1. Introduction

Asphalt material is used in road paving far more than other road material types and has become the main material for Chinese roads[

1]. The growing demand for asphalt materials urges the process of analysis of asphalt material performance. Asphalt material is sensitive to temperature, and its performance shows different states with the temperature. The matrix asphalt material can meet the basic performance requirements for roads, but its effect has not yet reached its best state. The analysis of asphalt materials and exploration of other channels to improve their route performance status are urgent problems that need to be solved[

2,

3].

Due to the different origins of asphalt material, the chemical components are different, and the proportion of internal components is also different, resulting in different differences in the performance of the road[

4]. To analyse the performance of asphalt materials itself, Jennings built eight standard asphalt models to divide them into aromatherapy, saturated scores and other components[

5]. Zhang used three components to divide the asphalt material structure and combined the effectiveness of the molecule of the molecule of the parameters such as density and vitrification temperature. Based on the previous analysis[

6].Zheng improved the division of the asphalt group and divided them into the four currently used groups of asphaltenes, saturation, aromatherapy and glue[

7]. Li continuously explored the real micro-structure of asphalt materials, proposed the four groups of molecular structures of asphalt, further exposed the true structure of asphalt materials and laid the foundation for the next research and analysis[

8].The analysis and research of asphalt materials can effectively illustrate the principle of its micro-structure that affects the performance of road performance.

Facing the producing area Of matrix asphalt, experts and scholars have added modified agents to improve the performance of matrix asphalt. In the 19th century, France pioneered the application of natural rubber modifiers as the beginning of modified asphalt material[

9].In 2000, a domestic rubber modified agent was successfully applied to asphalt materials[

10].The rubber embedded segment polymer is divided into two categories: but a diene phenyl rubber (SBR) and natural rubber (NR). When the high-temperature environment rubber modifiers are mixed with asphalt materials, the rubber material swells. The asphalt glue is bonded together and has good adhesion with the surface of the material, enhancing the adhesion effect of the asphalt mixture[

11].Yang Sanqiang studied the mechanism of high-viscosity asphalt and modified agent and explained the mechanism of interpretation of the interaction according to different viscosity performances. As a result, the SBS modified agent was the best compatible at 5%, which can greatly increase the viscosity of asphalt. Fibre, nanomaterials, diatomic soil and other different natures of asphalt modifiers can also improve and improve the performance of matrix asphalt from different perspectives[

12].

In response to the performance of asphalt materials on the performance of asphalt mixture, this article uses asphalt material molecular dynamics simulation matrix asphalt, SBS modified asphalt and rubber modified asphalt material. The radial distribution function and motion diffusion coefficient, compare the performance of asphalt material’s own performance and rubber modifiers, SBS modifiers to improve the route performance of asphalt materials.

2. Materials

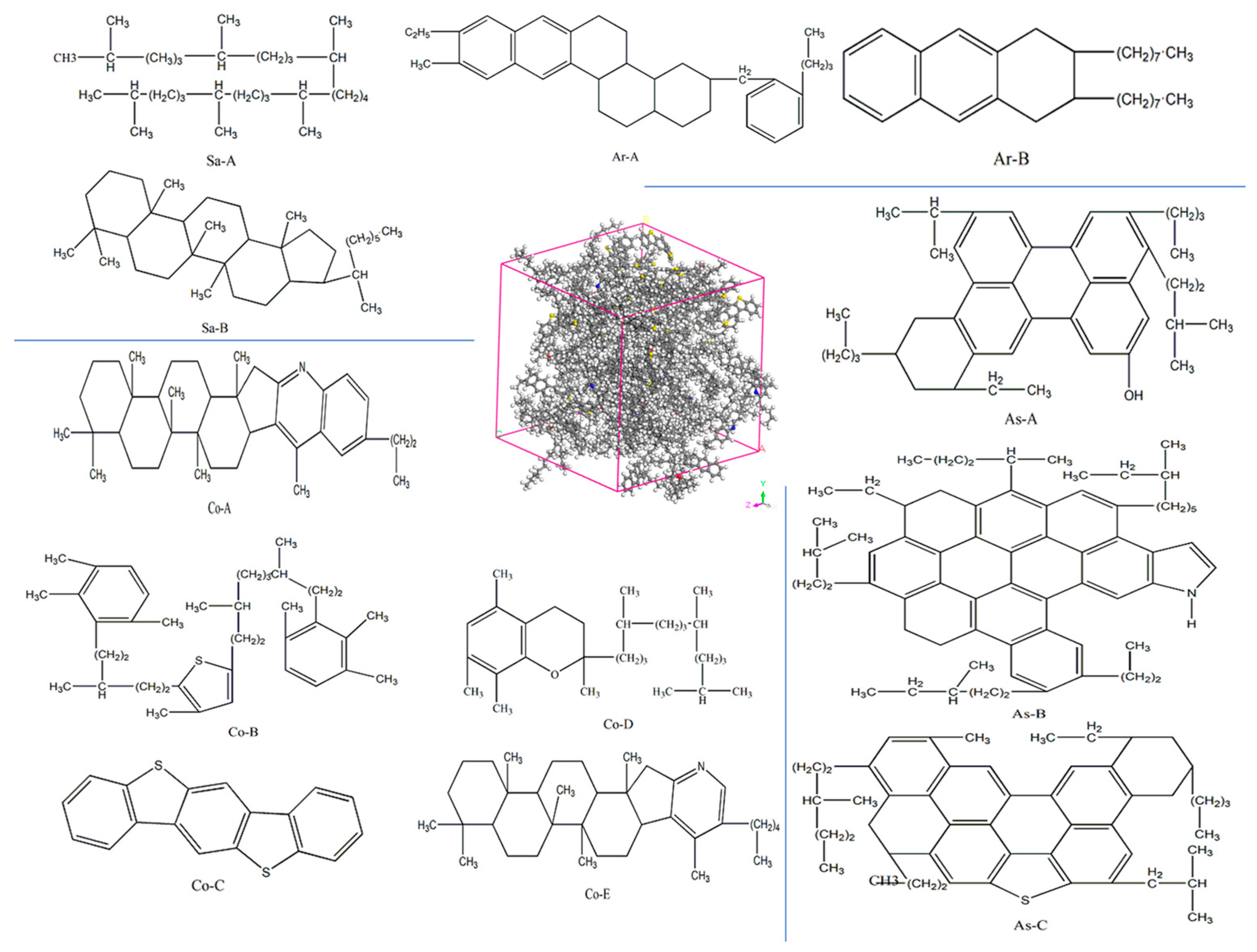

2.1. Asphalt material

The structure of the asphalt’s internal component is complicated, and it contains a variety of elements (e.g., C, H, O, N, S). In earlier periods, it was divided into three, four and six components through experiments [

13,

14,

15,

16]. Zhang et al. adopted three-way representative molecules for the construction of micro-models to analyse their related performance. Li et al. divided the asphalt molecule into 12 molecules with the AAA-1 model, representing the molecule of each component [

17,

18,

19,

20,

21]. Twelve molecular representative models were selected to build matrix asphalt [

22,

23], and the component distribution ratio of each asphalt molecular model was obtained to obtain the asphalt molecular model.

Steps of asphalt model construction[

24]:

(1) Random agency is used to build a distributed module amorphous cell. The construction command is selected to build a model. In a periodic architecture, each representative molecule is filled in, a model system of each representative is built, and a density of 0.1 g/cm3 is set.

(2) The forcite dynamic analysis module is adopted, geometric optimisation is used, the unstable molecular bonds of the molecules in the system are regulated, and the energy is optimised to achieve a stable system.

(3) Annealing settings are set to relax the molecular structure. The setting temperature is 300 to 500 K, and the cycle repeatedly relaxes to eliminate the adverse structure.

(4) At a temperature of 443.13 K (170 °C) temperature, the NPT ensemble and 1 standard atmospheric pressure are set, and 100 ps dynamics are optimised, the asphalt system model is made and compressed.

(5) On the basis of the NVT system with 100 ps dynamics optimisation, a stable architecture is obtained.

Through this operation process, the structure of each asphalt molecular is obtained. Further details are shown below.

Table 1.

Details of the components of the matrix asphalt.

Table 1.

Details of the components of the matrix asphalt.

| component |

molecular fame |

molecular |

molecular weight |

number of atoms |

number of molecules |

| saturation |

Sa-A |

C30H62

|

422.8 |

92 |

4 |

| Sa-B |

C35H62

|

482.9 |

97 |

4 |

| fragrance |

Ar-A |

C35H44

|

464.7 |

79 |

11 |

| Ar-B |

C30H46

|

406.7 |

76 |

13 |

| glue |

Co-A |

C40H59N |

553.9 |

100 |

4 |

| Co-B |

C40H60S |

573.0 |

101 |

4 |

| Co-C |

C18H10S2

|

290.4 |

30 |

15 |

| Co-D |

C36H57N |

503.9 |

94 |

4 |

| Co-E |

C29H78O |

414.7 |

80 |

5 |

| asphaltence |

As-A |

C42H54O |

574.9 |

97 |

3 |

| As-B |

C66H81N |

888.4 |

148 |

3 |

| As-C |

C51H62S |

7071 |

114 |

2 |

Figure 1.

Asphalt structure diagram, 12 molecular diagram.

Figure 1.

Asphalt structure diagram, 12 molecular diagram.

2.2. Modified agent

Due to the adverse performance of the asphalt material, external mixing materials are added to improve its performance. At present, the SBS modifiers, rubber modifiers and asphalt materials have good compatibility, and their modified effects are significant. SBS modifiers and rubber modifiers are used in large quantities in road asphalt materials, and the modified agent can improve the route performance of asphalt. In this paper, butadiene monomer molecule and 1-3- styrene monomer molecule are used as fragments, and SBS modifier of polymer block copolymer is formed by physical and chemical means. The molecular formula of asphalt monomer is m = 2, and the single chain when n = 6 represents its molecular composition[

24]. Rubber molecule is a high molecular polymer formed by polymerization of butadiene, and the molecular diagram of its linear structure: (

Figure 2):

3. Method

Compass II (Research on Simulation of Molecular Atoms at Constitutional Optimisation) represents a technical breakthrough of the force field method. It is the first to calculate the force field from scratch, which can accurately predict the gas phase properties (e.g., structure, structure, vibration) and condensing phase properties (e.g., status equation, internal agglomeration) of various molecules and polymers at the same time.

The non-key function form of different materials makes the non-key parameter generally transformable. In the mixed and interface system, the use of the Compass II force field can use a simple ion model in ion and semi-ion models. This model consists of Kulun items and VDW items. In this model, each atom is considered a key particle—there is no price key between any pair of atoms.

Molecular dynamics can accurately predict the internal agglomeration and state equation of such systems. Compass II is verified based on the energy minimisation method. For these molecular systems, Compass II has been parameterised to predict the various properties of separation and condensing phase molecules. These properties include molecular structure, vibration frequency, constructive energy, even pole, liquid structure, crystal structure, state equation and internal agglomeration density. Compass can predict various solid-state properties, including cell structure, lattice energy, elastic constant and vibration frequency.

3.1. Modified asphalt performance analysis

3.1.1. Free volume theory

Due to the space volume of asphalt materials due to its own material, part of the model volume occupied by the asphalt molecule’s own molecular structure, in order to occupy the volume; some are the free space in the asphalt molecular structure, so that it has space liquidity in a certain environment, which is both free volume essence. In the space system of asphalt, the higher the proportion of its free volume, the stronger the possibility of the molecular movement route of the components. This article explores the free volume score in the asphalt material system. Materials Studio software is used to build the asphalt molecular model. The molecule of the atom volume and surface tool calculation system occupies the volume and freedom volume (Eq.3) to obtain the free volume score of the asphalt material system. Given that the van der Waals radius of the water molecule is 1.45 Å , to further explore the performance of asphalt materials, the probe radius is set to 0 Å and 1.45 Å to analyse the stability and water damage resistance of the asphalt material.

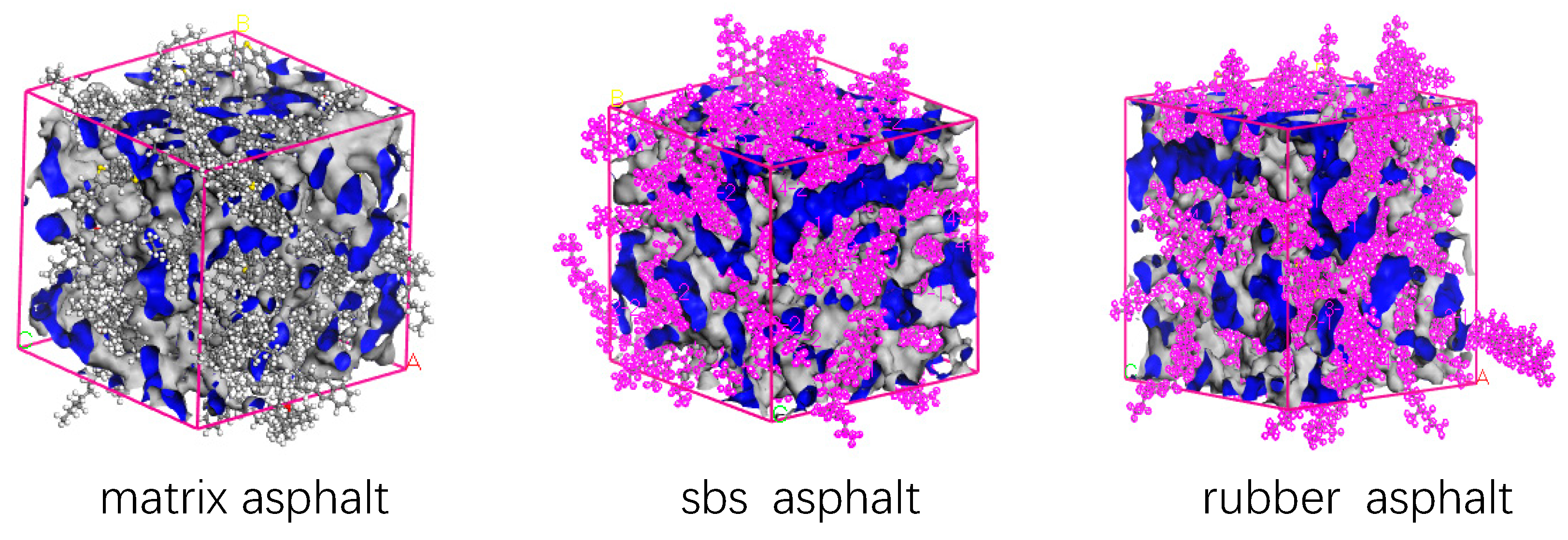

Figure 3.

Freedom volume calculation model diagram of asphalt material.

Figure 3.

Freedom volume calculation model diagram of asphalt material.

Table 2.

Freedom volume of asphalt materials calculated data table (Å3).

Table 2.

Freedom volume of asphalt materials calculated data table (Å3).

| species |

content |

probe radius 0 Å |

proportion |

probe radius 1.45 Å |

proportion |

| asphalt |

0% |

33107.86 |

19897.88 |

53005.74 |

0.37 |

44750.65 |

8255.09 |

53005.74 |

0.15 |

rubbe asphalt |

18% |

40605.17 |

23478.83 |

64084.00 |

0.36 |

54461.06 |

9622.94 |

64084.00 |

0.12 |

| 20% |

42201.74 |

23728.64 |

65930.38 |

0.36 |

58346.86 |

7583.52 |

65930.38 |

0.12 |

| 22% |

43391.79 |

24384.97 |

67776.76 |

0.35 |

59373.05 |

8403.71 |

67776.76 |

0.12 |

| 24% |

44535.79 |

25087.34 |

69623.13 |

0.35 |

60267.79 |

9355.34 |

69623.13 |

0.13 |

| 26% |

45735.50 |

25734.00 |

71469.5 |

0.35 |

61553.00 |

9916.51 |

71469.51 |

0.14 |

sbs

asphalt |

4% |

34622.97 |

20730.97 |

55353.94 |

0.37 |

47640.93 |

8407.22 |

56048.15 |

0.15 |

| 6% |

35344.28 |

20980.96 |

56325.24 |

0.37 |

48303.15 |

8022.08 |

56325.23 |

0.14 |

| 8% |

36089.70 |

21612.45 |

57702.15 |

0.37 |

49259.07 |

8443.08 |

57702.15 |

0.15 |

| 10% |

37130.95 |

22031.50 |

59162.45 |

0.37 |

50315.52 |

8846.93 |

59162.45 |

0.15 |

| 12% |

37569.33 |

22481.02 |

60050.35 |

0.37 |

50862.32 |

9188.03 |

60050.35 |

0.15 |

Through software calculation, the free volume data of asphalt materials (

Table 2) is obtained. According to the data in the table, the free volume proportion of the basic asphalt material is higher than the modified asphalt system, showing that the asphalt material itself can trigger spatial movement performance. The stability and water damage resistance of modified asphalt material system are lower than those of corresponding modified asphalt. In the rubber modified asphalt material, the corresponding free volume proportion under different measurement conditions is lower than that of the matrix asphalt material, indicating that the rubber modified agent can modify the stability and damage performance of the asphalt material itself. When the amount of rubber modifiers is 22%, its free volume proportion is the lowest, corresponding to the most impact of improving asphalt material performance. In SBS modified asphalt materials, the free volume proportion of asphalt materials under different measuring volumes is lower than that of the matrix asphalt material. The SBS modified agent can effectively improve the stability of the matrix asphalt material and resist water damage performance. When the SBS modified agent is 6%, the free volume proportion of the SBS modified asphalt is lower than that of other doping.

Compared with different modified asphalt materials, the free volume proportion of rubber modified asphalt materials is lower than the SBS modified asphalt material. The structure of the structure enhances the spatiality of the asphalt material. The free volume after the modification of the matrix asphalt is occupied, enhancing its spatial stability.

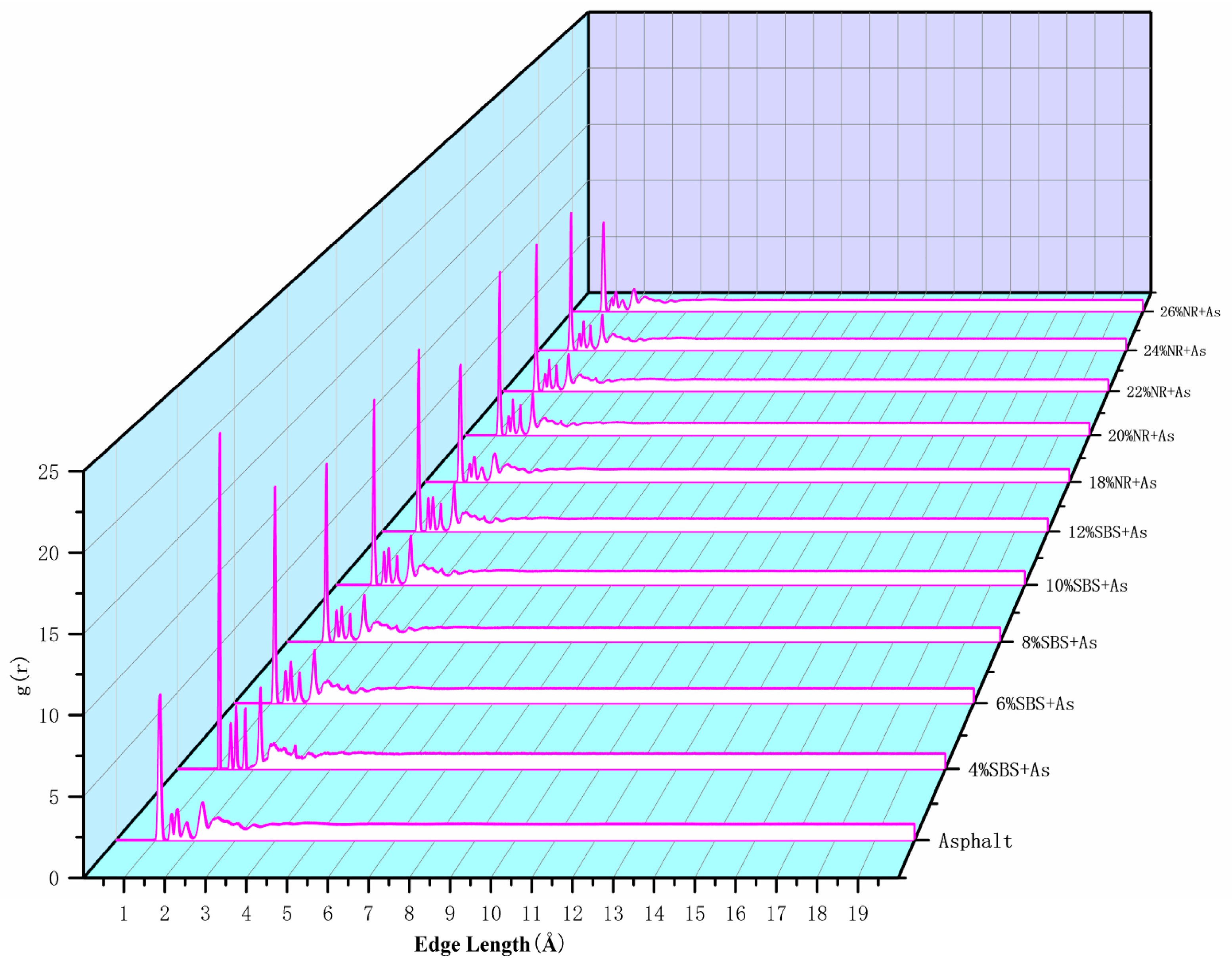

3.1.2. Radial Distribution Function

The radial distribution function is an analysis method of the material structure of the material structure, in which the local spatial distribution is calculated. The radial distribution function is the probability of another atom near a specified atom[

24]. The expression is:

In the formula, r is the atomic spacing and the quantity density of the atom. g (r) is the probability of other atoms specified at distance r of the atom. This can reflect the arrangement and interaction of molecules and atoms in the system. The peak position of the radial distribution function can determine the type of interaction, and the size of the interaction force can be inferred from the height of the peak.

To analyse the distribution of molecular agglomeration in the group in the asphalt material model, this article uses a radial distribution function to explore the position of its component molecular space. In the radial distribution function curve of Figure 3, on matrix asphalt material, the first peak value point is r = 1.1 Å, g (r) = 9.16, indicating that the asphaltene group with the most central position in the asphalt molecular model is higher than that of other groups. The distribution situation is as follows: r = 1.36 Å, g (r) = 1.66. The glue group is close to the asphalt group, and its molecular aggregation value is lower than that of asphalt quality. The component molecular energy is made more uniform, facilitating its closer proximity to the large number of benzene structures of asphalt components and therefore to the asphalt group points in the space. R = 1.53 Å, g (r) = 1.96 is the aromatic grouping. It is in the third layer of the gathering position, and its aggregation is higher than that of the glue group. It is lower than the agglomeration of the asphalt group. A large number of C-C long chains are at the edge of the asphalt space system, giving it a better space movement.

For the SBS modified agent asphalt material, the 4% SBS doping makes the aggregation of each component in the asphalt material higher than that of the matrix asphalt material and other SBS doped matrix asphalt materials, thereby improving the space gathering situation at the same space position. For the original peak value, the ratio is asphalt quality:glue:aroma division:saturation division = 2.1:1.81:2.11:3.54. The SBS modified agent mixed up makes the g (r) value higher, making the asphalt material more compact. This can effectively improve the ability of asphalt materials to resist the external environment.

For rubber modified asphalt materials, the use of 20% rubber modifiers mixes the amount of components in each component in the asphalt material compared with the matrix asphalt material and other rubber modifiers. The space agglomeration is increased to asphalt quality:gel quality:aroma division:saturation division = 1.44:1.06:1.48:2.20. The rubber modified agent results in higher g (r) values and improves the performance of matrix asphalt materials.

In the modified asphalt material, 4% SBS modifiers have a greater impact on the performance of matrix asphalt materials than 20% rubber modifiers.

Figure 3.

Modified asphalt radial distribution function.

Figure 3.

Modified asphalt radial distribution function.

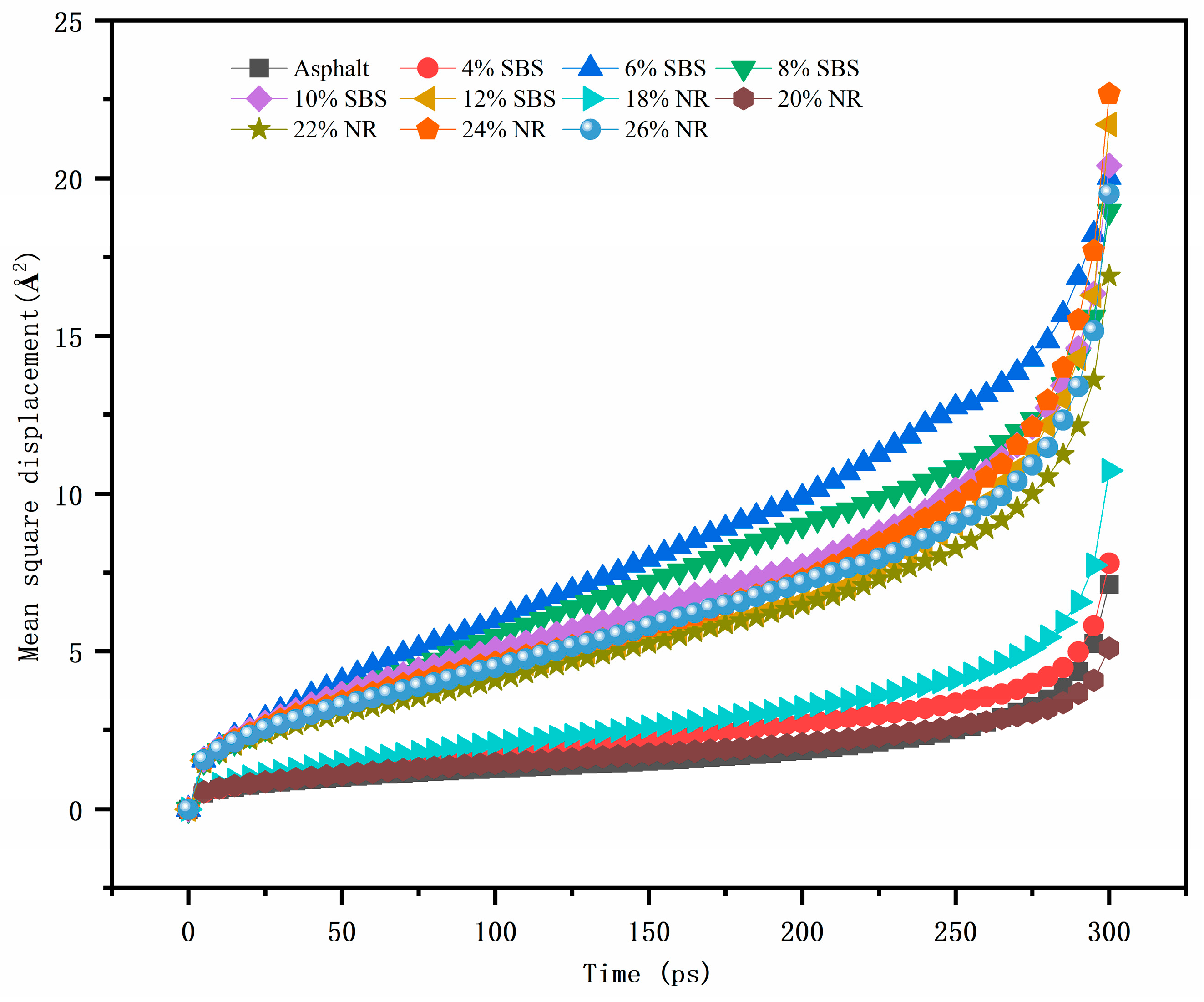

3.1.3. Diffusion coefficient

Einstein proposed the theory of the average number of the distance between the distance between the particle random movement.

where

the average displacement, D is the diffusion coefficient, and C is the constant. MSD is the average displacement of the model system, which represents the distance between the random particles in the asphalt molecule at the initial position of the particles at time t:

The formula of the diffusion coefficient is:

The molecular dynamic analysis asphalt material model is used, and the mean square displacement analysis task is set to set up a constructor in the Forcite module. The 300 ps simulation steps are calculated to get the MSD curve graph of each model (

Figure 4).

On the basis of the average orientation data curve and the calculation formula, the asphalt material in different modified asphalt materials in

Table 3 is at the asphalt material diffusion coefficient under the temperature condition of 298.13 K. The MSD curve in

Figure 4 indicates that the motion diffusion coefficient of modified asphalt materials under different amounts of SBS modified agents can be obtained. When the SBS modified asphalt is 6%, the motion performance of the asphalt material reaches the highest value, and its diffusion coefficient value is 8.46 × 10

−9 m

2/s. In different rubber modified asphalt materials, the motion diffusion coefficient of the modified asphalt material is 24%NR ﹥ 26%NR ﹥ 22%NR ﹥ 18%NR ﹥ 20%NR, of which the SBS modified asphalt is doped at 24%. and the movement performance of asphalt materials reaches the highest value when the SBS modified asphalt content is 24%, and its diffusion coefficient value is 8.46 × 10

−9 m

2/s. The diffusion coefficient values of different asphalt material molecular models are calculated, and comparison and analysis show that the motion diffusion performance of the asphalt material is lower than that of the modified asphalt material. These findings promote asphalt materials to have higher potential energy and stimulate the movement mechanism of touching asphalt materials in the external environment, enabling the effective storage of energy for motorsport.

4. Conclusion

This paper uses molecular dynamics simulation analysis of asphalt materials and modified asphalt materials to analyse the improvement of SBS modifiers and rubber modifiers on matrix asphalt materials. The following conclusions are obtained through the free volume score, radial distribution function, and average displacement of asphalt materials:

(1) A comparison of the free volume score parameters of the micro-model of asphalt materials shows that the structural stability is lower than the modified asphalt material when facing water damage and destruction. The amounts of SBS modifiers and rubber modifiers are 6% and 22%, respectively. The free volume score of the modified asphalt material is the lowest. It effectively faces external environment damage and has a good resistance to performance. Compared with modified asphalt materials, when the SBS modifier is mixed at 6%, its own stability and water resistance damage performance is better than that of rubber modified asphalt materials.

(2) In the modifier asphalt material, the amount of SBS modifiers and rubber modifiers is 4% and 20% of the rubber modified agent doping. The asphalt material of materials and other rubber modifiers is mixed by measuring the amount of space. This makes the space aggregation dense in the same space, increasing the G (R) value and improving the performance of the matrix asphalt material. For modified asphalt materials, the 4% SBS modified agent improves the performance of matrix asphalt materials more than the 20% rubber modifiers, potentially effectively improving the spatial gathering performance of matrix asphalt materials. Thus, asphalt materials can better resist the environmental impact.

(3) The motion diffusion coefficient parameters of the micro asphalt material model can be obtained. The motion diffusion coefficient of the modified asphalt material under different amounts of SBS modifiers is :6%SBS ﹥ 12%SBS ﹥ 10%SBS ﹥ 8%SBS﹥4%SBS, where the SBS modified asphalt is doped at 6%. The motion performance of the asphalt material reaches the highest value, and its diffusion coefficient value is 8.46 × 10−9 m2/s. In different rubber modified asphalt materials, the motion diffusion coefficient of the modified asphalt material is 24%NR ﹥ 26%NR ﹥ 22%NR ﹥ 18%NR ﹥ 20%NR, where the SBS modified asphalt is doped at 24%. 6%SBS modified agent doped modified asphalt material sports performance 24% rubber modified asphalt material. The maximum diffusion coefficient is 8.46 × 10−9 m2/s.

This article uses the free volume score, radial distribution function and average displacement diffusion coefficient parameter of the asphalt material micro dimension. Comparative analysis is conducted when the SBS modifiers are doped by 6%, and the improvement effect of the corresponding modified asphalt material is the most. When the amount of rubber modifiers is 22%, the improvement effect of the corresponding modified asphalt material is the best. When the SBS modified agent is 6%, its improvement of asphalt materials is better than that of rubber modifiers.

We express our gratitude for the funding provided by the Jilin Province Science and Technology Development Plan Key Research and Development Project (20220203092SF), Jilin Province Transportation Key Science and Technology Project (2023ZDGC-1-2).We would also like to thank the Laboratory of Road Building Materials, Jilin University, which provided advanced experimental equipment for this research. We also acknowledge the hard work of the research group to complete this research.

References

- Xu Guangji, et al."Experimental study and molecular simulation on regeneration feasibility of high-content waste tire crumb rubber modified asphalt." Construction and Building Materials 369.(2023). [CrossRef]

- Gao Pengyong, Chen Enli, Chang Weifeng, Si Chundi, Yan Comrade-in-arms. Study on bending failure of Asphalt pavement Materials under vehicle-Road Interaction [J]. Journal of Building Materials,2020,23(04):912-919. https://kns.cnki.net/kcms/detail/31.1764.TU.20190619.1409.008.html.

- Zhang Z W. Study on stability and durability of high viscosity modified asphalt and porous asphalt mixture [D]. Chang ’an University,2021. [CrossRef]

- Kim,Y.R,Little D.N,Benson F.C.Chemical and mechanical evaluation on healing mechanism of asphalt concrete.[J].AAPT,1990,59:240-275.

- Jennings PW, Pribanic JAS, Desando MA, Raub MF, Moats R, Smith JA, Mandersl.

- Liu Yonghong. Review on Self-healing properties of asphalt mixture [J]. Shanxi Architecture,2016,42(4):119-120.

- Shan Chao. Study on mechanical properties of asphalt-mineral interface based on molecular simulation technology D]. Jilin University,2021.

- Li D D,Greenfield M L.Chemical compositions of improved model asphalt systems for molecular simulations[J].Fuel,2014,115:347-356. [CrossRef]

- Ma Feng. DSC analysis of nano-calcium carbonate modified asphalt J. Journal of Zhengzhou University,2006,27(4):49-5.

- Li Jiancai. Asphalt Recovery and Regeneration [J. Northeast Highway,2001,24(3):24-25.

- Chen Xu, LI Li, JIANG Yuntian. Review on the development of modified asphalt [J. Sichuan Building Materials,2018,44(05):20-21.

- Wang Z H. Composition optimization of diatomaceous earth /BRA rock asphalt composite modified asphalt and study on performance of its mixture.[J] New building materials,2020,47(08):27-31.

- L Q Zhang,M L.Greenfifield,Analyzing properties of model asphaltsusing molecular simulation,Energy Fuels 21 (3)(2007)1712-1716. [CrossRef]

- J S Hansen,C A Lemarchand,E Nielsen,et al.Four-component united-atom model of bitumen,J.Chem.Phys.138 (2013). [CrossRef]

- L Q Zhang,M L.Greenfifield,Effects of polymer modifification on properties and microstructure of model asphalt systems,Energy Fuels.22(5)2008.3363-3375. [CrossRef]

- L Zhang,Physical and mechanical properties of model asphalt systems calculated using molecular simulation,Dissertations Theses-Gradworks,2007. [CrossRef]

- D A Storm,J C Edwards,S J Decanio,et al.,Molecular representations of Ratawi and Alaska north slope asphaltenes based on liquid and solid state NMR,Energy Fuels 8 (3)(1994)561-566. [CrossRef]

- J W Bunger,N C Li,Chemistry of Asphaltenes,Advances in Chemistry Series 195,American Chemical Society,Washington,D.C.,1981. [CrossRef]

- H Groenzin,O C Mullins,Molecular size and structure of asphaltenes from various sources,Energy Fuels.14 (3)(2000)677-684. [CrossRef]

- Xu M. Design and performance verification of asphalt regenerant based on molecular diffusion fusion mechanism [D]. Harbin Institute of Technology,2019. [CrossRef]

- Li DD,Greenfield M L.Chemical compositions of improved modelasphalt systems for molecular simulations[J].Fuel,2014,115:347-356. [CrossRef]

- Zhang L,Greenfield M L.Rotational relaxation times of individual compounds within simulations of molecular asphalt models[J].Journal of Ch-emical Physics,2010,132(18):1087. [CrossRef]

- Yao H,Dai Q,You Z.Molecular dynamics simulation of physicochemica1 properties of the asphalt model[J].Fuel,2016,164:83-93. [CrossRef]

- Luo Yang. Study on Micro-evaluation system and Influencing factors of asphalt Self-healing [D]. Jilin University.2022.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).