Introduction

The authenticity of food products is increasingly difficult to track in an era of globalisation of the food supply chain. Consumers are often unable to assess the quality of food products that are produced in different regions of the world and are new to the local market. Food products are particularly exposed to adulteration, dilution or mislabelling. This is now a global problem with an extremely significant impact on the health and, increasingly, the lives of people. Equally important are the socio-economic implications of this practice. One such product is beer. Foreign brands of beer are widely available around the world and their authenticity can be difficult to establish. (Gwenzi et al., 2023; Kumar and Vaithiyanatha, 2023)

Poland has emerged as one of the world’s leading producers of beer. The Polish and global beer markets continue to expand dynamically.

Poland is the second largest producer of beer in the European Union (ec.europa.eu/eurostat) and seventh in the world (atlasbig.com), responsible for 28% of global beer production in the world (

www.barthhaas.com). It is worth to note that in the 1980s this share was 47% (Szajner, 2018).

The growing popularity of craft, artisan, regional and homebrew beer has contributed to a “beer revolution” in the last decade. Artisan beer is usually of higher quality than industrial beer. The basic ingredients in beer production are water, malt, hops and yeast. Some industrial beers are malt-free and contain various additives such as grain, syrup, sugar, hops essential oil, sulfur dioxide and carbon dioxide. Tannic acid, clarifiers, foam stabilizers and reducing agents are also used in the brewing process (Lewis and Young, 2001) The quality of the final product is determined by the applied technology and additives. The wide availability of production technologies and ingredients contributes to the diversity of beers on the global market. Reputable manufacturers go to great lengths to ensure that their products are safe and meet stringent quality requirements. However, food adulteration is a wide spread problem, and according to estimates, every food product in the world is falsified (Kowalczyk, 2014). Beer is one of the food products with the longest history of adulteration, and the earliest historical evidence of beer dilution dates back to the reigns of Hammurabi (Kowalczyk, 2014). At present, counterfeit food labels or the complete absence of food labeling are the most popular falsification methods which prevent products from being traced or tracked. Food falsification poses a growing problem around the world, which can be partly attributed to the lack of rapid, objective and non-destructive methods for tracing the products’ origin. The existing methods require specialist laboratory equipment and trained personnel.

Ultrasound methods play an important role in food testing. These techniques rely on differences in the propagation speed of ultrasound waves in various materials. Ultrasound is the vibration of particles around their equilibrium position at frequencies higher than the upper limit of human hearing, i.e. above 20 kHz to about 100 MHz. Ultrasound tests can be destructive or non-destructive. Tests performed at low frequencies (below 200 - 300 kHz) and high power density (above 10 - 1000 W cm-2) can modify or even damage cellular structures and are used in the manufacturing process. Non-destructive testing (NDT) uses higher frequencies (1 - 100 MHz) and lower power density (below 1 - 10 W cm-2), which protects the analysed materials from damage and aids diagnosis. (Kobus, et al. 2023; Kumar, et al., 2023; Kaczmarski and Lewicki, 2005; Wesołowski, et al., 2016a; Wesołowski et al., 2016b; Dolatowski, 1999; Dolatowski and Stasiak, 2012; Konopacka et al., 2015; Latoch, 2009; Twarda and Dolatowski, 2006; Witrowa-Rajchert, 2012; Sienkiewicz et al., 2017).

Materials and methods

Nine beers brewed in different production systems were analyzed: Tatra, Heineken and Warka produced by Grupa Żywiec SA, Tyskie produced by Kompania Piwowarska SA, Rycerz produced by the Gościszewo Brewery, Warmińskie Rewolucje produced by the Kormoran Brewery, and three homebrew beers, including Irish red ale (IRA) made by Piotr Starowicz, M.Sc., of the Department of Food Biochemistry of the University of Warmia and Mazury in Olsztyn, Pszeniczny Lager and Colorado IPA.

The test stand was composed of the Olympus Panametrics-NDT 5800PR ultrasonic pulser-receiver, two INCO M02 2L0*20C ultrasonic probes with longitudinal wave propagation at a frequency of 2 MHz, the Tektronix TDS 1012B oscilloscope, a PC and a custom-designed measuring module (

Figure 1).

The module was designed to maintain a constant distance between the probes of 48 mm, a constant temperature of the analyzed medium, and the coaxial position of the ultrasound probes. The time taken by the ultrasound beam to penetrate the medium was measured. For this purpose, the “zero crossing” method was adopted, based on measurement of ultrasound travel time from the transmitting probe to the receiving probe.

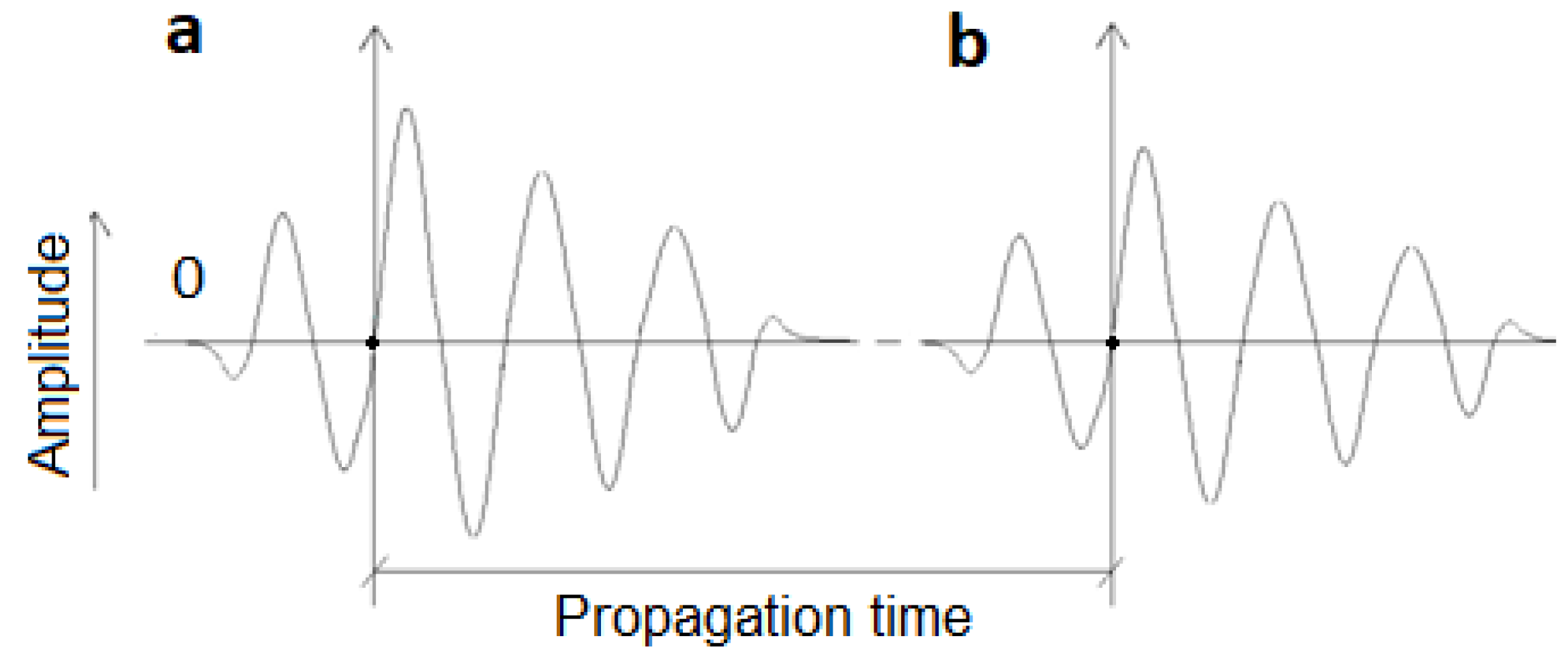

Figure 2 shows schematics of the method used. This is illustrated by the two waveforms presented. The points of reference were the places where the rising edge of the signal at the peak with the maximum amplitude crosses the zero axis on the transmitting and receiving sides.

The distance between the two points of intersection with the 0 axis indicates the transition time t, the value of which was used to determine the speed of ultrasound propagation characteristic for various materials.

Beer was poured into the measuring chamber, and ultrasound reflection time was displayed on the oscilloscope screen (

Figure 3).

The measurements were performed in 9 replications for each of the tested beers. Beer temperature was maintained at 17±1°C. The propagation speed of ultrasound waves in the analyzed medium was determined with formula (1) on the assumption that the velocity of ultrasonic vibration is constant over a short distance.

where: v – propagation speed of ultrasound waves, s – distance between ultrasonic probes [m], t – ultrasound transmission time through the medium [s].

The results were processed statistically in the Statistica 13.1 program (Stat Soft Inc., USA). The non-parametric Kruskal-Wallis test was applied to analyze data with non-normal distribution at a significance level of p (α)≤0.05.

Results and discussion

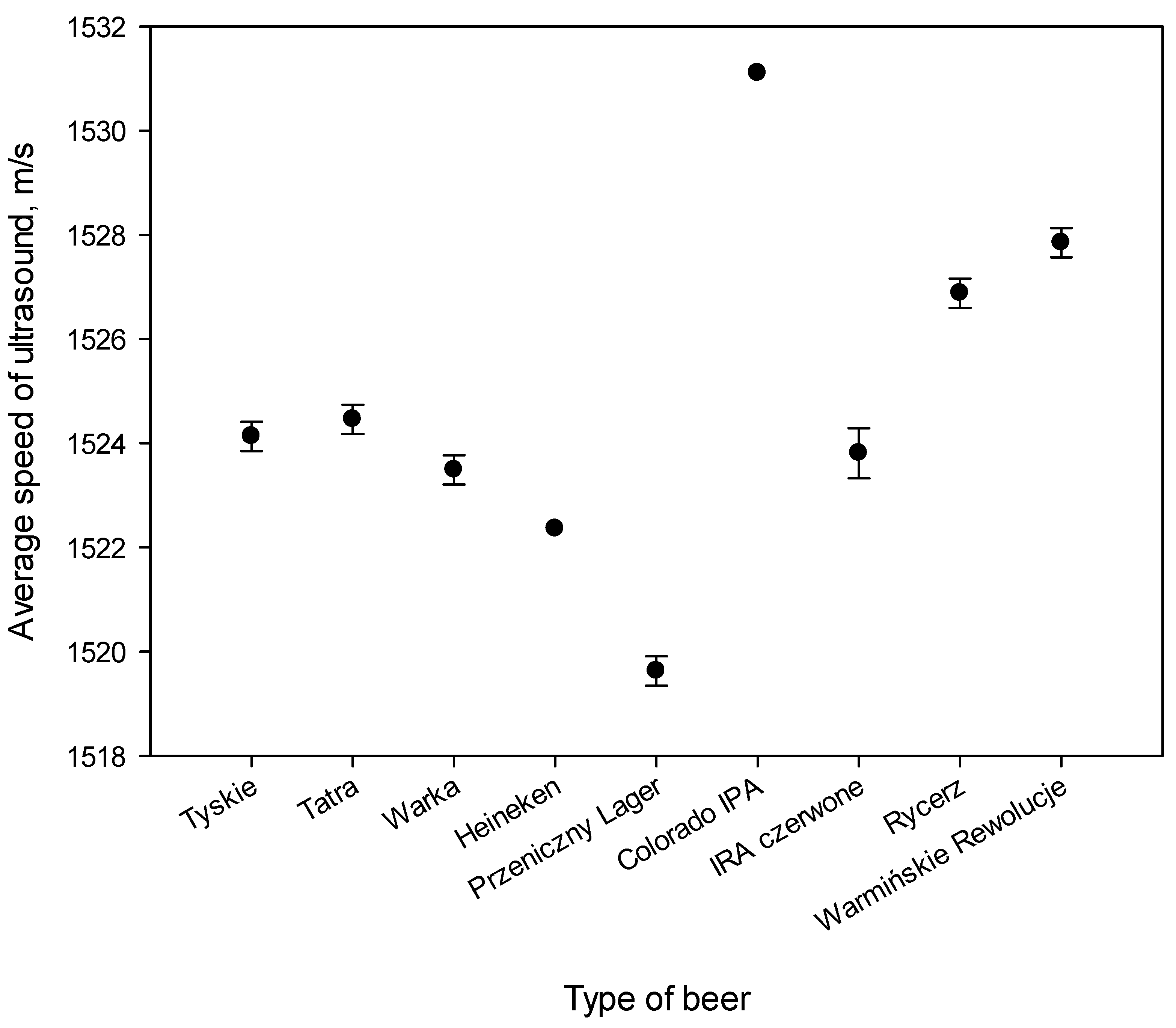

The calculated ultrasound velocity is presented graphically in

Figure 4.

The average propagation speed of ultrasound waves did not differ significantly in industrial beers (Warka, Tyskie, Tatra, Heineken) and was determined in the range of 1522.0±0.0 m s-1 to 1524.5±0.3 m s-1.

No significant differences were observed between regional beers (Warmińskie Rewolucje and Rycerz), either. In these media, propagation speed ranged from 1526.9±0.3 m s-1 to 1527.9±0.3 m s-1. Ultrasound propagation speeds differed significantly in homebrew beers and were determined at 1519.6±0.3 m s-1 in Pszeniczny Lager, 1523.8±0.5 m s-1 in Irish red ale, and 1531.0±0.0 m s-1 in Colorado IPA.

The results of the study indicate that non-destructive ultrasound measurements support the identification of various types of beer. Industrial beers were characterized by similar acoustic parameters and were successfully distinguished from regional beers with the use of ultrasound waves. The average ultrasound propagation speed in Tyskie, Tatra and Warka was 1524.03±0.49 m s-1. A minor but significant difference was noted only in Heineken beer, where average propagation speed was determined at 1522.36±0.36 m s-1. The above difference could be attributed to variations in production technology. Tyskie, Tatra and Warka are brewed according to traditional Polish recipes, whereas Heineken is produced under a Dutch license. Regional beers did not differ significantly in ultrasound propagation speed which was determined at 1527.29±0.80 m s-1 on average. There are no published data on the use of ultrasonic methods for discriminating different beer brands and types. Ultrasounds have been successfully applied to identify turkey meat and pork (Nowak, 2015)

Novoa-Dìaz et al. (2014) proposed an ultrasonic method for monitoring red wine ageing (Tempranillo, Spain). Ratajski et al. (2013) demonstrated the applicability of ultrasound testing for identifying selected types of honey (rapeseed and mixed flower honey). Ultrasonic measurements were also successfully deployed to test the ripeness of Cheddar and Mahón cheese (Benedito et al., 2002) as well as Manchego cheese (Benedito et al., 2005)

Conclusion

The presented non-destructive ultrasonic method supported the discrimination of industrial beers from beers manufactured in regional breweries. The results of this study indicate that beers can be effectively identified based on the average propagation speed of ultrasound waves. However, homebrew beer is produced with the involvement of various techniques, and the applicability of ultrasound tests for discriminating homebrew beers from industrial and regional beers cannot be reliably assessed based on our findings.

Acknowledgment

We would like to thank Professor Krystyna Skibniewska for valuable advice and support during the research and their description.

References

- Benedito, J., Carcel, J. A., Gonzalez, R., Mulet, A. (2002). Application of low intensity ultrasonics to cheese manufacturing processes. Ultrasonics, 40, 19-23. [CrossRef]

- Benedito, J., Simal, S., Clemente, G., Mulet, A. (2005). Manchego cheese texture evaluation by ultrasonics and surface probes. International Dairy Journal, 16, 431-438. [CrossRef]

- Dolatowski, Z.J. (1999). Wpływ obróbki ultradźwiękami o niskiej częstotliwości na strukturę i cechy jakościowe

mięsa. Lublin: Rozprawy naukowe AR.

- Dolatowski, Z.J., Stasiak, D.M. (2012). Czystość mikrobiologiczna mięsa i szynki parzonej po obróbce ultradźwiękowej. Technologia Alimentaria, 1(1), 55-65.

- Gwenzi, W., Makuvara, Z., Marumure, J., Simbanegavi, T. T., Mukonza, S. S., & Chaukura, N. (2023). Chicanery in the food supply chain! Food fraud, mitigation, and research needs in low-income countries. Trends in Food Science & Technology 136, 194-223. [CrossRef]

- Kaczmarski, Ł.K., Lewicki, P.P. (2005). Zastosowanie technik ultradźwiękowych w przetwarzaniu żywności. Przemysł Spożywczy, 9, 34-36.

- Kobus, Z., Osmólska, E., Starek-Wójcicka, A., Krzywicka M. (2023). Effect of High-Powered Ultrasound on Bioactive Compounds and Microbiological Stability of Juices - Review. Applied Science, 13(19). 10961. [CrossRef]

- Konopacka, D., Płocharski, W., Siucińska, K. (2015). Możliwości zastosowania ultradźwięków w przemyśle owocowo-warzywnym. Przemysł Fermentacyjny i Owocowo-Warzywny, 4, 16-20.

- Kowalczyk S. Prawo czystej żywności. Od Kodeksu Hammurabiego do Codex Alimentarius. Oficyna Wydawnicza SGH, Warszawa 2014.

- Kumar, G., Le, D.T., Durco, J., Cianciosi, S., Devkota, L., Dhital S. (2023). Innovations in legume processing: Ultrasound-based strategies for enhanced legume hydration and processing. Trends in Food Science and Technology, 104122. [CrossRef]

- Kumar, N.A., Vaithiyanathan, S. (2023). Authentication issues in foods of animal origin and advanced molecular techniques for identification and vulnerability assessment. Trends in Food Science & Technology, 138, 164-177. [CrossRef]

- Latoch, A. (2009). Właściwości miofibryli sonifikowanego mięsa wieprzowego o obniżonej jakości. Żywność. Nauka. Technologia. Jakość, 1(62), 140 – 149.

- Lewis, M. J., Young, T. Piwowarstwo. Wydawnictwo Naukowe PWN. Warszawa 2001.

- Novoa-Diaz, D., Rodriguez-Nogales, J.M., Fernandez-Fernandez, E., Vila-Crespo, J., Garcia-Alvarez, J., Amer, M.A., Chavez, J.A., Turo, A., Garcia-Hernandez, M.J., Salazar, J. (2014). Ultrasonic monitoring of malolactic fermentation in red wines. Ultrasonics, 54, 1575-1580. [CrossRef]

- Nowak, K.W. (2015). Identification of meat types by ultrasonic methods. Technical Sciences, 18(2), 79-84.

- Ratajski, A., Białobrzewski, I., Dajnowiec, F., Bakier, S. (2013). The use of ultrasonic methods In the identification of honey types. Technical Sciences, 13, 22-29.

- Sienkiewicz, J. J., Wesołowski, A., Kotowski, R., Stankiewicz, W. (2017). The influence of ultrasonic treatment on the growth of the strains of Salmonella enterica subs. Typhimurium. Journal of Food Science and Technology, 54(8), 2214-2223. [CrossRef]

- Szajner, P. (2018). Ewolucja światowego rynku piwa. Zeszyty Naukowe SGGW, Problemy rolnictwa światowego, 18(4), 60-68. [CrossRef]

- Twarda, J., Dolatowski, Z. J. (2006). Wpływ sonifikacji mięsa na dynamikę ubytku wody w procesie liofilizacji. Inżynieria Rolnicza, 7, 415-421.

- Wesołowski, A., Siemianowska, E., Skibniewska, K. A., Sienkiewicz, J. (2016a). Ultradźwięki – alternatywna technika badania i przetwarzania żywności. Przemysł Spożywczy, 9(70), 36-38.

- Wesołowski, A., Siemianowska, E., Sienkiewicz, J., Barszcz, A.A., Kolankowska, E., Anders, A. (2016b). Niekonwencjonalna metoda identyfikowalności żywności, Zeszyty Naukowe WSES w Ostrołęce, 21, 192-202.

- Witrowa-Rajchert, D. (2012). Ultradźwięki w produkcji żywności projektowanej. Przemysł Spożywczy 66, 41-43.

- Websites: atlasbig.com. Obtained from: https://www.atlasbig.com/en-us/countries-by-beer-production. [Accessed 12.03.2023].

- ec.europa.eu/eurostat. Obtained from: www. https://ec.europa.eu/eurostat/en/web/products-eurostat-news/-/ddn-20220830-1. [Accessed 12.03.2023].

- www.barthhaas.com. Obtained from: https://www.barthhaas.com. [Accessed 12.03.2023].

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).