C.1. Preamble file

function [rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, DBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal)

%=========================================================================

% Preamble for Missile Launched from Geostationary Orbit to Specific Target min time

%=========================================================================

%Scaled Values

rBar = primal.states(1,:); %States

thetaBar = primal.states(2,:);

phiBar = primal.states(3,:);

vBar = primal.states(4,:);

gammaBar = primal.states(5,:);

psiBar = primal.states(6,:);

LgammaBar = primal.controls(1,:); %Controls

LpsiBar = primal.controls(2,:);

tBar = primal.time; %Time

r0Bar = primal.initial.states(1); %Initial States

theta0Bar = primal.initial.states(2);

phi0Bar = primal.initial.states(3);

v0Bar = primal.initial.states(4);

gamma0Bar = primal.initial.states(5);

psi0Bar = primal.initial.states(6);

t0Bar = primal.initial.time; %Initial Time

rfBar = primal.final.states(1); %Final States

thetafBar = primal.final.states(2);

phifBar = primal.final.states(3);

vfBar = primal.final.states(4);

gammafBar = primal.final.states(5);

psifBar = primal.final.states(6);

tfBar = primal.final.time; %Final Time

uBar = primal.constants.uBar; %Constants

TBar = primal.constants.TBar;

mBar = primal.constants.mBar;

DBar = primal.constants.DBar;

g = primal.constants.g;

Cd = primal.constants.Cd;

S = primal.constants.S;

FU = primal.constants.FU;

R = primal.constants.R;

V = primal.constants.V;

TU = primal.constants.TU;

kq = primal.constants.kq;

DU = primal.constants.DU;

KU = primal.constants.KU;

%eof

C.1. Pz %Search Space for rBar

-pi, pi; %Search Space for thetaBar (Longitude)

-pi/2, pi/2; %Search Space for phiBar (Latitude)

0, 5; %Search Space for vBar

-pi, pi; %Search Space for gammaBar

-pi, pi]; %Search Space for psiBar

search.controls = [-11, 11; %Search Space for Lgamma

-11, 11]; %Search Space for Lpsi

%=========================================================================

%Defining Problem Specific Constants

%Unscaled Constants

mu = 3.986004418e5; %Earth Gravitational Parameter km/sec2

Thrust = 17.799; %4000lbf converted to kgkm/s^2

mass = 5000; %Initial Mass

MS4.constants.g = 0.00981; %Gravitational Constant of Earth in km/s^2

MS4.constants.Cd = 0.8; %Drag Coefficient

MS4.constants.S = 3.44e-6; %Drag Reference Area (km^2)

MS4.constants.kq = sqrt(1000)*9e-5; %kg^.5/km^.5

%Scaling Factors

MS4.constants.R = 6378; %Distance Scaling

MS4.constants.TU = sqrt(MS4.constants.R/MS4.constants.g);%Time Scaling

MS4.constants.AU = 1; %Angle Scaling => Radians remain unscaled

MS4.constants.V = MS4.constants.R/MS4.constants.TU; %Velocity Scaling

MS4.constants.M = 10; %Mass Scaling

MS4.constants.A = MS4.constants.R/(MS4.constants.TU^2);%Acceleration Scaling

MS4.constants.FU = MS4.constants.M*MS4.constants.A; %Force Scaling

MS4.constants.DU = MS4.constants.M/(MS4.constants.R^3); %Density Scaling

MS4.constants.KU = (MS4.constants.M^.5)/(MS4.constants.R^.5);

%Scaled Constants

MS4.constants.uBar = (MS4.constants.TU^2/(MS4.constants.R^3))*mu; %Scaled Earth Gravitational Parameter

%MS4.constants.TBar = Thrust/MS4.constants.FU; %Scaled Thrust

MS4.constants.TBar = Thrust;

MS4.constants.mBar = mass/MS4.constants.M; %Scaled Mass in kg

MS4.constants.DBar = 1.2344;

%=========================================================================

%Boundary Conditions

rInitial = 43378; %kilometers - Does not change

rFinal = 6378; %kilometers - Changes with tgt location

r0Bar = rInitial/MS4.constants.R; %Scale initial condition

rfBar = rFinal/MS4.constants.R; %Scale final condition

phi0Bar = deg2rad(0); %Latitude is unscaled in radians

theta0Bar = deg2rad(-90); %Longitude is unscaled in radians

v0Bar = 1/MS4.constants.V; %Initial velocity is near zero

gamma0Bar = deg2rad(-89); %Flight Path angle is unscaled in radians

psi0Bar = deg2rad(0); %Flight Path Azimuth is unscaled in radians

phifBar = deg2rad(36.6002); %Latitude of target to radians

thetafBar = deg2rad(-121.8947); %Longitude of target to radians

bounds.events = [r0Bar, r0Bar; %Radius of geosynchronous orbit

theta0Bar, theta0Bar;%Set initial latitude of orbit

phi0Bar, phi0Bar; %Set initial longitude of orbit

v0Bar, v0Bar; %v0 is 0

gamma0Bar, gamma0Bar;%Set initial flightpath angle

psi0Bar, psi0Bar; %Set initial flightpath azimuth

rfBar, rfBar; %Target radius

thetafBar, thetafBar;%Target latitude

phifBar, phifBar]; %Target longitude

%=========================================================================

%Initial and Final Time Constraints

bounds.initial.time = [0, 0]; %Clock starts at beginning

bounds.final.time = [0, 15]; %Guess on upper bound

%=========================================================================

%Path Constraints

bounds.path = [-10, 10; %Control Constraint, -10<=LBar<=10

-10, 10; %Control Constraint, -10<=LBar<=10

0, 4.9]; %Heating Rate Constraint

%=========================================================================

%Problem Definition

MS4.cost = 'MS4Cost';

MS4.dynamics = 'MS4Dynamics';

MS4.events = 'MS4Events';

MS4.path = 'MS4Path';

MS4.search = search;

MS4.bounds = bounds;

%=========================================================================

%DIDO Formulation check

check(MS4);

%=========================================================================

%Node selection

algorithm.nodes = 55;

%=========================================================================

%Run DIDO and time the program

tic

[cost, primal, dual] = dido(MS4, algorithm);

toc

%=========================================================================

%Output Analysis

[rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, DBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal);

MinTime = cost*MS4.constants.TU

lam_rBar = dual.dynamics(1,:);

lam_thetaBar = dual.dynamics(2,:);

lam_phiBar = dual.dynamics(3,:);

lam_vBar = dual.dynamics(4,:);

lam_gammaBar = dual.dynamics(5,:);

lam_psiBar = dual.dynamics(6,:);

eps1 = dual.path(1,:);

eps2 = dual.path(2,:);

eps3 = dual.path(3,:);

stat1 = lam_gammaBar./(mBar.*vBar);

stat2 = lam_psiBar./(mBar.*vBar.*cos(gammaBar));

%=========================================================================

%PLOTS

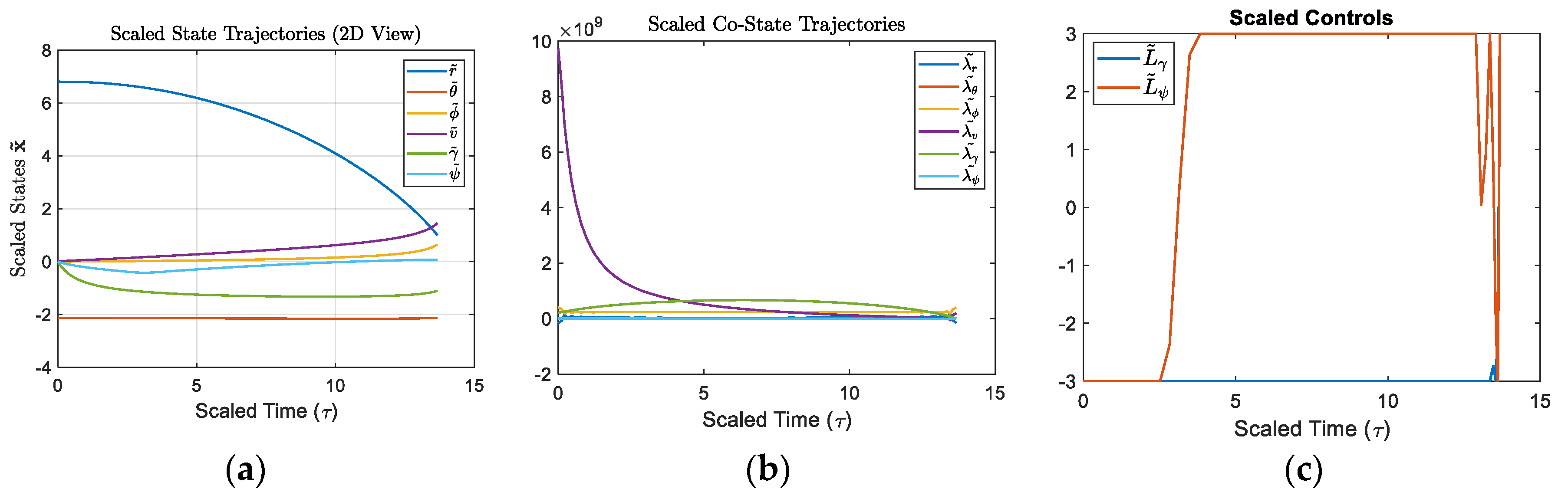

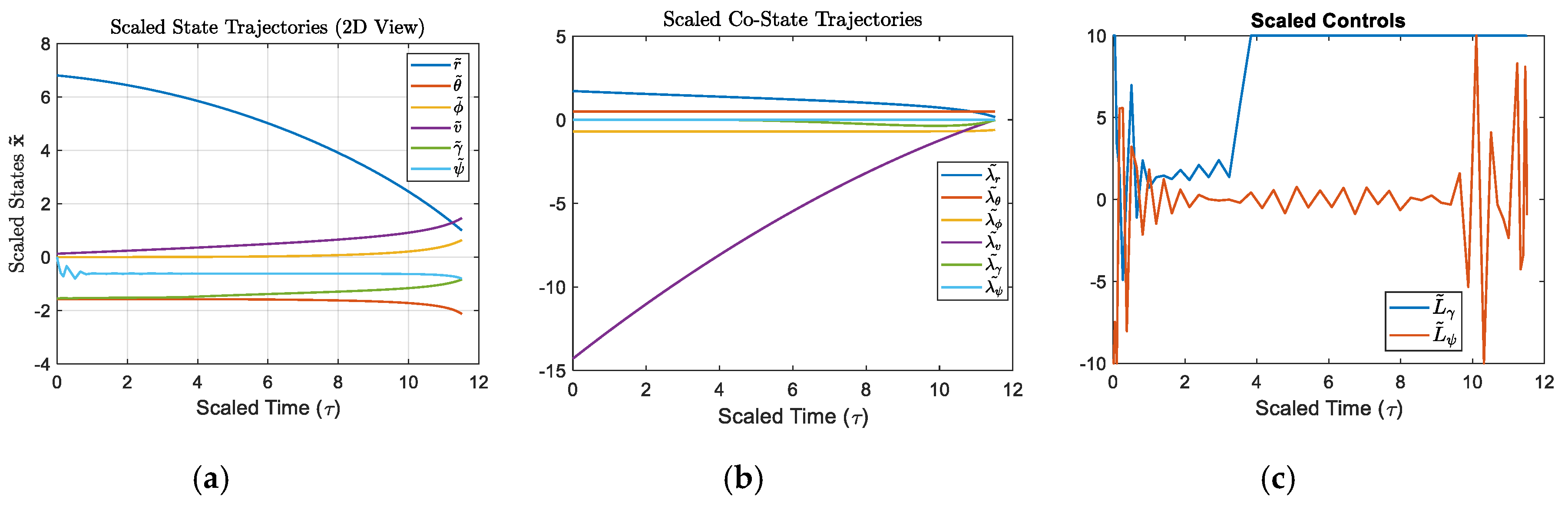

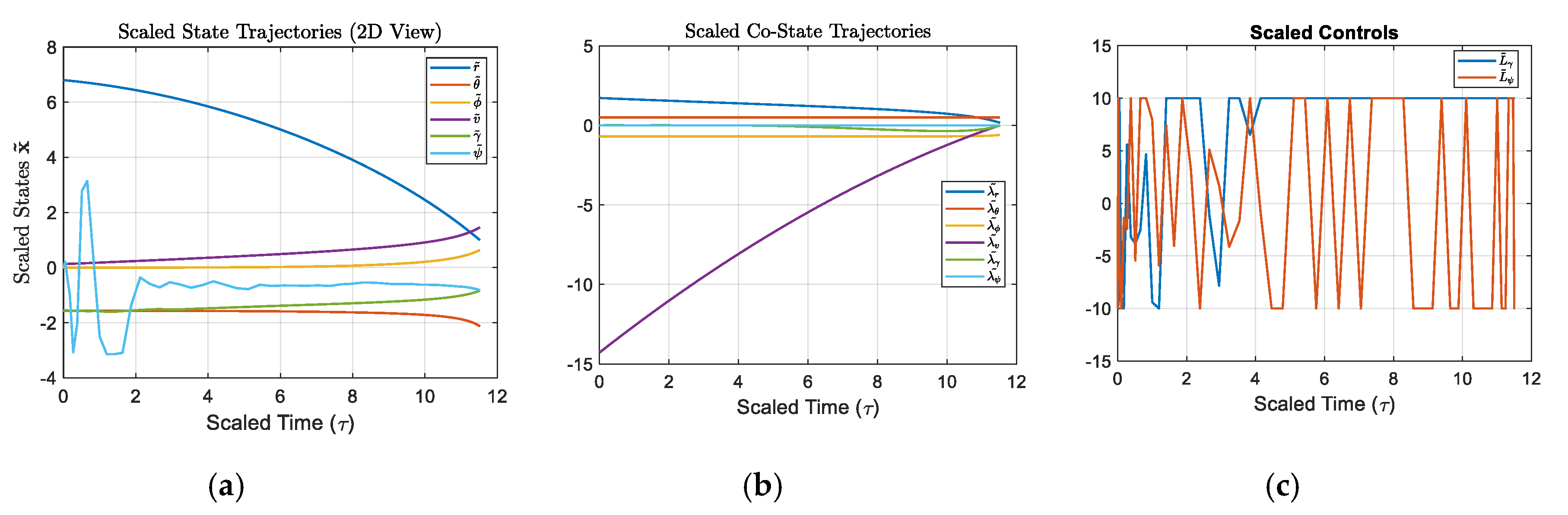

figure;

plot(tBar, [rBar; thetaBar; phiBar; vBar; gammaBar; psiBar]); grid on;

title('Scaled State Trajectories (2D View)','Interpreter','latex');

xlabel('Scaled Time (\tau)','FontSize',16);

ylabel('Scaled States $\mathbf{\tilde{x}}$','Interpreter','latex','FontSize',16);

legend('$\tilde{r}$','$\tilde{\theta}$','$\tilde{\phi}$','$\tilde{v}$','$\tilde{\gamma}$','$\tilde{\psi}$','Interpreter','latex','FontSize', 10);

figure;

plot(tBar, [LgammaBar; LpsiBar]); grid on;

title('Scaled Controls')

legend('$\tilde{L}_\gamma$','$\tilde{L}_\psi$','Interpreter','latex','FontSize',10)

xlabel('Scaled Time (\tau)','FontSize',16)

figure;

plot(tBar, [lam_rBar; lam_thetaBar; lam_phiBar; lam_vBar; lam_gammaBar; lam_psiBar]); grid on;

title('Scaled Co-State Trajectories','Interpreter','latex');

legend('$\tilde{\lambda_r}$','$\tilde{\lambda_\theta}$','$\tilde{\lambda_\phi}$','$\tilde{\lambda_v}$','$\tilde{\lambda_\gamma}$','$\tilde{\lambda_\psi}$','Interpreter','latex','FontSize', 10);

xlabel('Scaled Time (\tau)','FontSize',16);

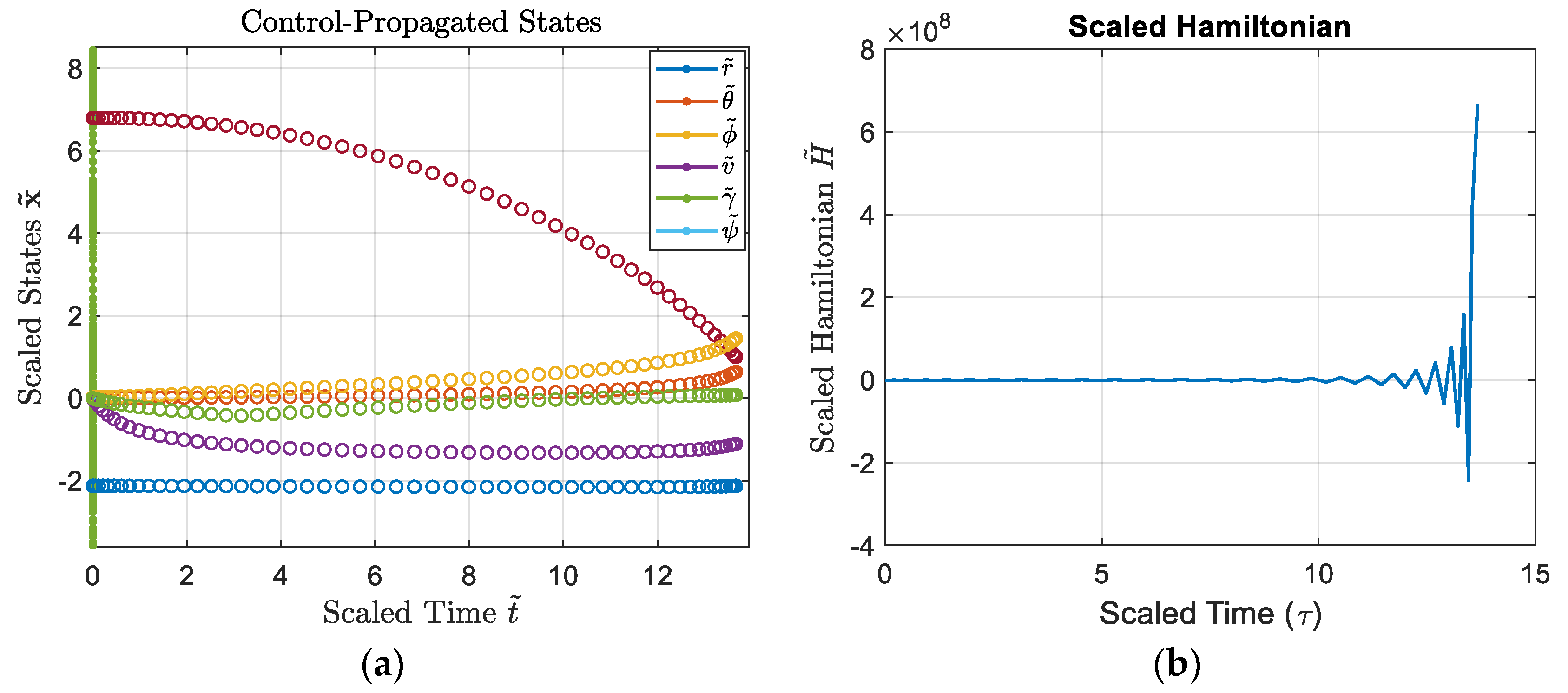

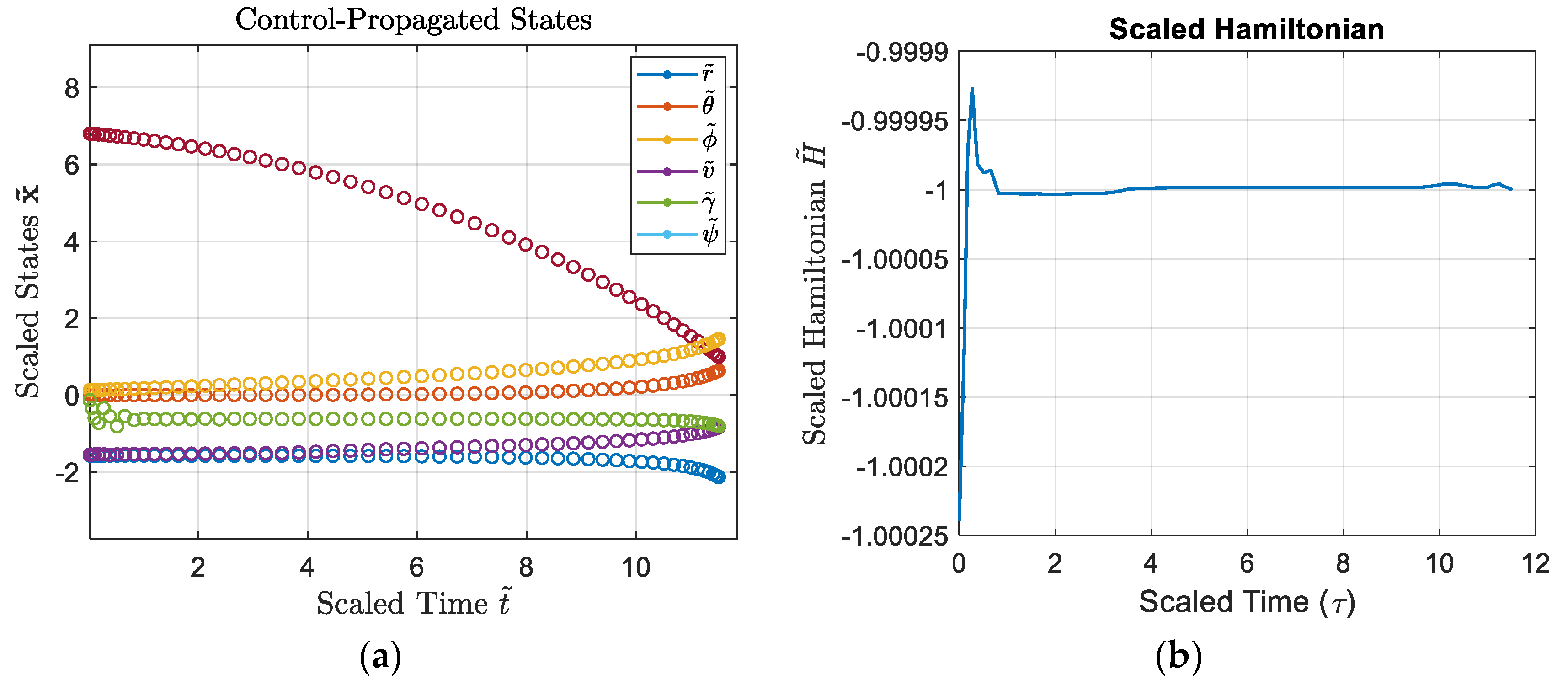

figure;

plot(tBar, dual.Hamiltonian); grid on;

title('Scaled Hamiltonian');

xlabel('Scaled Time (\tau)','FontSize',16);

ylabel('Scaled Hamiltonian $\tilde{H}$','Interpreter','latex','FontSize',16);

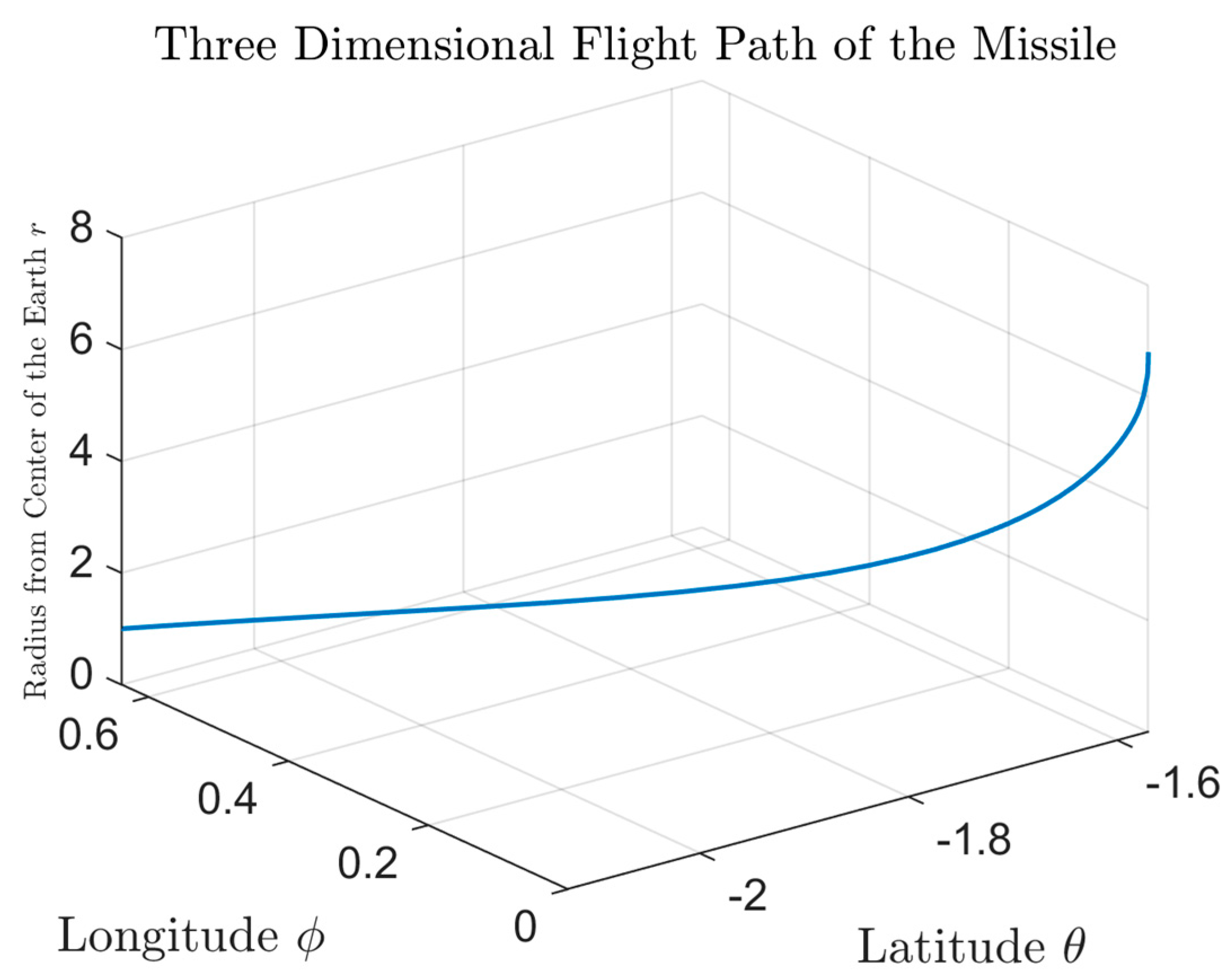

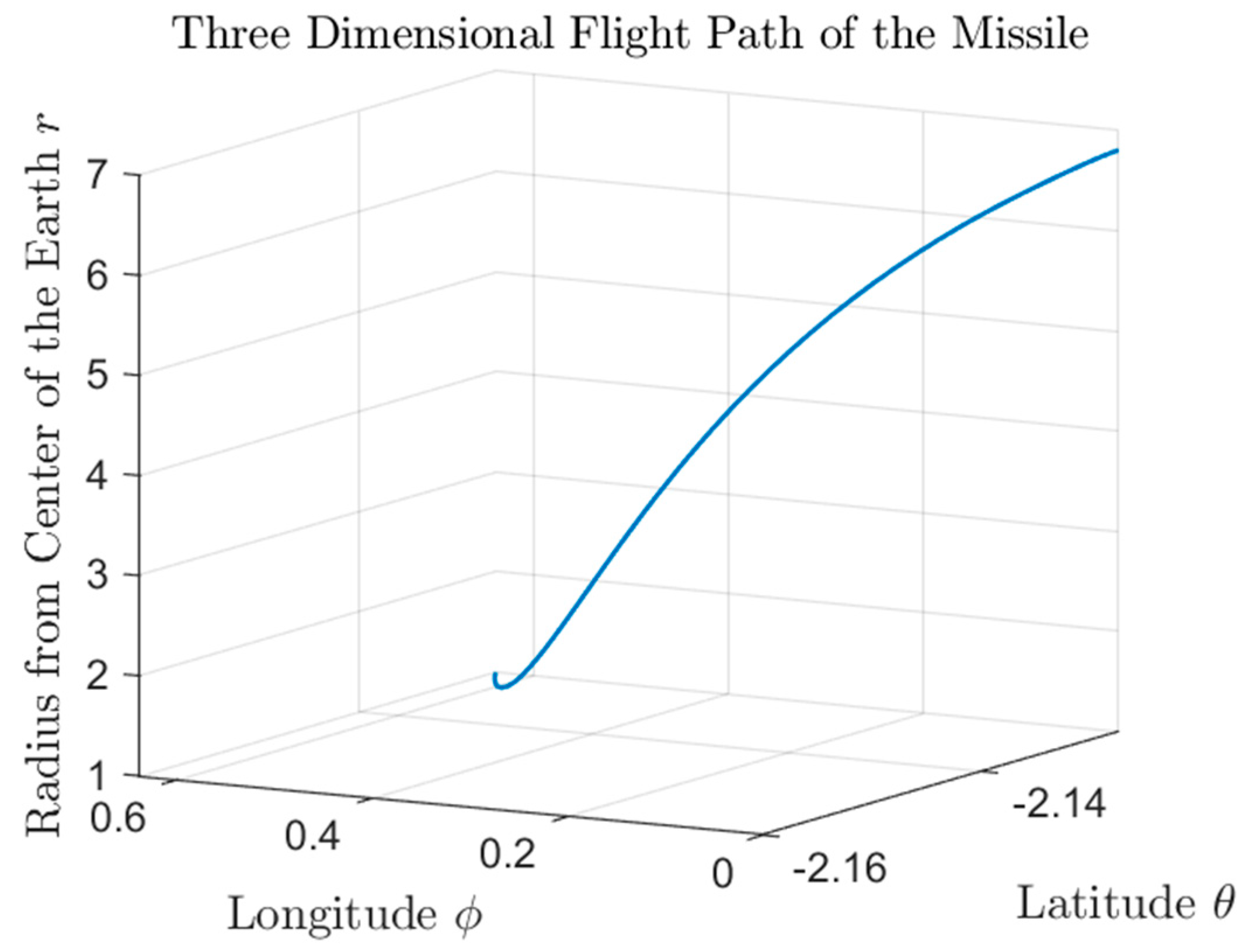

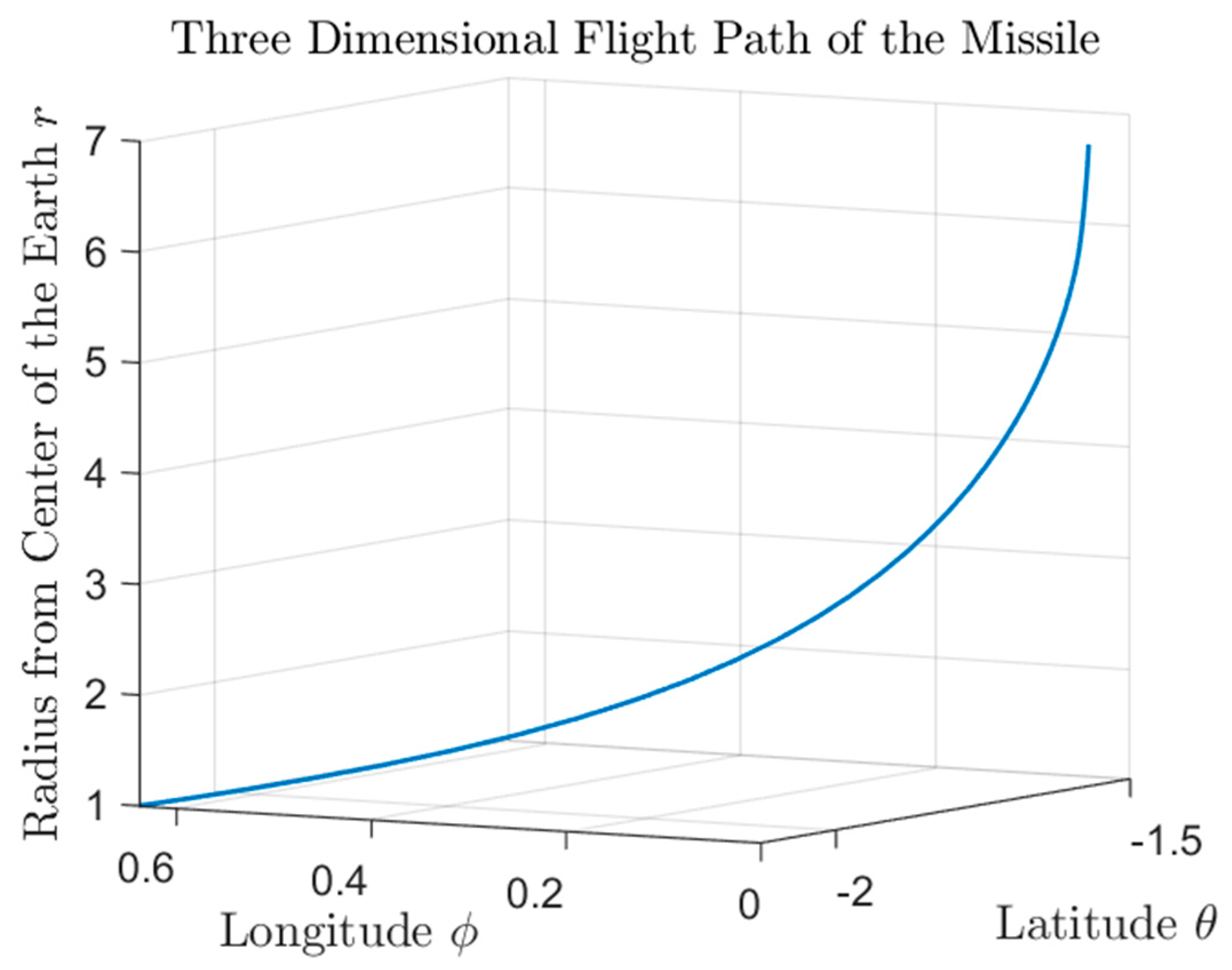

figure;

plot3(thetaBar,phiBar,rBar); grid on;

title('Three Dimensional Flight Path of the Missile','Interpreter','latex');

xlabel('Latitude ${\theta}$','Interpreter','latex','FontSize',16);

ylabel('Longitude ${\phi}$','Interpreter','latex','FontSize',16);

zlabel('Radius from Center of the Earth ${r}$','Interpreter','latex','FontSize',10);

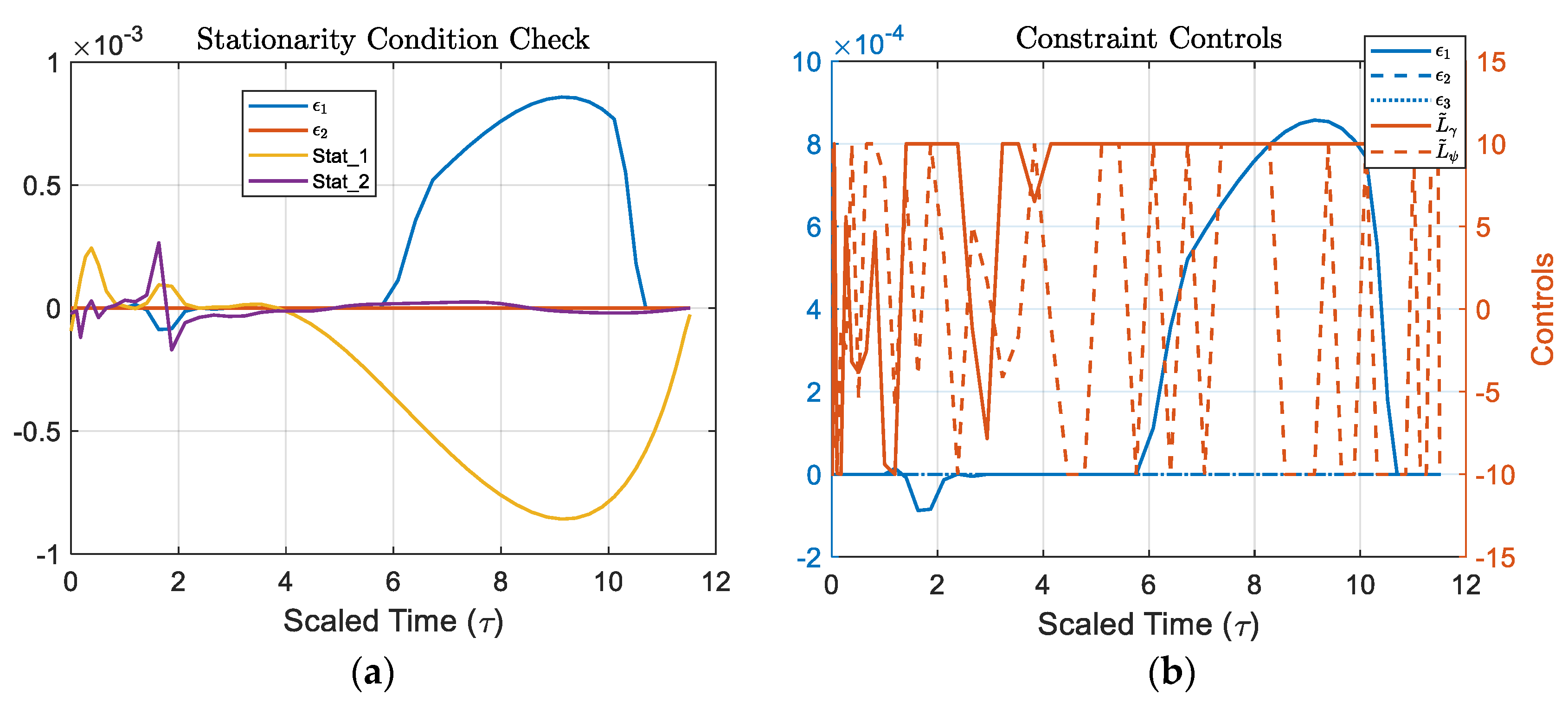

figure;

yyaxis left

plot(tBar, [eps1; eps2; eps3]); grid on;

title('Constraint Controls','Interpreter','latex');

xlabel('Scaled Time (\tau)','FontSize',16);

ylabel('${\epsilon}$','Interpreter','latex','FontSize',16);

yyaxis right

plot(tBar, [LgammaBar; LpsiBar]);

legend('${\epsilon_1}$','${\epsilon_2}$','${\epsilon_3}$','$\tilde{L}_\gamma$','$\tilde{L}_\psi$','Interpreter','latex','FontSize', 10);

ylabel('Controls');

figure;

plot(tBar, [eps1; eps2; stat1; stat2]); grid on;

title('Stationarity Condition Check','Interpreter','latex');

xlabel('Scaled Time (\tau)','FontSize',16);

legend('${\epsilon_1}$','${\epsilon_2}$','Stat_1','Stat_2','Interpreter','latex','FontSize',10);

%==========================================================================

%Unscale States, Co-States, Controls

r = rBar.*MS4.constants.R;

theta = thetaBar;

phi = phiBar;

v = MS4.constants.V.*vBar;

gamma = gammaBar;

psi = psiBar;

T = tBar.*MS4.constants.TU;

lam_r = (MS4.constants.TU/MS4.constants.R) .* lam_rBar;

lam_theta = (MS4.constants.TU/MS4.constants.AU) .* lam_thetaBar;

lam_phi = (MS4.constants.TU/MS4.constants.AU) .* lam_phiBar;

lam_v = (MS4.constants.TU/MS4.constants.V) .* lam_vBar;

lam_gamma = (MS4.constants.TU/MS4.constants.AU) .* lam_gammaBar;

lam_psi = (MS4.constants.TU/MS4.constants.AU) .* lam_psiBar;

Lgamma = LgammaBar./(MS4.constants.TU^2/(MS4.constants.R*MS4.constants.M));

Lpsi = LpsiBar./(MS4.constants.TU^2/(MS4.constants.R*MS4.constants.M));

% figure;

% plot(T, [(r.*.0003); v]); grid on;

% title('State Trajectories','Interpreter','latex');

% xlabel('Time ${t}$','Interpreter','latex','FontSize',16);

% ylabel('States $\mathbf{{x}}$','Interpreter','latex','Fontsize',16);

% legend('${r}$','${v}$','Interpreter','latex','FontSize',16);

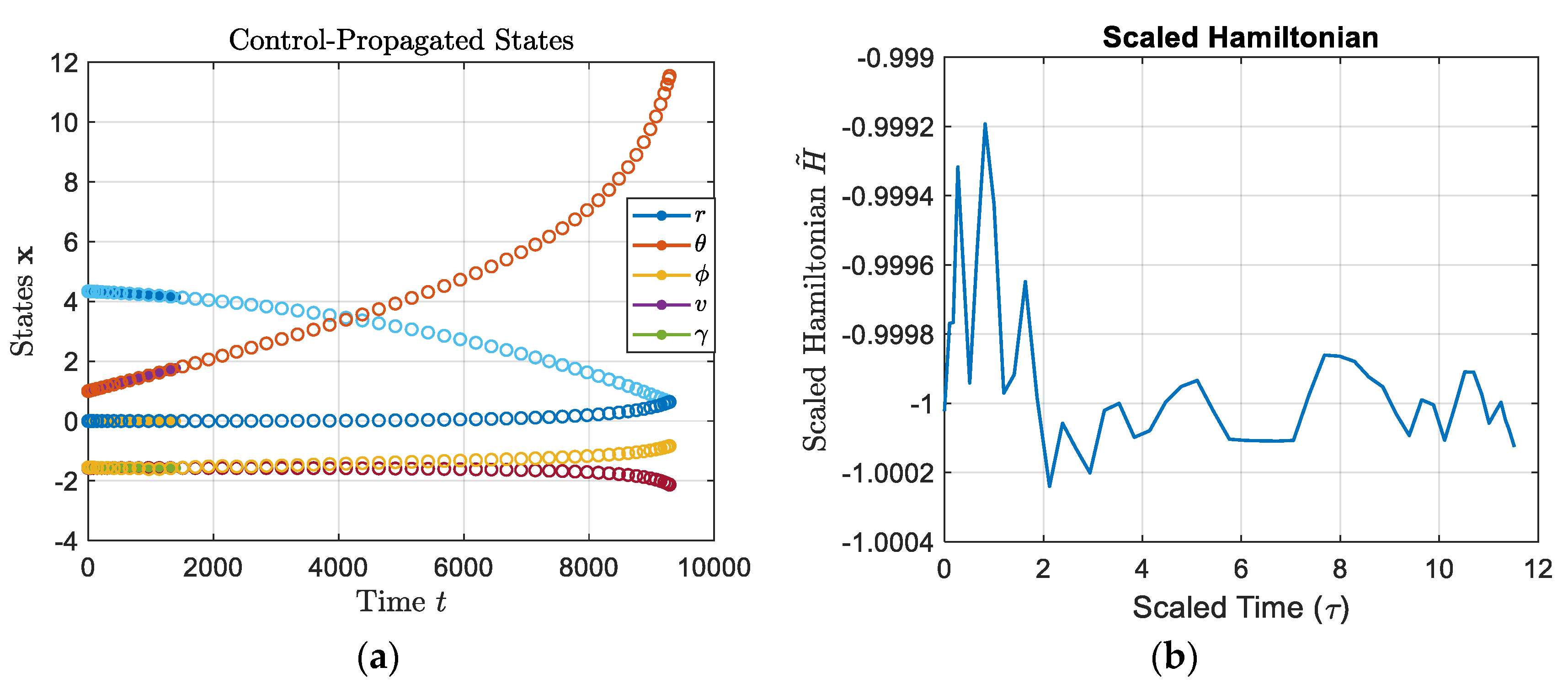

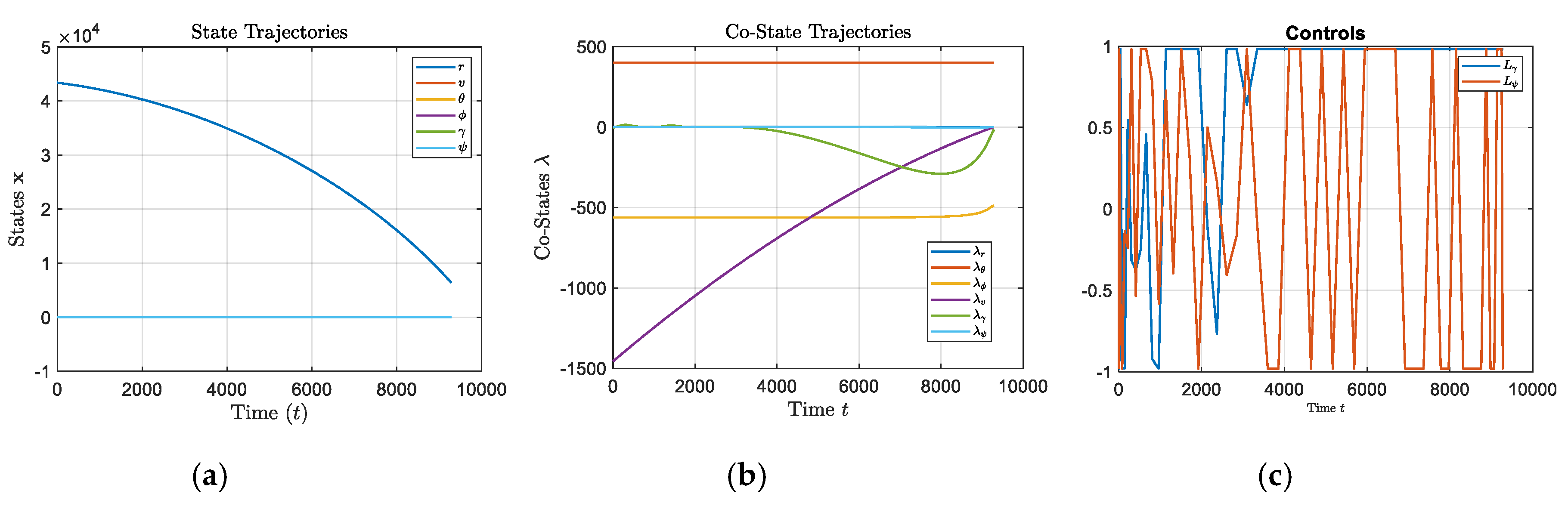

figure;

plot(T, [r; v; theta; phi; gamma; psi]); grid on;

title('State Trajectories','Interpreter','latex');

xlabel('Time $(t)$','Interpreter','latex','FontSize',16);

ylabel('States $\mathbf{{x}}$','Interpreter','latex','FontSize',16);

legend('${r}$','${v}$','${\theta}$','${\phi}$','${\gamma}$','${\psi}$','Interpreter','latex','FontSize',10);

figure;

plot(T, [lam_r; lam_theta; lam_phi; lam_v; lam_gamma; lam_psi]); grid on;

title('Co-State Trajectories','Interpreter','latex');

xlabel('Time ${t}$','Interpreter','latex','FontSize',16);

ylabel('Co-States $\mathbf{{\lambda}}$','Interpreter','latex','FontSize',16);

legend('${\lambda_r}$','${\lambda_\theta}$','${\lambda_\phi}$','${\lambda_v}$','${\lambda_\gamma}$','${\lambda_\psi}$','Interpreter','latex','FontSize',10);

figure;

plot(T, [Lgamma; Lpsi]); grid on;

title('Controls');

legend('${L_\gamma}$','${L_\psi}$','Interpreter','latex','FontSize',10);

xlabel('Time ${t}$','Interpreter','latex','FontSize',10);

%==========================================================================

%Individual State Comparisons

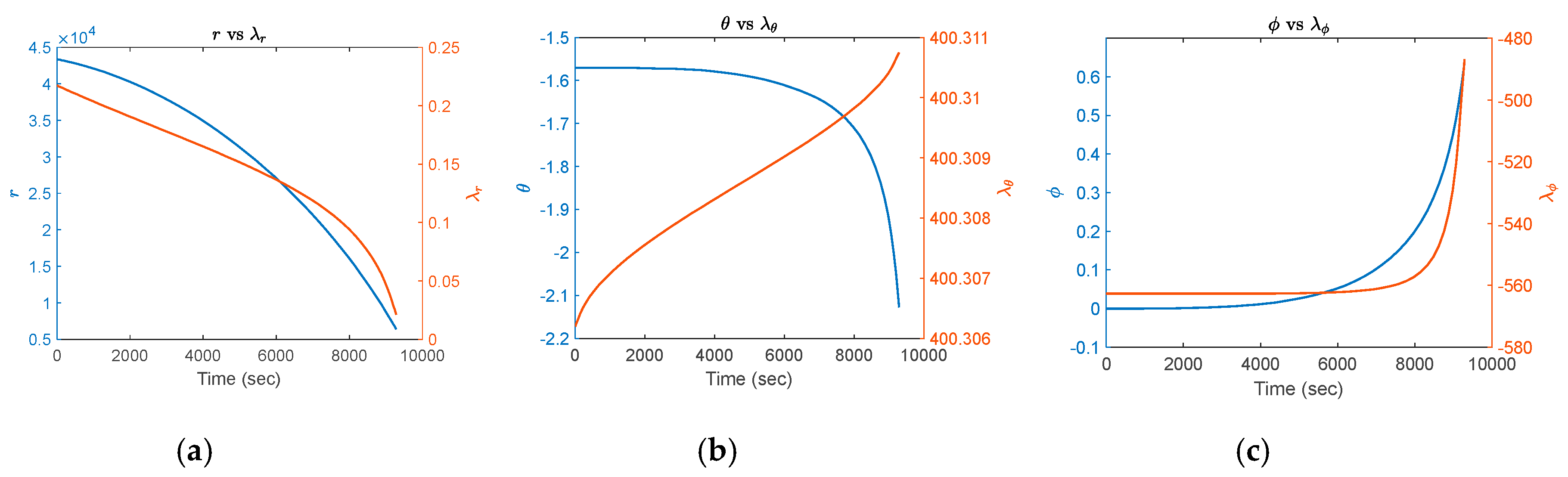

figure;

yyaxis left

plot(T,r);

xlabel('Time (sec)'),ylabel('${r}$','Interpreter','latex');

yyaxis right

plot(T,lam_r);

ylabel('${\lambda_r}$','Interpreter','latex')

title('${r}$ vs ${\lambda_r}$','Interpreter','latex')

figure;

yyaxis left

plot(T,theta);

xlabel('Time (sec)'),ylabel('${\theta}$','Interpreter','latex');

yyaxis right

plot(T,lam_theta);

ylabel('${\lambda_\theta}$','Interpreter','latex')

title('${\theta}$ vs ${\lambda_\theta}$','Interpreter','latex')

figure;

yyaxis left

plot(T,phi);

xlabel('Time (sec)'),ylabel('${\phi}$','Interpreter','latex');

yyaxis right

plot(T,lam_phi);

ylabel('${\lambda_\phi}$','Interpreter','latex')

title('${\phi}$ vs ${\lambda_\phi}$','Interpreter','latex')

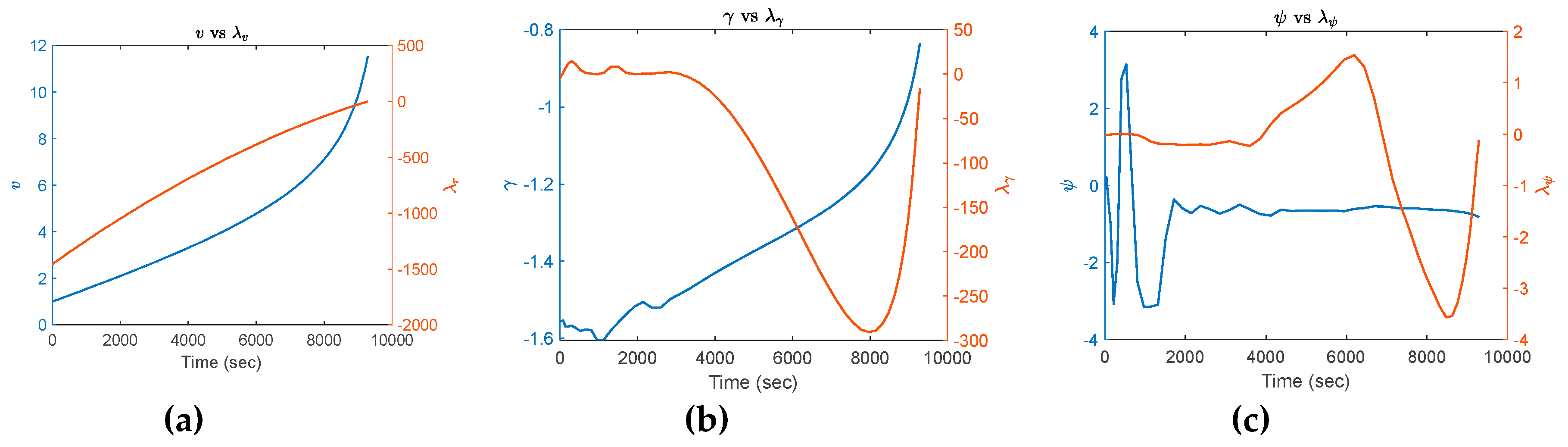

figure;

yyaxis left

plot(T,v);

xlabel('Time (sec)'),ylabel('${v}$','Interpreter','latex');

yyaxis right

plot(T,lam_v);

ylabel('${\lambda_r}$','Interpreter','latex')

title('${v}$ vs ${\lambda_v}$','Interpreter','latex')

figure;

yyaxis left

plot(T,gamma);

xlabel('Time (sec)'),ylabel('${\gamma}$','Interpreter','latex');

yyaxis right

plot(T,lam_gamma);

ylabel('${\lambda_\gamma}$','Interpreter','latex')

title('${\gamma}$ vs ${\lambda_\gamma}$','Interpreter','latex')

figure;

yyaxis left

plot(T,psi);

xlabel('Time (sec)'),ylabel('${\psi}$','Interpreter','latex');

yyaxis right

plot(T,lam_psi);

ylabel('${\lambda_\psi}$','Interpreter','latex')

title('${\psi}$ vs ${\lambda_\psi}$','Interpreter','latex')

% %==========================================================================

% Feasibility Check

t_vec = T(:);

[T_feas, X_feas] = ode45(@(t,y)stateDynamics(t,y,t_vec,[Lgamma; Lpsi]),[t_vec(1) t_vec(end)],[r(1);theta(1);phi(1);v(1);gamma(1);psi(1)]);

r_feas = X_feas(:,1);

theta_feas = X_feas(:,2);

phi_feas = X_feas(:,3);

v_feas = X_feas(:,4);

gam_feas = X_feas(:,5);

psi_feas = X_feas(:,6);

figure;

hLines = plot(T_feas,(r_feas./1e4),'.-',T_feas,theta_feas,'.-',T_feas,phi_feas,'.-',T_feas,v_feas,'.-',T_feas,gam_feas,'.-',T_feas,psi_feas,'.-'); hold on; grid on;

hMarkers4 = plot(t_vec,[r./1e4; theta; phi; v; gamma; psi],'o');

set(hLines,'MarkerSize',12);

set(hMarkers4,'LineWidth',1);

title('Control-Propagated States','Interpreter','latex');

xlabel('Time ${t}$','Interpreter','latex','FontSize',16);

ylabel('States $\mathbf{{x}}$','Interpreter','latex','FontSize',16);

legend('${r}$','${\theta}$','${\phi}$','${v}$','${\gamma}$','Interpreter','latex');

%==========================================================================

%% FEASIBILITY CHECK FUNCTION

function dXdt = stateDynamics(t,X,tData,uData,MS4)

Lg_t = interp1(tData,uData(1,:),t,'pchip');

Lp_t = interp1(tData,uData(2,:),t,'pchip');

r = X(1);

theta = X(2);

phi = X(3);

v = X(4);

gamma = X(5);

psi = X(6);

drdt = v .* sin(gamma);

dtdt = (v.*cos(gamma).*sin(psi))./(r.*cos(phi));

dpdt = (v.*cos(gamma).*cos(psi))./r;

dvdt = -(.1211/5000)-((3.986004418e5.*sin(gamma))./(r.^2))+(1.7461/5000);

dgdt = (Lg_t./(5000.*v))-((3.9860044815e5.*cos(gamma))./((r.^2).*v))+((v./r).*cos(gamma));

didt = (Lp_t./(5000.*v.*cos(gamma)))+((v./r).*cos(gamma).*sin(psi).*tan(phi));

dXdt = [drdt; dtdt; dpdt; dvdt; dgdt; didt];

end

C.1. Dynamics file

All appendix sections must be cited in the main text. In the appendices, Figures, Tables, etc. should be labeled starting with “A”—e.g., Figure A1, Figure A2, etc.

function dxdtBar = MS4Dynamics(primal)

%Missile from Geosynchronous Orbit to target on Earth in minimum time

%=========================================================================

[rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, DBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal);

%Equations of Motion

rdotBar = vBar.*sin(gammaBar);

thetadotBar = (vBar.*cos(gammaBar).*sin(psiBar))./(rBar.*cos(phiBar));

phidotBar = (vBar.*cos(gammaBar).*cos(psiBar))./rBar;

[T, a, P, rho] = atmosisa((rBar.*R.*1000)-(R*1000));%Unscale altitude and change to meters

rhoBar = rho./DU; %Scale Density by Density Unit Scale Factor

SBar = S/(R^2); %Scale ReferenceArea

Dscale = .5.*rhoBar.*vBar.^2*Cd*SBar; %Scaled Drag

vdotBar = -(DBar/mBar)-((uBar.*sin(gammaBar))./(rBar.^2))+(TBar./mBar);

gammadotBar = (LgammaBar./(mBar.*vBar))-((uBar*cos(gammaBar))./(rBar.^2.*vBar))+((vBar./rBar).*cos(gammaBar));

psidotBar = (LpsiBar./(mBar.*vBar.*cos(gammaBar)))+((vBar./rBar).*cos(gammaBar).*sin(psiBar).*tan(phiBar));

dxdtBar = [rdotBar;

thetadotBar;

phidotBar;

vdotBar;

gammadotBar;

psidotBar];

%eof

C.1. Cost file

function [EndpointCost, RunningCost] = MS4Cost(primal)

%Missile from Geosynchronous Orbit to target on Earth in minimum time

%=========================================================================

[rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, DBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal);

EndpointCost = tfBar;

RunningCost = 0;

%eof

C.1. Events file

function endpointFunction = MS4Events(primal)

%Missile from Geosynchronous Orbit to target on Earth in minimum time

%Endpoint File

%=========================================================================

[rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal);

endpointFunction = zeros(9,1);

%Beginnning Enpoints

endpointFunction(1) = r0Bar;

endpointFunction(2) = theta0Bar;

endpointFunction(3) = phi0Bar;

endpointFunction(4) = v0Bar;

endpointFunction(5) = gamma0Bar;

endpointFunction(6) = psi0Bar;

%Final Endpoints

endpointFunction(7) = rfBar;

endpointFunction(8) = thetafBar;

endpointFunction(9) = phifBar;

C.1. Path file

function H = MS4Path(primal)

%Missile from Geosynchronous Orbit to target on Earth in minimum time

%-----------------------------------------

% Call preamble and load primal variables:

%-----------------------------------------

[rBar, thetaBar, phiBar, vBar, gammaBar, psiBar, LgammaBar, LpsiBar, tBar, ...

r0Bar, theta0Bar, phi0Bar, v0Bar, gamma0Bar, psi0Bar, t0Bar, ...

rfBar, thetafBar, phifBar, vfBar, gammafBar, psifBar, tfBar, ...

uBar, TBar, mBar, DBar, Cd, S, R, V, kq, FU, DU, KU] ...

= MS4Preamble(primal);

%=======================================================

% path constraint function:

H(1,:) = LgammaBar;

H(2,:) = LpsiBar;

h = (rBar.*R.*1000);

rho0 = 1.225; %Sea level density in kg/m^3

Hs = 7500; %Height scale

rp = R*1000;

rho = rho0*exp(-(h-rp)/Hs);

vd = vBar.*V.*1000;

qdot = kq.*sqrt(rho).*(vd.^3);

H(3,:) = qdot/1e9; %Scale in Engineering Units