Submitted:

17 December 2023

Posted:

19 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

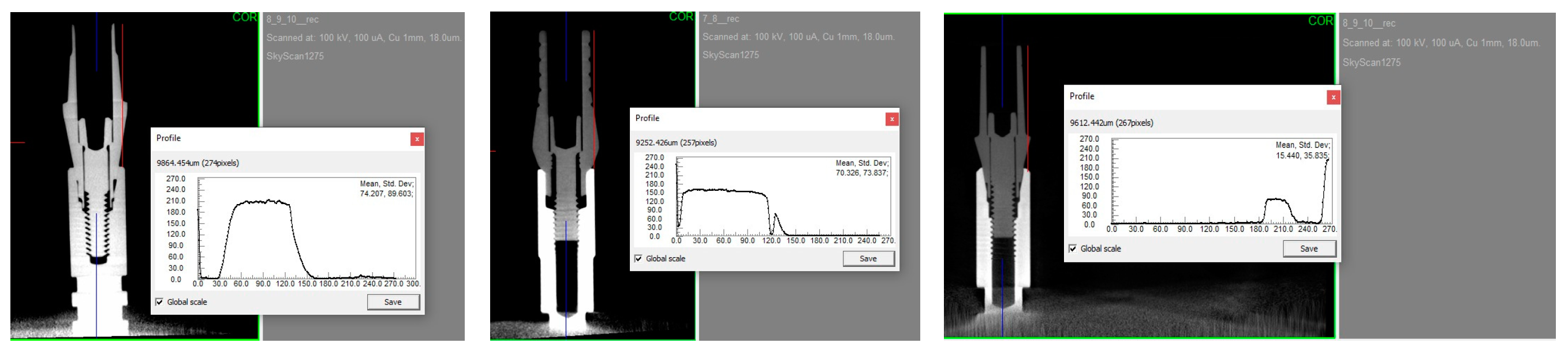

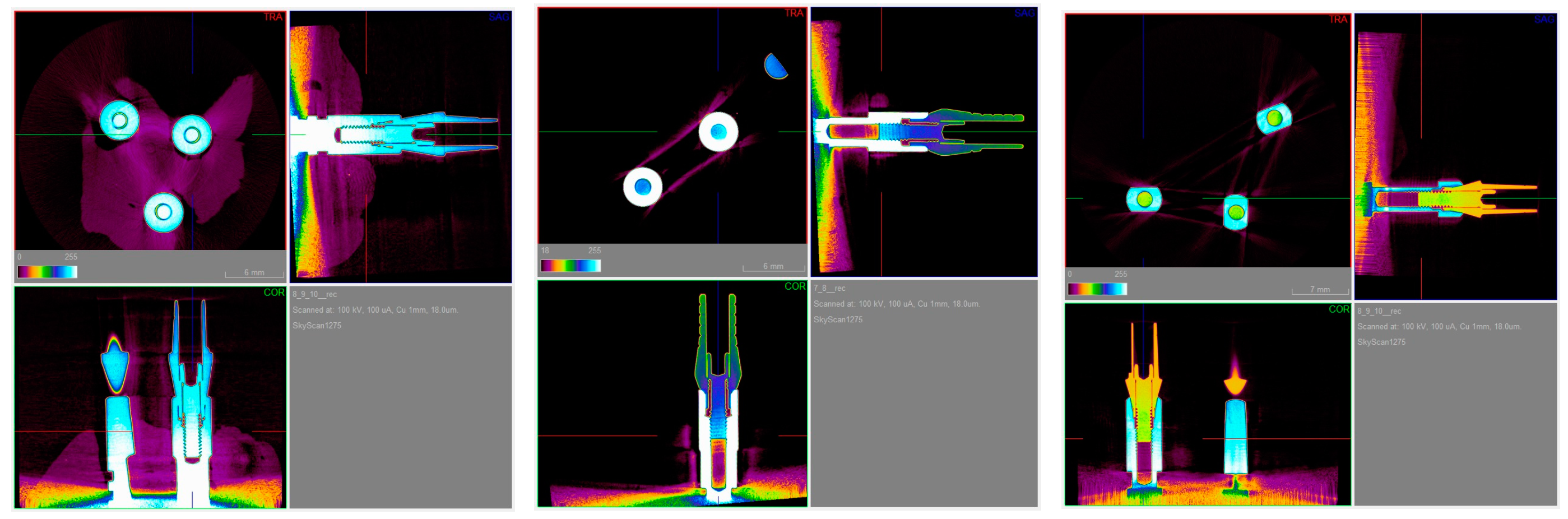

Scanning and Analysis

Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stavropoulos, A, Bertl, K, Eren, S, Gotfredsen, K. Mechanical and biological complications after implantoplasty—A systematic review. Clin Oral Impl Res. 2019; 30: 833–848. [CrossRef]

- Lang, N.P., Wilson, T.G. and Corbet, E.F. Biological complications with dental implants: their prevention, diagnosis and treatment Note. Clinical Oral Implants Research: Chapter 9, 2000, 11: 146-155. [CrossRef]

- Schwarz, Melvyn S. Mechanical complications of dental implants. Clinical Oral Implants Research: Chapter 10, 2000, 11: 156-158. [CrossRef]

- Georgios Siamos, Sheldon Winkler, Kenneth G. Boberick; The Relationship Between Implant Preload and Screw Loosening on Implant-supported Prostheses. J Oral Implantol 1 April 2002; 28 (2): 67–73. [CrossRef]

- Vélez, J.; Peláez, J.; López-Suárez, C.; Agustín-Panadero, R.; Tobar, C.; Suárez, M.J. Influence of Implant Connection, Abutment Design and Screw Insertion Torque on Implant-Abutment Misfit. J. Clin. Med. 2020, 9, 2365. [CrossRef]

- Singh, Himani, et al. Implant abutment using hand drivers versus torque wrench. Bioinformation, 2023, 19.2: 221-225. [CrossRef]

- Sameera Y, Rai R. Tightening torque of implant abutment using hand drivers against torque wrench and its effect on the internal surface of implant. The Journal of the Indian Prosthodontic Society, 2020, 20.2: 180. [CrossRef]

- Yang S., Qin Y., Guo X., Li Y. An In Vitro Study of Fluid Contaminations Influences on Reverse Torque Values of Implant-Abutment Connections. BioMed Research International, 2022, 2022. [CrossRef]

- Hu, E., Petrich, A., Imamura, G. and Hamlin, C.Effect of screw channel angulation on reverse torque values of dental implant abutment screws. Journal of Prosthodontics, 2019, 28.9: 969-972.. [CrossRef]

- He Y, Fok A, Aparicio C, Teng W. Contact analysis of gap formation at dental implant-abutment interface under oblique loading: A numerical-experimental study. Clin Implant Dent Relat Res. 2019; 21: 741–752. [CrossRef]

- Zipprich H, Weigl P, Ratka C, Lange B, Lauer H-C. The micromechanical behavior of implant-abutment connections under a dynamic load protocol. Clin Implant Dent Relat Res. 2018; 20: 814–823. [CrossRef]

- Vinhas, A.S.; Aroso, C.; Salazar, F.; López-Jarana, P.; Ríos-Santos, J.V.; Herrero-Climent, M. Review of the Mechanical Behavior of Different Implant–Abutment Connections. Int. J. Environ. Res. Public Health 2020, 17, 8685. [CrossRef]

- Aloise, J.P., Curcio, R., Laporta, M.Z., Rossi, L., Da Silva, A.M.Á. and Rapoport, A. Microbial leakage through the implant–abutment interface of Morse taper implants in vitro. Clinical oral implants research, 2010, 21.3: 328-335. [CrossRef]

- Larrucea Verdugo C, Jaramillo Núñez G, Acevedo Avila A, Larrucea San Martín C. Microleakage of the prosthetic abutment/implant interface with internal and external connection. In vitro study. Clin. Oral Impl. Res. 25, 2014, 1078–1083. [CrossRef]

- Yip, G., Schneider, P., Roberts, E. W. Micro-computed tomography: high resolution imaging of bone and implants in three dimensions. In: Seminars in Orthodontics. WB Saunders, 2004. p. 174-187. [CrossRef]

- Schicho, K., Kastner, J., Klingesberger, R., Seemann, R., Enislidis, G., Undt, G., Wanschitz, F., Figl, M., Wagner, A. and Ewers, R. Surface area analysis of dental implants using micro-computed tomography. Clinical oral implants research, 2007, 18.4: 459-464. [CrossRef]

- Narra, N., Antalainen, A. K., Zipprich, H., Sandor, G. K., Wolff, J. Microcomputed tomography-based assessment of retrieved dental implants. International Journal of Oral & Maxillofacial Implants, 2015, 30.2. [CrossRef]

- Erpaçal B, Adıgüzel Ö, Cangül S. The use of micro-computed tomography in dental applications. Int Dent Res 2019;9(2):78-91. [CrossRef]

- Maria, R., Tan, M.Y., Wong, K.M., Lee, B.C.H., Chia, V.A.P., Tan, K.B.C. Accuracy of implant analogs in 3D printed resin models. Journal of Prosthodontics, 2021, 30.1: 57-64. [CrossRef]

- Akat B, Şentürk A, Ocak M, Kiliçarslan MA, Özcan M. Does cad software affect the marginal and internal fit of milled full ceramic crowns?. Braz oral res. 2022;36:e042. [CrossRef]

- Bayrak A, Akat B, Ocak M, Kιlιçarslan MA, Özcan M. Micro-Computed Tomography Analysis of Fit of Ceramic Inlays Produced with Different CAD Software Programs. Eur J Prosthodont Restor Dent. 2021 Aug 31;29(3). PMID: 33393742. [CrossRef]

- Alikhasi, M., Kazemi, M., Jalali, H., Hashemzadeh, S., Dodangeh, H., Yilmaz, B. Clinician-generated torque on abutment screws using different hand screwdrivers. The Journal of Prosthetic Dentistry, 2017, 118.4: 488-492. [CrossRef]

- Saleh Saber F, Abolfazli N, Jannatii Ataei S, Taghizade Motlagh M, Gharekhani V. The effect of repeated torque tightening on total lengths of implant abutments in different internal implant‒abutment connections. J Dent Res Dent Clin Dent Prospects. 2017 Spring;11(2):110-116. Epub 2017 Jun 21. PMID: 28748052; PMCID: PMC5519991. [CrossRef]

- Bulaqi, H. A., Mashhadi, M. M., Safari, H., Samandari, M. M., Geramipanah, F. Dynamic nature of abutment screw retightening: finite element study of the effect of retightening on the settling effect. The Journal of prosthetic dentistry, 2015, 113.5: 412-419. [CrossRef]

- Min, C. K., and Kim, K. A. A. Quantitative analysis of metal artefacts of dental implant in CBCT image by correlation analysis to micro-CT: A microstructural study. Dentomaxillofacial Radiology, 2021, 50.3: 20200365. [CrossRef]

- Butkevica, A., Nathanson, D., Pober, R., Strating, H. Measurements of repeated tightening and loosening torque of seven different implant/abutment connection designs and their modifications: An in vitro study. Journal of Prosthodontics, 2018, 27.2: 153-161. [CrossRef]

- Kim, K.-S., Lim, Y.-J., Kim, M.-J., Kwon, H.-B., Yang, J.-H., Lee, J.-B., Yim, S.-H. Variation in the total lengths of abutment/implant assemblies generated with a function of applied tightening torque in external and internal implant–abutment connection. Clinical oral implants research, 2011, 22.8: 834-839. [CrossRef]

- Gehrke, S. A., Shibli, J. A., Aramburu Junior, J. S., Sánchez de Val, J. E. M., Calvo-Girardo, J. L., Dedavid, B. A. Effects of different torque levels on the implant-abutment interface in a conical internal connection. Brazilian oral research, 2016, 30. [CrossRef]

| Group | Connection |

Tightening | Mean | Standart deviation | Standart error | Min. | Max. | % 95 Lower bond |

95% Upper bound | p |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Implant Analog | Torqued | 9753,80 | 230,896 | 73,016 | 9348 | 9990 | 9588,63 | 9918,97 | A,a |

| Hand tightened | 9973,30 | 93,597 | 29,598 | 9760 | 10044 | 9906,34 | 10040,26 | A,b | ||

| Implant Body | Torqued | 9462,80 | 217,302 | 68,717 | 9094 | 9740 | 9307,35 | 9618,25 | A,c | |

| Hand tightened | 9770,00 | 110,623 | 34,982 | 9560 | 9972 | 9690,86 | 9849,14 | A,ab | ||

| 2 | Implant Analog | Torqued | 9202,40 | 81,998 | 25,930 | 9072 | 9311 | 9143,74 | 9261,06 | B,ac |

| Hand tightened | 9429,50 | 235,224 | 74,384 | 8905 | 9792 | 9261,23 | 9597,77 | B,b | ||

| Implant Body | Torqued | 9067,90 | 180,939 | 57,218 | 8730 | 9326 | 8938,46 | 9197,34 | B,c | |

| Hand tightened | 9313,20 | 90,785 | 28,709 | 9126 | 9444 | 9248,26 | 9378,14 | B,ab | ||

| 3 | Implant Analog | Torqued | 9138,30 | 86,271 | 27,281 | 8985 | 9288 | 9076,59 | 9200,01 | B,a |

| Hand tightened | 9331,70 | 141,769 | 44,831 | 9133 | 9612 | 9230,28 | 9433,12 | B,ab | ||

| Implant Body | Torqued | 9164,60 | 238,558 | 75,439 | 8910 | 9558 | 8993,95 | 9335,25 | B,a | |

| Hand tightened | 9466,70 | 250,168 | 79,110 | 9126 | 9927 | 9287,74 | 9645,66 | B,b |

| Group | Connection | Tightening | Mean | Standart deviation | Standart error | Min. | Max. | % 95 Lower bond | 95% Upper bound | p |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Implant Analog | Torqued | ,793 | ,084 | ,026 | ,696 | ,973 | ,733 | ,853 | A,a |

| Hand tightened | ,910 | ,131 | ,041 | ,717 | 1,137 | ,816 | 1,004 | B,a | ||

| Implant Body | Torqued | 1,289 | ,300 | ,095 | ,982 | 1,965 | 1,074 | 1,503 | C,b | |

| Hand tightened | 1,877 | ,096 | ,030 | 1,700 | 1,982 | 1,808 | 1,946 | D,c | ||

| 2 | Implant Analog | Torqued | 6,234 | ,774 | ,245 | 5,174 | 7,716 | 5,680 | 6,788 | E,ac |

| Hand tightened | 7,163 | ,698 | ,221 | 5,857 | 8,200 | 6,664 | 7,662 | F,b | ||

| Implant Body | Torqued | 3,339 | ,280 | ,088 | 3,010 | 3,744 | 3,139 | 3,539 | G,c | |

| Hand tightened | 3,597 | ,320 | ,101 | 3,183 | 4,181 | 3,368 | 3,826 | H,ab | ||

| 3 | Implant Analog | Torqued | 13,153 | ,455 | ,144 | 12,469 | 13,859 | 12,827 | 13,478 | I,a |

| Hand tightened | 13,705 | ,823 | ,260 | 12,737 | 15,285 | 13,116 | 14,293 | J,b | ||

| Implant Body | Torqued | 5,024 | ,223 | ,070 | 4,507 | 5,272 | 4,864 | 5,183 | K,c | |

| Hand tightened | 5,790 | ,413 | ,131 | 5,225 | 6,481 | 5,494 | 6,085 | L,c |

| Group | Connection | Mean | Standart deviation | Standart error | Min. | Max. | 95% Lower Bound | 95% Upper Bound | p |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Implant Analog | 219,5000 | 232,76705 | 73,60740 | 20,00 | 660,00 | 52,9885 | 386,012 | A,a |

| Implant Body | 307,2000 | 252,56190 | 79,86708 | 40,00 | 734,00 | 126,5281 | 487,8719 | A,a | |

| 2 | Implant Analog | 227,1000 | 272,69945 | 86,23514 | -371,00 | 576,00 | 32,0226 | 422,1774 | A,a |

| Implant Body | 245,3000 | 185,90502 | 58,78833 | 20,00 | 558,00 | 112,3116 | 378,2884 | A,a | |

| 3 | Implant Analog | 193,4000 | 145,95981 | 46,15655 | 12,00 | 468,00 | 88,9866 | 297,8134 | A,a |

| Implant Body | 302,1000 | 248,30557 | 78,52112 | 36,00 | 766,00 | 124,4729 | 479,7271 | A,a |

| Group | Connection | Mean | Standart deviation | Standart error | Min. | Max. | 95% Lower Bound | 95% Upper Bound | p |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Implant Analog | 219,5000 | 232,76705 | 73,60740 | 20,00 | 660,00 | 52,9885 | 386,012 | A,a |

| Implant Body | 307,2000 | 252,56190 | 79,86708 | 40,00 | 734,00 | 126,5281 | 487,8719 | A,a | |

| 2 | Implant Analog | 227,1000 | 272,69945 | 86,23514 | -371,00 | 576,00 | 32,0226 | 422,1774 | A,a |

| Implant Body | 245,3000 | 185,90502 | 58,78833 | 20,00 | 558,00 | 112,3116 | 378,2884 | A,a | |

| 3 | Implant Analog | 193,4000 | 145,95981 | 46,15655 | 12,00 | 468,00 | 88,9866 | 297,8134 | A,a |

| Implant Body | 302,1000 | 248,30557 | 78,52112 | 36,00 | 766,00 | 124,4729 | 479,7271 | A,a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).