Submitted:

08 December 2023

Posted:

11 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

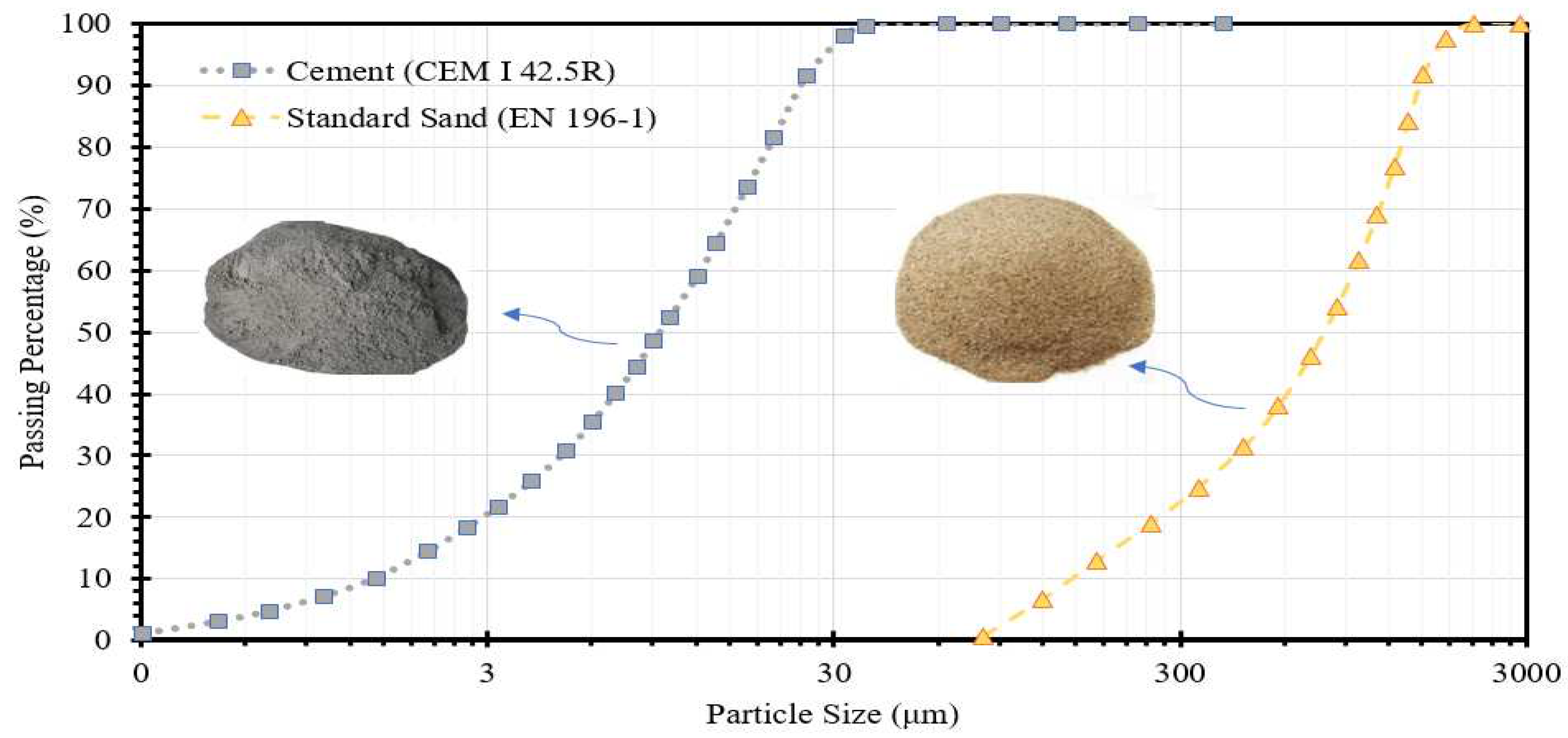

2.1. Materials

2.2. Mix design

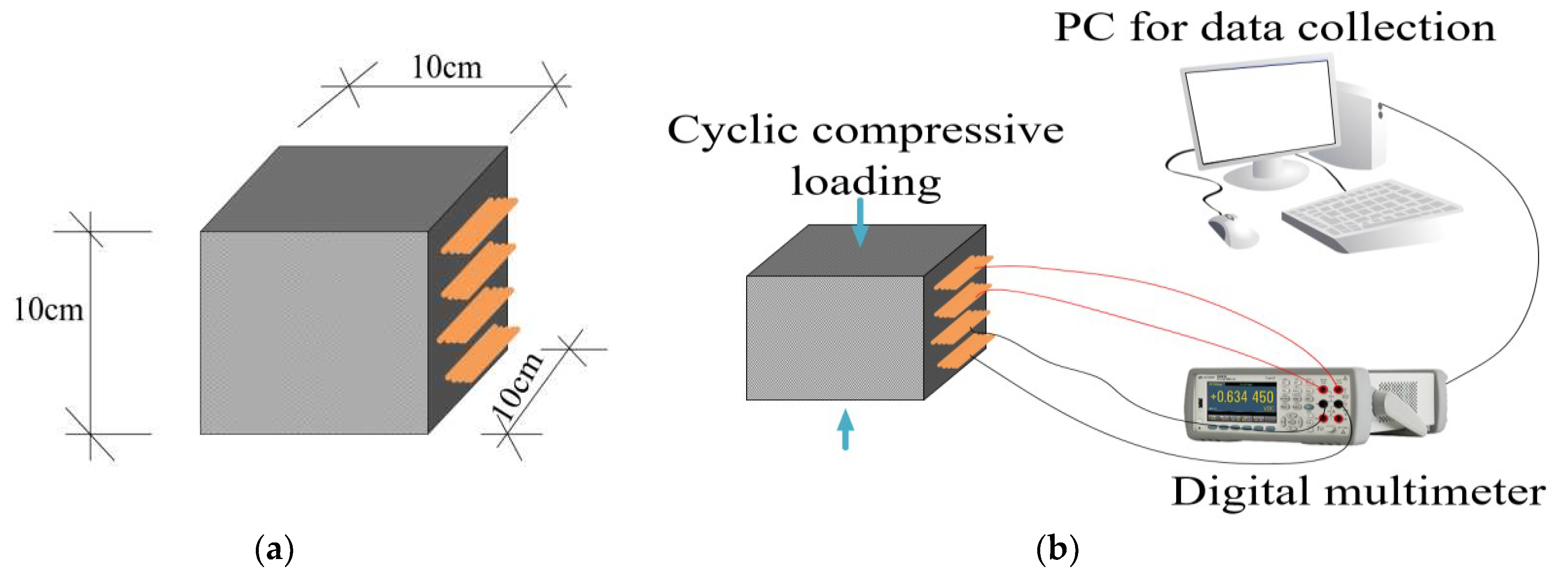

2.3. Piezoresistivity

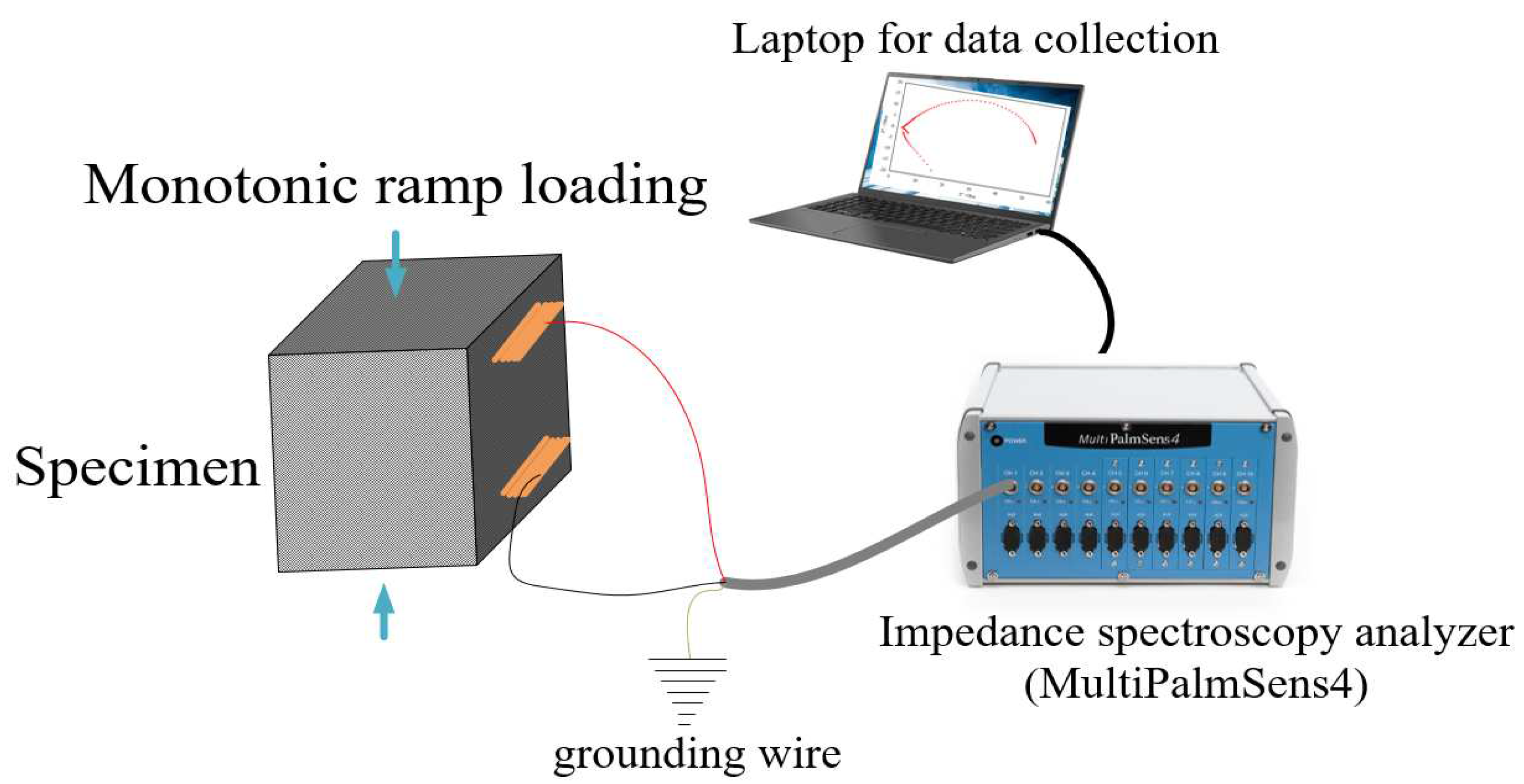

2.4. Electrochemical impedance spectroscopy (EIS)

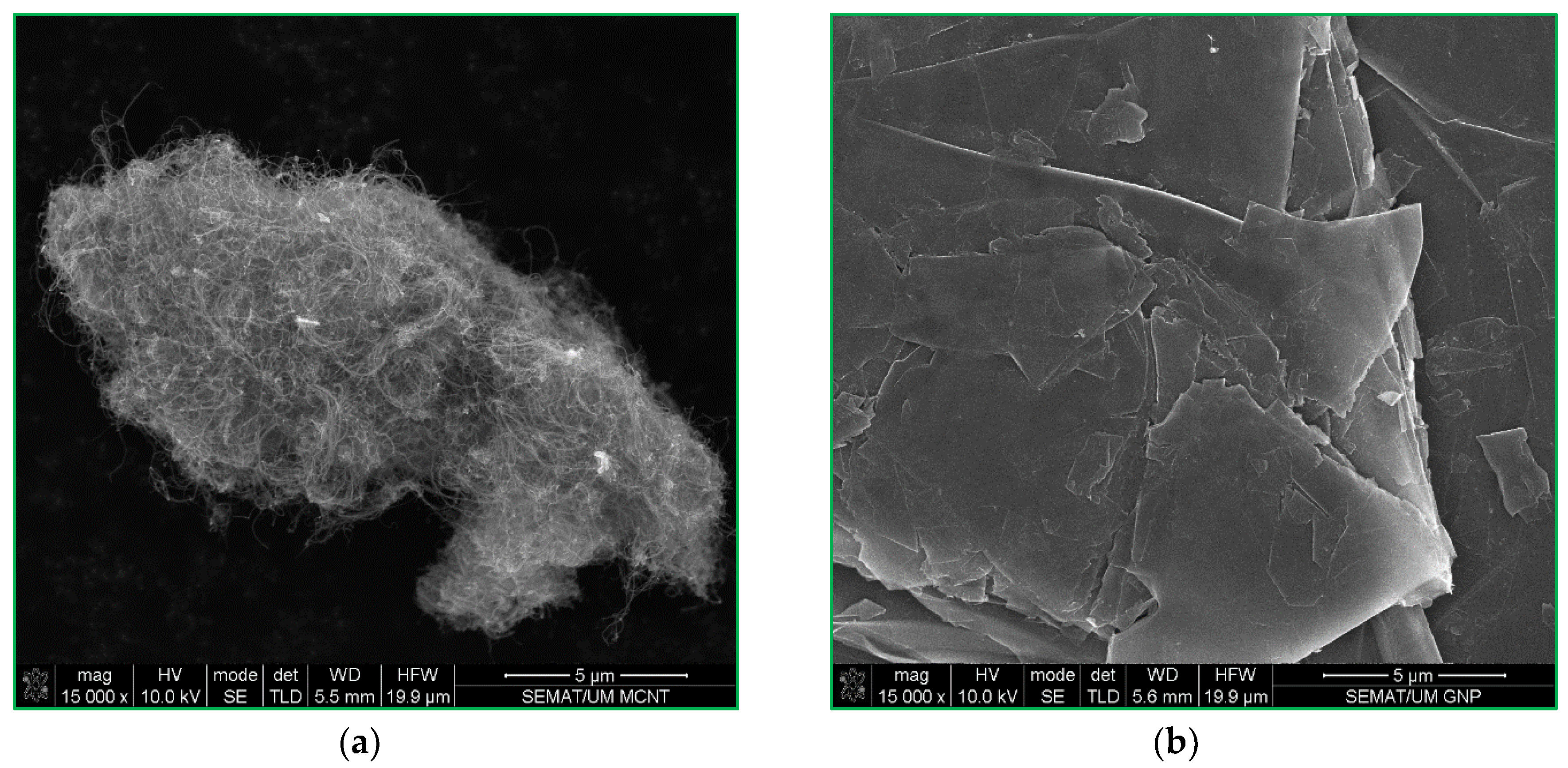

2.5. Scanning Electron Microscopy (SEM)

3. Results and discussion

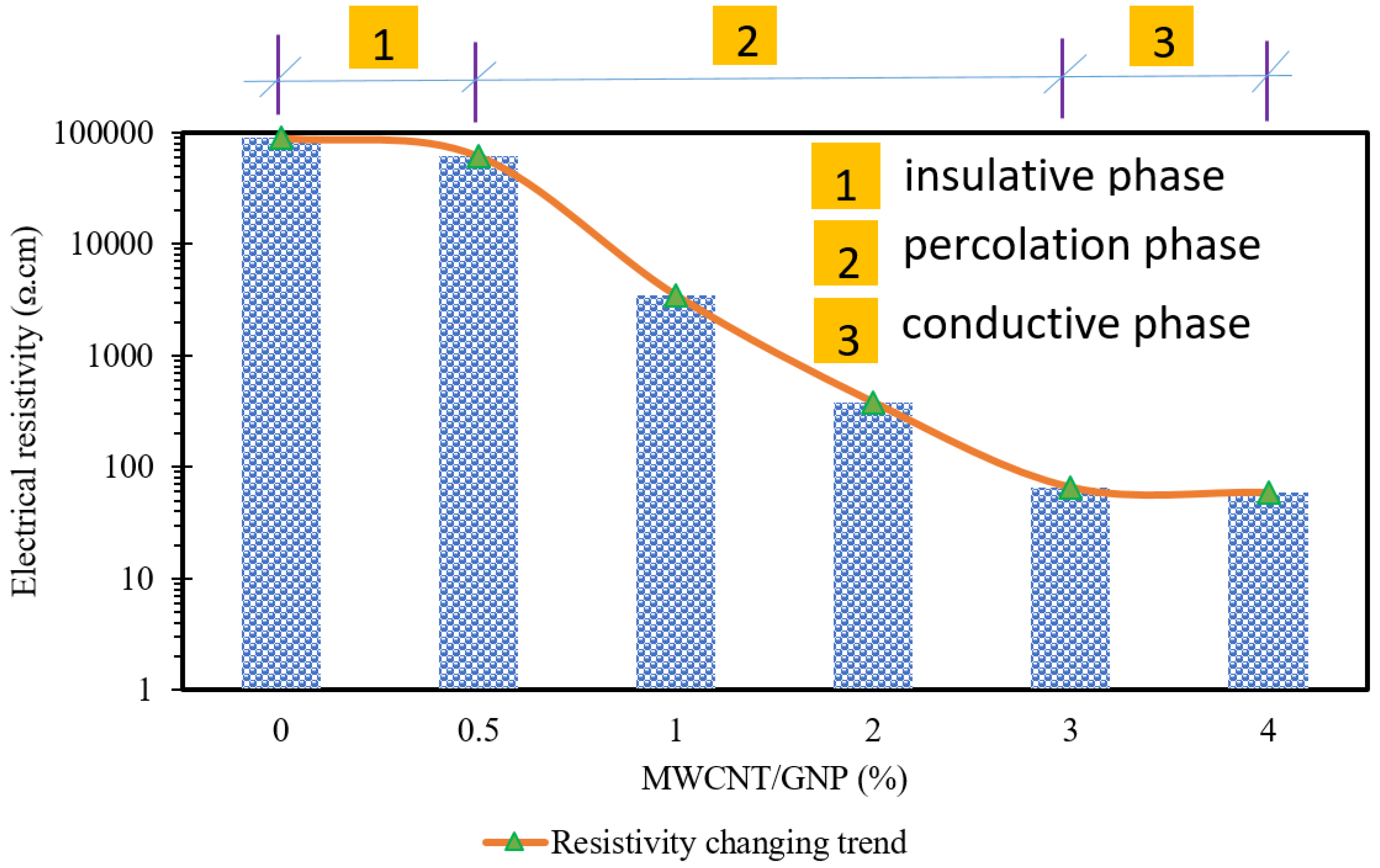

3.1. Influence of conductive filler concentration on electrical resistivity

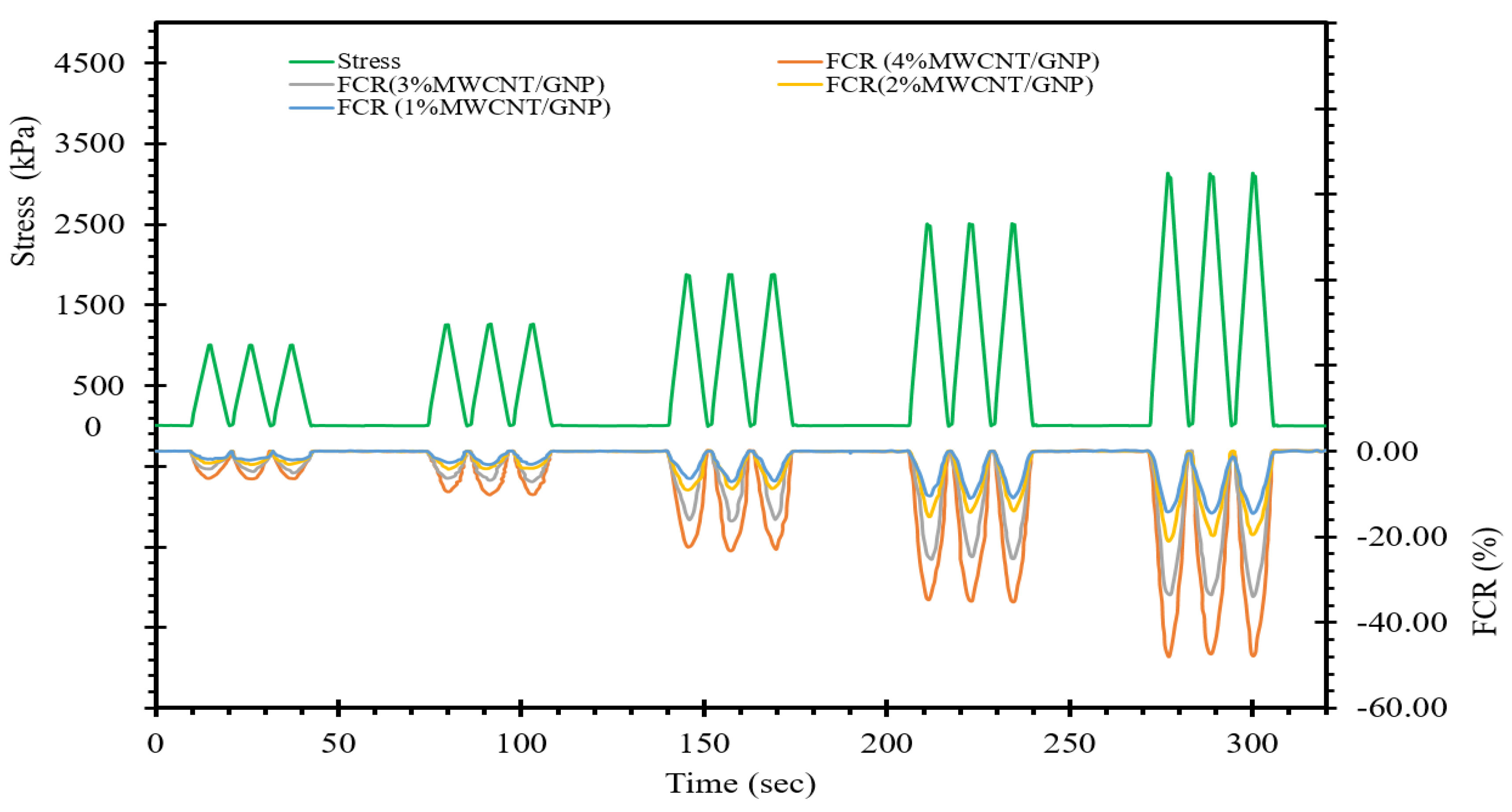

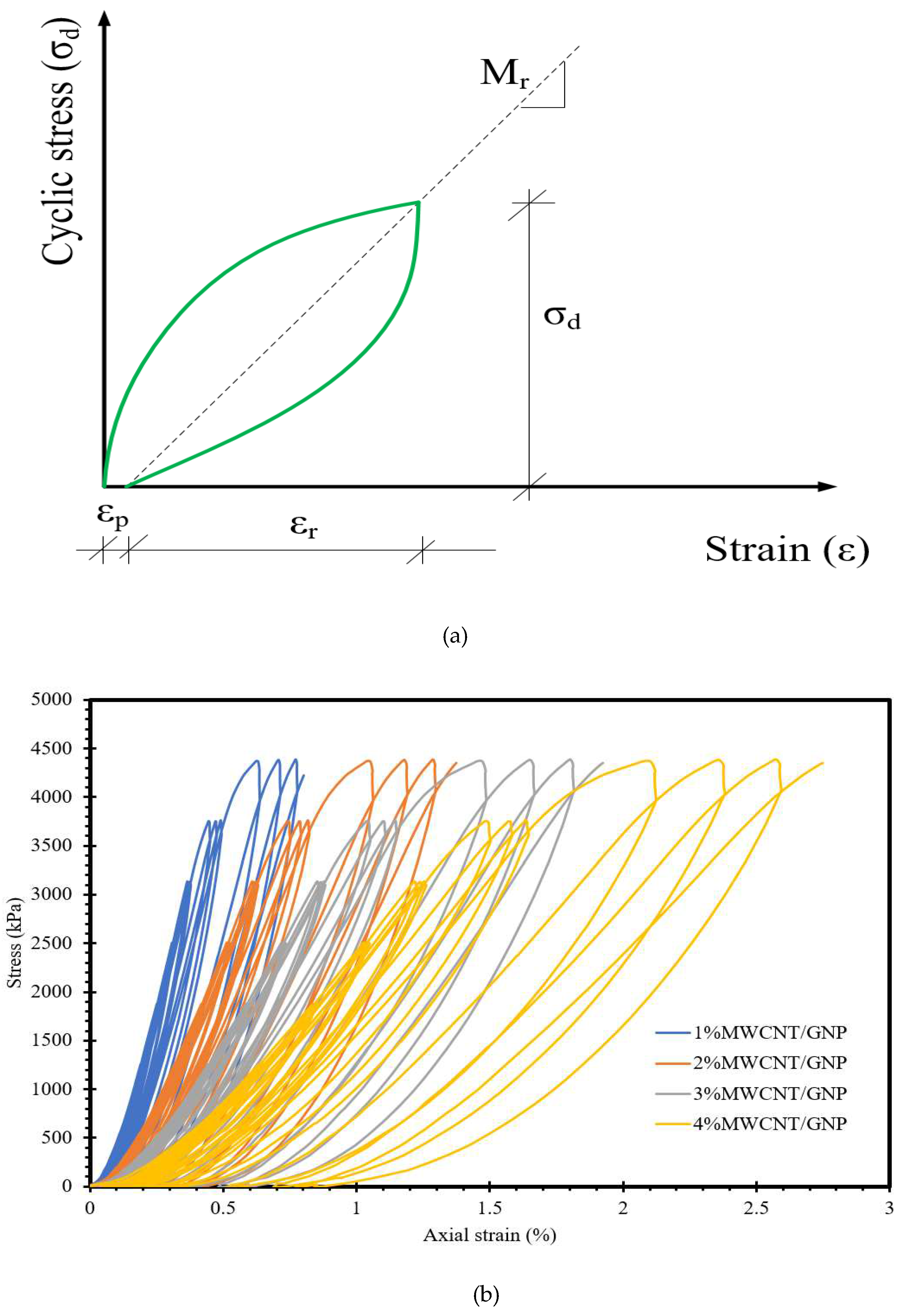

3.2. Piezoresistivity

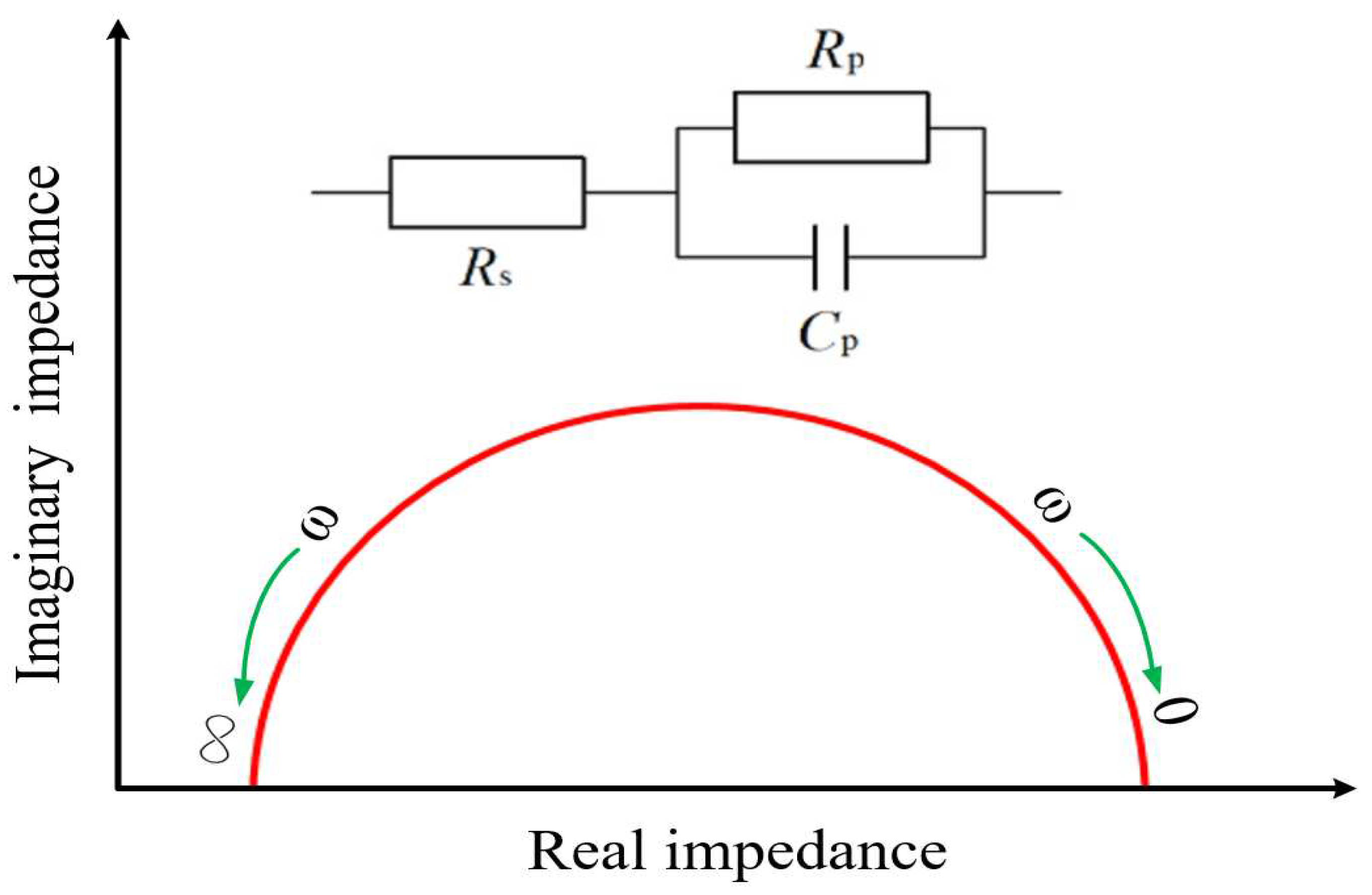

3.3. Electrochemical impedance spectroscopy (EIS)

3.4. Microstructure analysis

4. Conclusion

- In the present research, a hybrid dispersion method involving chemical treatment and ultrasonication was utilized to attain a homogeneous dispersion of conductive fillers within a self-sensing cementitious composite.

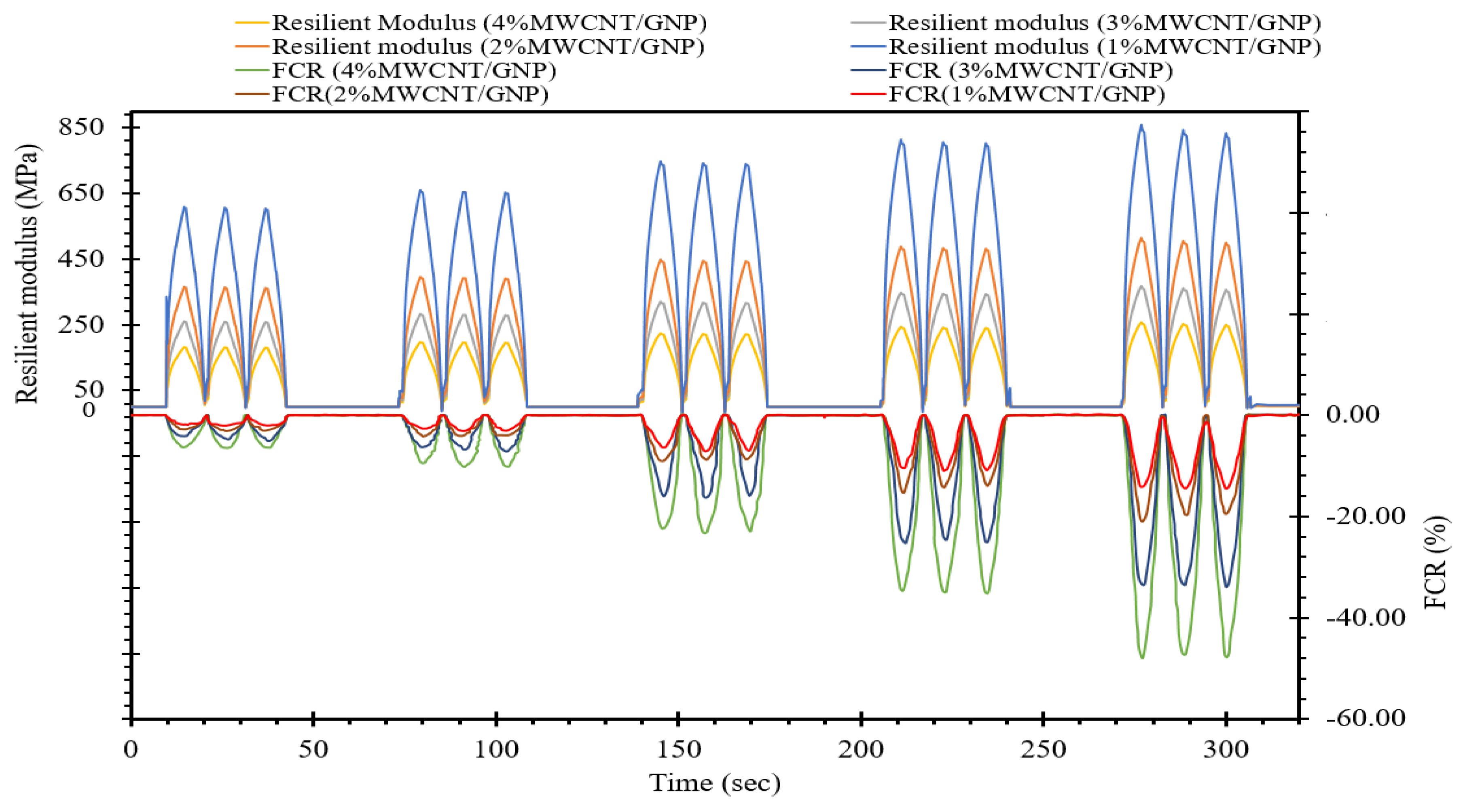

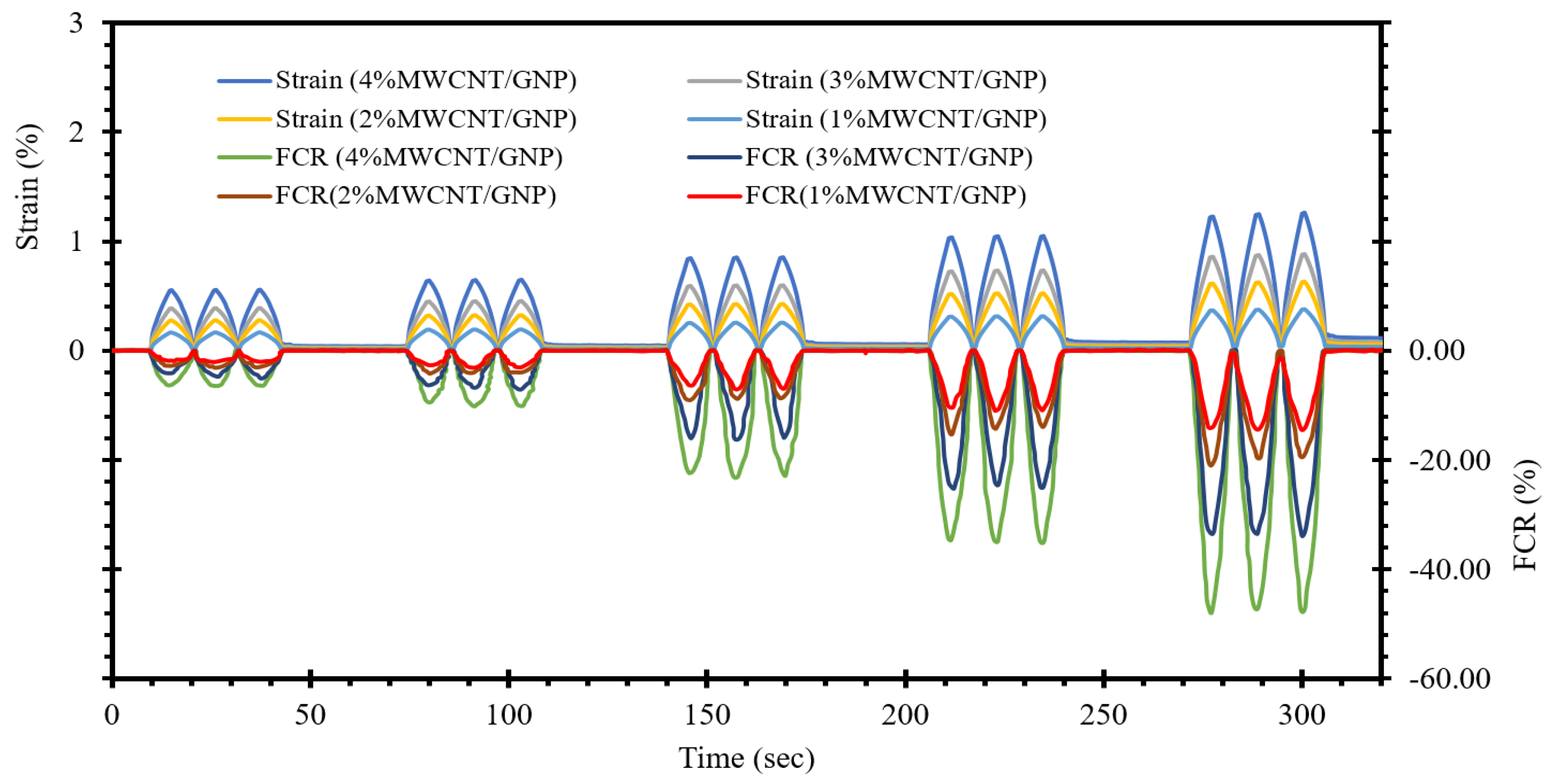

- The stress and strain sensing capabilities exhibit an upwards trend as the concentration of MWCNTs/GNPs is increased and as the applied stress levels are intensified. Nevertheless, it is important to emphasize that the stress levels employed in this study for evaluating stress and strain-sensing performance remain within the quasielastic region.

- The resilient modulus exhibits a declining trend with increasing percentage of MWCNTs/GNPs, signifying a reduction in stiffness in correlation with the increased MWCNT/GNP content. This reduced stiffness is observed to be associated with an augmented peak value for the FCR variation, which is attributed to a more pronounced variability in the conductive pathways formed by the conductive fillers.

- An assessment of the damage detection capacity for a self-sensing cementitious composite with a 3% MWCNT/GNP composition was conducted through electrochemical impedance spectroscopy (EIS) analysis. The findings reveal a reduction in the dimension of the Nyquist curves during the application of a compressive load prior to structural failure. Conversely, upon failure , the Nyquist curve exhibits an expansion. The decrease in the Nyquist curve size can be ascribed to the diminishing distances between conductive fillers. In contrast, the enlargement of the Nyquist curve is attributed to an increase in the separation between these conductive fillers.

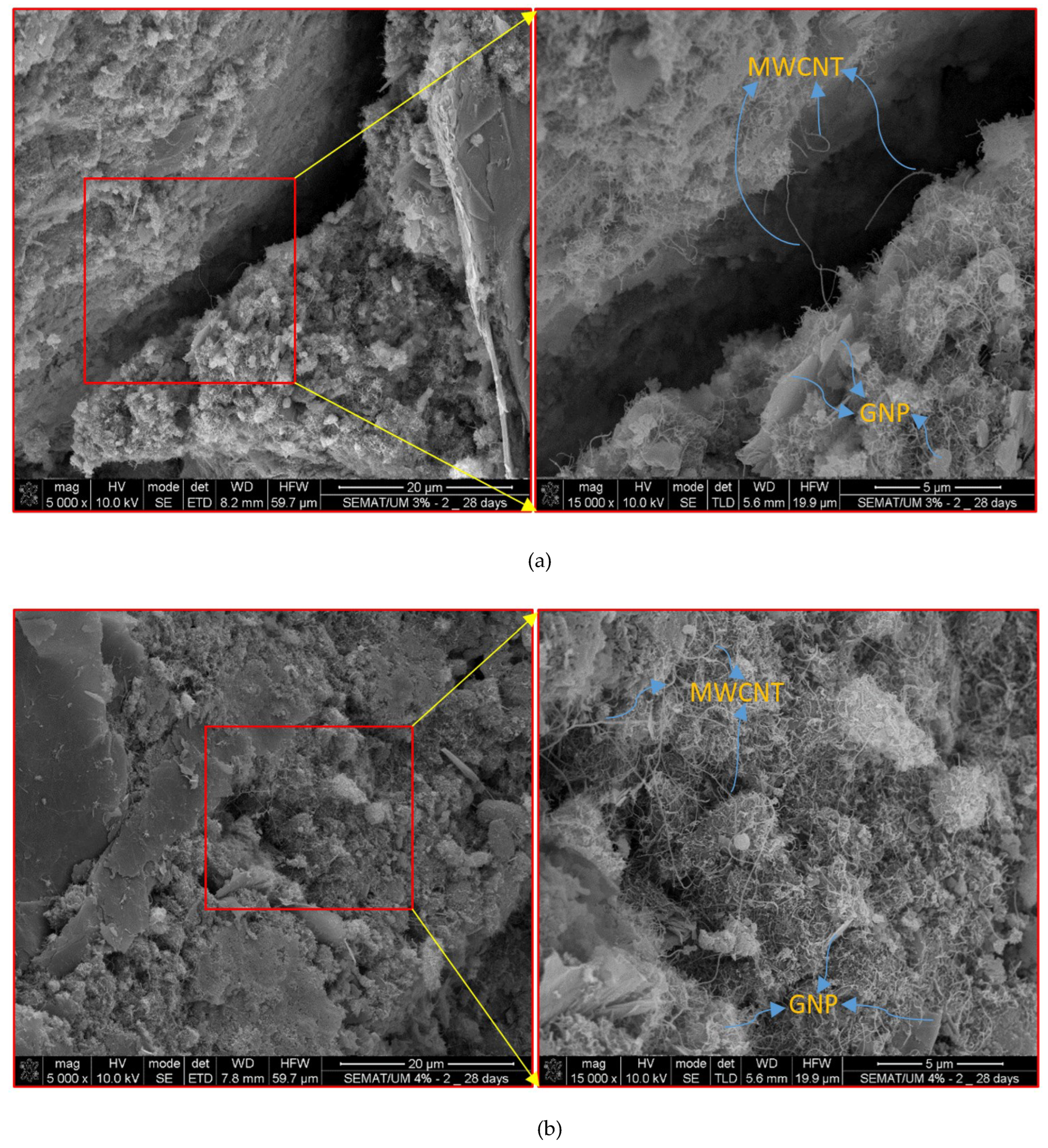

- Scanning electron microscopy (SEM) provides visual evidence for an accumulation of conductive pathways with increasing concentration of conductive fillers. The MWCNTs play a role in bridging microcracks and pore spaces, while the GNPs fill the voids. Consequently, incorporating hybrid conductive fillers in cementitious composites offers a more efficient approach to inducing sensory (stress/strain and damage sensing) performances.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- Roshan, M.J.; A Rashid, A.S.; Abdul Wahab, N.; Tamassoki, S.; Jusoh, S.N.; Hezmi, M.A.; Nik Daud, N.N.; Mohd Apandi, N.; Azmi, M. Improved Methods to Prevent Railway Embankment Failure and Subgrade Degradation: A Review. Transp. Geotech. 2022, 37, 100834. [Google Scholar] [CrossRef]

- Roshan, M.J.; Rashid, A.S.A.; Wahab, N.A.; Hezmi, M.A.; Jusoh, S.N.; Azmi, M. Stability of Railway Embankment in Saturated and Unsaturated Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1153, 012007. [Google Scholar] [CrossRef]

- Abadin, M.J.; Hayano, K. Investigation of Premature Failure Mechanism in Pavement Overlay of National Highway of Bangladesh. Constr. Build. Mater. 2022, 318, 126194. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H.; Li, S.; Dong, Q. Permanent Deformation Monitoring and Remaining Life Prediction of Asphalt Pavement Combining Full-Scale Accelerated Pavement Testing and FEM. Struct. Control Heal. Monit. 2023, 2023, 1–19. [Google Scholar] [CrossRef]

- Roshan, M.J.; Rashid, A.S.B.A.; Hezmi, M.A. Bin; Nejabi, M.N.; Bt. Jusoh, S.N.; Tamassoki, S.; Razali, R. Evaluation of Cement Stabilised Residual Soil on Macro- and Micro-Scale for Road Construction. J. Eng. Appl. Sci. 2022, 69, 109. [Google Scholar] [CrossRef]

- Abbil, A.; Kassim, A.; Ullah, A.; Rashid, A.S.A.; Roshan, M.J. Numerical Analysis of Embankment Resting on Floating Bottom Ash Columns Improved Soft Soil. IOP Conf. Ser. Earth Environ. Sci. 2022, 1022, 012023. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, H.; Li, J.; Zheng, J.; Ren, J. Effect of Loading Rate on Failure Characteristics of Asphalt Mixtures Using Acoustic Emission Technique. Constr. Build. Mater. 2023, 364, 129835. [Google Scholar] [CrossRef]

- Tamassoki, S.; Daud, N.N.N.; Wang, S.; Roshan, M.J. CBR of Stabilized and Reinforced Residual Soils Using Experimental, Numerical, and Machine-Learning Approaches. Transp. Geotech. 2023, 42, 101080. [Google Scholar] [CrossRef]

- Laporte, S.; Eichhorn, G.; Kingswood, J.; Siemens, G.; Beddoe, R. Physical Modelling of Climate-Soil-Infrastructure Interactions of Paved Roadways Constructed in Expansive Soil. Transp. Geotech. 2023, 43, 101126. [Google Scholar] [CrossRef]

- Jawed Roshan, M.; Safuan, A.; Rashid, A.; Abdul Wahab, N.; Azril Hezmi, M.; Norafida Jusoh, S.; Daud Nik Norsyahariati, N.; Tamasoki, S.; Zurairahetty Mohd Yunus, N.; Razali, R. EFFECTS OF ORDINARY PORTLAND CEMENT ON THE SOIL-WATER CHARACTERISTICS CURVE OF LATERITIC SOIL. Suranaree J. Sci. Technol. 2023, 30, 010183(1-10). [Google Scholar] [CrossRef]

- Razali, R.; Rashid, A.S.A.; Che Lat, D.; Horpibulsuk, S.; Roshan, M.J.; Rahman, N.S.A.; Ahmad Rizal, N.H. Shear Strength and Durability against Wetting and Drying Cycles of Lime-Stabilised Laterite Soil as Subgrade. Phys. Chem. Earth, Parts A/B/C 2023, 132, 103479. [Google Scholar] [CrossRef]

- Tamassoki, S.; Nik Daud, N.N.; Jakarni, F.M.; Mohd Kusin, F.; Rashid, A.S.A.; Roshan, M.J. Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon. Appl. Sci. 2022, 12, 8279. [Google Scholar] [CrossRef]

- Tamassoki, S.; Daud, N.N.N.; Jakarni, F.M.; Kusin, F.M.; Rashid, A.S.A.; Roshan, M.J. Compressive and Shear Strengths of Coir Fibre Reinforced Activated Carbon Stabilised Lateritic Soil. Sustainability 2022, 14, 9100. [Google Scholar] [CrossRef]

- Tamassoki, S.; Nik Daud, N.N.; Nejabi, M.N.; Roshan, M.J. Fibre-Reinforced Soil Mixed Lime/Cement Additives: A Review. Pertanika J. Sci. Technol. 2022, 31, 217–235. [Google Scholar] [CrossRef]

- Razali, R.; Rashid, A.S.A.; Hezmi, M.A.; Roshan, M.J.; Zakaria, N.S.S.; Lat, D.C.; Rahman, N.S.A. Experimental Study on Mechanical Behavior of Laterite Soil Treated with Quicklime. J. Mech. Eng. 2022, 11, 109–122. [Google Scholar] [CrossRef]

- Roshan, M.J.; Rashid, A.S.B.A. Geotechnical Characteristics of Cement Stabilized Soils from Various Aspects: A Comprehensive Review. Arab. J. Geosci. 2024, 17, 1. [Google Scholar] [CrossRef]

- Jawed Roshan, M.; Abedi, M.; Gomes Correia, A.; Fangueiro, R. Application of Self-Sensing Cement-Stabilized Sand for Damage Detection. Constr. Build. Mater. 2023, 403, 133080. [Google Scholar] [CrossRef]

- A., D.; D., S.; Pichumani, M. Electro-Mechanical Investigations of Steel Fiber Reinforced Self-Sensing Cement Composite and Their Implications for Real-Time Structural Health Monitoring. J. Build. Eng. 2022, 51, 104343. [Google Scholar] [CrossRef]

- Moldovan, I.D.; Gomes Correia, A.; Climent, N.; Almukashfi, A.; Roshan, M.J.; Arroyo, M. Coupled Experimental and Numerical Approaches in Bender Element Testing of Geomaterials. In Proceedings of the 10th European Conference on Numerical Methods in Geotechnical Engineering (NUMGE2023); Zdravkovic, L., Kontoe, S., Taborda, D.M.G., Tsiampousi, A., Eds.; London; 2023. [Google Scholar]

- HUFENUS, R.; RUEEGGER, R.; BANJAC, R.; MAYOR, P.; SPRINGMAN, S.; BRONNIMANN, R. Full-Scale Field Tests on Geosynthetic Reinforced Unpaved Roads on Soft Subgrade. Geotext. Geomembranes 2006, 24, 21–37. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, H.; Yang, J.; Qiu, C.; Javadi, A.A. Experimental Study of a 3D Printed Geogrid Embedded with FBG Sensor for Reinforcement of Subgrade with Underlying Cave. Geotext. Geomembranes 2023, 51, 81–92. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, H.; Xu, S.; Tao, M. Mechanical Responses of Subgrade with Natural Hard Crust through an Accelerated Laboratory Loading Test on Pavements Model. Case Stud. Constr. Mater. 2023, 19, e02449. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Burnham, T.; Kwon, E.; Yu, X. Integration and Road Tests of a Self-Sensing CNT Concrete Pavement System for Traffic Detection. Smart Mater. Struct. 2013, 22, 015020. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Guo, Y.; Sun, Z.; Qu, F.; Liang, R.; Shah, S.P. Application of Intrinsic Self-Sensing Cement-Based Sensor for Traffic Detection of Human Motion and Vehicle Speed. Constr. Build. Mater. 2022, 355, 129130. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-Based Sensors with Carbon Fibers and Carbon Nanotubes for Piezoresistive Sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Guo, Y.; Li, W.; Dong, W.; Wang, K.; He, X.; Vessalas, K.; Sheng, D. Self-Sensing Cement-Based Sensors with Superhydrophobic and Self-Cleaning Capacities after Silane-Based Surficial Treatments. Case Stud. Constr. Mater. 2022, 17, e01311. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L. Development of Self-Sensing Cementitious Composite Incorporating Hybrid Graphene Nanoplates and Carbon Nanotubes for Structural Health Monitoring. Sensors Actuators A Phys. 2022, 336, 113367. [Google Scholar] [CrossRef]

- Meng, X.; Feng, J.; Pai, N.; Zequan, H.; Kaiyuan, L.; Cheng, Z.; Yazhen, Z. Effects of Filler Type and Aging on Self-Sensing Capacity of Cement Paste Using Eddy Current-Based Nondestructive Detection. Meas. J. Int. Meas. Confed. 2021, 182, 109708. [Google Scholar] [CrossRef]

- Ding, S.; Xiang, Y.; Ni, Y.-Q.; Thakur, V.K.; Wang, X.; Han, B.; Ou, J. In-Situ Synthesizing Carbon Nanotubes on Cement to Develop Self-Sensing Cementitious Composites for Smart High-Speed Rail Infrastructures. Nano Today 2022, 43, 101438. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.M.S.; Gopalakrishnan, K.; Taylor, P.C.; Abdualla, H. Carbon Fiber-Based Electrically Conductive Concrete for Salt-Free Deicing of Pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

- Ding, S.; Dong, S.; Wang, X.; Ding, S.; Han, B.; Ou, J. Self-Heating Ultra-High Performance Concrete with Stainless Steel Wires for Active Deicing and Snow-Melting of Transportation Infrastructures. Cem. Concr. Compos. 2023, 138, 105005. [Google Scholar] [CrossRef]

- Sajid, H.U.; Jalal, A.; Kiran, R.; Al-Rahim, A. A Survey on the Effects of Deicing Materials on Properties of Cement-Based Materials. Constr. Build. Mater. 2022, 319, 126062. [Google Scholar] [CrossRef]

- Amândio, M.; Parente, M.; Neves, J.; Fonseca, P. Integration of Smart Pavement Data with Decision Support Systems: A Systematic Review. Buildings 2021, 11, 1–24. [Google Scholar] [CrossRef]

- Chung, D.D.L. A Critical Review of Electrical-Resistance-Based Self-Sensing in Conductive Cement-Based Materials. Carbon N. Y. 2023, 203, 311–325. [Google Scholar] [CrossRef]

- Yang, P.; Chowdhury, S.; Neithalath, N. Strain Sensing Ability of Metallic Particulate Reinforced Cementitious Composites: Experiments and Microstructure-Guided Finite Element Modeling. Cem. Concr. Compos. 2018, 90, 225–234. [Google Scholar] [CrossRef]

- Reddy, P.N.; Kavyateja, B.V.; Jindal, B.B. Structural Health Monitoring Methods, Dispersion of Fibers, Micro and Macro Structural Properties, Sensing, and Mechanical Properties of Self-sensing Concrete—A Review. Struct. Concr. 2021, 22, 793–805. [Google Scholar] [CrossRef]

- Gulisano, F.; Abedi, M.; Jurado-Piña, R.; Apaza, F.R.A.; Roshan, M.J.; Fangueiro, R.; Correia, A.G.; Gallego, J. Stress and Damage-Sensing Capabilities of Asphalt Mixtures Incorporating Graphene Nanoplatelets. Sensors Actuators A Phys. 2023, 359, 114494. [Google Scholar] [CrossRef]

- Falara, M.G.; Thomoglou, A.K.; Gkountakou, F.I.; Elenas, A.; Chalioris, C.E. Hybrid Smart Cementitious Materials Incorporating Ladder Scale Carbon Fiber Reinforcement: An Experimental Investigation. Case Stud. Constr. Mater. 2023, 18, e02035. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Wang, K.; Han, B.; Sheng, D.; Shah, S.P. Investigation on Physicochemical and Piezoresistive Properties of Smart MWCNT/Cementitious Composite Exposed to Elevated Temperatures. Cem. Concr. Compos. 2020, 112, 103675. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S. Strain Sensing Ability of GNP Reinforced Cementitious Composites: The Role of Exfoliation and Interlayer Spacing. Constr. Build. Mater. 2023, 390, 131593. [Google Scholar] [CrossRef]

- Le, J.-L.; Du, H.; Pang, S.D. Use of 2D Graphene Nanoplatelets (GNP) in Cement Composites for Structural Health Evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Xu, C.; Fu, J.; Sun, L.; Masuya, H.; Zhang, L. Fatigue Damage Self-Sensing of Bridge Deck Component with Built-in Giant Piezoresistive Cementitious Carbon Fiber Composites. Compos. Struct. 2021, 276, 114459. [Google Scholar] [CrossRef]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Strain and Damage Sensing Properties on Multifunctional Cement Composites with CNF Admixture. Cem. Concr. Compos. 2014, 46, 90–98. [Google Scholar] [CrossRef]

- Guo, Y.; Li, W.; Dong, W.; Luo, Z.; Qu, F.; Yang, F.; Wang, K. Self-Sensing Performance of Cement-Based Sensor with Carbon Black and Polypropylene Fibre Subjected to Different Loading Conditions. J. Build. Eng. 2022, 59, 105003. [Google Scholar] [CrossRef]

- Teomete, E. The Effect of Temperature and Moisture on Electrical Resistance, Strain Sensitivity and Crack Sensitivity of Steel Fiber Reinforced Smart Cement Composite. Smart Mater. Struct. 2016, 25, 075024. [Google Scholar] [CrossRef]

- Jang, S.-H.; Hochstein, D.P.; Kawashima, S.; Yin, H. Experiments and Micromechanical Modeling of Electrical Conductivity of Carbon Nanotube/Cement Composites with Moisture. Cem. Concr. Compos. 2017, 77, 49–59. [Google Scholar] [CrossRef]

- Yıldırım, G.; Öztürk, O.; Al-Dahawi, A.; Afşın Ulu, A.; Şahmaran, M. Self-Sensing Capability of Engineered Cementitious Composites: Effects of Aging and Loading Conditions. Constr. Build. Mater. 2020, 231, 117132. [Google Scholar] [CrossRef]

- Sevim, O.; Jiang, Z.; Ozbulut, O.E. Effects of Graphene Nanoplatelets Type on Self-Sensing Properties of Cement Mortar Composites. Constr. Build. Mater. 2022, 359, 129488. [Google Scholar] [CrossRef]

- Cabeza, M.; Keddam, M.; Nóvoa, X.R.; Sánchez, I.; Takenouti, H. Impedance Spectroscopy to Characterize the Pore Structure during the Hardening Process of Portland Cement Paste. Electrochim. Acta 2006, 51, 1831–1841. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Ding, W.; Li, S.; Han, N.; Xing, F.; Lu, Y. Electrochemical Impedance Study on Steel Corrosion in the Simulated Concrete System with a Novel Self-Healing Microcapsule. Constr. Build. Mater. 2014, 56, 1–6. [Google Scholar] [CrossRef]

- McCarter, W.J. The a.c. Impedance Response of Concrete during Early Hydration. J. Mater. Sci. 1996, 31, 6285–6292. [Google Scholar] [CrossRef]

- Dotelli, G.; Mari, C.M. The Evolution of Cement Paste Hydration Process by Impedance Spectroscopy. Mater. Sci. Eng. A 2001, 303, 54–59. [Google Scholar] [CrossRef]

- Hu, X.; Shi, C.; Yuan, Q.; de Schutter, G. AC Impedance Spectroscopy Characteristics of Chloride-Exposed Cement Pastes. Constr. Build. Mater. 2020, 233, 117267. [Google Scholar] [CrossRef]

- McCarter, W.J.; Garvin, S.; Bouzid, N. Impedance Measurements on Cement Paste. J. Mater. Sci. Lett. 1988, 7, 1056–1057. [Google Scholar] [CrossRef]

- Ravikumar, D.; Neithalath, N. An Electrical Impedance Investigation into the Chloride Ion Transport Resistance of Alkali Silicate Powder Activated Slag Concretes. Cem. Concr. Compos. 2013, 44, 58–68. [Google Scholar] [CrossRef]

- Pichór, W.; Frąc, M.; Radecka, M. Determination of Percolation Threshold in Cement Composites with Expanded Graphite by Impedance Spectroscopy. Cem. Concr. Compos. 2022, 125, 104328. [Google Scholar] [CrossRef]

- He, H.; Zhu, Y.; Zhou, A. Electrochemical Impedance Spectroscopy (EIS) Used to Evaluate Influence of Different External Pressures, Curing Ages and Self-Healing Environments on the Self-Healing Behavior of Engineered Cementitious Composites (ECC). Constr. Build. Mater. 2018, 188, 153–160. [Google Scholar] [CrossRef]

- Cruz, J.M.; Fita, I.C.; Soriano, L.; Payá, J.; Borrachero, M.V. The Use of Electrical Impedance Spectroscopy for Monitoring the Hydration Products of Portland Cement Mortars with High Percentage of Pozzolans. Cem. Concr. Res. 2013, 50, 51–61. [Google Scholar] [CrossRef]

- Dong, B.; Qiu, Q.; Gu, Z.; Xiang, J.; Huang, C.; Fang, Y.; Xing, F.; Liu, W. Characterization of Carbonation Behavior of Fly Ash Blended Cement Materials by the Electrochemical Impedance Spectroscopy Method. Cem. Concr. Compos. 2016, 65, 118–127. [Google Scholar] [CrossRef]

- Fan, S.; Li, X.; Li, M. The Effects of Damage and Self-Healing on Impedance Spectroscopy of Strain-Hardening Cementitious Materials. Cem. Concr. Res. 2018, 106, 77–90. [Google Scholar] [CrossRef]

- He, F.; Wang, R.; Zhang, R.; Chen, C.; Lin, L. Effect of the Sample–Electrode Contact Impedance on the Appearance of Dispersion in the AC Impedance Spectroscopy of Cement-Based Materials. J. Sustain. Cem. Mater. 2018, 7, 323–339. [Google Scholar] [CrossRef]

- Zhang, J.; Heath, A.; Abdalgadir, H.M.T.; Ball, R.J.; Paine, K. Electrical Impedance Behaviour of Carbon Fibre Reinforced Cement-Based Sensors at Different Moisture Contents. Constr. Build. Mater. 2022, 353, 129049. [Google Scholar] [CrossRef]

- Li, W.; Ji, W.; Fang, G.; Liu, Y.; Xing, F.; Liu, Y.; Dong, B. Electrochemical Impedance Interpretation for the Fracture Toughness of Carbon Nanotube/Cement Composites. Constr. Build. Mater. 2016, 114, 499–505. [Google Scholar] [CrossRef]

- da Silva, G.F.; Martini, S.; Moraes, J.C.B.; Teles, L.K. AC Impedance Spectroscopy (AC-IS) Analysis to Characterize the Effect of Nanomaterials in Cement-Based Mortars. Constr. Build. Mater. 2021, 269, 121260. [Google Scholar] [CrossRef]

- Taheri, S.; Georgaklis, J.; Ams, M.; Patabendigedara, S.; Belford, A.; Wu, S. Smart Self-Sensing Concrete: The Use of Multiscale Carbon Fillers. J. Mater. Sci. 2022, 57, 2667–2682. [Google Scholar] [CrossRef]

- Lu, D.; Wang, D.; Zhong, J. Highly Conductive and Sensitive Piezoresistive Cement Mortar with Graphene Coated Aggregates and Carbon Fiber. Cem. Concr. Compos. 2022, 134, 104731. [Google Scholar] [CrossRef]

- Gupta, S.; Lin, Y.-A.; Lee, H.-J.; Buscheck, J.; Wu, R.; Lynch, J.P.; Garg, N.; Loh, K.J. In Situ Crack Mapping of Large-Scale Self-Sensing Concrete Pavements Using Electrical Resistance Tomography. Cem. Concr. Compos. 2021, 122, 104154. [Google Scholar] [CrossRef]

- Ullah, R.; Abdullah, R.A.; Kassim, A.; Yunus, N.Z.M.; Ullah, A.; Junaid, M.; Roshan, M.J. Effectiveness of Laser Diffraction Method for Particle Size Evaluation of Residual Soil. Indian Geotech. J. 2022, 52, 1476–1486. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and Mechanical Properties of Carbon Nanotube Reinforced Cementitious Composites Developed Using a Novel Dispersion Technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Wahab, N.A.; Rashid, A.S.A.; Roshan, M.J.; Rizal, N.H.A.; Yunus, N.Z.M.; Hezmi, M.A.; Tadza, M.Y.M. Effects of Cement on the Compaction Properties of Lateritic Soil. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1153, 012015. [Google Scholar] [CrossRef]

- Rizal, N.H.A.A.; Hezmi, M.A.; Razali, R.; Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.A.; Hasbollah, D.Z.A.A. Effects of Lime on the Compaction Characteristics of Lateritic Soil in UTM, Johor. IOP Conf. Ser. Earth Environ. Sci. 2022, 971, 012031. [Google Scholar] [CrossRef]

- Han, J.; Pan, J.; Cai, J.; Li, X. A Review on Carbon-Based Self-Sensing Cementitious Composites. Constr. Build. Mater. 2020, 265, 120764. [Google Scholar] [CrossRef]

- Díaz, B.; Guitián, B.; Nóvoa, X.R.; Pérez, C. Analysis of the Microstructure of Carbon Fibre Reinforced Cement Pastes by Impedance Spectroscopy. Constr. Build. Mater. 2020, 243, 118207. [Google Scholar] [CrossRef]

- Xie, P.; Gu, P.; Xu, Z.; Beaudoin, J.J. A Rationalized a.c. Impedence Model for Microstructural Characterization of Hydrating Cement Systems. Cem. Concr. Res. 1993, 23, 359–367. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Thach Nguyen, B.; Setunge, S. Estimating the Resilient Modulus of Crushed Recycled Pavement Materials Containing Crumb Rubber Using the Clegg Impact Value. Resour. Conserv. Recycl. 2019, 141, 301–307. [Google Scholar] [CrossRef]

- Ackah, F.S.; Zhuochen, N.; Huaiping, F. Effect of Wetting and Drying on the Resilient Modulus and Permanent Strain of a Sandy Clay by RLTT. Int. J. Pavement Res. Technol. 2021, 14, 366–377. [Google Scholar] [CrossRef]

- Yang, S.; Lin, H.; Kung, J.H.S.; Huang, W. Suction-Controlled Laboratory Test on Resilient Modulus of Unsaturated Compacted Subgrade Soils. J. Geotech. Geoenvironmental Eng. 2008, 134, 1375–1384. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Zhou, C.; Yuan, Q.; Xu, J. Resilient Modulus of Unsaturated Subgrade Soil: Experimental and Theoretical Investigations. Can. Geotech. J. 2013, 50, 223–232. [Google Scholar] [CrossRef]

- Ikechukwu, A.F.; Hassan, M.M.; Moubarak, A. Resilient Modulus and Microstructure of Unsaturated Expansive Subgrade Stabilized with Activated Fly Ash. Int. J. Geotech. Eng. 2021, 15, 915–938. [Google Scholar] [CrossRef]

- Freitas, J.B. de; Rezende, L.R. de; Gitirana Jr., G. de F.N. Prediction of the Resilient Modulus of Two Tropical Subgrade Soils Considering Unsaturated Conditions. Eng. Geol. 2020, 270, 105580. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J.; Zeng, L.; Li, J.; Li, F. Rapid Estimation of Resilient Modulus of Subgrade Soils Using Performance-Related Soil Properties. Int. J. Pavement Eng. 2021, 22, 732–739. [Google Scholar] [CrossRef]

- Du, Y.-J.; Jiang, N.-J.; Liu, S.-Y.; Horpibulsuk, S.; Arulrajah, A. Field Evaluation of Soft Highway Subgrade Soil Stabilized with Calcium Carbide Residue. Soils Found. 2016, 56, 301–314. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance Spectroscopy Study of the Effect of Environmental Conditions in the Microstructure Development of OPC and Slag Cement Mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

| Designation | MWCNT/GNP (%) | Cement (% by weight of dry sand) | Pluronic F-127 (%by weight of MWCNT/GNP) | TBP-97 (% by weight of surfactant) |

| SCS1 | 1 | 10 | 10 | 50 |

| SCS2 | 2 | 10 | 10 | 50 |

| SCS3 | 3 | 10 | 10 | 50 |

| SCS4 | 4 | 10 | 10 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).