Introduction

Milkfish (Chanos chanos), locally called Bangus in the Philippines, is a popular food fish in many Southeast Asian countries, and is considered a top fish commodity in terms of production and consumption in the Philippines (Jaikumar et al., 2013; Macusi et al., 2021). On average, the total milkfish production has increased by 85% for the past 20 years, with 416,315 metric tons (MT) volume of production in 2020 or 18% of overall fisheries production contributing around PhP 43.5 billion to country’s Gross Domestic Product (GDP) (PSA, 2020). Moreover, about 10% of the per capita consumption of fish among Filipino households is milkfish (BFAR, 2020).

Aquaculture provides a sustainable way to supply this species of high demand (Dey et al., 2005). In fact, milkfish represents a top aquaculture commodity with a 13% total production share (Tahiluddin and Terzi, 2021), it is easy to culture and grows in a wide range of environments (Samson, 1984). Milkfish is also known for its adaptability to different water conditions and ability to consume a wide range of natural food sources, including algae epiphytic algae and bottom-living cyanobacteria, plankton masses, eating juvenile sardines and anchovies, copepods, small shrimps, and a variety of other zooplankton (Bagarinao, 1999). It can be cultured in brackish water, freshwater lakes, estuarine areas, and coastal marine waters using various culture systems like ponds, pens, and cages (Yap, 2007). Milkfish can tolerate temperature range of 20 0 C up to 41 0 C and a salinity level of freshwater to marine water (Jaikumar et al., 2013). Adult milkfish spawn at sea, their larvae migrate inshore, and juveniles settle in shallow-water habitats, and large juveniles and sub-adults return to sea but little is documented on their actual movements (Bagarinao, 1999). In the Philippines, culture of milkfish has been traditionally done through earthen ponds in brackish water, but also near lakes or rives and lately, the production has moved away from the traditional culture to floating fish cages in coastal marine waters (Gaitan et al., 2014). The culture systems vary from extensive pond culture, and semi-intensive systems with supplementary feeding, to more intensive cage culture in marine or freshwater environments. With the rapid growth of aquaculture, successive growth of milkfish aquaculture production has reached 13,398.77 MT in 2019, 16,527.34 MT in 2020 and 20,143.08 MT in 2021, valued at approximately Php 1.5 billion in 2019, Php 1.71 billion in 2020 and Php 2.46 billion in 2021 in Davao region (PSA, 2022). The rapid growth in aquaculture has been attributed to farmers’ innovative cultural practices, experiences, technical trainings and expanding area of mariculture in Davao region. Apart from a general study on milkfish value chain in the Philippines (Salayo et al., 2020) and vulnerability to climate change impacts (Macusi et al., 2021), there are no updated literature dealing with current farming practices, feed utilization, technical and social challenges in production or operation and cost benefit analysis of a typical milkfish farm operation in the province. While the milkfish value chain study plots the volume of needed fry, shows the land, labor and capital requirement for milkfish aquaculture and the actors involved in the industry, it fails to provide attention to actual details of the day-to-day farming operation including labor relations and typical challenges. This study will examine the current milkfish industry operation in the Davao region.

While typical farming operation in mariculture includes feeding and open exchange of water, excess nutrients are accumulated in bottom sediments in farmed areas, overtime, the accumulated nutrients disperse near beaches affecting water quality, livability and causes marine pollution (Abreo et al., 2015; Avenido et al., 2023; Shahidul Islam and Tanaka, 2004). These are serious issues that are consequences of the aquaculture industry. In intensive aquaculture, such as milkfish farming in cages, resources such as feeds, bamboo cage materials that were previously collected are concentrated in the farm and large coastal areas are utilized for the farming operations to turn a small fingerling into a meal for consumers despite farm wastes overloading the local ecosystem (Primavera, 2006). Examples of mariculture areas that experienced these problems are those in Bolinao, Pangasinan and Taal Batangas (Azanza et al., 2005; Macandog et al., 2014). Thus, environmental problems are seen to impact the nearby fishing or coastal communities due to marine pollution. Fishkill has been the overwhelming result of overfeeding and anoxic bottom waters of most of the intensively farmed areas in the Philippines (Jacinto, 2011; San Diego-McGlone et al., 2008). Fish farming whether done offshore or near coastal waters, should prioritize sustainability. It is important to keep the natural balance intact and protect varied species and ecosystems to maintain a healthy environment which is why studies looking at the farming operations are needed to provide policy support in cases where inevitable negative outcomes occur due to disregard to environmental sustainability (Macusi et al., 2022b)

Some ramifications of environmental pollution due to fed aquaculture includes, e.g. water quality degradation, impairment of the habitat, reduction or destruction of aesthetic natural beauty of beaches which are no longer viable for tourism due to the fish feeds accumulation in the area. Feed which is the primary input for the aquaculture of finfish and shrimp have been shown to be a dominant contributor to the environmental impact associated with aquaculture activities (Aubin, 2009; Philis, 2019). Other than this, the employment of the daily workers who have no basic rights or benefits from their jobs apart from daily wages.

These problems are typical for almost all over the Philippines and finding a viable solution for these by delving into the typology of milkfish farms in Davao region contributes to providing overview of milkfish farming operations in a mariculture parks and their social and economic related problems affecting these farms and their operations (Salayo et al., 2020). The information derived from our research can form the basis for policy changes to a more humane, livable and sustainable mariculture that incorporates human well-being as a value in its operation in the Philippines.

The Davao region especially the Panabo Mariculture Park is the center of operation of the National Mariculture Center of BFAR (Bureau of Fisheries and Aquatic Resources), thus, studies regarding the mariculture center and its typical operation is representative of the Philippine mariculture system. Current aquaculture in the area is focused on milkfish although in some areas there are polyculture systems where milkfish is cultured with a rabbitfish, or lobster. While in others, they have also evaluated whether milkfish can be co-cultured with sea cucumber. Thus, our survey aimed to document the existing grow-out milkfish farms in the Davao Region in terms of the socio-economic profile of its workers, farming practices, feed utilization as well as to collect data on economic costs, benefits and threats and challenges that these farms face, both in terms of environmental and financial sustainability.

Methods

Description of Study Area

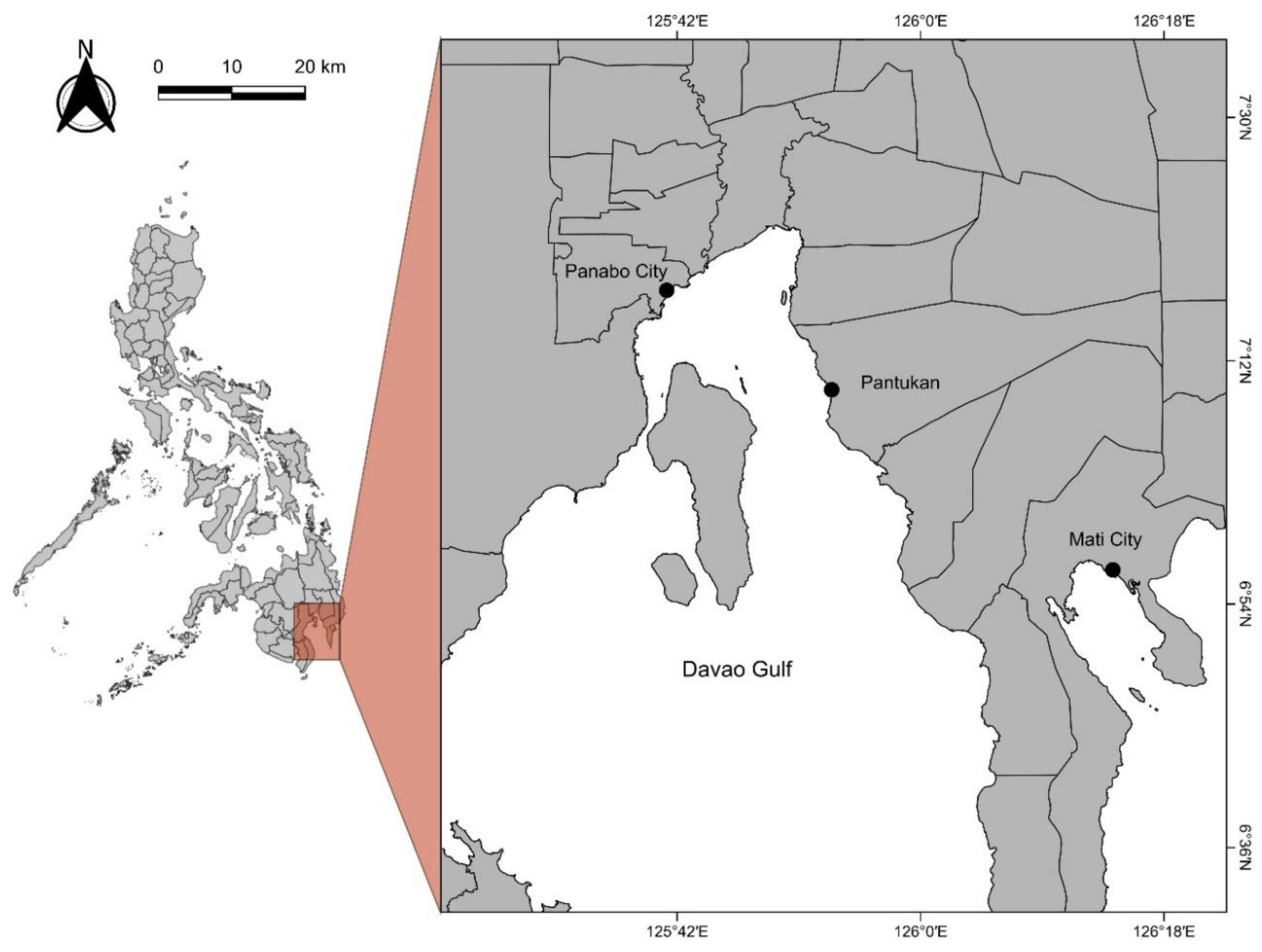

This study on the typology of milkfish farming was conducted in the Davao region, Philippines, held in three sites, Mati City, Pantukan and Panabo City (

Figure 1). The Davao region is home to the largest banana, cacao, coconut, and durian fruit crop production in the Philippines, including having large agricultural crops of coffee, mango and mangosteen. It is also adjacent to the Davao Gulf which is a source of marine fisheries resources including seaweeds, and various aquaculture species such as tilapia, milkfish, rabbitfish, mudcrabs, lobster and shrimp (Clapano et al., 2022; Villanueva, 2018). Common livelihoods include upland and lowland farming, municipal and offshore fishing, agricultural crop production, factory works in the industrial zones, largescale aquaculture, construction jobs, tourism, and trade, retail, financial and hospitality services. Recently, mariculture areas can be found in various parts of the country and Mati City, including, Pantukan and Panabo City have designated areas of their own municipal waters as mariculture areas for milkfish or cultured together with other species (Salayo et al., 2020). The first site was Mati City which has an area of 588.63 km

2 and a population of 147,547, the province of Davao Oriental has a poverty rate of 21.8%. The second site was Pantukan which has an area of 533 km

2 and a population of 90,786 and the Davao de Oro province has a poverty incidence of 17.7%. The third site was Panabo City which has an area of 251.23 km

2 and a population of 209,230 and the Davao del Norte province has a poverty incidence of 7.3% (PSA, 2021).

Data Collection

- A.

Key informant’s interview

This study on the typology of milkfish farming in the Davao region, Philippines, included three different study sites, Mati, Pantukan and Panabo. A key informant survey was first conducted to establish some baseline information and background knowledge for the final design of the questionnaire that would be used on milkfish farming. For this purpose, four sets of interviews were performed with technical personnel from the Bureau of Fisheries and Aquatic Resources (BFAR), the City Agriculture Office (CAO), and the Provincial Agriculture Office (PAGRO) in Mati City, Davao Oriental (

Figure 2). The contents of the questions focused on the feeds, feed composition and feeding regimen of the caretakers. Questions asked to the technical personnel on types of materials used for farming, and different farming methods also included costs and current challenges in the industry.’

- B.

Semistructured interview

The second method of data collection used semi-structured questionnaires for individual interviews. The questionnaire collected data on sociodemographic profile of the respondents, followed by asking them about their cultured species, stocking density, and the cost for each fry or fingerling, then the costs of feeds used in the culture process. In addition, questions related to their harvest and harvesting methods and the main causes of mortality and threats identified by them and the challenges affecting their culture were covered. The locations for interview included three different mariculture parks visited, namely in Baso (Davao Oriental), Pantukan (Davao del Norte) and Panabo (Davao del Norte). On site, semi-structured interviews were undertaken with the present staff of caretakers (N=43) (

Figure 3). Additional key informants were used to validate the information gathered from the semi-structured interview, provided by technicians, farm managers as well as supervisors of the mariculture parks or key stakeholders.

- C.

Actual farm visit

During the interview of farm workers in one of the study sites, the researchers also documented feeding and harvesting practices in the floating milkfish cages (

Figure 4). Key informants were also visited and interviewed in Panabo so that the results of the semi-structured interview can be validated based on the narratives of the officials from National Mariculture Center as well as from the City Agriculture Office of Panabo.

Data Analysis

After the interviews, the filled-in questionnaires were translated into English and transcribed to a standardised table format using Microsoft Excel. The same software was then used to analyse and visualise the data. We used multiple linear regression to assess the relationship of socioeconomic variables based on the interview, and to check whether there is a relationship between them and the harvest volume or the company income. To do that we first checked the normality of the dependent variables, income and harvest using KS (Kolmogorov-Smirnov) test for normality and checked the scatterplots of residuals of independent variables against the dependent variable to see their relationship. Because the volume and income data was not normally distributed, we transformed the volume and income data using log10 transformation which is commonly done to reduce the differences between large and small values on reported data. Next, the data was checked again for its equality of variance (F-test, test stat=0.84, P=0.576) and scatterplots of the variables being associated with the harvest and income data, we then used multiple linear regression to associate selected variables from the data. For this calculation we used Minitab 17 (State College, Pennsylvania, USA). In computing for the simple cost and return analysis, annual production data of two cropping season was used to determine the cost and net income of milkfish production. We employed sum of the years digit method to compute for the depreciation cost of the capital outlay.

Results

Sociodemographic Profile

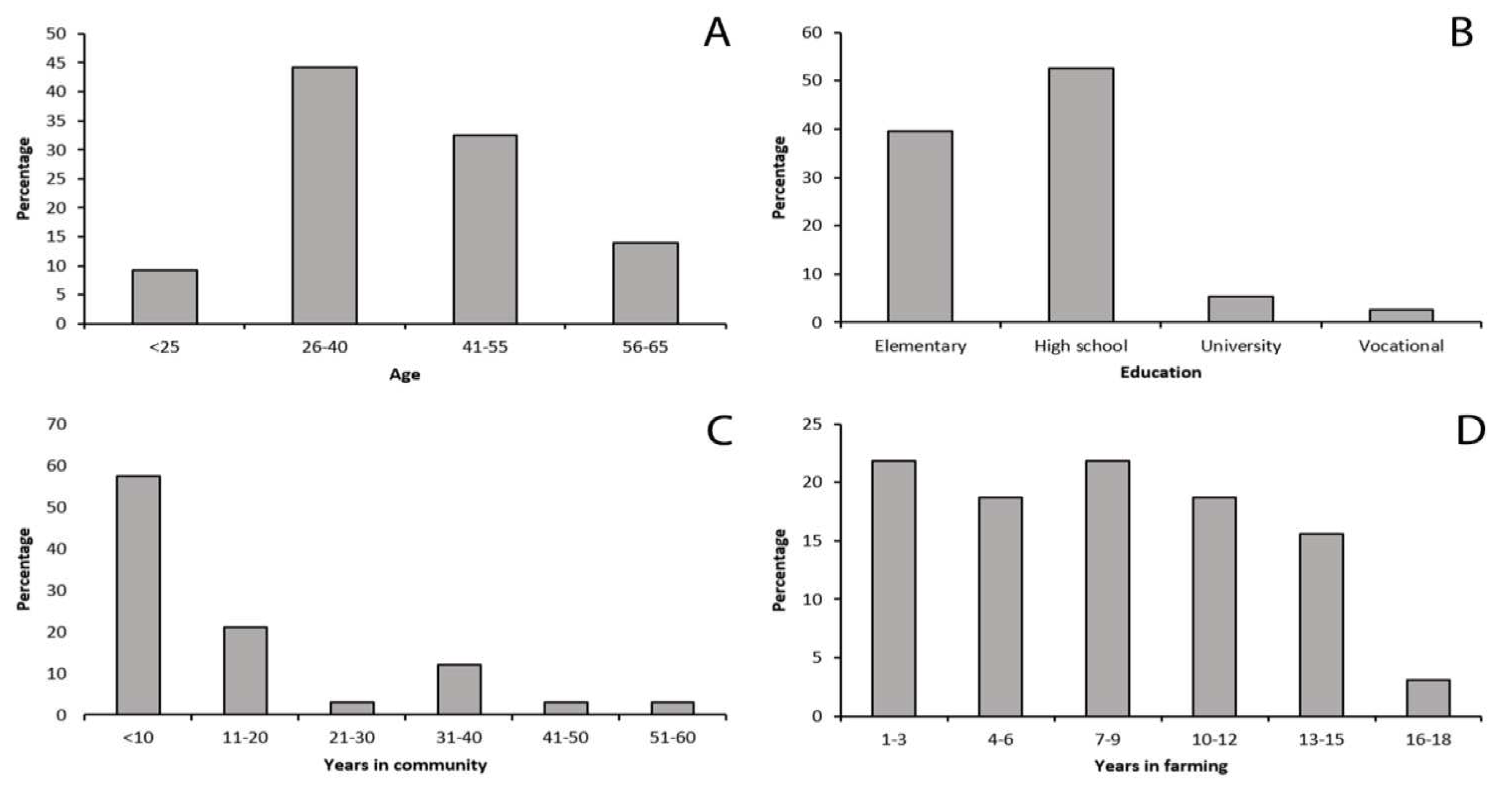

The variables selected for the sociodemographic profile include age, education, years in the community and years in milkfish farming (

Figure 5). The age of most of the fish farmers ranged from 26-40 years to 41-55 years (

Figure 5A). In terms of education, almost 60% of the respondents went to high school and 40% got the elementary grade, however less than 10% went to college or undertook vocational courses (

Figure 5B). Concerning the years in the community, more than 50% of the fish farmers have resided in the community for less than 10 years, approximately 15% has lived in the community for both 11-20 and 31-40 years (

Figure 5C). For the variable years in farming all the ranges have been similarly represented with 15-20% of the fish farmers. Nevertheless, only 5% of the fish farmers started culturing milkfish 16-18 years ago (

Figure 5D).

Feeding Times and Harvest

One of the key results of the survey included the frequent feeding of the cultured milkfish, and the lack of scientific information regarding why a cultured milkfish should be fed six times or seven times in a day when it could be fed three or four times only (

Table 1). ≤

Instead, the whole relationship was significant (

df=9, MS=0.0129,

F=5.74,

P=0.000) or having positive effect of the stocking density of the milkfish, is what determined the volume (

df=1,MS=0.0907,

F=40.13,

P=0.000) and later the income during the harvest (

df=1, MS=0.048,

F=21.22,

P=0.000) (

Table 2). We also included in the assessment selected socioeconomic variables such as age, years of education, years in community, but these were not positively related to the volume of harvest.≤

Milkfish Farming Practices

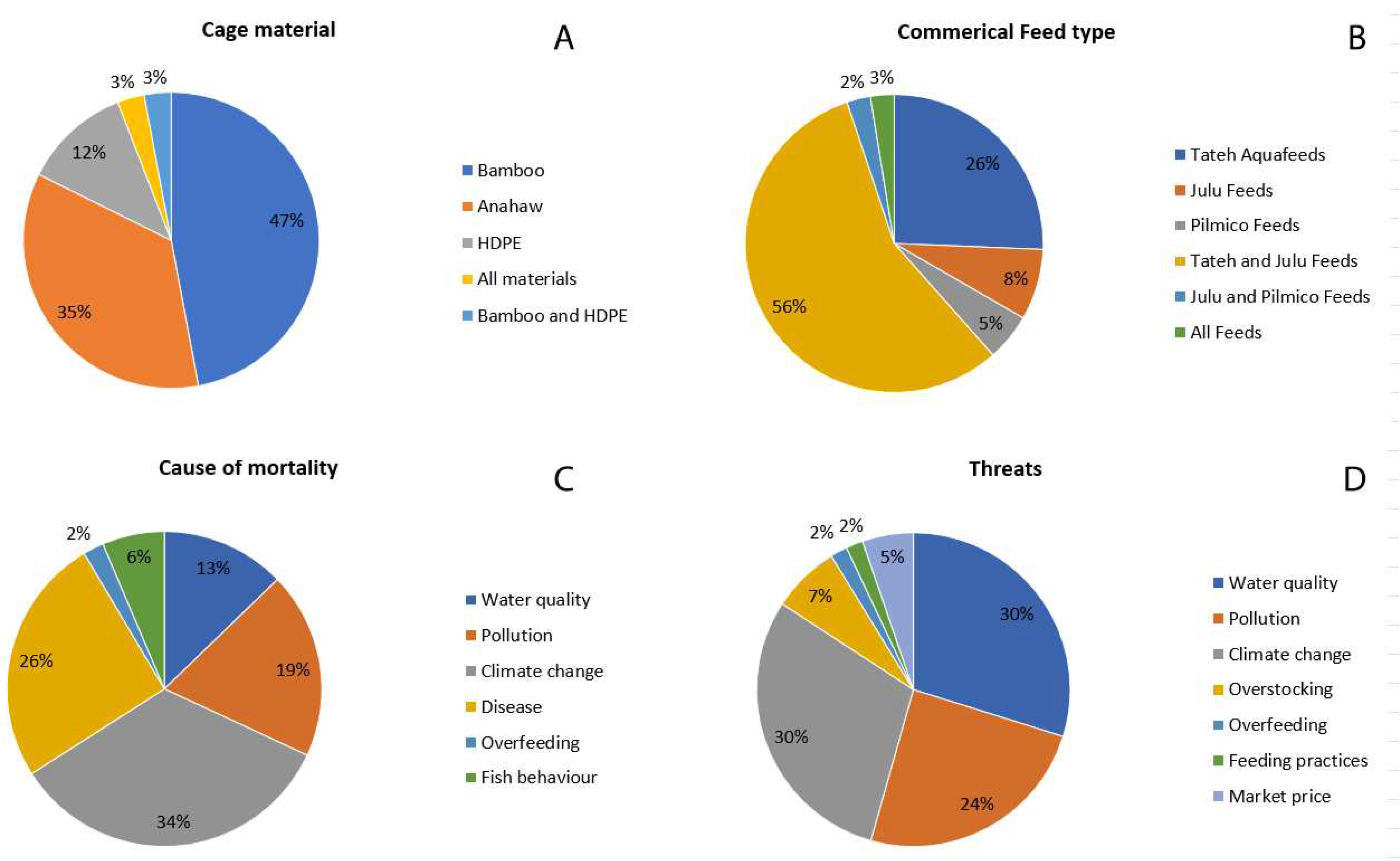

In general, the milkfish farmers of this study reported to adhere to the feeding and handling practices as taught during initial training provided by BFAR (Bureau of Fisheries and Aquatic Resources). The mean number of cages that were operating simultaneously in one harvesting was three (

Table 3). Cages were commonly rectangular and presented a dimension of 100 m

2 (10x10). Moreover, the material for 47% of these cages was bamboo, followed by anahaw

(Saribus rotundifolius) with 35% and HDPE (plastic) with 12% (

Figure 6A). The stocking density ranged between 15,000 and 17,500 fingerlings per cage. Concerning the milkfish feed practices, this species was fed six times a day with an interval of 1.43 hours. Usually, two cages are typically gated by one caretaker and they only used commercial feed as source of food for the cultured fish, 56% of them used the combination of Tateh Aquafeeds and Julu Feeds brands (

Figure 6B). Then, 26% of the fish farmers chose Tateh Aquafeeds and 8% Julu Feeds, Pilmico Feeds was only selected by 5% of the farmers. Some of the respondents also mentioned the use of probiotics, vitamins, and heavy weight liquid as supplemental feed components. Once a month, they hire another worker to replace or fix fish nets that have been worn out or that have oyster shell growing on it. The milkfish was cultured for 5.85 months from the deployment of the fingerlings in the cage until the harvesting. After this process, the fish was mainly sold to an intermediary buyer with a marketable weight of 0.5 kg with an average of PhP 150/kg market price. Moreover, respondents have stated that they no longer practiced partial harvest to avoid stressing out the fishes. Partial harvest could possibly cause danger to their return of investment.

Causes of Mortality and Threats

The respondents mentioned different causes of mortality that affected the milkfish farming, such as water quality, pollution, climate change, disease, overfeeding and fish behaviour (Fig. 8A). According to their experience, climate change was the most frequent cause of mortality with a percentage of 34%. Then, 26% of the fish farmers identified disease as a factor causing milkfish death and 19% mentioned pollution. Concerning the threats that can have an impact on milkfish production, the farmers referred to water quality, pollution, climate change, overstocking, overfeeding, and market price (

Figure 6C). For instance, climate change together with water quality represented 30% of the answers, followed by pollution with 24%. Water quality refers to the pH, temperature, salinity and level of dissolved oxygen in the water.

In terms of pollution, the main sources mentioned by the respondents were agricultural runoff from nearby banana plantations and mining for nickel or gold. The most common impacts of climate change were heat, change in water temperature, turbulence and wave action, floods, and heavy rain. When talking about disease occurrence, most of the respondents mentioned the infestation of their milkfish stocks with gill rats. Lastly, the threat of feeding practices refers to the use of incorrect feed products (

Figure 6D).

Cost and Return Analysis

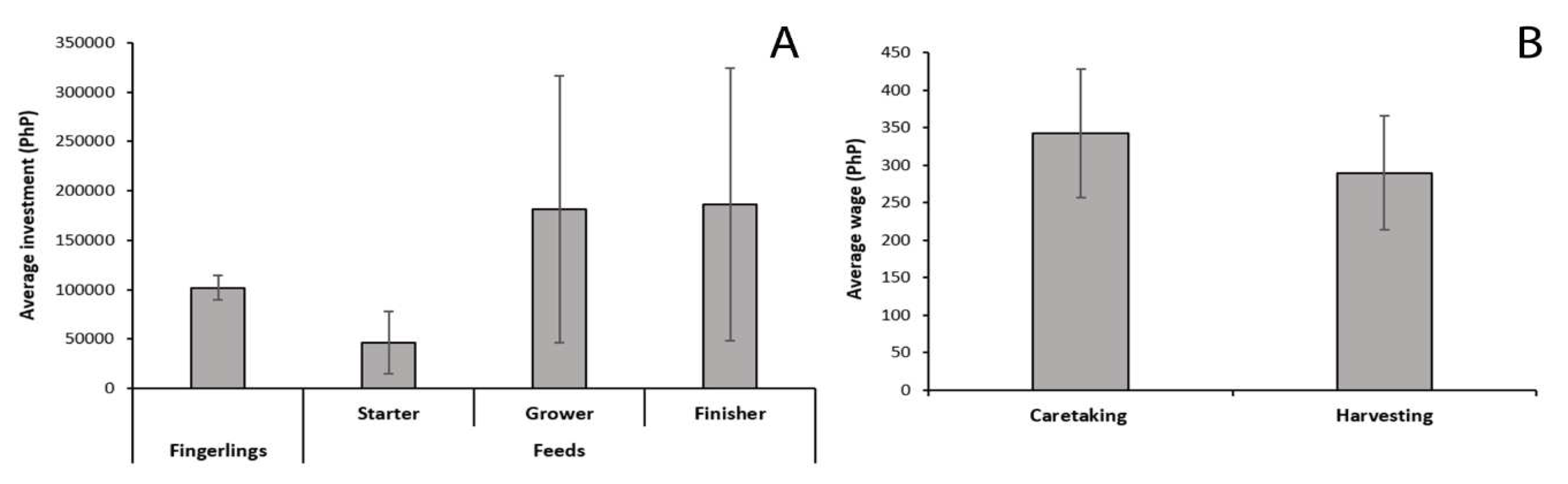

In terms of material inputs, the surveyed milkfish farms reported high investments for both the purchase of fingerlings and commercial feeds (

Figure 7A). With an average cost of 6.5 PhP (± 0.5) per fingerling and stocking density ranging from 10,000 to 19,000 individuals per production cycle, the average annual working capital for a one cage operation amounted to PhP 1,352,480. In general, the caretakers would feed around 60 sacks of starter feed to the milkfish within the first 2 months of cultivation and, depending on their growth, move onto feeding around 200 sacks of grower for another 2 months and before switching to finisher feed before harvest. The price per sack of different feed types does not significantly differ, however, the needed quantity of the feeds increases by more than 200% from the starter to the adult stage.

In terms of labour inputs, the average wage per day for caretaking and harvesting were found to be PhP 342.00 and PhP 290.00, respectively (

Figure 7B). For caretakers, a normal working day would last from 7 am to 4 pm and mainly consist of feeding the milkfish on average 6 times and with a time interval of 1.5 hours (

Table 1). During harvesting, an average number of 13 (± 4) laborers is hired for a range of 2 to 6 hours. This activity is performed after the documented 6-month culture period (

Table 1).

The average annual production of milkfish from marine cage culture is 12,400 kg per 10x10 meter dimension of bamboo floating cage (6 m depth). For a single cage operation, the annual gross revenue will be PhP 1,860,000, assuming that 90% of the total harvested milkfish weigh at least 500 grams in order to obtain the highest possible farmgate price. In terms of production cost in aquaculture, commercial feeds share the largest expense accounting for 76% of the overall operational cost. In the first year of operation, the return on investment for marine cage operations is 27% with an average payback period of 3.6 years.

Table 4.

Cost and Return Analysis for Milkfish Production - One (1) Cage Operation in Mati, Pantukan and Panabo,2023..

Table 4.

Cost and Return Analysis for Milkfish Production - One (1) Cage Operation in Mati, Pantukan and Panabo,2023..

| Particulars |

Price/unit (PhP) |

Unit/cage |

Amount/cage/cropping(PhP)

|

Amount/cage/year(PhP) (2 cropping)

|

| RETURNS |

|

|

|

|

| Harvested Milkfish (0.5 kg) |

150/kilo |

6,200 kg |

930,000 |

1,860,000 |

| |

|

|

|

|

| OPERATIONAL COST |

|

|

|

|

| Fingerlings |

6.5 |

15,500 |

100,750 |

201,500 |

| Feeds (25 kg/sack) |

|

|

|

|

| Starter |

1,170 |

65 |

70,200 |

152,100 |

| Grower |

1,020 |

197 |

200,940 |

401,880 |

| Finisher |

985 |

240 |

236,400 |

531,900 |

| Labor |

|

|

|

|

| Harvesting cost |

4,000 |

1 |

4,000 |

8,000 |

| Monthly salary of caretaker for 1 cage |

10,000 |

12 months (6 months per cropping) |

60,000 |

120,000 |

| Maintenance and Repair Cost (5% of capital outlay) |

|

|

3,950 |

7,900 |

| TOTAL OPERATIONAL COST |

|

|

676,240 |

1,352,480 |

| OVERHEAD COST |

|

|

|

|

| Bamboo frame with drum floats and mooring |

100,000 |

1 |

100,000 |

100,000 |

| Net cage (10x10x6m) |

9,000 |

1 |

9,000 |

9,000 |

| Business permits/licenses |

2,500 |

1 |

2,500 |

5,000 |

| Depreciation cost |

|

|

|

12,727 |

| TOTAL OVERHEAD COST |

|

|

111,500 |

126,727 |

| TOTAL COST |

|

|

787,740 |

1,479,207 |

| |

|

|

|

|

| NET INCOME |

398,793 |

|

|

|

| ROI |

27.29203 |

|

|

|

| PAYBACK PERIOD |

3.664074 |

|

|

|

Assumptions: 90% survival rate

Owner’s equity is 100% (no borrowed amount for investment)

No occurrence of natural disaster that may affect the production during culture perio

Discussion

Problem of Overfeeding

Milkfish production in the Davao region is subject to the feeding process that is essential from the stocking of the fish to the harvesting (Yap, 2007). The fingerlings are imported from other hatcheries and transferred to grow-out cages with stocking densities ranging from 15,000 to 17,500 fingerlings per cage. The most commonly used material for the cages was anahaw in Panabo and bamboo for Pantukan and Mati. Although these materials require a lower investment compared to Norwegian cages, the plastic ones might be profitable in the long term because they are more resistant to waves, structural damage and biofouling. Moreover, cage-based hatcheries were developed in the Philippines in the 1970s, and a decade or so later, the technology had spread throughout Southeast Asia. Cages can be used at different stages of the life cycle: for breeding, fry and fingerling rearing, and/or fish production (Beveridge, 2008). The milkfish farming is divided in stages: crumble, starter, grower and finisher, which require different formulated diets in terms of protein and also in the quantity of feeding sacks.

This is indicative of the highly intensive nature of the cultivation process whereby from fingerlings to sardine-like sizes, these aquaculture phases utilize different feed forms and nutrient levels. Moreover, farmers feed the fish several times in a day and most of the caretakers do not follow a scientifically based procedure to adjust the feeding intervals based on the weight of the fish. Proper feeding could be adjusted based on the weight of the cultured fish so that excess feeds could be avoided, as there was undue haste in growing the fish towards a marketable size or weight. Furthermore, milkfish feeding rates are affected by size of fish, water quality (such as temperature, salinity and dissolved oxygen), feeding frequency, and nutrient density of the diets, especially energy content. As with other fish, the feed consumption rate of milkfish is inversely related to fish size (Vasava et al., 2018). Thus, improper feeding can lead to waste of feed and overfeeding. Once it reached the marketable size of 400-500 grams, the harvesting can commence and this is a labour intensive operation regulated by the needs of the intermediary buyer. The marketable price of milkfish depends on their size; however the desired marketable weight is 500 grams or 0.5 kg. According to Cruz (1998), for the same level of productivity, a sea cage utilizes 1/50th the area of a pen and 1/30th the area of an extensive pond. The production of milkfish from a 6 m depth 1000 m2 cage was reported at 5.7 tons after 138 days, with 94% survival and a food conversion ratio of 1.77. After 138 days in a 6 m deep, 1000-m2 cage, 5.7 tons had been recorded, with a food conversion ratio of 1.77 and 94% survival (De la Vega, 1998).

Addressing Mortality Issues

The intensification of aquaculture in the country has led to the occurrence of infectious diseases particularly due to parasites at the hatchery stage (Cruz-Lacierda et al., 2015). However, during the cultivation phase, the most mentioned cause of mortality in milkfish farming is climate change. It is important to highlight this answer related to sea temperature, floods, turbulence and waves which are associated with climate change impacts because these are its impacts to aquaculture, showing that natural processes and anthropogenic activities could affect climate variability e.g. prolonged rainfall, strong waves, extremely hot weather which results to mass mortalities of several aquatic species including fish, corals, and mammals (Islam and Yasmin, 2017; Islam et al., 2020; Mohanty et al., 2010). Thus, milkfish farming and aquaculture is an activity that is a subject to a lot of threats in the future especially in the light of climate change impacts (Cochrane et al., 2009). For instance, the increase of sea water temperature, stronger and higher wave and water turbulence, as well as the decrease in dissolved oxygen and pH will have a negative impact on this sector (Macusi et al., 2022a; Macusi et al., 2021; Mamauag et al., 2013). Pollution is another threat that might gain importance in the coming years due to an increase in the use of fertilisers in agriculture, spraying and nearness to commercial plantations such as banana, pomelo and mango fields, uncontrolled solid waste generation, and expansion of the mining industry (Abreo et al., 2015; Abreo et al., 2020; Macusi et al., 2020). Given these possible future scenarios., incorporating a carrying capacity and strict regulation of water quality and regular coastal clean-ups should be included as part of the regular activities of pond owners, cage owners and fish pen owners. There is no question that a cleanear environment also enhances a cleaner and more sustainable production in the long-term. Hence, it is necessary to consider all these elements when selecting a potential site for milkfish farming and for its management (Abd El-alkhoris et al., 2020). Trainings on good aquaculture practices, including food safety and regular monitoring on feeding practices should be developed by BFAR and the local government units instead of relying on and waiting for a possible worst scenario.

Investments in the Milkfish Sector

For many communities in Philippines, and Taiwan, milkfish is a staple fish dish. However, the large quantity of spicules in the dorsal flesh makes preparation and eating challenging and, as a result, offers a barrier to market expansion. Most milkfish harvested are transported fresh to wholesale markets or processing facilities. The fish is then sold to domestic customers through wholesalers, retailers, and supermarkets. In processing facilities, some of the fish are frozen and exported (Su et al., 2002). Moreover, milkfish culture in cages in the Philippines has a high level of production but would also require a considerable investment primarily due to huge formulated feed requirements (Yap, 2007). In the last five years, no less than 1,000 cages with an aggregate capacity more than 10,000 metric tons a year have been invested in milkfish sea farming. The species now acounts for about 90% of the production from marine cages. In recent years, a drop in milkfish prices has motivated the industry to focus its attention on other fishes (Marte et al., 2000). Tacon (2007) estimated that the global production of industrially compounded aquafeeds in 2005 was about 23.13 million tons similar to a previous study that estimated the global aquafeed production to be approximately 25.4 million tons or 4 percent of global industrial animal feed production of 635 million tons in 2006 (Gill, 2007). From the results, the total investment for a floating bamboo cage of 10x10 m dimension is not less than PhP 1 million (USD=15,000), with more than half of the cost accounted for feeds. For small-scale aquaculture operations in developing countries, feed cost shares 80% or more of the total production cost. This is largely due to fish-derived meals and oils that comprised 40% of the formulated feeds (SEAFDEC, 2019). Aquaculture’s rapid expansion is pushing up demand for processed fish feed and its component ingredients. Any increase in the market price of these imported raw materials has a considerable negative impact on the operational cost of aquaculture worldwide. Considering that feed accounts for 60-80% of milkfish production costs, fish farmers also struggle with costly feed prices. For small-scale fish farmers in developing nations who largely rely on purchasing costly commercial feeds, rising feed and related costs are often too high to be absorbed into already-thin profit margins. Thus, it is important to provide good alternative to purchasing costly commercial feeds. especially for small-scale fish farmers who are vulnerable to fluctuations in feed costs. This can be done by reducing the amount of fish-based ingredients in feed formulations by utilizing alternative sources of feed ingredients that are sustainable, efficient and cost-saving that can compete with commercial feeds in terms of growth performance and other biological parameters. By making the feed cost-effective and sustainable it will increase profits and encourage more fish farmersfi that give higher return on investments.

The Farmer’s Rights for Association and Livable Wage

Workers in the mariculture park are laborers with specific tasks as cage care-takers, feeders, cage installers, cage net changers, net fabricators and menders, harvesters and stevedores (Salayo et al., 2020). While the use of floating cages currently represents the state-of-the-art technique for milkfish aquaculture, it requires a considerable investment and entails high-risk and labour-intensive operations (Yap, 2007). Nevertheless, the wages of caretakers are low in comparison and the employment conditions are harsh. Without labour benefits and the constant fear of being dismissed after three consecutive harvest failures, the workers are exposed to a high-pressure environment. Considering the strong involvement of the Bureau for Fisheries and Aquatic Resources (BFAR) thus far, there seems to be a large potential to effectively address this situation by means of governmental intervention, in order to ensure the development of a sector that is sustainable not just in terms of its environmental practices, but also in terms of its labour conditions.

Another intervention in pursuit of these rights could be the formation of a fish farmer’s labor association that offers the opportunity to act as a platform for the exchange of experiences, practices, and knowledge. Upon its establishment, this association can then be used as a labour union to advocate for better working conditions in milkfish farming. However, the labour conditions are not the only aspect of the power imbalances that are prevailing in this sector: Beside the restricted financial flow down the line of employment, the interviews with the milkfish farmers revealed a strong monopoly of the intermediary buyer. In all cases, these middlemen would exclusively decide on the timing and price for the full harvest. Again, a fish farmer’s association might help to build a stronger foundation of knowledge for negotiations with intermediaries, to enhance the monetary valuation of caretakers and increase the sustainability and transparency of the overall value chain. This target should also be supported by respective policies and regulations from the government. Additionally, aquaculture can greatly increase household income and offer a way out of poverty if it is supported by the right socioeconomic, environmental, and institutional frameworks. If a person is employed as a wage worker or operator, their wage income is only adequate to meet their minimum needs rather than being sufficient to produce income (Nagothu and Ortiz, 2007).

Conclusion

The assessment has shown that most floating cage farms were manned by caretakers who have been trained by BFAR once, but an on-going scientific training on proper culturing methods, updated knowledge on feeding, food safety and workforce security was largely missing. Based on the results of the study there is a possibility of overfeeding as shown by the interval of times the fish were being fed. In terms of relationship to harvestability of fish, this feeding interval was not related to its marketability, but it could aggravate marine pollution in farming areas. Moreover, overfeeding leads to environmental pollution, where beaches are polluted, and sediments are anoxic and water quality is highly degraded. Only stocking density was related to harvestability and income of the owners despite including other socioeconomic factors into the model. The cost and return analysis also showed that almost 80% of the overall operational cost accounted for commercial feeds. The ingredients of these formulated feeds come at a prohibitive cost to farmers. Facing a rising cost of aquafeeds, there is a need to produce effective low-cost feed formulations using cheaper and locally available materials to lower the production cost and improve the profitability of milkfish farms. There was also a general assessment result that farm workers were receiving too little benefit from on-going farming and they were untrained to form a labor union. Most benefits also go to the operators and owners.

Author Contributions

Conceptualization, E.D.M., E.S.M., H.P.B., M.A.C., and J.L.O.; methodology, E.D.M., E.S.M., H.P.B., M.A.C., J.L.O., L.L.S., M.S. and C.V.; software, E.D.M., M.S., C.V.; validation, E.D.M, E.S.M., H.P.B., M.A.C., M.S. and C.V.; formal analysis, E.D.M., H.P.B., M.A.C.; investigation, E.D.M., E.S.M., H.P.B., M.A.C., J.L.O., L.L.S., M.S. and C.V.; resources, E.D.M.; data curation, E.D.M, and M.A.C. writing—original draft preparation, M.A.C., C.V., M.S.; writing—review and editing, E.D.M, M.A.C., M.S., C.V.; visualization, E.D.M, M.A.C., M.S., C.V.; supervision, E.D.M, E.S.M, and H.P.B.; project administration, E.D.M.; funding acquisition, E.D.M.. All authors have read and agreed to the publication of this manuscript.

Funding

The first author received funding from the Department of Agriculture, Philippine Rural Development Project (DA-PRDP) and the Department of Science and Technology Region 11 (DOST-XI) with the study entitled: "Enhancing food security, social inclusion, and sustainability in the milkfish aquaculture through the use of indigenous raw materials as feed components".

Data Availability Statement

The data can be requested from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abd El-alkhoris, Y.S.; Abbas, M.S.; Sharaky, A.M.; Fahmy, M.A. Assessment of Water and Sediments Pollution in Maruit Lake, Egypt. Egyptian Journal of Aquatic Biology and Fisheries 2020, 24, 145–160. [Google Scholar] [CrossRef]

- Abreo, N.A.S.; Macusi, E.D.; Cuenca, G.C.; Ranara, C.T.B.; Andam, M.B.; Cardona, L.T.; Arabejo, G.F.P. Nutrient Enrichment, Sedimentation, Heavy Metals and Plastic Pollution in the Marine Environment and its Implications on Philippine Marine Biodiversity: A Review. IAMURE International Journal of Ecology and Conservation 2015, 15, 111–168. [Google Scholar] [CrossRef]

- Abreo, N.A.S.; Siblos, S.K.V.; Macusi, E.D. Anthropogenic Marine Debris (AMD) in Mangrove Forests of Pujada Bay, Davao Oriental, Philippines. Journal of Marine and Island Cultures 2020, 9, 38–53. [Google Scholar] [CrossRef]

- Aubin, J.; Papatryphon, E.; van der Werf, H.M.G.; Chatzifotis, S. Assessment of the environmental impact of carnivorous finfish production systems using life cycle assessment. J Clean Prod 2009, 17, 354–361. [Google Scholar] [CrossRef]

- Avenido, P.; Garley, L.; Bersaldo, M.J. Seasonal Fluctuation of Nutrients and Primary Productivity of the Coastal Waters of Culaman, Malita, Davao Occidental. Davao Research Journal 2023, 14, 55–72. [Google Scholar] [CrossRef]

- Azanza, R.V.; Fukuyo, Y.; Yap, L.G.; Takayama, H. Prorocentrum minimum bloom and its possible link to a massive fish kill in Bolinao, Pangasinan, Northern Philippines. Harmful Algae 2005, 4, 519–524. [Google Scholar] [CrossRef]

- Bagarinao, T. Ecology and Farming of Milkfish; Southeast Asia Fisheries Aquaculture Department (SEAFDEC): Tigbauan, Iloilo, 1999. [Google Scholar]

- BFAR. Philippine Fisheries Profile 2019; Bureau of Fisheries and Aquatic Resources: Quezon City, Philippines, 2020; p. 76. [Google Scholar]

- Clapano, M.B.; Diuyan, J.M.T.; Rapiz, F.G.B.; Macusi, E.D. Typology of Smallholder and Commercial Shrimp (Penaeus vannamei) Farms, including Threats and Challenges in Davao Region, Philippines. Sustainability 2022, 14. [Google Scholar] [CrossRef]

- Cochrane, K.; Young, C.D.; Soto, D.; Bahri, T. Climate change implications for fisheries and aquaculture: Overview of current scientific knowledge, Fao fisheries and aquaculture technical paper. 2009.

- Food and Agriculture Organization of the United Nations, Rome, Italy.

- Cruz-Lacierda, E.R.; Estante, E.G.; de Jesus-Ayson, E.G.T.; Corre, V.L., Jr. Health Management of Milkfish Chanos chanos; Aquaculture Department, Southeast Asian Fisheries Development Center: Tigbauan, Iloilo, Philippines, 2015. [Google Scholar]

- Dey, M.M.; Rab, M.A.; Paraguas, F.J.; Piumsombun, S.; Bhatta, R.; Alam, M.F.; Ahmed, M. Fish consumption and food security: A disaggregated analysis by types of fish and classes of consumers in selected Asian countries. Aquaculture Economics and Management 2005, 9, 89–111. [Google Scholar]

- Gaitan, A.G.; Toledo, J.D.; Arnaiz, M.T.; Ayson, E.G.D.; Altamirano, J.P.; Agbayani, R.F.; Salayo, N.D.; Marte, C.L. Milkfish Chanos chanos Cage Culture Operations; Aquaculture Department, Southeast Asian Fisheries Development Center: 2014.

- Gill, C. World feed panorama: bigger cities, more feed. Feed International 2007, 28, 5–9. [Google Scholar]

- Islam, M.; Yasmin, R. Impact of aquaculture contemporary environmental issues in Bangladesh. Int. J. Fish. Aquat. Stud. 2017, 5, 100–107. [Google Scholar]

- Islam, M.M.; Islam, N.; Habib, A.; Mozumder, M.M.H. Climate Change Impacts on a Tropical Fishery Ecosystem: Implications and Societal Responses. Sustainability 2020, 12, 7970. [Google Scholar] [CrossRef]

- Jacinto, G.S. Fish Kill in the Philippines—Déjà Vu. Science Diliman 2011, 23, 1–3. [Google Scholar]

- Jaikumar, M.; Suresh Kumar, C.; Robin, R.S.; Karthikeyan, P.; Nagarjuna, A. Milkfish Culture: Alternative Revenue for Mandapam Fisherfolk, Palk Bay, Southeast Coast of India. International Journal of Fisheries and Aquaculture Sciences 2013, 3, 31–43. [Google Scholar]

- Macandog, D.M.; de la Cruz, C.P.P.; Edrial, J.D.; Reblora, M.A.; Pabico, J.P.; Salvacion, A.R.; Marquez, J.T.L.; Macandog, P.B.M.; Perez, D.K.B. Eliciting Local Ecological Knowledge and Community Perception on Fishkill in Taal Lake through Participatory Approaches. Journal of Environmental Science and Management 2014, 17, 1–16. [Google Scholar] [CrossRef]

- Macusi, E.D.; Albarido, N.A.; Clapano, M.B.; Santos, M.D. Vulnerability Assessment of Pacific Whiteleg Shrimp (Penaeus vannamei) Farms and Vendors in Davao, Philippines Using FishVool. Sustainability 2022, 14, 4541. [Google Scholar] [CrossRef]

- Macusi, E.D.; Estor, D.E.P.; Borazon, E.Q.; Clapano, M.B.; Santos, M.D. Environmental and Socioeconomic Impacts of Shrimp Farming in the Philippines: A Critical Analysis Using PRISMA. Sustainability 2022, 14, 2977. [Google Scholar] [CrossRef]

- Macusi, E.D.; Geronimo, R.C.; Santos, M.D. Vulnerability drivers for small pelagics and milkfish aquaculture value chain determined through online participatory approach. Marine Policy 2021, 133, 104710. [Google Scholar] [CrossRef]

- Macusi, E.D.; Macusi, E.S.; Jimenez, L.A.; Catam-isan, J.P. Climate change vulnerability and perceived impacts on small-scale fisheries in eastern Mindanao. Ocean & Coastal Management 2020, 189, 105143. [Google Scholar]

- Mamauag, S.S.; Aliño, P.M.; Martinez, R.J.S.; Muallil, R.N.; Doctor, M.V.A.; Dizon, E.C.; Geronimo, R.C.; Panga, F.M.; Cabral, R.B. A framework for vulnerability assessment of coastal fisheries ecosystems to climate change—Tool for understanding resilience of fisheries (VA–TURF). Fisheries Research 2013, 147, 381–393. [Google Scholar] [CrossRef]

- Mohanty, B.; Mohanty, S.; Sahoo, J.; Sharma, A. Climate Change: Impacts on Fisheries and Aquaculture. In Climate Change and Variability; Suzanne, S., Ed.; IntechOpen: Rijeka, 2010. [Google Scholar]

- Nagothu, U.; Ortiz, I. Review and assessment of socio-economic issues of Aquaculture in the Philippines; NIVA (Norwegian Institute for Water Research): Manila, Philippines, 2007. [Google Scholar]

- Philis, G.; Ziegler, F.; Gansel, L.C.; Jansen, M.D.; Gracey, E.O.; Stene, A. Comparing life cycle assessment (LCA) of salmonid aquaculture production systems: Status and perspectives. Sustainability 2019, 11. [Google Scholar] [CrossRef]

- Primavera, J.H. Overcoming the impacts of aquaculture on the coastal zone. Ocean and Coastal Management 2006, 49, 531–545. [Google Scholar] [CrossRef]

- PSA. Official Poverty Statistics Philippine Statistics Authority; Diliman: Quezon City, Philippines, 2021. [Google Scholar]

- PSA Fisheries Statistics of the Philippines 2019-2021. In Philippine Statistics Agency; Mapa, D., Ed.; Quezon City, Philippines, 2022; p. 327.

- Salayo, N.D.; Marte, C.L.; Toledo, J.D.; Gaitan, A.G.; Agbayani, R.F. Developing a self-sufficient Philippine milkfish industry through value chain analysis. Ocean. Coast. Manag. 2020. [Google Scholar] [CrossRef]

- Samson, E. The milkfish industry in the Philippines. In Proceedings of the Second International Milkfish Aquaculture Conference Published by Island Publication House Iloilo City, Philippines; Juario, J.V., Ferraris, R.P., Benitez, L.V., Eds.; 1984; pp. 215–228. [Google Scholar]

- San Diego-McGlone, M.L.; Azanza, R.V.; Villanoy, C.L.; Jacinto, G.S. Eutrophic waters, algal bloom and fish kill in fish farming areas in Bolinao, Pangasinan, Philippines. Marine Pollution Bulletin 2008, 57, 295–301. [Google Scholar] [CrossRef]

- Shahidul Islam, M.; Tanaka, M. Impacts of pollution on coastal and marine ecosystems including coastal and marine fisheries and approach for management: a review and synthesis. Marine Pollution Bulletin 2004, 48, 624–649. [Google Scholar] [CrossRef]

- Su, M.-S.; Lee, C.-S.; Liao, I.C. Technical Responses to Challenges in Milkfish Aquaculture. Rev Fish Sci 2002, 10, 451–464. [Google Scholar] [CrossRef]

- Tacon, A.G.J. Global aquaculture production highlights and estimated compound aquafeed use in 2005. International Aquafeed 2007, 10, 40–44. [Google Scholar]

- Tahiluddin, A.B.; Terzi, E. An Overview of Fisheries Aquaculture in the Philippines. J. Anatol. Env. Anim. Sci. 2021, 6, 475–486. [Google Scholar] [CrossRef]

- Vasava, R.; Shrivastava, V.; Mahavadiya, D.; Sapra, D.; Vadher, D. Nutritional and feeding reuirement of milk fish (Chanos chanos). Int. J. Pure App. Biosci 2018, 6, 1210–1215. [Google Scholar] [CrossRef]

- Villanueva, J.A. Assessment of Commercially Important Small Pelagic Fishes in Davao Gulf CY 2004-2013. The Philippine Journal of Fisheries 2018, 25, 163–182. [Google Scholar] [CrossRef]

- Yap, W.G.; Villaluz, A.C.; Soriano, M.G.G.; Santos, M.N. Milkfish production and processing technologies in the Philippines, Milkfish Project Publication Series; 2007; p. 96.

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).