Submitted:

08 December 2023

Posted:

13 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- What is the most thermally efficient structural system to use in UAE housing projects?

- What are the thermal defects of these systems and how do these defects affect the energy demand of the housing projects post-occupancy?

2. Literature Review

2.1. Construction Systems in the UAE

2.2. Thermal Bridging and Thermal Inefficiency

2.3. Nondestructive Testing: Infrared Thermography

3. Materials and Methods

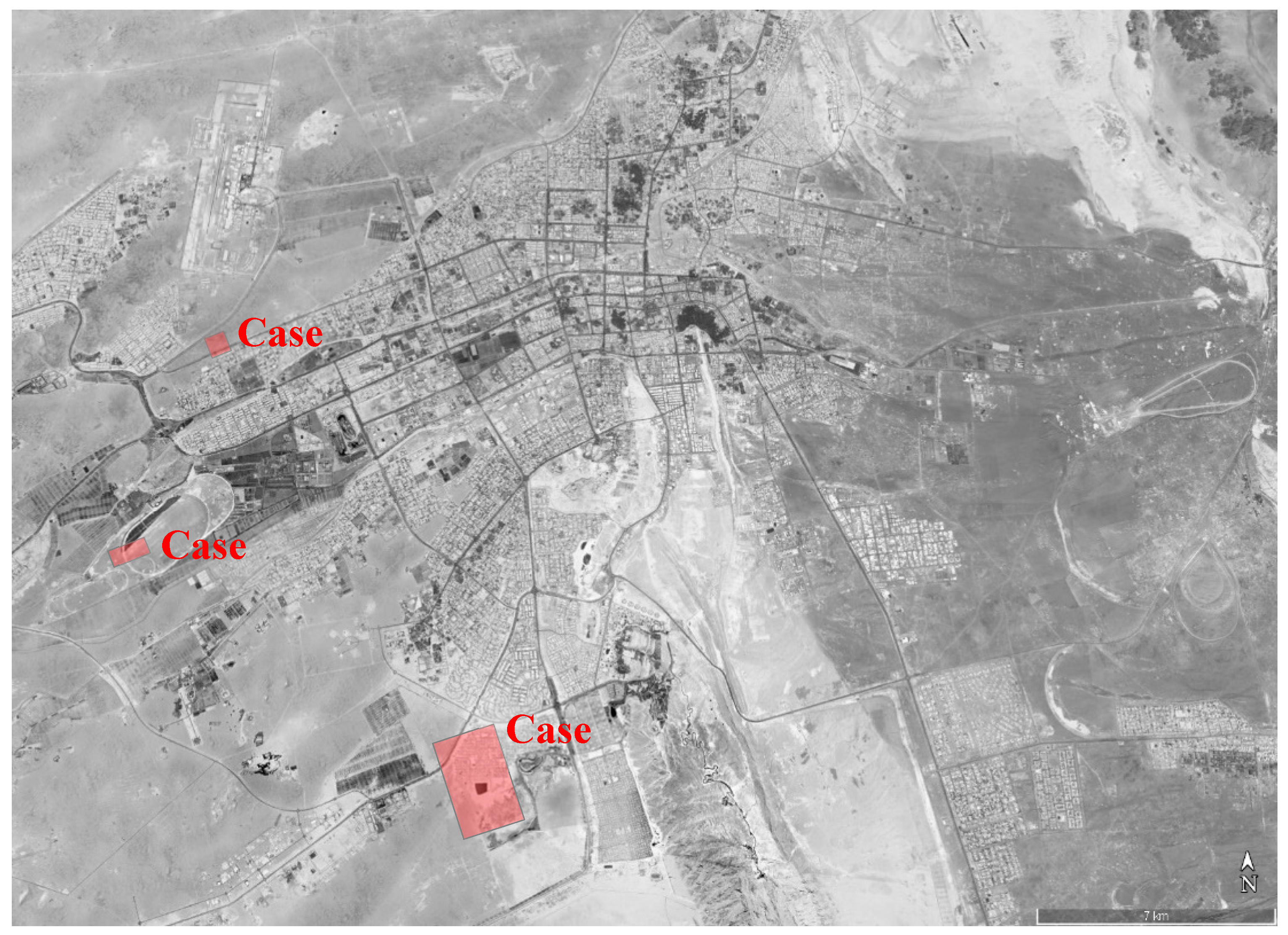

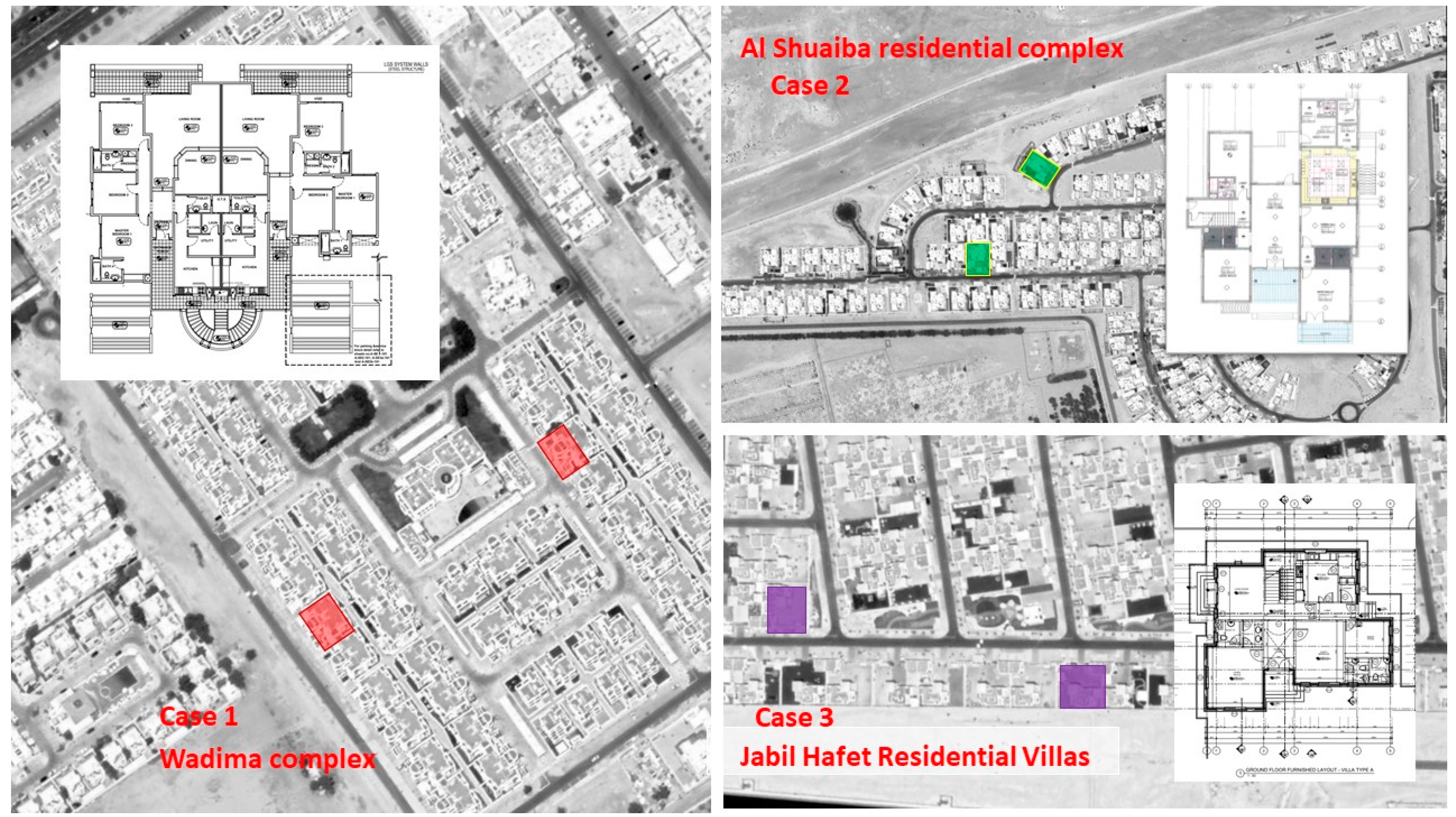

3.1. Case study and Investigation Criteria

- Case 1: Wadeema complex is a rental apartment attached to three different apartments and is part of a residential compound used mainly by expatriates. The LGS construction system was used for the four apartments. Due to the limited time frame of the study, we normalized all the other apartments based on the data obtained from one apartment.

- Case 2: Al Shuaiba Residential Villas constitute an emirate national villa constructed from concrete brick wood infill with reinforced concrete for beam and post structures. This is the most used construction method in Al Ain.

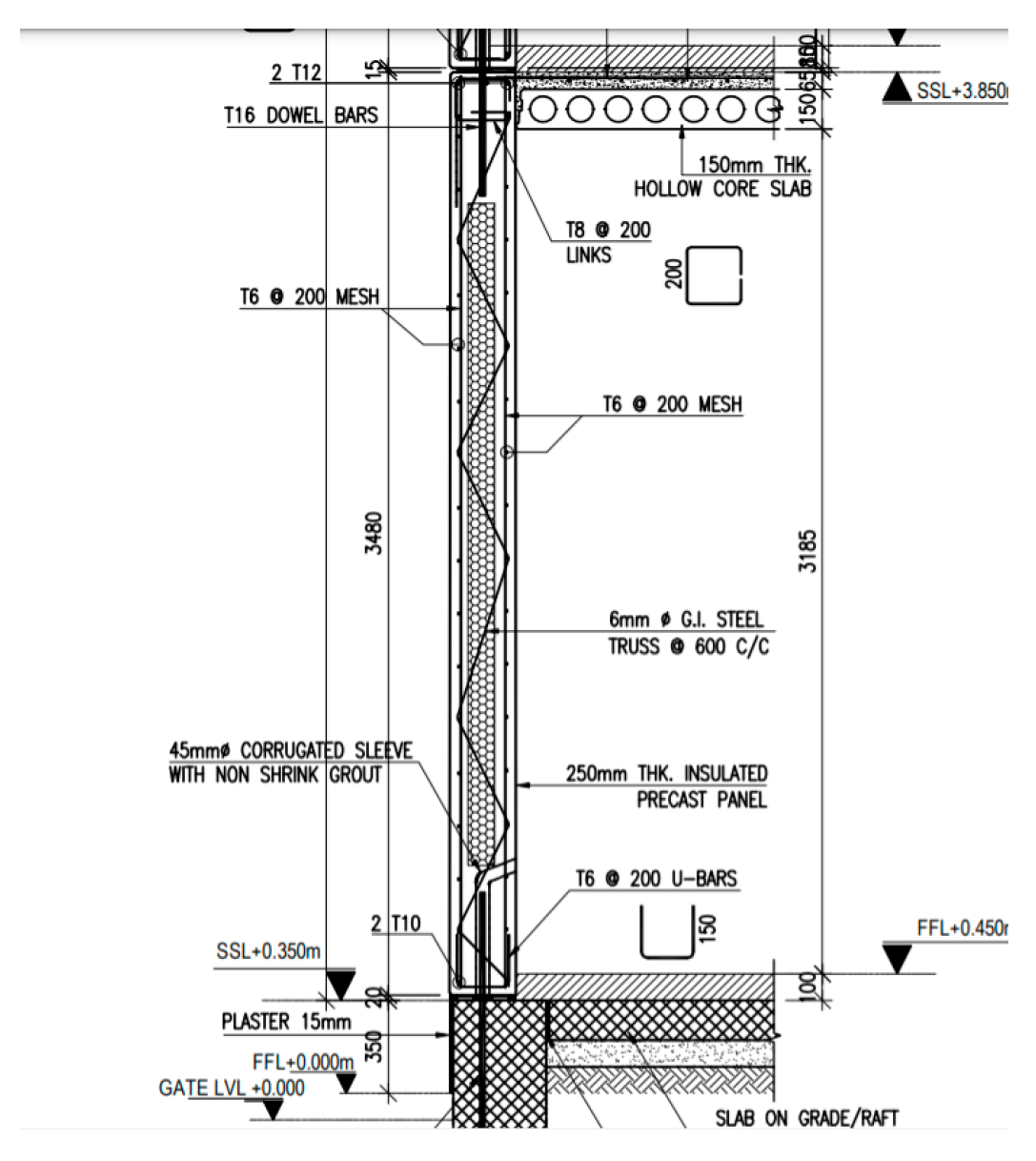

- Case 3: Jabel Hafeet Residential Villas are constructed from a precast concrete system that is the most used material for national houses in the UAE. As a result, the market for precast concrete has been growing rapidly in UAE.

4. Thermal Performance

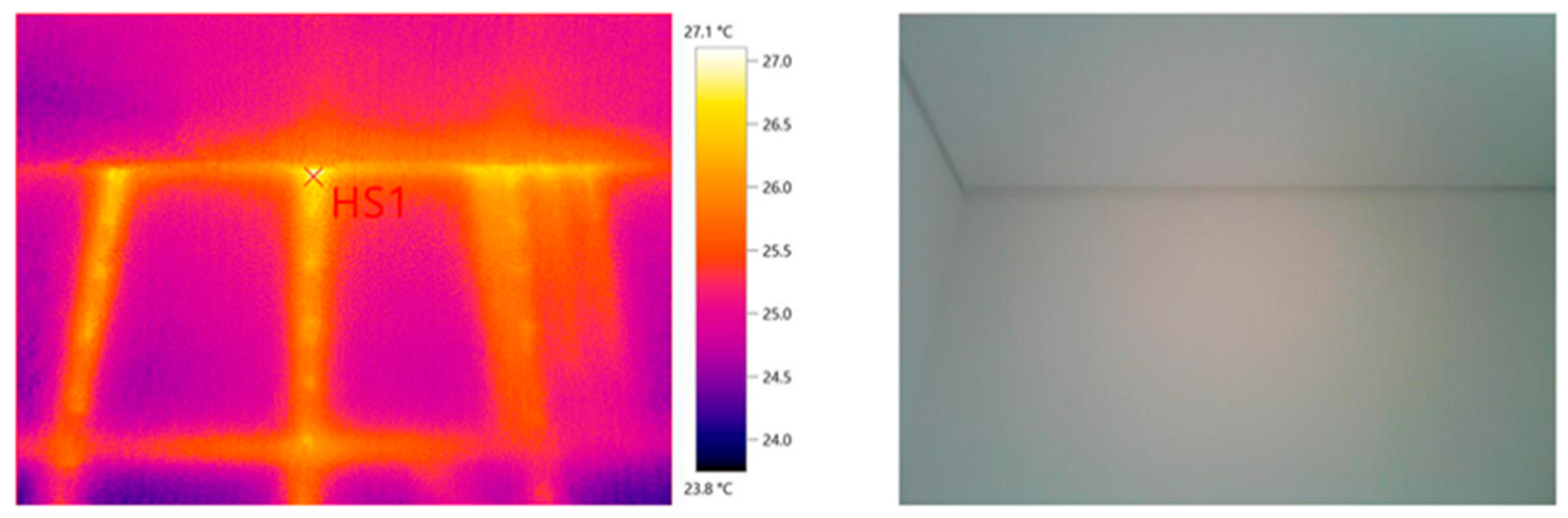

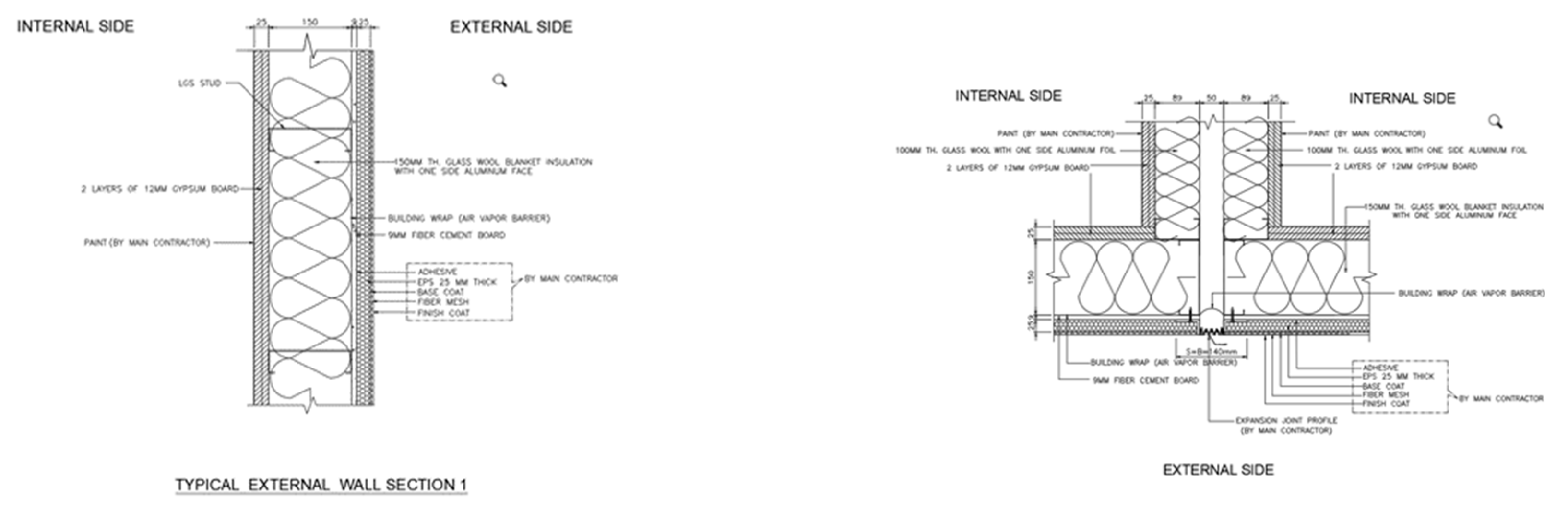

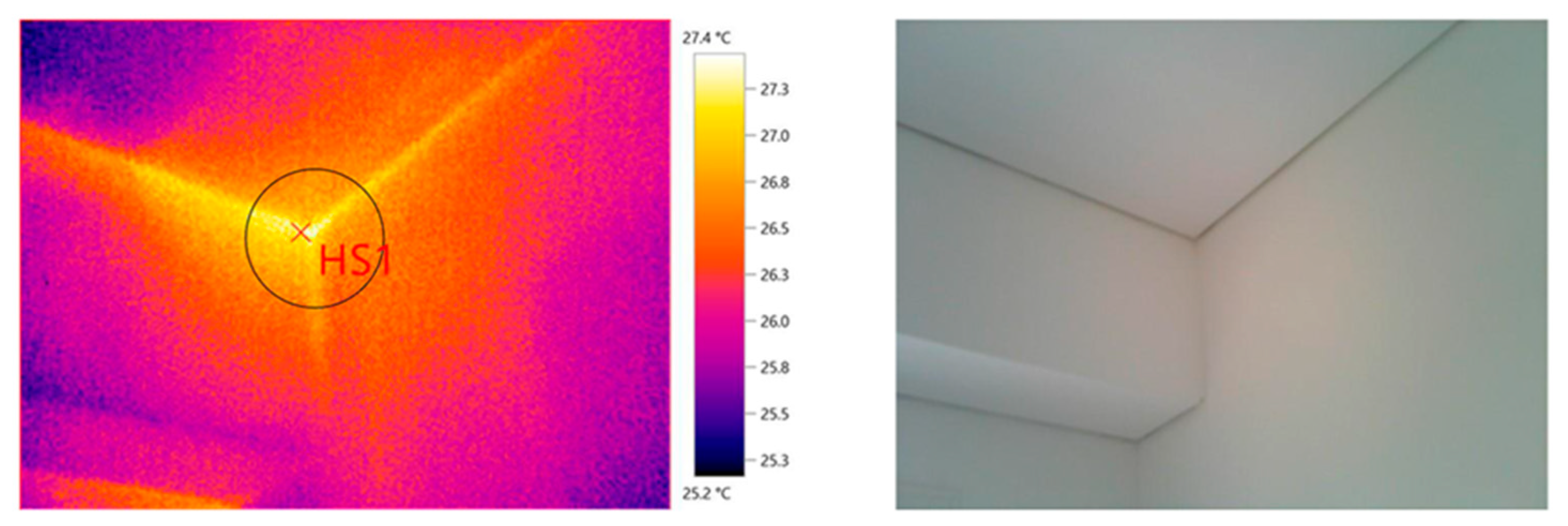

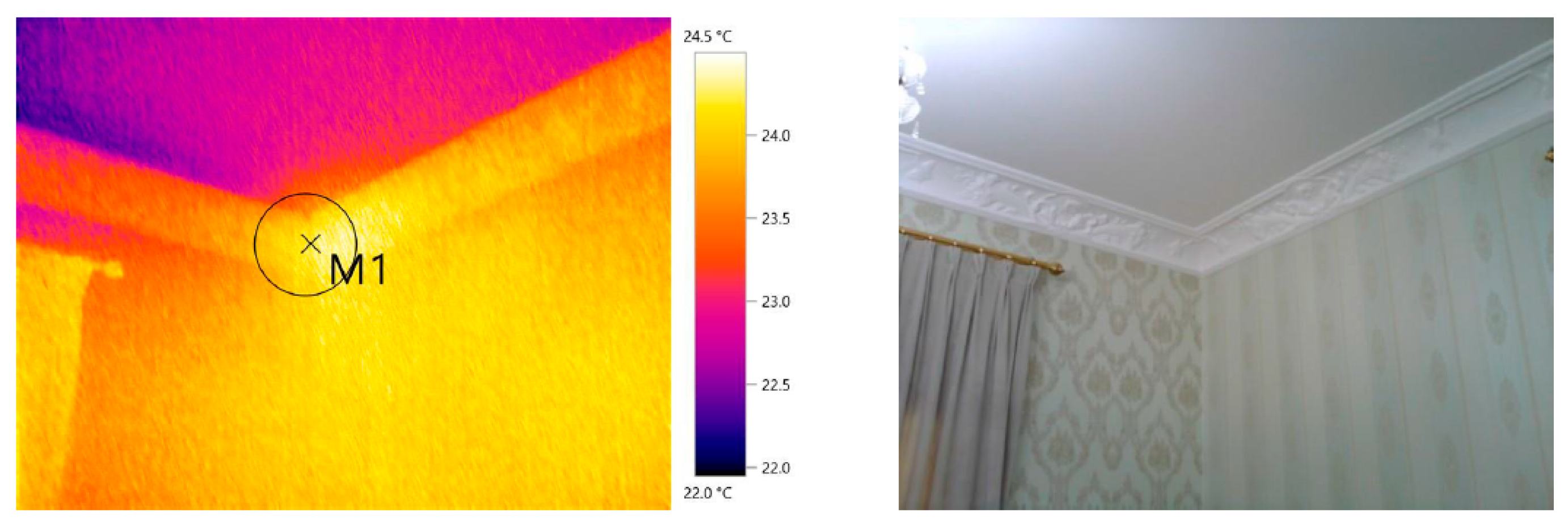

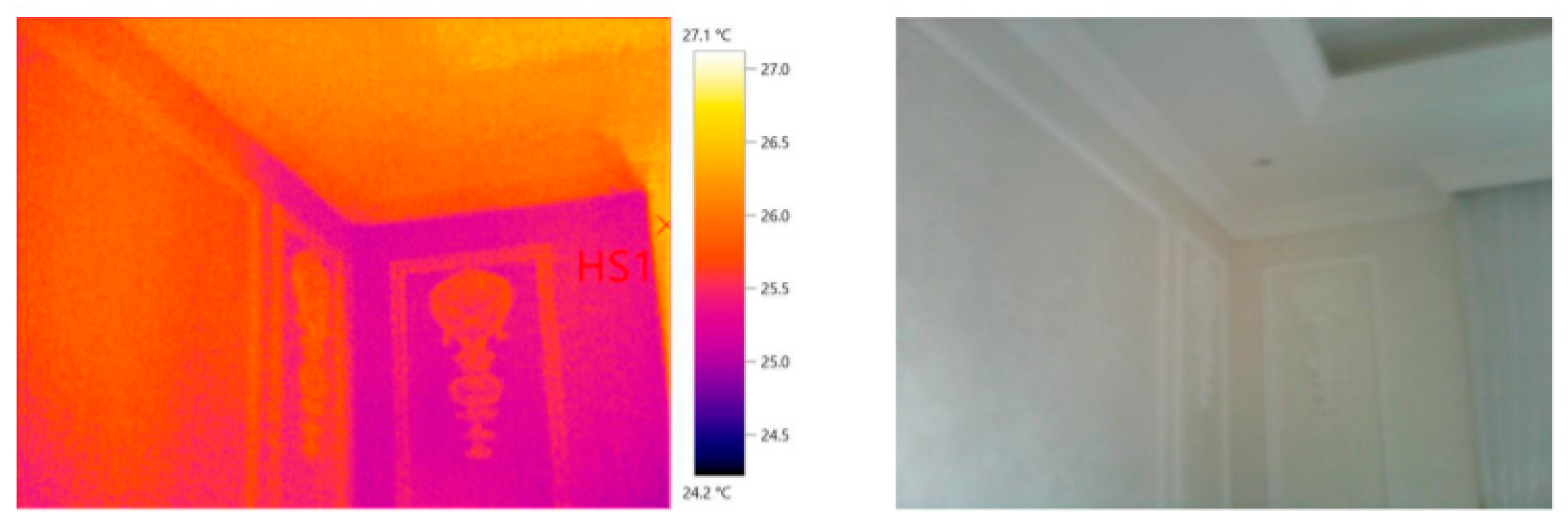

4.1. LGS Construction System

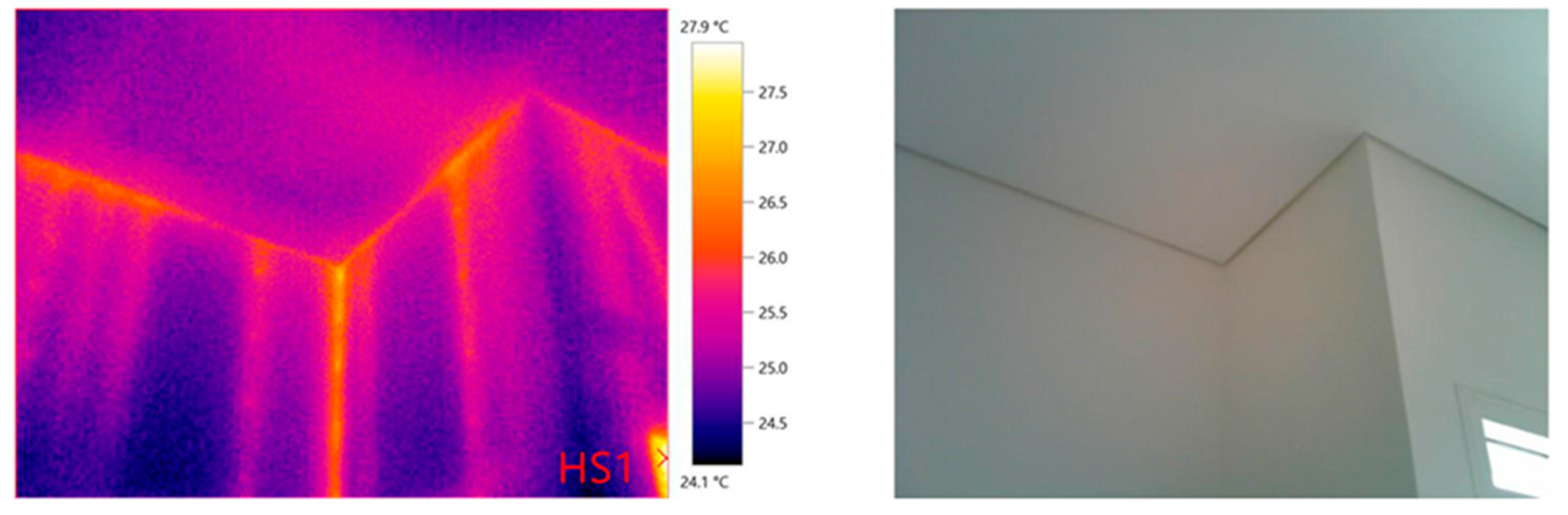

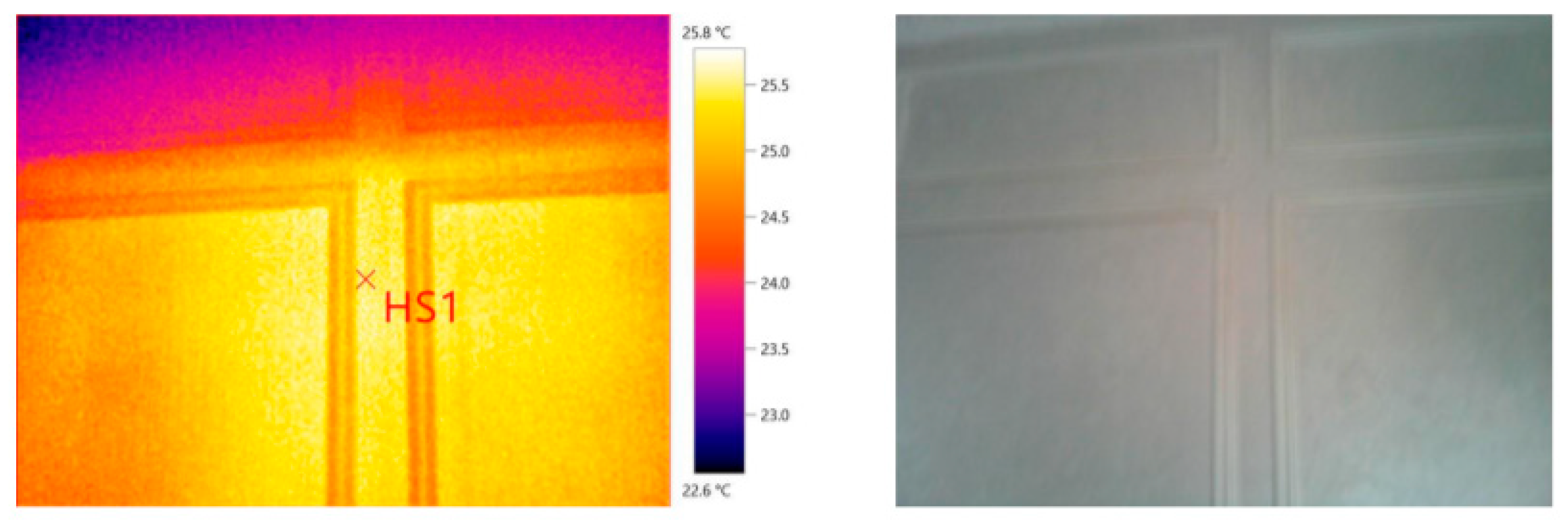

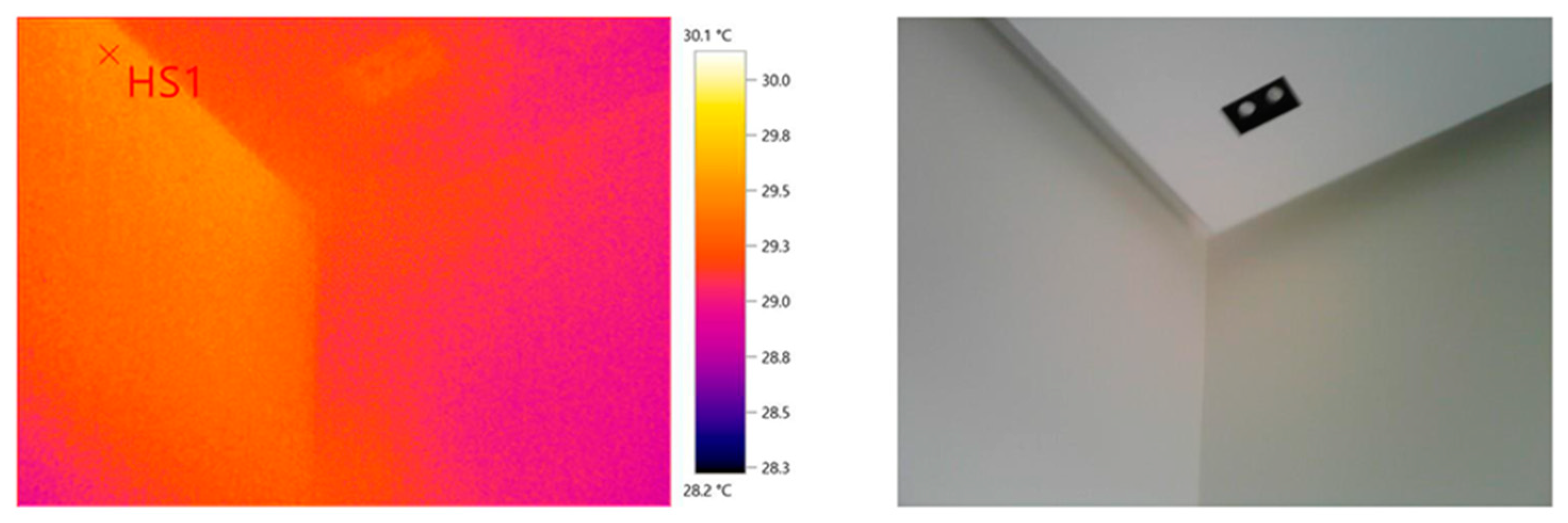

4.2. Reinforced Concrete Construction System

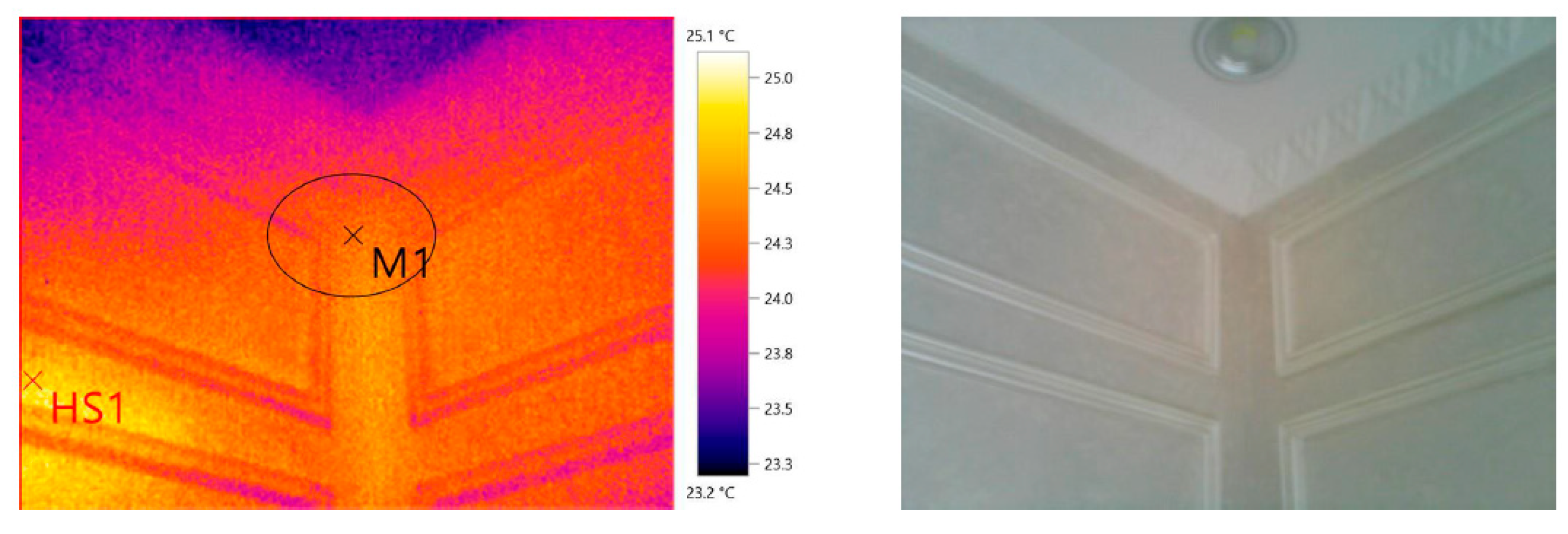

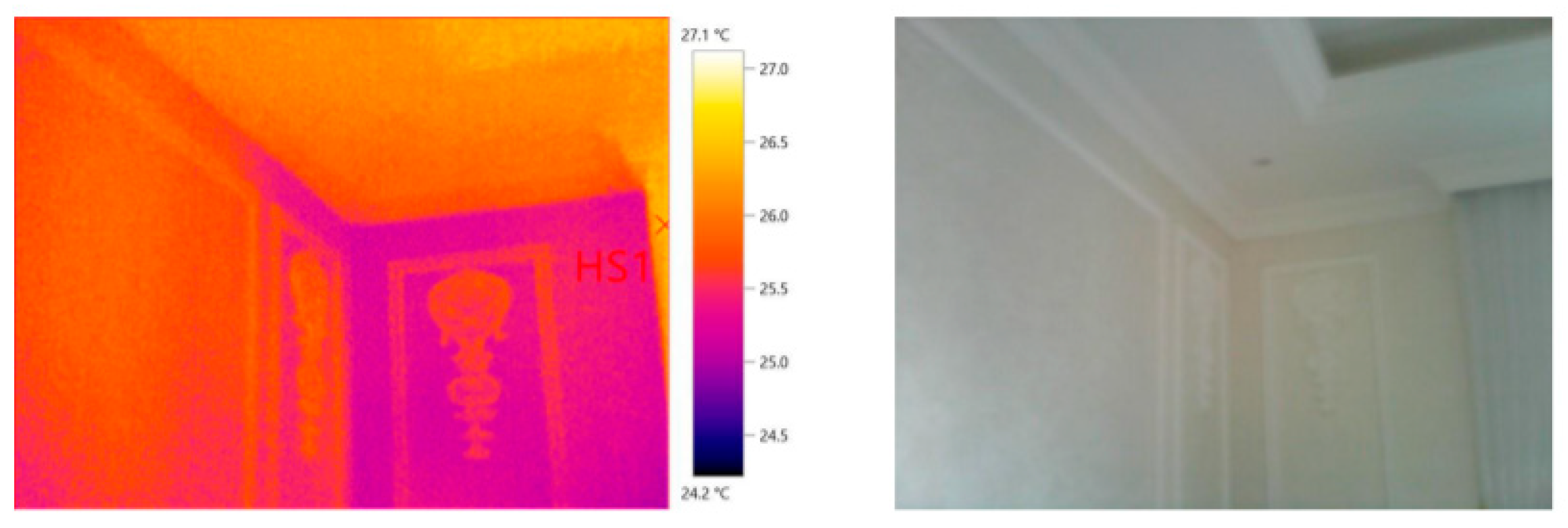

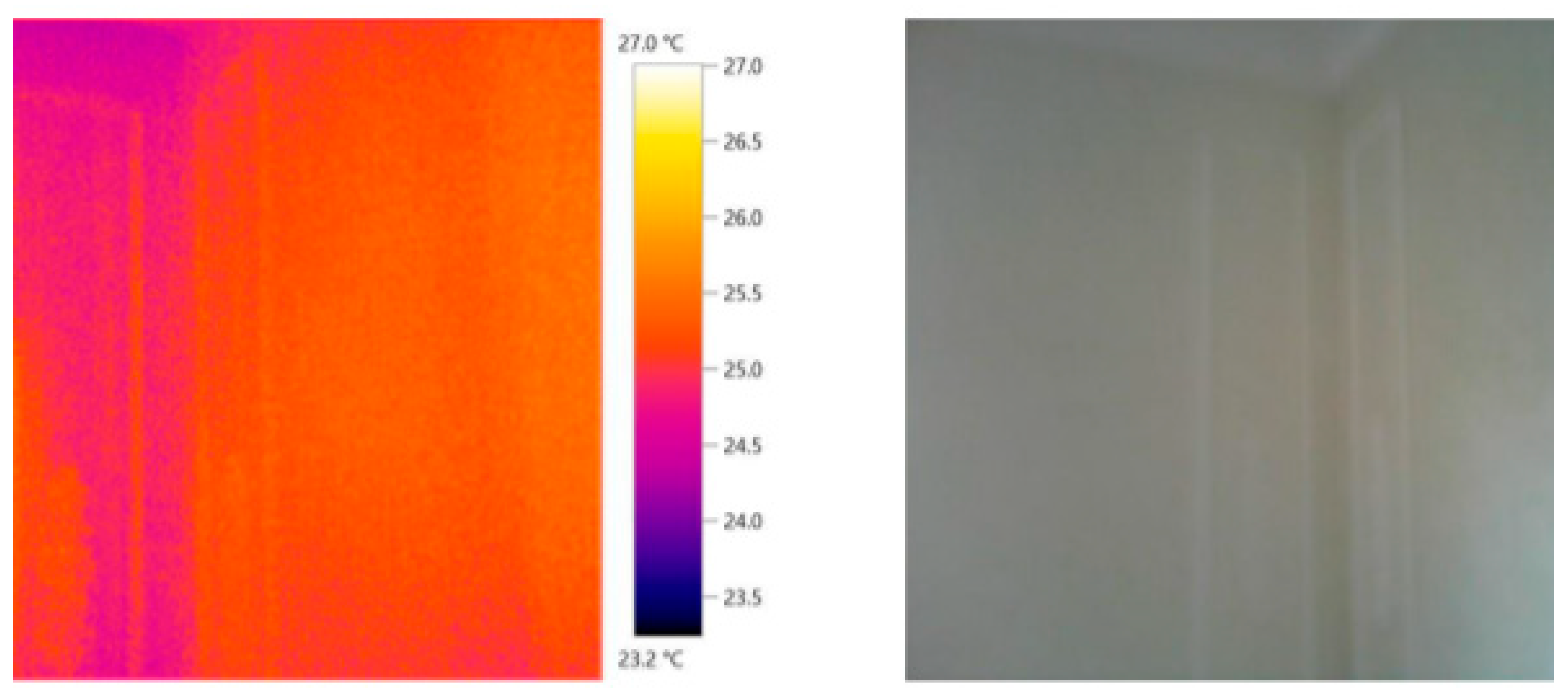

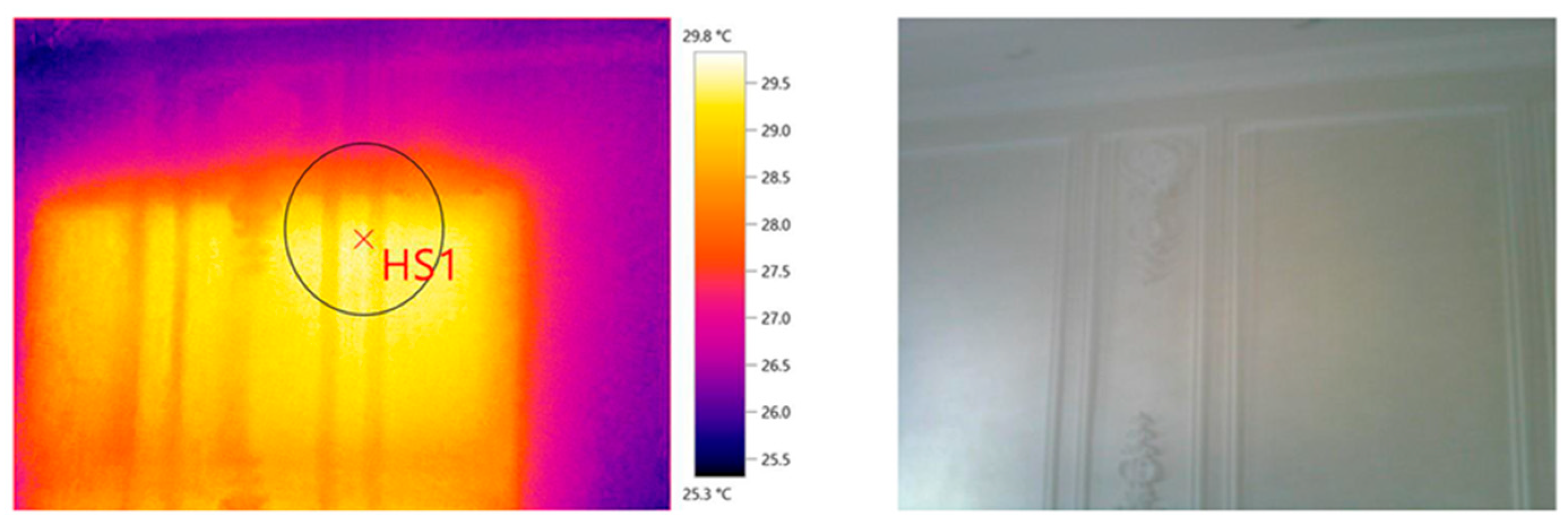

4.3. Precast Construction System

4.4. Annual Electricity Demand

5. Conclusions

References

- T. Barker, P. Ekins, and N. Johnstone, Global warming and energy demand. 1995.

- R. Broun and G. F. Menzies, “Life cycle energy and environmental analysis of partition wall systems in the UK,” Procedia Eng., vol. 21, pp. 864–873, 2011.

- Z. Zhou, C. Wang, X. Sun, F. Gao, W. Feng, and G. Zillante, “Heating energy saving potential from building envelope design and operation optimization in residential buildings: A case study in northern China,” J. Clean. Prod., vol. 174, pp. 413–423, 2018.

- A. Brás, F. Gonçalves, and P. Faustino, “Cork-based mortars for thermal bridges correction in a dwelling: Thermal performance and cost evaluation,” Energy Build., vol. 72, pp. 296–308, 2014.

- A. Al Amoodi and E. Azar, “Impact of human actions on building energy performance: A case study in the United Arab Emirates (UAE),” Sustainability, vol. 10, no. 5, 2018.

- G. Trotta, “Assessing energy efficiency improvements, energy dependence, and CO2 emissions in the European Union using a decomposition method,” Energy Effic., vol. 12, no. 7, pp. 1873–1890, 2019.

- I. Gerretsen, “Saudi Arabia pledges net zero by 2060, but no oil exit plan,” 2021. https://www.climatechangenews.com/2021/10/25/saudi-pledges-net-zero-2060-no-oil-exit-plan/#:~:text=Saudi Arabia has pledged to,the world’s leading oil producer.&text=Half of the country’s electricity,according to the updated plan (accessed Mar. 17, 2022).

- United Nations, “For a livable climate: Net-zero commitments must be backed by credible action.” https://www.un.org/en/climatechange/net-zero-coalition#:~:text=Through this UN-backed campaign,Off Air (accessed Mar. 17, 2022).

- X. Zhang, G.-J. Jung, and K.-N. Rhee, “Performance Evaluation of Thermal Bridge Reduction Method for Balcony in Apartment Buildings,” Buildings, vol. 12, no. 1, p. 63, 2022.

- K. A. T. Aoul, R. Hagi, R. Abdelghani, M. Syam, and B. Akhozheya, “Building envelope thermal defects in existing and under-construction housing in the UAE; infrared thermography diagnosis and qualitative impacts analysis,” Sustainability, vol. 13, no. 4, pp. 1–23, 2021.

- R. Hagi, K. A. T. Aoul, R. Abdelghani, B. Akhozheya, Y. Abdou, and N. Suleiman, “Thermal performance gap investigation using infrared thermal imagery in the UAE residential buildings,” 2019.

- M. A. Kadir, W. Lee, M. Jaafar, S. Sapuan, and A. Ali, “Construction performance comparison between conventional and industrialised building systems in Malaysia,” Struct. Surv., 2006.

- A. Al-Hajj and K. Hamani, “Material waste in the UAE construction industry: Main causes and minimization practices,” Archit. Eng. Des. Manag., vol. 7, no. 4, pp. 221–235, 2011.

- S. M. Wheeler, “Built landscapes of metropolitan regions: An international typology,” J. Am. Plan. Assoc., vol. 81, no. 3, pp. 167–190, 2015.

- G. Lahn, P. Stevens, and F. Preston, Saving oil and gas in the gulf. 2013.

- D. A. Steinhardt and W. Manley, KarenMiller, “Reshaping housing: the role of prefabricated systems,” 2013.

- R. Minunno, T. O’Grady, G. M. Morrison, R. L. Gruner, and M. Colling, “Strategies for applying the circular economy to prefabricated buildings,” Buildings, vol. 8, no. 9, 2018.

- M. Dave, B. Watson, and D. Prasad, “Performance and perception in prefab housing: An exploratory industry survey on sustainability and affordability,” Procedia Eng., vol. 180, pp. 676–686, 2017.

- M. R. Hosseini, I. Martek, E. K. Zavadskas, A. A. Aibinu, M. Arashpour, and N. Chileshe, “Critical evaluation of off-site construction research: A Scientometric analysis,” Autom. Constr., vol. 87, pp. 235–247, 2018.

- V. Ogyiri, “Comparative Cost Analysis of Precast and In Situ Concrete Floor Slabs in Ghana,” 2014.

- P. K. Priya and M. Neamitha, “A review on precast concrete,” Int. J. Eng. Technol., vol. 5, no. 1, 2018.

- S. T. Abey and K. Anand, “Embodied energy comparison of prefabricated and conventional building construction,” J. Inst. Eng. Ser. A, vol. 100, no. 4, pp. 777–790, 2019.

- M. Malik, Nabeel and Ahmad, Rafiq and Al-Hussein, “Generation of safe tool-paths for automatic manufacturing of light gauge steel panels in residential construction,” Autom. Constr., vol. 98, pp. 46–60, 2019.

- R. Mazumdar, “Construction activity can be fast tracked via LGS Construction Technology,” 2020. Construction Activity Can Be Fast-Tracked via LGS Construction Technology (accessed Mar. 17, 2022).

- H. E. S. Abdelghany, “Lifecycle Assessment LCA comparison for different prefabricated modular construction systems with the conventional construction system for affordable houses in Egypt,” 2017.

- A. P. Gomes, H. A. de Souza, and A. Tribess, “Impact of thermal bridging on the performance of buildings using Light Steel Framing in Brazil,” Appl. Therm. Eng., vol. 52, no. 1, pp. 84–89, 2013.

- E. Hamed, “Modeling, analysis, and behavior of load-carrying precast concrete sandwich panels,” J. Struct. Eng., vol. 142, no. 7, 2016.

- S. M. Bida, F. N. A. Abdul Aziz, M. S. Jaafar, F. Hejazi, and N. Abu Bakar, “Thermal Resistance of Insulated Precast Concrete Sandwich Panels,” Int. J. Concr. Struct. Mater., vol. 15, no. 1, pp. 1–12, 2021.

- P. Amin Einea, D. С. Salmon, G. J. Fogarasi, T. D. Culp, and M. K. Tadros, “State-of-the-art of precast concrete sandwich panels,” PCI J., vol. 36, no. 6, pp. 78–98, 1991.

- C. Martins, P. Santos, and L. Simoes da Silva, “Lighweight steel framed construction systems,” Contrib. Sustain. Build. to Meet EU, 2014.

- M. Ismaiel, Y. Chen, C. Cruz-Noguez, and M. Hagel, “Thermal resistance of masonry walls: a literature review on influence factors, evaluation, and improvement,” J. Build. Phys., 2021.

- M. F. Zedan, S. Al-Sanea, A. Al-Mujahid, and Z. Al-Suhaibani, “Effect of thermal bridges in insulated walls on air-conditioning loads using whole building energy analysis,” Sustainability, vol. 8, no. 6, 2016.

- A. Kylili, P. A. Fokaides, P. Christou, and S. A. Kalogirou, “Infrared thermography (IRT) applications for building diagnostics: A review,” Appl. Energy, vol. 134, pp. 531–549, 2014.

- F. Bianchi, A. L. Pisello, G. Baldinelli, and F. Asdrubali, “Infrared thermography assessment of thermal bridges in building envelope: Experimental validation in a test room setup,” Sustainability, vol. 6, no. 10, pp. 7107–7120, 2014.

- Y. K. Kim, L. Bande, K. A. Tabet Aoul, and H. Altan, “Dynamic energy performance gap analysis of a university building: Case studies at UAE university campus, UAE,” Sustainability, vol. 13, no. 1, p. 120, 2020.

- Climate-Data, “Al Ain Climate.” https://en.climate-data.org/asia/united-arab-emirates/abu-dhabi/al-ain-1210/ (accessed Mar. 17, 2022).

| Case | Area | Construction | Sample#break#units | Construction information | HVAC | Construction year |

|---|---|---|---|---|---|---|

| 1 | 164.7 m2 | LGS system | 2 (LC01)#break#(LC02) | Attached units – residential compound, two-bedroom apartment | Duct Unit; set point temperature 21 °C | 2014 |

| 2 | 525.7 m2 | Reinforced#break#Concrete | 2 (RC01)#break#(RC02) | Single-family house, two#break#levels | Split unit. set point temperature 21 °C | 2016 |

| 3 | 476.2 m2 | Precast concrete (PC) | 2 (PC01)#break#(PC02) | Single-family house, two#break#levels | Split unit. set point temperature 21 °C | 2017 |

| Case | Area | System | Average Annual Demand | Consumption/Area | Average Interior Hotspot Temperature |

|---|---|---|---|---|---|

| 1 | 164.7 m2 | LGS System | 35.7 kW | 0.21 kW/m2 | 27.9 °C |

| 2 | 525.7 m2 | Reinforced concrete | 119.3 kW | 0.22 kW/m2 | 25.3 °C |

| 3 | 476.2 m2 | Precast concrete (PC) | 93.1 kW | 0.19 kW/m2 | 23.6 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).