1. Introduction

Recent developments in concrete technology have made it possible to create concrete with a compressive strength of at least 100 MPa. In the 1970s and 1980s, advancements in chemical and mineral admixtures—most notably silica fume and superplasticizer—made it possible for these technological advances to be made [

1]. Low Strength Concrete has a compressive strength of less than 25 MPa, Normal Strength Concrete has a strength between 25 MPa and 50 MPa, High Strength Concrete has a strength between 50 MPa and 100 MPa, and Ultra-High Strength Concrete has a strength greater than 100 MPa [

2]. It is possible to make concrete with a compressive strength of over 200 MPa [

3]. Particular high-strength aggregate, along with the right amount of pressure and heat curing, is required under unusual conditions. A value of 810 MPa was attained using a mixture that included steel aggregate [

4]. Cementitious materials have been the focus of a great deal of study over the years as a means of creating composite compounds with superior mechanical qualities [

5]. High-strength concrete, according to the standards of many developed nations, must have a compressive strength of at least 45 MPa after 28 days when made with regular aggregate [

6,

7].

The drawbacks of HSC include the fact that workability is difficult to determine and frequently decreases rapidly after mixing as well as the rapid evolution of heat may demand the adoption of low-heat cement and cooling methods to avoid the thermal cracking at early-age [

8].

Reactive powder concrete (RPC) is a superplasticized silica fume concrete with compressive strengths greater than 200 MPa and a very dense microstructure [

9,

10]. RPC is produced using an entirely different methodology. It is a distinct combination from regular concrete in that it does not contain coarse aggregate. In its place, fine powders having particle sizes between 0.1 to 600 μm, For instance, quartz sand, crushed quartz, and silica fume, are employed to obtain the high density [

11]. As a by-product, silica fume includes more than 80-85% of amorphous SiO

2. As a result, it possesses high pozzolanic properties and can be used in concrete manufacturing [

12]. Metakaolin is made by calcining kaolin at temperatures ranging from 650 to 850 °C. It is also an amorphous silica substance that has been treated [

13]. Clays such as bauxite, flint or zirconia may be used as very fine powders to give high strength and refractory properties since they have high percentages of silica and alumina [

14,

15]. The use of superplasticizer reduces the w/b ratio to 0.2, as opposed to 0.4-0.5 for ordinary concrete [

5], furthermore to improve ductility, high-strength steel or non-metallic fibers may be used [

16]. Heat curing and applying pressure are optional procedures intended to improve performance [

4]. In addition, RPC typically has a lower water-cement ratio than regular concrete, which increases its strength. RPC also has improved durability compared to ordinary concrete as a result of its denser microstructure and reduced porosity. This makes them more resistant to chemical attacks and environmental factors such as freeze-thaw cycles. However, because RPC is a newer and more specialized material, it can be more expensive and more difficult to work than ordinary concrete, it also requires special processing methods to achieve its full-strength potential [

17].

Significant interest has been generated by the production of novel cementitious materials with enhanced properties. Reactive Powder Concrete (RPC), a newly developed cementitious substance, has been described as an innovative substance that can provide high strength and durability. RPC preparation, however, is not currently feasible in Iraq, and few studies have been done in this field, even though the RPC demonstrates excellent performances equivalent to those in other countries while being mixed using locally accessible materials without a difficult manufacturing method, according to that, this research introduces a new approach to study the reactive powder concrete (RPC) properties, a relatively recent type of cementitious material. The research primarily focuses on two key aspects: curing methods, which aims to comprehensively assess the influence of different curing methods on the production of RPC with high properties including heat curing as compared to traditional water curing, and the aspect of this research is its examination of the effects of immersing RPC specimens in sulfuric acid on their compressive strength. This aspect provides insights into the durability and resistance of RPC when subjected to aggressive environmental conditions.

2. Materials and Methods

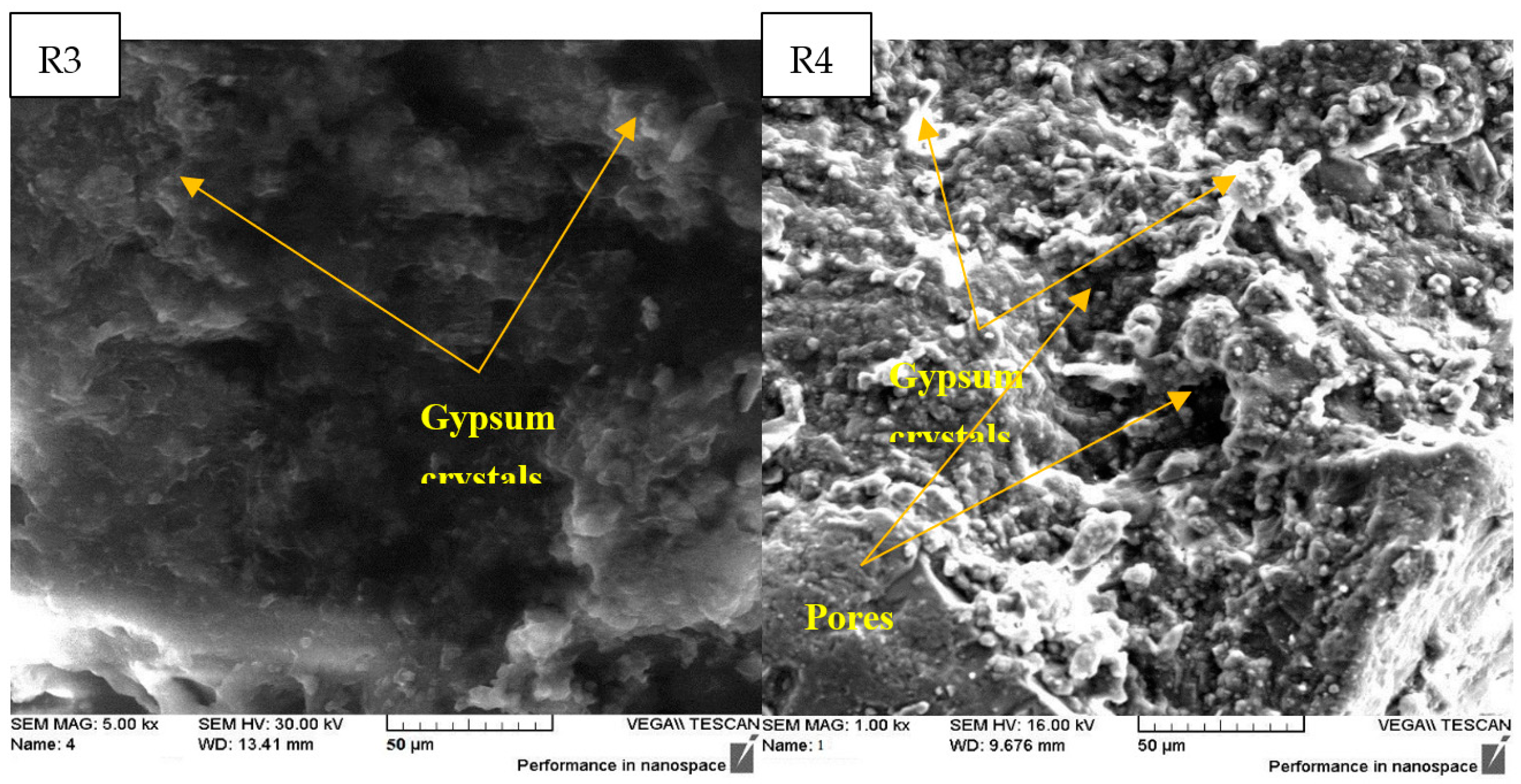

The ingredients comprising the RPC mix utilized in this work included cement, fine aggregate, mineral additives, superplasticizers, steel fibers, and water. The cement complies with (IQS5, 1984) [

18], and

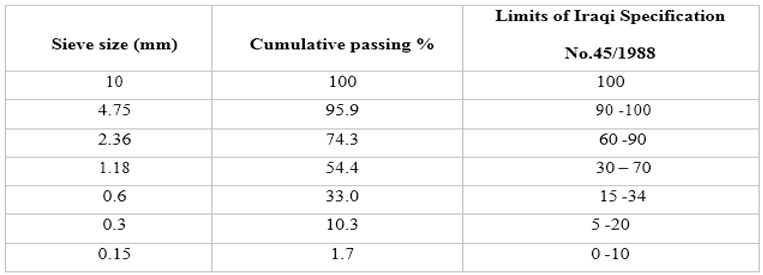

Table 1 shows its chemical composition. Natural sand was used as the fine aggregate and complies with (IQS45, 1988) [

19].

Table 2 and

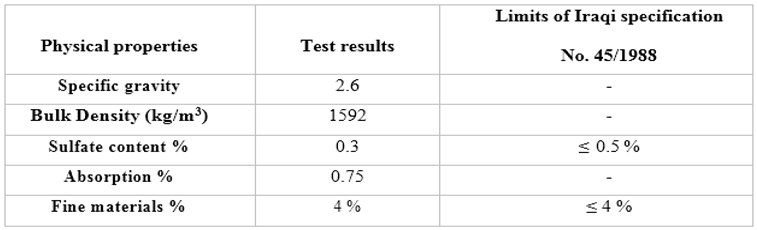

Table 3 display the sieve analysis results and physical properties of sand. Silica fume (SF) and metakaolin (MK) were used as mineral additives and partially substituted with cement. The physical and chemical characteristics, as well as the strength activity index, align with the ASTM C1240 [

20], and are illustrated in

Table 4 and

Figure 1.

Figure 2 shows the XRD results for metakaolin [

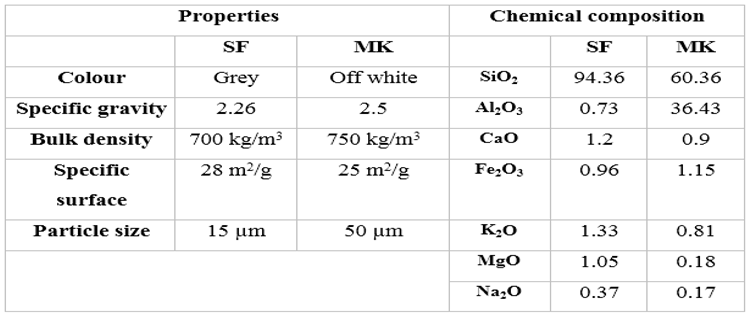

14] and silica fume. Hooked-end steel fibers (ST) produced by Sika with a length of 30mm and an aspect ratio of (L/d=60),

Table 5 illustrates the properties of the used steel fibers [

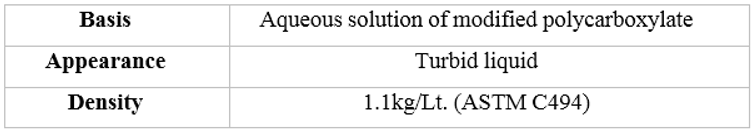

21]. The superplasticizer (SP) used throughout this study is known commercially as "Sika viscocrete-5930L” conforming to ASTM C494 [

22]. The properties of this superplasticizer are shown in

Table 6, whereas all RPC combinations were mixed and cured using regular tap water [

23]. The superplasticizer dosage was fixed for all mixes as 1.98% [

24].

Figure 2.

XRD of (A) silica fume, (B) metakaolin.

Figure 2.

XRD of (A) silica fume, (B) metakaolin.

Based on a number of studies and research from earlier years, a group of trial mixes were made to produce RPC with desirable and suitable characteristics [

25,

26].

Table 7 summarizes the mix design of RPC containing silica fume, metakaolin, steel fibers with a ratio of 0.4 by volume and superplasticizer with a dose of 1.98% of binder. The mineral additives (silica fume and metakaolin) were added in four groups as a cement replacement with a ratio of (R1) 25% SF, (R2) 25% MK, (R3) 15% SF and 10% MK, (R4) 10% SF and 15% MK.

In the mixing procedure, the constituents are first combined in a dried condition for a duration of 2 minutes. Subsequently, 80% of the total mixing water is added and mixed for a period of 3 minutes. Following this, an additional 15% water content and 70% superplasticizer are included in the mix, which is then subjected to an additional 3 minutes of mixing. The addition of the remaining water and superplasticizer is followed by a continuation of the mixing process for an additional duration of 4 minutes. Finally, the addition of steel fibers takes place and the mixing process is conducted for a duration of 3 minutes to ensure uniform distribution.

After finishing the mixing process, molds with 100 mm cubic and 100 x 200 mm were lubricated in preparation for pouring fresh concrete. For all specimens, the concrete was gradually put into three layers, and each layer underwent compaction using a steel rod. Following a period of one day, the specimens were demolded and cured.

Two curing methods were used in this work, the normal method where the specimens were cured in water, while the second method, the specimens were cured by heating to 90° C and then up to 150° C and finally left to cure in water to complete the 28 days as illustrated in

Figure 2.

Figure 2.

Cycle of heat curing.

Figure 2.

Cycle of heat curing.

After curing, cubic specimens were immersed in highly concentrated sulfuric acid for 60 days as illustrated in

Figure 3, then were tested by compressive strength to test the residual strength.

The specimens were tested by compressive and indirect tensile strengths and bulk density after 7 and 28 days, while ultrasonic pulse velocity (UPV) after 28 days. The compressive strength was calculated in accordance with BS EN 196-1 [

27]. Indirect tensile strength was calculated in accordance with ASTM C496-86 [

28]. UPV was measured using cubic specimens in accordance with ASTM C597 [

29], While bulk density was calculated according to ASTM C138 [

30].

3. Results and Discussion

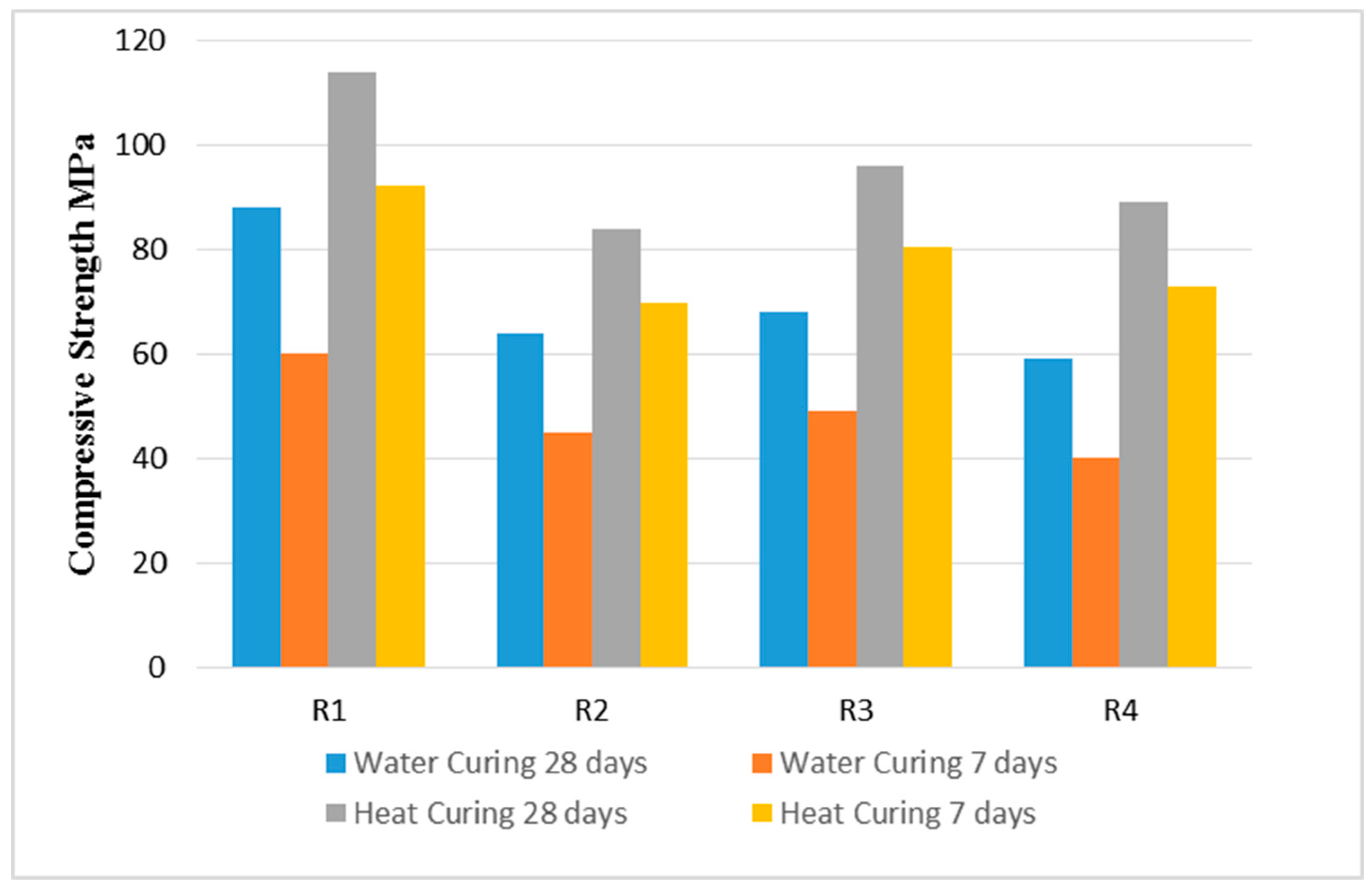

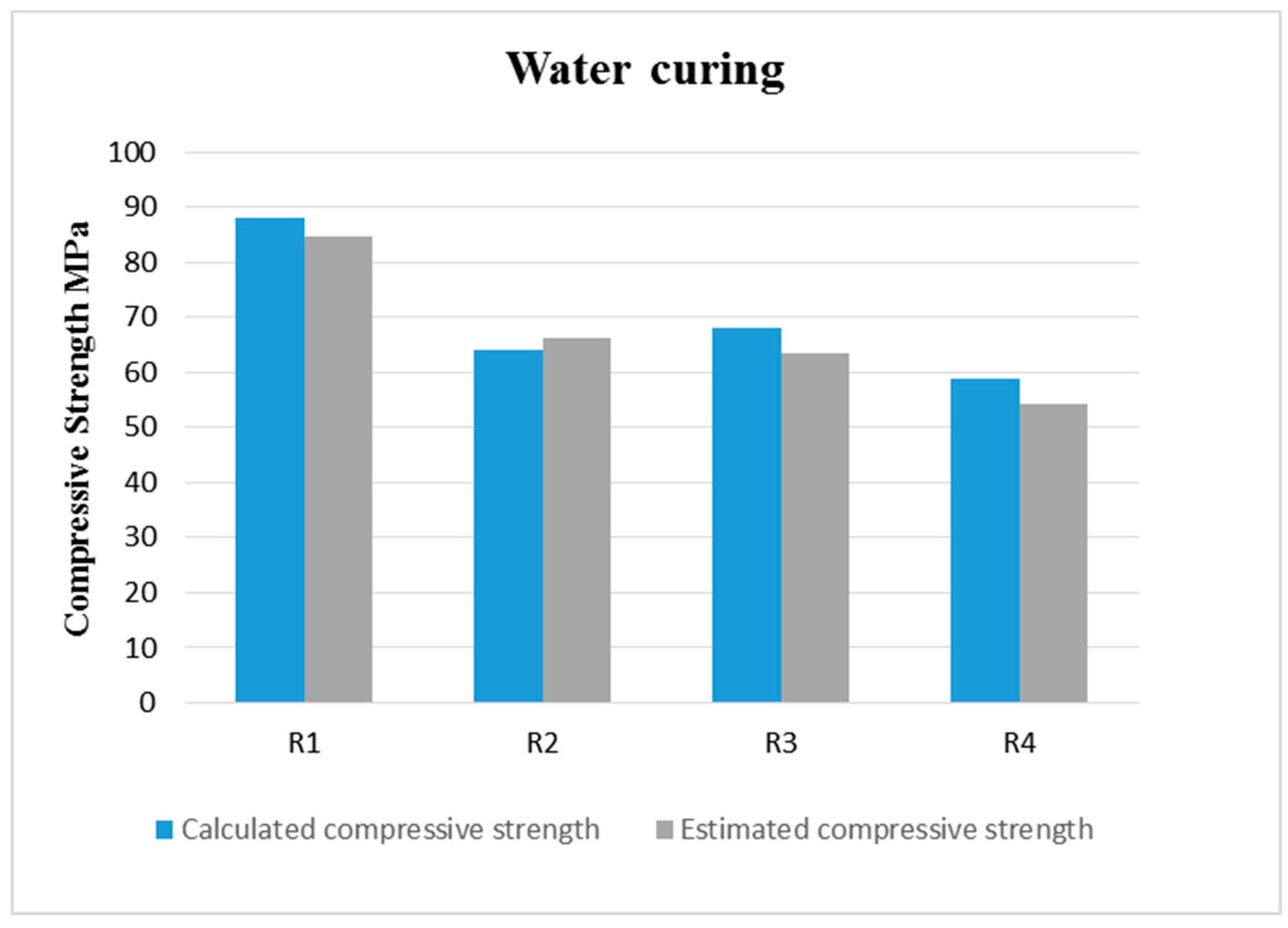

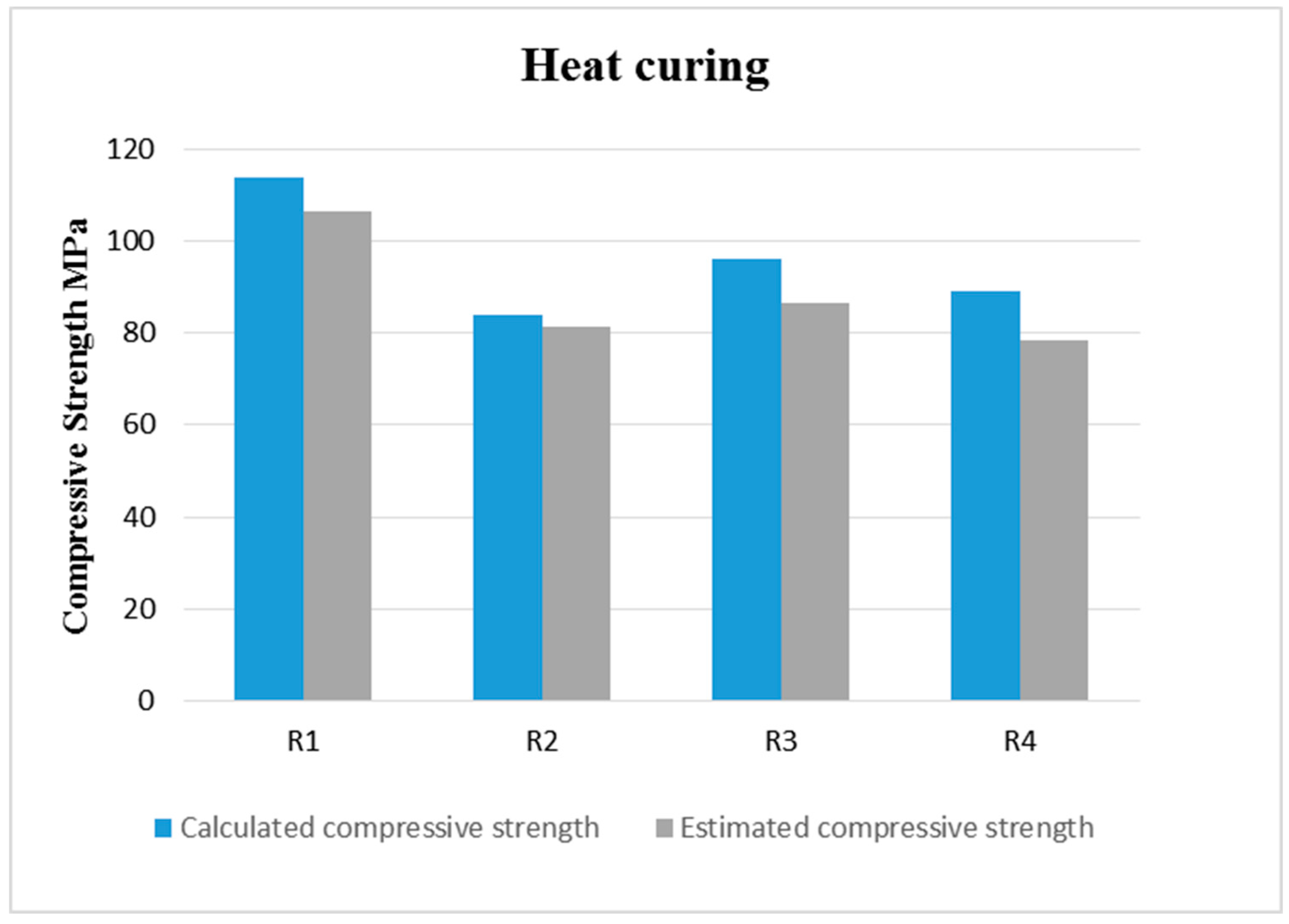

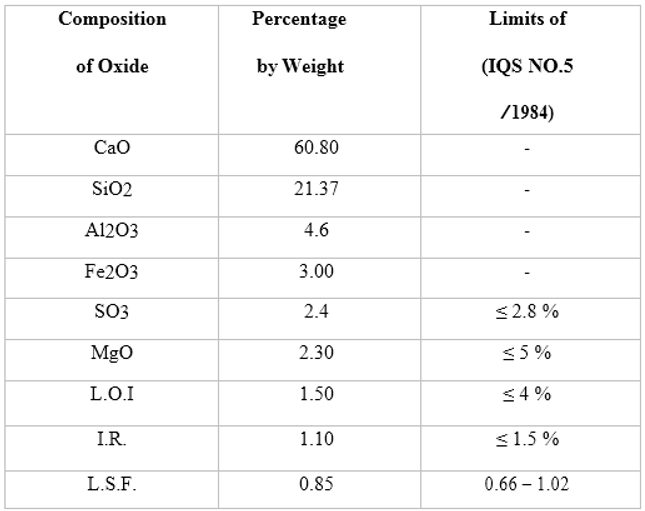

3.1. Compressive Strength

Figure 4 depicts compressive strength values for RPC mixtures. As anticipated, thermal curing resulted in greater strength than water curing. In comparison to other mixtures, R1 demonstrated the greatest compressive strength. However, the addition of silica fume to R3 increased its potency in comparison to that of metakaolin. As it is commonly understood, pozzolanic materials produce additional calcium silicate hydrate as a result of the reaction between the reactive silica in pozzolan and the calcium hydroxide that is formed during the hydration of cement. This behavior can be attributed to the extremely high values of the pozzolanic activity index and specific surface area exhibited by silica fume in comparison to metakaolin, hence resulting in enhanced strength properties. The pozzolanic reactions in the RPC mixes were strongly activated under heat curing which results in the formation of a microstructure that is denser and a rapid gain of strength. Additionally, the benefits that will result by silica fume addition to RPC will mainly become apparent after various curing methods have been applied to the RPC mix [

31]. Therefore, the curing process contributes a significant role in developing RPC’s strength. In addition to this, it was noted that the conventional curing procedure is not very adequate for RPC since the rate of strength development and the hardening process would be fairly slow [

32]. The most practical temperature for RPC heat curing can reach up to 250°C, although being subjected to temperatures higher than this may result in a reduction in compressive strength. This could additionally lead to major damage to the microstructure because of the fact that the surface of the specimens possesses many cracks and pores [

31,

33]. The primary benefits of heat curing can be simply outlined as it leads to the formation of a compacted microstructure and enhances the mechanical properties of (RPC) by promoting the early-stage reactivity of fresh RPC. This reactivity facilitates the accelerated pozzolanic reaction between supplementary cementitious materials (silica fume) and cement, resulting in the formation of new crystallized hydrates. The process of heat curing induces alterations in the chemical composition of the hydrated grains included in reactive powder concrete (RPC). Also, it has the potential to reduce the proportion of calcium oxide in relation to silicon dioxide. Additionally, it decreases the water-to-calcium oxide ratio [

34,

35]. Finally, the improvement in strength can be attributed to the presence of finely distributed silica fume, which is used as a filling supplemental cementitious material inside the matrix of the concrete. This increase after 7 days was 53%, 56%, 65% and 83%, while after 28 days was 30%, 31%, 41% and 51% for R1, R2, R3 and R4 respectively in comparison with water curing.

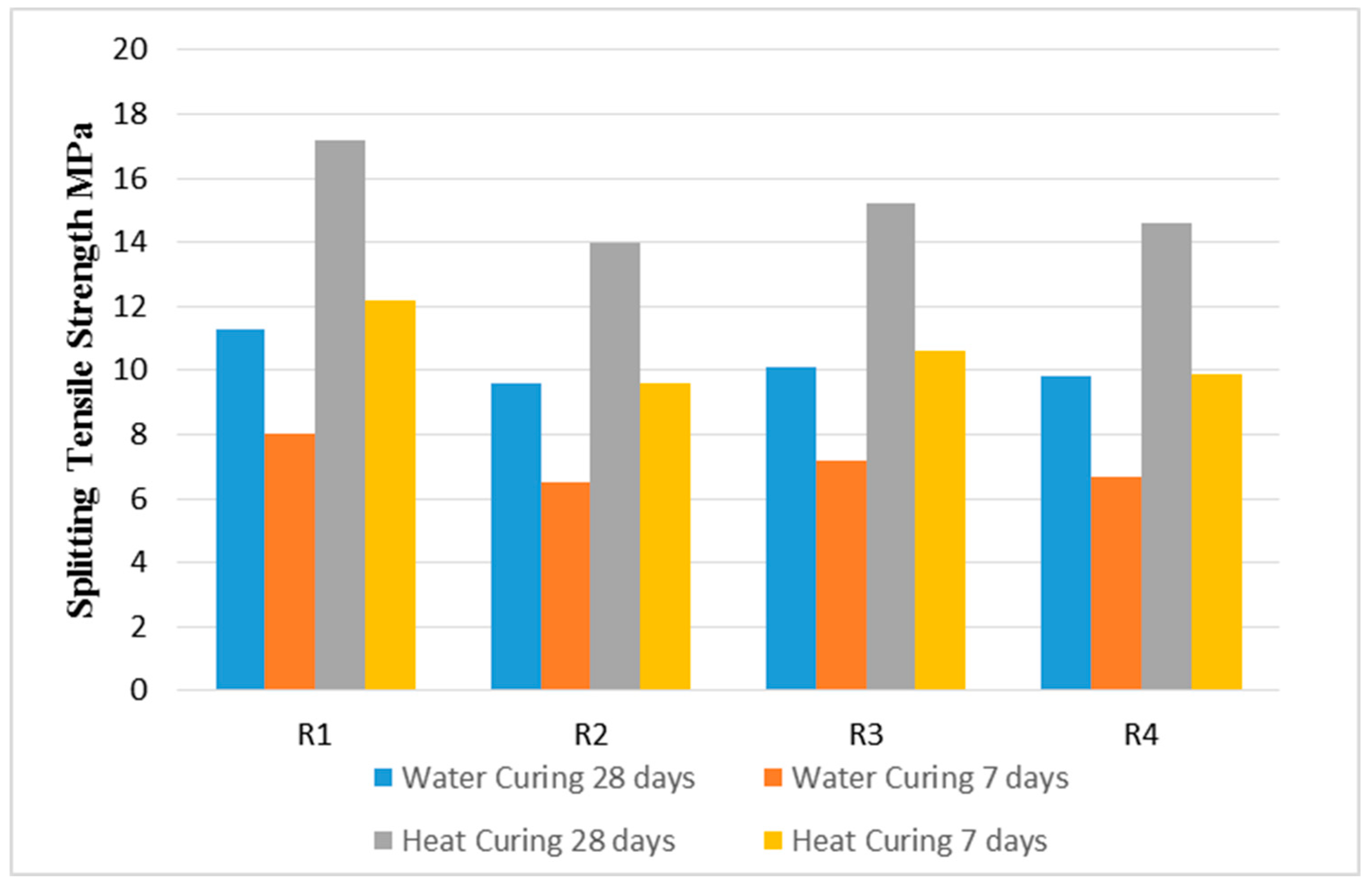

3.2. Indirect Tensile Strength

Figure 5 depicts the results of an indirect tensile strength test conducted on the various RPC mixtures used in this study. The use of heat curing for RPC mixes resulted in a considerable enhancement of the indirect tensile strength when compared to specimens that underwent water curing. This occurred due to the fact that this process and the steel fibers can be used to fill up cracks caused by tension and prevent their propagation due to the voids filling and high reactivity [

36]. Moreover, the utilization of hooked-end steel fibers results in a significant enhancement in tensile strength, which may be attributed to the effect of the hooked-end fiber shape on bond development, therefore leading to an increase in the energy required for removing the fiber from the specimen.

The addition of SF in R1 and R3 showed higher strength than in R2 and R4, This behavior may be ascribed to the fact that the incorporation of (SF) in the (RPC) has led to improve the bond between the steel fibers and the other components, which can be attributed to the interfacial-toughening effect. The influence of supplemental cementitious materials (SF) on the concrete results in an increase in the compaction of the cementitious matrix, mostly attributed to the improved particle packing. This densification process contributes to the enhancement of the microstructure of the RPC, leading to an increase in its density. Additionally, the intensified chemical reaction resulting from the pozzolanic reaction further contributes to the densification process [

37].

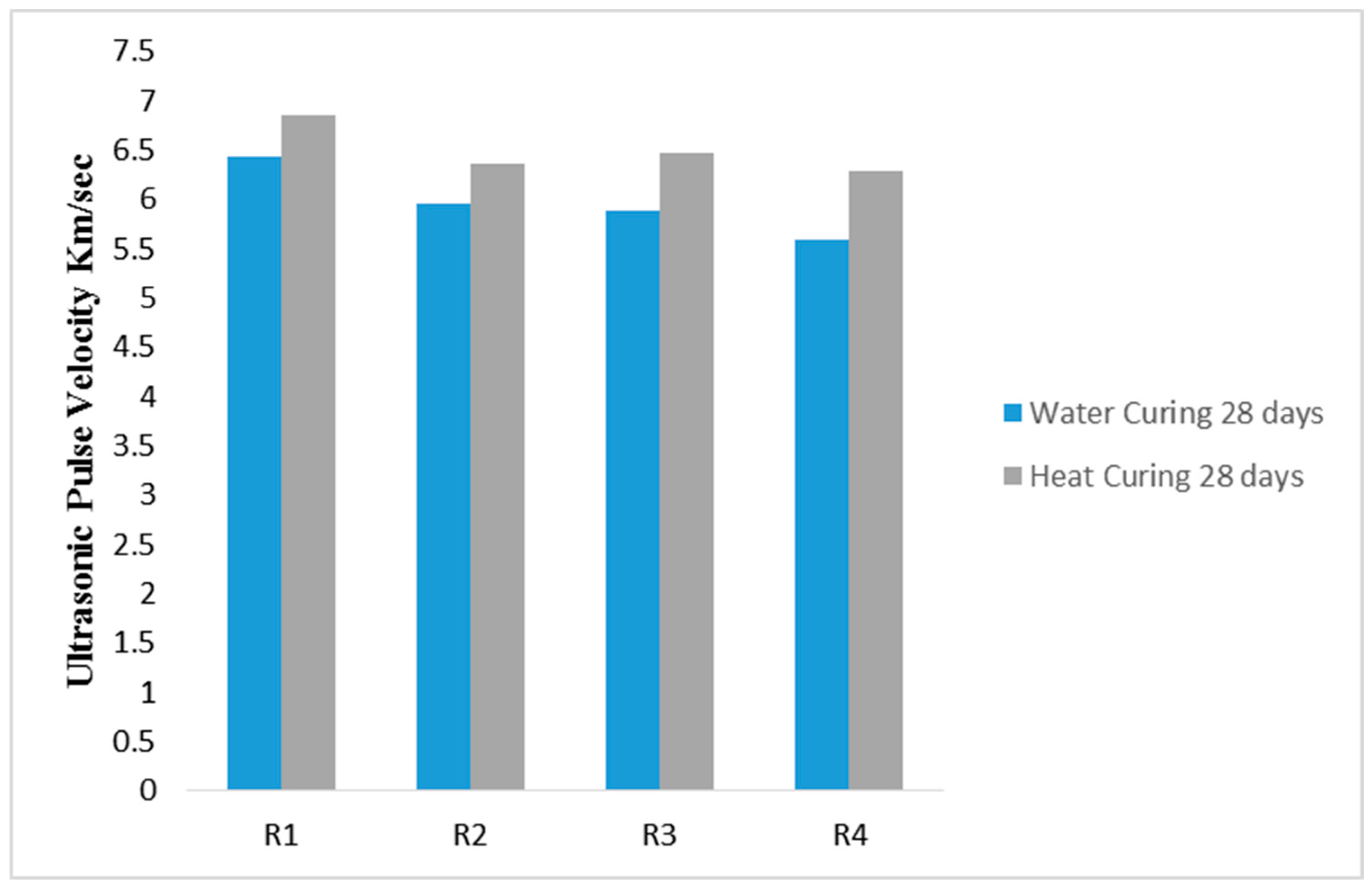

3.3. Ultrasonic Pulse Velocity (UPV)

Ultrasonic Pulse Velocity (UPV) is a widely employed non-destructive testing (NDT) technique utilized for the purpose of assessing the uniformity of concrete and qualitatively evaluating the compressive strength of existing buildings [

38]. The uniformity and quality of concrete may be effectively monitored by considering the density of the materials used, the elasticity modulus, and the mechanical characteristics of the concrete, all these factors have an effect on UPV [

39]. The findings of the UPV test are depicted in

Figure 6. It was found that heat curing showed higher velocities than water curing, this is an ordinary behavior, because as mentioned in compressive strength, this type of curing motivated and fastened the hydration reaction and the use of very fine admixtures filled the voids. As the influence of mixing, material characteristics, the structure of voids, and characteristics of the (ITZ) on ultrasonic pulse velocity (UPV) values are well-known, the presence of pozzolanic additives has a significant impact on the filling of voids in the (ITZ), with the extent of this effect being influenced by the fineness and activity of these materials. Furthermore, the presence of supplemental cementitious materials leads to the generation of additional calcium-silicate-hydrate through the process of pozzolanic reaction [

40]. Due to the fact that silica fume possesses a highly specific surface and activity, the highest UPV results were obtained.

The results of this investigation showed that the UPV results for RPC mixes fell in the range of 6.8634–5.5959 Km/s which is higher than the limits (3.660–4.575k m/s) set by [

41] for the excellent quality concrete, Also, the UPV results for every mix exceeded 4.5 km/s, which is the upper limit that Whitehurst specifies for strong concrete [

42].

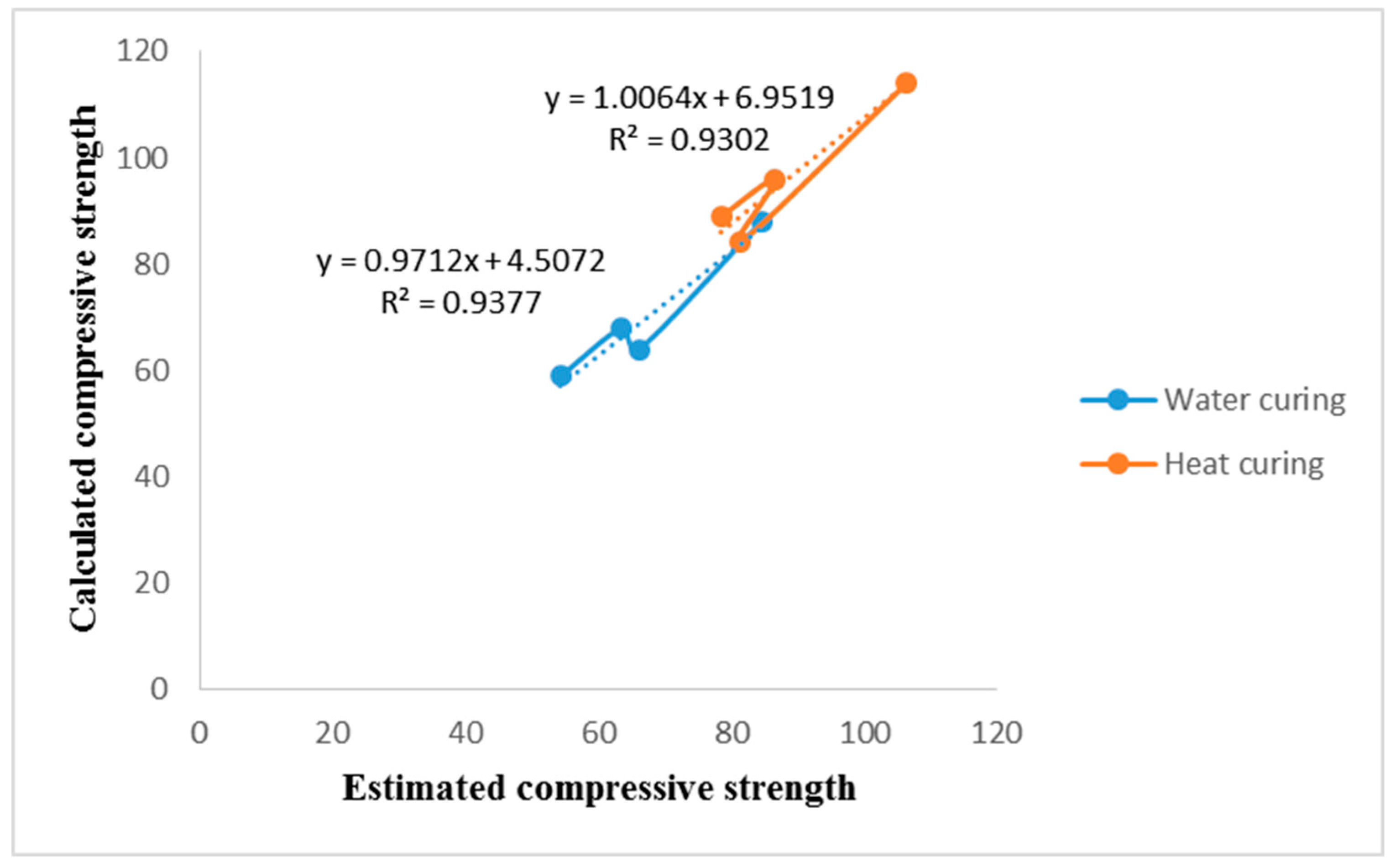

On the other hand, UPV was used to estimate the compressive strength by using linear equation and compare the results with the calculated compressive strength as shown in

Figure 7 and

Figure 8. Results indicated that the estimated compressive strength was almost close to the calculated compressive strength with R² = 0.9377 and R² = 0.9302 for water and heat curing respectively as illustrated in

Figure 9.

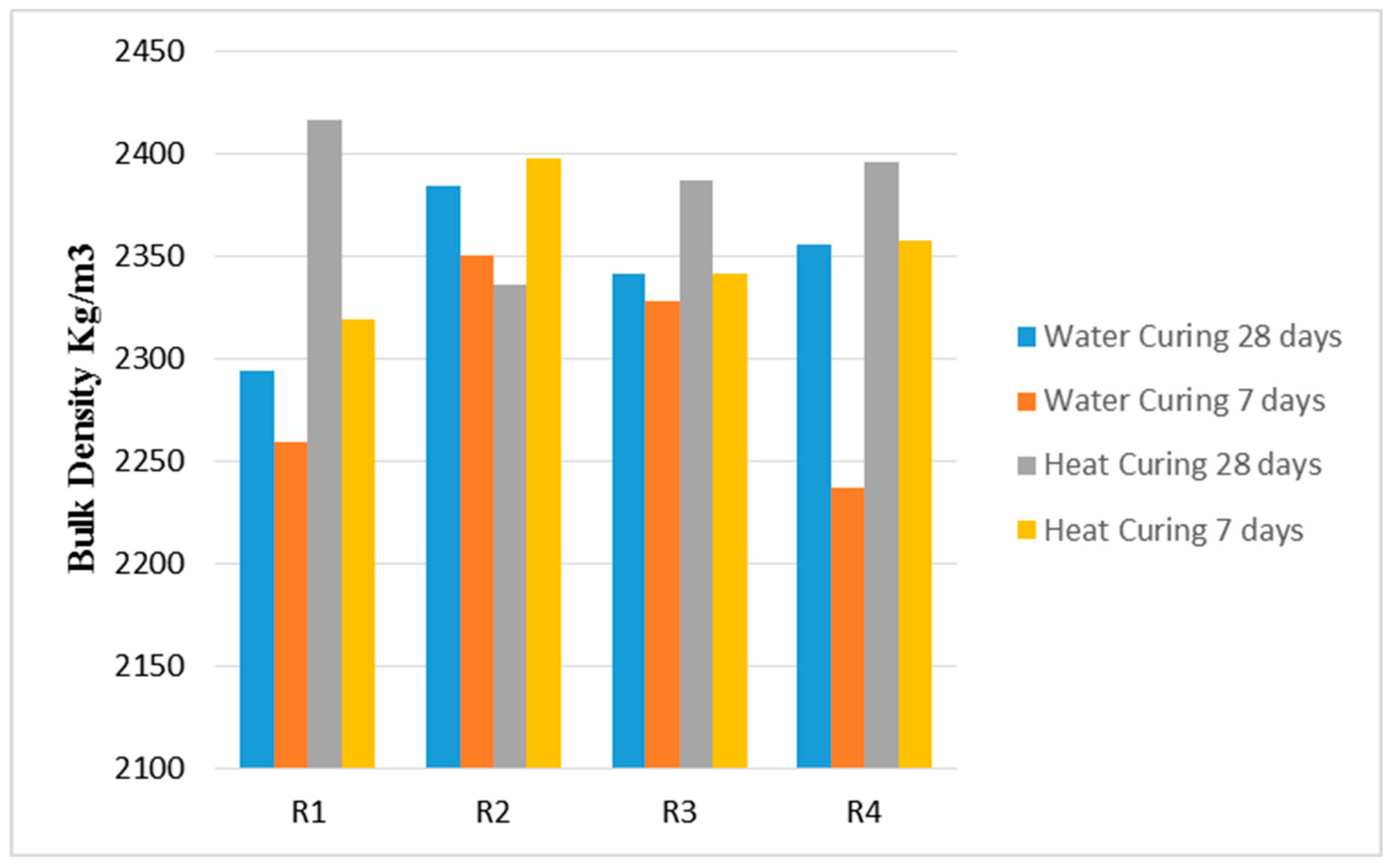

3.4. Bulk Density

Figure 10 displays the findings of a bulk density test performed on RPC mixes. Results showed that R1 possesses the highest density, while the heat curing provided higher density than that of water curing, also the replacement of cement with MK decreases the density more than SF. Heat curing showed higher density due to the high reactivity of pozzolanic materials which accelerate the reaction with water and the fact that these materials possess very high surface area and high fineness which helped fill the voids among the constituents. In addition, these materials possess a specific gravity lower than that of cement which causes this decrease. Additionally, it is generally known that applying heat curing to fresh RPC mixes may result in a denser structure by reducing the number and size of entrapped air voids as well as the related free water content.

Furthermore, while comparing the results of the UPV, it is obvious that the slowest velocity was found in R4 under water curing, while the fastest was recorded in R1 under heat curing, which matches how the density results behave. This result is to be anticipated due to the fact that the density is also influenced by the presence of voids inside the specimen, which in turn has an effect on the velocity.

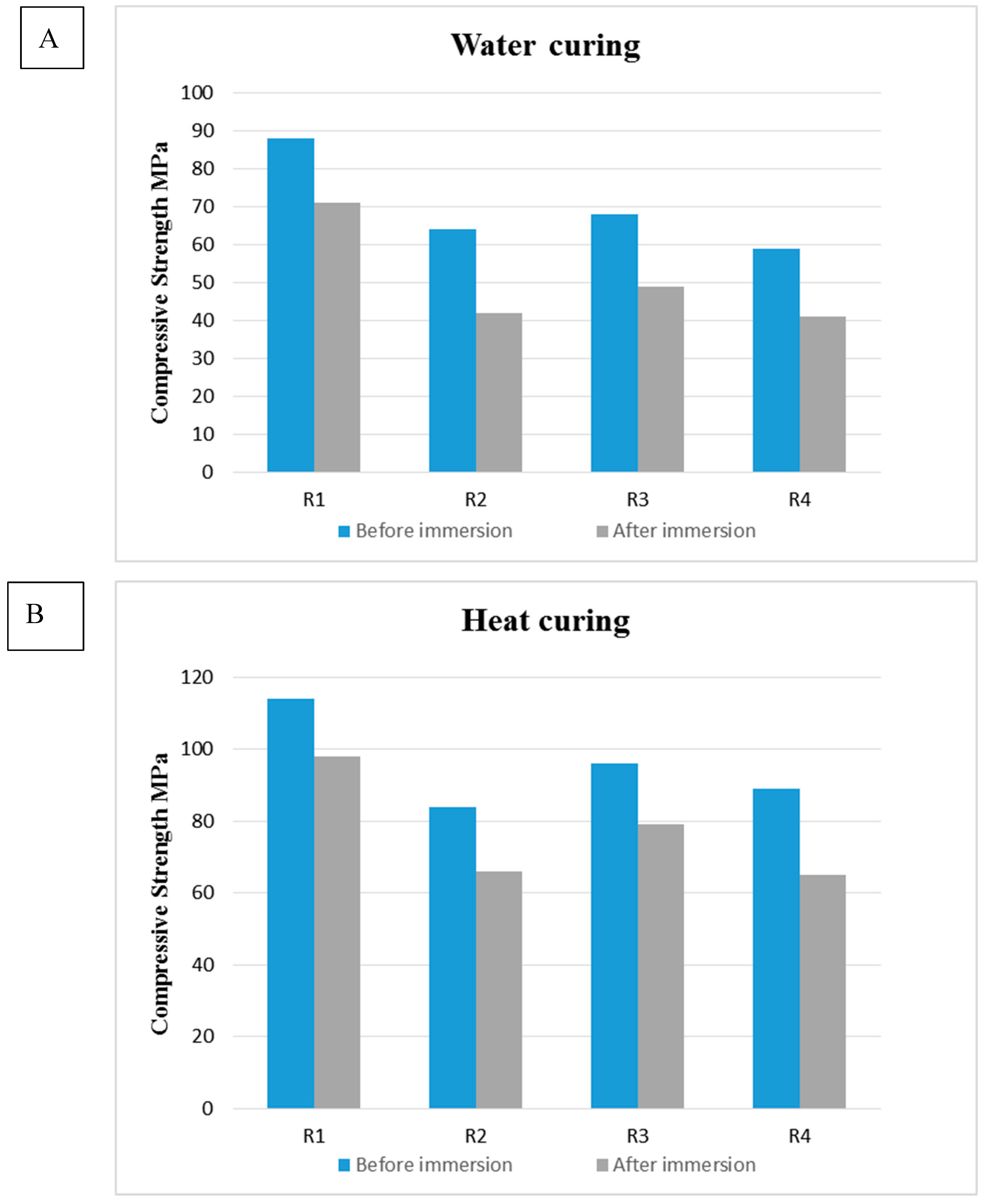

3.5. Exposure to Sulfuric Acid

The influence of sulfuric acid was determined by compressive strength based on the immersion time to assess the residual strength of the RPC against the chemical attack.

Figure 11 represents the variation in compressive strength of all mixes after 60 days under water and heat curing respectively. The results showed that the compressive strength decreased after the immersion in sulfuric acid, and it was 19%, 34%, 28% and 31% under water curing, while under heat curing the decrease was 14%, 21%, 18% and 27%. It is noticed that the specimens under heat curing possess a lower decreasing ratio. This occurred due to the high reactivity that resulted from heating causing the voids and pores to be filled, and also due to the very fine additives that helped in filling the pores and prevented the penetration of sulfuric acid.

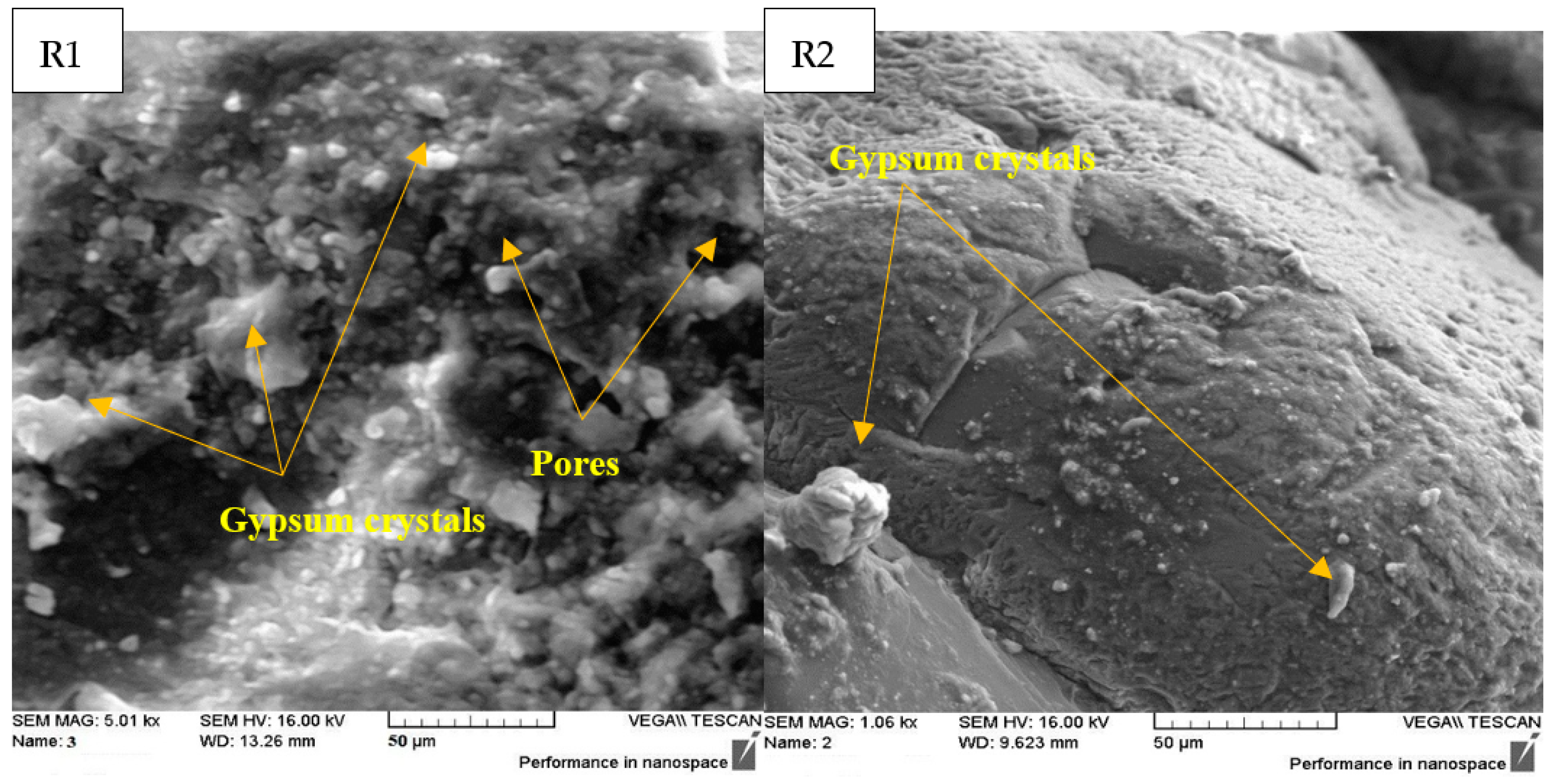

The evaluation of the damage is helpful for acquiring knowledge of the method of attack that sulfuric acid uses. However, it is challenging to acquire a quantitative evaluation of the damage. As illustrated in

Figure 12, during the process of immersion, there is a notable occurrence of significant amounts of gypsum precipitation on the surface of concrete. This occurrence is attributed to the continuous and controlled increase in acid, which is essential for maintaining a steady environment and subsequently leads to an increase in sulfate concentration. The formed gypsum induces an expansive reaction with a consequent cracking [

43].

3.6. Scanning Electron Microscopy

During the immersion, high precipitation of gypsum occurs on the concrete surface due to the continuously increasing sulfuric acid concentration and consequently, increasing gypsum concentration. As illustrated in

Figure 13 the SEM analysis reveals compelling insights into the surface characteristics and microstructural changes. The images captured by SEM showcase a distinct surface morphology, emphasizing the pronounced presence of gypsum crystals. These crystals, exhibiting well-defined geometric structures, contribute to the formation of crystalline coatings on the concrete surface. The analysis further elucidates the penetration of gypsum into the concrete pores, shedding light on alterations in the pore structure. Additionally, the SEM images may expose signs of surface deterioration, such as cracks or fissures, particularly influenced by the severity of acid exposure and gypsum precipitation. The comparative aspect of the analysis allows for a nuanced examination of samples with varying degrees of acid exposure, highlighting differences in gypsum deposition and its consequential impact on the concrete microstructure.

4. Conclusions

This research looked into how different curing techniques and sulfuric acid immersion treatments affected the characteristics of reactive powder concrete (RPC). The following are the findings of this study:

The research demonstrates that heat curing significantly enhances the strength of RPC in comparison to traditional water curing methods. This suggests that heat curing is an effective approach to achieve high-strength RPC.

The mechanical properties of RPC were notably improved with the inclusion of SF, with a more pronounced effect than MK additives. This highlights the importance of the choice and proportion of additives in optimizing RPC properties.

RPC specimens cured under heating exhibited greater resistance to the corrosive effects of sulfuric acid compared to those cured in water. This insight is vital for assessing the durability of RPC under aggressive environmental conditions.

Author Contributions

All authors contributed to the Conceptualization, Methodology, Software, Editing, Reviewing and Writing- Original draft preparation. Mustafa H. Omar was responsible for Visualization, Supervision and Validation. The authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. .

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data supporting this study are included within the article.

Conflicts of Interest

All authors declare that they have no conflict of interest.

References

- Kwan, A. K. H. (2003). Development of high performance concrete for Hong Kong. In Proceedings of Materials Science and Technology in Engineering Conference, Hong Kong (pp. 1-16).

- Aarsleff, L., Bredal-Jorgensen, J., & Poulsen, E. (1984). On the properties of ultra high strength concrete with particular reference to heat of hydration. MRS Online Proceedings Library (OPL), 42, 19.https://doi.org/10.1557/proc-42-19. [CrossRef]

- Baache, H. H. (1981, June). Superplasticizers in Concrete. In Proceedings of the 2nd International Conference on Superplasticizers in Concrete, Ottawa, Ontario, Canada (pp. 10-12).

- Richard, P., & Cheyrezy, M. (1995). Composition of reactive powder concretes. Cement and concrete research, 25(7), 1501-1511.https://doi.org/10.1016/0008-8846(95)00144-2. [CrossRef]

- Cyr, M. F., & Shah, S. P. (2002). Advances in concrete technology. In Advances in building technology (pp. 17-27). Elsevier.

- Shannag, M. J. (2000). High strength concrete containing natural pozzolan and silica fume. Cement and concrete composites, 22(6), 399-406.10.1016/s0958-9465(00)00037-8.

- Abdul Hadi, S., & Hassan Omar, M. (2016). Effect of hydrocarbon solutions on polymer concrete. Engineering and Technology Journal, 34(2B), 234-242. https://doi.org/10.30684/etj.34.2b.6. [CrossRef]

- Wong, K. Y. (1996). Development of high strength concrete for Hong Kong and investigation of their mechanical properties. HKU Theses Online (HKUTO).

- Shaheen, E., & Shrive, N. G. (2006). Optimization of mechanical properties and durability of reactive powder concrete. ACI Materials Journal, 103(6), 444.

- Semioli, W. J. (2001). The new concrete technology. Concrete international, 23(11), 75-79.

- Richard, P., & Cheyrezy, M. H. (1994). Reactive powder concretes with high ductility and 200-800 MPa compressive strength. Special Publication, 144, 507-518.

- Sezer, G. İ. (2012). Compressive strength and sulfate resistance of limestone and/or silica fume mortars. Construction and Building Materials, 26(1), 613-618.https://doi.org/10.1016/j.conbuildmat.2011.06.064. [CrossRef]

- Siddique, R., & Klaus, J. (2009). Influence of metakaolin on the properties of mortar and concrete: A review. Applied Clay Science, 43(3-4), 392-400.https://doi.org/10.1016/j.clay.2008.11.007. [CrossRef]

- Zaidan, S. A., & Omar, M. H. (2018). The effects of bauxite, metakaolin, and porosity on the thermal properties of prepared Iraqi clays refractory mortars. Applied Physics A, 124(5), 386.https://doi.org/10.1007/s00339-018-1759-2. [CrossRef]

- Jawad, S. I., & Omar, M. H. (2022). Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar. Journal of the Mechanical Behavior of Materials, 32(1), 20220265. https://doi.org/10.1515/jmbm-2022-0265. [CrossRef]

- Rebentrost, M., & Cavill, B. (2006). Reactive powder concrete bridges. In AUSTROADS BRIDGE CONFERENCE, 6TH, 2006, PERTH, WESTERN AUSTRALIA.

- Collepardi, M., Collepardi, S., Troli, R., & Coppola, L. (2003). Innovative concretes (SCC, HPC and RPC) in the field of architectural, civil and environmental engineering. In Proceedings of the Workshop on New Technologies and Material in Civil Engineering, Milan (pp. 1-8).

- Iraqi Standard. (1984) Portland cement. The Central Organization for Standardization and Quality Control. No. 5.

- Iraqi Specification. (1988). Aggregate from natural sources for concrete and construction. No 45.

- ASTM C1240. (2015). Standard specification for use of silica fume as mineral admixtures in hydraulic-cement concrete, mortar and grout. Annual Book of ASTM Standards, American Society for Testing and Materials.

- Omar, M. H., Almeshal, I., Tayeh, B. A., & Bakar, B. A. (2022). Studying the properties of epoxy polymer concrete reinforced with steel and glass fibers subjected to cycles of petroleum products. Case Studies in Construction Materials, 17, e01668. https://doi.org/10.1016/j.cscm.2022.e01668. [CrossRef]

- ASTM C494. (2005). Standard specification for chemical admixtures for concrete.

- Aldabagh, I. S., Abed, J. M., Khaleel, B. A., & Sor, N. H. (2022). Influence of water quality and slag on the development of mechanical properties of self compacting mortar. Materials Today: Proceedings, 57, 892-897. https://doi.org/10.1016/j.matpr.2022.02.575. [CrossRef]

- SOR, H., & Abdulwahid, N. A. D. H. I. M. (2018). The effect of superplasticizer dosage on fresh properties of self-compacting lightweight concrete produced with coarse pumice aggregate. Journal of Garmian University, 5(2), 190-209. https://doi.org/10.24271/garmian.336. [CrossRef]

- Sarika, S. (2015). A study on properties of reactive powder concrete. Literatures, 3(5), 10-17577.https://doi.org/10.17577/ijertv4is110170. [CrossRef]

- Hasan, Z. A., Nasr, M. S., & Abed, M. K. (2021). Properties of reactive powder concrete containing different combinations of fly ash and metakaolin. Materials Today: Proceedings, 42, 2436-2440.https://doi.org/10.1016/j.matpr.2020.12.556. [CrossRef]

- B.S.1881, Part 116. (1989). "Method for Determination of Compressive Strength of Concrete Cubes", British Standard Institution.

- ASTM C496-86. (1989). “Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens“, Annual Book of ASTM Standard, Vol.04.02.

- ASTM C597-02. (2002). “Standard Test Method for Pulse Velocity through Concrete. Annual Book of ASTM Standard, Vol. 04-02.

- ASTM C138. (2008). "Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete".

- Yazıcı, H., Deniz, E., & Baradan, B. (2013). The effect of autoclave pressure, temperature and duration time on mechanical properties of reactive powder concrete. Construction and Building Materials, 42, 53-63.https://doi.org/10.1016/j.conbuildmat.2013.01.003. [CrossRef]

- Hiremath, P. N., & Yaragal, S. C. (2017). Effect of different curing regimes and durations on early strength development of reactive powder concrete. Construction and Building Materials, 154, 72-87.https://doi.org/10.1016/j.conbuildmat.2017.07.181. [CrossRef]

- Tai, Y. S., Pan, H. H., & Kung, Y. N. (2011). Mechanical properties of steel fiber reinforced reactive powder concrete following exposure to high temperature reaching 800 C. Nuclear Engineering and Design, 241(7), 2416-2424.https://doi.org/10.1016/j.nucengdes.2011.04.008. [CrossRef]

- Hou, X., Cao, S., Rong, Q., Zheng, W., & Li, G. (2018). Effects of steel fiber and strain rate on the dynamic compressive stress-strain relationship in reactive powder concrete. Construction and Building Materials, 170, 570-581. https://doi.org/10.1016/j.conbuildmat.2018.03.101. [CrossRef]

- Omar, M. H., Younis, H. A., Hussian, W. A. (2022). Studying the polymer concrete hardening behavior under different heating conditions. In Minar congress 6 (p. 85).

- Mahdi, B. S. (2009). Properties of self compacted reactive powder concrete exposed to saline solution (Doctoral dissertation, Ph. D. Thesis, Building and Construction Engineering Department, University of Technology, Baghdad).

- Chan, Y. W., & Chu, S. H. (2004). Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cement and concrete research, 34(7), 1167-1172.https://doi.org/10.1016/j.cemconres.2003.12.023. [CrossRef]

- Shariq, M., Prasad, J., & Masood, A. (2013). Studies in ultrasonic pulse velocity of concrete containing GGBFS. Construction and Building Materials, 40, 944-950.https://doi.org/10.1016/j.conbuildmat.2012.11.070. [CrossRef]

- No, T. C. S. (2002). Guidebook on non-destructive testing of concrete structures. Training Course Series.

- Mardani-Aghabaglou, A., Sezer, G. İ., & Ramyar, K. (2014). Comparison of fly ash, silica fume and metakaolin from mechanical properties and durability performance of mortar mixtures view point. Construction and Building Materials, 70, 17-25.https://doi.org/10.1016/j.conbuildmat.2014.07.089. [CrossRef]

- ASTM C1012-04. (2004). Standard test method for length change of hydraulic-cement mortars exposed to a sulfate solution. Annual Book of ASTM Standards, American Society of Testing Materials, Philadelphia, PA, USA.

- Whitehurst, E. A. (1951, February). Soniscope tests concrete structures. In Journal Proceedings (Vol. 47, No. 2, pp. 433-444).

- Irico, S., De Meyst, L., Qvaeschning, D., Alonso, M. C., Villar, K., & De Belie, N. (2020). Severe sulfuric acid attack on self-compacting concrete with granulometrically optimized blast-furnace slag-comparison of different test methods. Materials, 13(6), 1431.https://doi.org/10.3390/ma13061431. [CrossRef]

Figure 1.

(A) silica fume, (B) metakaolin, (C) steel fibers.

Figure 1.

(A) silica fume, (B) metakaolin, (C) steel fibers.

Figure 3.

specimens’ immersion in H2SO4.

Figure 3.

specimens’ immersion in H2SO4.

Figure 4.

results of compressive strength for used RPC.

Figure 4.

results of compressive strength for used RPC.

Figure 5.

results of indirect tensile strength for used RPC.

Figure 5.

results of indirect tensile strength for used RPC.

Figure 6.

results of UPV for used RPC.

Figure 6.

results of UPV for used RPC.

Figure 7.

calculated and estimated compressive strength for used RPC under water curing.

Figure 7.

calculated and estimated compressive strength for used RPC under water curing.

Figure 8.

calculated and estimated compressive strength for used RPC under heat curing.

Figure 8.

calculated and estimated compressive strength for used RPC under heat curing.

Figure 9.

relationship between calculated and estimated compressive strength results for used RPC.

Figure 9.

relationship between calculated and estimated compressive strength results for used RPC.

Figure 10.

Results of bulk density for used RPC.

Figure 10.

Results of bulk density for used RPC.

Figure 11.

Compressive strength as a function of immersion in H2SO4 after 60 days, (A) under water curing, (B) under heat curing.

Figure 11.

Compressive strength as a function of immersion in H2SO4 after 60 days, (A) under water curing, (B) under heat curing.

Figure 12.

tested specimens of RPC after 60 days of immersion.

Figure 12.

tested specimens of RPC after 60 days of immersion.

Figure 13.

SEM images of prepared RPC specimens.

Figure 13.

SEM images of prepared RPC specimens.

Table 1.

chemical composition of used cement.

Table 1.

chemical composition of used cement.

Table 2.

sieve analysis results of used sand.

Table 2.

sieve analysis results of used sand.

Table 3.

physical properties of used sand.

Table 3.

physical properties of used sand.

Table 4.

properties of used SF and MK.

Table 4.

properties of used SF and MK.

Table 5.

properties of used ST.

Table 5.

properties of used ST.

Table 6.

properties of used SP.

Table 6.

properties of used SP.

Table 7.

mix design details used in this work.

Table 7.

mix design details used in this work.

| Mix No. |

Cement |

Sand |

Silica

Fume |

Metakaolin |

Steel

Fibers% |

Water |

W/C ratio |

W/b ratio |

| R1 |

712.5 |

1045 |

237.5 |

- |

0.4 |

208 |

0.29 |

0.22 |

| R2 |

712.5 |

1045 |

- |

237.5 |

0.4 |

208 |

0.29 |

0.22 |

| R3 |

712.5 |

1045 |

142.5 |

95 |

0.4 |

208 |

0.29 |

0.22 |

| R4 |

712.5 |

1045 |

95 |

142.5 |

0.4 |

208 |

0.29 |

0.22 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).