1. Introduction:

(Thakur 2017) stated that World economy is increasing rapidly due to the increased development activities of various nations; which increase the energy consumption of different forms. (Sanusi 2021) stated that the energy demand in different sectors of the society is increased enormously. World’s economy is mainly depends on the transportation sector. (Taghizadeh 2012) stated that The movement of the commodities and the public is depends on the automobiles, railways and airplanes. The transportation sector is consuming the bulk of the petroleum derived fuels. (Karikalan 2020) stated that the increasing petroleum fuel price because of increased demand and decreasing reserves has forced to consider the alternate fuels which might be used in existing engine with or without modification (Thakur 2017) stated that Due to the increased consumption of petroleum fuel, it is anticipated that the naturally available fossil fuel may exhaust rapidly. (Channapattana 2007) stated that Alternate fuels may be used in the engines as a substitute for petroleum fuels and also to prolong the availability of fossil fuels. The various types of alternate fuels are available which may be used readily in the contemporary engines. The alternate fuels considered at this juncture are biodiesels and are considered as one of the renewable alternate fuel in the recent years. There are different sources from which biodiesel can be extracted. The sources of biodiesel are tree borne oil of non-edible type and edible vegetable oils, biomass, animal fat etc. The sources of biodiesel considered for the research work are tree born oils of non-edible type. (Dey 2021) stated that Biodiesel are gaining importance as alternate fuel, since their Physico chemical properties are comparable with the diesel fuel. (Aydin 2020) stated that

Compression ignition engines are extensively used in different sectors of industries and automobiles due to their higher efficiency. On the other hand diesel engine emits more harmful exhaust emissions which are adversely affecting the leaving being and environment from quite number of years. An attempt is made to find an alternate fuel which can be a substitute for diesel fuel at the same time it must reduce the emissions without affecting the thermal performance of engine. Biodiesel does not contain any harmful stuff such as Sulphur, and minerals. Exhaust emissions are less because of inherent oxygen into the molecular structure of biodiesel. Researchers are working with biodiesel blends which are produced from different tree born oils to explore the consequence on the thermal performance and emissions. Traditional methods such as mathematical models for the analysis of the combustion characteristics are more of time consuming and also cumbersome. The alternate approaches are used by the researcher which makes the analysis to be simple, less time consuming and economical. So the researchers started approaching towards the new methods that can give the same results at faster rate and with lesser cost. Advancement of computer software’s and hardware technology, artificial neural network (ANN) methods are used in automotive as well as engine problem analysis. The substantial number of studies was reported on thermal performance and exhaust emissions of CI engines with biodiesel and diesel blends using ANN model. Experimental works was conducted to investigate the performance and exhaust emissions characteristics of CI engine using biodiesel and diesel blends at various injection pressures. The experimental results were optimized using ANN modeling and surface response methodology taking load, injection pressure and blends as inputs and brake thermal efficiency, exhaust temperature and various emissions as outputs. It was concluded that ANN mode land surface response methodology can support the researcher for optimization of engine performance and exhaust emissions. (Dey 2021) stated that artificial neural network was applied for the optimization of engine performance and emissions of engine using palm biodiesel, ethanol and diesel blends. The surface response methodology was also applied for the comparison of results. The inputs for ANN modeling and surface response methodology were load, palm biodiesel and ethanol blends and outputs were brake thermal efficiency, brake specific energy consumption, also NOx. The result shows that there was significant effect of load, palm biodiesel and ethanol blends on thermal performance. The results also predict that ANN model analysis was a better method compared to RSM. (Agrawal 2021) stated that The studies were carried out for analysis of the effect of rising carbon content in the atmosphere which is increasing the temperature and causing the unprecedented climate change. This was also one of the causes for the global warming and causes the heat waves, draught, melting of ice and raises the sea level. Vehicles were emitting maximum exhaust emissions which were harmful to the atmosphere and also carcinogenic which affect the human health. NOx and other emissions from automobiles were the source of smog and acid rain this may lead to adverse effect on the human health. The engine speed, fuel properties were inputs and outputs were BTE, BSFC and various emissions. Experimental results were compared with ANN estimated results with regression coefficient. It was concluded that ANN modeling was better system used for investigation performance and emissions. (Uslu,2018) stated that Tests were carried out for investigation of thermal performance and exhaust emissions of CI engine using diethyl ether with blends in diesel. ANN method was applied for the comparison and study of thermal performance and emissions of engine. The input for ANN modeling were load, speed and blend ratio and outputs were BSFC, BTE, EGT and NOx, CO, HC and smoke emissions. Regression coefficient, R was used for optimization of the inputs and outputs. (Channapattana 2017) stated that ANN model were applied for optimizing of thermal performance and emission parameters of CI engine using the blends of biodiesel and diesel. Four special transfer functions were used for the optimization and the one which has minimum error and maximum anticipating accuracy was considered. The inputs were compression ratio, injection pressure, load and the blends and the outputs were BSEC, BTE, EGT, and emissions such as CO, CO2, HC, NOx and smoke. The study was aimed to have an optimized engine performance with minimum emissions. (Seyyed 2020) stated that Thermal performance and emissions of engine were investigated with blends of diesel and biodiesel with Nano particles as additives. Aluminum Nano additives were utilized for improving the thermal and emission characteristics with reduced vibrations. ANN modeling techniques were employed to optimize the input and output variables. Blends, speed, fuel density, viscosity, lower heating value, intake manifold pressure, fuel consumption, EGT, presence of O2 in burned gas, oil temperature, relative humidity, ambient pressure were the inputs and target variables were engine power, torque, emissions such as CO, HC, NO, smoke and engine vibrations. The study concludes that ANN model presents a satisfactory result which relates the input and output variables for the thermal behavior and emissions characteristics. (Hosamani 2020) stated that Thermal performance and emission parameters of the engine were investigated using blends of two biodiesel mixture with diesel. The performance and emissions characteristics were analyzed and the same were assessed by using the ANN estimation. The key inputs were load, compression ratio, mixture ratio and blends the target variables were BSFC, BTE, EGT, and emissions like CO, HC, NOx, CO2, and opacity. The predicted results of the ANN model were in match with experimental results. It was concluded as ANN methods may be applied to predict the engine performance and emission characteristics. (Karimmaslak 2021) stated that ANN model was employed for optimization of thermal and emissions characteristics of CI engine. Thermal and emissions characteristics of engine were studied with propylene glycol, biodiesel and diesel blends. It was optimized through ANN-GA-RSM. Hybrid machine learning language was used for ANN-GA-RSM (artificial neural network-genetic algorithms-surface response method). Correlation coefficient, R and root mean square error were used for assessment. The study concluded that ANN-GA could be maximum prediction narration. (Işcan 2020) stated that Experimental works were carried out to investigate combustion, thermal and emission quality of engine. ANN estimation methods were applied for comparison of test results. The various combustion aspect such as cylinder pressure, MFB, NHRR, CHR, average gas temperature, heat transfer velocity for various loads were modeled. The input and output data were analyzed using the ANN model for comparison of test results. The analysis shows that the calculated and estimated results were in excellent match with each other. (MohdNor 2019) stated that ANN model were developed for the comparison of combustion pressure of CI engine using biodiesel and diesel blends. The inputs to ANN model were engine speed, load, crank angle and biodiesel blends. The developed ANN model approach predicts the cylinder pressures through high-quality accuracy and was in comparison with the test results. The ANN estimated consequences were confirmed with the experimental values. (Karami 2019) stated that Thermal performance and emissions of CI engine were investigated using diesel and biodiesel blends at different load and speeds. The test results were analyzed with ANN estimated results for comparison. ANN model shows higher competence of estimating the thermal and emission characteristics of engine through better accuracy. (Sevinc 2020) stated that Present work is on the comprehensive analysis of different combustion parameters of diesel engine by means of blends of mixture of two biodiesel with diesel as fuel at different load and CR and comparing experimental results with of ANN estimated results. The referred literature presents the study of ANN model approach for the analysis of thermal performance and exhaust emission of CI engines using blends of biodiesel and diesel. It is also evident that little work is being done on the analysis of combustion characteristics of CI engine with ANN model. Hence it is appropriate to apply ANN model for the analysis of combustion characteristics of CI engines. In view of statement an attempt is made to apply ANN model to create precise system to estimate the combustion characteristics of diesel engine.

2. Materials and evaluation methods:

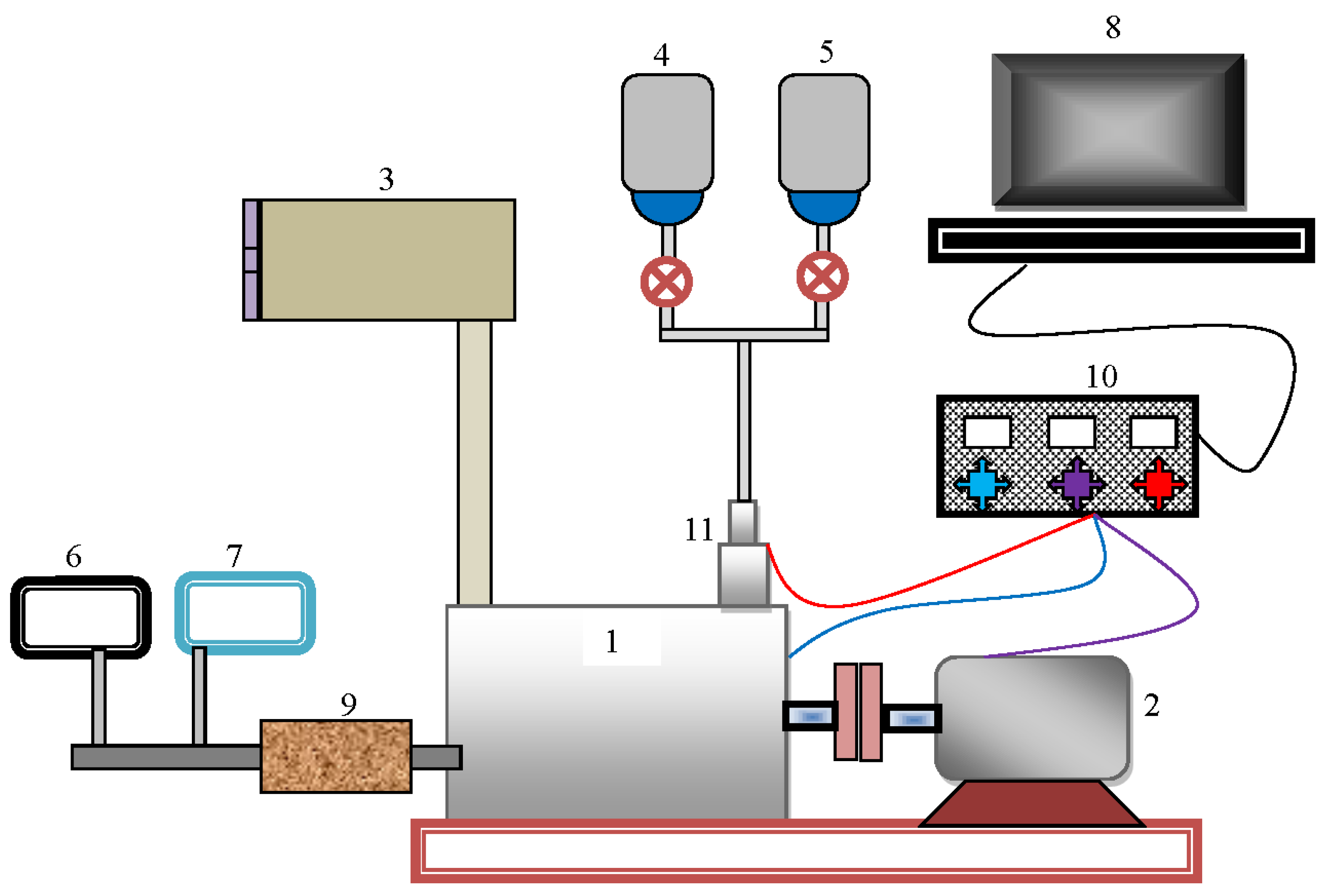

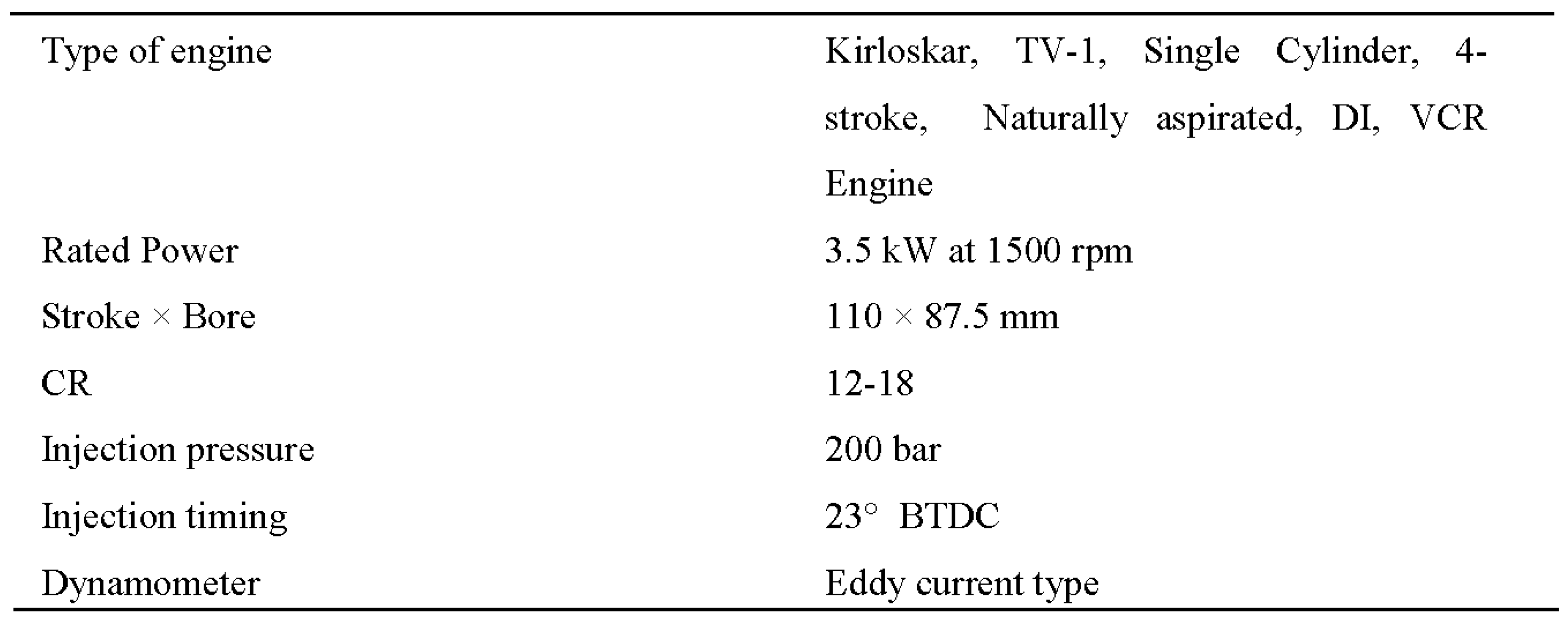

Schematic of experimental set up is shown in

Figure 1 with the accessories and technical niceties of engine in

Table 1. Single cylinder, 4-stroke, direct injection, water cooled, constant speed, CI DI VCR engine coupled to eddy current dynamometer was used. Test setup is provided with data logging system with dedicated software. Engine is interfaced to computer loaded with ‘Engine Soft Software for data acquisition. The various measurements are carried out using the calibrated transmitters and other measuring systems. The load on the engine is varied using load cell and the different temperatures are measured using thermocouples fixed on engine and calorimeter. Flow of water to engine and calorimeter is measured and controlled with Rota-meter. Pressure sensors are calibrated and fitted on to cylinder and fuel injector. The cylinder pressure and injection pressures are measured using sensors. For long life and excellent thermodynamic behavior, pressure sensors are cooled with water circulation. Engine is fixed with fuel pump with static injection timing of 23° BTDC. The outcome of the work and deliberations are with static injection timing.

Experimental investigations are carried out with neat diesel fuel at different compression ratio and at different load. The results obtained from diesel are the base line results used for the comparison with the blends. The engine tests are carried out with 20%, 60%, and 100% of the rated load. The experiments are repeated for CR of 16, 17 and 18 with diesel fuel, as well as with different blends of mixture of two biodiesel (J75+S25) with diesel. For each load various combustion parameters are recorded. Computerized data acquisition techniques are used towards the collection and accumulation of the data throughout the testing with suitable instrumentation.

3. Application of ANN Modeling:

(Niu 2017) stated that The Artificial Neural Network (ANN) has the capability to learn through examples. They were information processing model which has inspired by biological neuron system. (Mehra 2018) stated that ANN model has the capability to recognize both linear and nonlinear association amongst the experimental input and output data used in experimental work with less time and complexity whereas the conventional modeling method were more time consuming. (Gulum 2018) stated that Now a days, ANN modeling is most commonly used technique in the automotive industry for the analysis of combustion quality of the engine by creating computational and mathematical model for the input and output information. (Sevinc 2020) stated that The ANN technique mainly consist of three layers namely input, hidden and an output layer. (Najafi 2009) stated that each layer contains the nodes called neurons. A node is building block of ANN model that processes the data by sum and transfer function. Number of hidden layers and neurons may perhaps be changed based on experimental data and complexity of the problem. Three data sets are generally used in different phases of the formation of the model; training, validation and testing. (Dey 2020) stated that the most commonly used neural networks be feed forward neural network which appear to be simple. This has been used for processing the input and output data from the experimental results. The data are processed in one direction from input to output node through the hidden layer. The Leven berg-Marquardt training (Train-lm) function is employed for fast processing as well as for the critical prediction and repeated error variations. (Gupta 2019) stated that It is established to facilitate Train-lm functions reporting more rapidly compared to other training algorithms and number of epochs and duration for the convergence is less significant. (Cay 2012) stated that the nonlinear models use the logistic-sigmoid differential continuous activation function for enhanced and appropriate performance of the network. In the anticipated network mean square errors (MSE) are employed for resolving the loss of function. Prior to the development of model input and output data are standardized to avoid overriding. Standardization is to be made into a minor offset from 0.1 to 0.9 rather than 0 to 1 using the equation (1) shown below. It evades dissemination of sigmoid function within the route on the way to shun low and no learning.

Where

Xi is the normalized value of x

i; x

i,

min and x

i,

max are the minimum and maximum of

xi.

4. Results and Discussion:

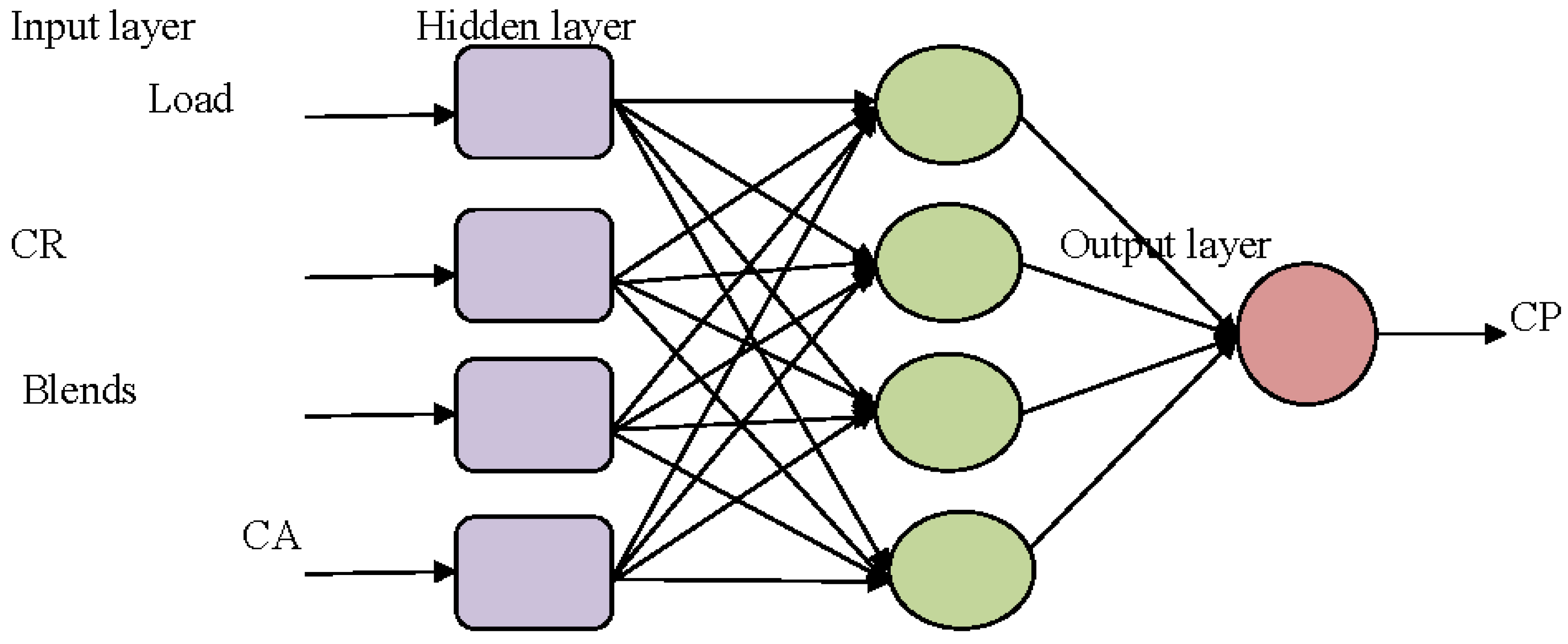

The experimental results of combustion characteristics are compared with artificial neural network estimated results. Combustion characteristics of engine are estimated with ANN model through MAT-LAB software. The design and structure of architecture is shown in the

Figure 2,it has four inputs and one output. The four inputs to ANN model are CR, % load, blends and crank angle. The output variables considered one at a time and they are cylinder pressure (CP), net heat release rate (NHRR), cumulative heat release, rate of pressure rise, mass fraction burned and maximum cylinder pressure. Primarily it is essential to acquire the necessary information of input and output variables which are to be used in ANN model. The input and output data are acquired using Engine Soft software’ throughout the engine testing. The mean square error and coefficient of regression are applied for recognizing the success of expected outcome of the anticipated model. The regression coefficient (R) and mean square error (MSE) are used for recognizing the attainment of prediction of the anticipated model [

32,

33,

34,

35].The regression coefficient R indicates the proximity between the experimental measurements and inference from ANN estimation. If the value of regression coefficient approaches unity, this shows that there is close relationship between the output and the targets. The mean square error and correlation coefficient can be ascertained by using the equation2 and 3.

Correlation coefficient,

Where t signifies target value and

indicates mean value of target, o refers to the output and N is a symbol of the total number of data considered for the assessment.

Number of neurons embedded in hidden layers is found out by means of means of trial and error technique in turn to make out the best possible architecture. Moreover if many neurons are engaged, network generalization may reduce; whereas lesser number of neurons might decrease the capability of network precisely to learn the pattern. Hence number of neurons in the hidden layer is condensed to be 2-24. The inputs and outputs accumulated from the experimentation are used for ANN modeling. The70% of the data is used for the training and 30% are used for simulation of the model for testing and validation. The network is trained by Leven berg Marquardt algorithm, because they are recognized and designated as fastest organized algorithm in creating the moderate sized feed forward model [

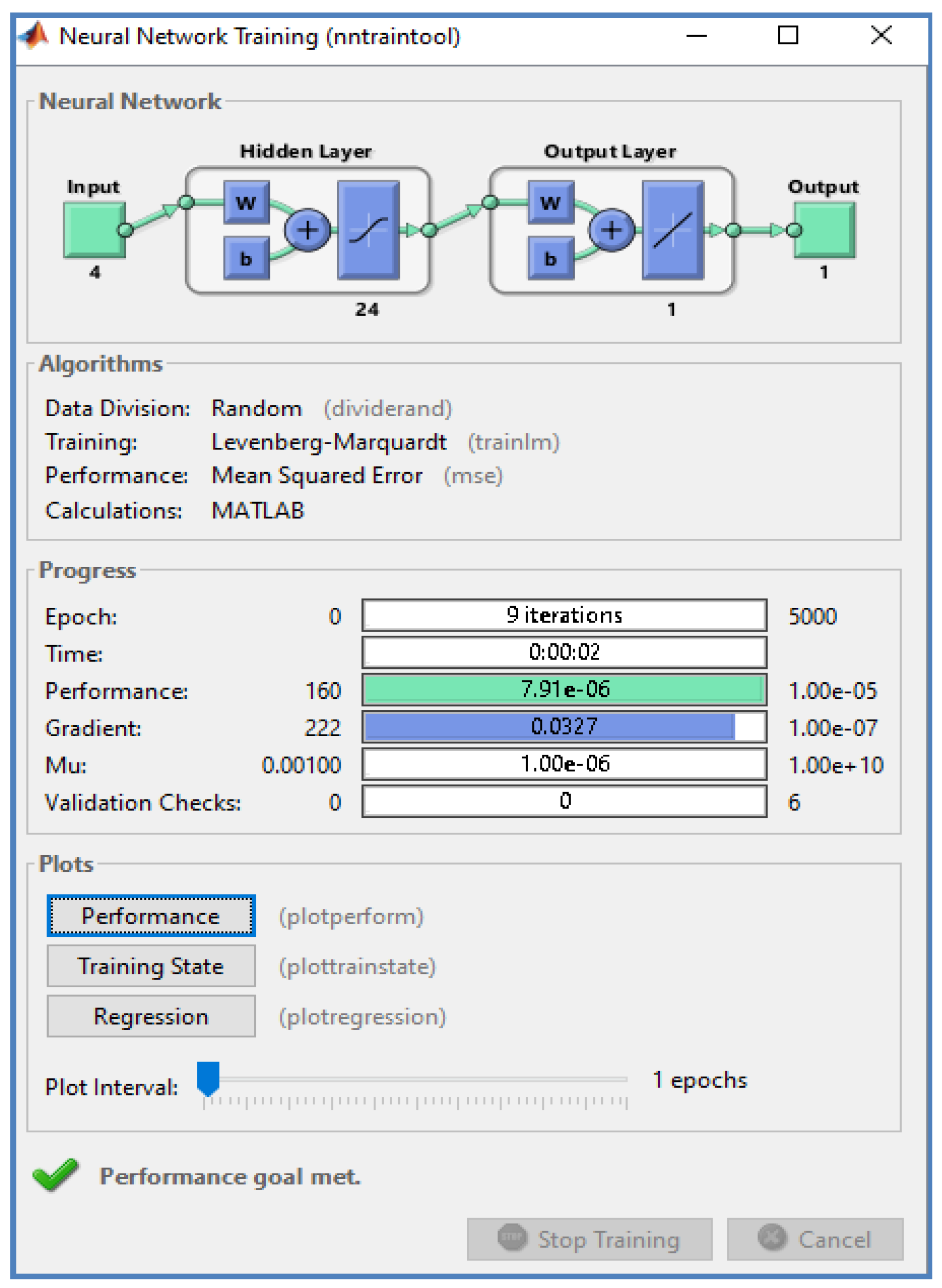

36], although it requires additional memory of the computer in comparison to additional algorithms. The in sequence about the artificial neural network training design is shown in

Figure 3.In training process weights as well as bias are used with the system towards optimization and presentation of network based upon gradient descent method. Also correspondingly tangent- sigmoid and pure linier are used as transfer function with hidden and output layers. The large variations among the input and target value are reduced with standardizing them within the range of -1 to +1 earlier on the way to the training procedure.

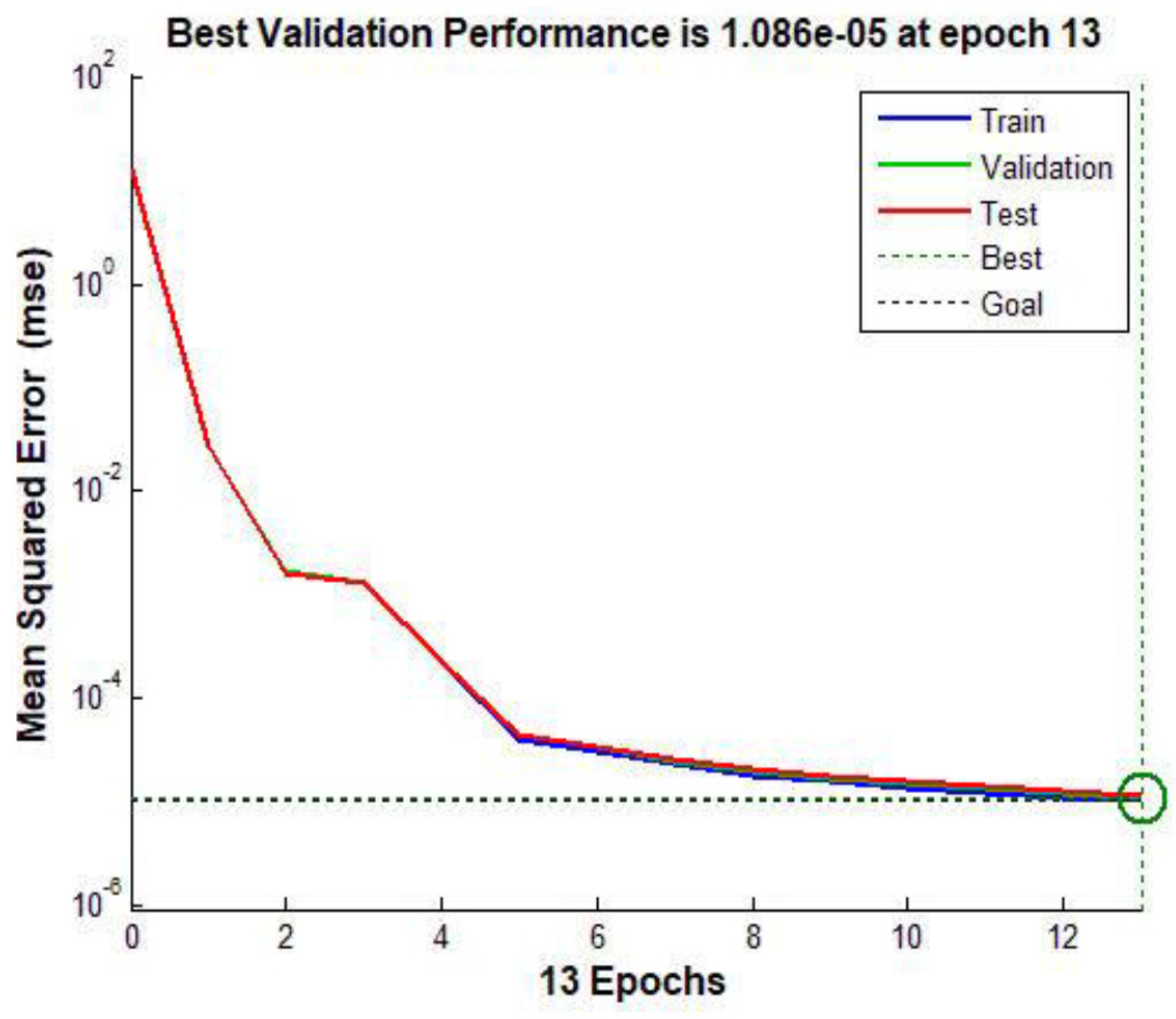

The predicted curve for the performance of the system is presented in

Figure 4. The model is effectively trained with input information, which is indicates in the trained curve. The justification and the test curve which appears comparable to end changes dismiss the phenomenon of the data over fitting. In reality best validation accomplishment is achieved at epoch number of 13with mean square error value of0.00001086.

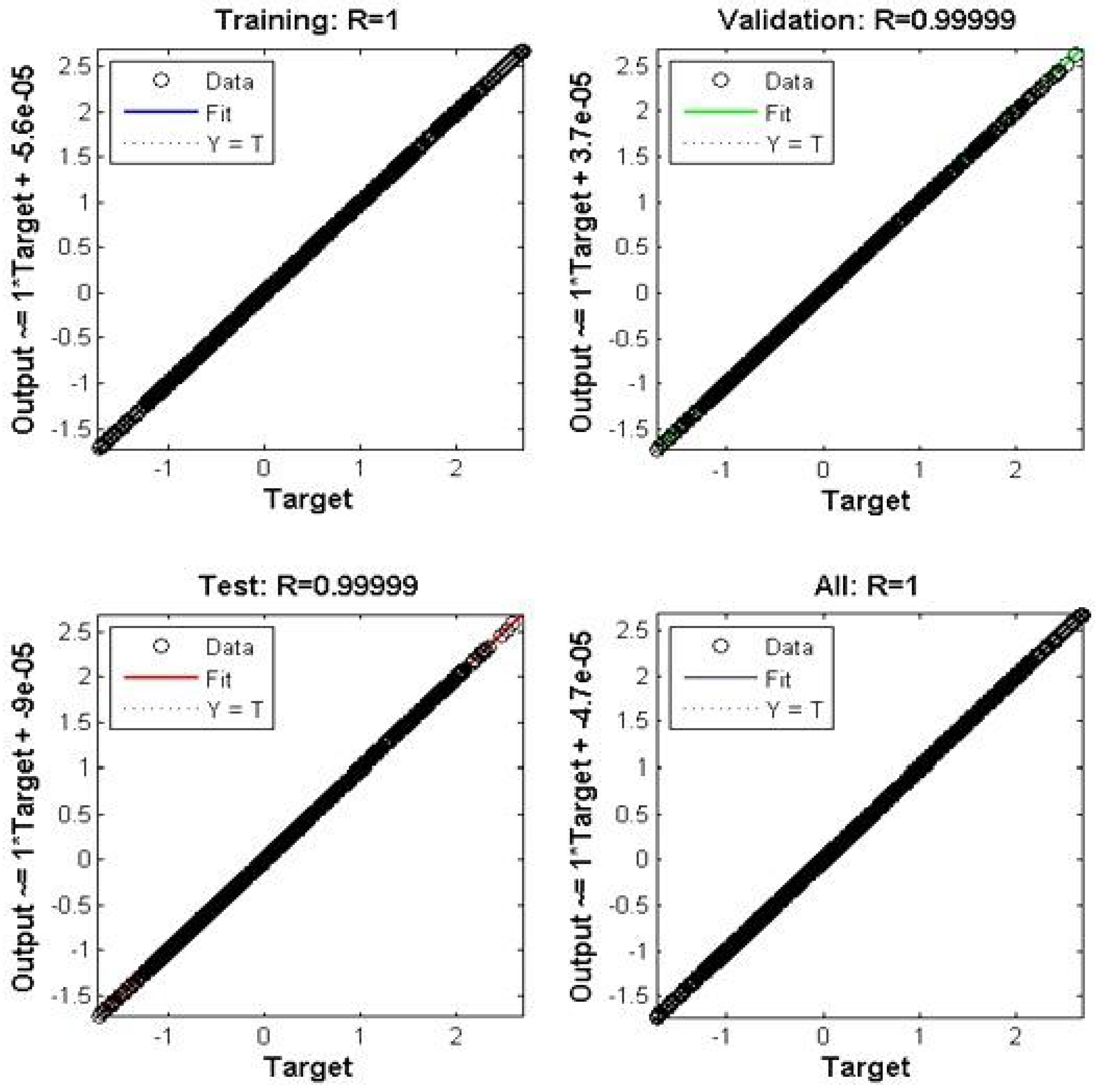

The chosen ANN models are trained to ensure the validity of the combustion characteristics. The regression plots that display correlation among the model inputs and corresponding targets for training, validation and test for entire datasets is presented in

Figure 5. The dotted line in every one of the plot indicates ideal result among output and target. In the meantime full line represents most excellent fit of linear regression line stuck among the output and target datasets. A predicted result shows excellent conformity with the experimental results, it is indicated with R value which is very close to unity. This may perhaps be because experimental data’s are acquired using engine soft software which gave accurate results for different combustion characteristics.

4.1. Comparison of experimental results and discussion with ANN model:

The various combustion characteristics such as cylinder pressure, net heat release rate, cumulative heat release, rate of pressure rise, mass fraction burned and maximum cylinder pressure are collected from experimentation. The experimental results are analyzed with artificial neural network model. The results of these parameters are analyzed one by one independently. The two figures presented for individual parameters one is for regression coefficient and another one to illustrate comparison of experimental results with artificial neural network estimated results. Analysis of experimental results and ANN estimated results are the robust estimation carried out for comparison.

4.1.1. Cylinder Pressure:

Comparison of cylinder pressure from experimental results with artificial neural network estimated results of VCR engine at different load and compression ratio and for different blends and diesel fuel are presented in

Figure 6. The number of data sets used for performing ANN model is 4716. It might be observed from figures that the experimental results are matching with ANN estimated results which are presenting the robust estimation [

12,

15]. The same is observed from regression coefficient, R which is very close to unity and the other figure show the cylinder pressure from experimental results are very closely matching with ANN estimated results. The mean square error is 0.0000186, which is extremely less. This shows that the robust estimation carried out through ANN model might be applied for analysis of combustion characteristics of variable compression ratio engine.

4.1.2. Net Heat Release Rate:

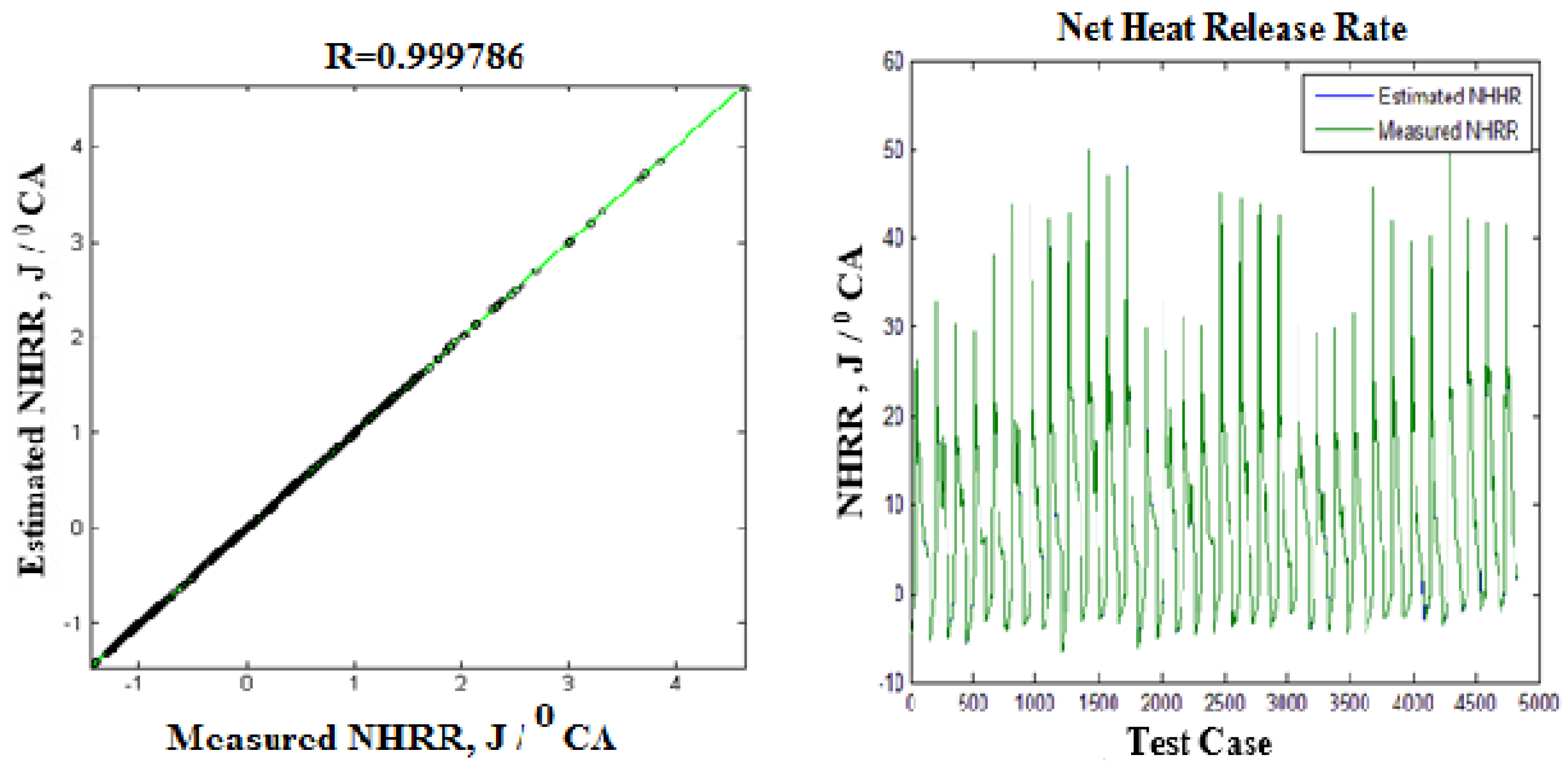

The ANN models are developed for the net heat release rate considering four inputs and one output for the system. The total number of data sets used in ANN modelling of net heat release rate are 4832. The experimental results and artificial neural network estimated results of net heat release rate for the VCR engine at different CR, at different laod and for various blends are presented in

Figure 7. From two figuresit be observedthat, the experimental results of net heat relaese rate are in very good match with the artificial neural network estimated results. This can be confirmed from the regression coeffient R which is very close to unity.The comparison of experimental results and estimated results from ANN model lie on each other.The same can be observed from regression coefficient R and it is 0.99876 and the value of MSE is 0.0000041918.

4.1.3. Cumulative Heat Release:

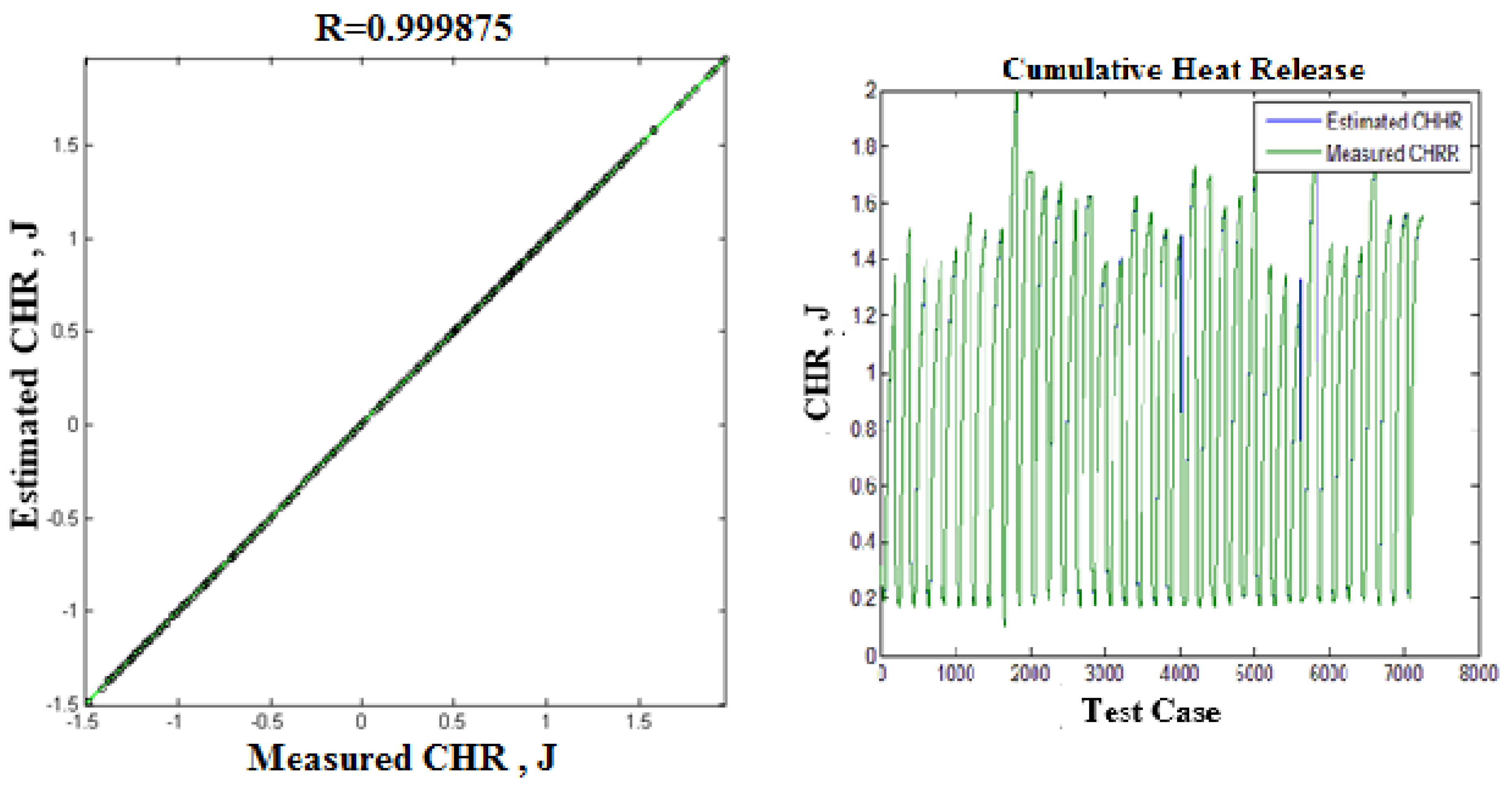

Comparison of experimental results and ANN estimated results of CHR at different load, compression ratio and for different blends are presented in

Figure 8. The number of data sets used for performing ANN estimation model of cumulative heat release is 7236. The following observations are made from figures, experimental results are very closely matching with ANN estimated results. The same might be observed from figures from regression coefficient, R which is pretty close to unity and comparison of experimental results with ANN estimated results are in excellent match with one another. This demonstrates that artificial neural network model can be applied for estimation of combustion characteristics of engine without complexity.

4.1.4. Rate of pressure Rise:

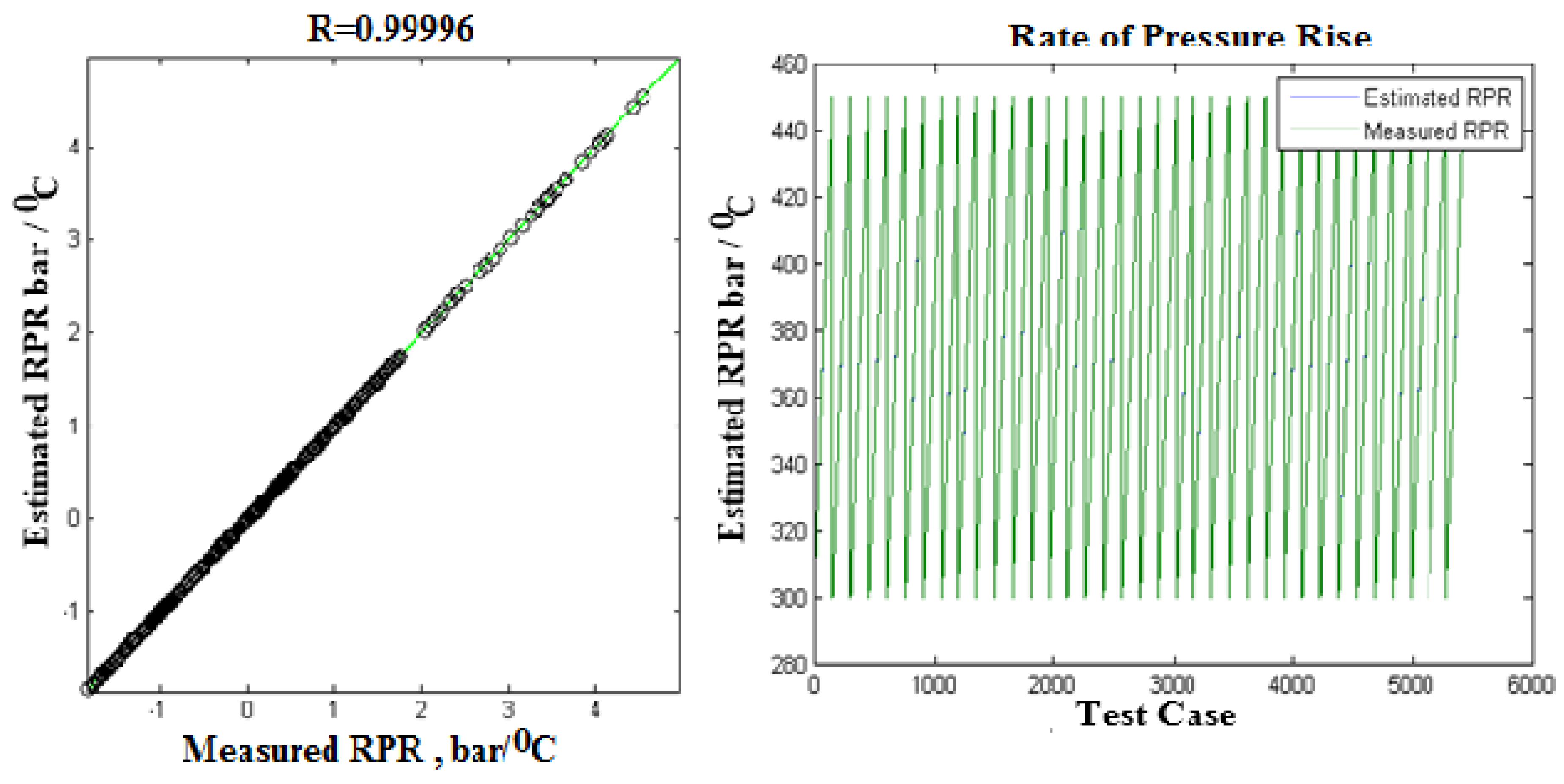

Assessment of experimental outcomes with ANN estimated results for the rate pressure rise at different load, CR and for various blends and diesel fuel are presented in

Figure 9. The number of experimental data sets used in the ANN results estimation is 5436. It can be observed from the figures that regression coefficient; R is quite close to unity. The other figure compares the experimental results and ANN estimated results which show by means of very good fit over each other with very close comparison and mean square error is quite small. Hence ANN model be capable of estimating the rate pressure rise with exceptionally good accuracy.

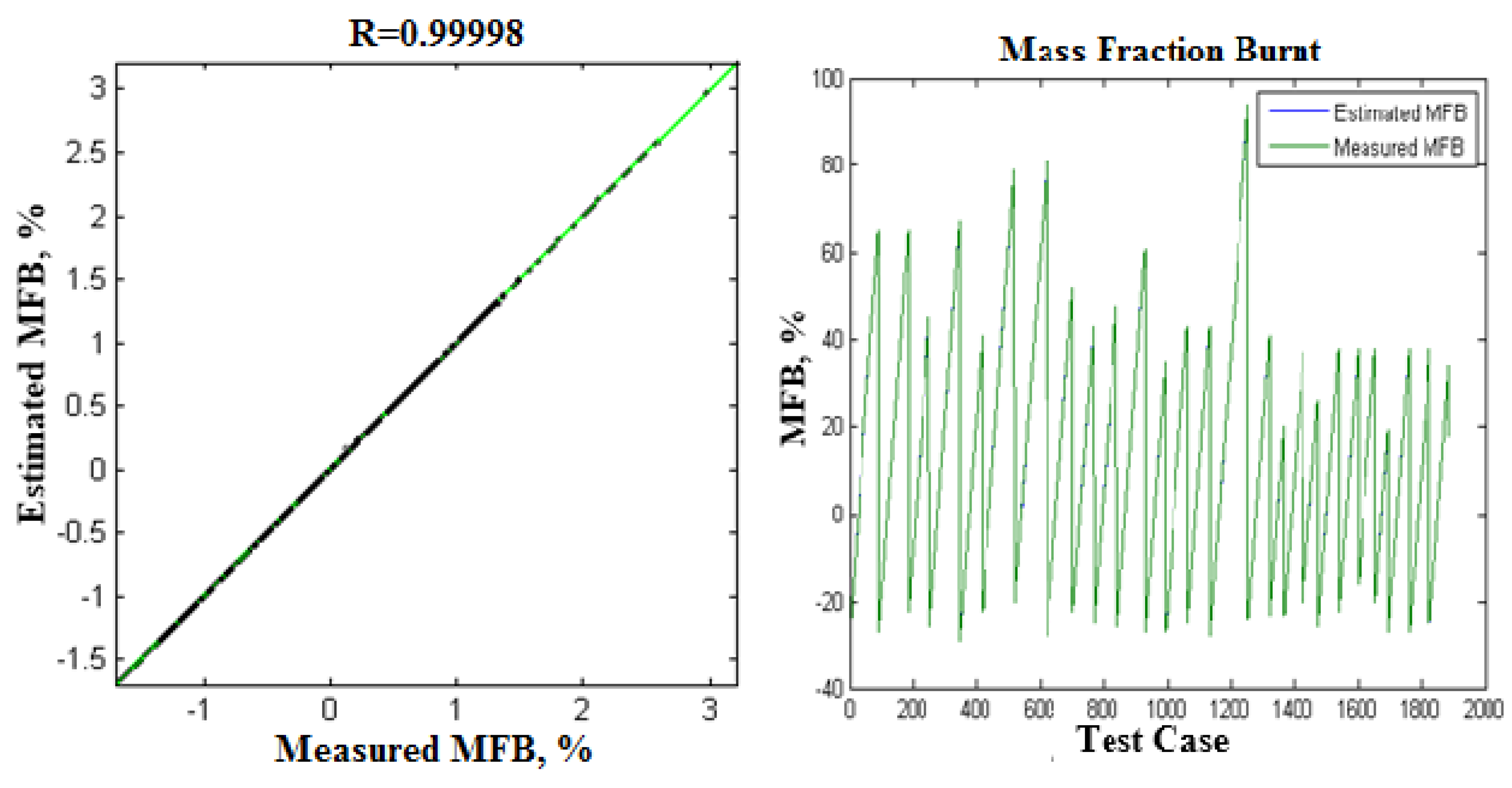

4.1.5. Mass Fraction Burned:

Measuring the MFB at different crank angle is the evidence for effective working of the engine anticipated. The experimental results and ANN estimated outcome of percentage of MFB for VCR engine using various blends of biodiesel with diesel and pure diesel at different load and compression ratios are presented in

Figure 10. It is observed from the figures that experimental results are quite in comparison with ANN estimated results. The same can be observed from the regression coefficient; R which is very close to unity. Results of comparison of mass fraction burned from the experimentation are in very good match with the ANN estimation. The mean square error is 0.000005037 which is quite less. Consequently ANN modeling will be valuable to estimate the mass fraction burned in the diesel engines.

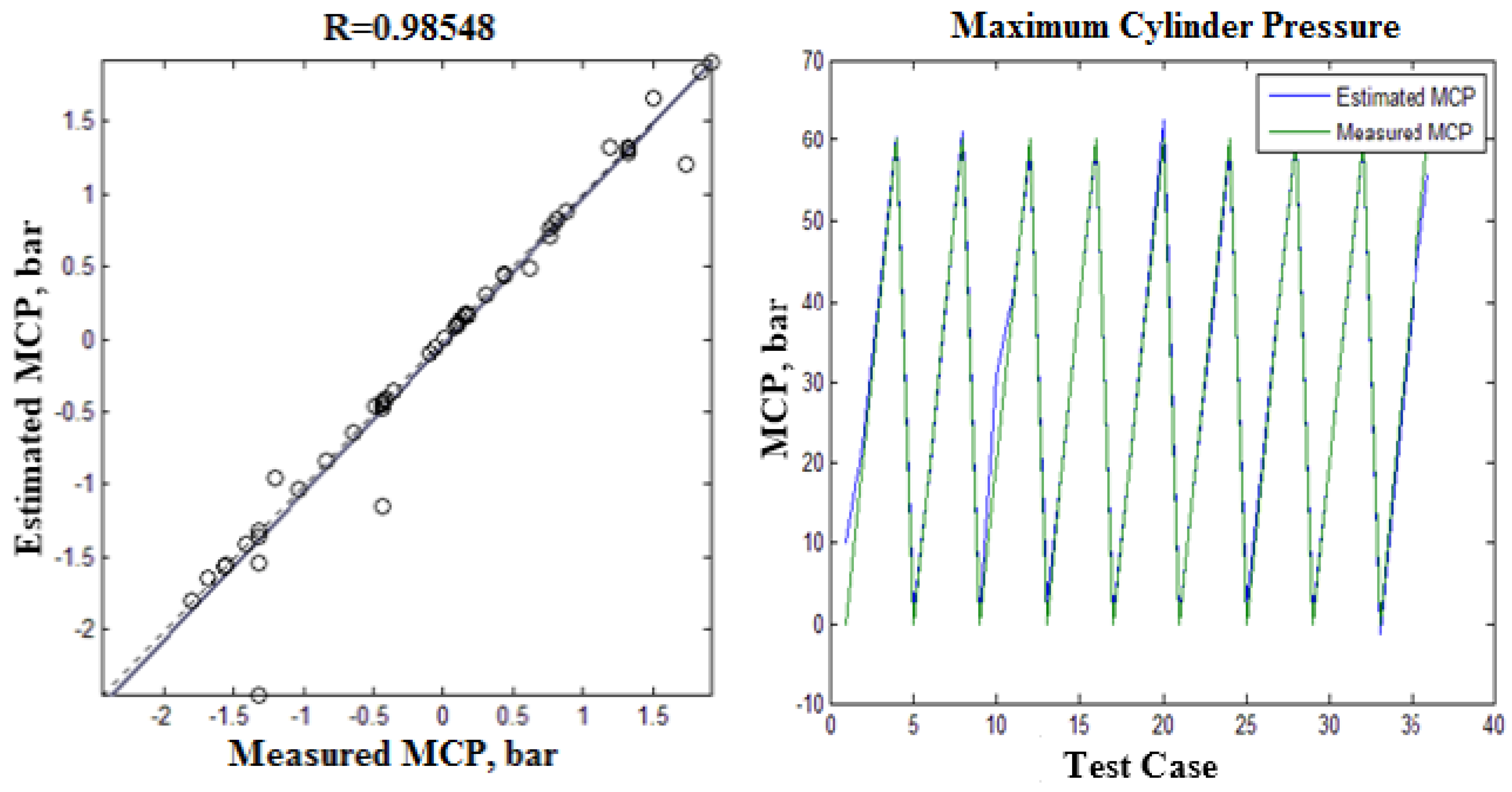

4.1.6. Maximum Cylinder pressure:

Comparison of maximum cylinder pressure of experimental results with artificial neural network results are presented in

Figure 11. The maximum cylinder pressure for VCR engine with mixture of two biodiesel blends and neat diesel fuel at different % load and CR are collected from experimental work. It is observed from the figures that the experimental results are in good match with ANN estimated results. This can be confirmed from the value of regression coefficient; ‘R’ which is very close to unity. Another figure point towards the comparison of experimental outcomes are compared with ANN estimated results of maximum cylinder pressure; these results are in very good match with each other. This indicates that the ANN model can be applied to estimate maximum cylinder pressure of the engine. The mean square error is also quite small and is equal to 0.0000097352. Therefore ANN model can be suitably useful for the estimation maximum cylinder pressure of compression ignition VCR engine.

5. Conclusions:

Experimental investigations are carried out using VCR diesel engine with mixture of two biodiesel in blend with diesel fuel. The various combustion characteristics of VCR engine at different % of load, at different CR and for various blends are collected with Engine Soft Software. ANN model is applied to the experimental results for the analysis of combustion characteristics of engine. From the comparison of experimental results and ANN results the conclusions drawn are:

ANN architecture with13 neuron in the hidden layer appears to be most excellent setup for the prediction of model.

Experimental results are in very good match with ANN estimated results for the various combustion characteristics investigated. It interpret that tests carried out are quite accurate.

The same can be observed with regression coefficient ‘R’ for different combustion characteristics investigated. The value of regression coefficient is very close to unity.

The mean square error is quite less for all the combustion characteristics.

The study makes to known that ANN model approach is competent towards predicting the combustion aspect of diesel engine with excellent degree of accuracy.

ANN model technique is a powerful tool which can be suitably applied to nonlinear state of applications with high-quality of accuracy.

ANN model demonstrate that it can be used in the analysis of automotive engines.

Nomenclature

| ANN |

artificial neural network |

-- |

| CI |

Compression ignition |

-- |

| MLNN |

multilayer neural network |

-- |

| NN |

neural network |

-- |

| J75 |

Jatropha biodiesel |

75% |

| S25 |

Simarouba biodiesel |

25% |

| CA |

crank angle |

º |

| CP |

cylinder pressure |

Bar |

| NHRR |

net heat release rate |

J/º CA |

| CHR |

cumulative heat release |

J |

| RPR |

rate of pressure rise |

bar/º CA |

| MFB |

mass fraction burned |

% |

| CR |

compression ratio |

non dimensional |

References

- Thakur AK, Kaviti AK, Mehra R, Mer KKS. Progress in performance analysis of ethanol-gasoline blends on SI engine, Renewable Sustainable. Energy Rev 2017; 69: 324-340. [CrossRef]

- Sanusi BA, Surajudeen OO, Abolanle SA, Olaoluwa RO, Olusegun SO, Combustion and emission study of sandbox seed oil biodiesel performance in a compression ignition (CI) engine. Energy Report 2021;7: 3869-3876. [CrossRef]

- Taghizadeh-Alisaraei A, Ghobadian B, Tavakoli-Hashjin T, Mohtasebi SSSS. Vibration analysis of a diesel engine using biodiesel and petro diesel fuel blends. Fuel 2012; 102: 414-422. [CrossRef]

- Sarin A, Arora R, Singh NP, Sarin R, Malhotra RK, Kundu K. Effect of blends of Palm–Jatropha–Pongamia biodiesels on cloud point and pour point. Energy 2009; 34: 2016-21. [CrossRef]

- Vallinayagam R, Vedharaj S, Yang WM, Lee PS, Chua KJE, Chou SK. Pine oil– biodiesel blends: a double biofuel strategy to completely eliminate the use of diesel in a diesel engine. Appl Energy 2014; 130: 466–73. [CrossRef]

- Tan PQ, Ruan SS, Hu ZY, Lou DM, Li H. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions. Appl. Energy 2014; 113: 22e31. [CrossRef]

- Karikalan L, Baskar JS, Venugopal S. Analyzing the influence of varied fuel injection pressure on diesel engine fueled with Karanja biodiesel. Mater Today: Proc., 2019. [CrossRef]

- Channapattana SV, Pawar AA, Kamble PG, Optimisation of operating parameters of DI-CI engine fueled with second generation Bio-fuel and development of ANN based prediction model. Applied Energy 2017; 187: 84-95. [CrossRef]

- Dey S, Reang NM, Das PK, Deb M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J Cleaner Prod. 286; 2021: 124981. [CrossRef]

- Guido C, Beatrice C, Napolitano P. Application of bioethanol / RME / diesel blend in a Euro5 automotive diesel engine: potentiality of closed loop combustion control technology. Appl. Energy 2013; 102: 13-23. [CrossRef]

- Gulum M, Bilgin A. An experimental optimization research of methyl and ethyl esters production from safflower oil. Environ Climate Technology 2018; 22: 132-48. [CrossRef]

- Aydin M, Uslub S, Bahattin Çelikb M. Performance and emission prediction of a compression ignition engine fueled with biodiesel-diesel blends: A combined application of ANN and RSM based optimization. Fuel 2020; 269: 117472. [CrossRef]

- Dey S, Reang NM, Das PK, Deb . Comparative study using RSM and ANN modelling for performance-emission prediction of CI engine fuelled with bio-diesohol blends: A fuzzy optimization approach, Fuel; 2021; 292: 123056. [CrossRef]

- Agrawal T, Gautam R, Agrawal S, Singh V, Kumar M, Kumar S. Optimization of engine performance parameters and exhaust emissions in compression ignition engine fueled with biodiesel-alcohol blends using taguchi method, multiple regression and artificial neural network. Sustainable Features2020; 2: 100039. [CrossRef]

- Uslu S, Celik MB. Prediction of engine emissions and performance with artificial neural networks in a single cylinder diesel engine using diethyl ether. Engineering Science and Technology, an International Journal.2018; 21(6): 1194-1201. [CrossRef]

- Seyyed Hassan Hosseini, Ahmad Taghizadeh-Alisaraei, Barat Ghobadian, Ahmad Abbaszadeh-Mayvan, Artificial neural network modeling of performance, emission, and vibration of a CI engine using alumina nano-catalyst added to dieselbiodiesel blends, Renewable Energy, 149 (2020) 951-961. [CrossRef]

- Hosamani BR, Ali AB, Katti VV. Assessment of performance and exhaust emission quality of different compression ratio engine using two biodiesel mixture: Artificial neural network approach. Alexandria Engineering Journal 2021; 60,1:837-844. [CrossRef]

- Karimmaslak H, Najafi B, Band SS, Ardabili S, Shoar FH, Mosavi A. Optimization of performance and emission of compression ignition engine fueled with propylene glycol and biodiesel–diesel blends using artificial intelligence method of ANN-GA-RSM. Engineering Applications of Computational Fluid Mechanics2021; 15 (1):413-425. [CrossRef]

- Işcan B. ANN modeling for justification of thermodynamic analysis of experimental applications on combustion parameters of a diesel engine using diesel and safflower biodiesel fuels. Fuel 2020; 279, 1: 118391. [CrossRef]

- Mohd Nor CW,Mamat R, Najafi G, Bakar AA, Samo K. Determination of Bio-Diesel Engine Combustion Pressure using Neural Network based Model. Journal of Engineering Science and Technology 2019; 14 (2): 909 - 921.

- Karami K. Performance Analysis of Direct Injection Diesel Engine Fueled with Diesel- Tomato Seed Oil Biodiesel Blending by ANOVA and ANN.Energies 2019; 12: 442. [CrossRef]

- Niu X, Yang C, Wang H, Wang Y. Investigation of ANN and SVM based on limited samples for performance and emissions prediction of a CRDI-assisted marine diesel engine. Appl Therm Eng. 2017; 111: 1353-1364. [CrossRef]

- Mehra RK, Duan H, Luo S, Rao A, Ma F. Experimental and artificial neural network (ANN) study of hydrogen enriched compressed natural gas (HCNG) engine under various ignition timings and excess air ratios. Appl Energy 2018;228: 736-54. [CrossRef]

- Gulum M, Kutlu Onay F, Bilgin A. Evaluation of Predictive Capabilities of Regression Models and Artificial Neural Networks for Density and Viscosity Measurements of Different Biodiesel-Diesel-Vegetable Oil Ternary Blends. Environmental and Climate Technologies 2018; 22: 179-205. [CrossRef]

- Uslu S, Celik MB. Prediction of engine emissions and performance with artificial neural networks in a single cylinder diesel engine using diethyl ether. Eng Sci Technol. 2018; 21(6): 1194-1201. [CrossRef]

- Sevinc H, Hazar H. Investigation of performance and exhaust emissions of a chromium oxide coated diesel engine fueled with dibutyl maleate mixtures by experimental and ANN technique. Fuel 2020; 278: 118338. [CrossRef]

- Najafi G, Ghobadian B, Tavakoli T, Buttsworth DR, Yusaf TF, Faizollahnejad M. Performance and exhaust emissions of a gasoline engine with ethanol blended gasoline fuels using artificial neural network. Appl Energy 2009: 86 (5): 630-9. [CrossRef]

- Dey S, Reang NM, Majumder A, Deb M, Das PK. A hybrid ANN-Fuzzy approach for optimization of engine operating parameters of a CI engine fueled with diesel-palm biodiesel-ethanol blend. Energy 2020; 202: 117813. [CrossRef]

- Gupta JND, Majumder A, Laha D. Flowshop scheduling with artificial neural networks. J Operational Res Soc. 2019; 71 (10):1619-1637. [CrossRef]

- Islamoglu Y, Kurt A. Heat transfer analysis using ANNs with experimental data for air flowing in corrugated channels. Int J Heat Mass Transf, 2004; 47: 1361-5. [CrossRef]

- Cay Y, Cicek A, Kara F, Sagiroglu S. Prediction of engine performance for an alternative fuel using artificial neural network. Appl Therm Eng, 2012; 37: 217-25. [CrossRef]

- Dharma S, Hassan MH, Ong HC, Sebayang AH, Silitonga AS, Kusumo F. Experimental study and prediction of the performance and exhaust emissions of mixed Jatropha curcas-Ceiba pentandra biodiesel blends in diesel engine using artificial neural networks. J Cleaner Prod. 2017; 164: 618-33. [CrossRef]

- Javed S, Satyanarayana Murthy YVV, Baig RU, Prasada Rao D. Development of ANN model for prediction of performance and emission characteristics of hydrogen dual fueled diesel engine with Jatropha Methyl Ester biodiesel blends. J Natural Gas Sci Eng. 2015; 26: 549-57. [CrossRef]

- Dey S, Reang NM, Majumder A, Deb M, Das PK. A hybrid ANN-Fuzzy approach for optimization of engine operating parameters of a CI engine fueled with diesel-palm biodiesel-ethanol blend. Energy 2020; 202: 117813. [CrossRef]

- Deb M, Majumder P, Majumder A, Roy S, Banerjee R. Application of artificial intelligence (AI) in characterization of the performance–emission profile of a single cylinder CI engine operating with hydrogen in dual fuel mode: An ANN approach with fuzzy-logic based topology optimization. Int. J. Hydrogen Energy 2016; 41: 14330-50. [CrossRef]

- Masoudi S, Sima M, and Tolouei-Rad M. Comparative study of ANN and ANFIS models for predicting temperature in machining. Journal of Engineering Science and Technology (JESTEC), (2018); 13(1): 211-225.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).