1. Introduction

Equipment becomes more highly effective, more accurate, and more reliable with its service. Automation has invaded numerous industries, including industry, manufacturing, and even some basic household products. Agriculture is one of the industries into which automation has made inroads (Kanjilal, Singh, et.al.,2014). Agriculture is confronted with both a difficulty and an opportunity since population expansion necessitates tripling food output in four to five decades. Greater investment is required to ensure agricultural growth, particularly in sponsoring international research institutes aimed at promoting development (Norwood, Colin, et.al.,2012). Indeed, from a global viewpoint, we are currently on the right track. As an agriculture-dependent country, it employs automation to boost agricultural productivity. According to Amogbai (2013), before the introduction of automatic feeder technology, people were used to manually filling containers with grains and feeds to feed chickens. A manual feeding schedule presents difficulties in managing production costs effectively in chicken farming ( Adei and Asante, 2012). The cost of production in poultry management may be traced back to feeding expenditures at 75% (Mikail,2014 ). It has been established that there is a clear link between the high cost of chicken raising and people's engagement in this agricultural system. This has resulted in a huge increase in the total labor cost for this agricultural approach ( Grandin,2015).Human labor will be replaced by this system in feeding the chickens on time. This system will be helpful in the poultry industry because labor problems will be overcome, the chickens will be fed at a specific time, and the use of temperature sensors to maintain the freshness of the foods for the chicken. Creating this system will improve poultry's temperature conditions save food and prevent the foods from being contaminated (Jindarat & Wuttidittachotti, 2015).According to the research of Zainal et al., the Automatic Chicken Feeder system is a great help in terms of reducing the amount of manpower because this is fully automatic. The owner doesn't need a high monthly cost for hiring laborers to feed the chickens. It will be more efficient for the owner because even without the presence of the owner during the time for feeding, the food is automatically fed to the chickens. This system strives at labor reduction and waste of food during the time of feeding for the breeders, especially for those who own a small or medium poultry business (Zainal, et al., 2017).According to the research of Rupesh Muttha, Sanket N.Deshpande et al, many chicken farming businesses have been done mechanically till now so the breeders are not capable of getting extreme benefits. Numerous years ago, the feeding system that was used was the traditional way which was done manually. Years passed and the technology was growing, the chicken feeder systems became automatic and adopted by some big poultry businesses as the best choice for chicken feeding (Muttha, Deshpande, Chaudhari, & Wagh, 2014).On the other hand, manually, the task of a caretaker or the owner is always checking the availability of the food and water that should be given to the chickens.. A strategy for raising a strong, automatic chicken feeder is presented by P. Jayarajan et.al., (2021) to make the work run efficiently and smoothly. According to the research conducted by Islam (2019), the automatic chicken feeder is essential nowadays. Hambali (2020) added that automatic feeder production gives precise constant monitoring in a chicken.

2. Materials and Method

Materials:

Microprocessor – Raspberry Pi 3 Model B+. The Raspberry Pi 3 Model B+ boards served as the device's primary CPU and controller. It has 40 pre-soldered GPIO pins, a clock speed of 1.4 GHz, 1 Gigabyte LPDDR2 SDRAM, and a 64-bit quad-core CPU.

Raspberry Pi Camera v1.3. This 5-megapixel sensor with an OV5647 camera module can capture 1080p video and still photographs and connects to your Raspberry Pi directly. The camera can capture with a resolution of 2592 x 1944 pixels and also supports 1080p30, 720p60, and 640x480p90 video.

MG996r Servo Motors. A servo motor is a self-contained electrical device that spins machine parts with high efficiency and precision.

Load Cells (10kg)...It is often made up of a metal beam or platform coupled to a sensor. The force or weight is converted into an electrical signal via the sensor, which may then be measured and displayed.

HX711 Load Cell Amplifier By connecting the amplifier to your CPU, such as a Raspberry Pi, you can read changes in the load cell's resistance and receive quite exact weight measurements.

Temperature Sensor (DHT22). It measures the surrounding air with a capacitive humidity sensor and a thermistor and outputs a digital signal on the data pin (no analog input connections are required).

1 Channel 5V SPDT Relay Module. It was utilized to regulate the temperature of the feeds in the primary storage of the device. It is linked to an incandescent bulb, and when the temperature drops, it is responsible for sending a signal to the bulb and turning it on.

Incandescent Bulb. It serves as a heater in the device.

3W 4 Ohms Speaker. This speaker was employed in the gadget to direct the chickens' attention to the feeder.

PAM8406 Class D Digital Amplifier. This component raises the level of the speaker's sound to attract the chickens' attention. PAM8406 has a low THD+N and a high SNR, enabling for high-quality sound reproduction.

16 x 2 LCD Display with i2c LCD Display Module. It was utilized to track and show the number of identified chicken as well as the temperature of the food in the main storage. The character LCD is ideal for displaying text, numbers, and special characters.

Raspberry Pi Power Supply. An electrical power supply delivers electricity to a load, such as a laptop computer, server, or other electronic device.

Jumper wires. It links the device's components to the Raspberry Pi microcontroller. By connecting the jumper wire to the circuit, it is possible to manage the power, stop the circuit from operating, and run a circuit that does not work with standard wiring.

Breadboard. A breadboard is a board that is used to construct and test electrical circuits

Keyboard, Mouse, and Monitor used in the device.

A mouse is used to move the pointer on the screen by tracking the user's motion. A monitor is used to show program code and observe what happens to the device.

Other Miscellaneous Hardware. These are the components that are not listed in the preceding list but should be utilized in the device's construction, such as metals used for the feeding trough, primary feed storage (Recyclable plastic bucket), and so on.

Method:

Design and Construction of Automated Chicken Feeder

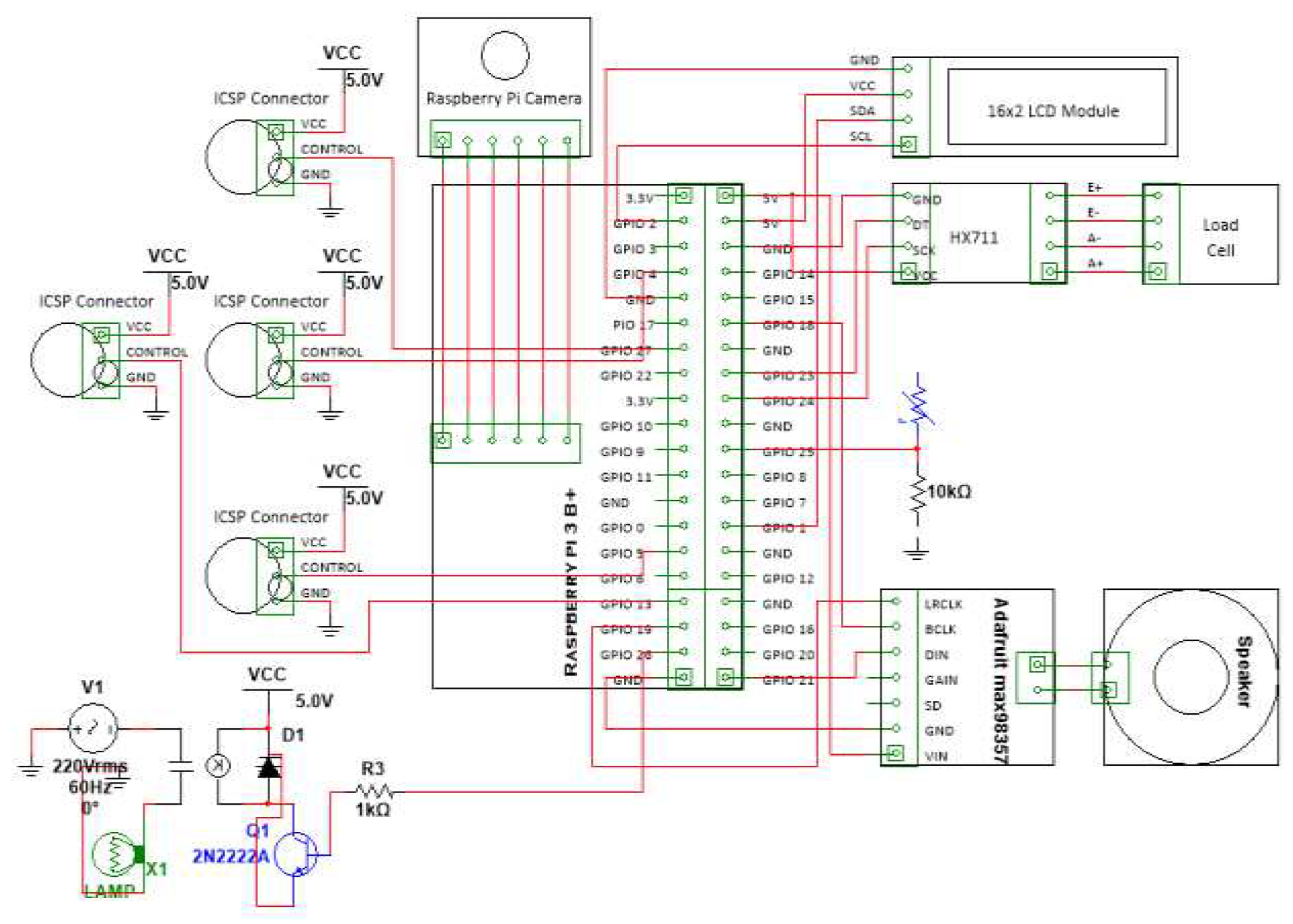

Figure 4 shows the schematic design of the YoloV4 algorithm-powered automatic chicken feeder and counter. Raspberry Pi 3 Model B+, servo motors, load cell, raspberry pi camera, lamp, speaker, sound amplifier, LCD, temperature regulator, and temperature sensor (DHT22) are the primary hardware components.

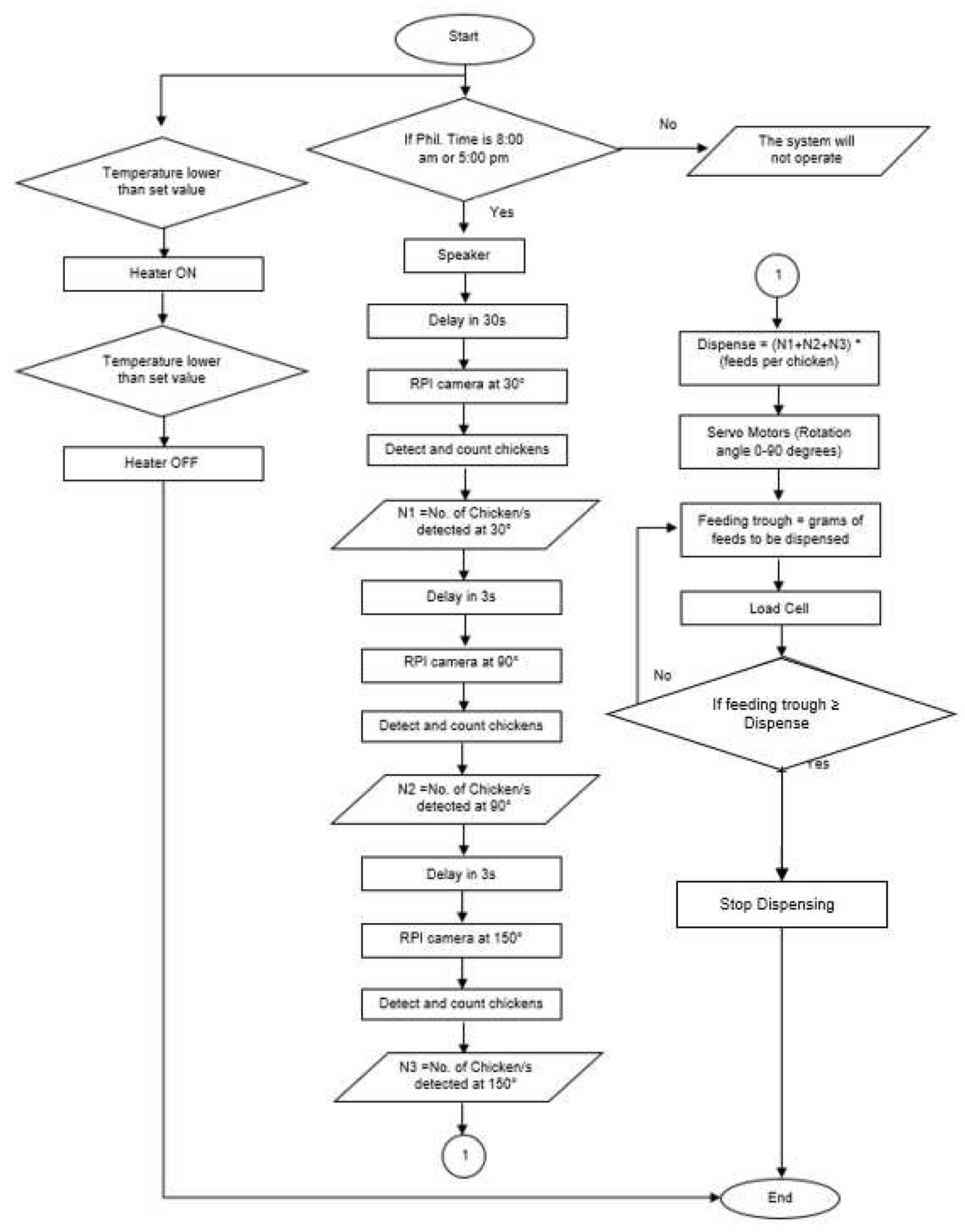

The Raspberry Pi 3 Model B+ board served as the device's CPU. The device is only supposed to work between 8 a.m. and noon. And 12 p.m. in Philippine Time. And 5 p.m. because it is free-range chicken feeding time; otherwise, the device would not function. Every morning at 8 a.m. and 5 p.m. Within 30 seconds, the device's speaker would summon and draw the free-range chickens' attention. Once the speaker had ceased, the raspberry pi camera would catch the free-range chickens in three separate directions. Yolov4 was used as an image processor in conjunction with TensorFlow software to recognize and count free-range hens. The device will compute the total identified free-range chickens and multiply it by the predicted amount of feeds per bird after detecting and counting the chickens from three distinct perspectives. The three servo motors attached in the feeding trough in different positions would then activate and dispense the feeds from the main store. The feeds in the main storage must be isolated from the chicken feeder in order for the servo motor to open and close the valve. The number of free-range hens observed by the raspberry pi camera determines the specified amount of feed. The chicken feeder will continue to discharge feeds if the feeding trough is empty or below the maximum limit.One of the aims of this study is to keep the grains fresh during the feeding period. The DHT22 temperature sensor regulates or maintains the freshness of the grains. The temperature sensor DHT22 is used to monitor the temperature of the chicken feed storage, and the information is delivered to the Raspberry Pi 3 Model B+ board, which sends the current data and performs an action based on the data received. The temperature sensor will monitor the ambient temperature and will either switch on or off the bulb based on the temperature of the feed container at the time indicated in

Table 1.When the temperature falls below the threshold, the bulb will turn on automatically to raise the interior temperature of the food container. A 240V 100 Watt Bulb was employed to keep the grains fresh because it can provide enough heat quickly once the sensor senses the decreased surrounding temperature of the grains container, as illustrated in

Figures 1.a and 1.b. When the temperature of the grain container exceeds the threshold value, the light will turn off, as shown in

Figure 1.c. The LCD displays the temperature of the food container as well as the number of birds detected.

Table 1.

Temperature condition and bulb decision.

Table 1.

Temperature condition and bulb decision.

| NO. |

CONDITIONS |

DECISION |

| 1 |

Temperature < 28 |

Bulb will ON until it reaches 33 degrees |

| 2 |

Temperature >= 33 |

Bulb will OFF until it drops 28 degrees |

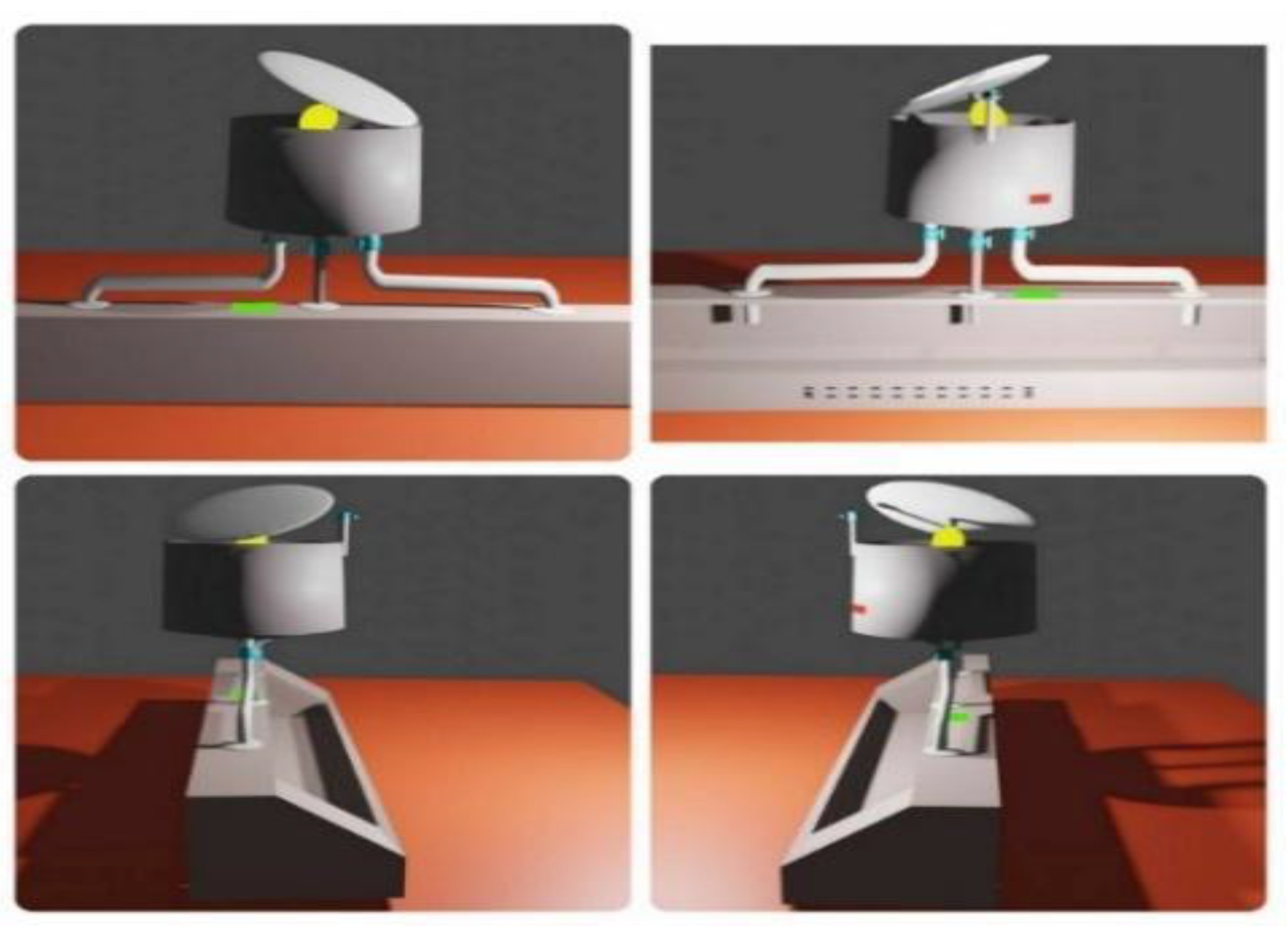

Figure 1.

(Based on the respective pictures) 1. A) Temperature is less than 28°C, the lLamp bulb will turn ON. 2. B) Temperature is less than 28°C, the lamp bulb will turn ON (Outside view). 3. c) Temperature is greater than or equal to 33°C, the lamp bulb will turn OFF.

Figure 1.

(Based on the respective pictures) 1. A) Temperature is less than 28°C, the lLamp bulb will turn ON. 2. B) Temperature is less than 28°C, the lamp bulb will turn ON (Outside view). 3. c) Temperature is greater than or equal to 33°C, the lamp bulb will turn OFF.

Figure 4.

Schematic design of Automatic Chicken.

Figure 4.

Schematic design of Automatic Chicken.

Figure 5.

a to d shows the expected output of the feeder including the dimensions and the views.

Figure 5.

a to d shows the expected output of the feeder including the dimensions and the views.

Figure 6.

Flowchart of the chicken feeder.

Figure 6.

Flowchart of the chicken feeder.

3. Result and Discussion

Evaluation of the Device

The device was tested on 50 free-range chickens from the farm by the researchers. The acquired samples were combined with cockerels and pul-lets. The researchers tested the automatic chicken feeder for a month to see if it was genuinely effective on the farm in terms of labor reduction. Another crucial feature is that the weight of the free-range chickens grew during the study.

Table 2 shows the device's chicken detection performance over the course of a month. The average number of chickens identified in a month out of 50 free-range chickens was 47.27. The average number of chickens recorded in all frames was 48.65, implying that only 1.35 chicks were missed by the device in the frames. The average number of chickens missing from the frames was 1.35, implying that some birds were unable to hear the sound. Throughout the month of testing, the average accuracy percentage of the device's detection was 94.54%, with 25 times of testing receiving 100 percent accuracy, 20 times receiving 90-99 percent accuracy, and 15 times receiving 80-89 percent accuracy.

Table 3 illustrates the dispensing system's accuracy by recording the predicted weight of feeds to be dispensed, the actual weight of feeds delivered, and the excess weight of feeds throughout the month. The average projected weight of feeds supplied is 2363.33 grams, whereas the actual weight dispensed is 2370.15 grams. The total extra weight of feeds is 409 grams, resulting in an average of 6.82 surplus feeds each day. The amount of extra weight is divided by the projected weight to be dispensed by the device, then multiplied by 100 to get the average percentage of excess weight of feeds.

Table 4 shows the temperature sensor's accuracy. Following the assessment, the average temperature measured by the temperature sensor on Day 1 was 30.78°C, while the digital thermometer recorded 31.21°C with an accuracy percentage of 98.62%. On Day 2, the average temperature measured by the temperature sensor was 30.54°C, whereas the digital thermometer read 31.04°C with a 98.39% accuracy. On Day 3, the average temperature reported by the temperature sensor was 30.48°C, whereas the digital thermometer read 31°C with a 98.30% accuracy. On Day 4, the average temperature dd reported by the temperature sensor was 30.65°C, whereas the digital thermometer read 31.11°C with a 98.53% accuracy. On Day 5, the average temperature detected by the temperature sensor was 30.82°C while the digital thermometer was 31.29°C with an average accuracy percentage of 98.47%the temperature sensor used in this device was DHT22. According to the DHT22 datasheet (Aosong Electronics Co., 2012), this temperature sensor has +-0.5 degrees accuracy. It means that the device's temperature control performance was very accurate based on the results of the evaluation.

In Alfonso, Cavite, the researchers performed a study of 50 commercial and backyard poultry owners and farmers.

Table 5 displays the survey findings in terms of usefulness, usability, efficiency, and maintainability. Respondents indicate their level of agreement and disagreement with each criteria by ticking the box.

Conclusion

It was concluded that the Automated Chicken Feeders and Counter using YoloV4 Algorithm have the potential to provide several benefits to poultry farmers. They can help to reduce the amount of time that farmers need to spend feeding their chickens, as well as improve the quality of the food that the chickens eat because of the installed temperature sensor and a heater. In addition, automated chicken feeders can help to reduce the number of accidents on poultry farms and improve the working conditions for farmers. Finally, automated chicken feeders can help to reduce the cost of production on poultry farms.

References

- Aosong Electronics Co., L. (2012, July 29). alldatasheet.com. Retrieved July 15, 2022, from https://pdf1.alldatasheet.com/datasheet-pdf/view/1132459/ETC2/DHT22.html.

- J. Ryan, C. Norwood, and J. Diekmann. (2012). Features of an Experimental Station at an International Agricultural Research Center that Enhance Regional Impact. Aleppo, Syria: Canadian Center of Science and Education. [CrossRef]

- Muttha, R. Muttha, R., Deshpande, S., Chaudhari, M., & Wagh, N. PLC Based Poultry Automation System. International Journal of Scientific Research. 2014. [Google Scholar]

- Jindarat, S. , & Wuttidittachotti, P. (2015). Smart Farm Monitoring Using Raspberry Pi and Arduino. [CrossRef]

- Drishti Kanjilal, Divyata Singh, Rakhi Reddy, Prof Jimmy Mathew (2014). Smart Farm: Extending Automation to the Farm Level, International Journal of Scientific & Technology Research Volume 3, Issue 7, 109 – 113.

- Ryan, John, Norwood, Colin and Diekmann, Juergen (2012). Features of an Experimental Station at an International Agricultural Research Center that Enhance Regional Impact. Sustainable Agriculture Research; Vol. 1, No. 2 (Aug 2012), 88-99. [CrossRef]

- D. Adei and B. Asante, “The Challenges and Prospects of the Poultry Industry in Dormaa District,” Journal of Science and Technology Ghana, vol. 32, no. 1, pp. 104–116, Apr. 2012. [CrossRef]

- Olayemi Mikail, “Design of an Intelligent Poultry Feed and Water Dispensing System Using Fuzzy Logic Control Technique,” Journal Of Control Theory and Informatics, vol. 4, pp. 61–72, Dec. 2014.

- T. Grandin, “The design and construction of facilities for handling cattle,” Livestock Production Science, vol. 49, no. 2, pp. 103–119, Sep. 2015. [CrossRef]

- Che Soh, Zainal & Ismail, Mohd & Otthaman, Firzana & Safie, Muhamad & Zukri, Muhamad & Che Abdullah, Syahrul Afzal. (2017). Development of automatic chicken feeder using Arduino Uno. 120-124. [CrossRef]

- P. Jayarajan, M. P. Jayarajan, M. Annamalai, V. A. Jannifer, and A. A. Prakash, “IOT Based Automated Poultry Farm for Layer Chicken,” in 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India,Mar.2021,pp. 733–737. [CrossRef]

- Zain, A. (2008), Automatic Chicken Feeder System Using Microcontroller, Asian Journal of Agriculture and Development, Vol. 2, Nos. 1 & 2.

- Md. M. Islam, S. Sourov Tonmoy, S. Quayum, A. R. Sarker, S. Umme Hani, and M. A. Mannan, “Design and implementation of Automated poultry farm with Distinguish Features,” in 2019 International Conference on Robotics,Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, Jan. 2019, pp. 273–276. [CrossRef]

- M. F. H. Hambali, R. K. Patchmuthu, and A. T. Wan, “IoT Based Smart Poultry Farm in Brunei,” in 2020 8th International Conference on Information and Communication Technology (ICoICT), Yogyakarta, Indonesia, Jun. 2020, pp. 1–5. [CrossRef]

- Mumbelli, R. C. Brito, V. Pegorini, and L. F. Priester, “Low Cost IoT-Based System for Monitoring and Remote Controlling Aviaries,” in 2020 3rd International Conference on Information and Computer Technologies (ICICT), San Jose, CA, USA, Mar. 2020, pp. 531–535. [CrossRef]

Table 2.

Device Accuracy Percentage.

Table 2.

Device Accuracy Percentage.

| TOTAL DAYS OF FEEDING |

TOTAL NUMBER OF CHICKEN |

AVERAGE NUMBER OF CHICKEN DETECTED |

AVERAGE NUMBER OF CHICKEN IN ALL FRAMES |

AVERAGE NUMBER OF CHICKEN NOT IN THE FRAMES |

AVERAGE ACCURACY PERCENTAGE OF THE DEVICE (%) |

| 30 days (two times a day) |

50 |

47.27 |

48.65 |

1.35 |

94.54 |

Table 3.

Accuracy of dispensing system.

Table 3.

Accuracy of dispensing system.

| TOTAL DAYS OF FEEDING |

TOTAL NUMBER OF CHICKEN |

AVERAGE OF EXPECTED WEIGHT OF FEEDS TO BE DISPENSED (G) |

AVERAGE OF ACTUAL WEIGHT OF FEEDS THAT WAS DISPENSED (G) |

AVERAGE EXCESSED WEIGHT OF FEEDS (G) |

AVERAGE PERCENTAGE OF EXCESSED WEIGHT OF FEEDS (%) |

| 30 days (two times a day) |

50 |

2363.33 |

2370.15 |

6.82 |

0.288 |

Table 4.

Temperature control evaluation.

Table 4.

Temperature control evaluation.

DAYS OF TESTING

(12 TIMES PER DAY) |

AVERAGE TEMPERATURE DETECTED BY TEMPERATURE SENSOR

(°C) |

AVERAGE TEMPERATURE DETECTED BY DIGITAL THERMOMETER

(°C) |

AVERAGE ACCURACY PERCENTAGE

(%) |

| Day 1 |

30.78 |

31.21 |

98.62 |

| Day 2 |

30.54 |

31.04 |

98.39 |

| Day 3 |

30.48 |

31 |

98.30 |

| Day 4 |

30.65 |

31.11 |

98.53 |

| Day 5 |

30.82 |

31.29 |

98.47 |

Table 5.

Results of user acceptability survey.

Table 5.

Results of user acceptability survey.

| |

STRONGLY AGREE (5) |

AGREE

(4) |

NEUTRAL (3) |

DISAGREE

(2) |

STRONGLY DISAGREE (1) |

| FUNCTIONALITY |

|

|

|

|

|

|

Sustainability: The module of the device performs each of the required task. |

42 |

8 |

0 |

0 |

0 |

|

Interoperability: The device is suitable for detection of chicken. |

43 |

7 |

0 |

0 |

0 |

|

Security: The device is safe to use. |

43 |

7 |

0 |

0 |

0 |

|

Compliance: The functions, features, and controls of the device are relevant. |

43 |

7 |

0 |

0 |

0 |

| USABILITY |

|

|

|

|

|

|

Operability: The device is simple and can be use or operated by almost anyone. |

44 |

6 |

0 |

0 |

0 |

|

Attractiveness: The design of the device is interesting, attractive, and has nostalgic feel. |

39 |

11 |

0 |

0 |

0 |

| EFFICIENCY |

|

|

|

|

|

|

Time Behavior: The device quickly responds when it is in use. The device is stable all throughout the using time. |

37 |

13 |

0 |

0 |

0 |

| MAINTAINABILITY |

|

|

|

|

|

|

Analyzability: The developers can easily resolve any issues or errors within the device. |

41 |

9 |

0 |

0 |

0 |

|

Testability: The device requires very minimal time to evaluate. |

38 |

12 |

0 |

0 |

0 |

|

Changeability: Changes or updates are easy to implement (such as changing the amount of feeds per chicken) |

42 |

8 |

0 |

0 |

0 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).