Submitted:

28 December 2023

Posted:

28 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction:

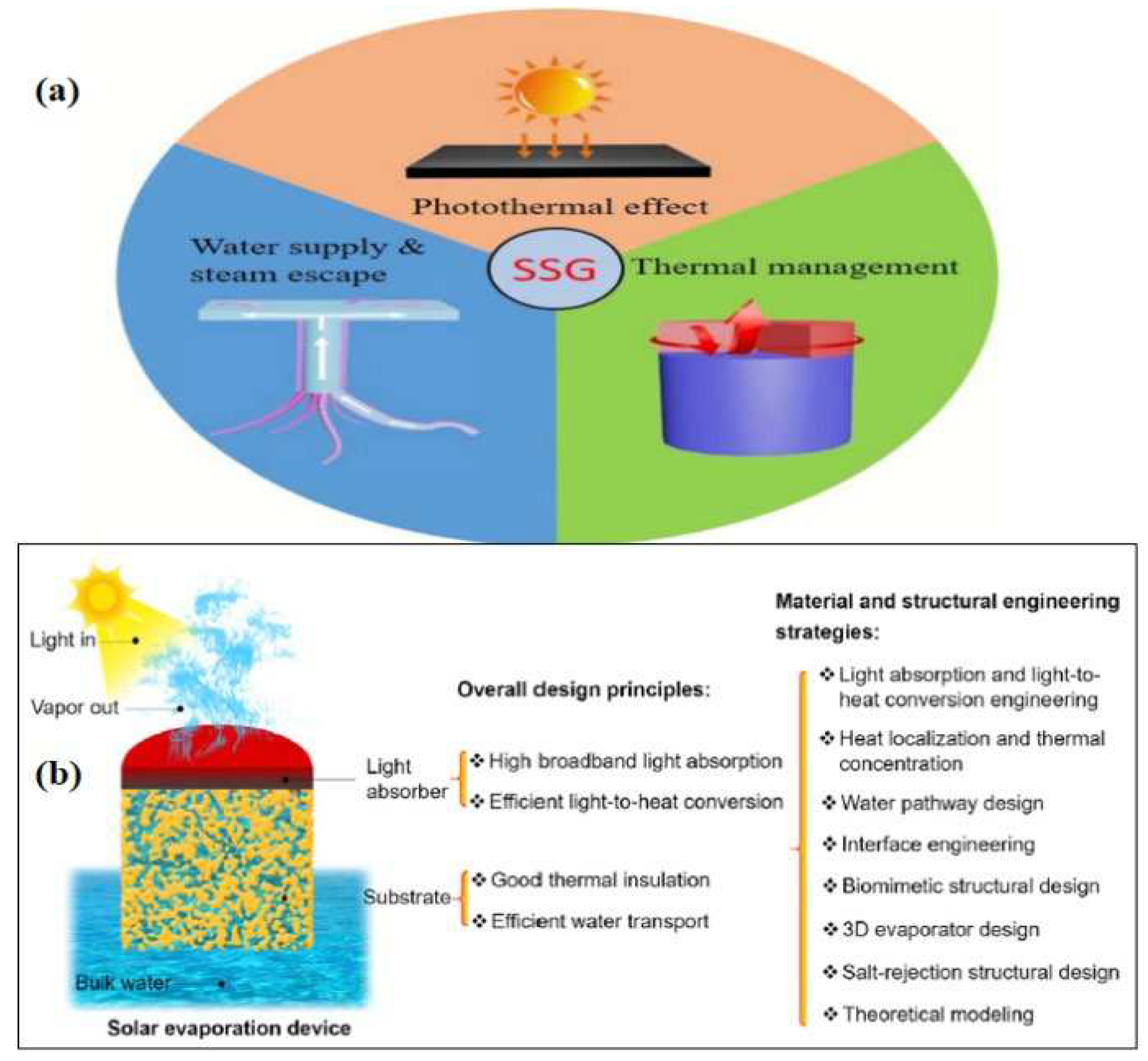

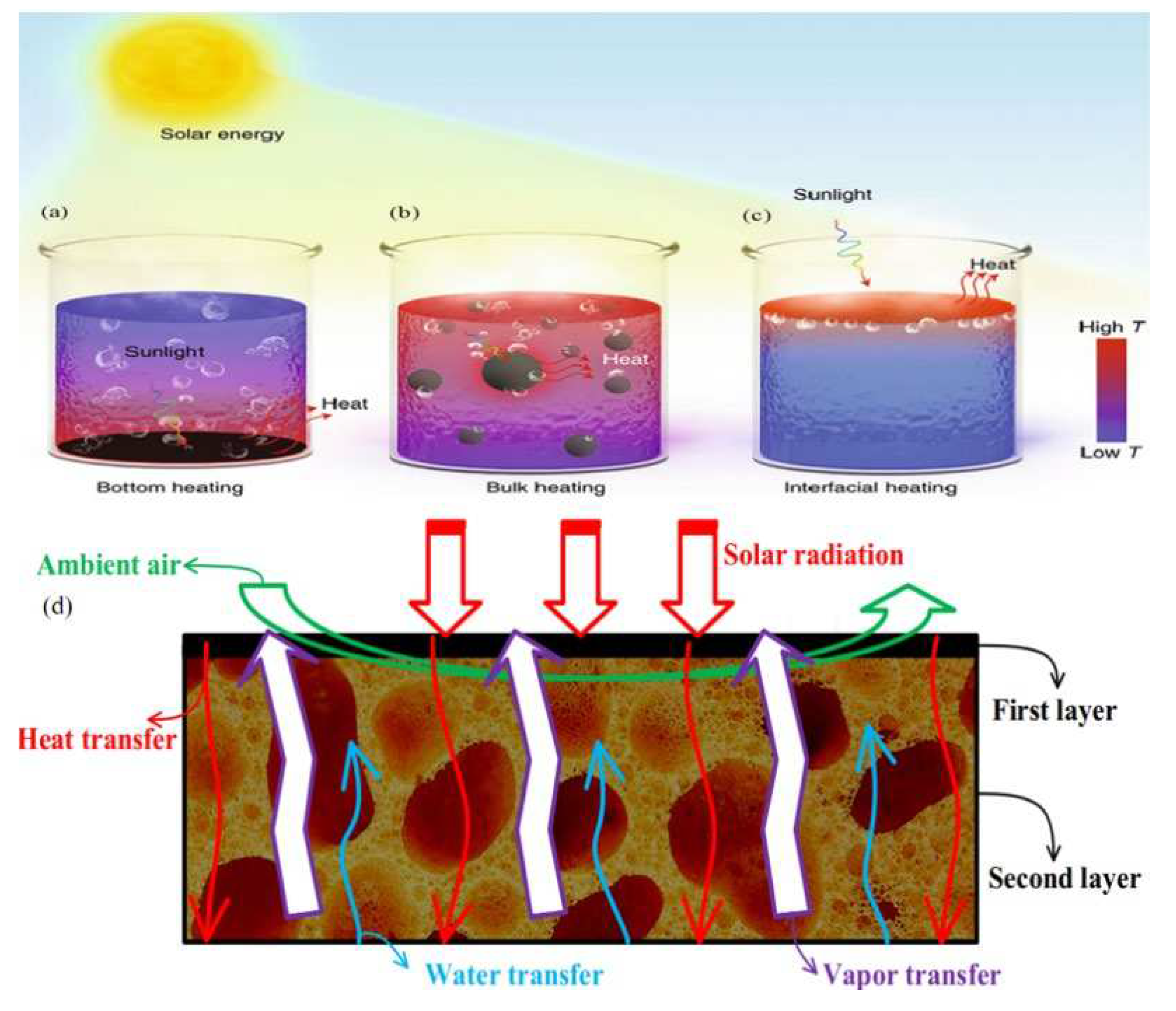

1.1. Interfacial Solar Steam Generation (ISSG):

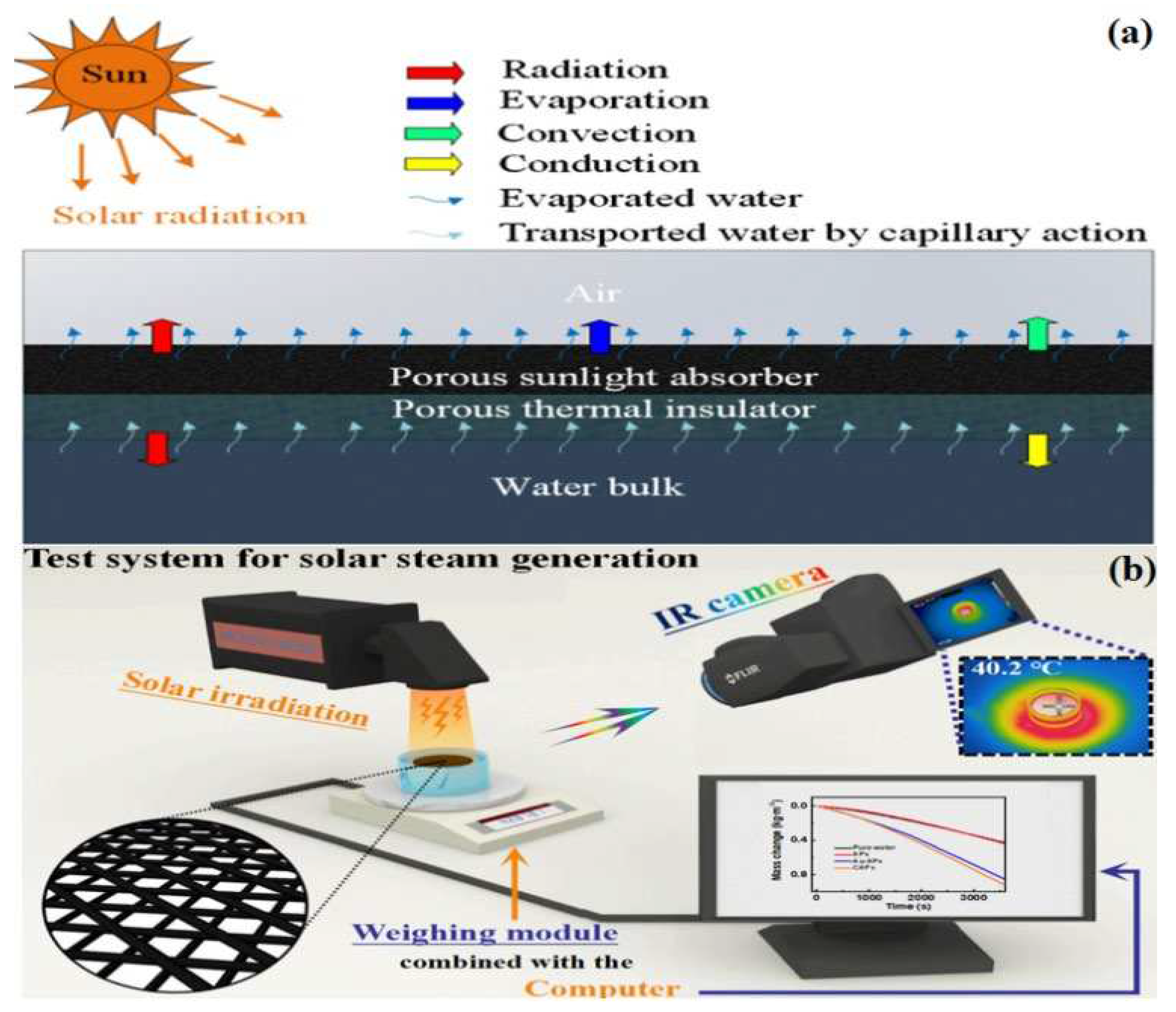

1.2. Fundamental principles for the design of ISSG devices:

1.2.1. The sunlight absorption:

1.2.2. The principles of ISSG design:

1.2.3. Water supply system in ISSG devices:

2. The role of textile materials in ISSG systems:

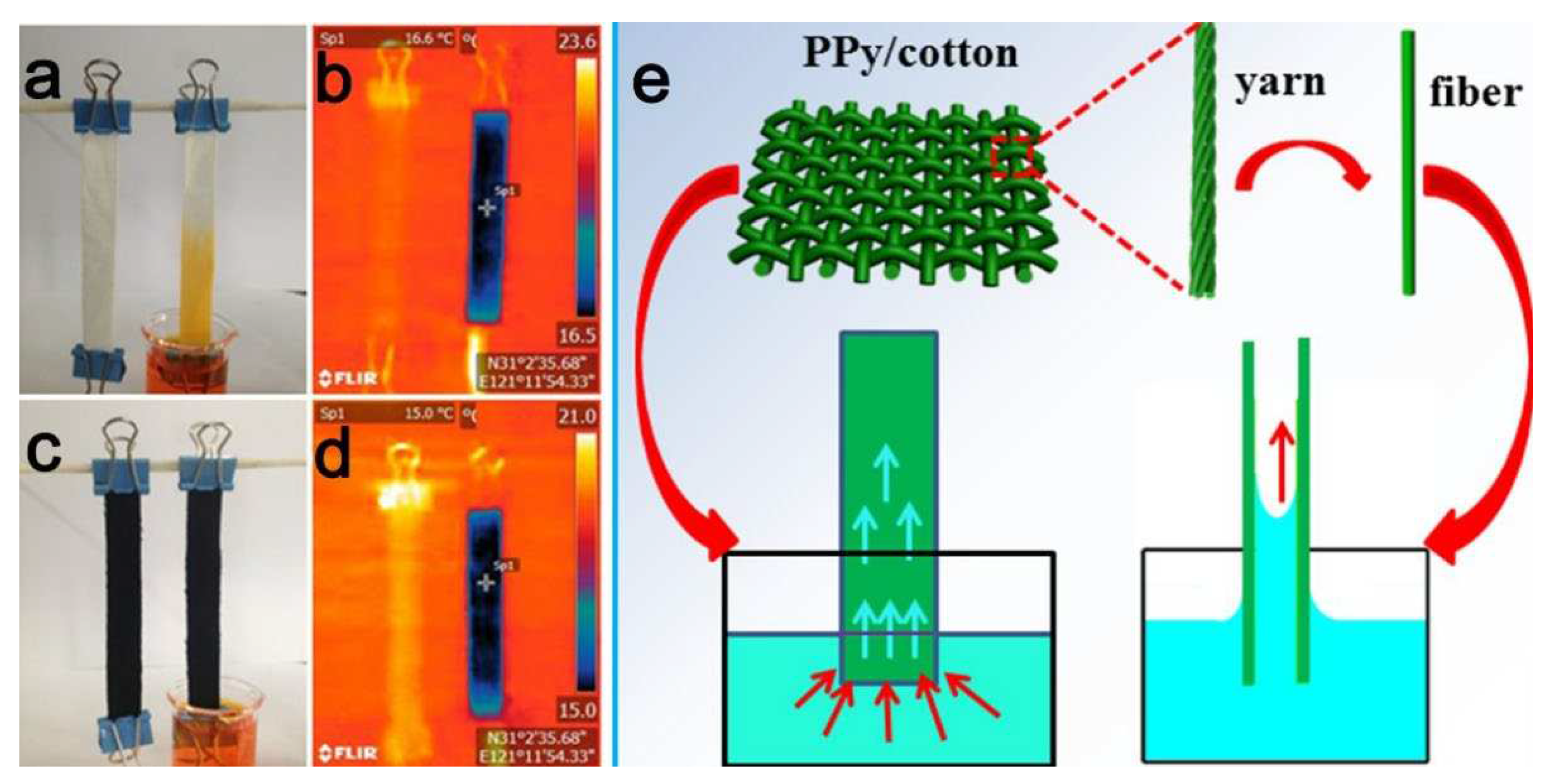

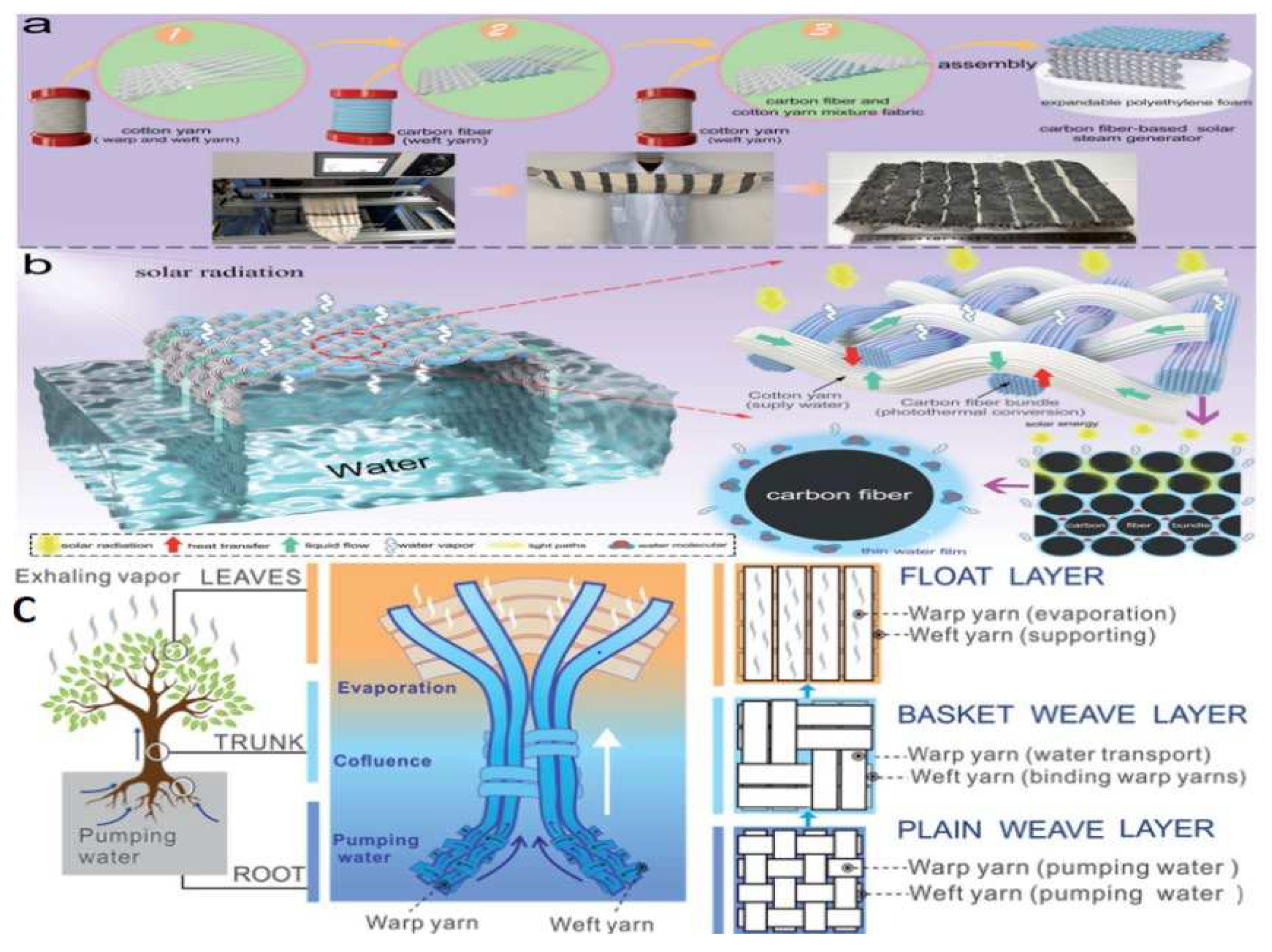

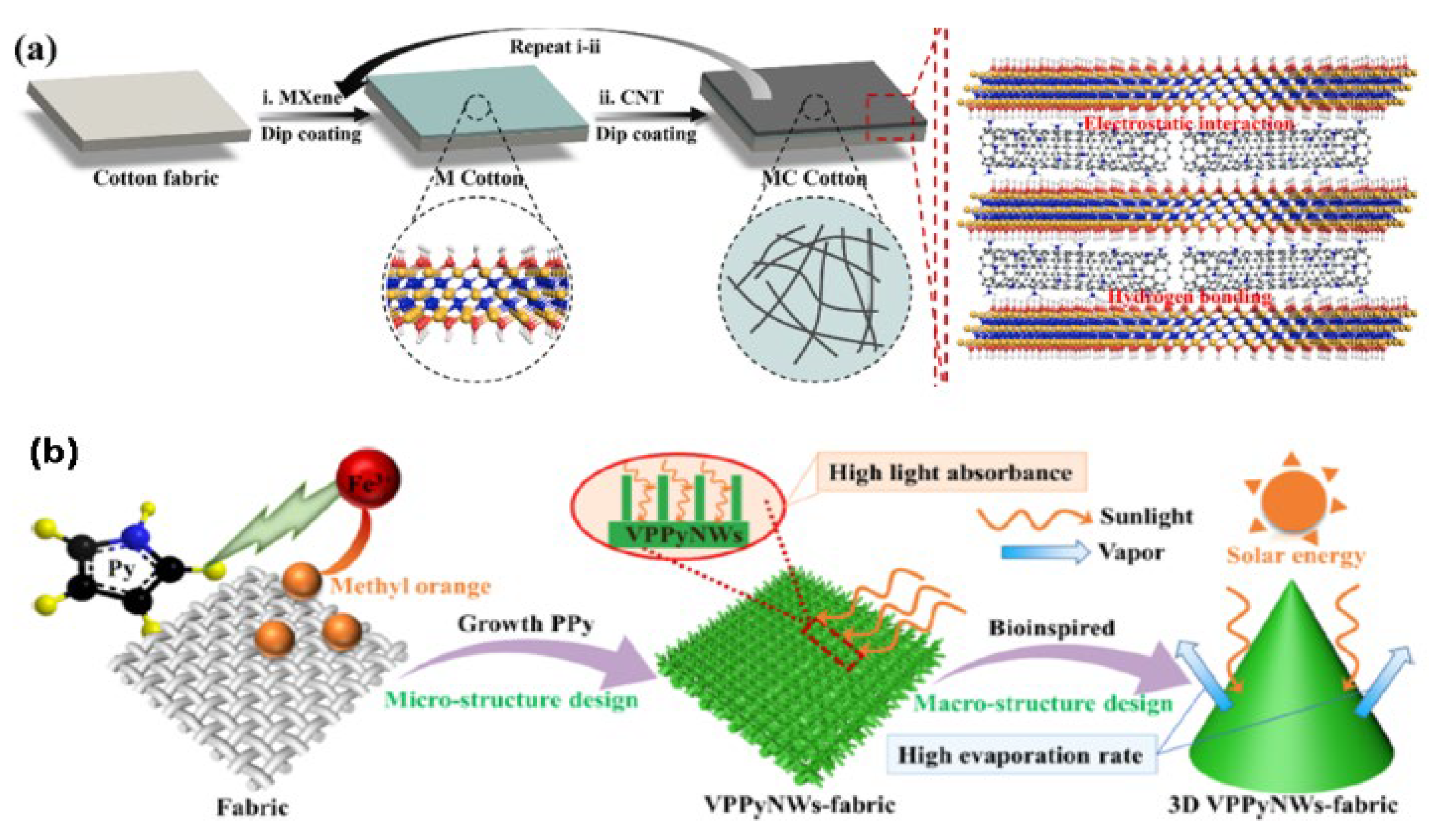

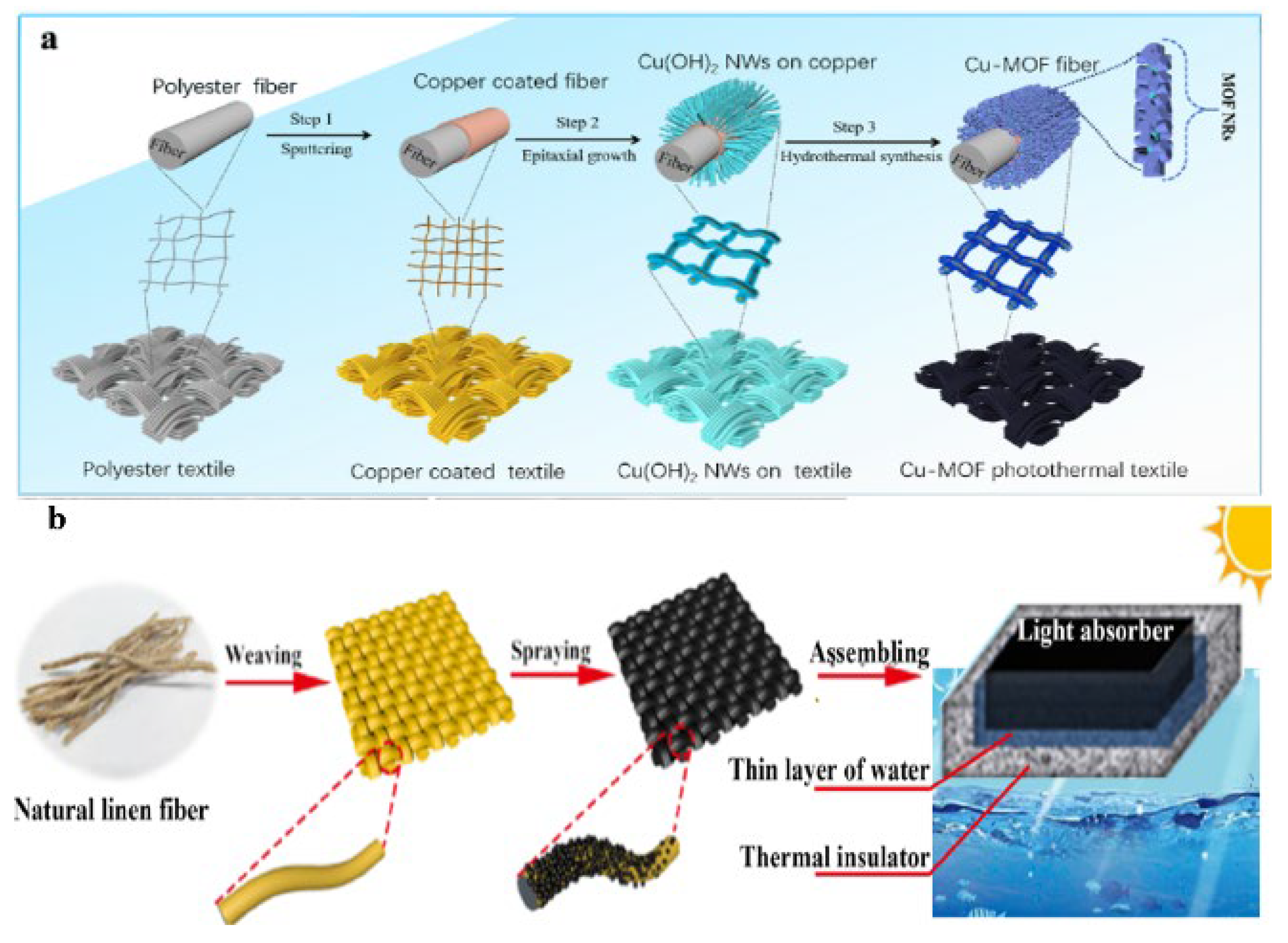

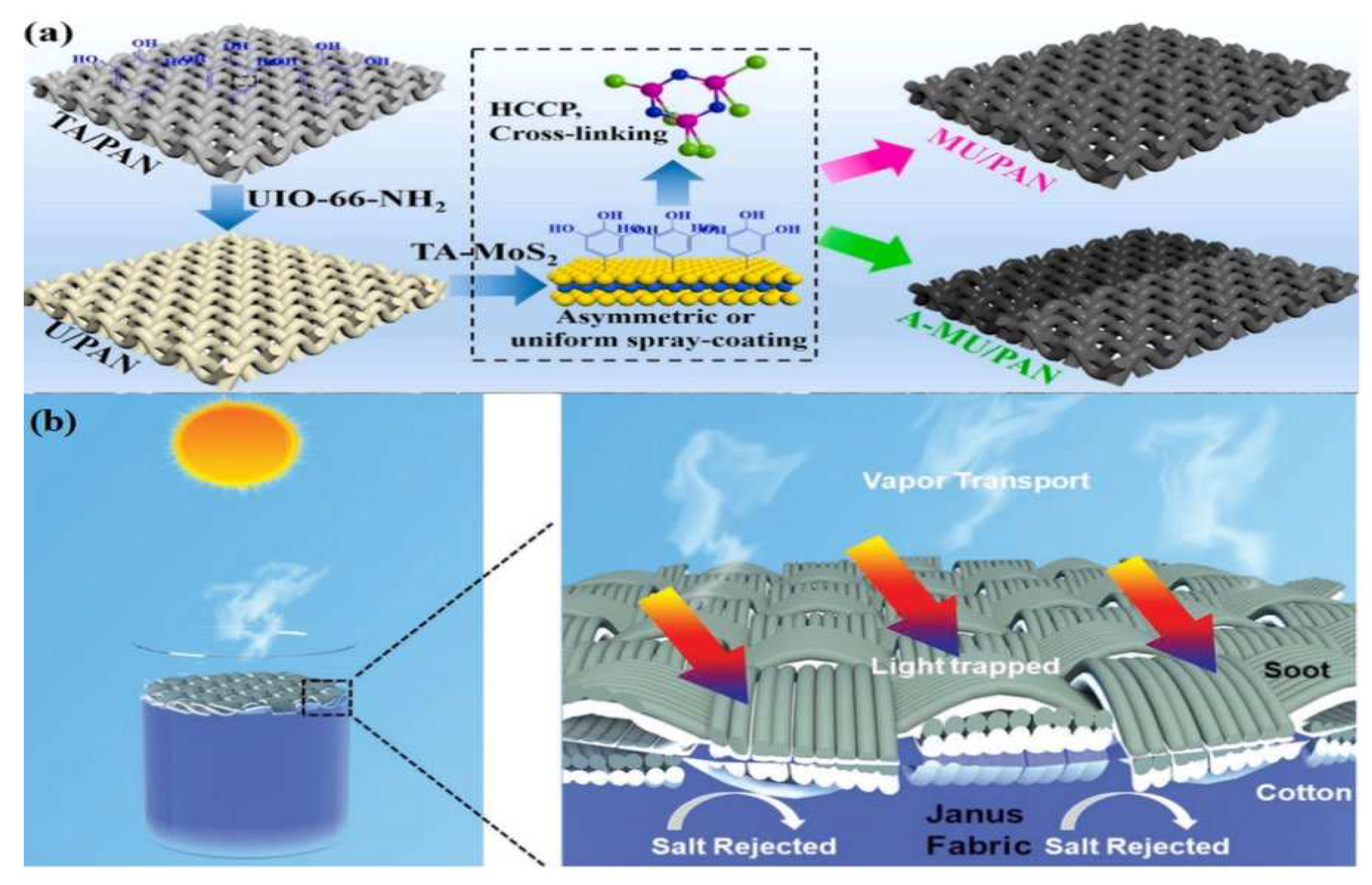

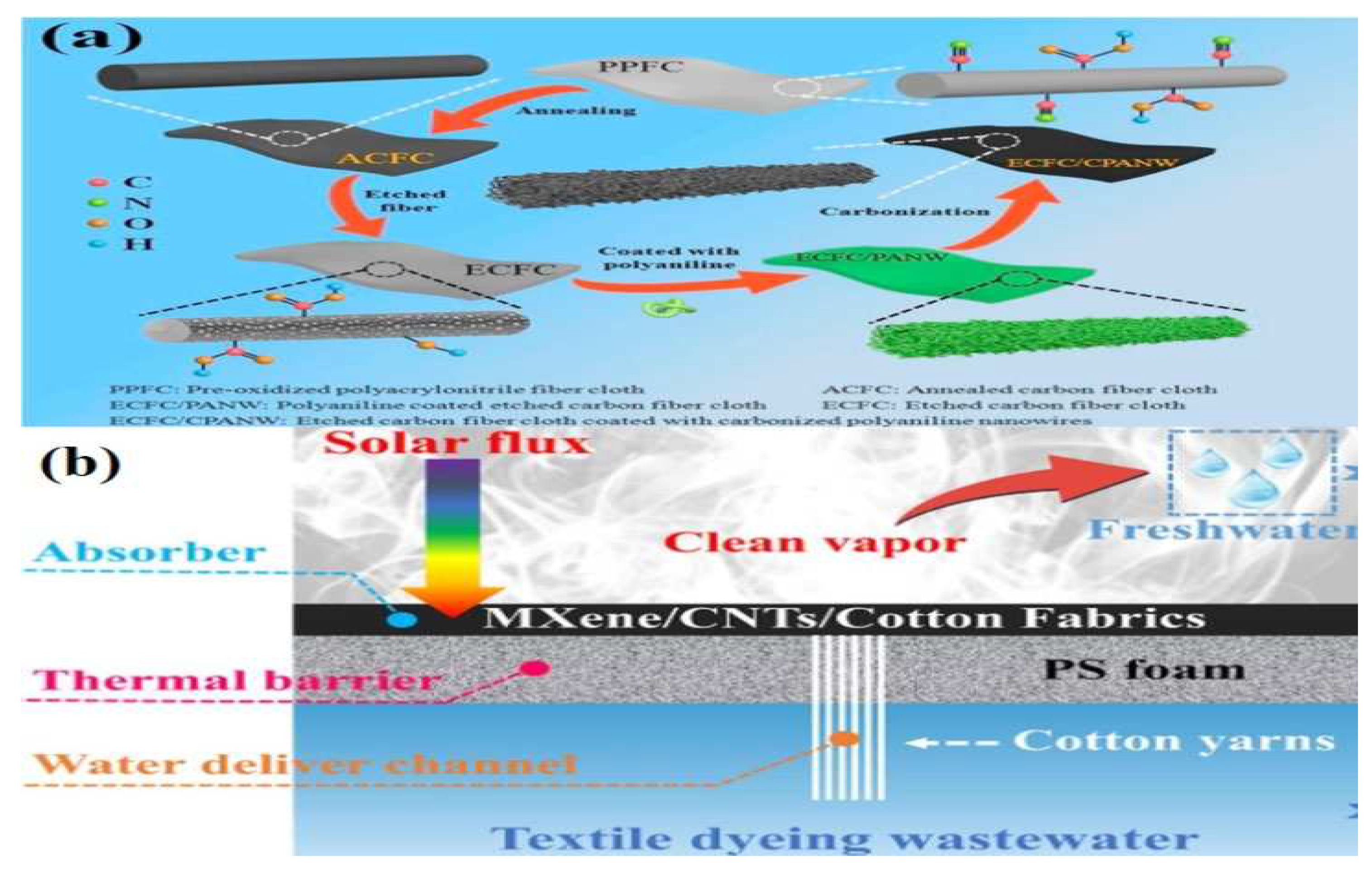

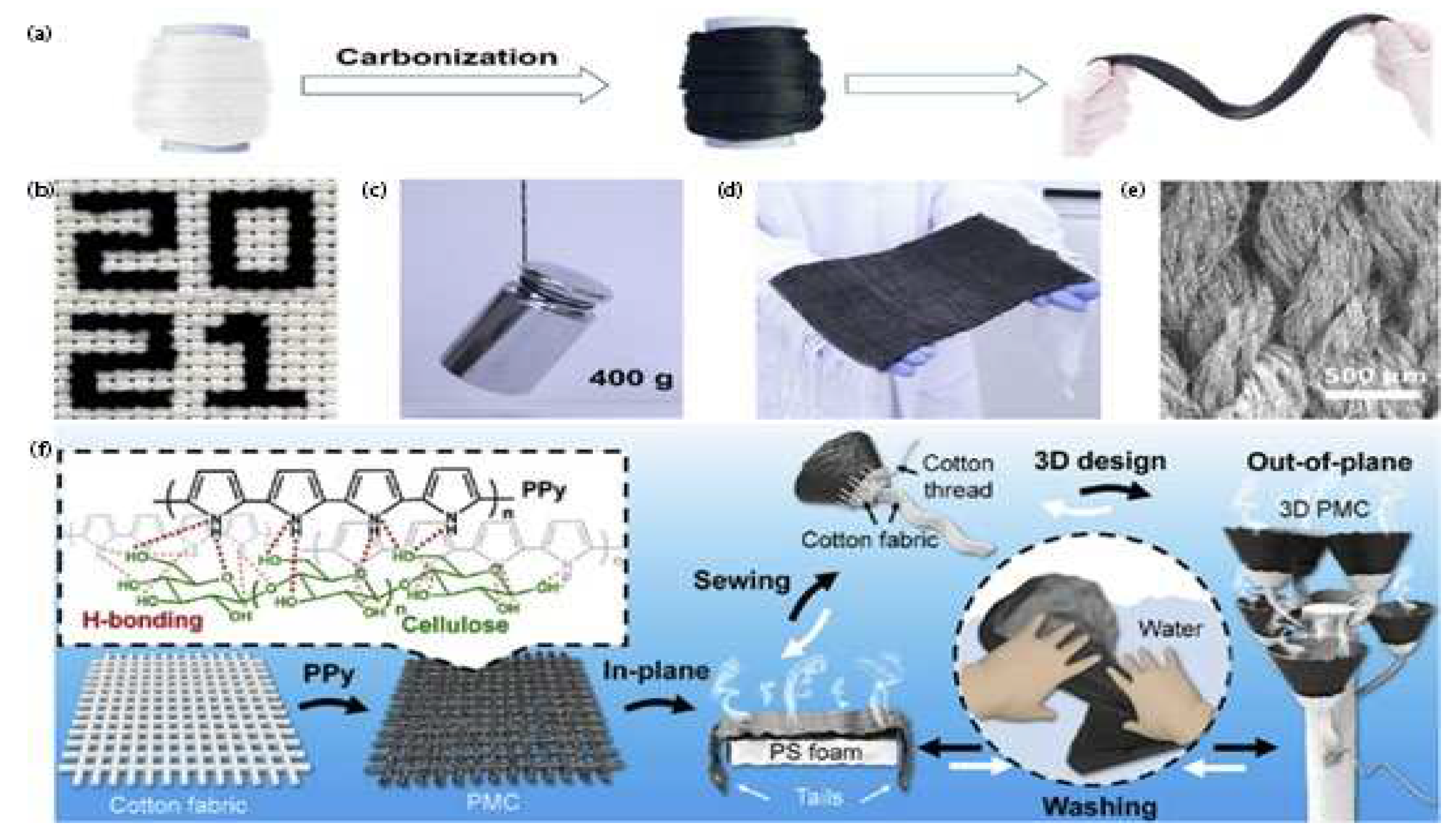

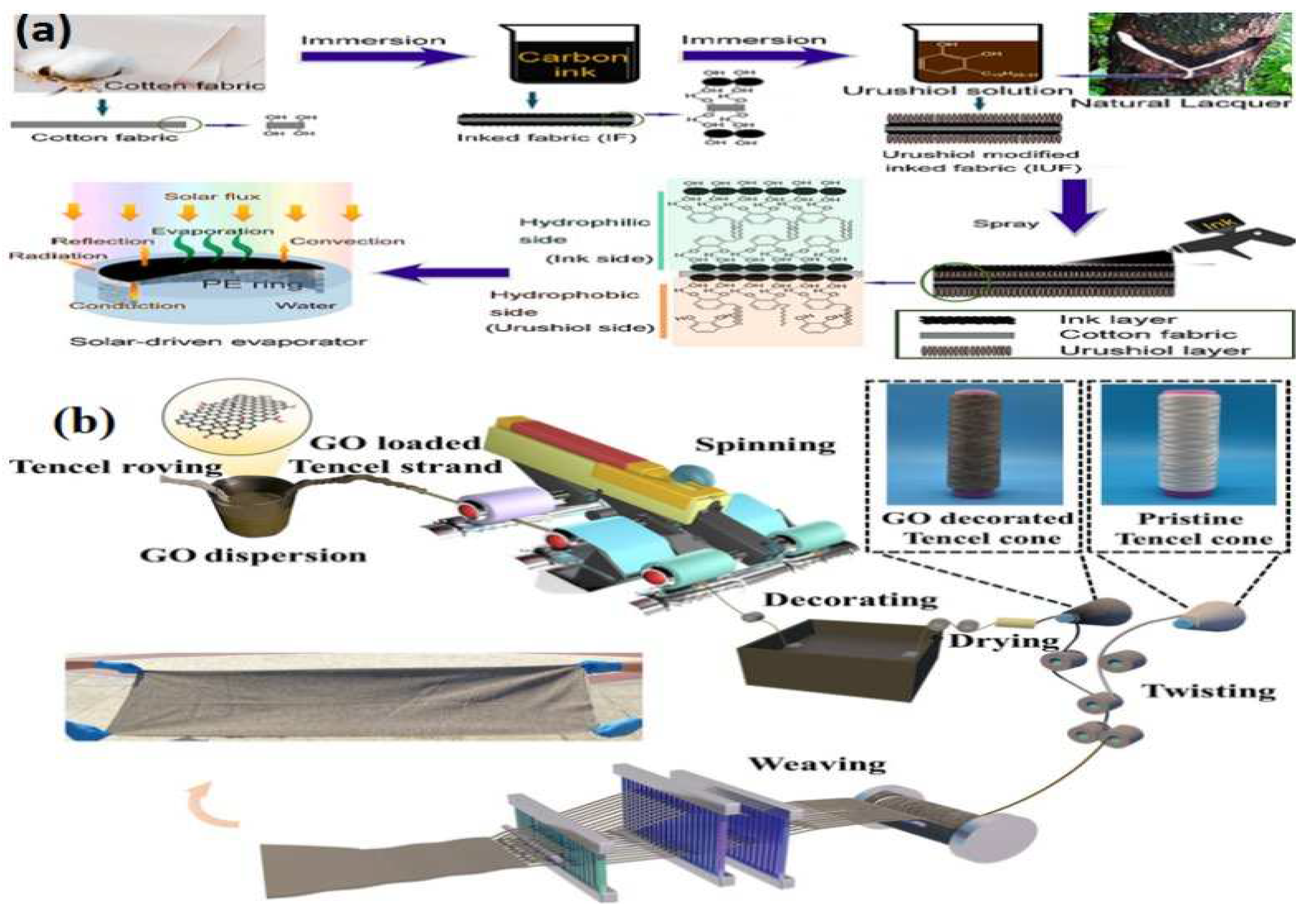

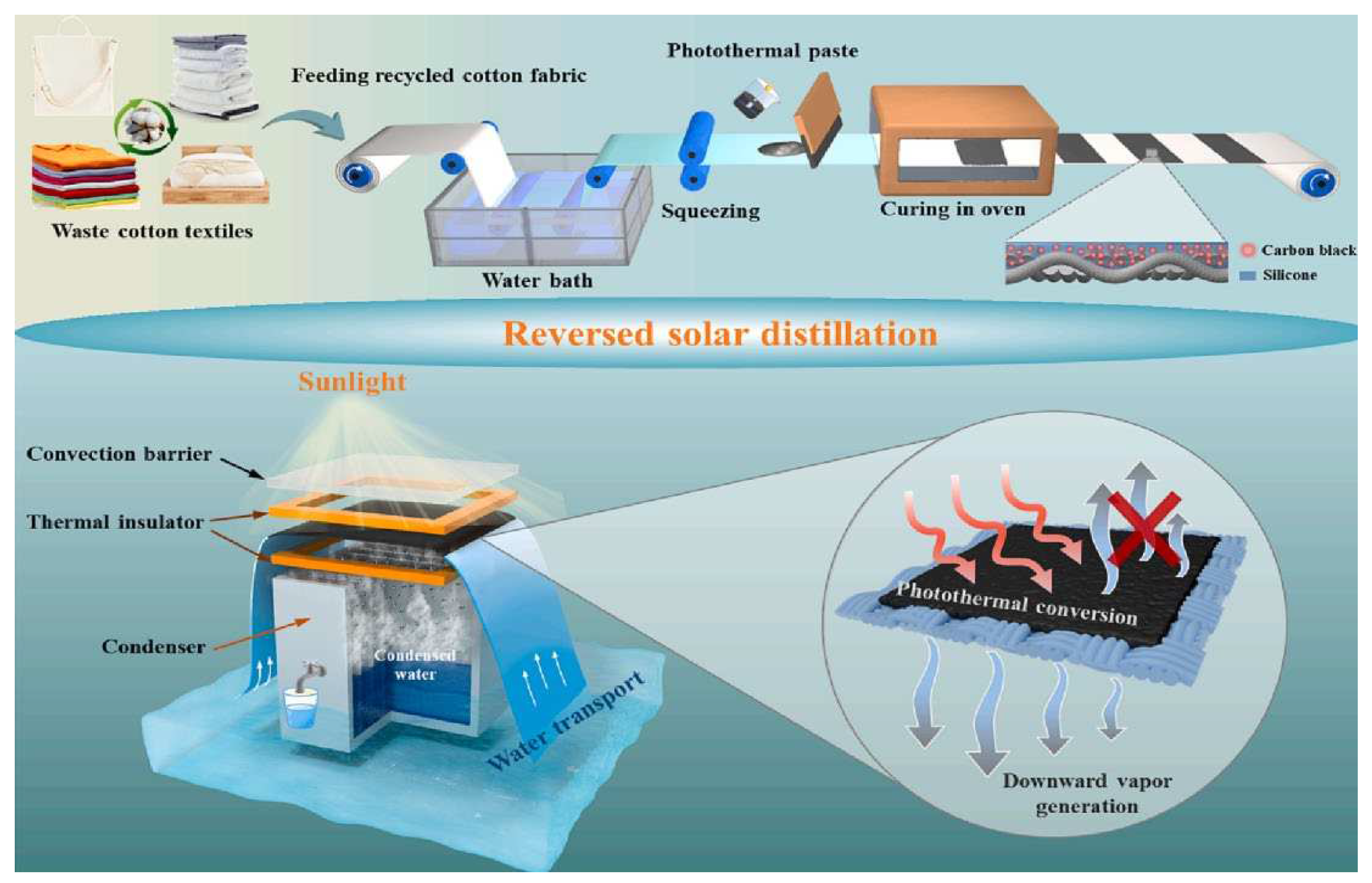

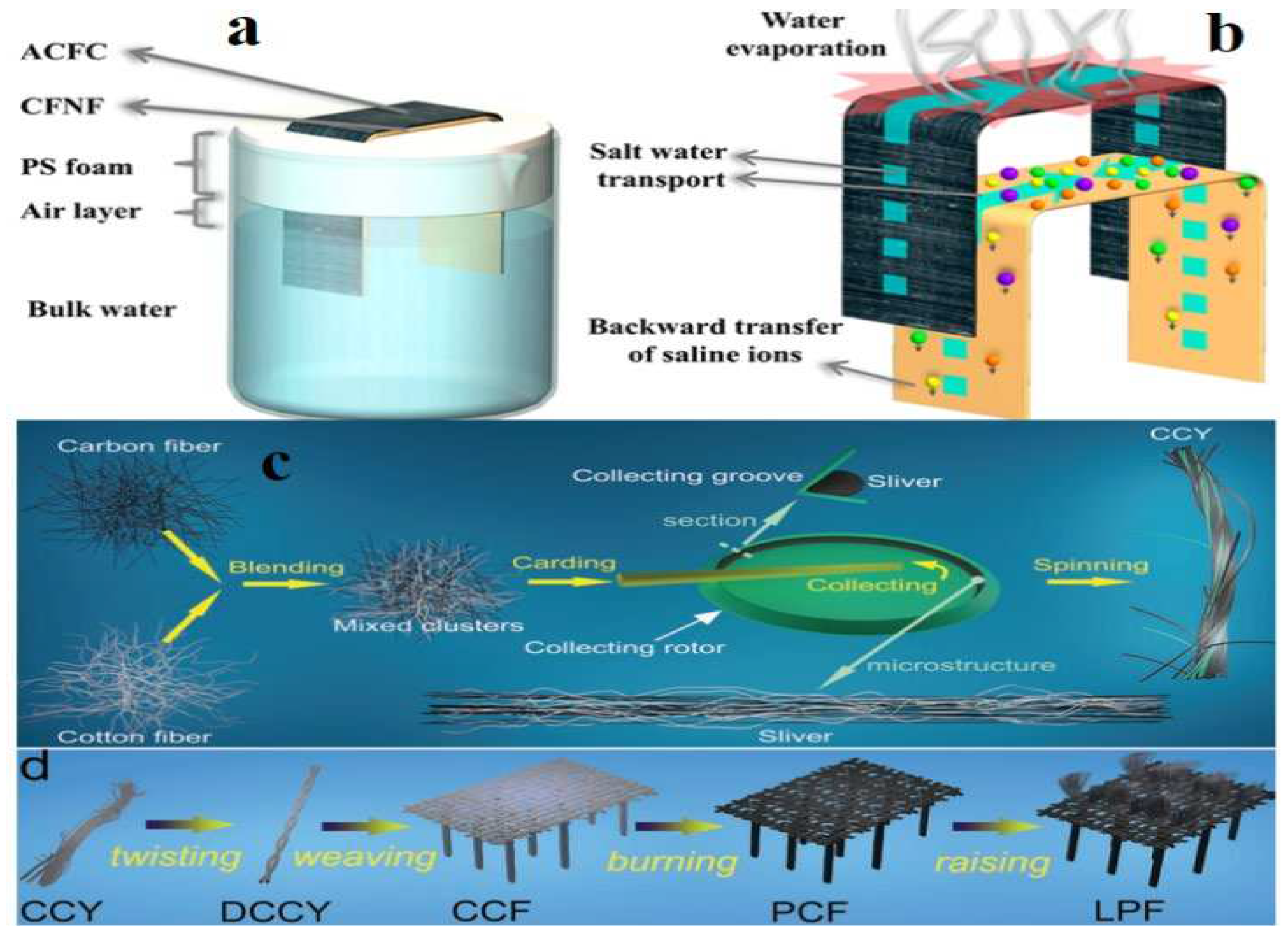

2.1. Woven Fabrics:

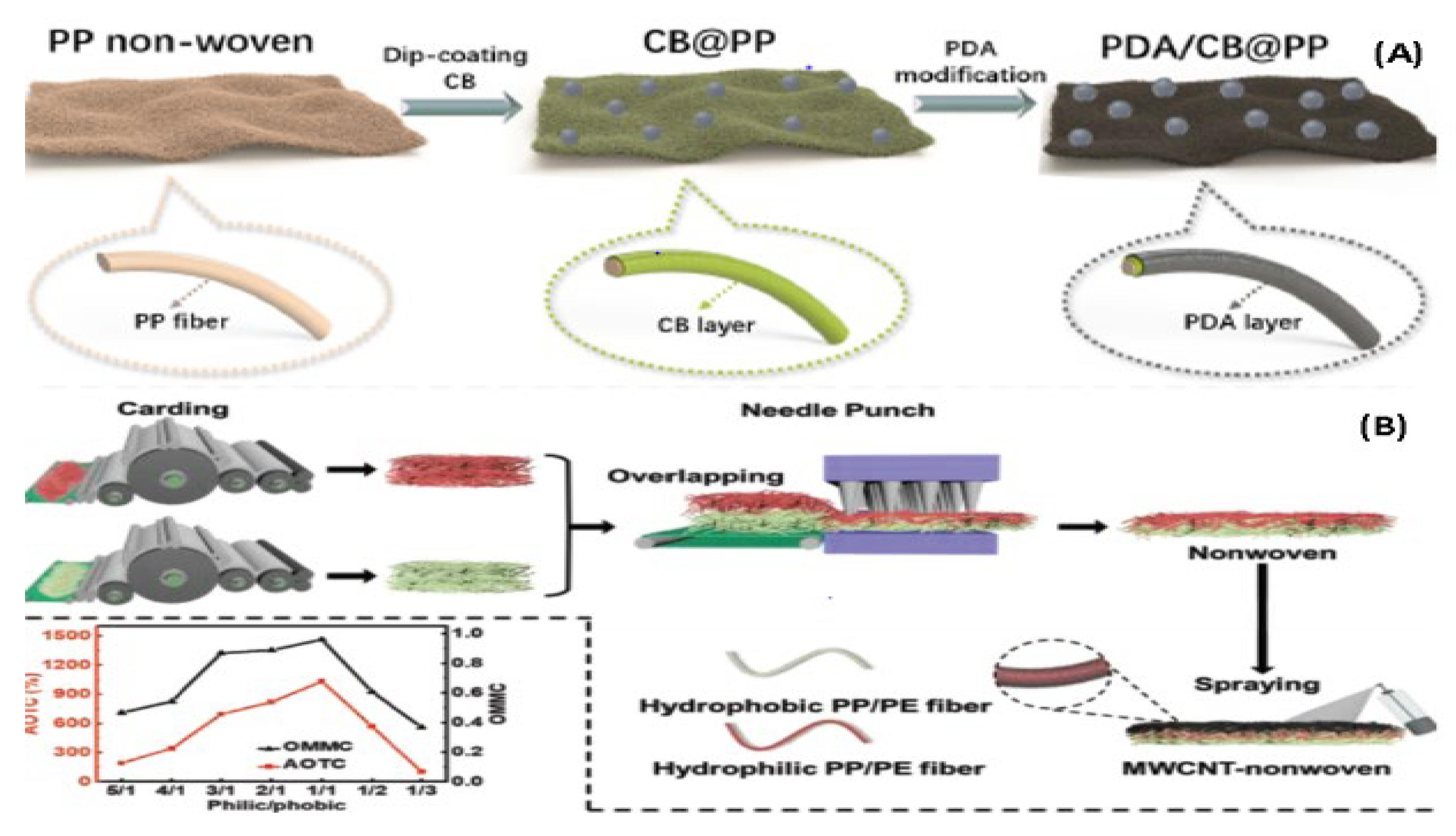

2.2. Non-Woven fabrics:

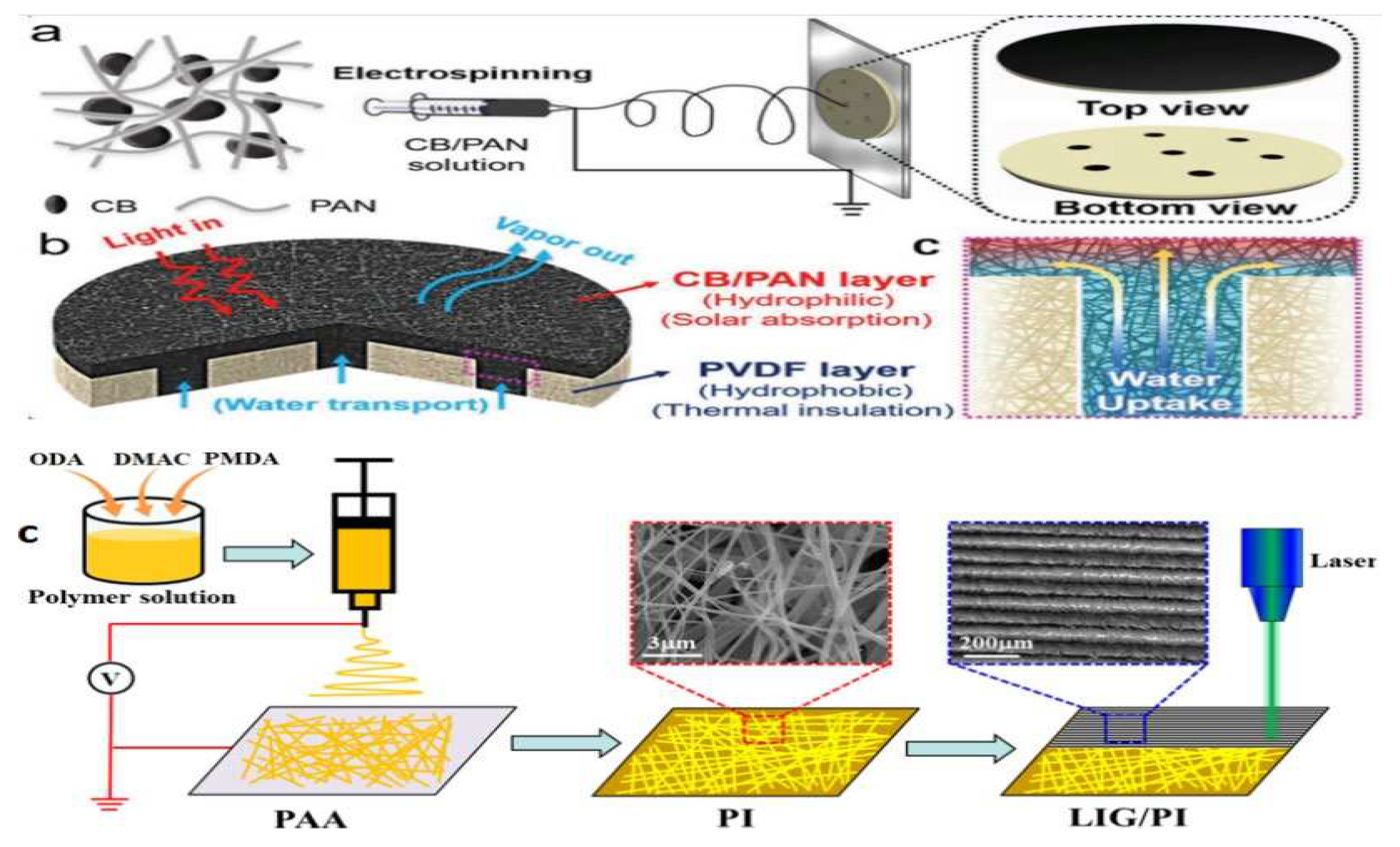

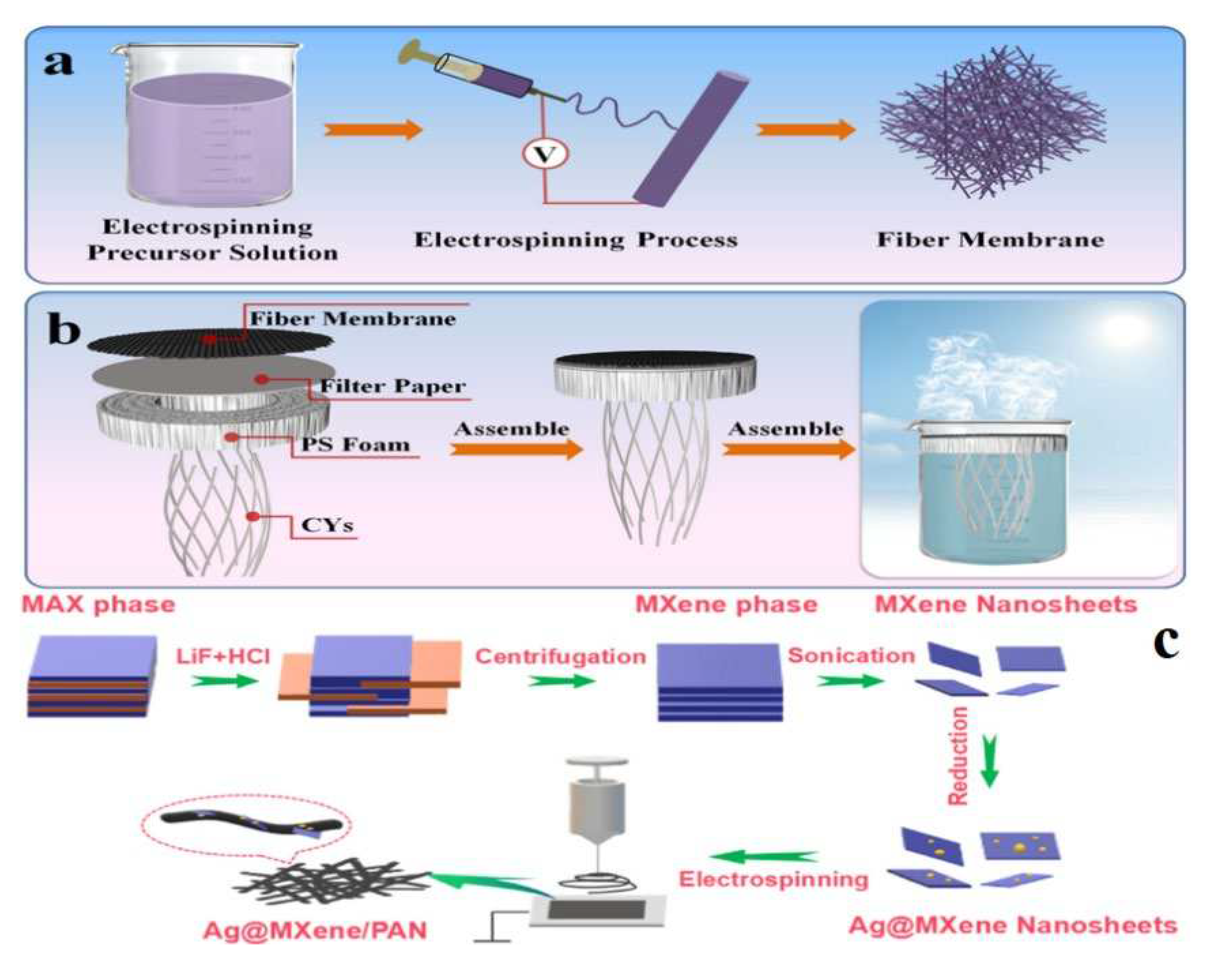

2.3. Electro-spun membranes:

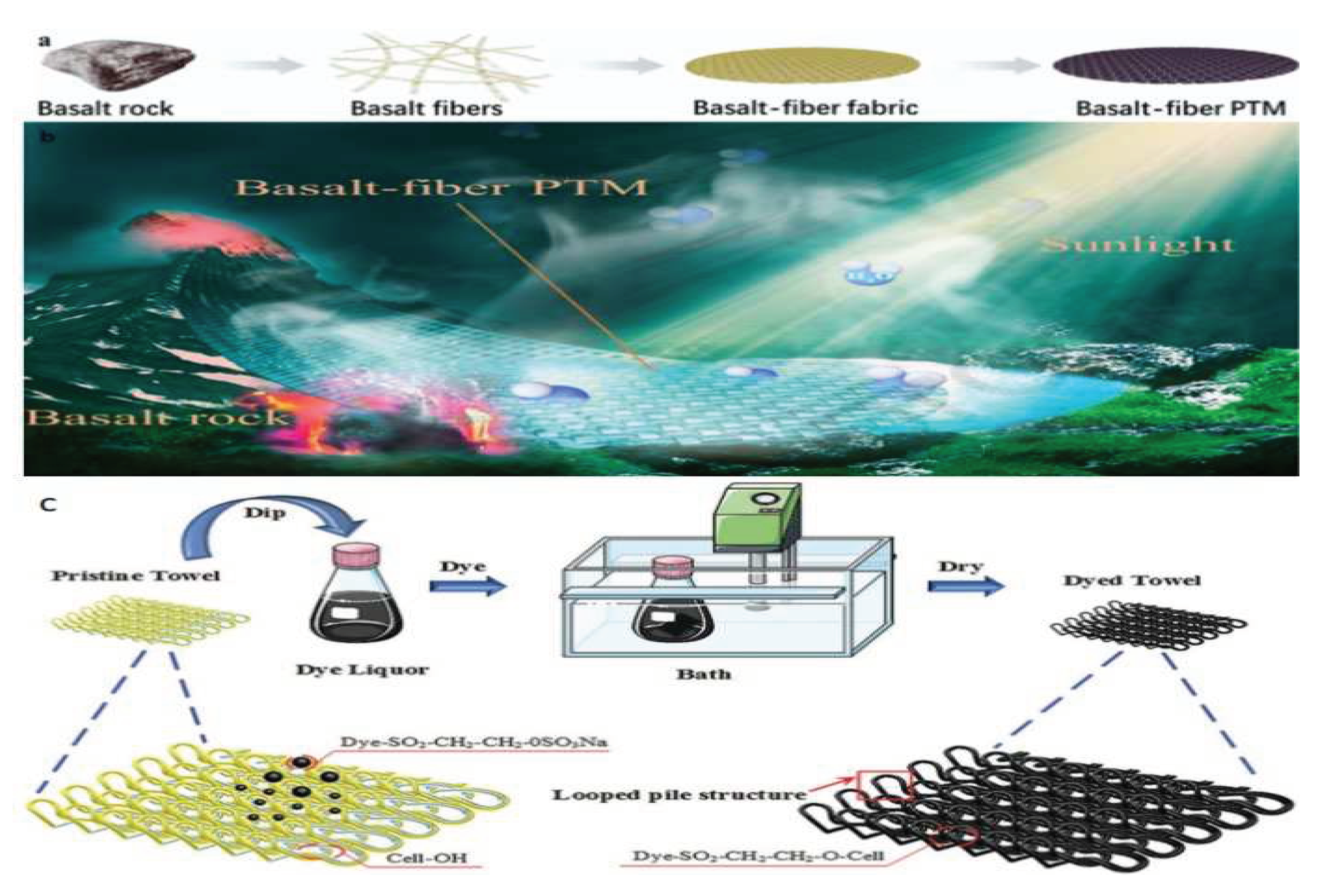

2.4. Knitting Fabrics:

3. Salt rejection and accumulation in textile materials based ISSG system:

4. The drawbacks and the challenges of textile materials-based ISSG devices:

- Scaling up: Many of the current solar interfacial evaporation techniques are still at the laboratory or small-scale prototype stage. Scaling up the technology to an industrial level presents challenges in terms of maintaining efficiency, cost-effectiveness, and system stability. Further research and development are needed to optimize the design and manufacturing processes for large-scale implementation.

- Adaptability: Solar interfacial evaporation systems need to be adaptable to various environmental conditions and water sources. Factors such as solar intensity, temperature variations, water quality, and impurities can affect the performance of the system. Developing adaptable and robust systems that can operate effectively under different conditions is essential.

- Stability and durability: Solar interfacial evaporation systems operate in harsh environments, including exposure to sunlight, saltwater, and other contaminants. The materials used in these systems should be stable, durable, and resistant to degradation over extended periods. Ensuring long-term stability is crucial for the practical and reliable operation of the technology.

- Integration with existing infrastructure: To facilitate widespread adoption, solar interfacial evaporation systems need to be compatible with existing water treatment and distribution infrastructure. Integration with existing systems, such as storage and distribution networks, would enable seamless implementation and utilization of the produced freshwater.

5. Future Prospects and Recommendations:

- Solar steam generation can be employed for desalination, wherein saltwater or brackish water is transformed into potable water via evaporation and condensation. Textile materials, such as woven or knitted with appropriate surface coatings, can be highly effective solar absorbers for capturing solar energy and producing steam for desalination. Due to their adaptability and capacity for expansion, they are well-suited for solar desalination processes on a wide scale.

- Textile materials can be employed in the production of solar steam generation systems. Textiles featuring sophisticated coatings or fibers modified for specific functions can be integral in constructing solar collectors, steam chambers, or heat transfer systems. Integrating textile manufacturing experience can improve the efficiency and performance of solar steam generation systems.

- Further gains can be achieved by ongoing research and innovation in textile materials and their utilization in solar steam generation. This encompasses the creation of innovative textile architectures, surface treatments, or substances with heightened sun absorption capabilities, enhanced heat conduction attributes, and augmented longevity. Textile-based solar steam-generating methods can be further enhanced by advancements in nanotechnology, intelligent fabrics, and improved manufacturing techniques.

- It is crucial to acknowledge that textile materials present promising opportunities for generating solar steam. However, there remain obstacles to address, including the need to enhance textile-based systems' efficiency, longevity, and adaptability. Additionally, ensuring stability over time in harsh environments and effectively integrating these systems into current structures pose significant considerations. Nevertheless, with continuous research and improvement endeavors, the utilization of textile materials in generating steam from solar energy is expected to broaden. This will aid in providing sustainable energy solutions and tackling worldwide issues related to water shortages, energy accessibility, and environmental sustainability.

6. Conclusions:

Acknowledgments

References

- Yan, J.; Su, Q.; Xiao, W.; Wu, Z.; Chen, L.; Tang, L.; Zheng, N.; Gao, J.; Xue, H. A review of nanofiber membranes for solar interface evaporation. Desalination. 2022, 531, 115686. [Google Scholar] [CrossRef]

- Li, H.; Wen, H.; Li, J.; Huang, J.; Wang, D.; Tang, B.Z. Doping AIE Photothermal Molecule into All-Fiber Aerogel with Self-Pumping Water Function for Efficiency Solar Steam Generation. ACS Appl. Mater. Interfaces. 2020, 12, 26033–26040. [Google Scholar] [CrossRef]

- Tessema, A.A.; Wu, C.-M.; Motora, K.G.; Naseem, S. Highly-efficient and salt-resistant CsxWO3@g-C3N4/PVDF fiber membranes for interfacial water evaporation, desalination, and sewage treatment. Compos. Sci. Technol. 2021, 211, 108865. [Google Scholar] [CrossRef]

- Gao, Z.; Yang, H.; Li, J.; Kang, L.; Wang, L.; Wu, J.; Guo, S. Simultaneous evaporation and decontamination of water on a novel membrane under simulated solar light irradiation. Appl. Catal. B 2020, 267, 118695. [Google Scholar] [CrossRef]

- Guo, X.; Gao, H.; Wang, S.; Yin, L.; Dai, Y. Scalable, flexible and reusable graphene oxide-functionalized electrospun nanofibrous membrane for solar photothermal desalination. Desalination. 2020, 488, 114535. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Guo, S.; Tan, S.C. Towards highly salt-rejecting solar interfacial evaporation: Photothermal materials selection, structural designs, and energy management. Nano Research Energy. 2022, 1, 9120014. [Google Scholar] [CrossRef]

- Lu, F.; Wu, S.-L.; Quan, L.-N.; Zhong, Z.-H.; Yang, H.-C.; Xue, M. Twisting two-dimensional photothermal sponges for boosting solar steam generation. J. Chem. Eng. 2023, 474, 145747. [Google Scholar] [CrossRef]

- Yang, Y.; Sui, Y.; Cai, Z.; Xu, B. Low-Cost and High-Efficiency Solar-Driven Vapor Generation Using a 3D Dyed Cotton Towel. Global chall. 2019, 3, 1900004. [Google Scholar] [CrossRef]

- Mei, T.; Chen, J.; Zhao, Q.; Wang, D. Nanofibrous aerogels with vertically aligned microchannels for efficient solar steam generation. ACS Appl. Mater. Interfaces. 2020, 12, 42686–42695. [Google Scholar] [CrossRef]

- Dong, X.; Si, Y.; Chen, C.; Ding, B.; Deng, H. Reed Leaves Inspired Silica Nanofibrous Aerogels with Parallel-Arranged Vessels for Salt-Resistant Solar Desalination. ACS Nano. 2021, 15, 12256–12266. [Google Scholar] [CrossRef]

- Dong, X.; Cao, L.; Si, Y.; Ding, B.; Deng, H. Cellular Structured CNTs@SiO2 Nanofibrous Aerogels with Vertically Aligned Vessels for Salt-Resistant Solar Desalination. Adv. Mater. 2020, 32, 1908269. [Google Scholar] [CrossRef]

- Zhang, W.; Xia, Y.; Wen, Z.; Han, W.; Wang, S.; Cao, Y.; He, R.X.; Liu, Y.; Chen, B. Enhanced adsorption-based atmospheric water harvesting using a photothermal cotton rod for freshwater production in cold climates. RSC Adv. 2021, 11, 35695–35702. [Google Scholar] [CrossRef]

- Chen, C.; Wang, M.; Chen, X.; Chen, X.; Fu, Q.; Deng, H. Recent progress in solar photothermal steam technology for water purification and energy utilization. J. Chem. Eng. 2022, 448, 137603. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, F.; Yu, Y.; Wu, J.; Cai, Y.; Shi, J.; Morikawa, H.; Zhu, C. Multi-bioinspired hierarchical integrated hydrogel for passive fog harvesting and solar-driven seawater desalination. J. Chem. Eng. 2023, 466, 143330. [Google Scholar] [CrossRef]

- Liu, X.; Mishra, D.D.; Wang, X.; Peng, H.; Hu, C. Towards highly efficient solar-driven interfacial evaporation for desalination. J. Mater. Chem. A. 2020, 8, 17907–17937. [Google Scholar] [CrossRef]

- Yan, J.; Xiao, W.; Chen, L.; Wu, Z.; Gao, J.; Xue, H. Superhydrophilic carbon nanofiber membrane with a hierarchically macro/meso porous structure for high performance solar steam generators. Desalination. 2021, 516, 115224. [Google Scholar] [CrossRef]

- Gao, C.; Zhu, J.; Bai, Z.; Lin, Z.; Guo, J. Novel ramie fabric-based draping evaporator for tunable water supply and highly efficient solar desalination. ACS Appl. Mater. Interfaces. 2021, 13, 7200–7207. [Google Scholar] [CrossRef]

- Wang, L.; Ma, Y.; Yang, G.; Li, X.; Liu, D.; Qin, S.; Lei, W. Asymmetric solar evaporator with salt-resistance capability for freshwater and energy generation. J. Chem. Eng. 2023, 472, 144761. [Google Scholar] [CrossRef]

- Wu, S.-L.; Chen, H.; Wang, H.-L.; Chen, X.; Yang, H.-C.; Darling, S.B. Solar-driven evaporators for water treatment: challenges and opportunities. Environmental Science: Environ. Sci. Water Res. 2021, 7, 24–39. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, X.; Li, C.; Peng, H.; Zhang, T.; Ye, M. A salt-rejecting solar evaporator for continuous steam generation. J. Environ. Chem. Eng. 2021, 9, 105010. [Google Scholar] [CrossRef]

- Qi, Q.; Wang, Y.; Wang, W.; Ding, X.; Yu, D. High-efficiency solar evaporator prepared by one-step carbon nanotubes loading on cotton fabric toward water purification. Sci. Total Environ. 2020, 698, 134136. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, J.; Zang, S.; Zhou, W.; Wang, Z.; Han, M.; Osman, S.M.; Wang, C.; Yamauchi, Y.; You, J.; et al. Multifunctional composite membranes for interfacial solar steam and electricity generation. J. Chem. Eng. 2023, 472, 144600. [Google Scholar] [CrossRef]

- Huang, H.; Zhao, L.; Yu, Q.; Lin, P.; Xu, J.; Yin, X.; Chen, S.; Wang, H.; Wang, L. Flexible and Highly Efficient Bilayer Photothermal Paper for Water Desalination and Purification: Self-Floating, Rapid Water Transport, and Localized Heat. ACS Appl. Mater. Interfaces. 2020, 12, 11204–11213. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, P.; Ni, F.; Yang, Y.; Gu, J.; Zhang, L.; Xia, J.; Huang, Y.; Wang, W.; Chen, T. Programmable Interface Asymmetric Integration of Carbon Nanotubes and Gold Nanoparticles toward Flexible, Configurable, and Surface-Enhanced Raman Scattering Active All-In-One Solar-Driven Evaporators. Energy Technol. 2019, 7, 1900787. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Wei, G.; Su, Z.J.C.E.J. All-weather photothermal-electrothermal integrated system for efficient solar steam generation. J. Chem. Eng. 2023, 458, 141520. [Google Scholar] [CrossRef]

- Li, W.; Tian, X.; Li, X.; Liu, J.; Li, C.; Feng, X.; Shu, C.; Yu, Z.-Z. An environmental energy-enhanced solar steam evaporator derived from MXene-decorated cellulose acetate cigarette filter with ultrahigh solar steam generation efficiency. J. Colloid Interface Sci. 2022, 606, 748–757. [Google Scholar] [CrossRef]

- Jiang, M.; Shen, Q.; Zhang, J.; An, S.; Ma, S.; Tao, P.; Song, C.; Fu, B.; Wang, J.; Deng, T.; et al. Bioinspired Temperature Regulation in Interfacial Evaporation. Adv. Funct. Mater. 2020, 30, 1910481. [Google Scholar] [CrossRef]

- Liu, H.; Alam, M.K.; He, M.; Liu, Y.; Wang, L.; Qin, X.; Yu, J. Sustainable Cellulose Aerogel from Waste Cotton Fabric for High-Performance Solar Steam Generation. ACS Appl. Mater. Interfaces. 2021, 13, 49860–49867. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, X.; Yi, C.; Jiang, H.; Liu, F.; Cheng, G.J. 3D-printed hierarchical porous cellulose/alginate/carbon black hydrogel for high-efficiency solar steam generation. J. Chem. Eng. 2022, 430, 132765. [Google Scholar] [CrossRef]

- Sun, S.; Sun, B.; Wang, Y.; Antwi-Afari, M.F.; Mi, H.-Y.; Guo, Z.; Liu, C.; Shen, C. Carbon black and polydopamine modified non-woven fabric enabling efficient solar steam generation towards seawater desalination and wastewater purification. Sep. Purif. Technol. 2021, 278, 119621. [Google Scholar] [CrossRef]

- Song, L.; Mu, P.; Geng, L.; Wang, Q.; Li, J. A Novel Salt-Rejecting Linen Fabric-Based Solar Evaporator for Stable and Efficient Water Desalination under Highly Saline Water. ACS Sustain. Chem. Eng. 2020, 8, 11845–11852. [Google Scholar] [CrossRef]

- Wu, X.; Robson, M.E.; Phelps, J.L.; Tan, J.S.; Shao, B.; Owens, G.; Xu, H. A flexible photothermal cotton-CuS nanocage-agarose aerogel towards portable solar steam generation. Nano Energy. 2019, 56, 708–715. [Google Scholar] [CrossRef]

- Liu, Z.; Zhong, Q.; Wu, N.; Zhou, H.; Wang, L.; Zhu, L.; Jiang, N.; Zhu, B.; Chen, Z.; Zhu, M. Vertically symmetrical evaporator based on photothermal fabrics for efficient continuous desalination through inversion strategy. Desalination. 2021, 509, 115072. [Google Scholar] [CrossRef]

- Kou, H.; Liu, Z.; Zhu, B.; Macharia, D.K.; Ahmed, S.; Wu, B.; Zhu, M.; Liu, X.; Chen, Z. Recyclable CNT-coupled cotton fabrics for low-cost and efficient desalination of seawater under sunlight. Desalination. 2019, 462, 29–38. [Google Scholar] [CrossRef]

- Li, H.; Yan, Z.; Li, Y.; Hong, W. Latest development in salt removal from solar-driven interfacial saline water evaporators: Advanced strategies and challenges. Water Res. 2020, 177, 115770. [Google Scholar] [CrossRef]

- Cao, P.; Yuan, P.; Zhao, L.; Yang, Z.; Zhang, Y.; Wang, B.; Cao, Y.; Yong, Z.; Niu, Y.; Zhang, J.; et al. Plant-inspired multi-environmentally adaptive, flexible, and washable solar steam generation fabric. J. Chem. Eng. 2023, 471, 144286. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, G.; Liu, Y.; Li, H.; Zhang, P.; Zhan, L.; Gao, R.; Huang, C. Low-cost, unsinkable, and highly efficient solar evaporators based on coating MWCNTs on nonwovens with unidirectional water-transfer. Adv. Sci. 2021, 8, 2101727. [Google Scholar] [CrossRef]

- Liang, P.; Liu, S.; Ding, Y.; Wen, X.; Wang, K.; Shao, C.; Hong, X.; Liu, Y. A self-floating electrospun nanofiber mat for continuously high-efficiency solar desalination. Chemosphere. 2021, 280, 130719. [Google Scholar] [CrossRef]

- Wu, X.; Wu, Z.; Wang, Y.; Gao, T.; Li, Q.; Xu, H. All-Cold Evaporation under One Sun with Zero Energy Loss by Using a Heatsink Inspired Solar Evaporator. Adv. Sci. 2021, 8, 2002501. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Wang, J.; Li, D.; Yu, K.; Jiang, Z. A Novel Flake-like Cu7S4 Solar Absorber for High-Performance Large-Scale Water Evaporation. ACS Appl. Energy Mater. 2019, 2, 5154–5161. [Google Scholar] [CrossRef]

- Jin, Y.; Chang, J.; Shi, Y.; Shi, L.; Hong, S.; Wang, P. A highly flexible and washable nonwoven photothermal cloth for efficient and practical solar steam generation. J. Mater. Chem. A. 2018, 6, 7942–7949. [Google Scholar] [CrossRef]

- Higgins, M.W.; Shakeel Rahmaan, A.R.; Devarapalli, R.R.; Shelke, M.V.; Jha, N. Carbon fabric based solar steam generation for waste water treatment. Sol. Energy 2018, 159, 800–810. [Google Scholar] [CrossRef]

- Jia, J.; Liang, W.; Sun, H.; Zhu, Z.; Wang, C.; Li, A. Fabrication of bilayered attapulgite for solar steam generation with high conversion efficiency. J. Chem. Eng. 2019, 361, 999–1006. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C. Enhanced solar evaporation efficiency based on the inserted preheating zone of silver nanowires. Sol. Energy 2020, 195, 304–309. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.; Wang, R.; Shou, W.; Wang, L.; Liu, Y. 3D tree-shaped hierarchical flax fabric for highly efficient solar steam generation. J. Mater. Chem. A. 2021, 9, 2248–2258. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Hu, L. Challenges and opportunities for solar evaporation. Joule. 2019, 3, 683–718. [Google Scholar] [CrossRef]

- Wang, F.; Wei, D.; Li, Y.; Chen, T.; Mu, P.; Sun, H.; Zhu, Z.; Liang, W.; Li, A. Chitosan/reduced graphene oxide-modified spacer fabric as a salt-resistant solar absorber for efficient solar steam generation. J. Mater. Chem. A. 2019, 7, 18311–18317. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; Hu, Y.; Wang, X. Commercially Available Activated Carbon Fiber Felt Enables Efficient Solar Steam Generation. ACS Appl. Mater. Interfaces. 2018, 10, 9362–9368. [Google Scholar] [CrossRef]

- Zhang, L.-Z.; Li, G.-P. Energy and economic analysis of a hollow fiber membrane-based desalination system driven by solar energy. Desalination. 2017, 404, 200–214. [Google Scholar] [CrossRef]

- Dao, V.D.; Choi, H.S. Carbon-based sunlight absorbers in solar-driven steam generation devices. Global chall. 2018, 2, 1700094. [Google Scholar] [CrossRef]

- Li, T.; Fang, Q.; Xi, X.; Chen, Y.; Liu, F. Ultra-robust carbon fibers for multi-media purification via solar-evaporation. J. Mater. Chem. A. 2019, 7, 586–593. [Google Scholar] [CrossRef]

- Meng, X.; Xu, W.; Li, Z.; Yang, J.; Zhao, J.; Zou, X.; Sun, Y.; Dai, Y. Coupling of hierarchical Al 2 O 3/TiO 2 nanofibers into 3D photothermal aerogels toward simultaneous water evaporation and purification. Adv. Fiber Mater. 2020, 2, 93–104. [Google Scholar] [CrossRef]

- Li, Y.; Jin, X.; Zheng, Y.; Li, W.; Zheng, F.; Wang, W.; Lin, T.; Zhu, Z. Tunable Water Delivery in Carbon-Coated Fabrics for High-Efficiency Solar Vapor Generation. ACS Appl. Mater. Interfaces. 2019, 11, 46938–46946. [Google Scholar] [CrossRef]

- Ge, C.; Xu, D.; Du, H.; Chen, Z.; Chen, J.; Shen, Z.; Xu, W.; Zhang, Q.; Fang, J. Recent advances in fibrous materials for interfacial solar steam generation. Adv. Fiber Mater. 2023, 5, 791–818. [Google Scholar] [CrossRef]

- Wu, T.; Li, H.; Xie, M.; Shen, S.; Wang, W.; Zhao, M.; Mo, X.; Xia, Y. Incorporation of gold nanocages into electrospun nanofibers for efficient water evaporation through photothermal heating. Mater. Today Energy 2019, 12, 129–135. [Google Scholar] [CrossRef]

- Chen, M.; Wu, Y.; Song, W.; Mo, Y.; Lin, X.; He, Q.; Guo, B. Plasmonic nanoparticle-embedded poly (p-phenylene benzobisoxazole) nanofibrous composite films for solar steam generation. Nanoscale. 2018, 10, 6186–6193. [Google Scholar] [CrossRef]

- Lin, X.; Yang, M.; Hong, W.; Yu, D.; Chen, X. Commercial Fiber Products Derived Free-Standing Porous Carbonized-Membranes for Highly Efficient Solar Steam Generation. Front. Mater. Sci. 2018, 5. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, Q.; Fan, J.; Wang, W.; Yu, D. Simple and robust MXene/carbon nanotubes/cotton fabrics for textile wastewater purification via solar-driven interfacial water evaporation. Sep. Purif. Technol. 2021, 254, 117615. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, B.; Liang, Y.; Yang, L.; Bai, L.; Yang, H.; Wei, D.; Wang, F.; Wang, Q.; Wang, W. Carbon nanofibers enhanced solar steam generation device based on loofah biomass for water purification. Mater. Chem. Phys. 2021, 258, 123998. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Q.; Chen, X. Porous Graphene/Polyimide Membrane with a Three-Dimensional Architecture for Rapid and Efficient Solar Desalination via Interfacial Evaporation. ACS Sustain. Chem. Eng. 2020, 8, 13850–13858. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, H.; Shan, X.; Di, Y.; Zhao, A.; Hu, Y.; Gan, Z. Solar steam generation based on the photothermal effect: from designs to applications, and beyond. J. Mater. Chem. A. 2019, 7, 19203–19227. [Google Scholar] [CrossRef]

- Liu, C.; Yin, Z.; Hou, Y.; Yin, C.; Yin, Z. Overview of Solar Steam Devices from Materials and Structures. Polymers. 2023, 15, 2742. [Google Scholar] [CrossRef]

- Zhong, J.; Huang, C.; Wu, D.; Lin, Z. Influence factors of the evaporation rate of a solar steam generation system: A numerical study. Int. J. Heat Mass Transf. 2019, 128, 860–864. [Google Scholar] [CrossRef]

- Li, Y.; Gao, T.; Yang, Z.; Chen, C.; Luo, W.; Song, J.; Hitz, E.; Jia, C.; Zhou, Y.; Liu, B.; et al. 3D-Printed, All-in-One Evaporator for High-Efficiency Solar Steam Generation under 1 Sun Illumination. Adv. Mater. 2017, 29, 1700981. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, V.; Ghasemi, H. Solar heat localization: concept and emerging applications. J. Mater. Chem. A. 2020, 8, 7035–7065. [Google Scholar] [CrossRef]

- Li, D.; Cheng, Y.; Luo, Y.; Teng, Y.; Liu, Y.; Feng, L.; Wang, N.; Zhao, Y. Electrospun Nanofiber Materials for Photothermal Interfacial Evaporation. Materials. 2023, 16, 5676. [Google Scholar] [CrossRef] [PubMed]

- Guan, W.; Guo, Y.; Yu, G. Carbon materials for solar water evaporation and desalination. Small. 2021, 17, 2007176. [Google Scholar] [CrossRef] [PubMed]

- Elsheikh, A.H.; Sharshir, S.W.; Ali, M.K.A.; Shaibo, J.; Edreis, E.M.; Abdelhamid, T.; Du, C.; Haiou, Z. Thin film technology for solar steam generation: A new dawn. Sol. Energy. 2019, 177, 561–575. [Google Scholar] [CrossRef]

- Wu, Z.; Sun, H.; Xu, Z.; Chi, H.; Li, X.; Wang, S.; Zhang, T.; Zhao, Y. Underwater Mechanically Tough, Elastic, Superhydrophilic Cellulose Nanofiber-Based Aerogels for Water-in-Oil Emulsion Separation and Solar Steam Generation. ACS Appl. Nano Mater. 2021, 4, 8979–8989. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, H.; Xiao, X.; Wang, H.; Yan, L.; Shi, Z.; Chen, Y.; Xu, W.; Wang, X. A new self-desalting solar evaporation system based on a vertically oriented porous polyacrylonitrile foam. J. Mater. Chem. A. 2019, 7, 14620–14628. [Google Scholar] [CrossRef]

- Fang, Q.; Li, T.; Lin, H.; Jiang, R.; Liu, F. Highly Efficient Solar Steam Generation from Activated Carbon Fiber Cloth with Matching Water Supply and Durable Fouling Resistance. ACS Appl. Energy Mater. 2019, 2, 4354–4361. [Google Scholar] [CrossRef]

- Hao, D.; Yang, Y.; Xu, B.; Cai, Z. Efficient solar water vapor generation enabled by water-absorbing polypyrrole coated cotton fabric with enhanced heat localization. Appl. Therm. Eng. 2018, 141, 406–412. [Google Scholar] [CrossRef]

- Wang, J.; Shi, Q.; Li, C.; Zhang, Y.; Du, S.; Mao, J.; Wang, J. Pistia-Inspired Photothermal Fabric based on Waste Carbon Fiber for Low-Cost Vapor Generation: An Industrialization Route. Adv. Funct. Mater. 2022, 32, 2201922. [Google Scholar] [CrossRef]

- Li, E.; Pan, Y.; Wang, C.; Liu, C.; Shen, C.; Pan, C.; Liu, X. Asymmetric superhydrophobic textiles for electromagnetic interference shielding, photothermal conversion, and solar water evaporation. ACS Appl. Mater. Interfaces. 2021, 13, 28996–29007. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, X.; Zhao, G.; Yang, H.; Cheng, H.; Qu, L.; Xu, W.; Wang, X. An all-in-one and scalable carbon fibre-based evaporator by using the weaving craft for high-efficiency and stable solar desalination. J. Mater. Chem. A. 2021, 9, 10945–10952. [Google Scholar] [CrossRef]

- Hu, N.; Xu, Y.; Liu, Z.; Liu, M.; Shao, X.; Wang, J. Double-layer cellulose hydrogel solar steam generation for high-efficiency desalination. Carbohydr. Polym. 2020, 243, 116480. [Google Scholar] [CrossRef]

- Zha, X.-J.; Zhao, X.; Pu, J.-H.; Tang, L.-S.; Ke, K.; Bao, R.-Y.; Bai, L.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. Flexible Anti-Biofouling MXene/Cellulose Fibrous Membrane for Sustainable Solar-Driven Water Purification. ACS Appl. Mater. Interfaces. 2019, 11, 36589–36597. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, X.; Liu, X.; He, Y.; Balakin, B.V. Enhanced interfacial solar steam generation with composite reduced graphene oxide membrane. Sol. Energy. 2019, 194, 415–430. [Google Scholar] [CrossRef]

- Zhu, B.; Kou, H.; Liu, Z.; Wang, Z.; Macharia, D.K.; Zhu, M.; Wu, B.; Liu, X.; Chen, Z. Flexible and washable CNT-embedded PAN nonwoven fabrics for solar-enabled evaporation and desalination of seawater. ACS Appl. Mater. Interfaces. 2019, 11, 35005–35014. [Google Scholar] [CrossRef]

- Cai, G.; Xu, Z.; Yang, M.; Tang, B.; Wang, X. Functionalization of cotton fabrics through thermal reduction of graphene oxide. Appl. Surf. Sci. 2017, 393, 441–448. [Google Scholar] [CrossRef]

- He, M.; Dai, H.; Liu, H.; Cai, Q.; Liu, Y.; Wang, L.; Qin, X.; Yu, J. High-performance solar steam generator based on polypyrrole-coated fabric via 3D macro-and microstructure design. ACS Appl. Mater. Interfaces. 2021, 13, 40664–40672. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, W.; Feng, L.; Yang, J.; Li, W.; Shi, J.; Lei, T.; Wang, C. A salt-free superhydrophilic metal-organic framework photothermal textile for portable and efficient solar evaporator. Sol. Energy Mater Sol. Cells. 2021, 231, 111329. [Google Scholar] [CrossRef]

- Peng, H.; Wang, D.; Fu, S. Artificial transpiration with asymmetric photothermal textile for continuous solar-driven evaporation, spatial salt harvesting and electrokinetic power generation. J. Chem. Eng. 2021, 426, 131818. [Google Scholar] [CrossRef]

- Gao, S.; Dong, X.; Huang, J.; Dong, J.; Maggio, F.D.; Wang, S.; Guo, F.; Zhu, T.; Chen, Z.; Lai, Y. Bioinspired Soot-Deposited Janus Fabrics for Sustainable Solar Steam Generation with Salt-Rejection. Global chall. 2019, 3, 1800117. [Google Scholar] [CrossRef]

- Qin, Z.; Sun, H.; Tang, Y.; Yin, S.; Yang, L.; Xu, M.; Liu, Z. Bioinspired Hydrophilic-Hydrophobic Janus Composites for Highly Efficient Solar Steam Generation. ACS Appl. Mater. Interfaces. 2021, 13, 19467–19475. [Google Scholar] [CrossRef]

- Wang, K.; Huo, B.; Liu, F.; Zheng, Y.; Zhang, M.; Cui, L.; Liu, J. In situ generation of carbonized polyaniline nanowires on thermally-treated and electrochemically-etched carbon fiber cloth for high efficient solar seawater desalination. Desalination. 2020, 481, 114303. [Google Scholar] [CrossRef]

- Qi, P.; Ren, J.; Ling, S. Animal Silk-Derived Amorphous Carbon Fibers for Electricity Generation and Solar Steam Evaporation. Front. Chem. 2021, 9. [Google Scholar] [CrossRef]

- Xiao, P.; Gu, J.; Zhang, C.; Ni, F.; Liang, Y.; He, J.; Zhang, L.; Ouyang, J.; Kuo, S.-W.; Chen, T. A scalable, low-cost and robust photo-thermal fabric with tunable and programmable 2D/3D structures towards environmentally adaptable liquid/solid-medium water extraction. Nano Energy. 2019, 65, 104002. [Google Scholar] [CrossRef]

- Bai, W.; Zhang, X.; Chen, Y.; Lian, Z.; Zheng, S.; Chen, X.; Lin, Y.; Jian, R. Environmental-friendly biomass-based Janus ink/urushiol modified cotton fabric for efficient solar-driven interfacial evaporation. J. Chem. Eng. 2023, 476, 146784. [Google Scholar] [CrossRef]

- Du, H.; Ge, C.; Xu, D.; Qian, Y.; Chen, Z.; Gao, C.; Song, B.; Shen, Z.; Chen, J.; Liu, K.; et al. Multifunctional woven fabric for integrated solar-driven water generation and personal thermal management. Cellulose. 2023, 30, 9207–9220. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, B.; Li, J.; Chen, Y.; Wang, Q.; Mao, J.; Guo, J. Reversed vapor generation with Janus fabric evaporator and comprehensive thermal management for efficient interfacial solar distillation. J. Chem. Eng. 2023, 463, 142002. [Google Scholar] [CrossRef]

- Wu, D.; Liang, J.; Zhang, D.; Zhang, C.; Zhu, H. Solar evaporation and electricity generation of porous carbonaceous membrane prepared by electrospinning and carbonization. Sol. Energy Mater. Sol. Cells. 2020, 215, 110591. [Google Scholar] [CrossRef]

- Fan, X.; Lv, B.; Xu, Y.; Huang, H.; Yang, Y.; Wang, Y.; Xiao, J.; Song, C. Electrospun reduced graphene oxide/polyacrylonitrile membrane for high-performance solar evaporation. Solar Energy. 2020, 209, 325–333. [Google Scholar] [CrossRef]

- Tessema, A.A.; Wu, C.-M.; Motora, K.G.; Naseem, S. Highly-efficient and salt-resistant CsxWO3@ g-C3N4/PVDF fiber membranes for interfacial water evaporation, desalination, and sewage treatment. Compos Sci Technol. 2021, 211, 108865. [Google Scholar] [CrossRef]

- Ding, Q.; Guan, C.; Li, H.; Shi, M.; Yang, W.; Yan, H.; Zuo, X.; An, Y.; Ramakrishna, S.; Mohankumar, P. Solar-driven interfacial evaporation based on double-layer polylactic acid fibrous membranes loading Chinese ink nanoparticles. Solar Energy. 2020, 195, 636–643. [Google Scholar] [CrossRef]

- Waisi, B.I.; Manickam, S.S.; Benes, N.E.; Nijmeijer, A.; McCutcheon, J.R. Activated Carbon Nanofiber Nonwovens: Improving Strength and Surface Area by Tuning Fabrication Procedure. Ind. Eng. Chem. Res. 2019, 58, 4084–4089. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Xiong, J.; Li, A.; Wang, R.; Wang, L.; Qin, X.; Yu, J. Bioinspired design of electrospun nanofiber based aerogel for efficient and cost-effective solar vapor generation. J. Chem. Eng. 2022, 427, 131539. [Google Scholar] [CrossRef]

- Gao, T.; Li, Y.; Chen, C.; Yang, Z.; Kuang, Y.; Jia, C.; Song, J.; Hitz, E.M.; Liu, B.; Huang, H.; et al. Architecting a Floatable, Durable, and Scalable Steam Generator:Hydrophobic/Hydrophilic Bifunctional Structure for Solar Evaporation Enhancement. Small Methods. 2019, 3, 1800176. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Wang, L.; Qin, X.; Yu, J. Nanofiber based origami evaporator for multifunctional and omnidirectional solar steam generation. Carbon. 2021, 177, 199–206. [Google Scholar] [CrossRef]

- Qi, Q.; Wang, W.; Wang, Y.; Yu, D. Robust light-driven interfacial water evaporator by electrospinning SiO2/MWCNTs-COOH/PAN photothermal fiber membrane. Sep. Purif. Technol. 2020, 239, 116595. [Google Scholar] [CrossRef]

- Liu, Y.; Xiong, J.; Li, A.; Wang, R.; Wang, L.; Qin, X. Plasmonic silver nanoparticle-decorated electrospun nanofiber membrane for interfacial solar vapor generation. Text. Res. J. 2021, 91, 2624–2634. [Google Scholar] [CrossRef]

- Xu, W.; Hu, X.; Zhuang, S.; Wang, Y.; Li, X.; Zhou, L.; Zhu, S.; Zhu, J. Flexible and salt resistant Janus absorbers by electrospinning for stable and efficient solar desalination. Adv. Energy Mater. 2018, 8, 1702884. [Google Scholar] [CrossRef]

- Zang, L.; Sun, L.; Zhang, S.; Finnerty, C.; Kim, A.; Ma, J.; Mi, B. Nanofibrous hydrogel-reduced graphene oxide membranes for effective solar-driven interfacial evaporation and desalination. J. Chem. Eng. 2021, 422, 129998. [Google Scholar] [CrossRef]

- Wan, P.; Gu, X.; Ouyang, X.; Shi, S.; Deng, B.; Liu, J.; Chu, P.K.; Yu, X.-F. A versatile solar-powered vapor generating membrane for multi-media purification. Sep. Purif. Technol. 2021, 260, 117952. [Google Scholar] [CrossRef]

- He, M.; Alam, M.K.; Liu, H.; Zheng, M.; Zhao, J.; Wang, L.; Liu, L.; Qin, X.; Yu, J. Textile waste derived cellulose based composite aerogel for efficient solar steam generation. Comp. Comm. 2021, 28, 100936. [Google Scholar] [CrossRef]

- Mao, N.; Russell, S.J.; Pourdeyhimi, B. Chapter 12 - Characterisation, testing, and modelling of nonwoven fabrics, in Handbook of Nonwovens (Second Edition), S.J. Russell, Editor. 2022, Woodhead Publishing. p. 509-626.

- Zhang, C.; Shi, Y.; Shi, L.; Li, H.; Li, R.; Hong, S.; Zhuo, S.; Zhang, T.; Wang, P. Designing a next generation solar crystallizer for real seawater brine treatment with zero liquid discharge. Nat. Commun. 2021, 12, 998. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, P.; Ni, F.; Gu, J.; Chen, J.; Nie, Y.; Kuo, S.-W.; Chen, T. Breathable and superhydrophobic photothermic fabric enables efficient interface energy management via confined heating strategy for sustainable seawater evaporation. J. Chem. Eng. 2022, 428, 131142. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, G.; Ming, X.; Mei, T.; Wang, J.; Li, J.; Qian, J.; Wang, X. PEGylated Self-Growth MoS2 on a Cotton Cloth Substrate for High-Efficiency Solar Energy Utilization. ACS Appl. Mater. Interfaces. 2018, 10, 24583–24589. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wu, B.; Zhu, B.; Chen, Z.; Zhu, M.; Liu, X. Continuously Producing Watersteam and Concentrated Brine from Seawater by Hanging Photothermal Fabrics under Sunlight. Adv. Funct. Mater. 2019, 29, 1905485. [Google Scholar] [CrossRef]

- Wang, H.; Yao, L.; Zhang, M.; Xu, R.; Ye, F.; Zhu, K.; Wang, H.; Zuo, H.; Ruan, F.; Feng, Q. In-Situ polymerized polypyrrole Janus cotton fabric for Solar-driven water evaporation in Textile-dying wastewater. Mater. Lett. 2023, 341, 134299. [Google Scholar] [CrossRef]

- Zhang, H.; Ou, J.; Fang, X.; Lei, S.; Wang, F.; Li, C.; Li, W.; Hu, Y.; Amirfazli, A.; Wang, P. Robust superhydrophobic fabric via UV-accelerated atmospheric deposition of polydopamine and silver nanoparticles for solar evaporation and water/oil separation. J. Chem. Eng. 2022, 429, 132539. [Google Scholar] [CrossRef]

- Irshad, M.S.; Wang, X.; Abbas, A.; Yu, F.; Li, J.; Wang, J.; Mei, T.; Qian, J.; Wu, S.; Javed, M.Q. Salt-resistant carbon dots modified solar steam system enhanced by chemical advection. Carbon. 2021, 176, 313–326. [Google Scholar] [CrossRef]

- Chen, F.; Xu, L.; Tian, Y.; Caratenuto, A.; Liu, X.; Zheng, Y. Electrospun Polycaprolactone Nanofiber Composites with Embedded Carbon Nanotubes/Nanoparticles for Photothermal Absorption. ACS Appl. Nano Mater. 2021, 4, 5230–5239. [Google Scholar] [CrossRef]

- Li, A.; Xiong, J.; Liu, Y.; Wang, L.; Qin, X.; Yu, J. Fiber-intercepting-particle structured MOF fabrics for simultaneous solar vapor generation and organic pollutant adsorption. J. Chem. Eng. 2022, 428, 131365. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, Y.; Xu, X.; Wang, Y. Bilayer fiber membrane electrospun from MOF derived Co3S4 and PAN for solar steam generation induced sea water desalination. J. Solid State Chem. 2021, 303, 122423. [Google Scholar] [CrossRef]

| Textile Material | Materials |

Efficiency (%) Under 1 sun |

Evaporation rate (kg m−2 h−1) |

Ref. |

| Woven fabrics | ||||

| PDA/PPy nanofibers/ flax fabric | 87.40 | 1.37 | [45] | |

| carbon fiber/cotton yarns | 83.70 | 1.87 | [75] | |

| MXene/ PET fabric | 80.00 | 1.22 | [74] | |

| Grapheme oxide /spacer fabric | 86.00 | 1.43 | [47] | |

| VPPyNWs-fabric | 98.56 | 2.32 | [81] | |

| CB/SA/ramie fabric | 96.60 | 1.81 | [17] | |

| CNTs/cotton fabrics | 95.70 | 1.59 | [34] | |

| MXene/CNT/Cotton fabric | 88.20 | 1.35 | [58] | |

| carbon black/cotton fabric | 88.90 | 1.33 | [53] | |

| CsxWO3 ink/cotton fabric | 86.80 | 1.56 | [33] | |

| Candle soot/ Linen fabric | 90.00 | 1.44 | [31] | |

| Cu/polyester textile | 88.00 | 1.52 | [82] | |

| MU/PAN textile | 89.20 | 1.36 | [83] | |

| Nafion coating/(cotton cloth-NCC) | 89.90 | 1.52 | [85] | |

| Polyester/cotton Janus fabric | 86.30 | 1.37 | [84] | |

| polypyrrole fabric/PSHF | 91.68 | 1.49 | [108] | |

| TiO2 nanorods/Carbon Fabric | 93.00 | 1.42 | [42] | |

| PPy/cotton fabric | 82.99 | 1.20 | [72] | |

| carbon fiber cloth/PAN fiber cloth | 93.70 | 1.43 | [86] | |

| RGO/cotton fabric | N/A | 1.47 | [70] | |

| Au-CNTs /cotton fabric | N/A | 2.19 | [24] | |

| MXene/CNTs/cotton fabric | 88.20 | 1.35 | [58] | |

| MXene/cotton fabric | 83.10 | 1.38 | [69] | |

| MWCNTs -COOH/ cotton fabric | 86.0 1 | 1.18 | [21] | |

| PEGylated MoS2/cotton fabric | 80.50 | 1.30 | [109] | |

| PPy/cotton fabric | N/A | 1.54 | [88] | |

| Carbon/cotton composite fabrics | 82.00 | 1.25 | [87] | |

| Polyaniline/cotton fabrics | 89.90 | 1.94 | [110] | |

| Janus ink/urushiol cotton fabric | 94.30 | 1.64 | [89] | |

| Polypyrrole/Janus cotton fabric | 91.00 | 1.45 | [111] | |

| Polyacrylonitrile/waste carbon fiber | 88.70 | 1.50 | [73] | |

| Graphene oxide/composite Tencel (GOT) fabric | 90.40 | 1.33 | [90] | |

| (Ag NPs)/cotton fabric | 91.00 | 1.66 | [112] | |

| Non-woven fabrics | ||||

| PDA/CB@PP non-woven fabric | 91.50 | 1.68 | [30] | |

| CNT/ polyacrylonitrile nonwoven fabrics | 90.80 | 1.44 | [79] | |

| PP/PE nonwoven/ MWCNTs. | 89.70 | 1.44 | [37] | |

| carbon black/ nylon fabric | 83.00 | 1.24 | [41] | |

| Carbon fiber/Cotton fiber nonwoven fabric | 93.30 | 1.59 | [71] | |

| MnCDs@PPy/non-woven cotton fabric | 96.40 | 1.68 | [113] | |

| Electro-spun membranes | ||||

| CB/PAN//PVDF composite layer | 82.00 | 1.20 | [98] | |

| Graphene/polyimide LIG/PI membrane | 92.55 | 1.42 | [60] | |

| PAN/CNTs nanofiber | 94.50 | 2.13 | [97] | |

| CNP/PCL nanofiber composites | N/A | 1.95 | [114] | |

| CNT/PCL nanofiber composites | N/A | 2.00 | [114] | |

| FIP-PZ/MOF fabrics | 94.20 | 1.50 | [115] | |

| Ag@MXene/PAN nanofiber membrane | 92.40 | 2.08 | [99] | |

| Ag@PAN nanofiber membrane | 76.00 | 1.34 | [101] | |

| SiO2/MWCNTs-COOH/PAN fiber membrane | 82.52 | 1.28 | [100] | |

| GO/PVA EFMs membrane | 94.20 | 1.42 | [5] | |

| CNFs/PAN/TPA nanofibrous membrane | 89.50 | 1.36 | [16] | |

| CNT/PVDF/PVP nanofiber mats | 86.10 | 1.37 | [38] | |

| Co3S4HP/PAN membrane | 86.50 | 1.26 | [116] | |

| CNTs@SiO2 Nanofibrous Aerogels | 98.00 | 1.50 | [11] | |

| rGO/PAN membrane | 89.40 | 1.46 | [93] | |

| CB/PAN membrane | 72.00 | 1.30 | [102] | |

| rGO/NHrG membrane | 95.40 | 1.85 | [103] | |

| GO/PVA EFMs nanofiber mats | 90.00 | 1.40 | [5] | |

| Carbonized ultrafine PAN fibers | 81.71 | 1.33 | [92] | |

| Chinese ink/PLA fibrous mat | 81.00 | 1.29 | [95] | |

| Knitting fabrics | ||||

| Carbonized basalt-fiber fabric | 82.50 | 1.50 | [104] | |

| 3D dyed black cotton towel | 72.00 | 1.40 | [8] | |

| Chitosan/graphene oxide /3D spacer fabric | 86.00 | 1.44 | [47] | |

| PEI@CNTs/waste cotton fabric | 91.40 | 1.90 | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).