1. Introduction

In majority of industrial

countries, nuclear power plants (NPPs) are used worldwide to generate

electricity. There are two reasons for the current use of nuclear power:

increased world prices for fossil fuels and the fear of climate change due to

CO2 emissions during combustion. Today 353 reactors in the world are older than

25 years among which, 154 are above 40 years. The long-term operation (LTO) of

existing NPPs has already been accepted in many countries as a strategic

objective to ensure adequate supply of electricity over the coming decades [1,

2]. The public and energy experts may disagree as to whether or not nuclear

reactors are indispensable as an energy source for today's human society, but

both supporters and opponents of nuclear energy agree that the safety of

reactors must be maintained at the highest possible level.

The design lifetimes are affected

by operating conditions, such as neutron exposure (fluence), and also by

magnitude and number of temperature and/or pressure cycles [3,4]. The two basic regulatory

approaches are the license renewal and the periodic safety reviews, which are

required for an authorization of the long-term operation of NPPs [1]. Evaluation of these parameters

makes possible an estimation of the operational NPP lifetime

[3].

One of the most important and

irreplaceable parts that limits the lifetime of NPPs is the steel reactor

pressure vessels (RPV), which encloses the extremely radioactive part of the

whole system. RPV must be tough, solid, strong and absolutely reliable. It

should never be cracked or leak or in any way allow the radioactive contents to

escape from inside. However, it is well known, that the mechanical properties

of the RPV wall are modified during the operation

[5]

. The ageing of the structure of

the RPV steel near to reactor core is generated by long term and high-energy

neutron irradiation and also, by thermal effects. These effects change the

microstructure of the steel and changes the RPV material to become more and

more brittle, more susceptible to unwanted cracks.

Evaluation of these parameters

allows for an estimation of the operational lifetime of NPPs. Currently,

destructive tests are performed on surveillance samples in the frame of

periodic safety reviews (PSRs) in order to assess the material degradation induced

by the neutron irradiation in RPV. Charpy impact test, which is performed on

surveillance specimens is the presently applied traditional and highly reliable

way of the RPV toughness inspections. Surveillance specimens are standard

tensile and ISO-V Charpy specimens of exactly the same RPV steels and their

welds [6]. These

specimens experience exactly the same history as does the RPV steel of the

vessel. It is supposed that their physical conditions are varying during the

whole lifetime of the reactor in the same way as that of the vessel. Their

physical condition testifies even about the “near future” condition of the

vessel material.

The neutron irradiation induced

embrittlement is usually described by the ductile-to brittle-transition

temperature (DBTT). To obtain a single DBTT value, several specimens must be

tested. For assessing structural material information over a long period, a lot

of Charpy samples are needed. In parallel, tensile specimens tested under a

quasistatic loading rate are used to determine yield strength, tensile

strength, uniform elongation, total elongation, and reduction in diameter.

Due to possible material

heterogeneities such as macro-segregated regions, hydrogen flakes, inclusion

areas in such large components the surveillance specimens might not necessarily

represent the whole vessel material. Furthermore, the destructive methods do

not allow for the characterization of the progress of material properties of

the same specimen when successively damaged. They are not applicable to the

actual component and finally, the amount of surveillance Charpy samples are

limited for monitoring over an elongated period.

It is evident, that a nondestructive

technique of RPV steel material testing can avoid many of the aforementioned

problems. It could be either a nondestructive inspection of an alternative

series of surveillance specimens, which would be measured outside of the

pressure vessel, then returned back into the vessel after each investigation,

and measured again, at the next periodic inspection phase. Alternatively,

special inspection methods and devices employing non-destructive techniques

could be utilized, enabling an inside inspection of the vessel with the aid of

specially equipped electrical leads. Even, a non-invasive evaluation of the

vessel material could be per-formed, focusing on carefully chosen external

areas of the vessel whenever feasible.

However, unlike mechanical tests,

nondestructive tests do not directly measure the material property. Currently,

no single nondestructive test has re-placed existing testing methods such as

the destructive Charpy test.

A project (“NOMAD”), oriented

towards the development of novel electromagnetic nondestructive methods for the

inspection of operation-induced material degradation in nuclear power plants

received funding from the Euratom research and training programme. The purpose

of this review paper is to give a comprehensive survey about the results,

achieved within the project. In the project a combination of several

nondestructive methods was used to examine how accurately and reliably the

degradation of cladded RPV material could be determined, especially when

compared to sample-based destructive testing. Charpy samples, cladded and

non-cladded blocks of various RPV steels along with different levels of

irradiation states, were provided. Different non-destructive evaluation

techniques were adapted and applied to measure the irradiated and

non-irradiated samples. The applied NDE methods were magnetic, electrical and

ultrasonic methods. Destructive reference tests for the determination of the

DBTT and other material characteristics were carried out as well. The

irradiated samples were handled and measured in hot cells. The measured data

were evaluated and correlated with the destructively determined DBTT values

using machine learning methods. In this way a predictive model was generated

which is able to non-destructively determine the DBTT for various RPV steel

types by intelligently combining the information of several non-destructive

testing methods. The outcome of the data-driven approach was finally validated.

The validation was established by

a detailed evaluation of the functionality of the NOMAD tool. This was done in

the context of the regression approach as well as it was complemented by a

classification approach. Furthermore, the evaluation provided insight into the

relevance of the different measurement features. Based on these achievements,

recommendations were made under the assumption of a continuation of the

development toward a higher TRL.

A short description of the

physical background of the radiation embrittlement of RPV steel is devoted in

Section 2. The state-of-the

art regarding nondestructive investigation before the NOMAD project is

summarized in

Section 3. Electromagnetic nondestructive tests of various irradiated RPV

steels are summarized in

Section 4. The purpose of the NOMAD project is described in

Section 5. The sample

preparation and description of destructive tests are described in

Section 6 and

Section 7. The results

of the measurement, performed in the project, both on Charpy and block

specimens are summarized and, in addition different methods are compared with

each other in

Section 8.

Section 9

is devoted to studying the evaluation of multi-output-parameter

(i.e. combined) NDE technique with the help of advanced classification methods,

particularly Machine Learning (ML) technique and its applicability.

Section 10

is the discussion

and interpretation of the project, while in summary and conclusions (

Section 11) the summary of the

whole project and recommendations are given for future research and application

of the investigated techniques.

The different methods, applied in

the project are described detailed in

Appendix A, while in

Appendix B, the interpretation of the scatter of measured points

is analysed.

2. The Radiation Embrittlement

The main ageing process of the

reactor pressure vessels is the irradiation embrittlement of the metallic

structural materials. A large number of experimental and theoretical studies

were published on the influence of radiation embrittlement. Several reviews

were published about this phenomenon [7-18].

Radiation embrittlement is caused

by the high energy fast neutron radiation (over 0.1 MeV), and high energy gamma

radiation. Embrittlement refers to a decrease in the fracture toughness of

reactor vessel materials and affects the vessel materials in the vicinity of

the reactor fuel, referred to as the vessel's "beltline”. It is one of the

most significant life limiting degradation phenomena of the pressurized and

boiling water reactors. Consequently, the monitoring of this ageing process is

primary interest of the Nuclear Power Plant Operators and the Regulatory

Bodies.

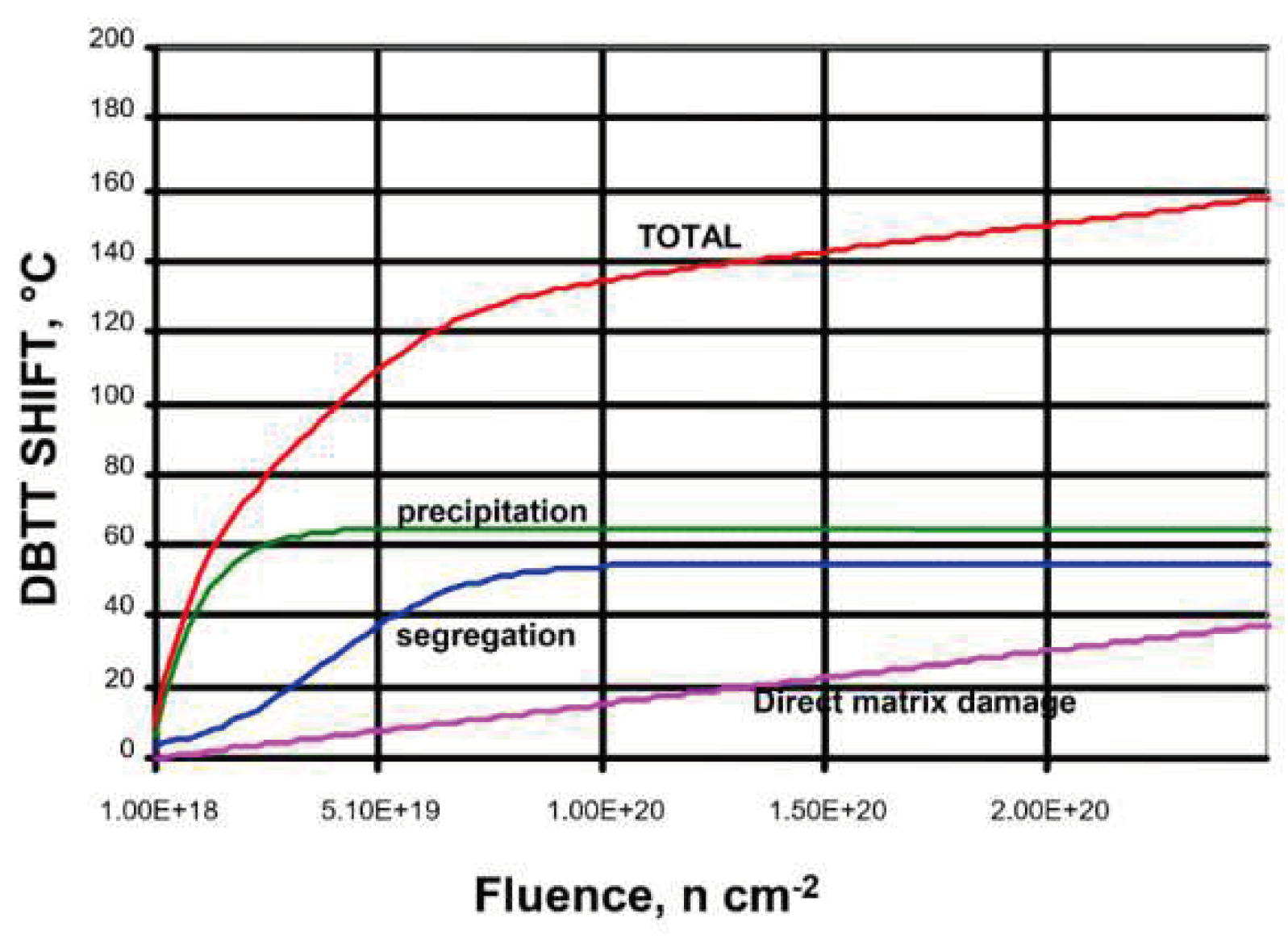

Testing and evaluation of

radiation embrittlement is a difficult task. The radiation embrittlement is not

one simple degradation mechanism but the sum of several processes as it is

shown in

Figure 1.

direct matrix damage due to neutron bombardment (increase of the dislocation density)

precipitation hardening of the matrix (Cu is the leading element but Ni, Mn, Si etc. also has influence)

segregation (P is a recognized segregating element) and if P covers the grain boundary even only in one atom thickness it can cause non-hardening embrittlement.

Direct matrix damage due to

neutron irradiation can be assumed to be simply root square dependent on

fluence for a given material and a given temperature. At higher irradiation

temperatures the rate of damage is considered to be decreasing due to increased

atoms mobility. During direct matrix damage formation, Cu, together with other

elements, is known to lead to precipitation mechanisms of nano-precipitates

also inducing matrix hardening and embrittlement. Such mechanism continues

until saturation depending on available amount of precipitants, Cu

concentration in particular. In addition, other elements, like P, can

segregate, in the grains (and or through diffusion processes at grain boundary)

also in combination to matrix damage or attracted into the Cu-type

precipitates. Diffusion of segregates also plays a role making this mechanism

rather difficult to understand in detail. P segregation to the grain boundaries

generally doesn’t cause hardening.

The so-called Master Curve

approach for assessing fracture toughness of an irradiated reactor pressure

vessel (RPV) steel has been gaining acceptance throughout the world. This

direct measurement approach is preferred over the correlative and indirect methods

used in the past to assess irradiated RPV integrity. Experience in using

results obtained from Master Curve testing has been illustrated by Wallin

[19], and the approach has been

applied utilizing ASTM Standard Test Method E 1921

[20]

in the USA

[21]. There have been comparisons

made using Master Curve data in other countries, but the primary attempts at

licensing implementation for nuclear reactor safety of RPVs have been in the

USA.

Furthermore, several other effects

have to be considered. Thermal ageing and thermal annealing are accelerated by

irradiation (irradiation speeds up the diffusion processes even at relatively

low temperature). These processes are time dependent; consequently, the

irradiation flux rate may also affect the rate of the embrittlement. Through

the cross section of an RPV wall (especially in the case of forgings) the

fracture toughness properties are changing and the rate of thermal ageing is

different [22-24]. Significant differences can be found in thermal expansion

coefficients with respect to pressure vessel base metals, which can cause a

stress peak

[25]. This

is the so-called pressurized thermal shock and it is a potential risk of

interfacial crack initiation and propagation. Safety analysis of this

phenomenon has lately become a subject of interest for operators of nuclear

power plants

[26].

There is a literature review

available that presents the current understanding of the mechanisms behind

radiation-induced embrittlement in low alloy reactor pressure vessel steels and

irradiation-assisted stress corrosion cracking in the core internals of

stainless steels

[27].

3. NDT Methods - State of Art

As outlined in the previous

sections, the mechanical properties of the reactor pressure vessel wall are

modified during its operation. As a result, the regular inspection of nuclear

power plants is an extremely important task. The DBTT, measured by destructive

Charpy tests is the standardized parameter in the nuclear industry, which

characterizes the embrittlement. A significant drawback of this method is that

many samples are necessarily used for this inspection. Additionally, the

measurement error is high. Because of these arguments, different nondestructive

methods have also been recommended and applied for monitoring the degradation

of nuclear pressure vessel steel material. The life prediction and NDE of

materials properties in the power plant industry was given in

[28].

However, as already mentioned in

the introduction, nondestructive tests cannot directly measure the material

property that needs to be determined - un-like destructive methods. They can

measure quantitative values of other physical properties (like different

electromagnetic parameters), which are influenced by similar reasons, such as,

for instance by presence and quality of structural material defects and

therefore correlate with the mechanical properties. The reliable way to obtain

quantitative information on a destructive-test-based required property, such as

DBTT, when using nondestructive measurements, is through establishing a

credible one-to-one correlation between the destructively and nondestructively

measured properties. This requires series of comparative experimental

investigations. All nondestructive tests must be rigorously correlated to

relevant destructive tests through multiple series of checked and re-checked

measurements before reliable application. This lack of correlation is the

primary reason that no non-destructive test has been able to replace

destructive tests, or even be applied as an auxiliary test, which could build a

strong foundation for correlation verification. Nevertheless, a number of

potential nondestructive tests were recommended and tested, and the mosaic of

the requested correlations is presently being built up.

These tests could be done with the

aid of armoured electrical leads through special bushing/containment within the

vessel. Furthermore − at least in principle − it could be a nondestructive

quality inspection of the vessel material itself, at different well selected

positions, from outside of the vessel. Several indirect physical methods (e.g.

magnetic, ultrasound, acoustic, X-rays, and others) of nondestructive testing

exist, and they can be principally applied for such inspections.

Number of nondestructive methods

have recently been suggested for studying the neutron irradiation-generated

embrittlement of RPV steel material. Paper

[29]

gives a summary of electromagnetic techniques used for

nondestructive testing (NDT) of degradation of nuclear reactor components.

However, since neutron irradiation makes the investigated material radioactive

and this causes significant difficulty in their measurement, simulation

techniques, such as ion irradiation, thermal ageing and cold working, can also

be used to simulate irradiation damages [30-32].

3.1 Piezoelectric Ultrasound

(Piezo-US)

The well known ultrasonic method

is widely applied in the inspection of NPPs [33-35]. Piezoelectric transducers

use the so-called piezoelectric effect to excite ultrasonic waves. This effect

is based on the occurrence of an electrical voltage when piezoelectric crystals

are mechanically expanded and compressed (direct piezoelectric effect).

Applying an electrical voltage to these crystals will, in turn, lead to their

deformation proportional to the electric field (indirect piezoelectric effect).

Thus, by using the piezoelectric effect, electrical energy is transformed into

mechanical energy and vice versa. The indirect piezoelectric effect is used to

transmit ultrasonic waves; the direct one is used to receive ultrasonic waves.

As in this case the ultrasonic waves are generated in the transducers

themselves, a coupling agent is needed to transfer these waves into the test

object as well as to receive them.

The ultrasonic time-of-flight

(TOF) method can be used as well, as the main measured quantity of the

ultrasonic testing method. The TOF is defined as the time the ultrasonic wave

requires for propagating from transmitter to receiver. For a given wave mode,

microstructure changes and mechanical properties influence the effective ultrasound

velocity and, therefore, they affect the TOF. The TOF is determined by fitting

a peak of the received waveform with a parabolic function and determining the

peak position analytically. The achievable accuracy lies in the single-digit

nanosecond range [36, 37].

3.2. Electrical Methods

3.2.1. Thermoelectric Power Measuring Method (TEPMM)

Thermoelectricity is based on the

fact that a thermal flux driven by a temperature gradient in an electrically

conductive material is accompanied by an electric current. The voltage or

thermoelectric power (TEP) created hereby is proportional to the temperature

gradient. The material-dependent proportionality factor is called Seebeck

coefficient (SC). Today, thermoelectric devices as temperature sensors

(thermocouples), heat sources or sinks and remote power generators are based on

thermoelectric effects and widely used. The change of the SC due to neutron

irradiation, thermal and mechanical ageing was observed experimentally. These

effects are well known as a cause of drift in thermocouples, which are widely

used as temperature sensors [38-40].

3.2.2. Direct Current-Reversal Potential Drop (DCRPD)

Four-point probe direct

current-reversal potential drop (DCRPD) method is based on the measurement of

electrical resistivity of metal. Material property changes in irradiated RPV

can be used as indicators for the state of the degradation. One physical effect

that can be used for the detection of irradiated material degradation is the

electrical resistivity. If the change of electrical resistivity is a

well-defined function of the neutron fluence, and if the effect is large enough

compared with that of other influencing parameters, it can be used the monitor

the material embrittlement. The development and testing is done to investigate

the suitability of electrical resistivity measurement for the characterization

of the irradiation embrittlement in irradiated pressure vessel steel.

Characterizing irradiated RPV base metal, electrical resistivity requires

measurement of very low resistance changes with high accuracy

[41,42].

3.3. Magnetic Methods

The majority of the nuclear

reactors, which are used presently are pressurized water reactors. The steel

used in the reactor pressure vessel is ferromagnetic, allowing for effective

inspection using magnetic methods. Magnetic nondestructive methods are an

important part of all the possible techniques, especially because of their

simplicity. Furthermore, it is known and understood that magnetic and

mechanical properties of ferromagnetic materials are very closely correlated:

regularity of microstructure of ferromagnetic construction materials (e.g. of

RPVs) and density and quality of its defects, has a significant influence on

both the mechanical and magnetic properties of the material. Domain wall motion

and dislocation movement are both influenced by the microstructure of the

material. The correlation between mechanical and magnetic hardness in

ferromagnetic materials is well-known and understood

[43,44]. The practical

applicability of magnetic methods for quantitative indication of steels

micro-structural modifications resulting embrittlement were proved by numerous

successful measurements.

In [45-49] overviews can be found

about nondestructive magnetic methods. These papers provide guideline to the

literature of magnetic techniques for nondestructive material testing. Compared

to other NDE techniques such as ultrasonics or eddy currents, the literature on

magnetic methods is limited, yet one of the challenges is its wide-spread

dispersion. The above mentioned reviews present a fairly comprehensive summary

of works on the known methods, such as Barkhausen noise effect, magnetoacoustic

emission, magnetic hysteresis method, residual field and magnetically induced

velocity change methods that can be used in practice.

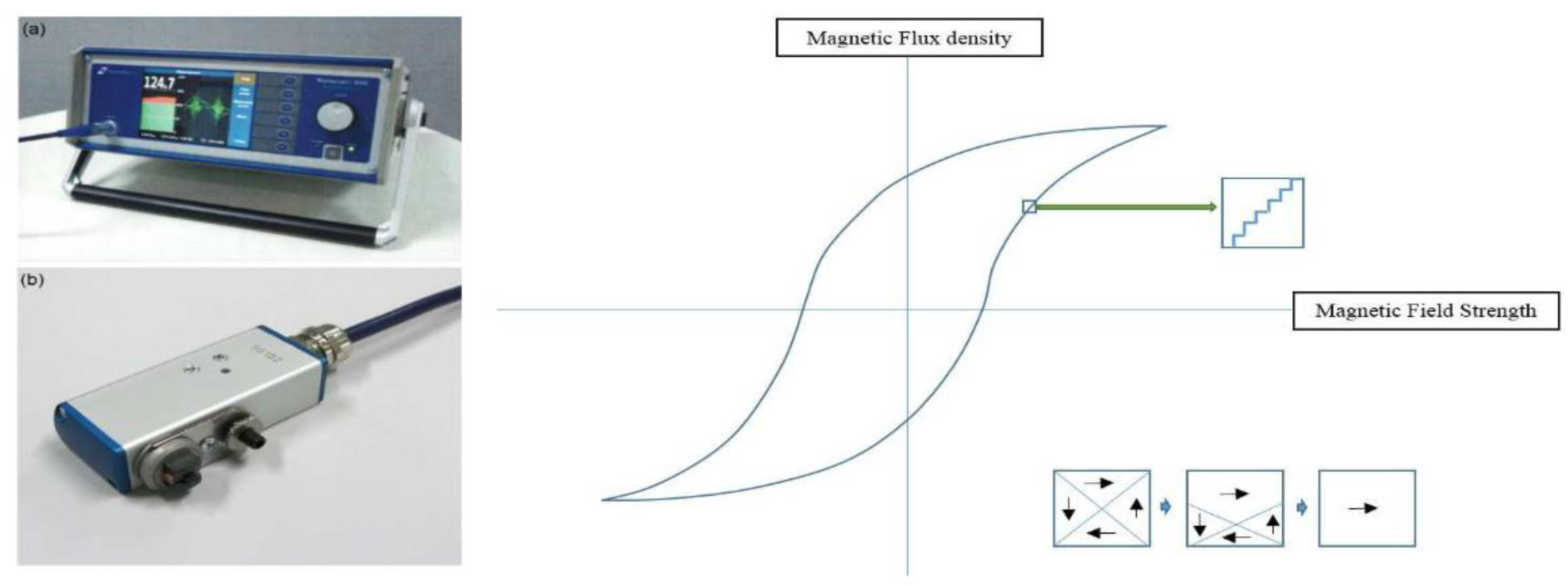

The well-known magnetic Barkhausen

noise technique (MBN) was originally developed for inspection of surface

defects, of residual stresses and of microstructure changes

[50]. There is a wide choice in the

literature how MBN can be applied for material characterization [51-60].

Magnetoacoustic emission, another

magnetic method, can also be successfully used for the monitoring of residual

stresses

[61,62].

A nondestructive magnetic method

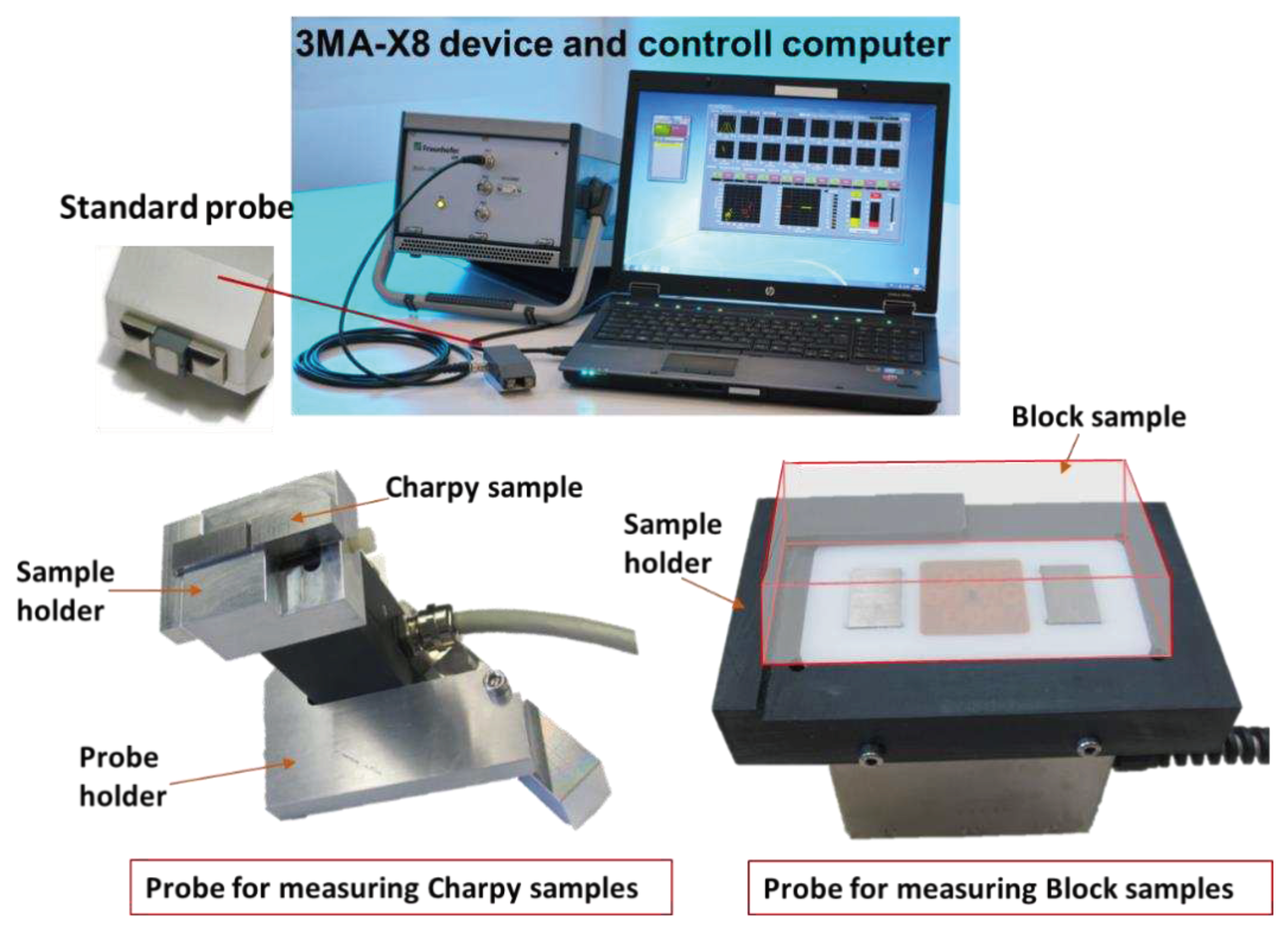

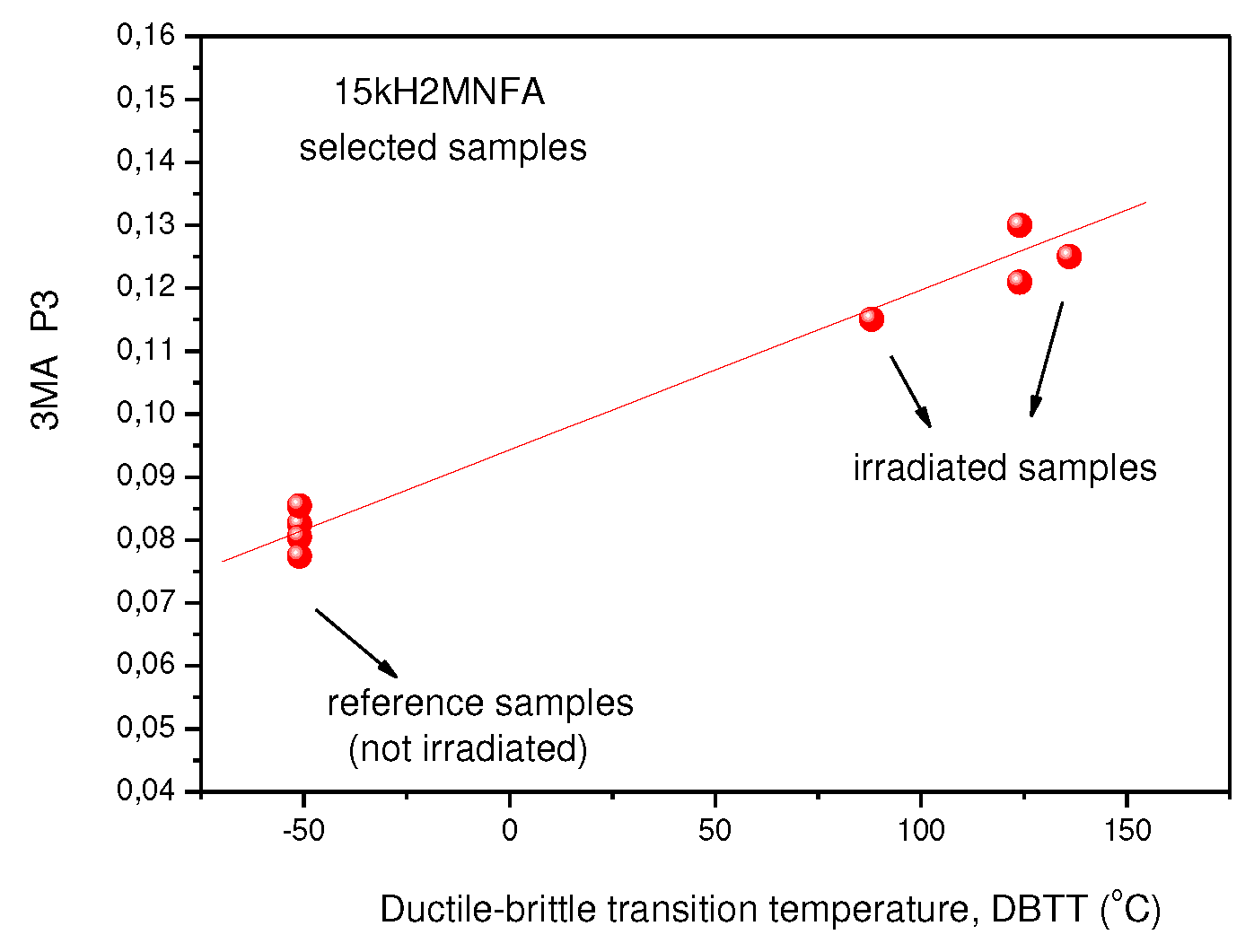

was previously developed, which is called as 3MA approach (3MA = micromagnetic,

multiparameter, microstructure and stress analysis) and this technique uses

different methods [63-65].

The measurement of the magnetic

hysteresis loops is also among the perspective candidates of magnetic NDE.

Theory of ferromagnetic hysteresis is given in several papers, see

[66] as an example.

The magnetic hysteretic

characterization of ferromagnetic materials with objectives towards NDE of

material degradation was discussed in

[67].

In

[31] cold rolling was applied to

generate crystalline defects in RPV steel. Magnetic hysteresis measurement

together with Vickers hardness and tensile properties measurements were

performed. The variations of remanence, hysteresis loss and coercivity were discussed

in detail. It was found that the strength, the hardness and the coercivity

increased with increasing deformation. A good linear correlation between the

increment of coercivity, hardness and yield strength was found.

In traditional measurements of

magnetic hysteresis, the major loop is measured, and several characteristic

parameters, like remanence magnetization, coercive force, maximal permeability

are determined from the major loop. However, in recently developed novel

methods, the series of minor loops are measured instead the major loop, and a

lot of different parameters of minor hysteresis loops are used for material

characterization. One of these novel methods is the magnetic minor loops power

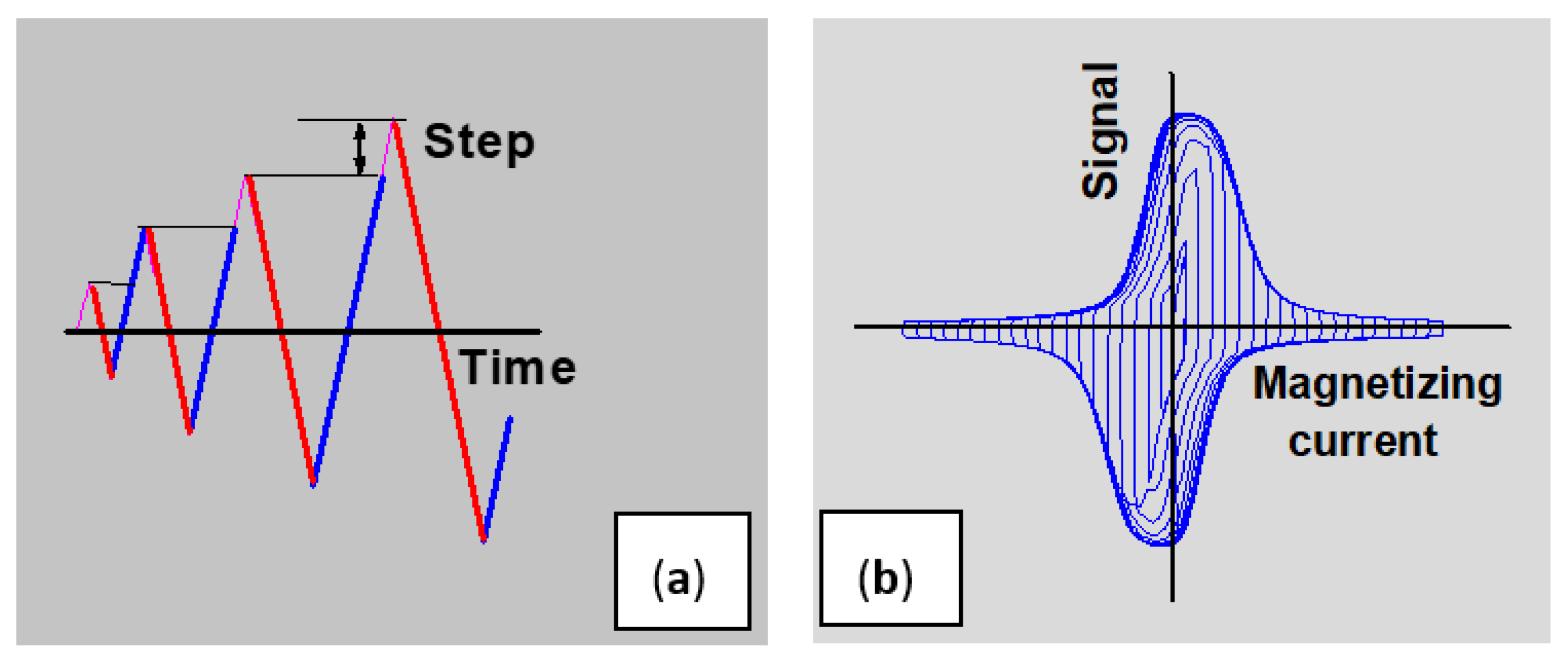

scaling laws (PSL) [31, 68]. A similar method, called magnetic adaptive testing

(MAT) also measures systematically the minor magnetic hysteresis loops [69-71].

As it was demonstrated, all 3MA, PSL and MAT methods are multi-parametric,

powerful and sensitive method of magnetic inspection. In case of MAT method

systematic comparisons were made between different magnetic nondestructive

techniques: different methods

−

full hysteresis loop measurement, MAT and MBN

−

were applied in

series of plastically deformed transformation induced plasticity (TRIP) steel

specimens, and the results of these methods were compared with each other

[72]. As a conclusion:

Good correlation was found between

magnetic parameters, measured by different techniques, which is a direct proof

that all magnetic methods accurately characterize the material degradation.

MAT seems to be the most sensitive

method among the other investigated ones.

Good correlation was also found

between magnetic parameters and with the destructively measured Vickers

hardness values. This fact makes possible the future potential use of magnetic

methods in the inspection of RPVs’ structural integrity.

All of these parameters were

determined without magnetic saturation of the investigated samples. This fact

is very important in practical applications.

In the next section it will be

reviewed, how these methods have been applied for investigation of the material

degradation, caused by neutron irradiation.

The methods 3MA, MAT and MBN were

applied in the NOMAD project.

4. Magnetic Nondestructive Tests of Various Neutron Irradiated RPV Steels - State of Art

The practical applicability of

magnetic methods have been proved recently by several successful measurements.

These methods are suitable for quantitative indication of micro-structural

modifications of RPV steel, causing steel embrittlement. Based on these results

the future potential application of magnetic methods seems to be promising in

the inspection of RPVs’ structural integrity. Possibilities and difficulties of

the NDE evaluation of irradiation degradation is analysed in Ref.

[73]. There is a comprehensive

summary about the investigation of the hardening in neutron irradiated and

thermally aged iron-copper alloys, on the basis of mechanical and magnetic

relaxation phenomena in Ref.

[74]. In this subsection the results, which were achieved in the area of

magnetic nondestructive tests of various irradiated RPVs are shown, with

separated results for each of the applied methods.

4.1. Major Hysteresis Loop Measurements

The modification of the magnetic

hysteretic behaviour generated by neutron irradiation was studied for different

materials in

[75]. Two

parameters of the hysteresis loop (maximum relative differential permeability

and peak intensity of interaction field) were determined as a function of

neutron fluence. A decreasing trend (change up to 40%) was found in magnetic

parameters during embrittlement, regardless the origin of the embrittlement.

The influence of the neutron

irradiation on the M-H magnetization curve of the RPV material was studied in

[76]. The saturation and the

residual magnetic induction and the initial magnetic susceptibility were

determined. It was found that the clockwise variation of the magnetization of

the hysteresis curves before irradiation was lower than than after irradiation.

Furthermore, the magnetization of the specimens before and after irradiation

were not sensitive to temperature changes. The residual magnetization intensity

was found as linearly related to the irradiation fluences less than 0.154 dpa.

An exponential relationship of initial magnetic susceptibility with the

radiation fluence was found as well.

The modification of saturation

magnetization of RPV steel, caused by neutron irradiation was studied in

[77]. Magnetic and metallurgical

properties were investigated by hysteresis loop and ferromagnetic resonance

(FMR) techniques. Saturation magnetization of neutron-irradiated steel

increased. To explain the cause of this increase, FMR experiments were also conducted

and a large difference was experienced in the resonance fields of

non-irradiated and irradiated samples.

Irradiation-generated changes in

the magnetic behaviour and in the mechanical properties were measured and

compared in RPV forging and weld surveillance Charpy specimens to reveal the

possible correlations between them

[78]. The samples were irradiated by E>1.0 MeV energy neutrons up to

the fluence of 2.3×1019 n cm-2. Tensile and Charpy impact

tests and Vickers microhardness measurements were carried out as mechanical

parameters. Magnetic parameters, such as saturation magnetization, remanence,

coercivity and Barkhausen noise amplitude were determined for none irradiated

and for irradiated specimens. Hysteresis loops were found to turn clockwise,

which resulted an increase in coercivity. Barkhausen noise amplitude decreased

after irradiation. These magnetic parameters revealed correlation with the

changes of mechanical parameters.

Recently, research on magnetic

methods to investigate the neutron irradiation embrittlement processes of RPV

steel have been focused mainly on Barkhausen emission measurements, and on

minor hysteresis loop measurements as will be discussed in next subsections.

4.2. Barkhausen Emission Measurements

Promising results were achieved in

the field of magnetic nondestructive tests of irradiated RPV steel also by

applying Barkhausen emission measurements. One of them was already mentioned in

previous sub-section

[59].

As shown in

[79], the measurement of Barkhausen

emission can reveal neutron irradiation caused degradation in pressure vessel

this parameter were in the range of −20% to −45% in case of fluences up to

25×1018 n/ cm-2.

MBN and magnetomechanical acoustic

emission were applied in Mn–Mo–Ni pressure-vessel steels, having different

microstructures for studying the influence of microstructural changes on these

parameters

[80]. The

measured signals were significantly affected the microstructural features. MBN

energy varied inversely with hardness and it depended also by the

microstructure. The results indicated that these quantities were closely

related to the dislocation density and residual stress which.

Barkhausen noise measurements were

used for the investigation of the radiation damage and thermal recovery of

irradiated RPV steel samples

[81]. There were identified two recovery stages from the hardness

measurements results. This effect resulted from isochronal annealing, and it

was presumed to be accountable for it. The mechanism can be explained by using

the results of MBN measurement on the basis of the interaction between

radiation induced defects and the magnetic domain wall. Irradiation caused an

increase in the maximum magnetic induction, but the coercivity was not modified

by neutron irradiation. MBN parameters associated with the magnetic domain wall

motion decreased due to neutron irradiation, and they recovered with subsequent

heat treatments.

Papers

[82,83] deal with the use of MBN

measurements to study the irradiation effects on nuclear reactor structural

materials. Different RPV materials were investigated, and the specimens were

irradiated with different neutron fluences. A stabilised flux mode was used,

the magnetic flux within the sample was controlled to compensate for leakage

and variations on the flux. Anisotropy effect caused by the sample cutting

direction was found, which masked the magnetic signal induced by the

irradiation effects. Specimens cut in the same direction correlate with

irradiation-generated material hardening and its dependency on fluence. It was

found that different materials resulted in different hardening levels. MBN

parameters were correlated to neutron fluence by taking into account the

cutting direction.

Microstructure effects on MBN

emission and on first-order reversal curve (FORC) analysis was studied in

ferritic/martensitic alloy (HT-9), which can be interesting for the experts in

nuclear materials

[84].

It was found that MBN emission and reversible component of magnetization,

determined from the FORC data, decreased with increasing mechanical hardness.

The results were discussed in terms of the use of magnetic signatures for use

in NDE of radiation damage and other microstructural changes in

ferritic/martensitic alloys. It is shown in this work, that FORC analysis is

particularly useful for characterization of defect density and pinning, which

can be correlated to bulk NDE field measurements such as MBN emission.

4.3. Measurement of Minor Hysteresis Loops

By applying the magnetic minor

loops power scaling laws (PSL), neutron irradiation generated modification of

minor loops was found in pure Fe and in different model alloys

[85]. Minor hysteresis loop

coefficients which were determined from scaling relations between minor-loop

parameters and in proportion to internal stress decreased in all materials,

irradiated by a neutron fluence of 3.32×1019 n cm−2. The

decrease of the coefficients was found to be larger for alloys containing Cu,

and it is enhanced by 1% Mn addition. This decrease can be caused by the

reduction of internal stress during irradiation. It is in contrast with the

changes of yield strength after neutron irradiation, which is increasing with

Cu and Mn contents. In this paper, a qualitative explanation can be found on

the basis of the preferential formation of Cu precipitates along pre-existing

dislocations, which decreases internal stress of the dislocations.

The same PSL method was used for

the measurement of low carbon steel and Fe metal, which were irradiated at 563K

in a 50MW nuclear reactor

[86]. Special attention was devoted to minor-loop coefficients

investigating the nucleation mechanism of copper precipitates and dislocation

loops during neutron radiation. The minor-loop parameters was found to be very

sensitive to lattice defects, such as dislocations, copper precipitates, and

grain boundaries. The minor-loop coefficients increased monotonously with the

increase of neutron fluence in Fe metal. Here the dislocation loops has an

important role for the brittleness.

Minor magnetic hysteresis loops

were also measured on A533B-type RPV steels having various combinations of Cu

and Ni content. Samples were irradiated by neutrons to a fluence up to 3.32x 1019

n cm-2

[87].

There was found a strong compositional dependence in the minor-loop

coefficient, which is obtained from a scaling power law between minor-loop

parameters. This is due to the internal stress. A large increase was found in

the low fluence regime (below 0.4x1019 n cm-2) in the

properties of high Ni and high-Cu steel, which was followed by a slow decrease.

However, in low Ni and low-Cu content steel, a sudden decrease was experienced.

These variations are mostly in a linear relationship with changes in yield strength.

The results were interpreted from the viewpoint of the formation and growth of

Cu-rich precipitates and/or fine scale defects in the matrix and along

pre-existing dislocations. A model analysis, assuming Avrami-type growth of

Cu-rich precipitates and an empirical logarithmic law for relaxation of

residual stress demonstrated that an increment of the coefficient due to

Cu-rich precipitates increased with Cu and Ni contents and was in proportion to

a yield stress change, related to irradiation hardening

[88,89].

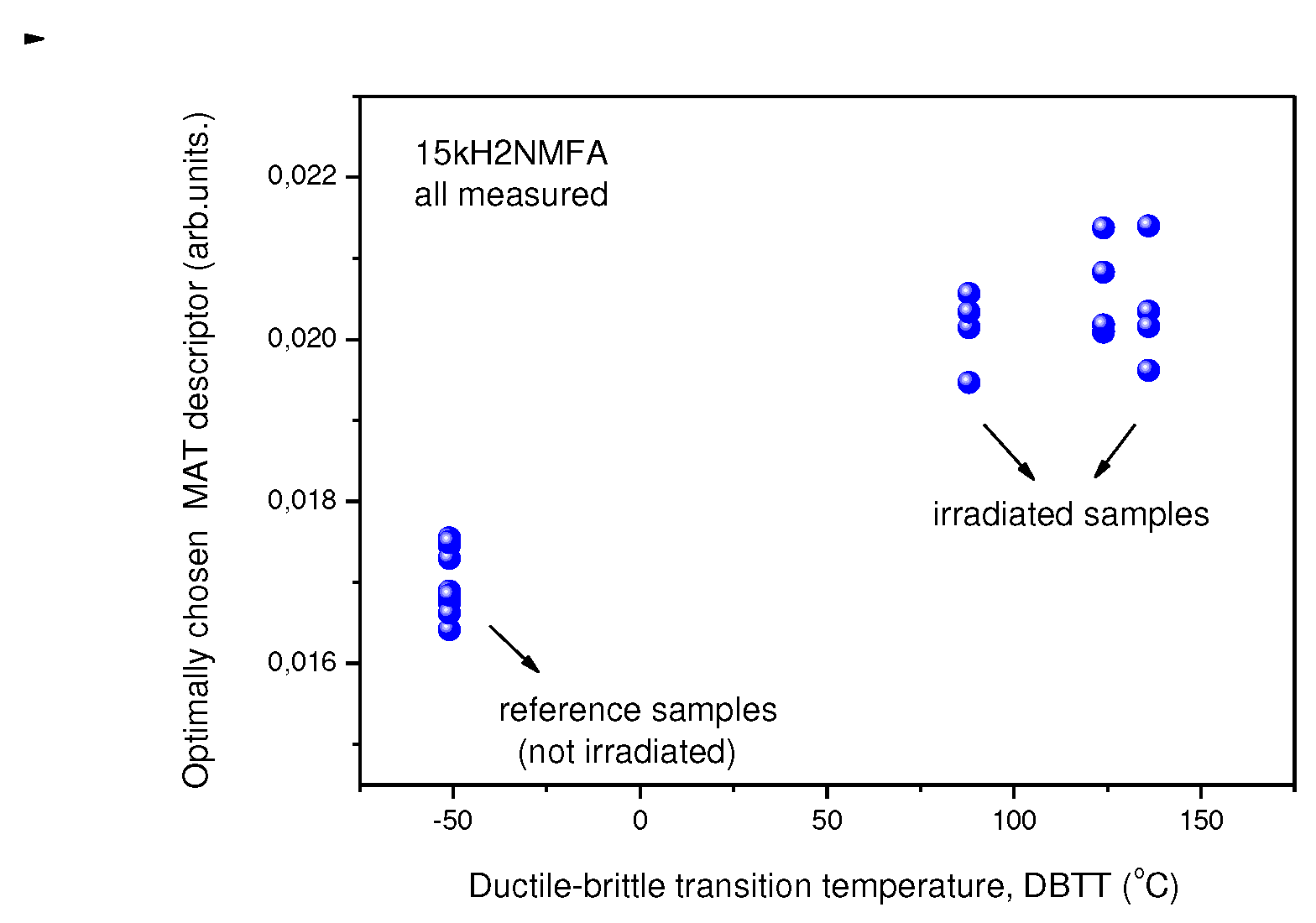

In

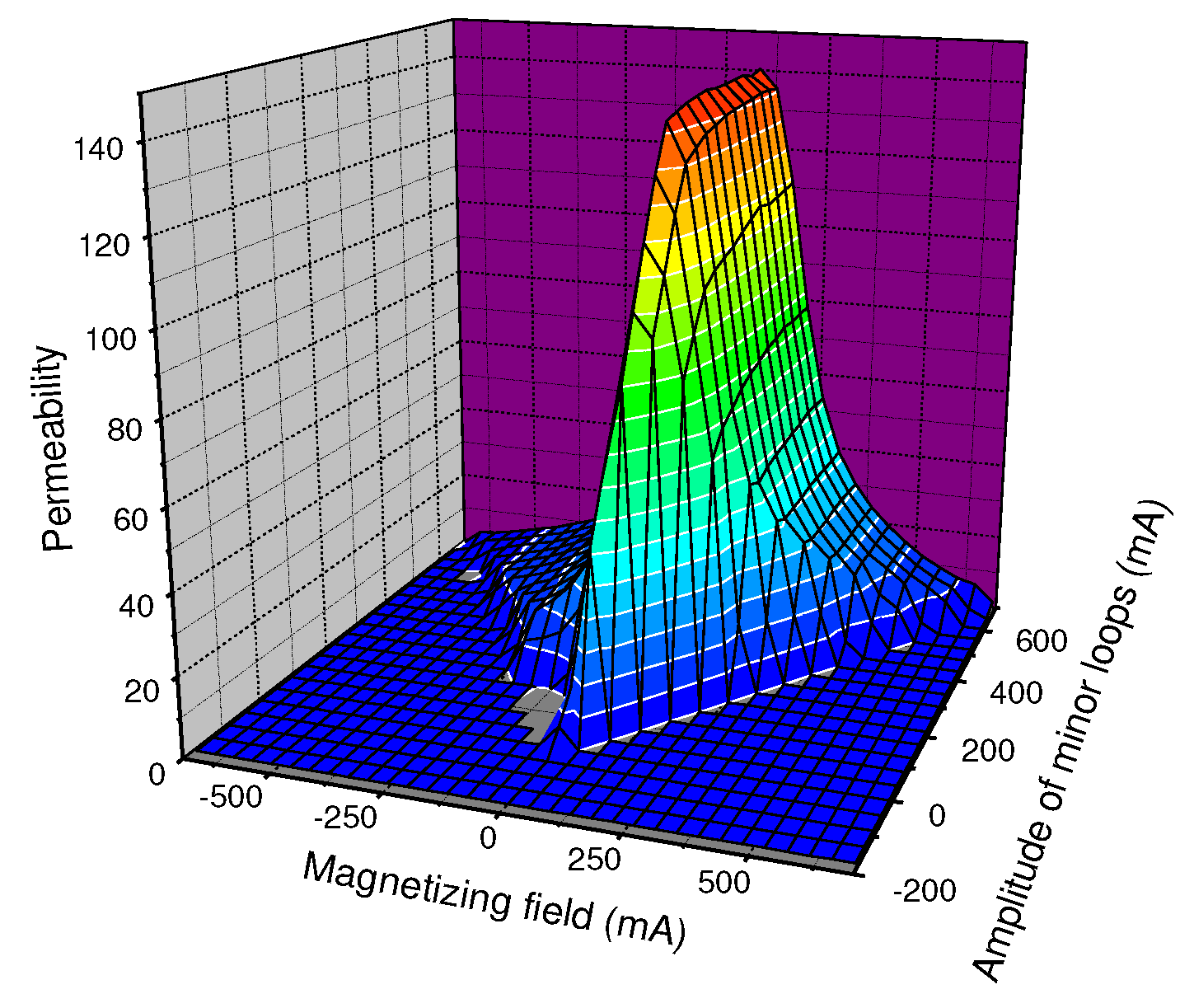

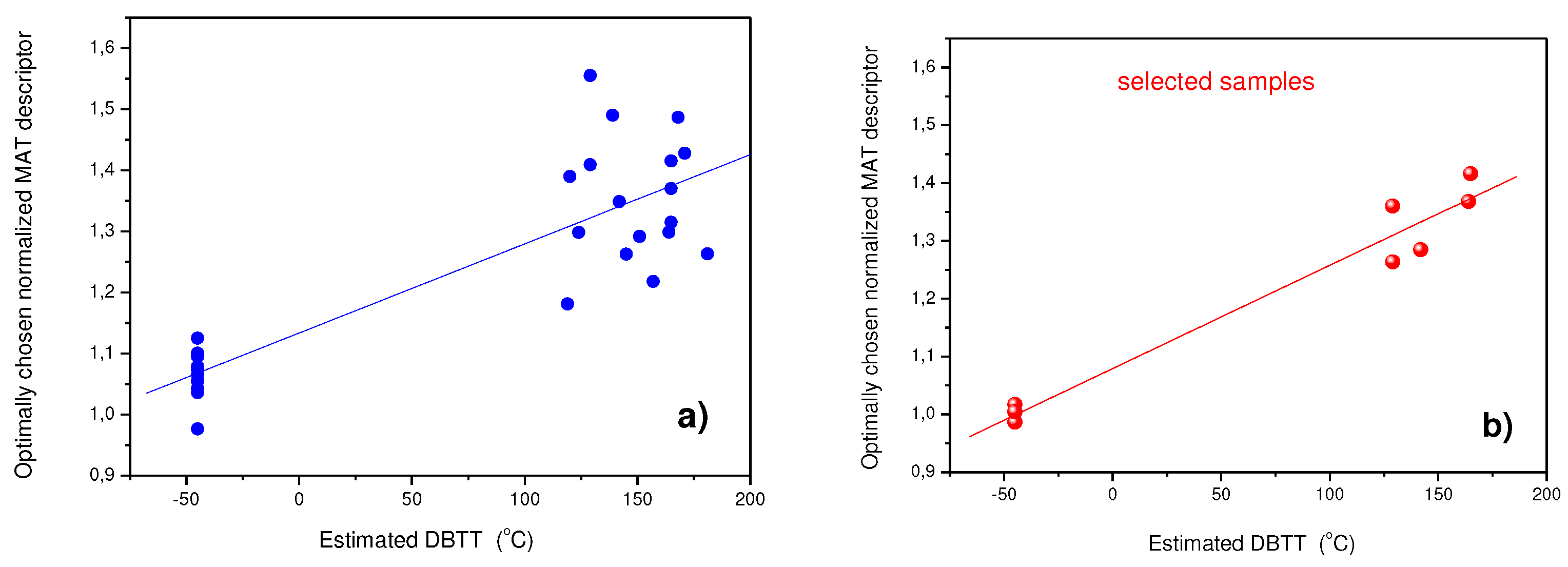

[90]

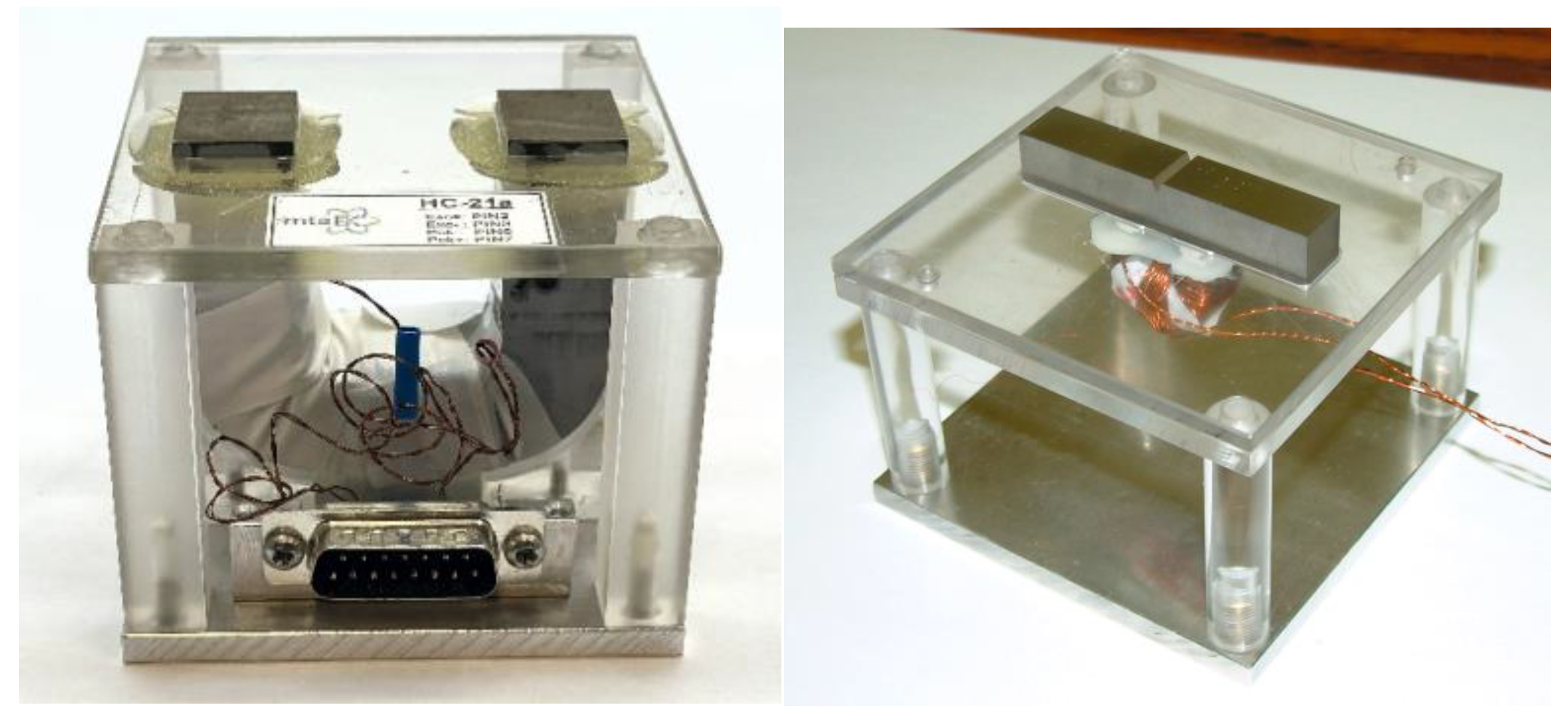

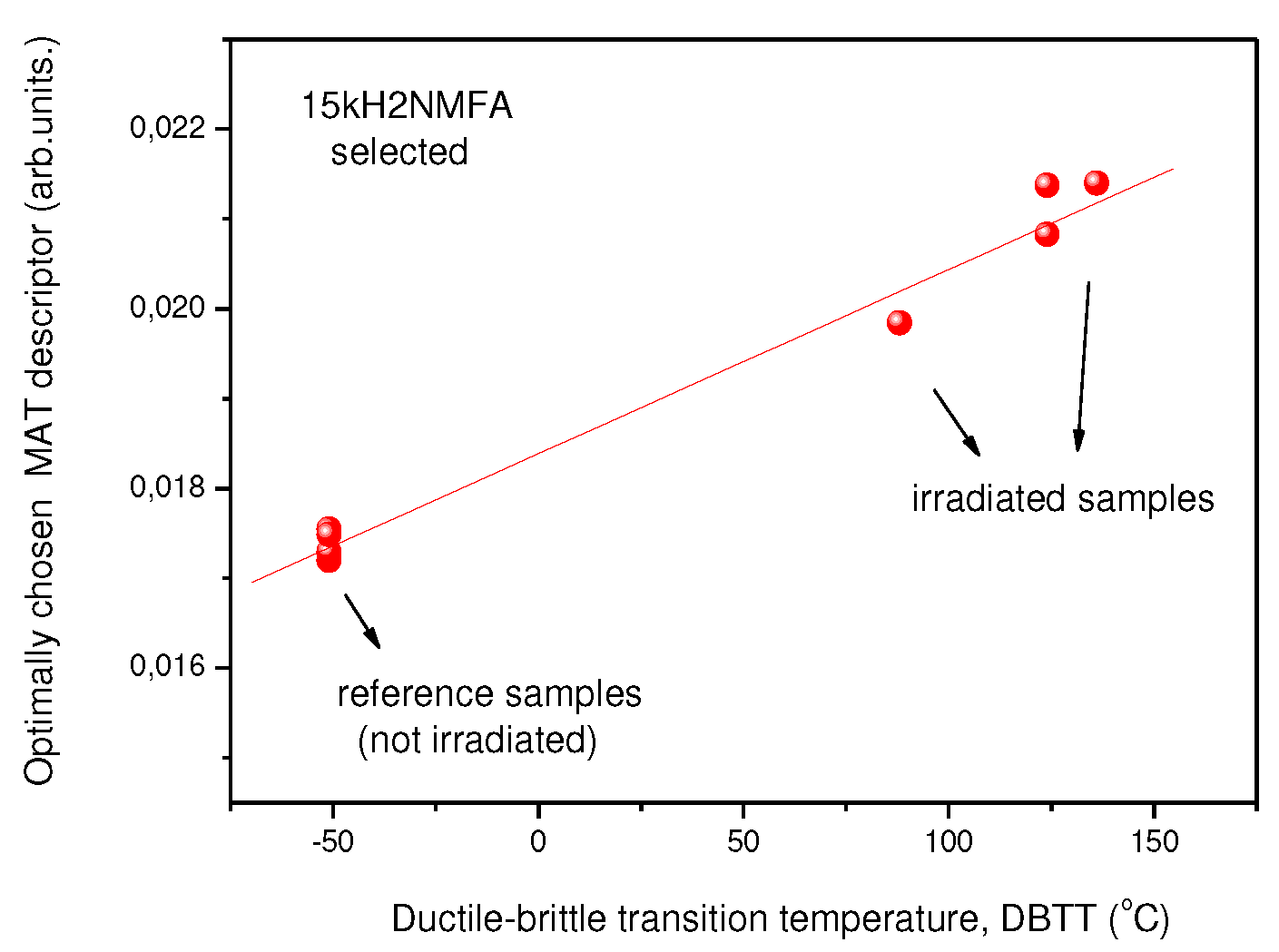

the applicability of MAT, an

alternative way of minor hysteresis loop measurement is demonstrated for the

inspection of neutron irradiation embrittlement in RPV steels. Three series of

samples (JRQ, 15CH2MFA and 10ChMFT type steels), irradiated by E > 1 MeV

energy neutrons with total neutron fluence of 1.58 – 11.9 x 1019 n

cm-2 were investigated by this method. Correlation was demonstrated

between the MAT parameters and the neutron fluence in all types of the

investigated materials. Shift of DBTT as a function of the neutron fluence for

the 15CH2MFA type material was also evaluated. In this case, a sensitive,

linear correlation was found between DBTT and MAT parameters. Based on these

results, MAT was shown as a promising, complimentary tool of the destructive

tests within the surveillance programs, currently used for the inspection of

neutron-irradiation-generated embrittlement of RPV steels. It was also found

that the sensitivity depended also on the structural anisotropy due to the

original direction of the material rolling/forging. The samples magnetized

along the original direction of steel rolling provided the most sensitive

results. Another conclusion of these measurements was that the magnetic

properties of the samples were affected by the quality of the magnetic contact

between the sample surface and the attached soft magnetic yoke. It was

concluded that if the yoke was not in good contact with the sample surface, the

results would be strongly influenced.

In other work

[91]

three methods (MBN emission

measurements, PSL and MAT) were compared with each other on the same series of

neutron irradiated RPV steel material. JRQ and 15Kh2MFA material and 10KhMFT

type welding steels (for WWER 440-type Russian reactors) were used for the

measurements, which were irradiated by high-energy (>1MeV) neutrons with up

to 11.9x1019n cm-2 fluences. MAT was found as the most

sensitive method among the investigated techniques. It revealed the most

straightforward linear correlation with the independently measured DBTT values.

The other magnetic methods (MBE and PSL) were found to be less sensitive than

MAT, and also, they did not correlate with DBTT, nor with each other.

Considering that both MBN and PSL are highly structure-sensitive magnetic methods,

the lower sensitivity and their poor correlation with DBTT can be primarily

attributed to the different sensitivity to lattice defects from that of DBTT.

It was also concluded, similarly to experiences in

[90], that an uncontrolled

fluctuation of surface quality of the slightly corroded specimens made the

measurement difficult. Contact-less ways of investigating of more conveniently

shaped irradiated nuclear pressure vessel steel samples was suggested for future

inspections.

The influence of the rough surface

on MAT measurements was carefully analysed in

[92], and it was found that this harmful effect could be significantly

reduced by applying a non-magnetic spacer between the sample surface and the

magnetizing yoke.

4.4. Electromagnetic NDT Techniques

3MA method (micromagnetic,

multiparameter, microstructure and stress analysis) has been found as a

suitable tool for the characterization of the degradation of ferromagnetic

materials (like RPV steels).

The microstructure of the steels

is modified by the neutron induced embrittlement. This phenomenon depends on

the neutron fluence but also on the special design of the RPV of nuclear power

plants. Embrittlement contributes to the increase of hardness and strength on

the basis of vacancies and Cu-rich precipitates, and also to the shift of the

DBTT to higher temperatures. Micromagnetic investigations were done at full

Charpy specimen and material of the last generation of German NPP in order to

characterize the material degradation

[93]. This contribution reports on the results obtained by the

application of the 3MA method and the magnetostrictive excitation of ultrasound

using an EMAT. Both technologies document potential to be further developed to

an in-service inspection technique.

By using the electromagnetic

non-destructive techniques the ability of characterization of material ageing

was demonstrated

[94].

Thermal degradation causes hardness enhancement and appearance of Cu

precipitation. An early warning can be done before fatigue life is elapsed due

to Low Cycle Fatigue.

By using the micromagnetic

non-destructive techniques the ability of characterization of material ageing

was demonstrated

[94].

Thermal degradation causes hardness enhancement and appearance of Cu

precipitation. An early warning can be done before fatigue life is elapsed due

to Low Cycle Fatigue.

The DBTT shift was indicating when

material degradation was at well-defined laboratory-type specimens. A high

sensitivity and confidence in the results was obtained. As the special

application of EMAT sensors demonstrated its reliable use at a service temperature

of 300 oC, the integration of this sensor type into plant lifetime

management systems is an engineering problem. The purpose is to solve the

proper selection of cooling devices for the driving microelectronic systems and

to apply heat resistant wires for coils and cables especially isolated for high

temperature access.

5. NOMAD Project

As it is outlined in the

introduction, the long-term operation (LTO) of existing nuclear power plants

(NPPs) has already been accepted in many countries as a strategic objective to

ensure adequate supply of electricity over the coming decades. In order to

estimate the

remaining

useful

lifetime of NPP components, LTO requires reliable and accurate tools.

To achieve a step forward in this important area, a joint research

work was initiated by ten different laboratories from seven different European

countries.

The project (Non-destructive Evaluation

System for the Inspection of Operation-Induced Material Degradation in Nuclear

Power Plants, or, NOMAD for short) has received funding from the Euratom

research and training programme 2014-2018 under grant agreement No 755330. The

common work started in 2017

[95].

The

objective

of NOMAD was the development, demonstration and validation of a NDE

tool for the local and volumetric characterisation of the embrittlement in

operational reactor pressure vessels (RPVs). In order to address these

objectives, the following steps were taken:

Development and demonstration of an NDE tool for the characterisation of RPV embrittlement, especially accounting for material heterogeneities and exceeding the existing information from surveillance programmes.

Extension of the existing database of RPV material degradation by adding correlations of mechanical, microstructural and NDE parameters as well as including quantification of reliability and uncertainty.

Application of the developed tool to cladded material resembling the actual RPV inspection scenario.

The project NOMAD took into

account the priorities of reactor operation, responding to stringent safety

requirements from regulators, and sought to foster the convergence of nuclear

safety approaches. The approach developed within NOMAD delivers information

complementary to and exceeding the information obtained by destructive tests of

surveillance samples, which are currently assumed to represent the whole

component and do not take into account possible local material variations.

NOMAD’s aim was to fulfil requirements for nuclear safety in the framework of

assessment for lifetime operation.

In the previous section different

application possibilities of several novel – mainly magnetic – nondestructive

methods are reviewed. As it is seen, good results were achieved, how these

methods could be applied for the inspection of neutron irradiation generated

embrittlement of RPV steel. However, only few of them were done on mechanically

intact RPV steel, which would form a continuous series from not-irradiated

samples up to samples of the same RPV material having the same shape, which

would be subjected to high fluence of neutrons in a nuclear reactor. Hence, it

can be stated that presently there is no really effective nondestructive method

for radiation embrittlement evaluation in practical use. One of the reasons of

the contradictory results is that the investigated irradiated specimens were

mostly collected from different surveillance programs. Furthermore the

investigated specimens were often mechanically deformed, sometimes corroded,

and in several cases the zero level specimens were missing, or they were cut

from different parts of the material.

Within NOMAD project several

different nondestructive techiques were applied to detect the neutron

irradiation generated material degradation in many different RPV steel

materials, having either Charpy geometry or larger, cladded or non-cladded

blocks. The same series of samples were measured before and after neutron

irradiation, and the results, obtained by different methods were compared with

each other. The purpose was to reveal the benefits and drawbacks of different

methods, and finally to find, which techniques are suitable for future,

practical applications. The parameters extracted from different methods were

compared with the destructively measured DBTT values. A combination of several

NDE methods has been used to examine how accurately and reliably the

degradation of RPV material can be determined, especially when compared to

sample-based destructive testing.

Charpy samples, cladded and

non-cladded blocks of various RPV steels and irradiation states were provided.

NDE techniques were adapted and applied to measure the irradiated and

non-irradiated samples. The applied NDE methods were the magnetic methods MAT,

3MA-X8, MBN, the electrical methods DCRPD, TEP and the ultrasonic method

Piezo-US. They were used to characterise the microstructure changes and the

variation of the material properties as a function of progressing exposure

(fluence level).

Table 1

gives an overview on the NDE methods applied to different specimen

geometries (Charpy and blocks) within the project.

Destructive reference tests for

the determination of the DBTT and other material characteristics were carried

out. The irradiated samples were measured and the data were correlated with the

DBTT values by using machine learning methods.

The ultimate goal was to produce a

machine learning-based computational tool that can estimate the neutron

irradiation-induced embrittlement of reactor pressure vessel steel alloys based

on the NDE parameters. This would revolutionize the current surveillance

procedures, which rely heavily on destructive methods.

The non-destructive

characterization was carried out by means of micromagnetic, electrical and

ultrasonic methods at various stages of material degradation caused by neutron

irradiation. They were used to characterise the microstructure changes and the

variation of the material properties as a function of progressing exposure

(fluence level).

Table 1

gives an overview on the NDE methods applied to different specimen

geometries (Charpy and blocks) within the project.

In the following chapters the results of NOMAD project will be presented and analyzed.

6. Materials

Several sets of samples with

various irradiation and embrittlement conditions were provided. The first

specimen set consists of ISO-V Charpy samples of the four materials 18MND5

(weld), 22NiMoCr37, HSST-03 (A533-B) and A508-B. These were existing samples

from previous CHIVAS - surveillance programs, which were available in

non-irradiated states and in two or three irradiation states. The second

specimens set consists also of ISO-V Charpy samples of the two materials

A508Cl.2 and 15kH2NMFA. The A508Cl.2 was cut out from ¾ depth of a large part

of the Lemoniz reactor vessel, a Spanish reactor of Western type that was never

operated,

[96,97]. The

15kH2NMFA material was cut out from original eastern 1000 MW RPV from the ¼

depth. The 15Kh2NMFA (CrNiMoV) forging steel was manufactured by the Russian

IZHORA company for a 1000 MW WWER reactor. The original heat number is 181358

and the forging steel was produced according to the Russian specification TU

108.765-78. These Charpy samples were irradiated at three well-defined levels

at the Belgium Reactor BR2. The neutron irradiation was performed in a

specially designed rig where 24 Charpy specimens were directly irradiated

[98]. The second set of specimens

could be non-destructively measured before and after irradiation, so an

evaluation of the progressive change of the embrittlement could be performed.

Table 2

shows the

corresponding material compositions.

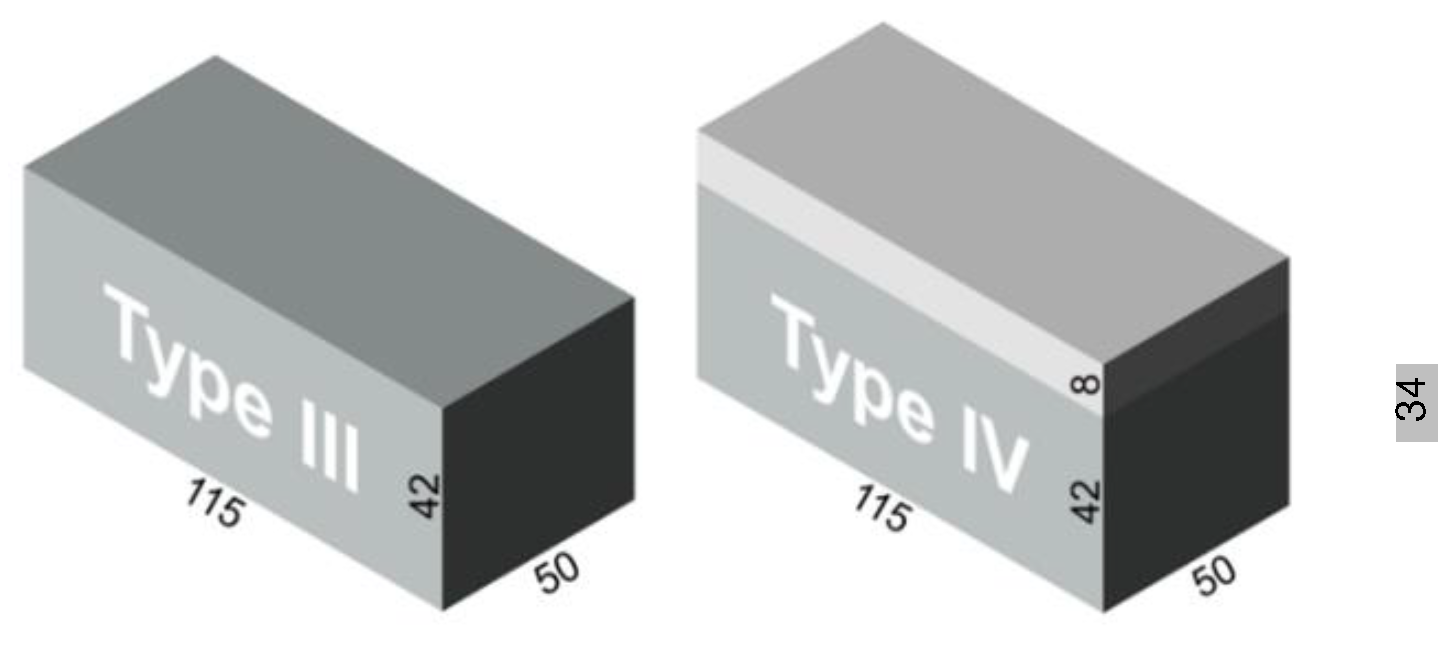

Finally, in order to characterize the neutron-irradiation induced embrittlement through the cladding, a third specimen set was chosen consisting of six cladded and six non-cladded blocks of Western RPV material A508 Cl.2 (See also in

Table 2). They are more representative for in-situ vessel inspection than the standard test Charpy samples, and has been fabricated and irradiated over a large range of neutron fluences at BR2. One part of the block samples without cladding was made of compact material cut out of the mid area of a real RPV, whereby another part of the block samples with cladding was cut out from the cladded surface of the RPV. So, the latest can be used to examine the capability of the non-destructive measuring methods for testing the irradiation induced material degradation through the cladding. The dimensions of both types of block samples are shown in

Figure 2.

These blocks were irradiated at

three defined levels within BR2 similarly to the second specimens set. Two

different strategies have been applied for the irradiation. The first one aimed

to achieve an as uniform as possible neutron fluence profile and was applied on

three cladded blocks and three, non-cladded blocks. The second one aimed to

achieve damage that is much more realistic since the blocks have experienced a

fluence attenuation profile.

7. Mechanical Testing

Charpy impact tests were performed

on all of the samples previously investigated non-destructively in order to

determinate the DBTT. For the determination of DBTT of the blocks, Charpy

samples have been cut out from the top layer as well as from the bottom layer.

By this procedure individual DBTT values for both sides of the block specimens

could be provided. The results of the mechanical testing for all three

specimens sets are shown in the

Table 3,

Table 4 and

Table 5.

For the CHIVAS-samples (first

sample set) it is visible that the DBTT is not strongly correlated with the

real fluence level. Probably the overlapping varying fluence temperature may

cause an annealing effect, which reduces the influence of the irradiation.

For the Charpy and block samples

(second and third sample set) where the irradiation temperature was constant it

can be seen that there is a strong correlation between the fluence level and

the DBTT for the samples with 0, low and medium fluence. However, for the

samples with medium and high fluence there is no more increasing of the DBTT.

There is a clear saturation effect.

8. Experimental Results

8.1. Measuring Procedure

In order to guarantee reproducible measurements and a stable sample-probe coupling, sample/probe holders were constructed for each NDE technique. These were relevant especially for measuring the irradiated samples in the hot cell by the mechanical manipulation for handling and positioning the samples onto the NDE probe.

In order to define a unique way to perform all NDE measurements, an inspection and quality assurance procedure was defined. According to this procedure, each sample was measured five times, each time picking up the probe and replacing it on the sample. Although sample/probe holders were used the remaining scattering caused by the handling could be averaged by the repetitions.

As the measuring activities were spread over three years it was necessary to monitor the stability and functionality of the measuring NDE devices and probes. Therefore calibration samples were defined and were periodically measured by NDE. The analysis of the resulting outcome of these NDE measurements yields to the conclusion that all NDE results are stable over the time.

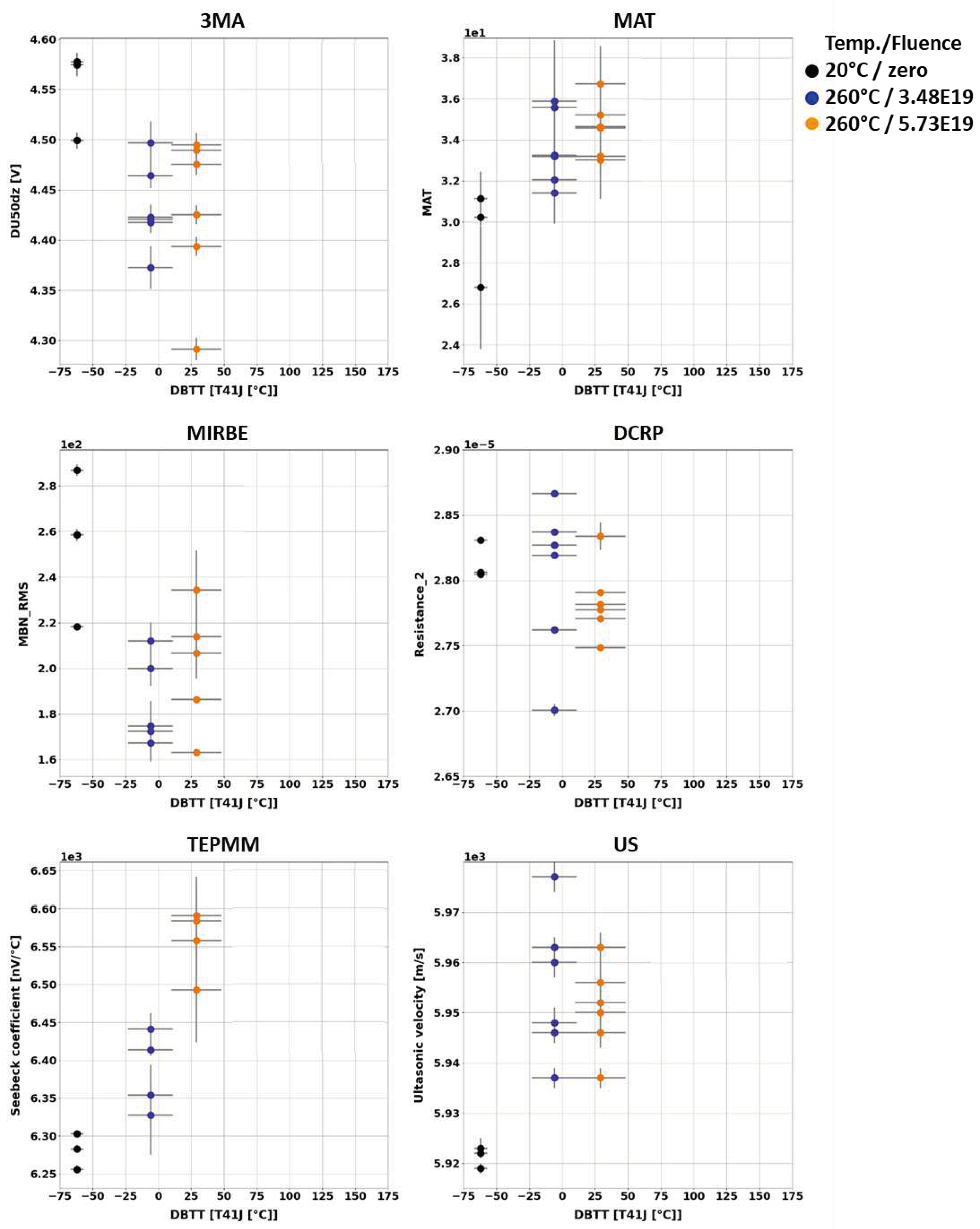

8.2. Description of the NDE of Embrittlement

8.2.1. Charpy Specimens

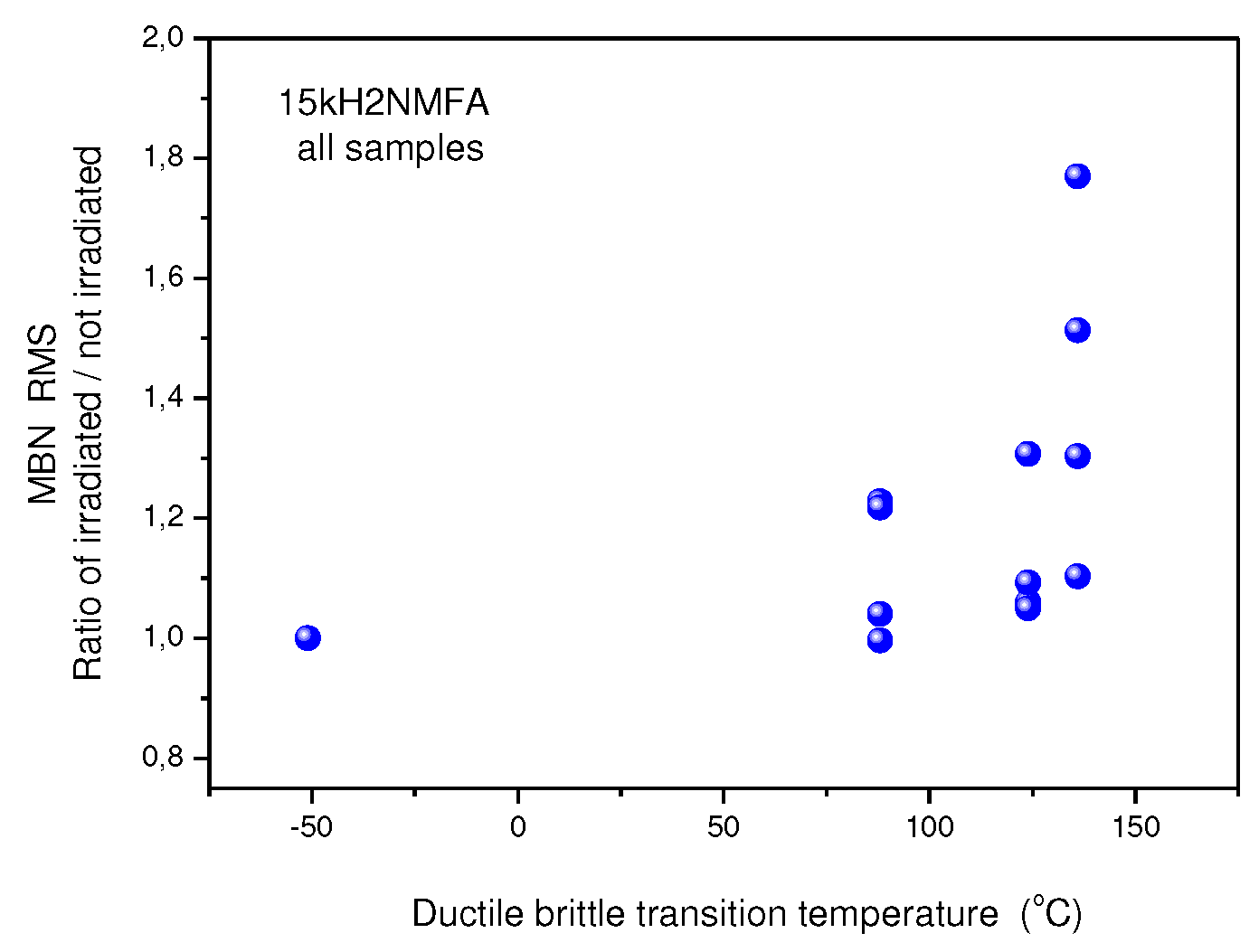

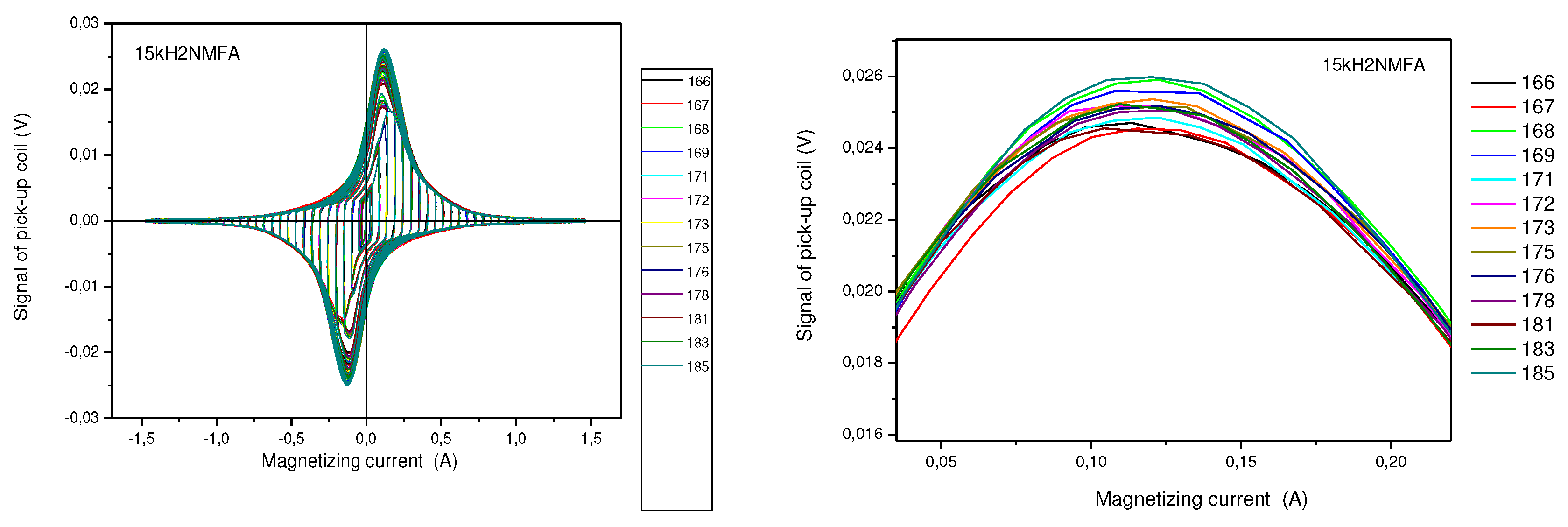

Generally, it has been observed that the outcome of the individual NDE measurements performed on different Charpy samples of the same material and the same irradiation condition scatter.

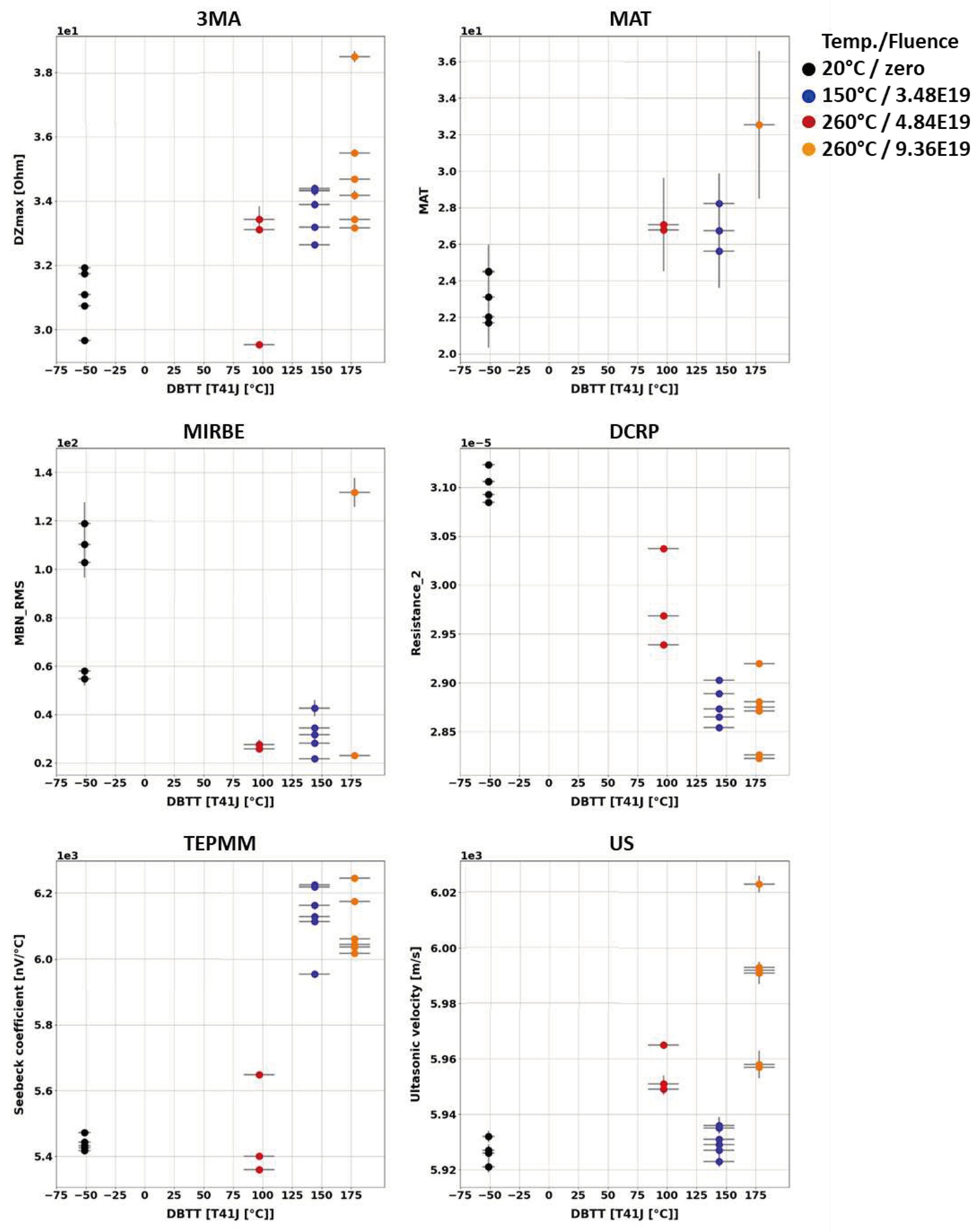

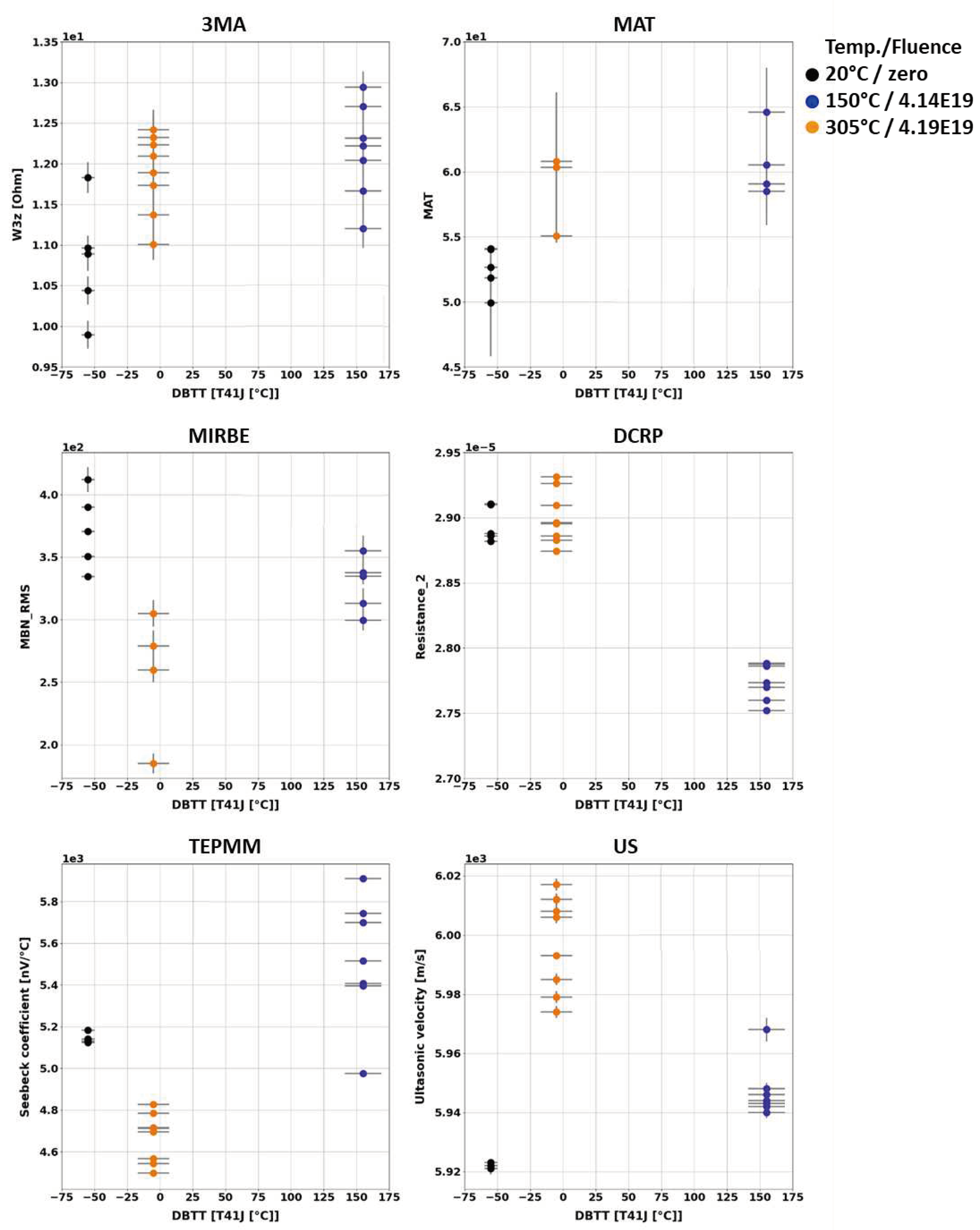

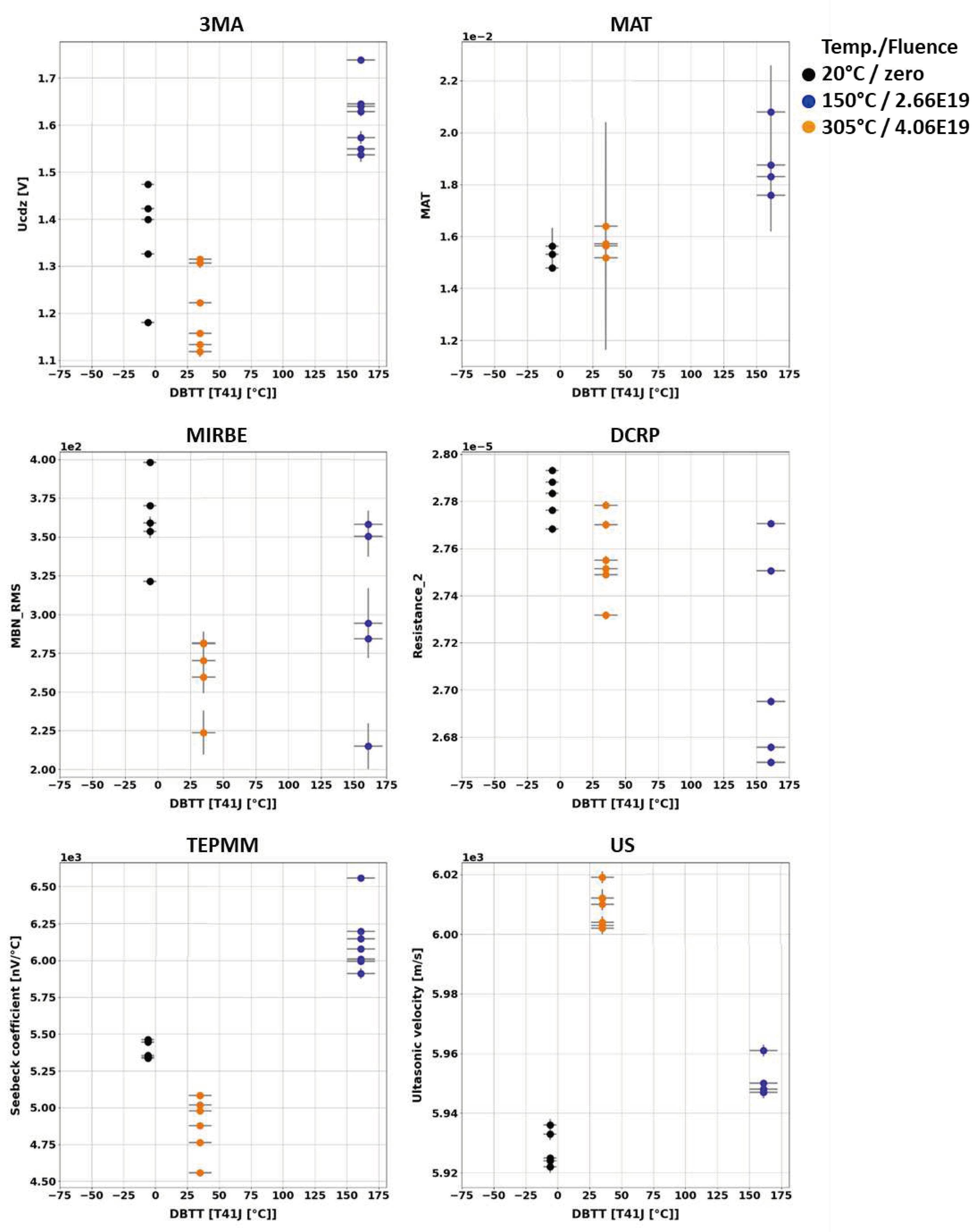

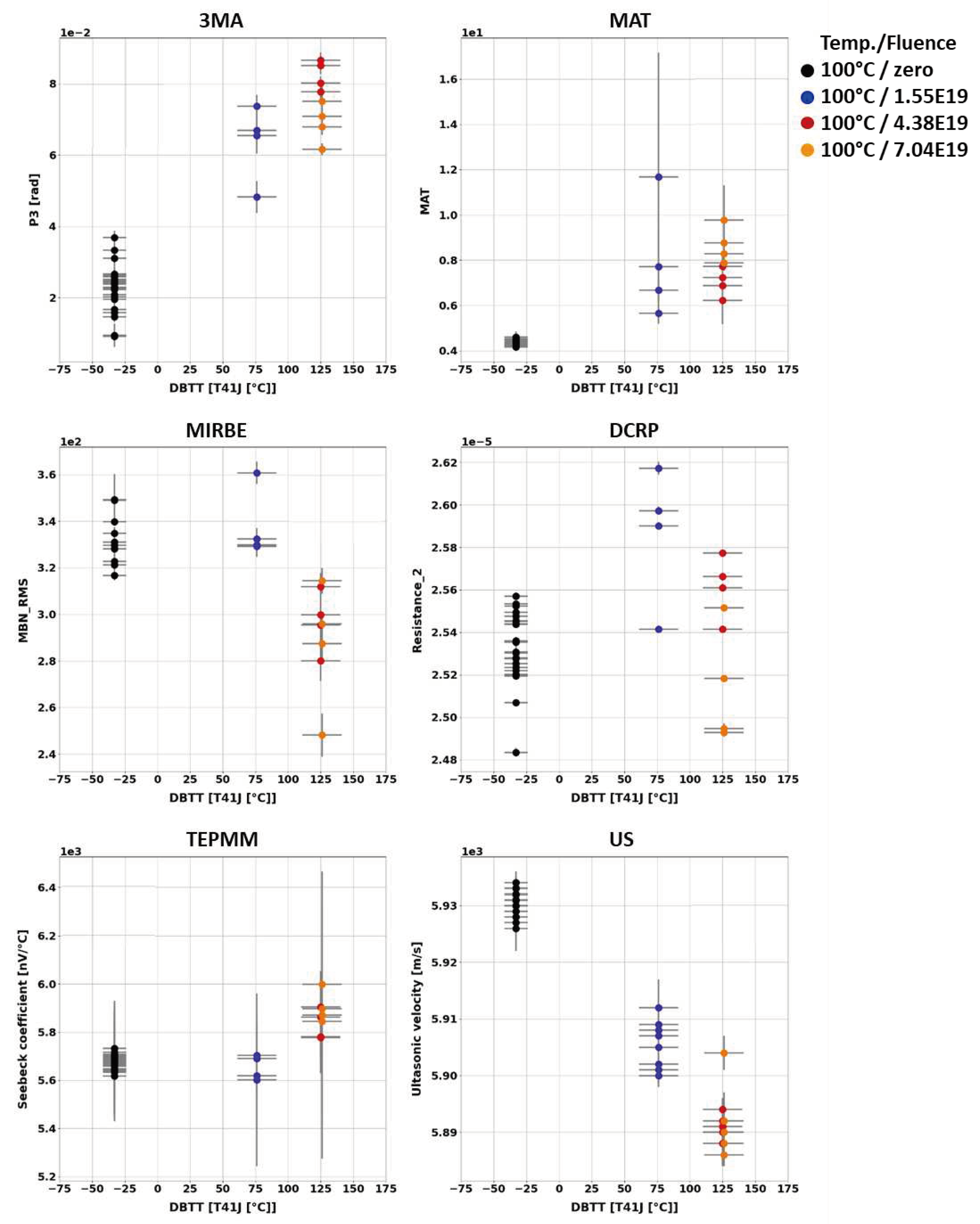

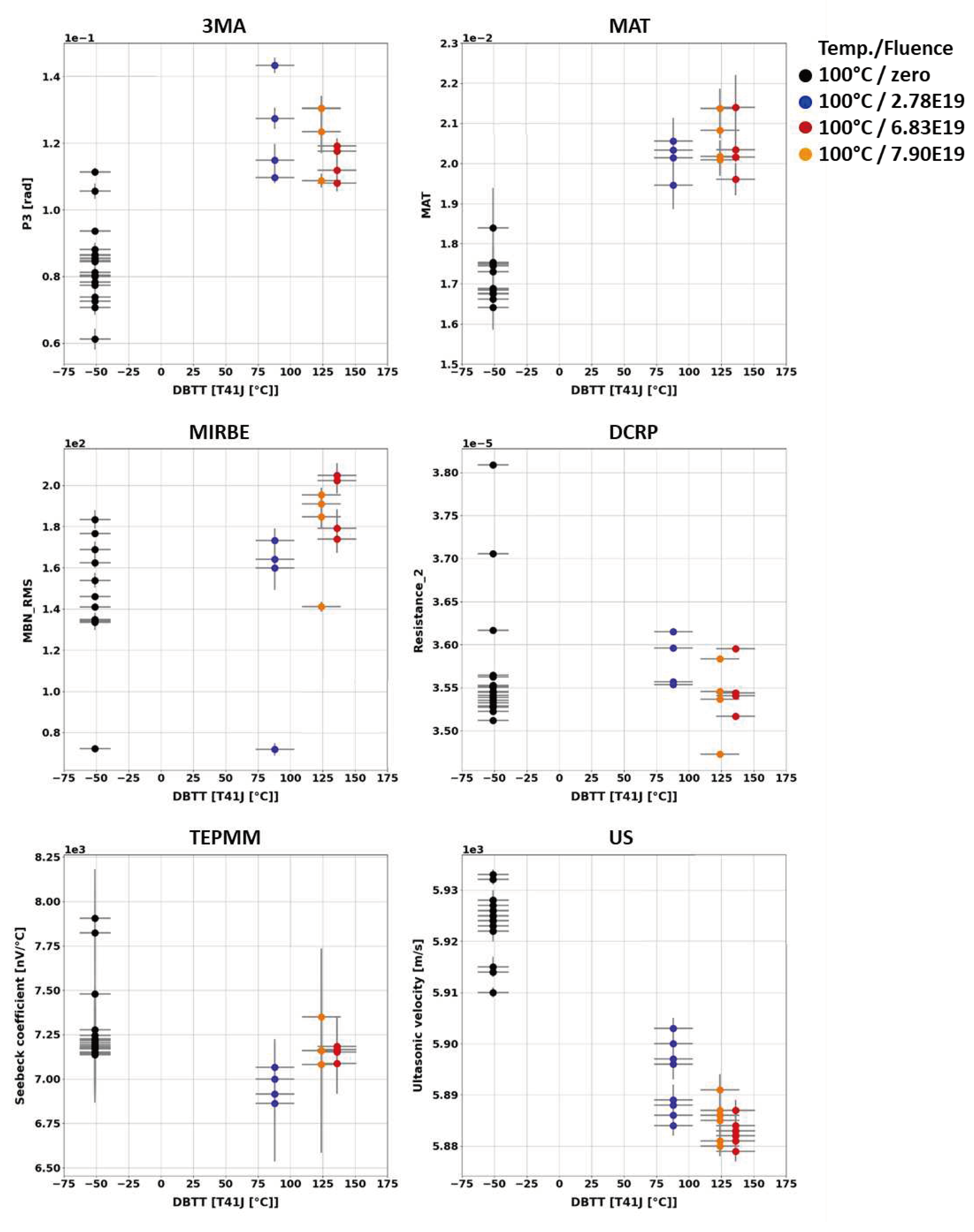

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8 give an overview about the measuring results for each set of Charpy specimens and for each NDE method in dependency on the corresponding DBTT. A possible explanation of this scattering lies in different origin of the samples having the same irradiation condition and, consequently, slightly different material properties before irradiation. (This effect is discussed in detail in Appendix B). This causes different progress of the material properties during neutron irradiation. Long-term repetition measurements carried out during the measurement campaigns on a reference sample showed stable results. Uncertainty studies were performed in order to find out the origin of this scatter. These studies concluded that the uncertainty of the samples can be estimated to be higher than the uncertainty of the “inspection system” [99]. Nevertheless, correlation of the nondestructively extracted features with embrittlement have been identified. Several trends correlate with each other and deliver complementary information regarding the material properties. It was expected that the NDE features show either a continuously increasing or a continuously decreasing trend for a certain material. This behaviour cannot be confirmed in case of all materials (see Figure 6 - material HSST03).

Moreover, it was observed that the same NDE feature shows different trends for different materials: Seebeck coefficient is expected to increase with embrittlement. However it decreases in case of the materials A508b and HSST03 irradiated at 305°C compared with the non-irradiated condition.

The behaviour of the NDE features is affected by both the irradiation fluence and the irradiation temperature. The increase of the fluence causes an increase of the embrittlement. The increase of the temperature has different effects on some of the NDE features: whereas temperatures below 260°C have the same influence like the irradiation fluence, it seems that higher temperatures have a contrary effect especially on the ultrasonic (US) method and Seebeck coefficient measurement (TEPMM).

In the case of the 3MA method only the most significant feature of the 21 measured features are shown. (In these figures the terminology “Micromagnetic Inductive Response & Barkhausen Emission (MIRBE)” is used for the Barkhausen noise measurements”.)

In case of the material 22NiMoCr37 (irradiated between fluences of 3x10

19n cm

-2 and 6x10

19 n cm

-2) only the Seebeck coefficient continuously changed with increasing DBTT. No difference in terms of the other NDE parameters has been observed for both irradiated conditions (

Figure 3). The variation of the DBTT due to increasing fluence taking into account the scatter of points of the 95% confidence bounds of the Charpy test results can’t be detected accurately probably due to variations in the microstructure of the material before irradiation.

In case of the weld material 18MND5-W (

Figure 4) several NDE features show continuous trends. However, in case of this material the ultrasonic time-of-flight (TOF) of the samples irradiated at 150°C is comparable with the TOF of the non-irradiated samples.

In case of the materials A508-B (

Figure 5) and HSST03 (

Figure 6) the high irradiation temperature of 305°C affects the outcome of the NDE measurements. Especially the results of the methods MIRBE, Piezo-US and TEPM show an anomalous behavior compared with the other irradiation conditions.

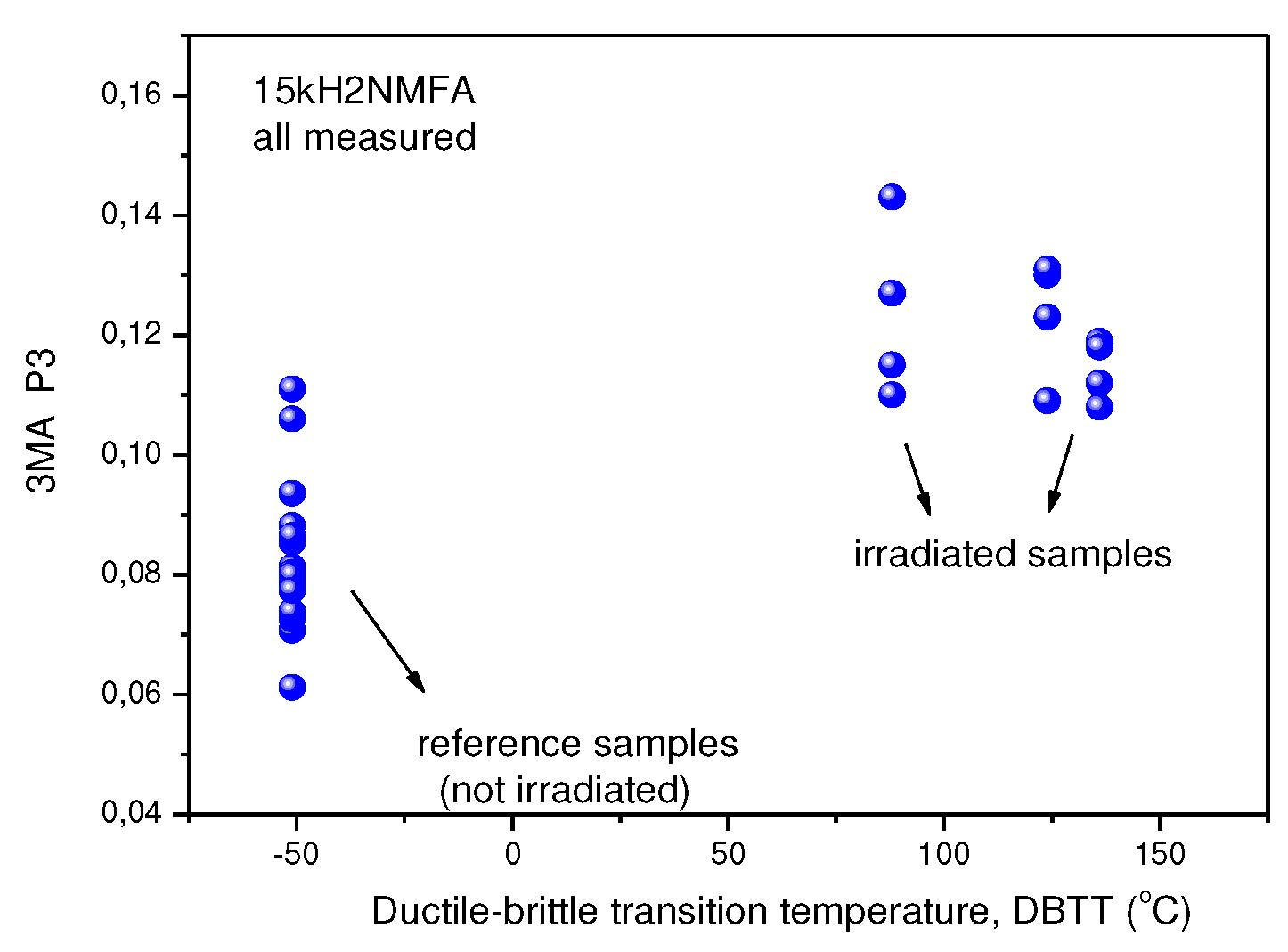

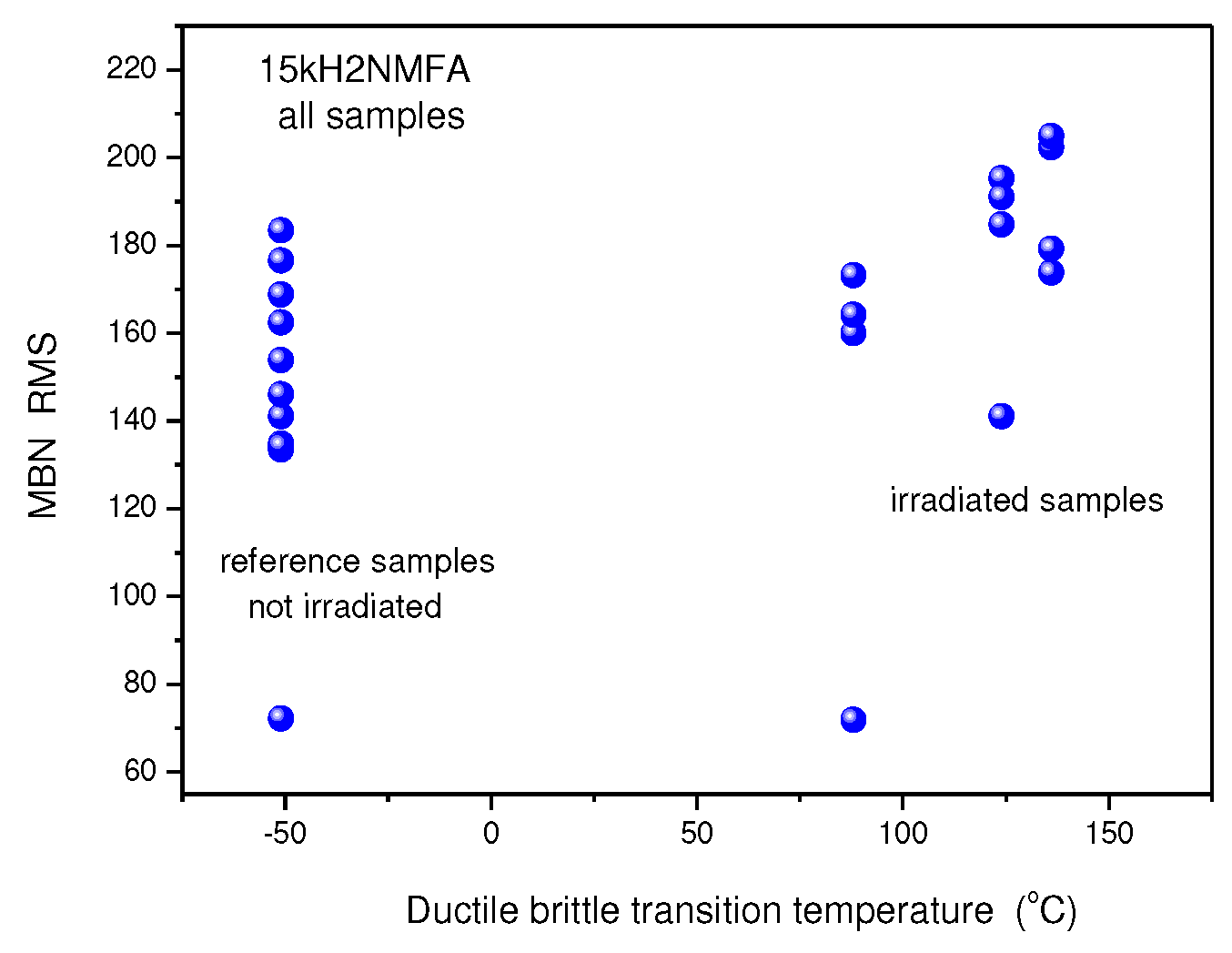

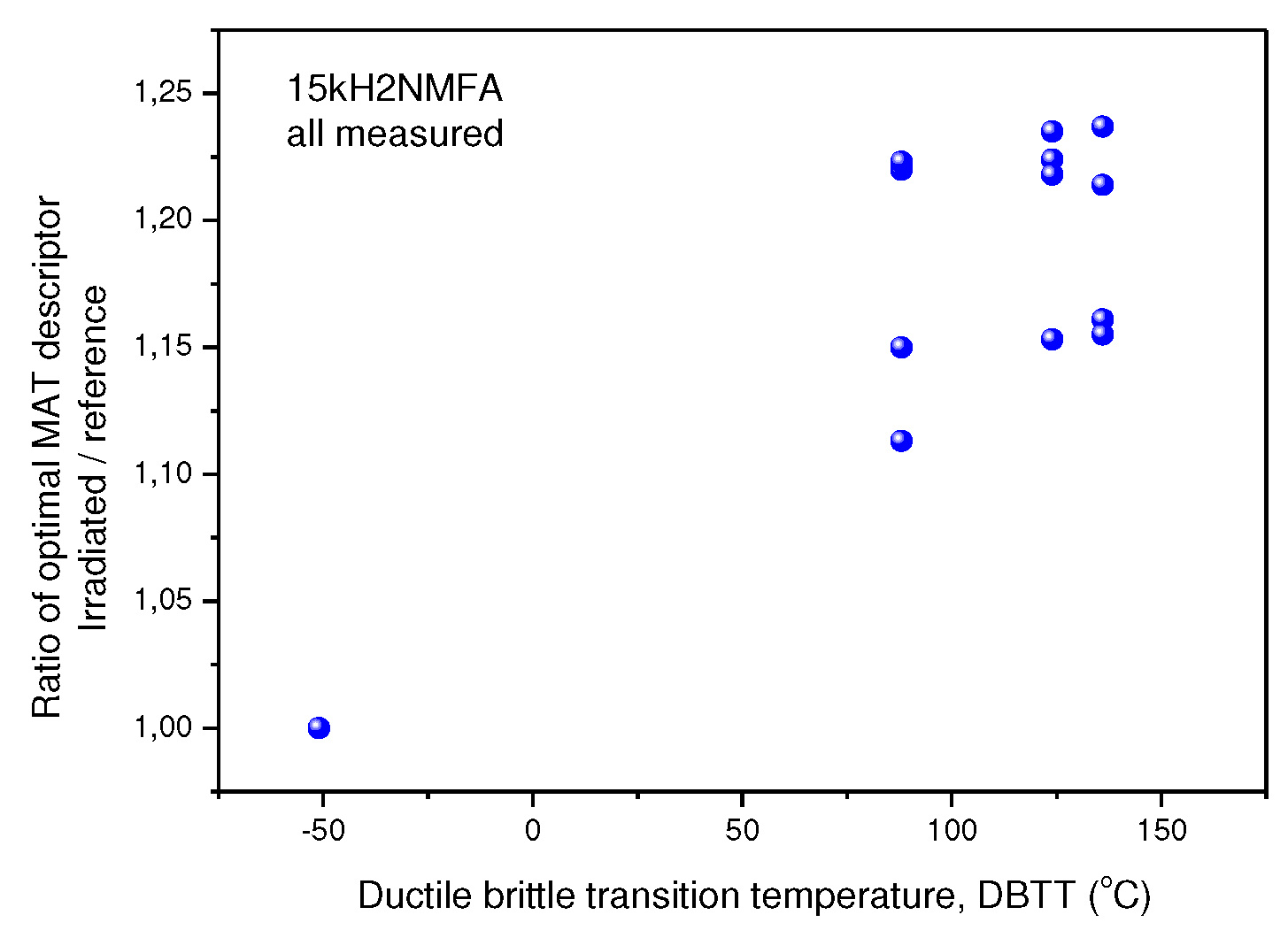

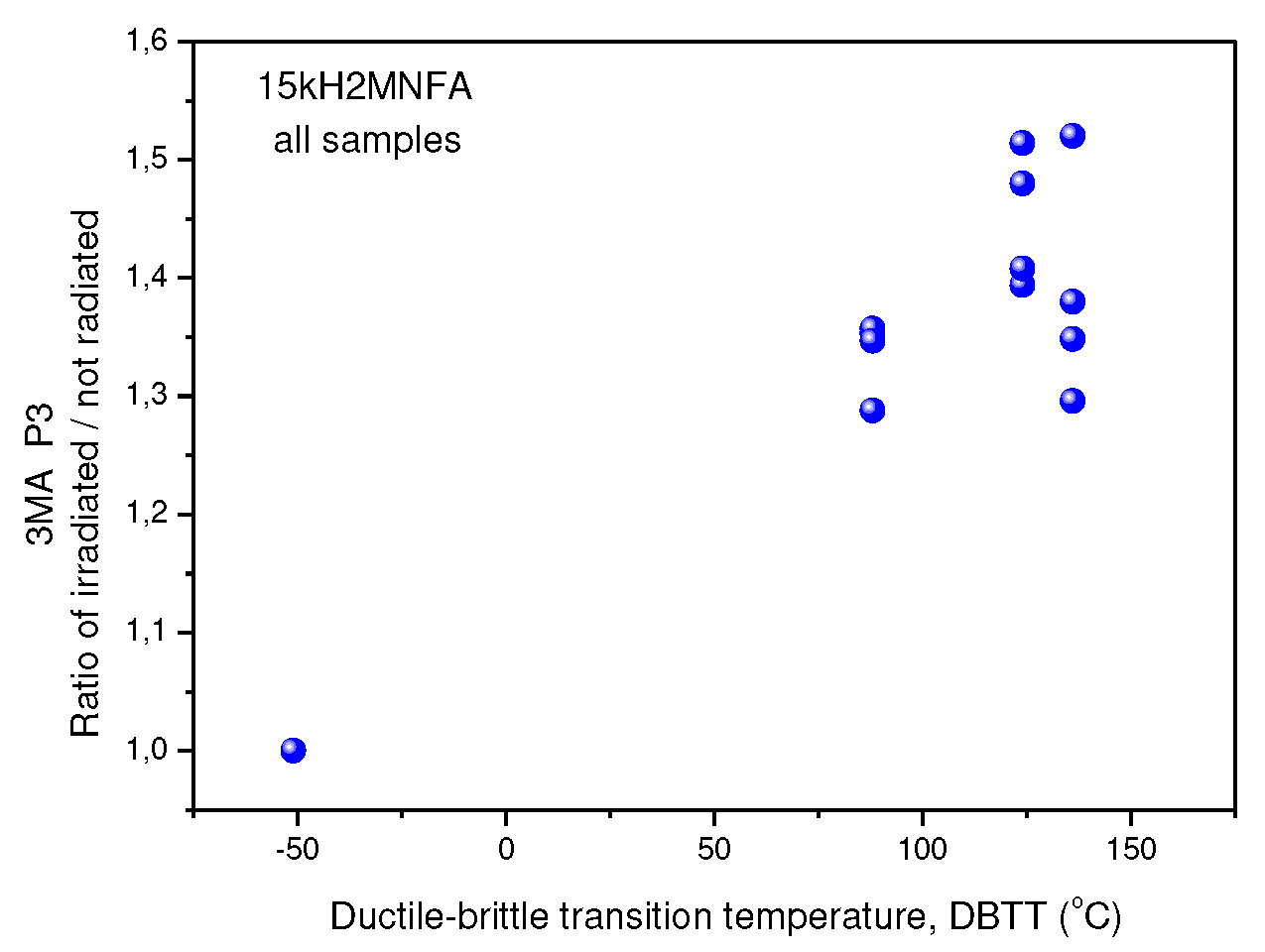

The NDE measurements on the Charpy sample sets of RPV materials of A508Cl.2 (

Figure 7) and 15kH2NMFA (

Figure 8) investigated before and after irradiation allowed for the first time the characterization of progressive change of embrittlement taking into account the initial condition of the materials (before irradiation). In case of these set of samples it has been observed that the scattering of outcome of the individual NDE measurements performed on different Charpy samples of the same material and the same irradiation condition is lower.

The influences of the neutron irradiation on several NDE parameters of Charpy specimens have been previously published and discussed in detail [100,101].

8.2.2. Cladded and Non-Cladded Blocks

One of the challenging task of the NOMAD project was to develop a method that can follow the degradation of the base material through the cladding, i.e. the probe can be applied from the inside of the reactor vessel wall. This task raises two problems simultaneously: on one hand to find a way to excite the base material through the cladding, and also to detect the response through the same. On the other hand, the degradation of the base material has to be differentiated from the changes of the cladding properties due to the irradiation.

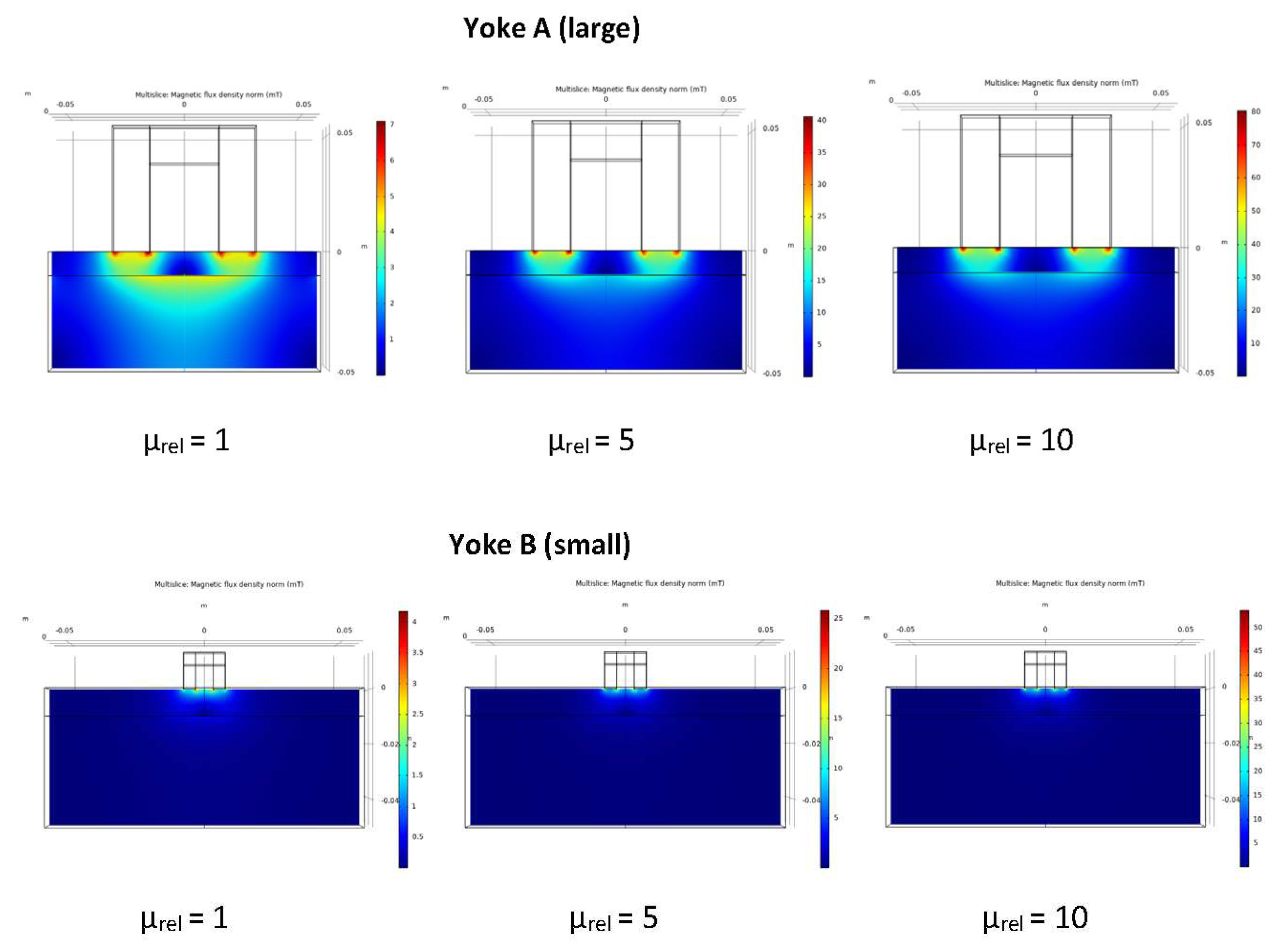

To decide whether the ferromagnetic base material can be investigated through the austenitic cladding by magnetic methods using an attached magnetizing yoke, numerical simulation of magnetic field was performed to show, how the magnetic field, generated by the magnetizing yoke penetrates into the base material through cladding [102]. The result of this simulation is presented in

Figure 9. The result of numerical simulation revealed that by using the large magnetizing yoke for generating exciting magnetic field, the base material could be magnetized sufficiently even through the cladding. On the other hand, when a yoke of a small-sized compared to the thickness of the cladding is applied, it can excite the region of cladding mostly, and the density of the penetrating exciting field in the base material is very limited, almost negligible. This way the cladded system and the cladding only can be studied separately.

To characterize the neutron irradiation induced embrittlement independent of the initial microstructure that can be heterogeneous all blocks have been non-destructively investigated by means of all previously optimized NDE methods before and after neutron irradiation. Some NDE methods (DCRP and EMAT) are not suitable for the materials characterization through the austenitic cladding.

NDE measurements carried out before neutron irradiation have shown that, similar to the Charpy samples made of the same material, the blocks (non-cladded or cladded) have different material properties. The explanation therefore lies in the different microstructure at different positions in the component where these investigated blocks originate from.

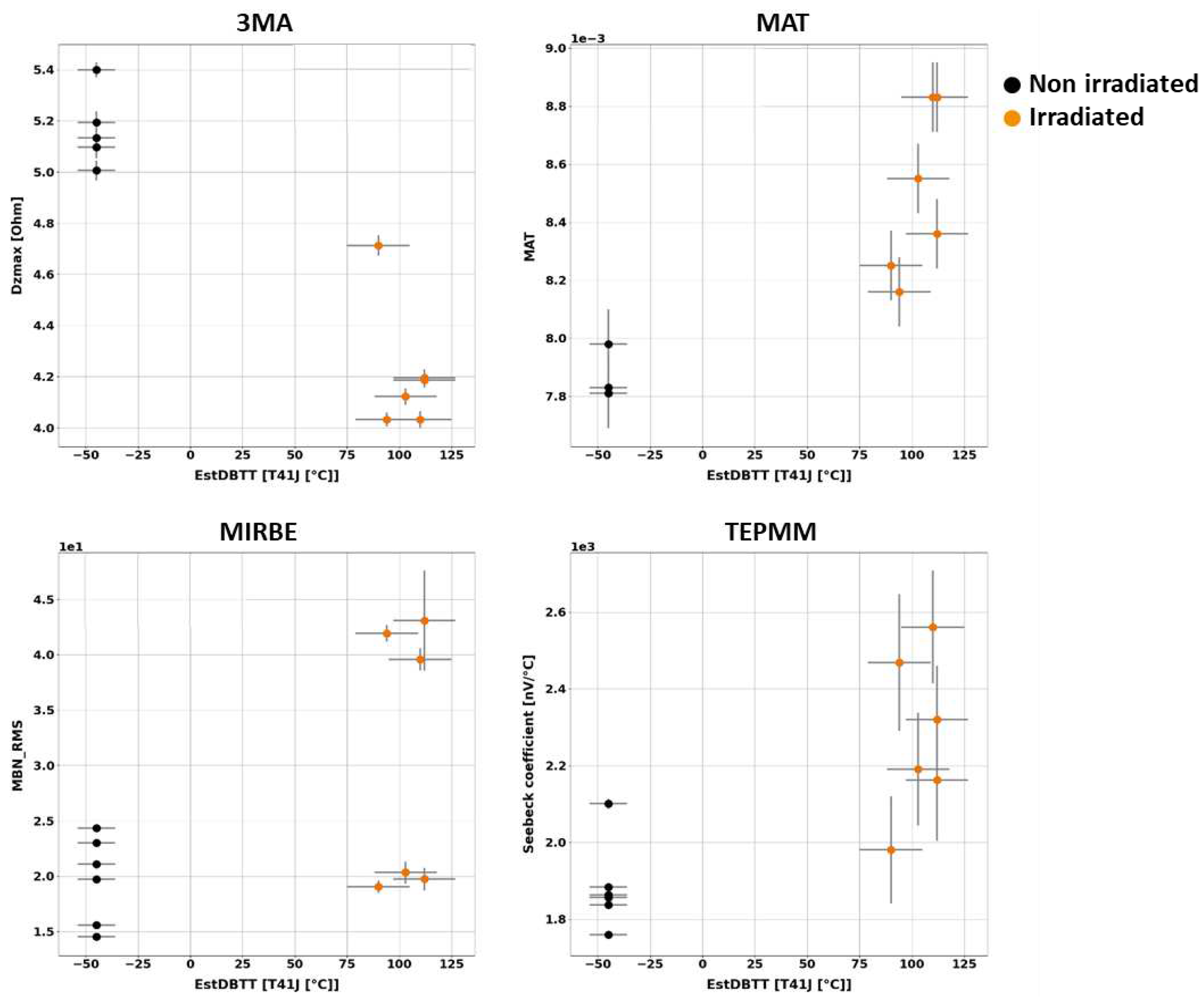

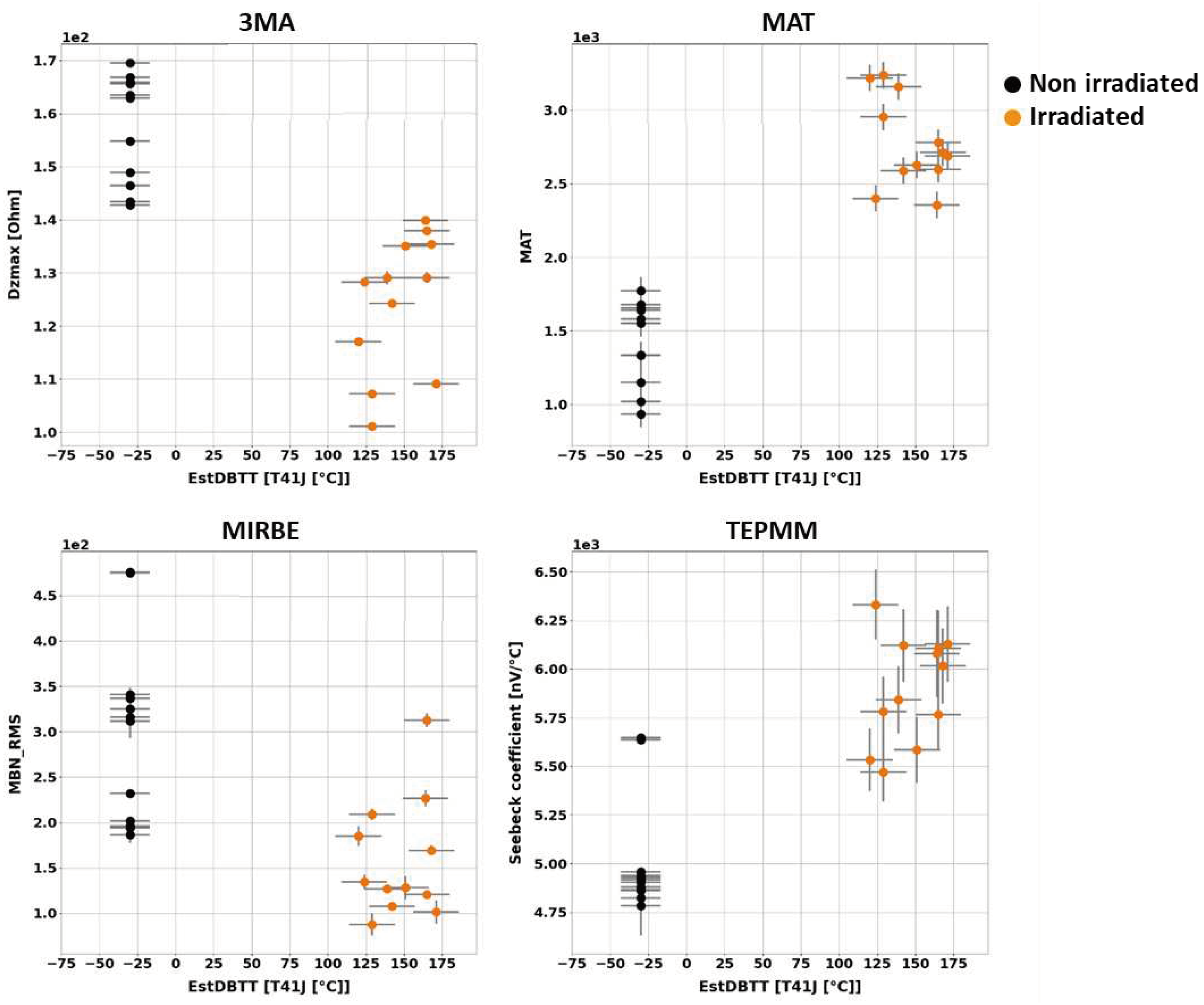

After irradiation, NDE measurements have been carried out again on all non-cladded and cladded blocks. Measuring quantities derived from the NDE methods have been individually collected and analyzed in terms of DBTT. Trends of the non-destructively determined measuring quantities have been identified. An overview of the results obtained on the block samples is given below (

Figure 10 and

Figure 11).

The influences of the neutron irradiation on MAT parameters of blocks specimens have been previously published and discussed in detail [103,104].

The results of the individual NDE methods have shown the difficulty to characterize the embrittlement by using single-parameter methods.

9. Results for Prediction of Embrittlement by Means of a Multi-Parameter Machine Learning (ML)-Driven Approach

9.1. Multiparameter Method

Since the individual test quantities have differently weighted sensitivities to target and disturbance quantities, the influence of the disturbance quantities can be eliminated or at least reduced by combining several features that have the potential to suppress overlapped disturbance influences. The advantages of combining test quantities in a multiparameter method are manifold. Such a combination of methods is particularly indispensable when the target quantities, so called independent parameters are to be measured (e.g. DBTT) and the disturbance quantities (temperature, residual stresses, surface condition) can vary simultaneously. The ultimate goal was to produce a machine learning-based computational tool that can estimate the neutron irradiation-induced embrittlement of reactor pressure vessel steel alloys based on the NDE parameters.

In case of multi-parameter, i.e. multi-dimensional nonlinear problems the required analytical expression cannot be formulated typically, so another statistical approach is required. ML algorithms are powerful tools that can be used to automatically create a regression model based on given data. The data must consist of one or several features, which are the input to the model, and one or several target variables, which are the desired prediction of the independent parameters, or in other words, the output of the model.

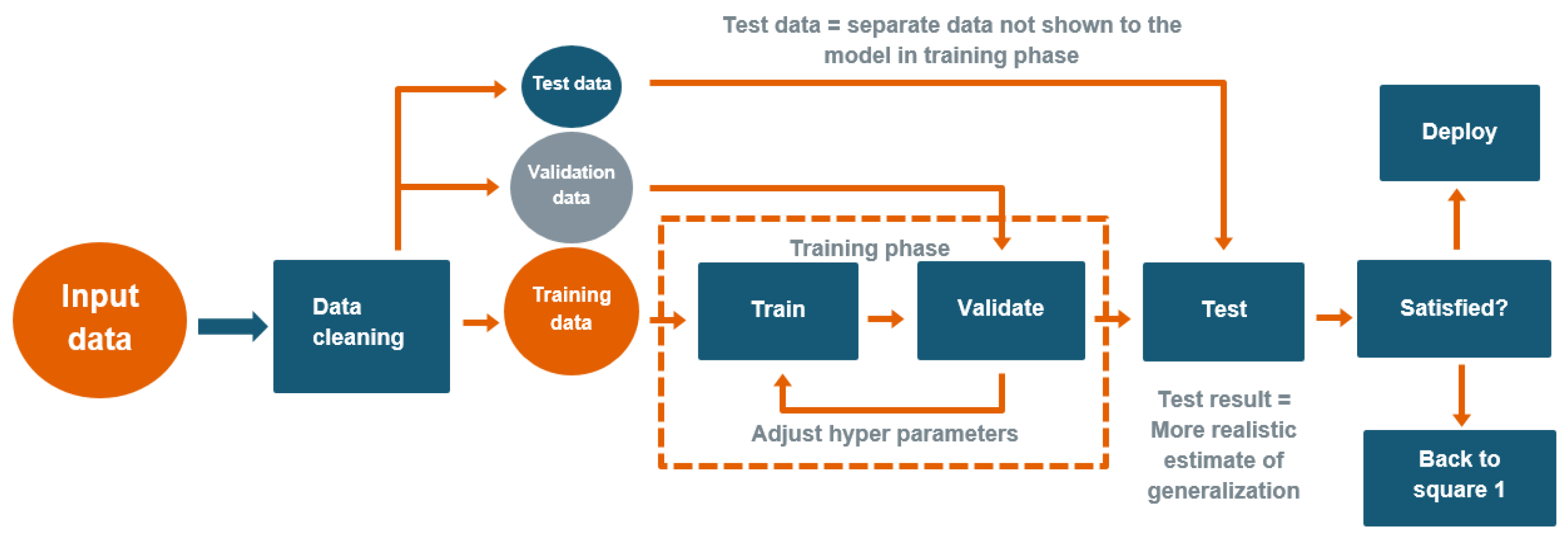

Since the analytical expression that links the input and the output parameters are not known in case of ML, the transparency is essential for the application of ML, especially in safety areas. Extra attention has to paid to careful studies of these methods and to their verification. In typical supervised machine learning, the model learns from a given training data, and traditionally, a separate validation data set is used to evaluate the performance of the trained model. But here, an additional data set is required for testing the reliability of the method. This set comprises not only some randomly selected elements, but data selected also from the interval boundaries (See in

Figure 12). When test result is unsatisfactory, the whole procedure has to be restarted (i.e. “Back to square 1”), by experimenting with new model structure and hyperparameters.

9.2. Database Preparation

Statistical methods work well on a large data set. This raises a quite frequent problem of ML applications: the insufficient number of the achievable measured samples or experimental data, i.e. the limited size of the true result database. The ML methods do not generate any novel information. Instead, they can be used to circumscribe and recognize the information that can be found in the database. Pre-processing the obtained database of the physical test results aims to ease this task of the ML approach and increases its performance, i.e. increases the precision of the regression or classification. Any operation on the experimental data set should be carried out with special attention not to degrade the targeted information content or falsify it.

There are basically two options for processing the database: eliminating some of its elements considered as useless ones, and modifying its entries, or even generating novel ones in an artificial way.

9.2.1 Reduction of Input Space Dimension

If the analysis includes too many features that have a weak correlation with the target variable, they can reduce computational efficiency, increase model complexity, and make it harder to interpret. Moreover, increased model com-plexity results in a higher probability of overfitting. A large number of features prompts a problem known as the curse of dimensionality: when the number of dimensions increases, the volume of the feature space increases, and the data becomes sparser. As the number of features increases, the number of samples required to maintain accuracy grows exponentially [105].

One of the most evident methods for reducing the dimension of the input space is to remove the least relevant features (i.e. input parameters). This reduces the complexity of the ML algorithm's problem. There are various simple statistical evaluations or more complex regression methods to study the importance of the different features.

9.2.2. Determining Feature Importance

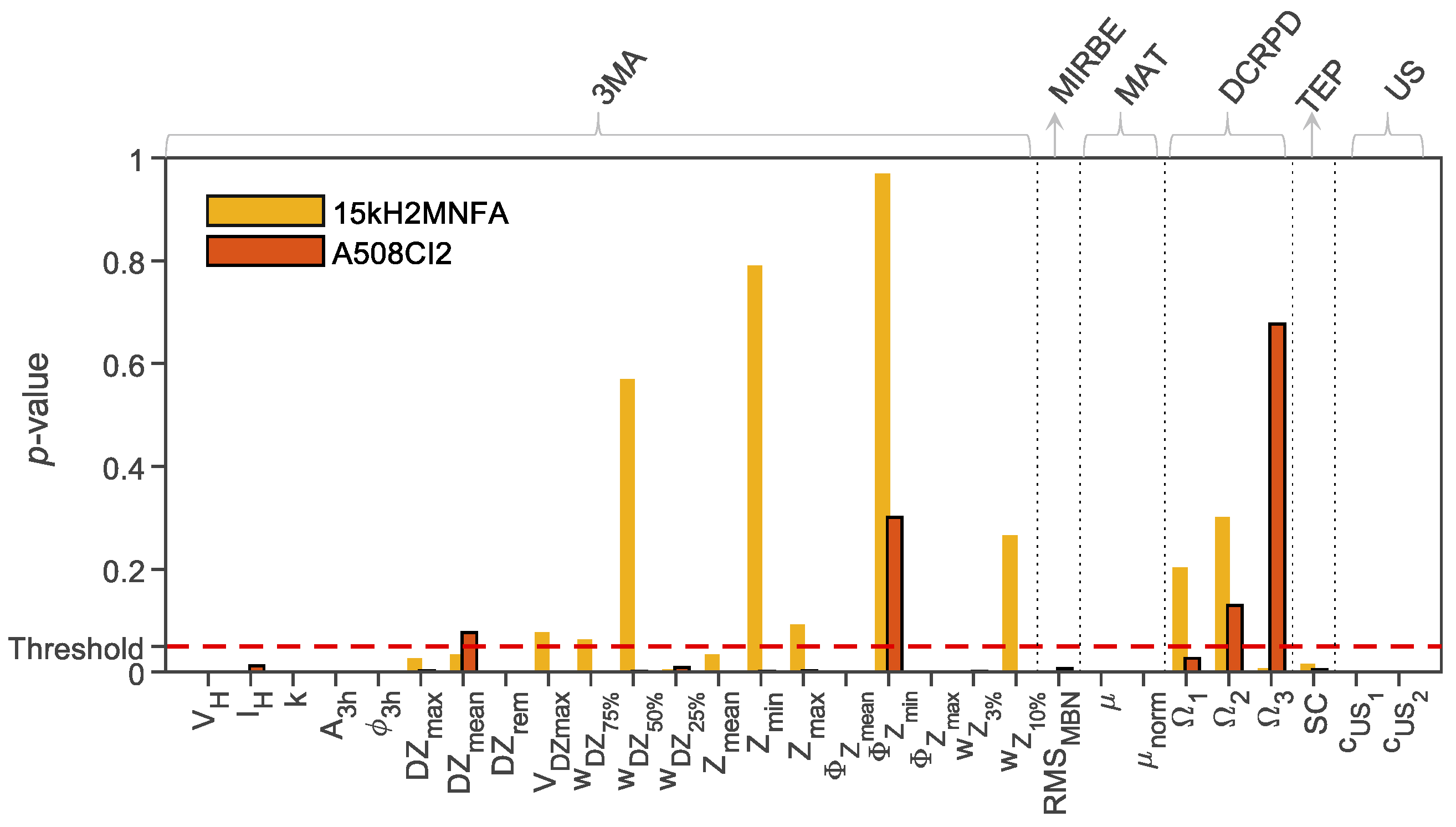

As an example, the Wilcoxon signed-rank test [106] can be used to study the statistical significance of materials properties caused by the irradiation in this paired data set. This test calculates the synthetic parameter differences for each pair of measurements and separately for each NDE feature. The outcome of the test is the p-value for the null hypothesis that the difference has a zero expectation value and a symmetric distribution. This corresponds to the conclusion that the irradiation did not affect the feature. The p-value is compared to a predefined significance level: If the p-value is greater than the significance level (threshold), the null hypothesis is accepted and we conclude that the irradiation has not caused a change in the feature, which can then be excluded from the analysis.

In the NOMAD project, the analysis focused on identifying which NDE parameters out of the 28 available contribute to precision and can aid in recognizing and suppressing side effects. In addition, the project isolated the parameters that are irrelevant and have no impact. Different types of ML algorithms tested in competition and their performances have been evaluated (see the example in Figure13).

Figure 13.

Example: Wilcoxon test results obtained on 29 NDE features (i.e. measurement output parameters) of the NOMAD project [105].

Figure 13.

Example: Wilcoxon test results obtained on 29 NDE features (i.e. measurement output parameters) of the NOMAD project [105].

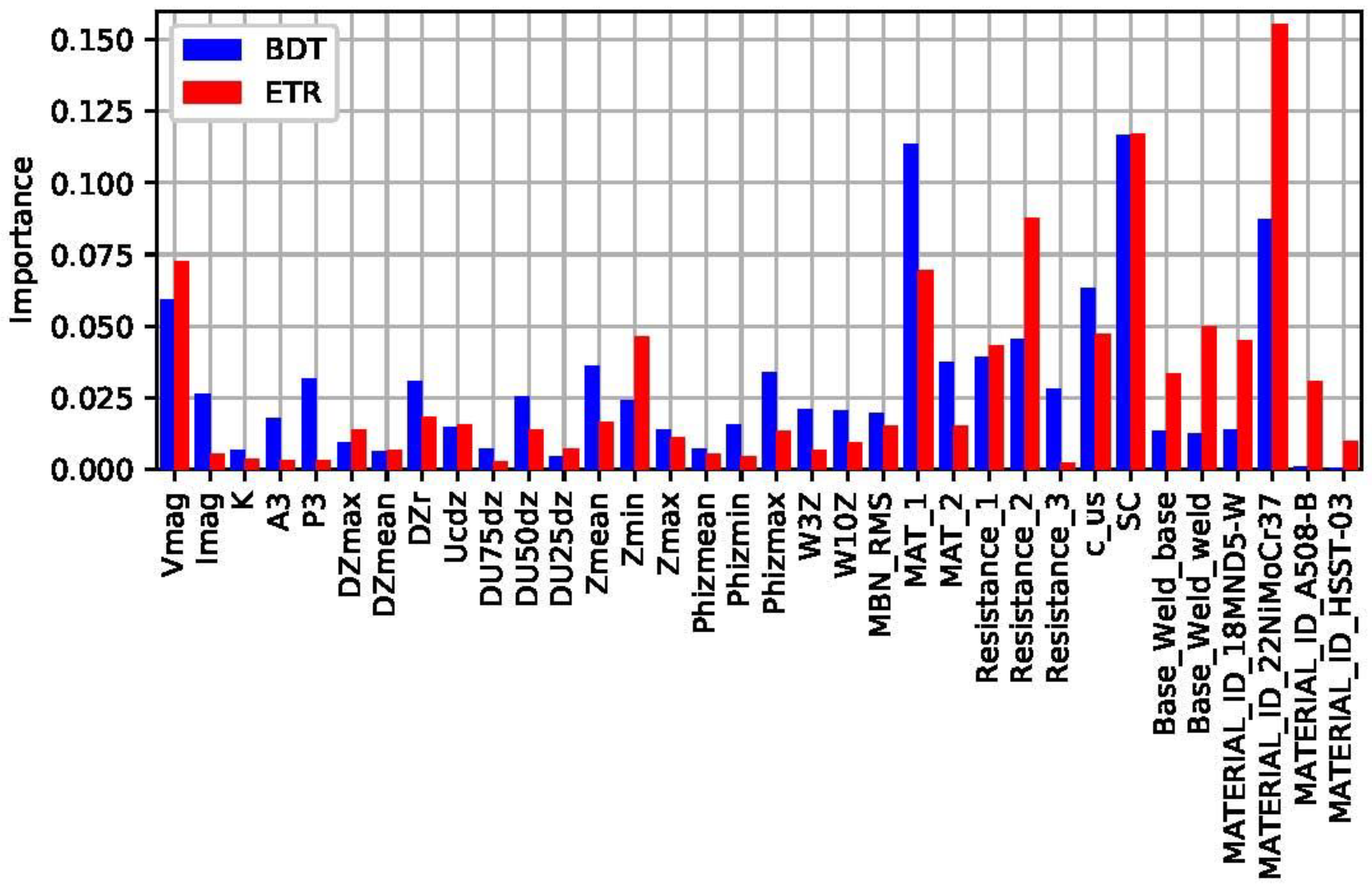

Wilcoxon signed-rank test is a simple approach that can be applied even on very limited dataset but also with limited accuracy. However, when the dimension of the database allows it, even more sophisticated methods can be implemented to study the importance of the input features. Ensembles of decision trees can be used for this purpose. The boosted decision tree (BDT) algorithm and the extra-trees regressor (ETR) algorithm can be used for better evaluation of the different feature significance (see in

Figure 14). These methods are typically not for the primary assessment, but rather for optimizing the ML tool to be developed [104].

9.2.3. K-Fold Cross-Validation Score

A traditional method to train a machine learning model is to set aside a third data set from the training data, known as testing data set that is used to test the different hyperparameter combinations (i.e. the combinations of those external configuration variables used to manage machine learning model training), for example. However, the model can be also trained using k-fold cross-validation [107], where the training set is divided into k parts, known as folds, and then one by one, each fold is used as a so-called test, or validation, set while the other k−1 folds are used to train the model. This is repeated k times and an averaged cross-validation score is calculated based on the predictions. Obviously, the separate test set must still exist and should be held out of this training process. There are several benefits to cross-validation: the real test set is not shown to the model at any point of the training process, and the k-fold cross-validation score provides an estimate of the test accuracy of the model.

The k-fold score is used to fine-tune the data pre-processing steps and the hyperparameters of the model. But it can also be used for determining the less relevant parameters. Dropping one of the features reduces the dimensionality of the feature space and can improve the performance of some algorithms. This way, dropping one by one the one-hot encoded features and calculating the k-fold cross-validation score for each feature, the least significant features can be identified and eliminated from the database [108].

9.3. Manipulating the Database

In order to increase the achievable classification accuracy of the ML methods, the quality of the otherwise limited database can be improved by manipulating its content. Artificial manipulation of any data obtained from real, i.e. physical experiments sounds surprising at first, since this involves significant risks of falsification and of losing the transparency of the ML method application.

It is quite typical when multiple different measurement principles are utilized for obtaining multidimensional response on the tested target, that some of measurement parameters become invalid in certain measurement cases. Here, invalid means that the related method cannot be applied in the given circumstances or some of the NDE probes fail because of a side effect occurring. As a consequence, the aggregated database will be not only limited due to the limited availability of test cases, but it will also be incomplete: there will be missing elements or existing elements having invalid values in it. Either the missing elements or the invalid elements degrade the classification accuracy.

9.3.1 Cleaning the Database

Database cleaning covers the efforts on identification and marking or eliminating database elements that can be recognized as undoubtedly false or missing before the database is used for training the ML methods. This step is not only an option but rather a necessary step in the practice.

The missing elements, as well as the invalid elements can be marked in the same way and both types can be considered as holding no information. One of the possibilities in practice is to substitute these values with a special number value, that is defined exactly for this purpose: NaN (i.e. Not a Number) [104]. This way the database becomes uniform and suitable for further processing in terms of meaning that all of its elements will contain uniformly encoded elements. Inserting or replacing elements to NaNs in the database does not alter the information it holds, but this makes possible to work on it with standard algorithms and software codes.

9.3.2 Dealing with NaNs

By having NaNs in the database further steps are available for improving the database for ML. If the elements of a certain test case contain too many NaNs or several of its significant elements are NaNs, such test cases (i.e. database rows) can be eliminated completely from the database since they cannot contribute to training the ML methods. Obviously, if all the measurement cases are deleted, where at least one parameter is missing (so called listwise deletion) it does not cause any bias in the prediction of the ML methods, but dramatically degrades the power of the classification. Therefore, the listwise deletion cannot be applied practically where the database is rather limited.

Instead of deletion, there are also different methods of predicting the missing values by either considering the statistics of its available neighbors, when possible, or filling them automatically by algorithms even by the help of ML techniques that consider global features not local ones.

9.3.3. Data Augmentation and Imputation

The aim of both the data augmentation and the imputation is to increase the classification accuracy [109]. Obviously, extending the database of the measured data with “artificially generated” values involves the possibility of either falsification or it can establish a “positive” feedback that can lead to miss prediction or misclassification at the end. The database extension has relevance primarily for the training of ML algorithms. This way the unwanted side effect of the database manipulation can be caught by testing the algorithm that was trained on the extended database and on the database without any extension.

9.4 Using ML methods

In the NOMAD project, following the database pre-processing, the training data was used to train three models: Huber loss regression (HLR) [110], support vector regression (SVR) [111] and an artificial neural network (ANN) [112]. In order to compare the performance of these three methods, the 10-fold cross-validation score is measured as the mean absolute error (MAE). Both test and training scores are reported as MAE, root mean square error (RMSE) and R

2 i.e. coefficient of determination score.

Table 6 summarizes the result of this study:

In certain applications of the NOMAD project, +/-25°C DBTT shift had to be detected. All of these three methods could provide significantly better prediction of the DBTT shift than this error threshold. It can be also deducted, that practically all three methods reached similar performance, i.e. the test scores vary 16…18 °C. The most complex approach, the ANN could also perform very well, despite the extraordinarily limited dataset.

Since the ANN requires the largest computational power, this test resulted in the SVR prevailing, as this method provides the optimal balance between the classification accuracy and the required computational power. Certainly, this claim is valid only for the given NOMAD database.

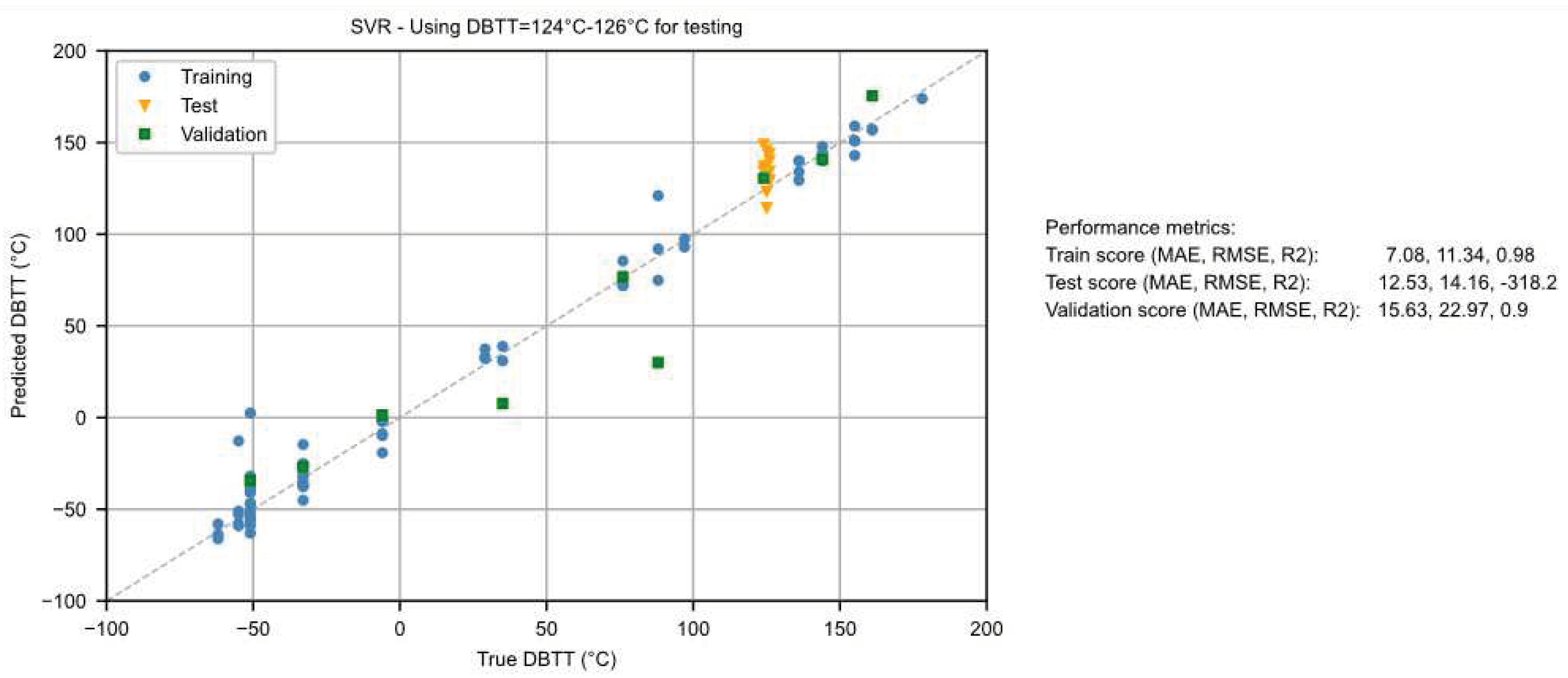

9.5. Results of NOMAD ML Approach

Within the framework of the NOMAD project, an SVR method was used to create models that accurately predict the neutron irradiation-induced embrittlement, measured as the DBTT, even though the data set is small. The SVR is a supervised machine learning algorithm that relies on kernel functions to solve problems that cannot be handled directly by linear classification. The SVR is flexible enough that it provides robust results even though the number of data points is low, and it is considerably simpler to optimize than other, e.g., neural network algorithms [104]. To evaluate the performance of the trained models in predicting the neutron irradiation-induced embrittlement of steel alloys based on non-destructive measurements two different model evaluation metrics were used.

9.5.1 Test Score in NOMAD

The traditional method to analyze the generalization skill of a machine learning model is to split the data set into training and test sets. The model is trained entirely based on the training set, and when the model has been fully trained, the generalization skill of the model is tested using the test set by feeding it to the model without its target values. After the test set has been shown to the model, the model should not be modified to produce an improved test result. The training process refers to the optimization of the model hyperparameters, and most of the time it also includes pre-processing steps, such as the selection of the feature scaling scheme. The trained model makes predictions based on the test set features and the predictions of the independent parameters are compared to the true target values of the test set. The test and training sets must be equally representative of the whole data set; otherwise, the test score does not represent the generalization skill of the model with the best accuracy. Commonly, the test set is a random subset of the whole data set, with a size of 20% of the size of the whole data set. The rest, 80% of the data then constitutes to the training set (this procedure is referred to as the 80/20 split). The larger and more diverse the training data set is, the more flexible and accurate the model will yield.

Three models were generated for the prediction of the embrittlement: one based on data obtained on Charpy specimens only, one based on data obtained on Blocks only and one based on mixed data obtained on Charpy and block specimens. The models to predict DBTT are based on supervised ML using the SVR model implemented in scikit learn and were trained and tested using the database. The database contains different materials which are marked by one-hot Boolean values in both the database and the tool. The input data is prepared using the Min/Max Scaler function within scikit learn.

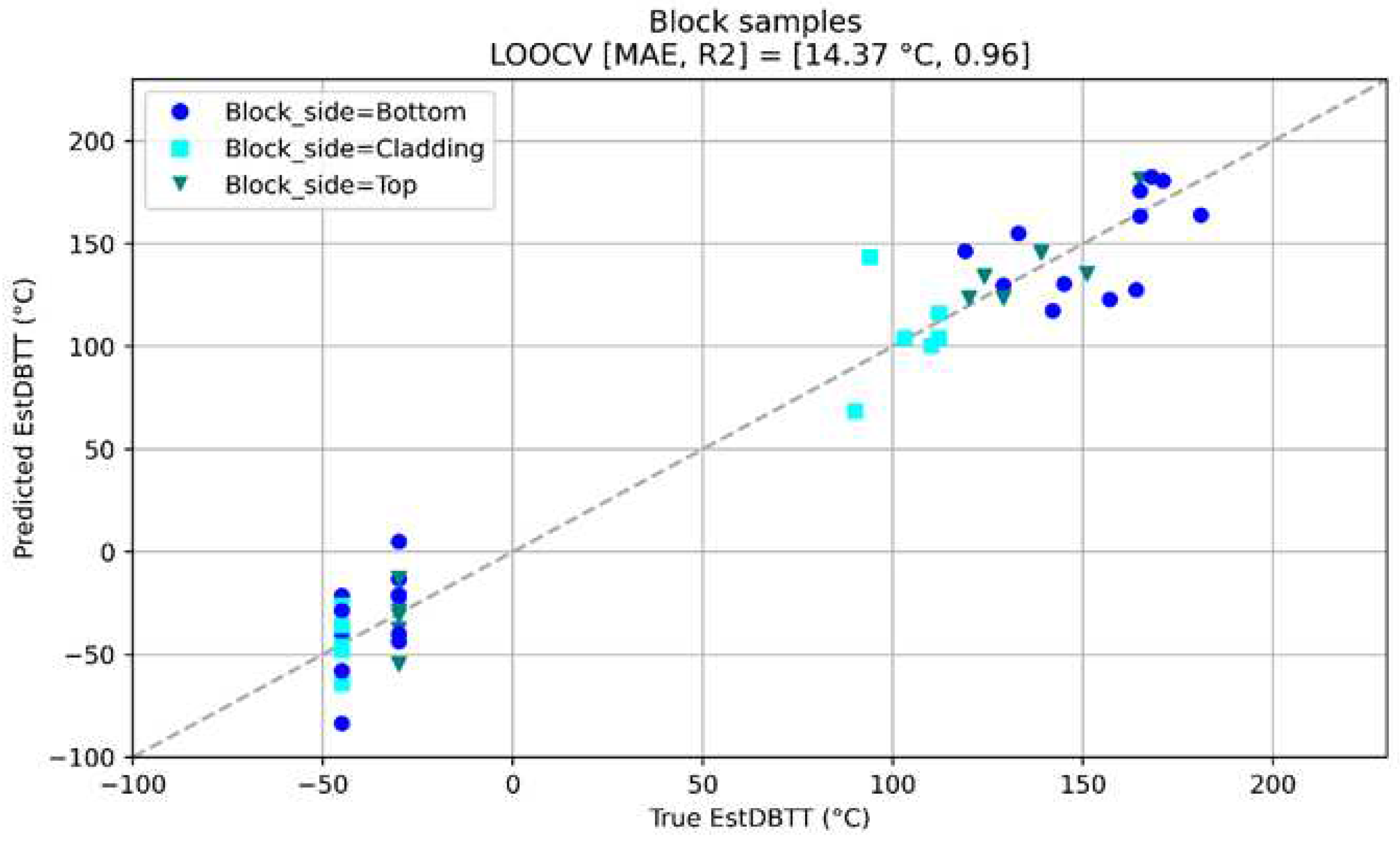

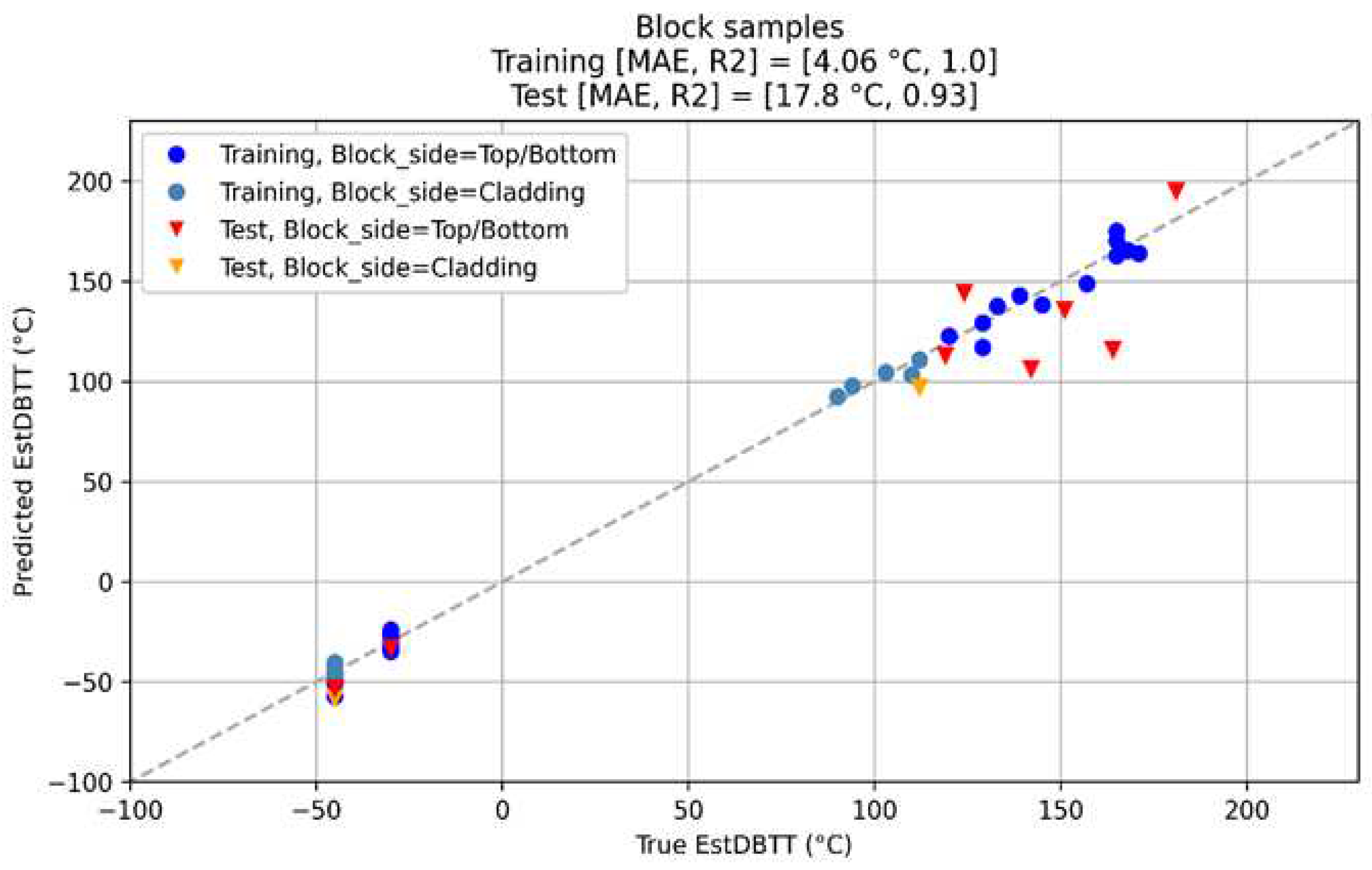

The results obtained for the three different models are summarized in

Table 7. The table presents the cross-validation scores of the fine-tuned models, the training scores, and the test scores. As can be seen from the results, all test MAEs are under 19 °C and the test R2 scores are equal or greater than 0.9. The accuracies of the models are also visualized in form of correlation plots in

Figure 15,

Figure 16 and

Figure 17, where the predictions made by a model are plotted as a function of the DBTT values

determined with Charpy tests.