Submitted:

30 December 2023

Posted:

03 January 2024

You are already at the latest version

Abstract

Keywords:

1. INTRODUCTION

2. MATERIALS & METHODS

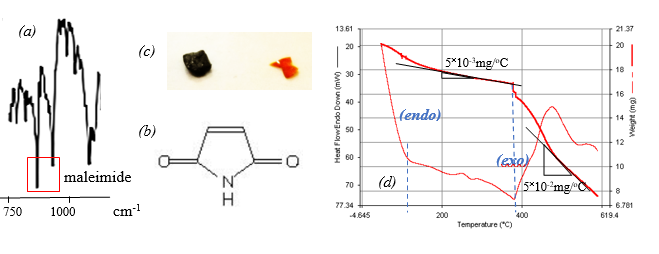

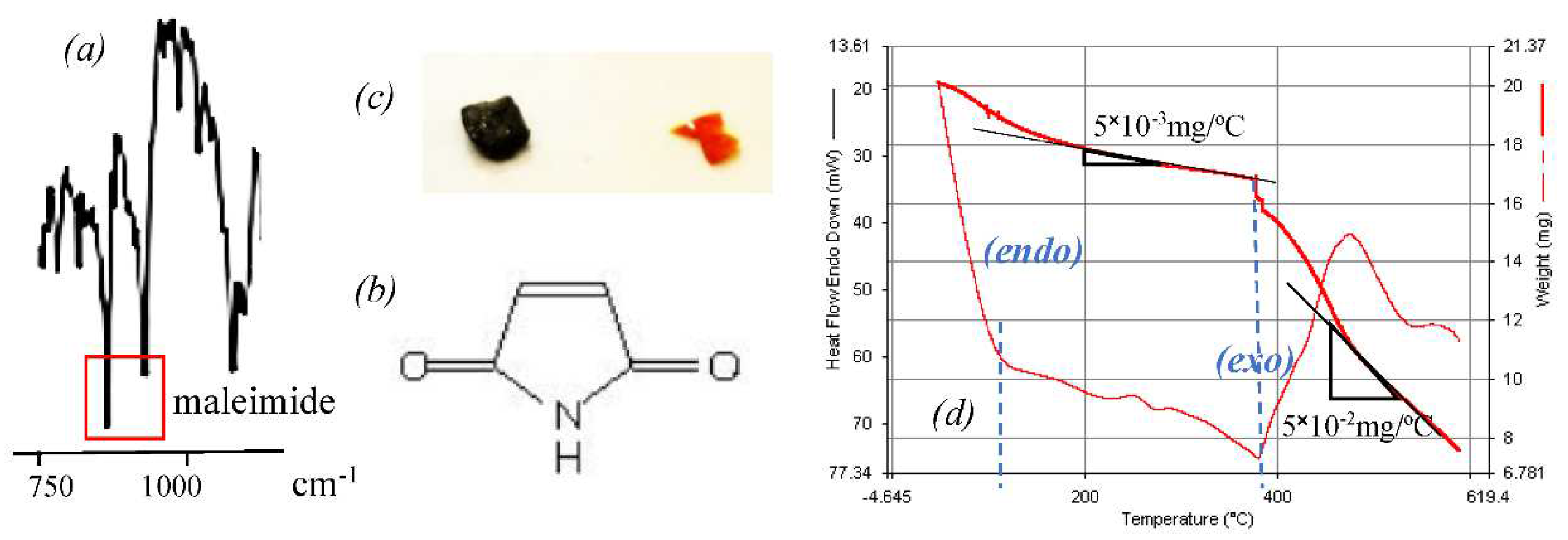

3. RESULTS & DISCUSSIONS

4. CONCLUSIONS

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- Kuriger RJ, Alam MK, Anderson DP, et al. Processing and characterization of aligned vapor grown carbon fiber reinforced polypropylene, Compos A 2002;33: 53. Available online: https://acnpsearch.unibo.it/journal/924374. [CrossRef]

- Faraz MI, et al. Thermal, Morphological and Mechanical Characterization of Novel Carbon Nanofiber Filled Bismaleimide Composites, J Appl Polym Sci 2010; 117: 2159–2167. [CrossRef]

- HOS Technik. Production of high-temperature resins - polybenzimidazole, bismaleimide, catalysts. Available online: http://www.hos-tec.com.

- Cheng FT, Man HC, Chan WM, et al. Corrosion protection of Nd–Fe–B magnets by bismaleimide coating. J Appl Phys 1999; 85: 5690. [CrossRef]

- Bhattacharyya AS, Paul D, Dutta PP, Bhattacharjee G. Surface and Mechanical Studies of Bismaleimide Coatings Adv. Eng. Tec. Appl. 5, No. 1, 11-17 (2016) and arXiv 1509.01016 [cond-mat. mtrl-sci].

- Bhattacharyya AS, Kumar S, Sharma A, Kumar D, Patel SB, Paul D, Dutta PP, Bhattacharjee G, Metallization and APPJ treatment of Bismaleimide, arXiv preprint arXiv:1508.04933, 2015 [cond-mat.mtrl-sci].

- Bhattacharyya AS, Kumar S, Sharma A, Kumar D, Patel SB, Paul D, Dutta PP, Bhattacharjee G, Metallization and APPJ treatment of Bismaleimide, High Performance Polymer, 2017, 29 (7), 816-826. [CrossRef]

- Lu G, Huang Y Novel Bismaleimide Resin/Silsesquioxane and Titania Nanocomposites by the Sol-Gel Process: the Preparation, Morphology, Thermal and Thermo-mechanical Properties, arXiv:1304.0288 [cond-mat.mtrl-sci]. [CrossRef]

- Wilson D, Stenzenberger HD, Hergenrother PM, Polyimides, Springer Science+ Business Media New York, 1990.

- Liu M, Wang Y, Zhao Y, Diazonium functionalization of graphene nanosheets and impact response of aniline modified graphene/bismaleimide nanocomposites, Mater. Des, 2014, 53, 466 – 474. [CrossRef]

- Chao Liu, Hongxia Yan, Zhengyan Chen, Lingxia Yuan and Tianye Liu, Enhanced tribological properties of bismaleimides filled with aligned graphene nanosheets coated with Fe3O4 nanorods, J. Mater. Chem A, 2015,3, 10559–10565. [CrossRef]

- Dash R, Kumari N, Kommu P, Bhattacharyya AS, Structural characterization of fillers of Inorganic materials in Bismaleimide resins, J. Polymer Eng. (2022). [CrossRef]

- I. Gouzman, N. Atar, E. Grossman, R. Verker, A. Bolker, M. Pokrass, S. Sultan, O. Sinwani, A. Wagner, T. Lück, Ch. Seifarth, 3D Printing of Bismaleimides: From New Ink Formulation to Printed Thermosetting Polymer Objects. Adv. Mater. Technol. 2019, 4, 1900368. [CrossRef]

- Shaoyun Chen, Lanqin Yu, Shiyu Zhang, Xiaolu Sun, Bo Qu, Rui Wang, Yanyu Zheng, Xiaoying Liu, Wenjie Li, Jianhong Gao, Dongxian Zhuo,Synergistic strengthening and toughening of 3D printing photosensitive resin by bismaleimide and acrylic liquid-crystal resin, Journal of Science: Advanced Materials and Devices, 8(3), 2023, 100565. [CrossRef]

- Wagner, Annika, Gouzman, Irina, Atar, Nurit, Grossman, Eitan, Pokrass, Mariana, Fuchsbauer, Anita, Schranzhofer, Leo and Paulik, Christian. (2019), Cure kinetics of bismaleimides as basis for polyimide-like inks for PolyJet™-3D-printing. J. Appl. Polym. Sci., 136, 47244. [CrossRef]

- Wang, K., Wang, Y., Chen, P., Xia, L. and Xiong, X. (2018), Novel Bismaleimide Resins Modified by Allyl Compound Containing Liquid Crystalline Structure. Adv. Polym. Technol., 37: 281-289. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).