally a mixture of paraffin and silicone [

2]. The influence of these three final stages on the permeability of natural cork has been studied separately. The results obtained are shown below.

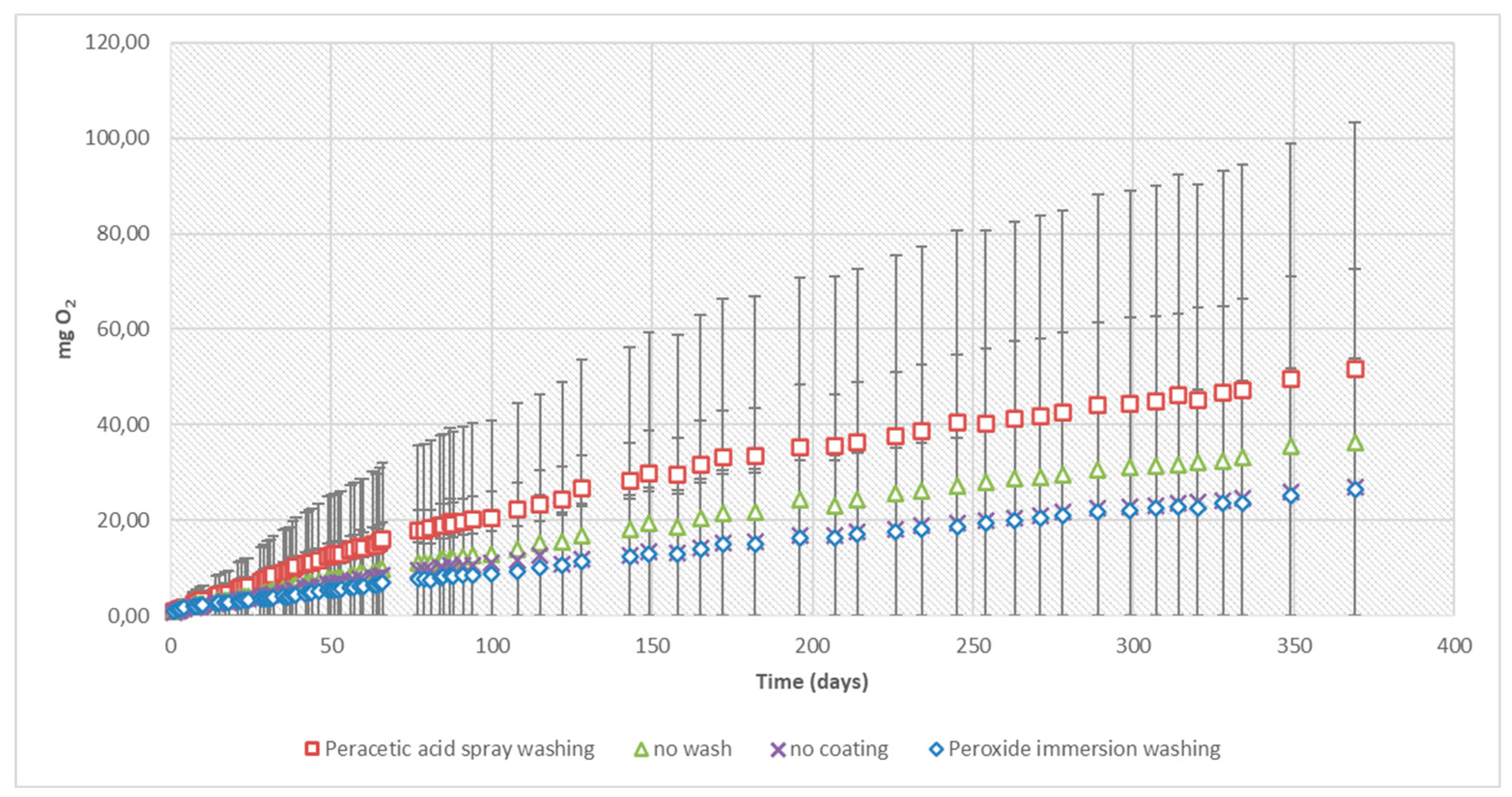

3.1. Washing Stage

The washing stage of cork stoppers plays the defining role in cleaning/disinfection surface dust or loosened lenticular material and appearance (primarily the colour homogeneity and whiteness) [

27]. Nowadays the standard cork washing and bleaching is done by using a hydrogen peroxide aqueous solution (about 10% of 130vol. H2O2 solution) with 1% sodium hydroxide, with a neutralization agent. Washing with other chemicals such as sodium metabisulphite, sulphamic acid or peracetic acid is more rarely and depends on client’s demand [

2]. Moreover, the washing process can be applied by spray washing or immersion washing. In the present study, 4 groups had followed: no wash, peroxide spray washing, peroxide immersion washing and peracetic acid spray washing (

Figure 3).The stoppers studied were manufactured by the same company, from the same batch, with the same surface treatment and colourless coating (solvent-based coated).Both peroxide washes seemed to have a similar behaviour over time, presenting comparable oxygen input values. However, the groups not washed and washed by spraying with peracetic acid, presented higher values throughout the study time, being peracetic washing the group that presents the highest oxygen inlet.

The analytical data showed significant different between the washing trails groups (p value>0.05). The multiple comparisons of means: Tukey Contrasts presented the group washed with peroxide by immersion and washed with peracetic spray with the most different groups. The statistical pooling, therefore, gave different pools to these trials. In addition, it put no washed and peroxide immersion washing in the same pool, which in turn these two share characteristics with the other pools. To the best of our knowledge, no study has been published on the interaction or relationship that the washing process of natural cork stoppers may have with their permeability. For this reason, we believe that this study may open a new field of research. Some authors have pointed out the importance of the washing process and the alterations it can cause on the surface of the stopper [

26].

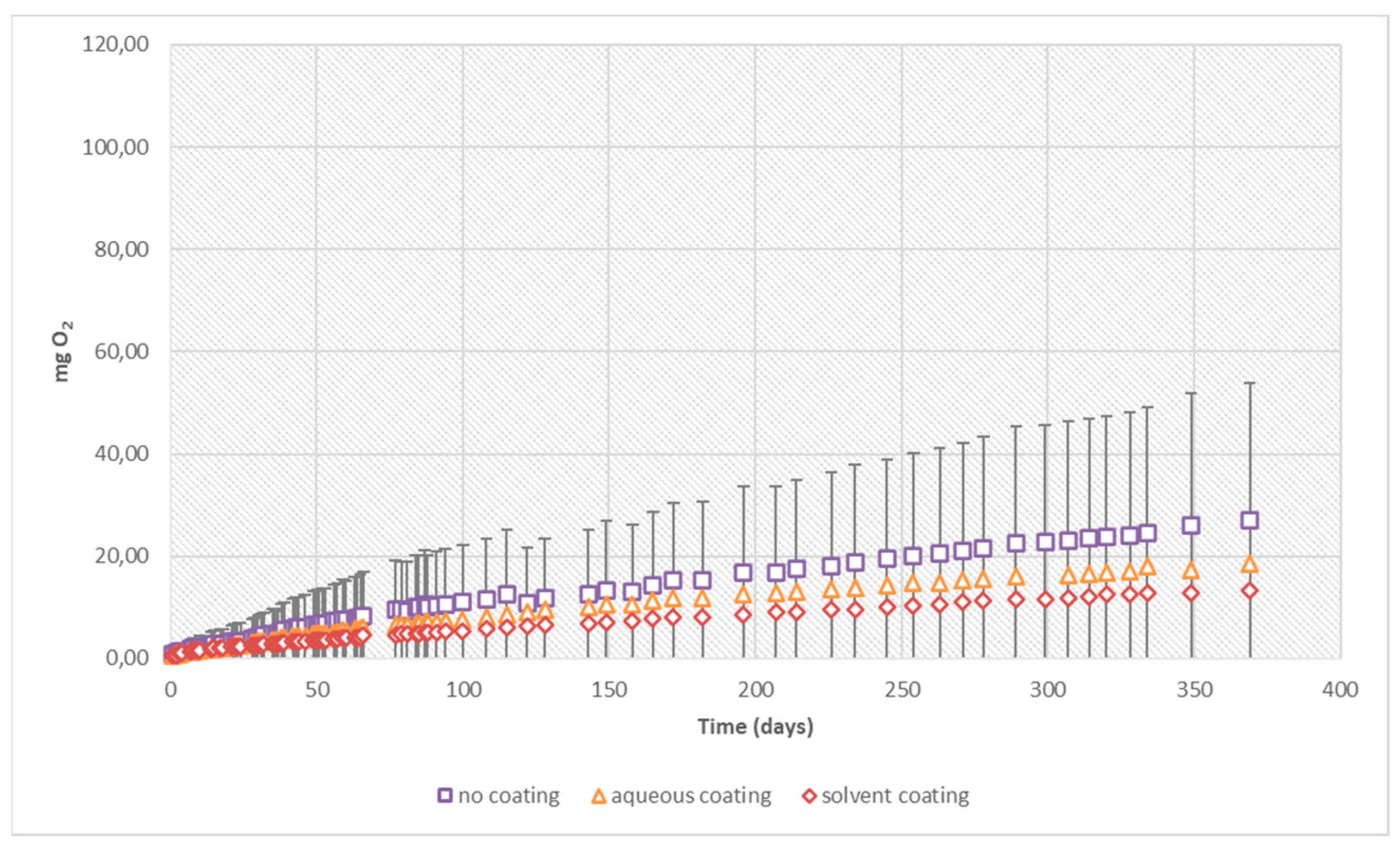

3.2. Coloured Coating Stage

The colored coating is the application of a colored layer on the stopper surface to give it a uniform color [

24]. This stage is not carried out routinely; it is only executed in some cases or at the request of the client. In this study, different colored coating of natural cork stoppers were compared: not coated, water-based coated stoppers and solvent-based coated stoppers (

Figure 4). The stoppers studied were manufactured by the same company, from the same batch, with the same washing (peroxide spray) and the surface treatment. No differences were observed nor were there statistical differences between the three colored coating study groups in reference to its permeability.

3.3. Surface Tretament Stage

The surface treatment has the objective to coat the stopper with a lubricant film to reduce friction. It allows an easier introduction and extraction into and out the neck of the bottle [

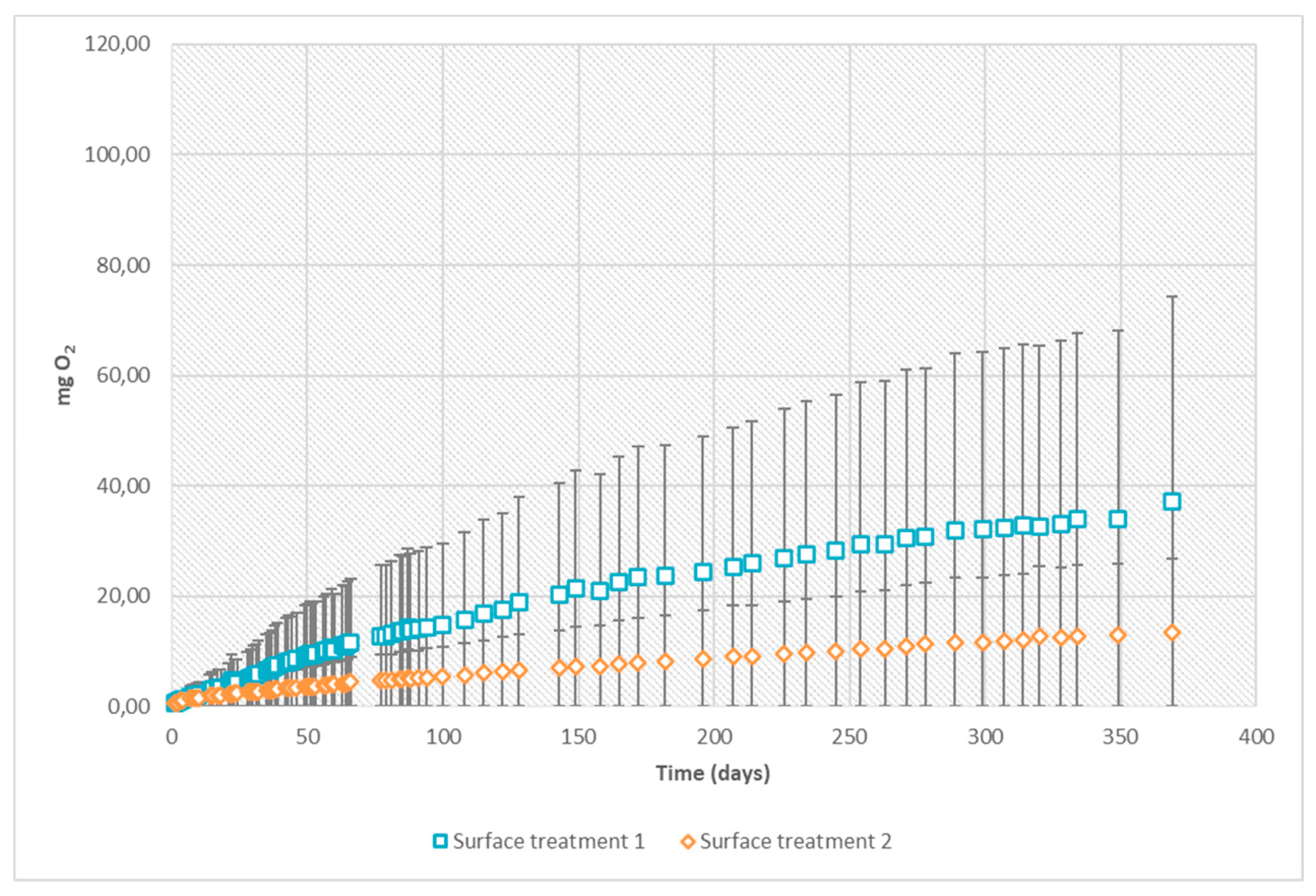

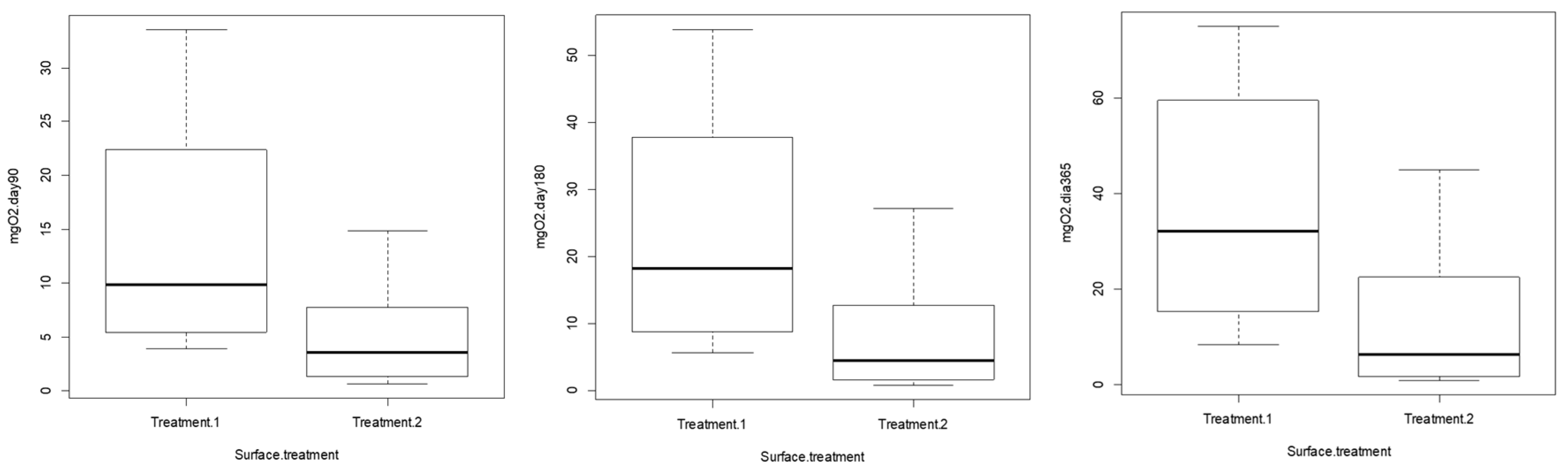

2]. Previous studies from our research centre showed that stoppers without surface treatment had higher permeability than stoppers with surface treatment (this data not shown). This fact would suggest that the surface treatment played an important role in the transfer of oxygen, thereby acting like a kind of barrier. For this reason, two groups of natural cork stoppers with two different surface treatments (1 and 2) were chosen (

Figure 5). The stoppers studied were manufactured by the same company, from the same batch, with the same washing (peroxide spray) and the same-coloured coating (solvent-based coated).

Surface treatment 1 presented twice inlet oxygen as treatment 2 over time. The analytical data showed statistical differences (p value >0.05) from the day 90 from the end on the study (

Figure 6). As happened in the case of the study groups with different washes, the authors are not aware that this phenomenon has been previously reported. Therefore, the results of this study show that the finishing stages of cork stoppers could modulate oxygen entry. Thus, knowing and characterizing the different stages of the industrial finishing process can help to have stoppers with different tendencies of oxygen permeability.

4. Discussion

Do these differences observed translate into the wine? The results obtained that have been previously presented were shared with the company that manufactured the stoppers and it was decided to extend the study for a few more months. It was chosen to continue studying the surface treatments. In this case, the company produced two groups of natural cork stoppers (superior class, the second visual class in range on classification) from the same batch, with two different surface treatments (1 and 2) but with the same washing (peroxide spray) and the same colored coating (solvent-based coated). One hundred and twenty bottles of the same young red wine were bottled: sixty of them with cork stoppers from treatment 1 and sixty more with cork stoppers from treatment 2. The bottling process in this case was conducted in the winery with its own industrial bottling line. After bottling, 6 bottles samples were taken to analyze the initial wine. The wine bottles were aged under cellar conditions in the winery itself during the 30 months of study. During this time, 4 samplings were done to analyze some oenological parameters of the wine followed by a sensory test. The studied wine was a young red wine that is normally on the market a few months after bottling and its shelf-life usually is between 12 and 18 months. The sanitary conditions experienced throughout the years 2020 and 2021 with COVID led to the modification and expansion of the study.

An oxygen permeability analysis of this new set of stoppers was performed. The oxygen transfer rate (OTR) was showed below (

Table 2). The differential trend observed in the first part of the study remained. The two surface treatments behave the same in this new batch of stoppers: surface treatment 1 presented more permeability than surface treatment 2.A clear evolution of the oenological parameters from the initial sample to the later sample points were seen in

Table 3. There was a decrease in total and free sulphur dioxide, an increase in parameters related to coloring and some variations in total polyphenols, anthocyanins, and tannins. These changes were typical of the evolution in wine chemistry and of maturation itself. The red-purple colour of young red wines changes towards brick-red, which is attributed to the progressive formation of new pigments [

28,

29] from the initial free anthocyanins [

30,

31] causing the reduction of these and therefore reducing the violet notes of the wines. This evolution of the color was observed over time, being more accelerated in the bottles of treatment 1 stopper than in 2 (see months 12 and 18 of evolution). In addition, total sulphur dioxide is higher in the samples from the surface treatment 2 than the stoppers with surface treatment 1 at 30 months. The stoppers with surface treatment 2 had lower oxygen permeability, therefore it was expected that the total sulphur dioxide value would be higher since this compound can be considered an antioxidant agent.

During the corresponding sensory tastings, the testing panel described that the wines corked with the stoppers with the surface treatment 1, were more developed after 12, 18 and 30 months of aging in general terms. On the other hand, the wines corked with surface treatment 2seemedunderdeveloped after 12 and 18 month and still within the shelf-life range in 30 months.

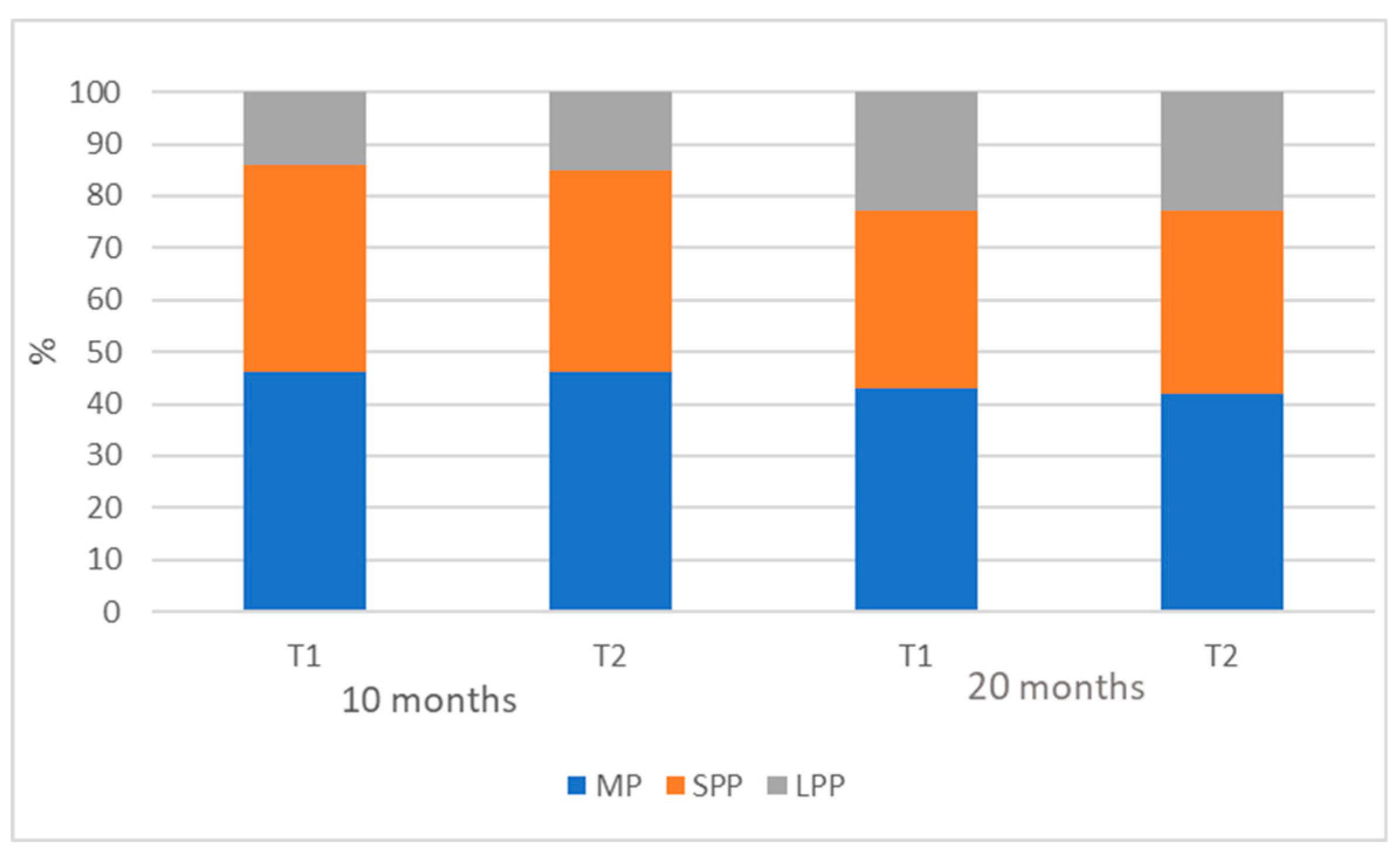

At the same time, different samples of the wines were sent to the Instituto de Ciencias de la Vid y el Vino of the Universidad de la Rioja to study the evolution of the monomeric phenolic compounds of the wines. The combination of anthocyanins and flavanols/tannins can take place by direct condensation or by formation of ethyl bridges formed from acetaldehyde (reaction favoured by the presence of oxygen).The formation of these combinations allows the change of the red-blue tones in young wines to brick-red. In general, these new pigments are more stable than the anthocyanins from which they come from, which imply that their formation increases colour stability in aged red wines.Pigments formed from anthocyanins have long been recognized as the stable form of colour in aged red wines. After a period of aging of the wine, most of the colour is due to the pigments formed from the anthocyanins from the grape [

32,

33]. In the studied wines, the large polymer pigments (LPP) increase with the storage time of bottled wines, while small polymeric pigments (SPP) and monomeric pigments (MP) decrease (

Figure 7). At 10 months LPP had a proportion of around 15% and SPP of 39%, being MP of 46%. At 20 months, the LPP increased to 23% and, the SSP and the non-combined MP decreased by around 34% and 42%, respectively. The percentages for each group of compounds change significantly with aging time. This fact can be explained because during aging anthocyanins, dimeric and trimer flavanols tend to decrease, since these can continue to polymerize, forming high molecular weight polymeric pigments [

34], as observed with the increase in the LPPs.

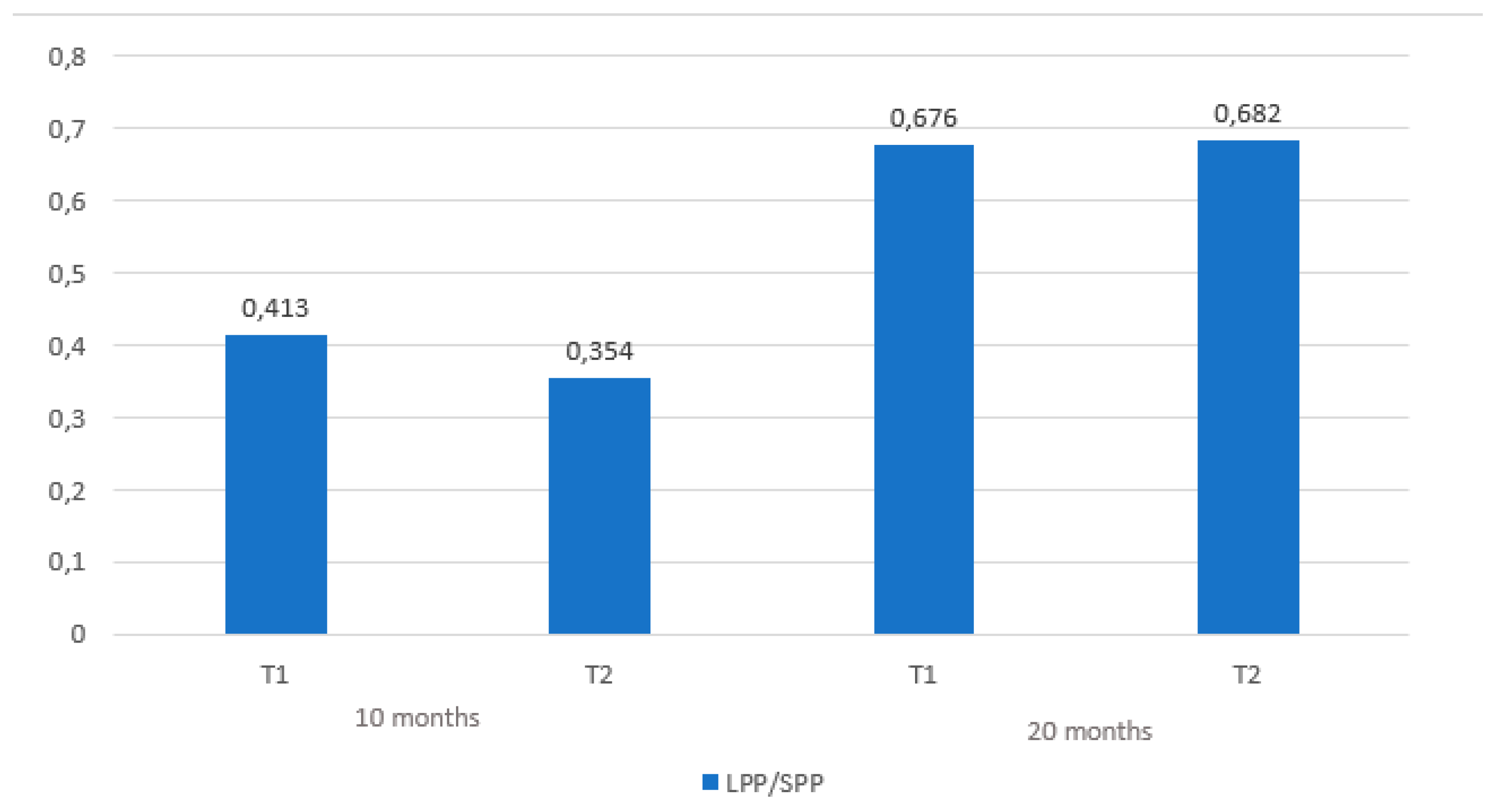

The ratio of LPP/SPP polymeric pigments was observed to increase by a factor of 1.6 and 1.9 with time, indicating an increase in LPP relative to SPP in the aging period. After 10 months of evolution, a difference of 0.5 was observed between the wines from the different stoppers (

Figure 8). This may indicate a differential evolution between the wines, since the wines from treatment 1 present a greater proportion of LPP than those from treatment 2, indicating that the pigments have evolved more.

According to the results presented, the corks produced in the same way by the company with two surface treatments show different oxygenpermeability. After one year of evolution, the sample of stoppers with surface treatment 1 presented three times more oxygen inlet than the stoppers with surface treatment 2. The surface treatment seems to be a determining factor for OTR oxygen permeability. And, what's more, the differences detected in the permeability test are translated into a differential evolution of the same wine corked with the two types of study stoppers with different surface treatment both at the sensory level and in some analytical parameters.

It should always bear in mind that the amount absorbed in the bottlingstage is about 1-3mg/L and depends on the best practices in the bottling and corking process (the method of bottling, the use of inert gases, the type of machine used, the corking system, maintenance of the jaws, control of the volume of bottling and control the head space) [

35].The amount of oxygen absorbed during bottling, and this found in the free space in a bottle (Total OxygenPackage, TPO) usually reaches a values of 1-9mg/L [

36,

37]. Our study is focused on ageing oxygen. Oxygen penetrates through the natural cork during the aging in bottles in an amount of 0,005-5mg/L/year [

38] process and can only be understood within a context of good bottling practices, since if only this last step of the process was controlled the contribution of oxygen stoppers could be ridiculous compared to all other processes.

5. Conclusions

Chemiluminescencewas validated as a method of measuring the oxygen permeability of natural cork stoppers, since the conclusions drawn at the laboratory level can be extrapolated to wine.Cork stopper finishing operations include a stage of washing, optionally colouredcoating, andsurface treatment. The influence on stoppers permeability of different of these finishing operations was studied in this paper by chemiluminescence method. The analytical data showedthat the type of surface treatment and washing process has a significant effect on the permeability of cork stoppers, unlike the colouring process.To the best of our knowledge, no study has been published on the relationship that the washing processor the surface treatment of natural cork stoppers may have with their permeability. Therefore, the knowledge acquired during the project study should allow modulating the production processing benefit of the homogeneity of the natural cork stoppers.

A red wine was corked with these two types of cork stoppers and its evolution was monitored up to 30 months of ageing. Differences were observed in the evolution of the wines both in certain oenological parameters such as the free SO2, colour and evolution of the polyphenols as well as at the sensory level. The wine corked with the stoppers of treatment 1 presented a faster evolution and a higher valuation in the sensory tastes of months 12th, while from the 18th month it presented an over evolution, and the score was below that of the wine with the corks of treatment 2.

Highlight the OTR results can only be understood within the context of best bottling practices.The method of bottling, the use of inert gases, the type of machine used, the corking system, maintenance of the jaws, control of the volume of bottling and control the head space are essential processes to have a desiredwine evolution into the bottle, where the oxygen of the cork also hasa relevant contribution in still wine. Thus, it means that aging stage contributes very little oxygen inlet compared to the rest of the process. For this reason, it has become evident the importance of the correct bottling process by the wineries to ensure the correct conservation of their wines in bottles.

Acknowledgments

This research has been carried out within the framework of the Operational Groups of the European Association for Innovation (AEI)(GO OTR-56.26043.2017.3A), with the financial support of Operation 16.01.01 (Cooperation for innovation) through the Rural Development Program of Catalonia 2014-2020 with the participation of the EAFRD fund. This work was co-financed by AECORK and its companies. We express our gratitude to Manuel Serra and J. Vigas for providing the stopper in the study. We thank the winery (VinyesdelsAspres) for agreeing to collaborate in the study. We would also like to thank our coworkers from ICSuro and all the students and scholars who helped with the laboratory work. Lastbutnotleast, wethank Marta Mª Inés Dizy, Maria Purificación Fernandez y Shuyan Liu from Instituto de Ciencias de la Vid y el Vino ofthe Universidad de la Rioja.

References

- Silva, S. P. , Sabino, M. A., Fernandes, E. M., Correlo, V. M., Boesel, l. F., & Reis, R. L. Cork: properties, capabilities and applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar]

- Pereira, H. Cork: biology, production and uses. 1st ed. Elsevier, Oxford, United Kingdom, 2011.

- Rives, J. , Fernandez-Rodriguez, I., Rieradevall, J., & Gabarrell, X. Environmental analysis of the production of natural cork stoppers in southern Europe (Catalonia–Spain). J. Clean. Prod. 2011, 19, 259–271. [Google Scholar]

- PricewaterhouseCoopers/ECOBILAN. Evaluation of the environmental impacts of Cork Stoppers versus Aluminium and Plastic Closures. Analysis of the life cycle of Cork, Aluminium and Plastic Wine Closures. Report, 2008.

- Demertzi, M. , Dias, A. C., Matos, A., & Arroja, L. M. Evaluation of different end-of-life management alternatives for used natural cork stoppers through life cycle assessment. Waste Manag. 2015, 46, 668–680. [Google Scholar]

- LequinS. , Chassagne D., Karbowiak T., Simon J.M., Paulin C. and Bellat J.P. Diffusion of oxygen in cork. J. Agric Food Chem 2012, 60, 3348–3356. [Google Scholar]

- Zaldivar, E., Rodriguez, F., Carrillo, D., Borinaga, I., Aguado, A. and Palacios, A. La vida útil del vino y su relación con los marcadores de longevidad. La semanaVitivinicola. 2017. June 2017.

- Laurie V., F. and Clark A. C. Wine oxidation. In: Decker EA, Elias RJ, McClements DJ (eds) Oxidation in foods and beverages and antioxidant applications. 2010. Volume 2: Management in different industry sectors. Woodhead, Cambridge, pp 445–475.

- Dias Silva, P. Métodos de análise da cinética de entrada de oxigénio em garrafa de vinho tranquilo e espumante por quimioluminescência. Thesis, Universidade do Porto, Faculdade de Engenharia, Departamento de Engenharia Química.2014.

- Godden, P. W. , Francis, L., Field, J., Gishen, M., Coulter, A. D., Valente, P., Hoj, P., Robinson, E. (2001) Wine bottle closures: physical characteristics and effect on composition and sensory properties of a Semillon wine. 1. Performance up to 20 months post-bottling. Aust. J. Grape Wine Res. 2001, 7, 62–104. [Google Scholar] [CrossRef]

- Skouroumounis, G. K. , Kwiatkowski, M. J., Francis, I. L., Oakey, H., Capone, D., Duncan, B., Sefton, M. A., Waters, E. J. (2005) The impact of closure type and storage conditions on the composition, colour and flavour properties of a Riesling and a wooded Chardonnay wine during five years’storage. Aust. J. Grape Wine Res. 2005, 11, 369–384. [Google Scholar]

- Caillé, S. , Samson, A., Wirth, J., Diéval, J.-B., Vidal, S., Cheynier, V. Sensory characteristics changes of red Grenache wines submitted to different oxygen exposures pre and post bottling. Anal Chim Acta 2010, 660, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Wirth, J. , Caillé, S., Souquet, J. M., Samson, A., Dieval, J. B., Vidal, S., Fulcrand, H., Cheynier, V. Impact of post-bottling oxygen exposure on the sensory characteristics and phenolic composition of Grenache rosé wines. Food Chemistry 2012, 132, 1861–1871. [Google Scholar] [CrossRef]

- Guaita, M. , Petrozziello, M., Motta, S., Bonello, F., Cravero, M.C., Marulli, C., Bosso, A. Effect of the closure type on the evolution of the physical-chemical and sensory characteristics of a Montepulciano d’Abruzzo Rosé wine. J Food Sci 2013, 78, 2. [Google Scholar] [CrossRef]

- Gambuti, A. , Rinaldi, A., Ugliano. M., Moio, L. Evolution of Phenolic Compounds and Astringency during Aging of Red Wine: Effect of Oxygen Exposure before and after Bottling. J. Agric Food Chem 2013, 61, 1618–1627. [Google Scholar] [CrossRef]

- Godden, P. , Lattey, K., Francis, L., Gishen, M., Cowey, G., Holdstock, M., Robinson, E., Waters, E. J., Skouroumounis, G., Sefton, M., Capone, D., Kwiatkowski, M., Field, J., Coulter, A., D’Costa, N., Bramley, B. Towards offering wine to the consumer in optimal condition - the wine, the closures and other packaging variables: a review of AWRI research examining the changes that occur in wine after bottling. Aust NZ Wine Ind J 2005, 20, 20–30. [Google Scholar]

- Lopes, P. , Saucier, C., Teissedre, P.L., Glories Y. Main routes of oxygen ingress through different closures into wine bottles. J. Agric Food Chem 2007, 55, 5167–70. [Google Scholar] [CrossRef]

- Brotto, L. , Battistutta, F., Tat, L., Comuzzo, P., Zironi, R. (2010) Modified Nondestructive Colorimetric Method to Evaluate the Variability of Oxygen Diffusion Rate through Wine Bottle Closures. J. Agric. Food Chem. 2010, 58, 3567–3572. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, V. , Pons A. y Loisel C. (2019). Impacto del cierre en el envejecimiento de los vinos en botella. Sem. Vitivinícola 2019, 3535, 2038–2043. [Google Scholar]

- Cardoso, A. C. L. , Rajbux, C., Silva, C. L., & Poças, F. Modelling oxygen ingress through cork closures. Impact of test conditions. J. Food Eng 2022, 331, 111105. [Google Scholar]

- Oliveira, V. , Lopes, P., Cabral, M., Pereira, H. Kinetics of oxygen ingress into wine bottles closed with natural cork stoppers with different qualities. AJEV 2013, 64, 395–399. [Google Scholar]

- Oliveira, V. , Lopes, P., Cabral, M., Pereira, H. Influence of cork defects in the oxygen ingress through wine stoppers: Insights with X-Ray tomography. J.Food Eng 2015, 165, 66–73. [Google Scholar] [CrossRef]

- Lopes, P. , Saucier, C., Teissedre, P. L., & Glories, Y. Main routes of oxygen ingress through different closures into wine bottles. J. Agric Food Chem 2007, 55, 5167–5170. [Google Scholar]

- ISO 633 International Standard. Cork – Vocabulary (633), 2019.

- UNE 56921 Spanish Standard. Tapones de corcho natural para vinos tranquilos. Ensayos y especificaciones (56921), 2020, Ediciones AENOR.

- UNE-EN 12726 Spanish Standard Packaging - Cork mouth finish with a bore diameter of 18,5 mm for corks and tamper evident capsules (12726), 2018, Ediciones AENOR.

- Branco, D. G. , Santiago, C. A., Oliveira, F. J., Cabrita, L., &Evtuguin, D. V. Surface properties of cork in relation to reactive washing. Colloids Surf. A Physicochem. Eng. Asp 2021, 624, 126762. [Google Scholar]

- Villamor, R. R. , Harbertson, J. F., & Ross, C. F. Influence of Tannin Concentration, Storage Temperature, and Time on Chemical and Sensory Properties of Cabernet Sauvignon and Merlot Wines. Am. J. Enol. Vitic 2009, 60, 442–449. [Google Scholar]

- Gambuti, A. , Siani, T., Picariello, L., Rinaldi, A., Lisanti, M. T., Ugliano, M., Dieval, J. B., &Moio, L. (2017). Oxygen exposure of tannins-rich red wines during bottle aging. Influence on phenolics and color, astringency markers and sensory attributes. Eur. Food Res. Technol. 2017, 243, 669–680. [Google Scholar]

- Monagas, M. , Gómez-Cordovés, C., Bartolomé, B., & Anthocyanins, I. Evolution of polyphenols in red wines from Vitis vinifera L. during aging in the bottle. EurFood Res Technol 2005, 220, 607–614. [Google Scholar]

- Sánchez-Iglesias, M. , González-Sanjosé, M. L., Pérez-Magariño, S., Ortega-Heras, M., & González-Huerta, C. Effect of micro-oxygenation and wood type on the phenolic composition and color of an aged red wine. J. Agric Food Chem 2009, 57, 11498–11509. [Google Scholar]

- Puértolas, E. , Saldaña, G., Condón, S., Álvarez, I., & Raso, J. Evolution of polyphenolic compounds in red wine from Cabernet Sauvignon grapes processed by pulsed electric fields during aging in bottle. Food Chem. 2010, 119, 1063–1070. [Google Scholar]

- Peng, Z. P.G. Iland, A. Oberholzer, M.A. Sefton, and E.J. Waters. Analysis of pigmented polymers in red wine by reverse phase HPLC. Aust. J. Grape Wine Res. 2002, 8, 70–75. [Google Scholar] [CrossRef]

- Sommers, T. C. Pigment profiles of grapes and of wines. Vitis 1968, 7, 303–320. [Google Scholar]

- Saucier, C. , Little, D., & Glories, Y. First Evidence of Acetaldehyde-Flavanol Condensation Products in Red Wine. AJEV 1997, 48, 370–373. [Google Scholar]

- Tarko, T. , Duda-Chodak, A., Sroka, P., & Siuta, M. The impact of oxygen at various stages of vinification on the chemical composition and the antioxidant and sensory properties of white and red wines. Int. J. Food Sci. 2020, 2020. [Google Scholar]

- Coetzee, C. , & Du Toit, W. J. Sauvignon blanc wine: Contribution of ageing and oxygen on aromatic and non-aromatic compounds and sensory composition-A review. SAJEV 2015, 36, 347–365. [Google Scholar]

- Smith, P. A. , McRae, J. M., & Bindon, K. A. Impact of winemaking practices on the concentration and composition of tannins in red wine. Aust. J. Grape Wine Res. 2015, 21, 601–614. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).