Submitted:

29 November 2023

Posted:

30 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

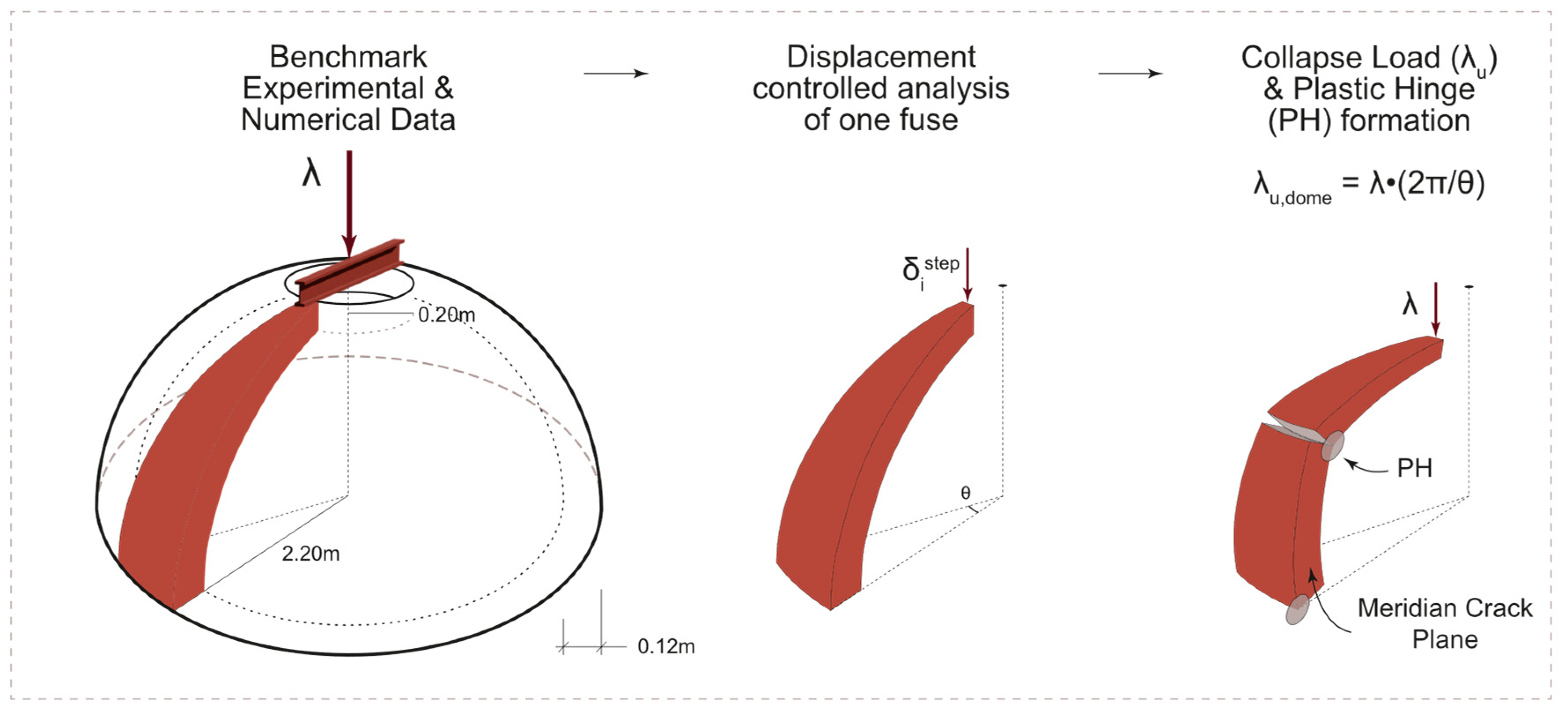

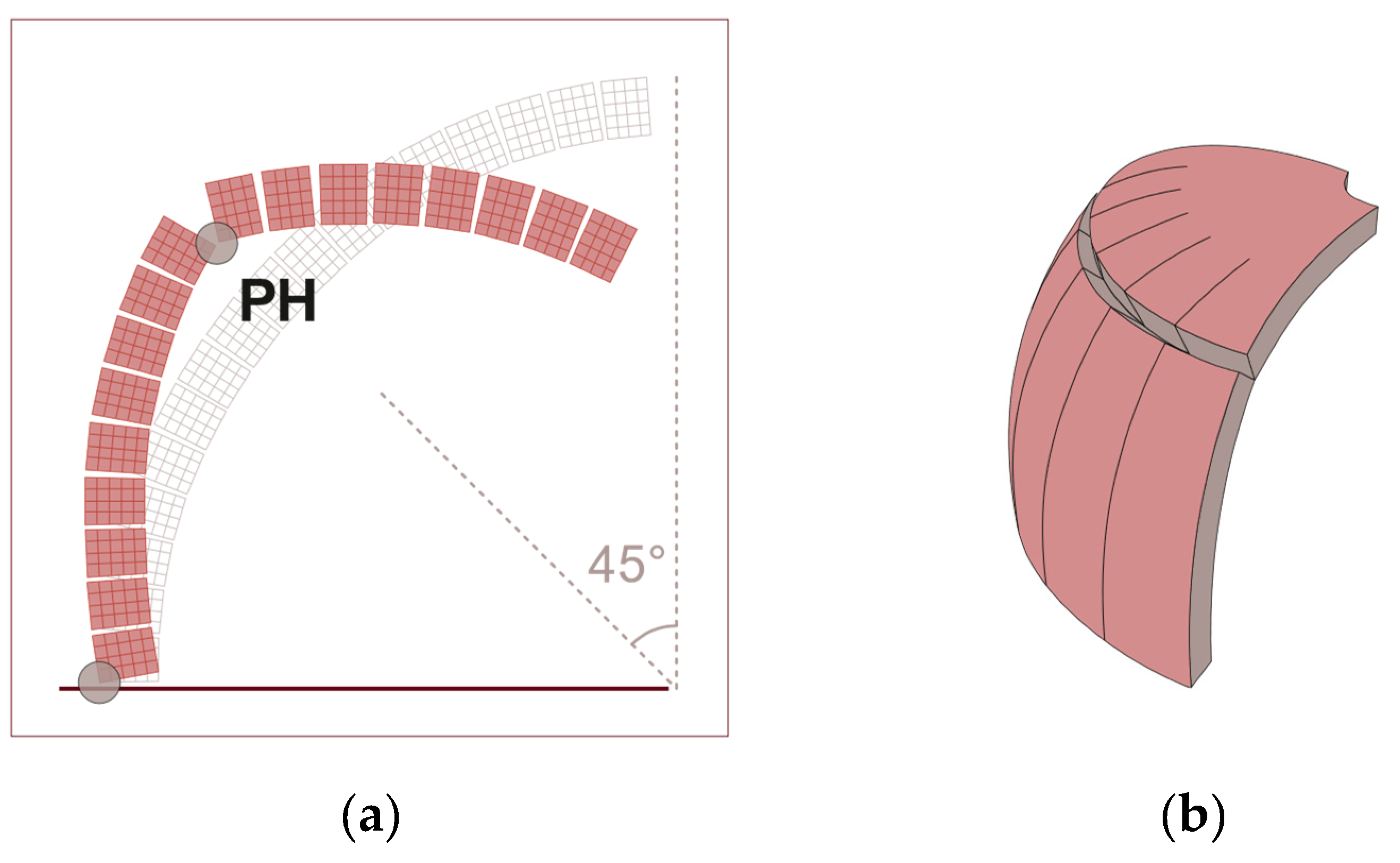

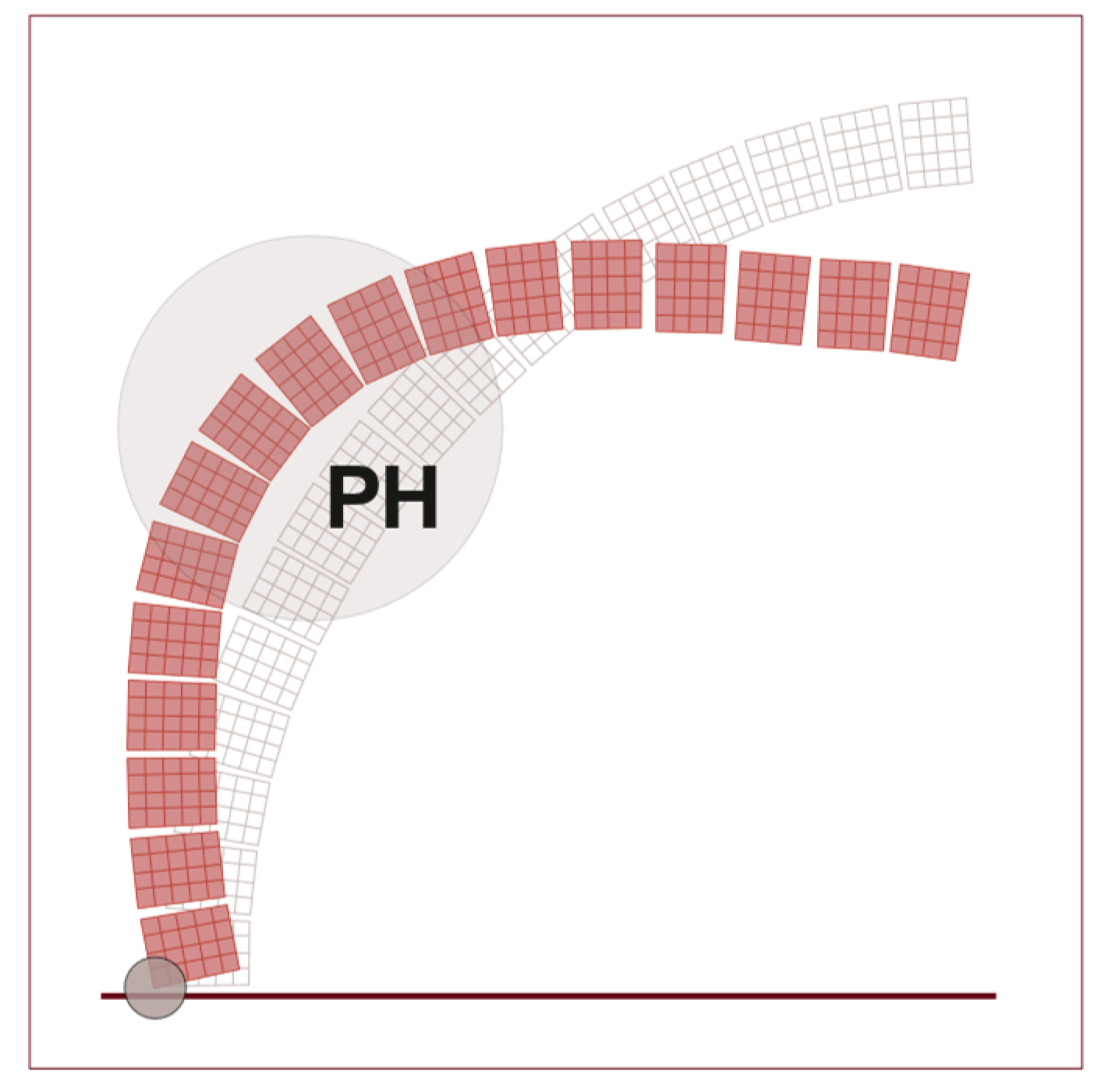

1. FE Modelling

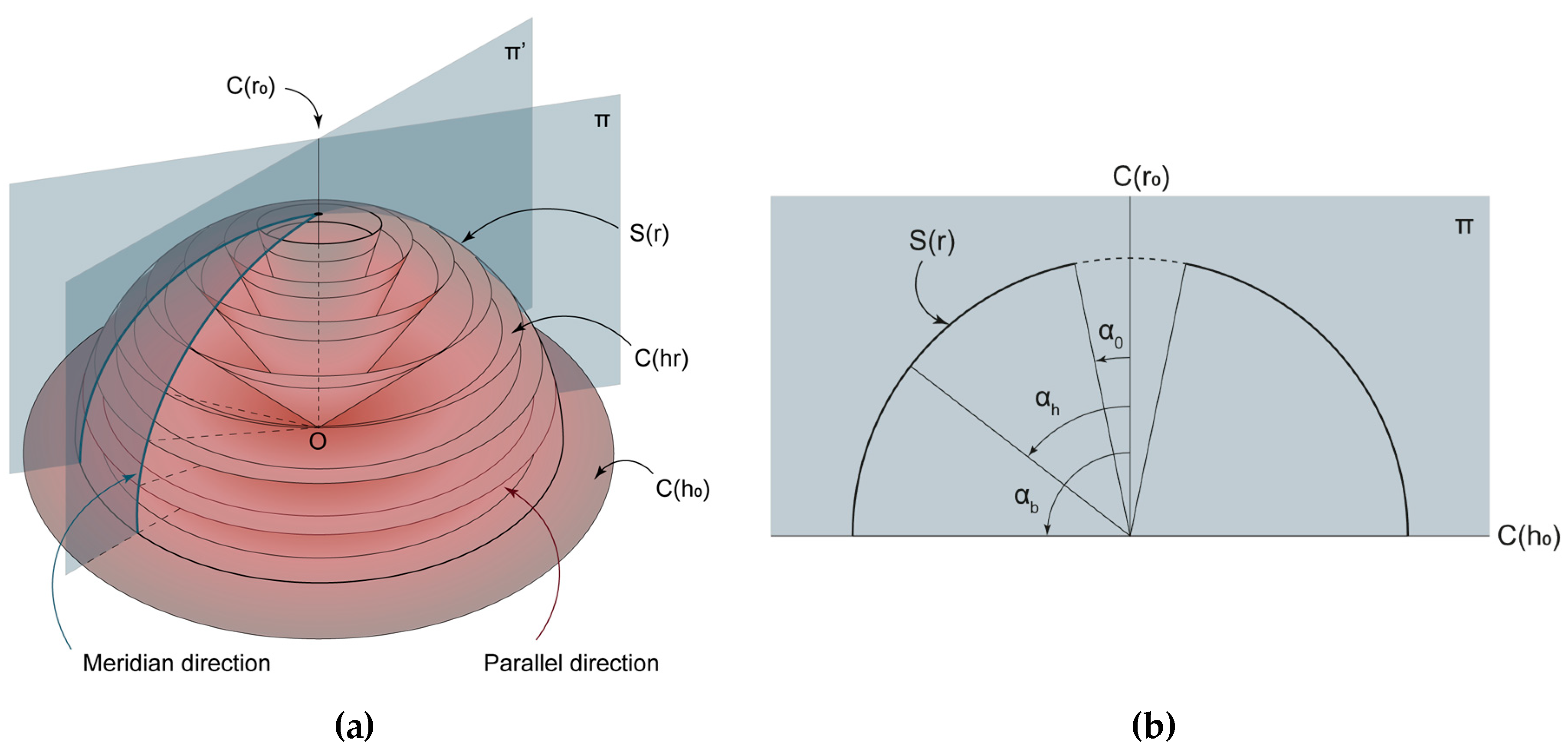

1.1. Modelling for Nonlinear Analysis

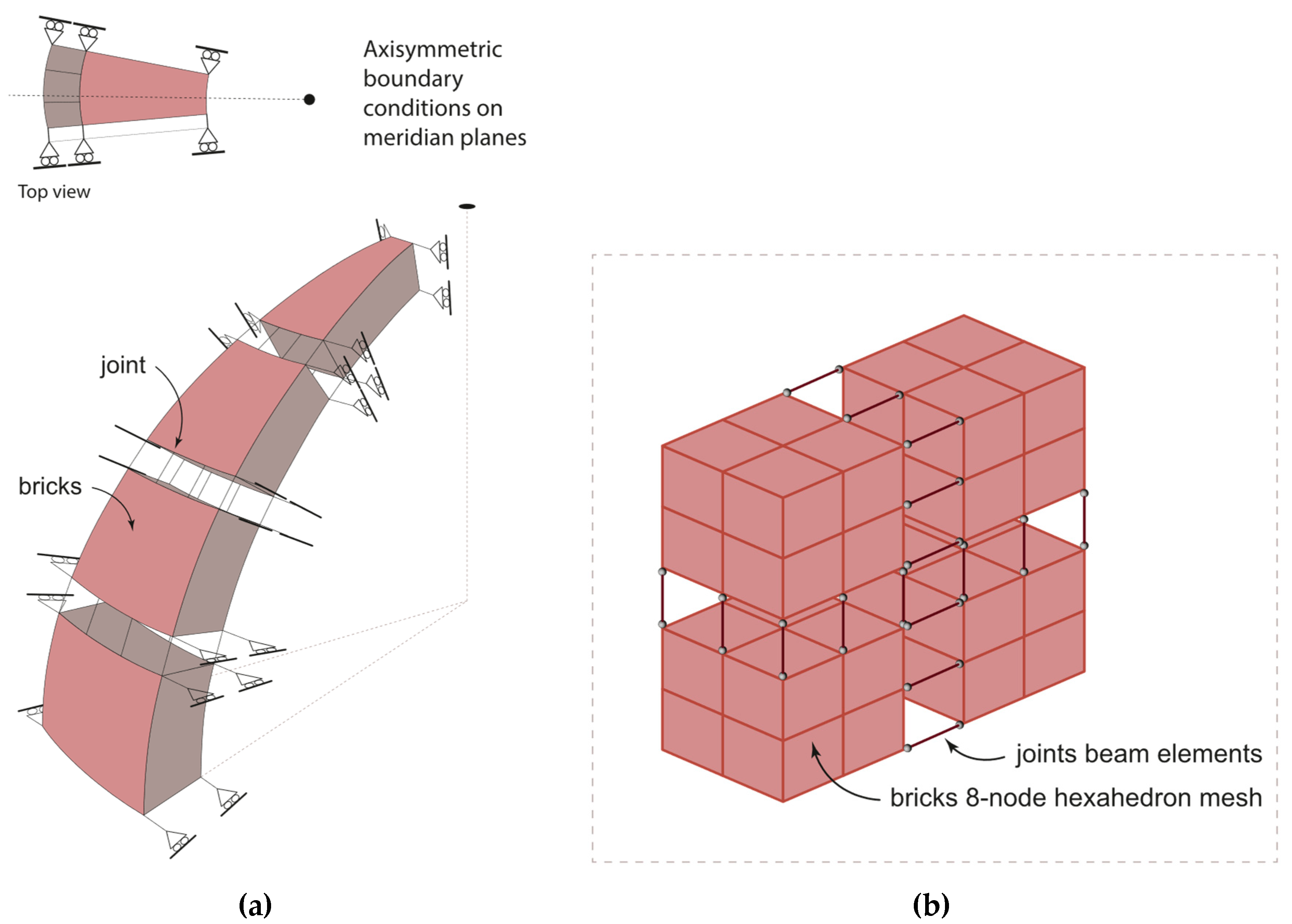

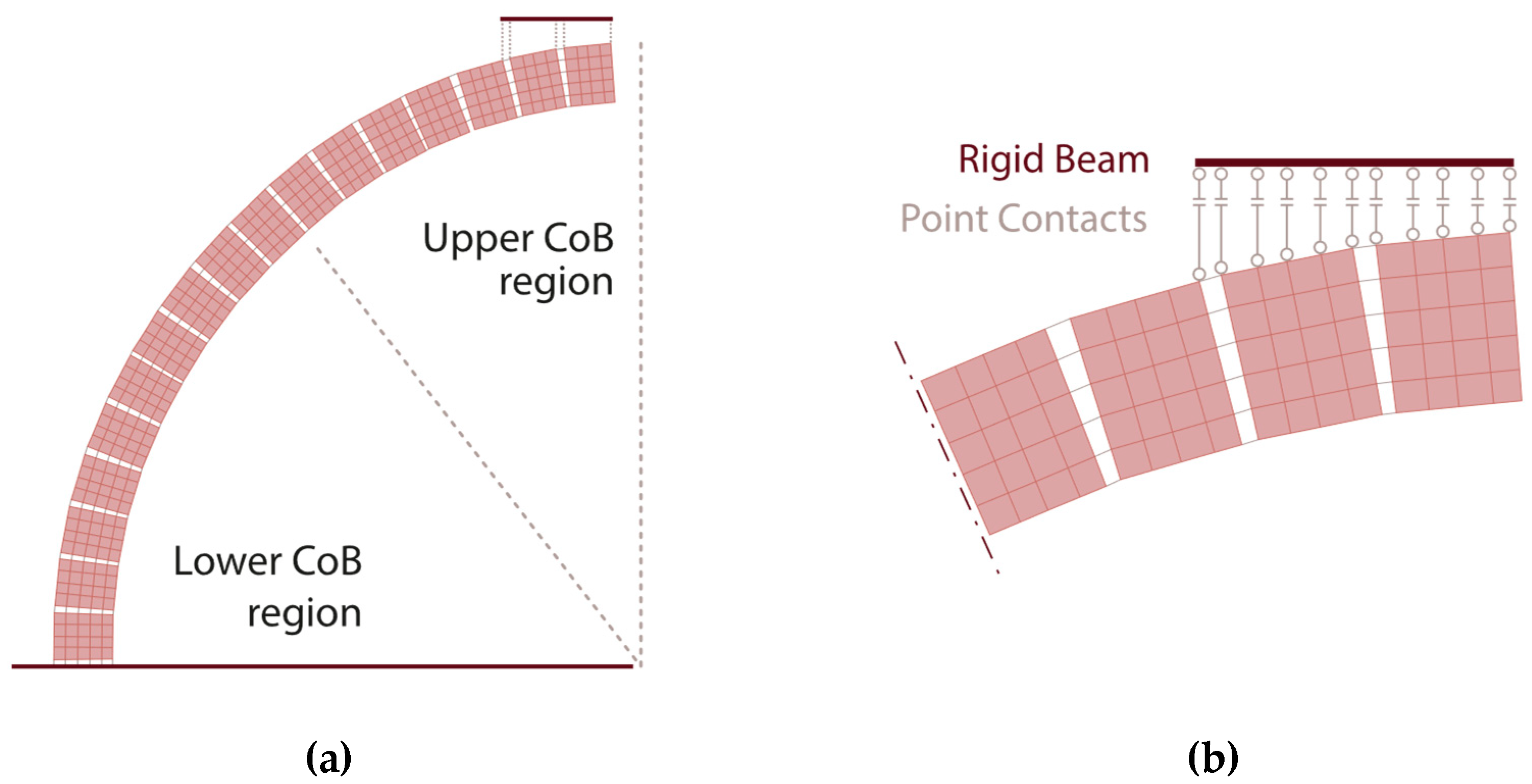

1.2. Modelling of Joints by Means of Point Contacts

2.3. Load Distribution

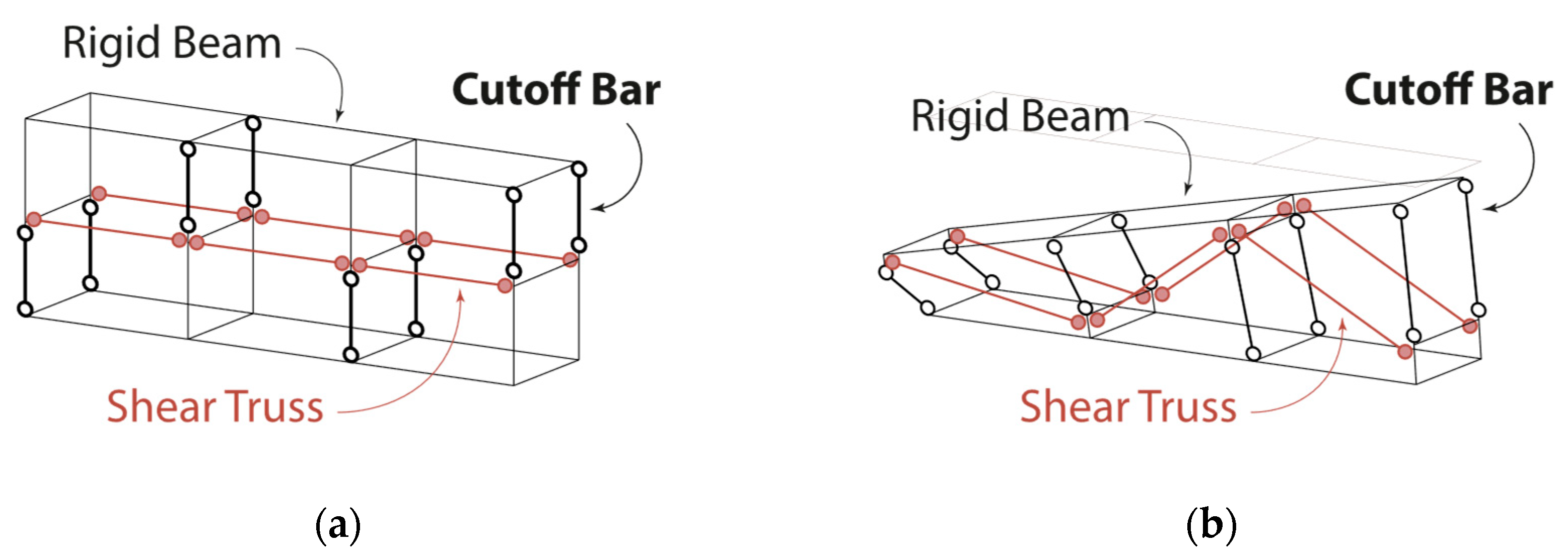

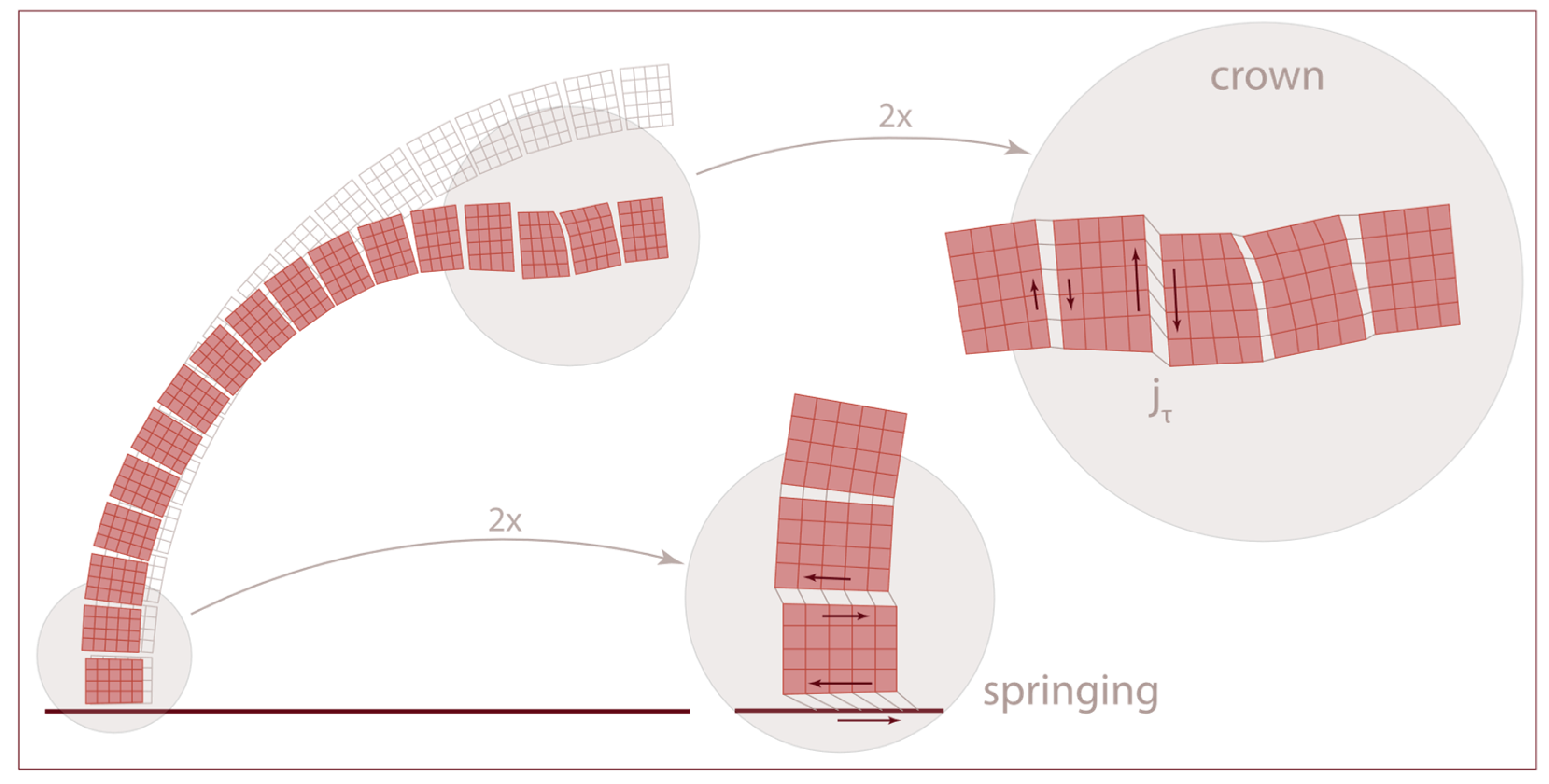

2.4. Modelling of Joints by Means of Cutoff Bars

2.4.1. Joint Modelling

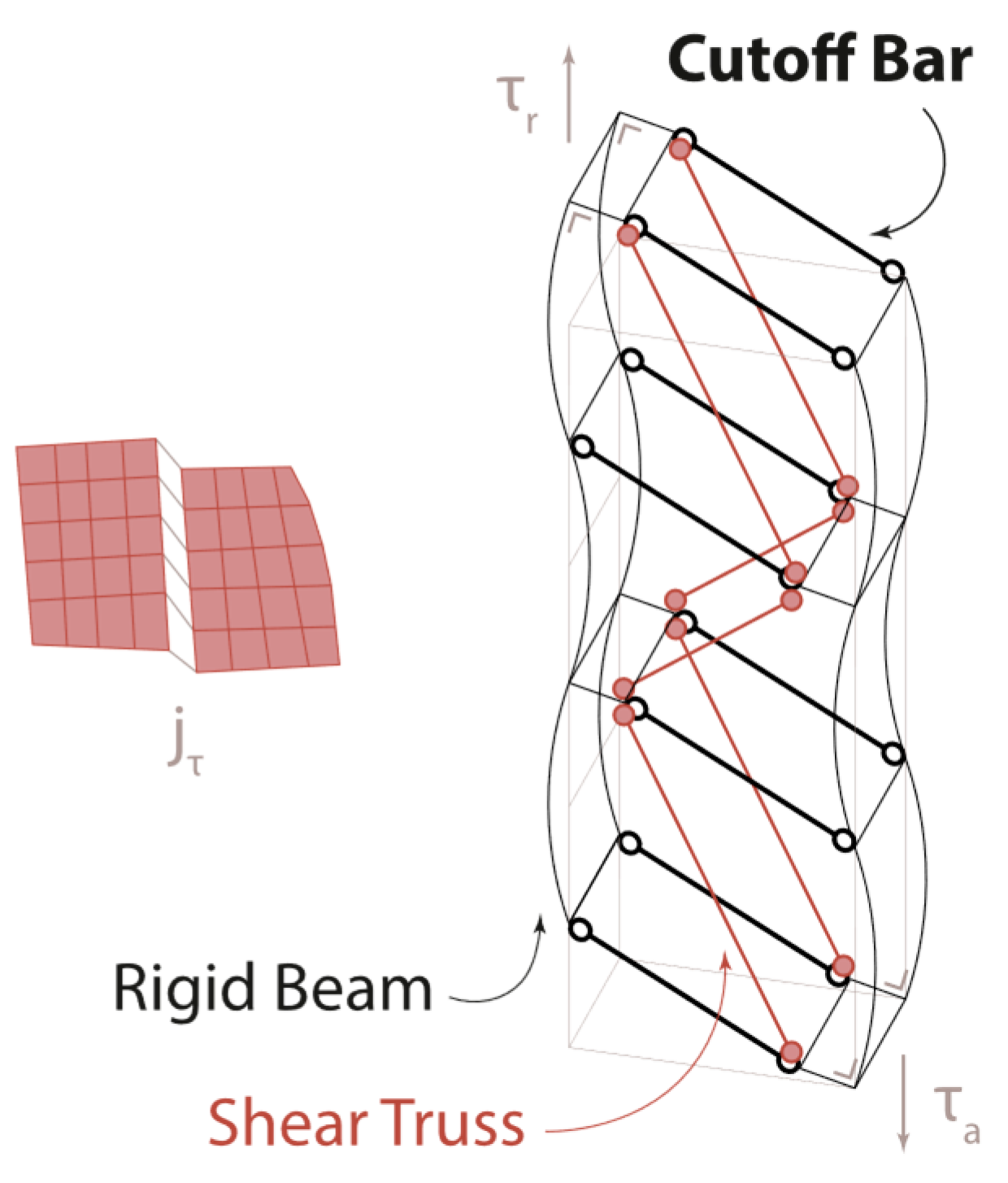

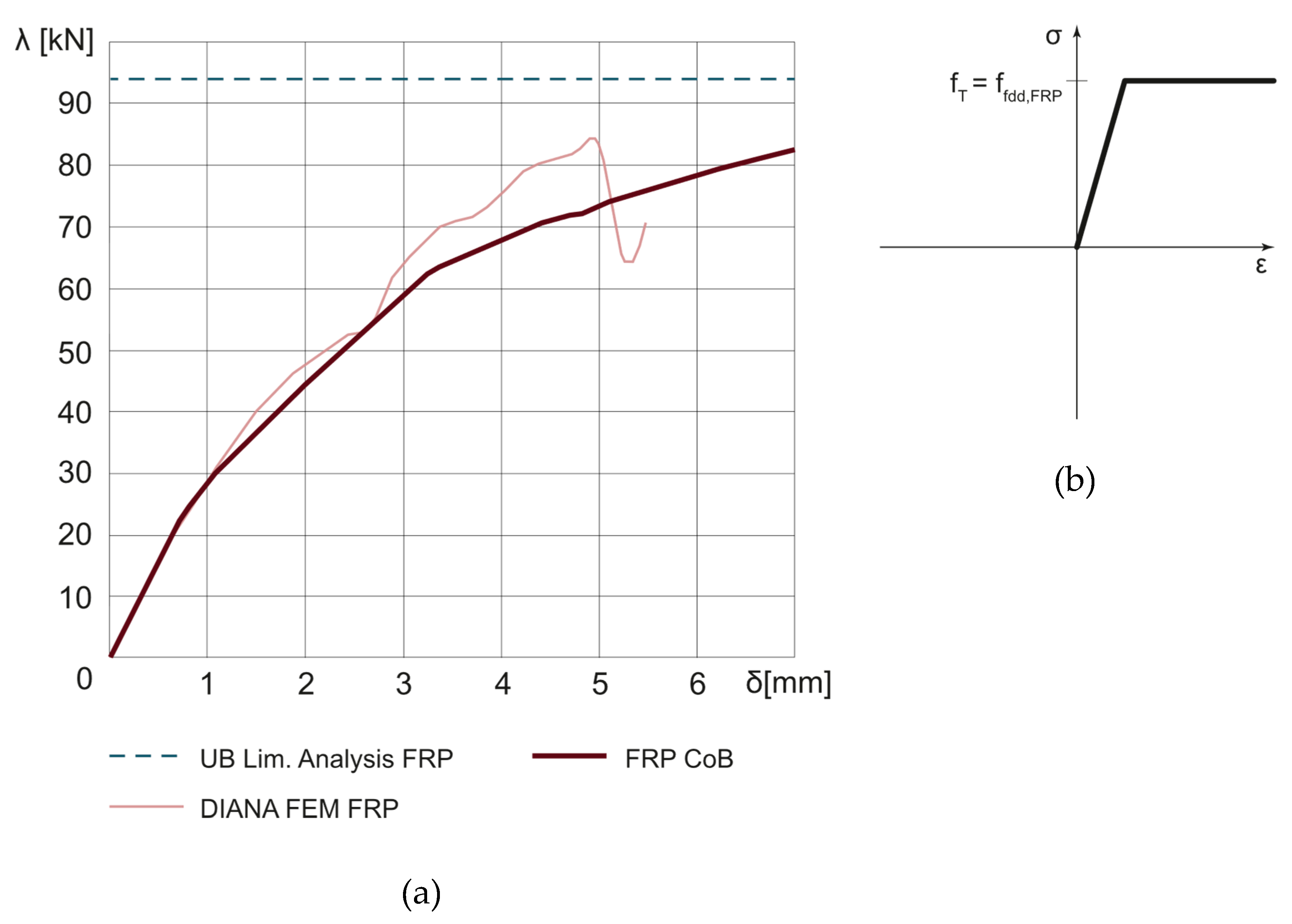

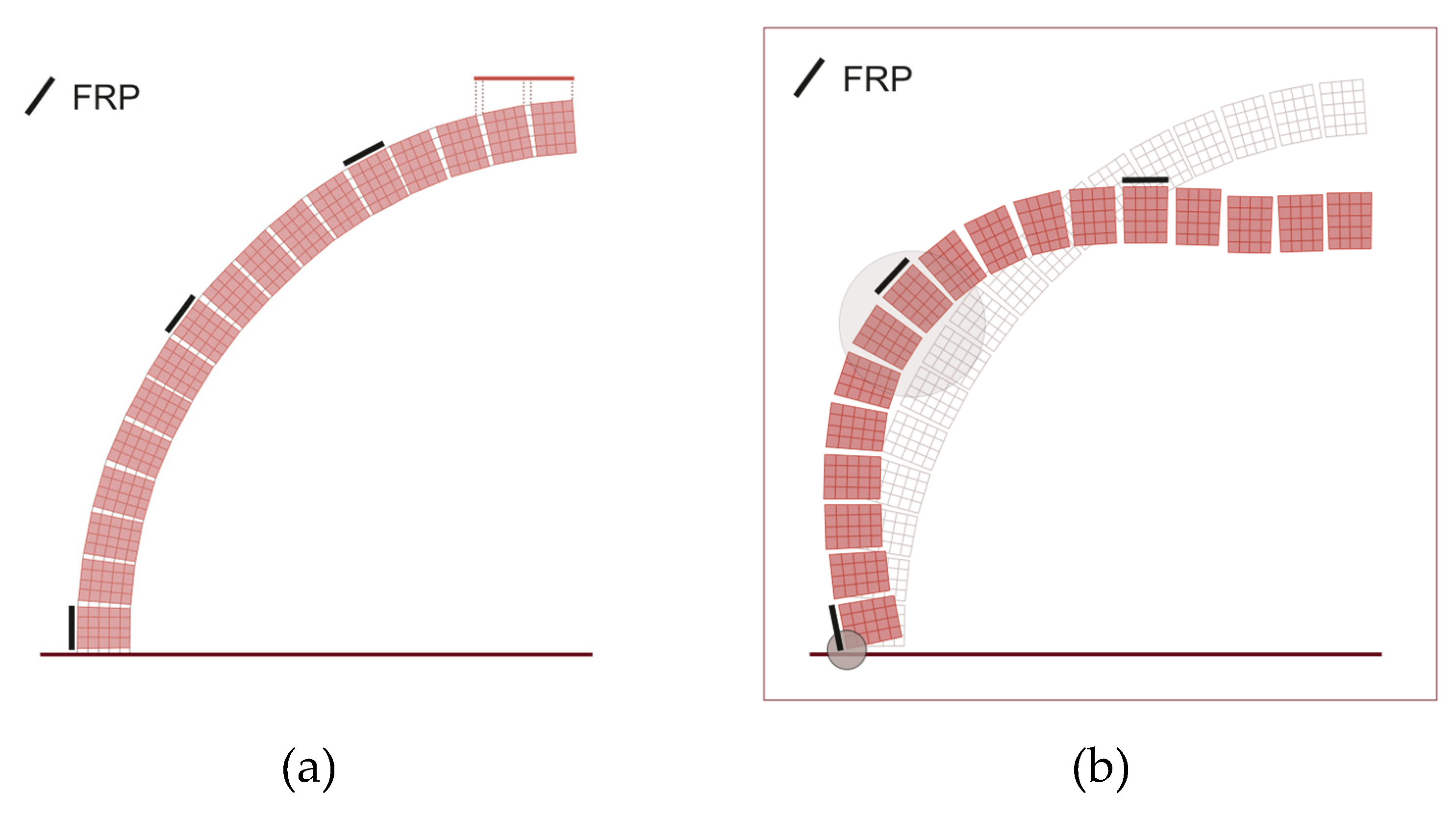

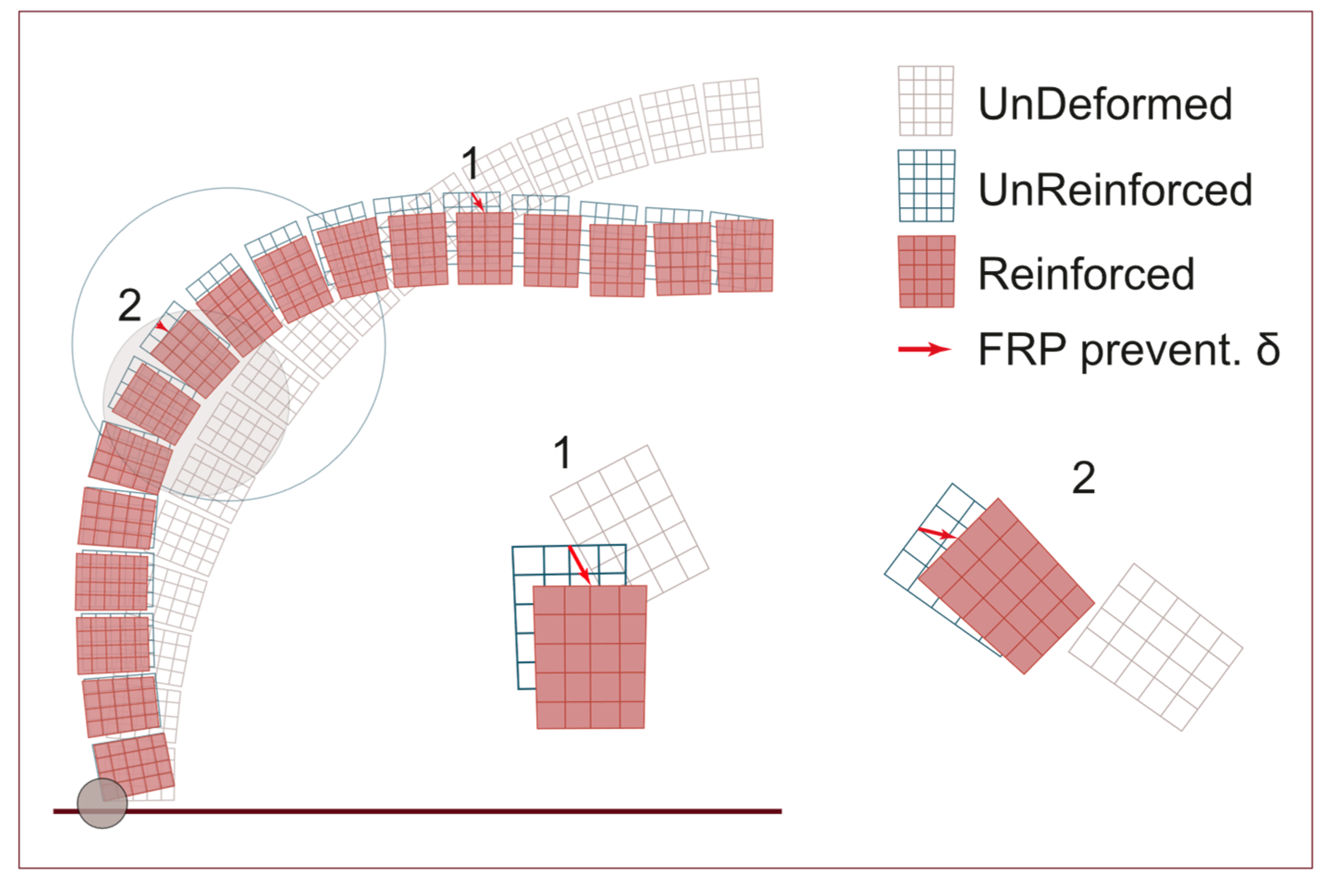

2.5. Modelling of FRP by Means of Cutoff Bars

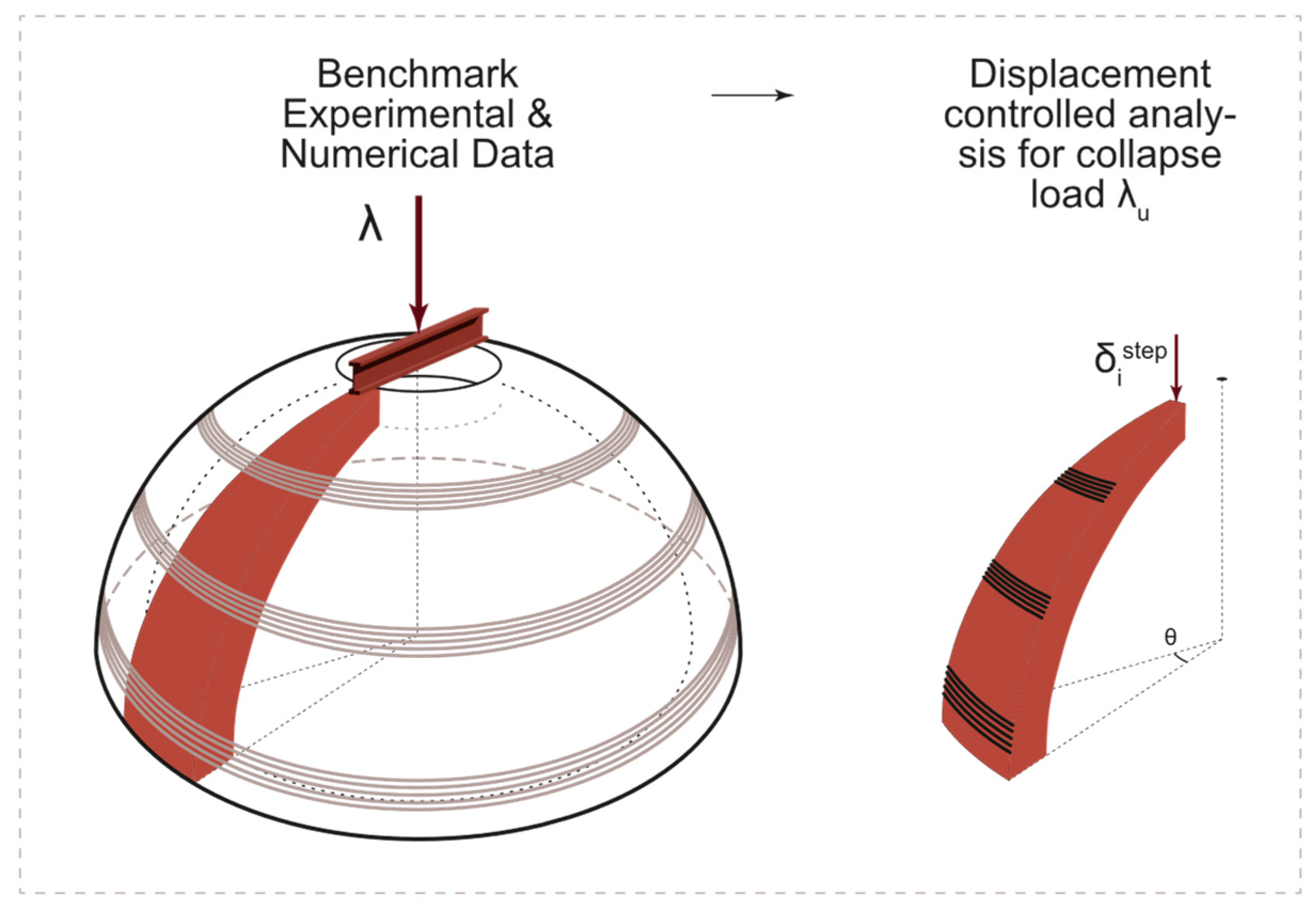

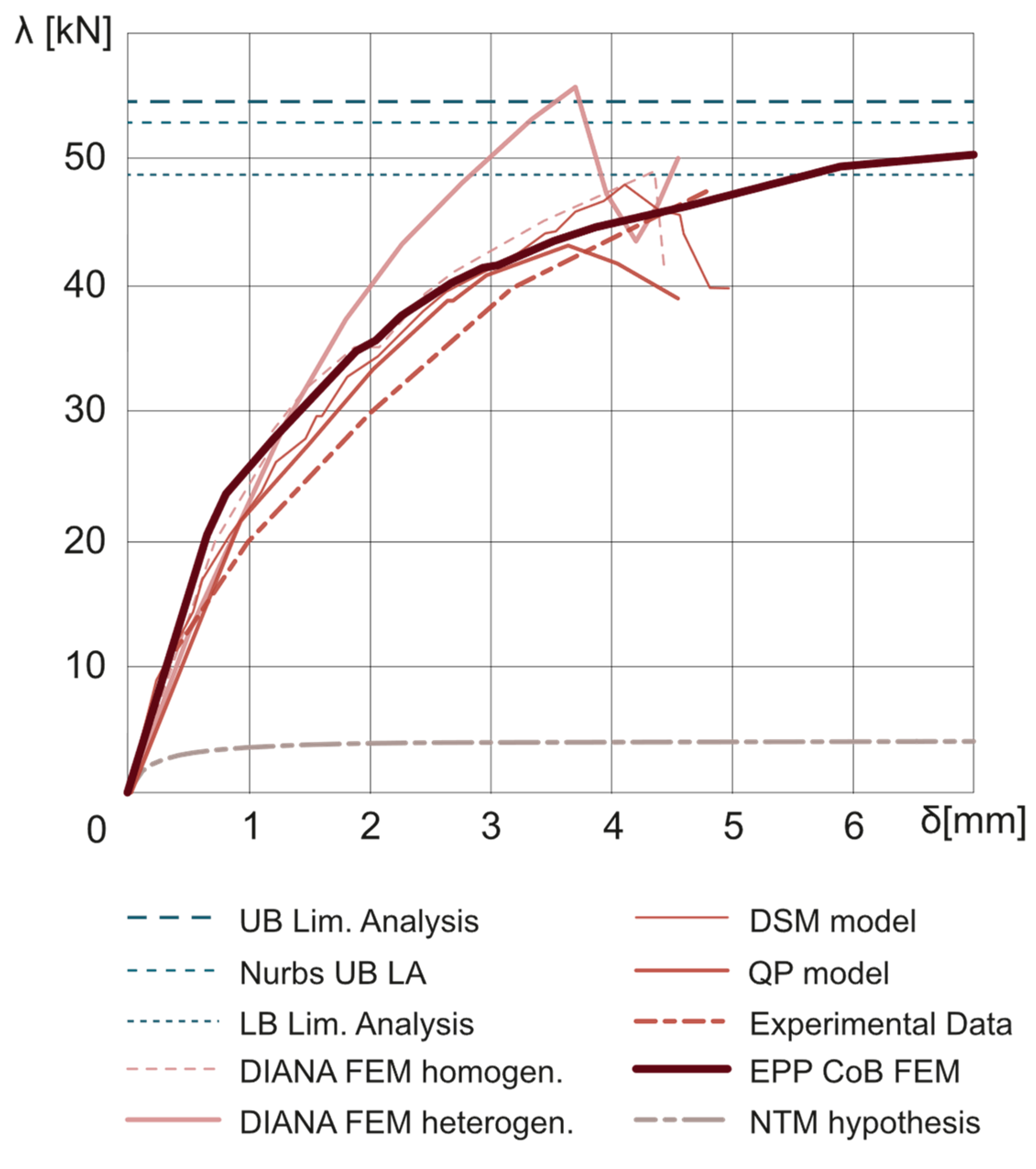

3. Non-Linear Static Analyses

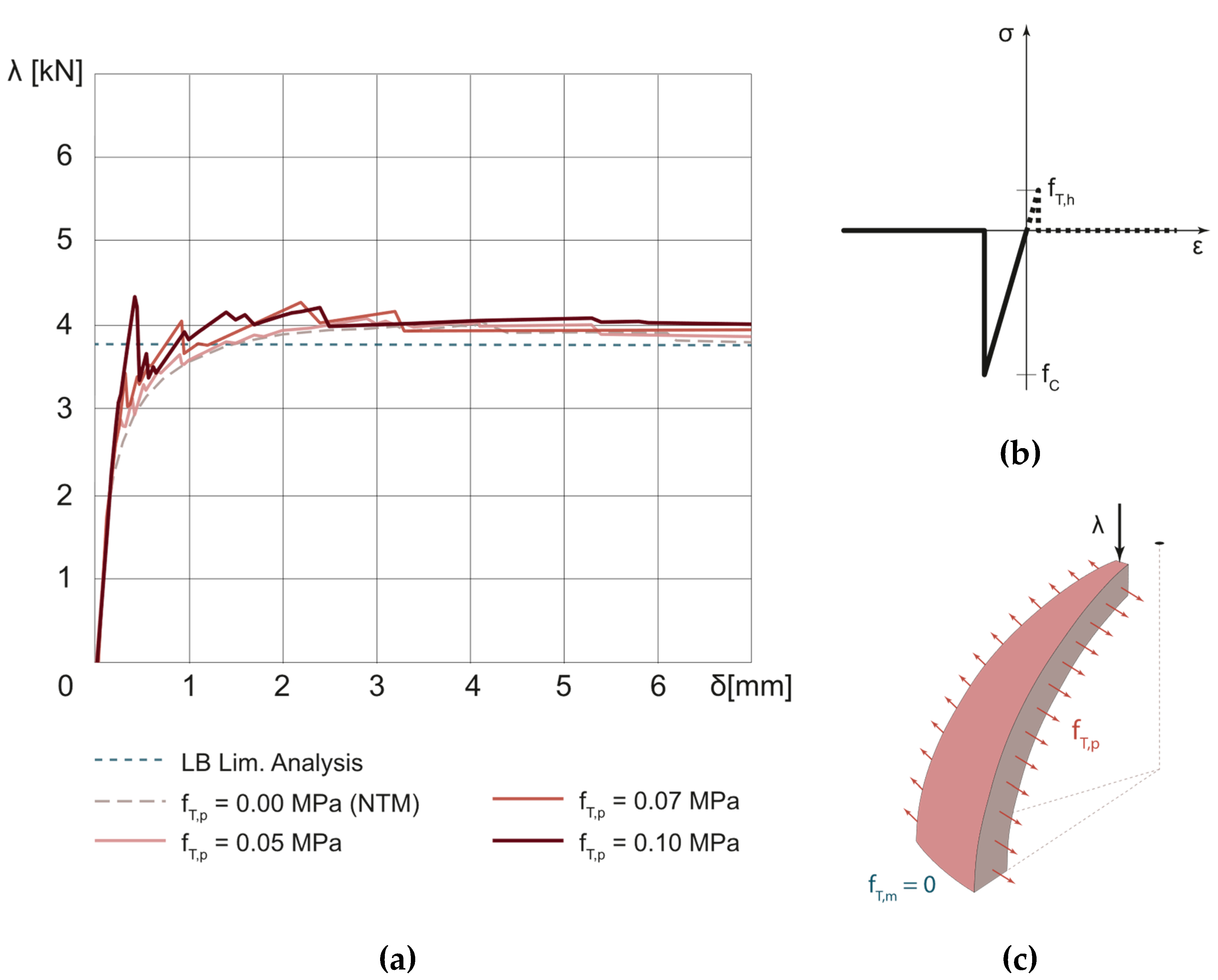

3.4. Unreinforced Dome

3.4.1. NTM hypothesis: Sensitivity Analysis

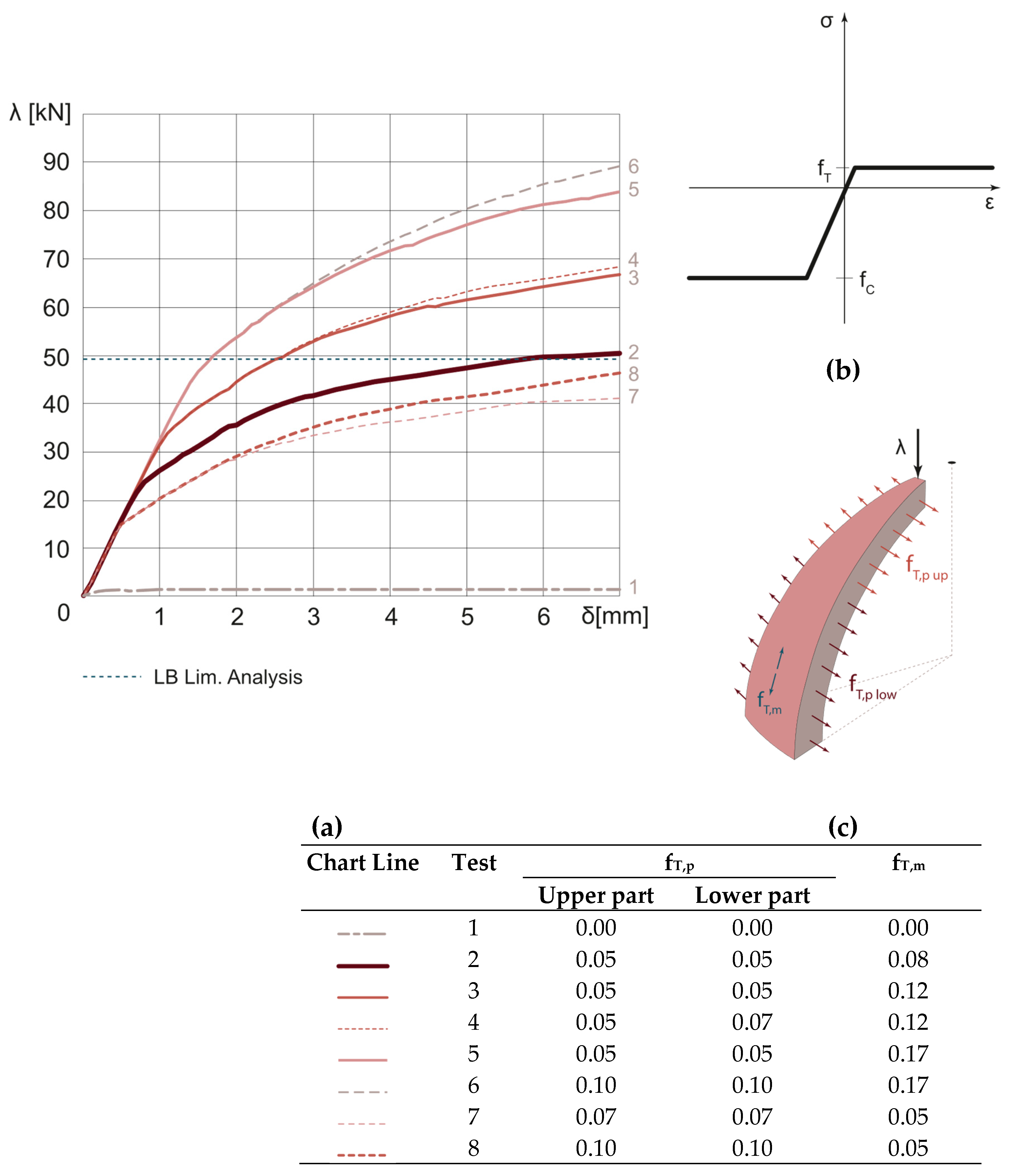

3.1.2. Orthotropic Material: Sensitivity Analysis

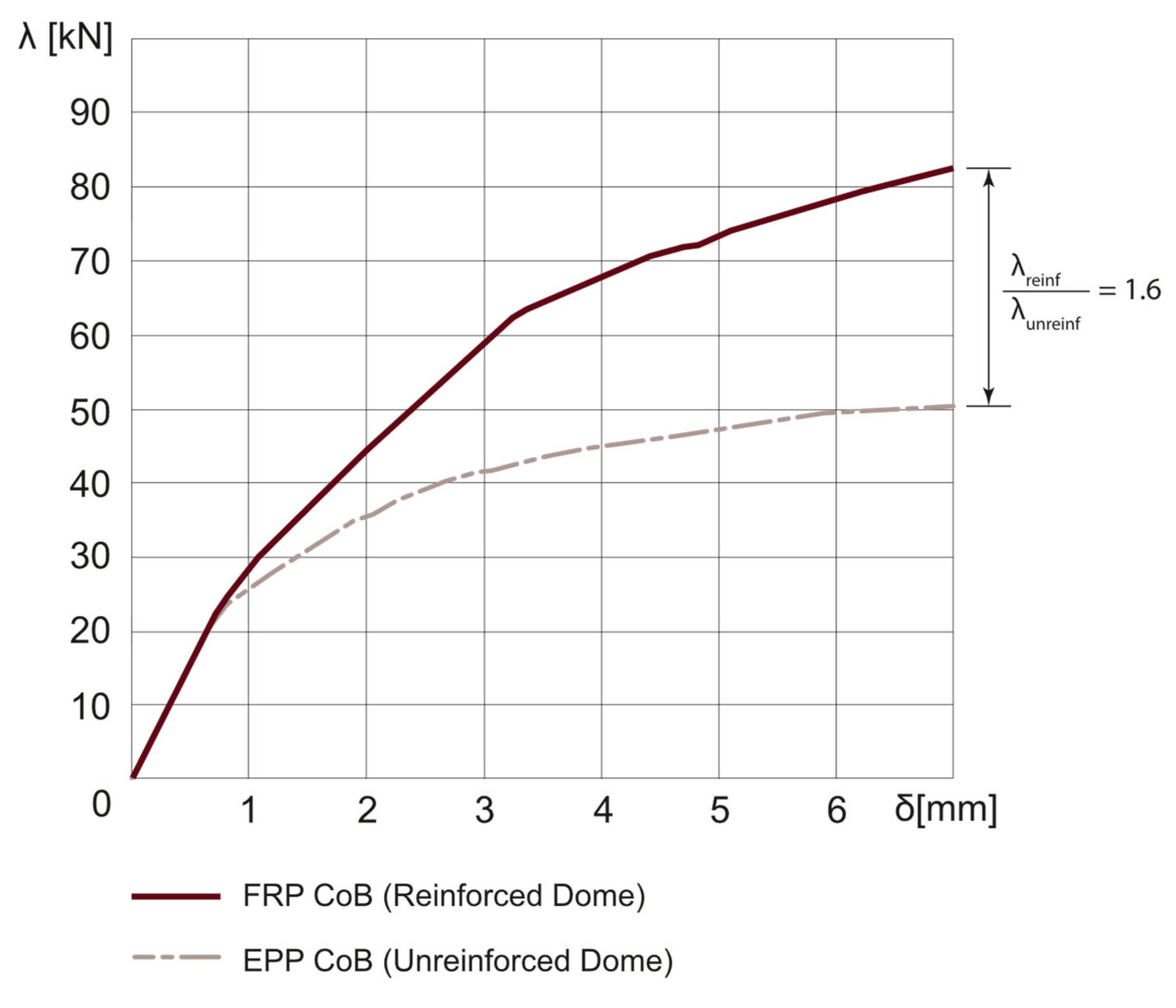

3.2. Reinforced Dome

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- A. Tralli, C. Alessandri, and G. Milani, “Computational Methods for Masonry Vaults: A Review of Recent Results,” The Open Civil Engineering Journal, vol. 8, no. 1, pp. 272–287, 2014. [CrossRef]

- J. Heyman, The Stone Skeleton. 1996.

- D. Aita, G. Milani, and A. Taliercio, “Limit analysis of masonry domes with oculus and lantern: a comparison between different approaches,” Mathematics and Mechanics of Solids, 2023. In press.

- S. Szabó, M. F. Funari, and P. B. Lourenço, “Masonry patterns’ influence on the damage assessment of URM walls: Current and future trends,” Developments in the Built Environment, vol. 13, no. January, 2023. [CrossRef]

- P. Faccio, P. Foraboschi, and E. Siviero, “Masonry vaults reinforced with FPR strips,” L’Edilizia, vol. 7, pp. 44–50, 1999.

- P. Foraboschi, “Strengthening of Masonry Arches with Fiber-Reinforced Polymer Strips,” Journal of Composites for Construction, vol. 8, no. 3, pp. 191–202, 2004. [CrossRef]

- G. Creazza, A. V. Saetta, R. Matteazzi, and R. V. Vitaliani, “Analyses of masonry vaulted structures by using 3-D damage model,” European Congress on Computational Methods in Applied Sciences and Engineering, ECCOMAS 2000, no. September, pp. 11–14, 2000.

- P. B. Lourenço, R. De Borst, and J. G. Rots, “A plane stress softening plasticity model for orthotropic materials,” Int J Numer Methods Eng, vol. 40, no. 21, pp. 4033–4057, 1997. [CrossRef]

- G. Milani, “Simple lower bound limit analysis model for masonry double curvature structures,” Comput Struct, vol. 269, p. 106831, 2022. [CrossRef]

- A. Chiozzi, G. Milani, and A. Tralli, “A Genetic Algorithm NURBS-based new approach for fast kinematic limit analysis of masonry vaults,” Comput Struct, vol. 182, pp. 187–204, 2017. [CrossRef]

- G. Milani, E. Milani, and A. Tralli, “Upper bound limit analysis model for FRP-reinforced masonry curved structures. Part II: Structural analyses,” Comput Struct, vol. 87, no. 23–24, pp. 1534–1558, 2009. [CrossRef]

- G. Milani, “Homogenized limit analysis of FRP-reinforced masonry walls out-of-plane loaded,” Comput Mech, vol. 43, no. 5, pp. 617–639, 2009. [CrossRef]

- E. Milani, G. Milani, and A. Tralli, “Limit analysis of masonry vaults by means of curved shell finite elements and homogenization,” Int J Solids Struct, vol. 45, no. 20, pp. 5258–5288, 2008. [CrossRef]

- G. Milani, “Closed form solutions in Limit Analysis for masonry cloister vaults and domes subjected to concentrated vertical loads applied at the top crown,” International Journal of Masonry Research and Innovation.

- N. R. Varma, “Global Vipassana Pagoda : Main features and history of construction,” 2023.

- M. N. Varma and S. Ghosh, “Finite element thrust line analysis of axisymmetric masonry domes,” International Journal of Masonry Research and Innovation, vol. 1, no. 1, pp. 59–73, 2016. [CrossRef]

- M. Varma et al., “Global Vipassana Pagoda : Finite Element Thrust Line FETLA analyses,” pp. 1–6, 2023.

- M. Pavlovic, E. Reccia, and A. Cecchi, “A Procedure to Investigate the Collapse Behavior of Masonry Domes: Some Meaningful Cases,” International Journal of Architectural Heritage, vol. 10, no. 1, pp. 67–83, 2016.

- M. Como, “Equilibrium and collapse analysis of masonry bodies,” Meccanica, vol. 27, no. 3, pp. 185–194, 1992.

- P. Block and J. Ochsendorf, “Thrust network analysis: A new methodology for three-dimensional equilibrium,” Journal of the International Association for Shell and Spatial Structures, vol. 48, no. 155, pp. 167–173, 2007.

- M. Varma, G. Milani, and S. Ghosh, “Finite element thrust line analysis of cracked axisymmetric masonry domes reinforced with tension rings,” International Journal of Masonry Research and Innovation 3(1), pp. 72–78, 2018. [CrossRef]

- N. Pingaro and G. Milani, “Simple non-linear numerical modelling of masonry arches reinforced with SRG using elasto-fragile and elasto-ductile truss finite elements,” Eng Struct, vol. 293, no. July, p. 116637, 2023. [CrossRef]

- J. Heyman, Arches, vaults and buttresses: masonry structures and their engineering. Variorum Ashgate Publishing, 1996.

- J. Heyman, “The safety of masonry arches,” Int J Mech Sci, vol. 11, no. 4, pp. 363–385, Apr. 1969. [CrossRef]

- A. Tralli, A. Chiozzi, N. Grillanda, and G. Milani, “Masonry structures in the presence of foundation settlements and unilateral contact problems,” Int J Solids Struct, vol. 191–192, pp. 187–201, 2020. [CrossRef]

- G. Fichera, “Elastostatic problems with unilateral constraints: the Signorini problem with ambigous boundary conditions (in Italian),” 1964.

- G. Fichera, “Boundary Value Problems of Elasticity with Unilateral Constraints,” in Linear Theories of Elasticity and Thermoelasticity, T. C., Ed., Springer, Berlin, Heidelberg, 1973.

- Strand7 Pty Ltd., Theoretical Manual. Theoretical backgrund to the Straus7 finite element analysis system. 2004.

- M. N. Varma, R. S. Jangid, and V. G. Achwal, “Tension Ring in Masonry Domes,” pp. 1–8, 2006.

- CNR-DT 200 R1/2013, “Istruzioni per la Progettazione, l’Esecuzione ed il Controllo di Interventi di Consolidamento Statico mediante l’utilizzo di Compositi Fibrorinforzati Materiali, strutture di c.a. e di c.a.p., strutture murarie,” 2013.

- E. Grande, G. Milani, and E. Sacco, “Modelling and analysis of FRP-strengthened masonry panels,” Eng Struct, vol. 30, no. 7, pp. 1842–1860, 2008. [CrossRef]

- D. Aita, R. Barsotti, and S. Bennati, “Collapse of masonry arches in Romanesque and Gothic constructions,” 2007. [Online]. Available: https://www.researchgate.net/publication/276205523.

- G. Milani and A. Tralli, “A simple meso-macro model based on SQP for the non-linear analysis of masonry double curvature structures,” Int J Solids Struct, vol. 49, no. 5, pp. 808–834, 2012. [CrossRef]

- N. Pingaro, A. S. Calabrese, G. Milani, and C. Poggi, “Debonding sawtooth analytical model and FE implementation with in-house experimental validation for SRG-strengthened joints subjected to direct shear,” Compos Struct, vol. 319, no. March, p. 117113, 2023. [CrossRef]

- G. Milani, “Simple model with in-parallel elasto-fragile trusses to characterize debonding on FRP-reinforced flat substrates,” Compos Struct, vol. 296, no. February, p. 115874, 2022. [CrossRef]

- E. Bertolesi, G. Milani, and R. Fedele, “Fast and reliable non-linear heterogeneous FE approach for the analysis of FRP-reinforced masonry arches,” Compos B Eng, vol. 88, pp. 189–200, 2016. [CrossRef]

| Mechanical Properties | u.m. | ||

|---|---|---|---|

| Young’s Modulus | E | 1.7 ∙ 103 | MPa |

| Poisson Ratio | ν | 0 | - |

| Density | ρ | 2.0 ∙ 10-6 | Kg ∙ mm-3 |

| Nonlinear Type | Elastic Plastic | ||

| Yield Criterion | Von Mieses |

| Joint | Position | Type |

Friction Coefficients |

Stiffness Values |

||

| C1 | C2 |

Initial k0 [kN∙mm-1] |

Initial kiter | |||

| Parallel | IN OUT |

Tension Tension |

- - |

- - |

61.2 30.6 |

- - |

| Meridian | IN OUT |

Normal Normal |

1 1 |

1 1 |

93.84 46.92 |

✓ ✓ |

| Mechanical Properties | u.m. | ||

|---|---|---|---|

| Rigid Beams (Load Plate) | |||

| Young’s Modulus | E | 1.7 ∙ 108 | MPa |

| Section Area | A | 100 | mm2 |

| I11 = I22 | I | 8.33 ∙ 102 | mm4 |

| Point Contact | |||

| Type | Tension | ||

| Initial Stiffness | K0 | 1.0 ∙ 103 | kN ∙ mm-1 |

| Max Tension | Tmax | 0 | kN |

| Mechanical Properties | u.m. | ||

|---|---|---|---|

| Rigid Beams (Joints) | |||

| Young’s Modulus | E | 1.0 ∙ 103 | MPa |

| Section Area | A | 100 | mm2 |

| I11 = I22 | I | 8.33 ∙ 102 | mm4 |

| Inertia | J | 1.41 ∙ 103 | mm4 |

| Shear Truss (CoB) | |||

| Young’s Modulus | E | 1.7 ∙ 104 | MPa |

| Initial Stiffness | K0 | 1.00 | mm2 |

| Max Compression | Cmax | 1.0 ∙ 1011 | kN |

| Max Tension | Tmax | 1.0 ∙ 1011 | kN |

| CFRP Properties | u.m. | ||

|---|---|---|---|

| Thickness | tfibre | 0.2 | mm |

| Young’s Modulus | EFRP | 1.6 ∙ 105 | MPa |

| Factor c1 | c1 | 0.015 | - |

| Reducing code factor | γfd | 1.2 | - |

| Masonry partial safety factor | γM | 1 | - |

| Fracture Energy | ΓFK | 0.073 | N ∙ mm-1 |

| Design Bond Strength | ffdd | 164 | MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).