Submitted:

09 January 2024

Posted:

11 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Governing Equations and Turbulence Model

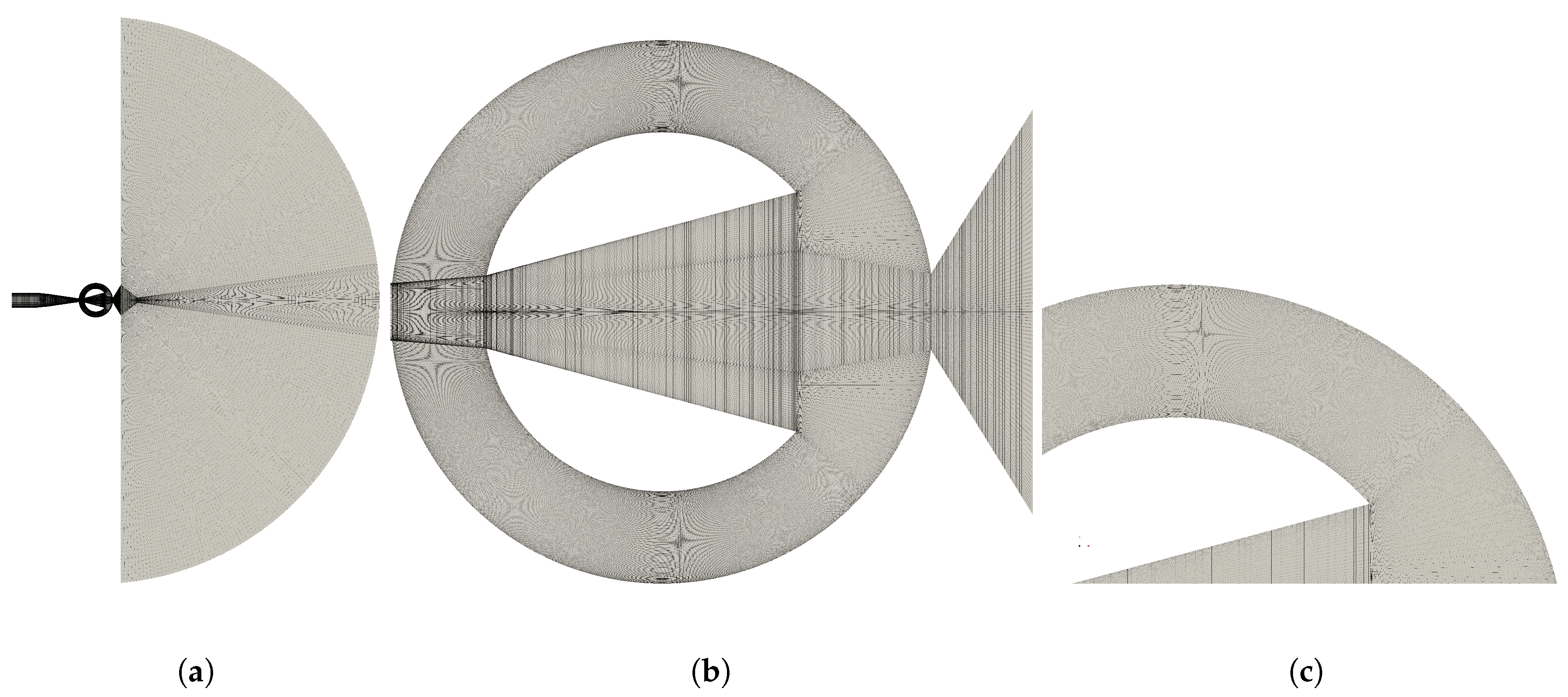

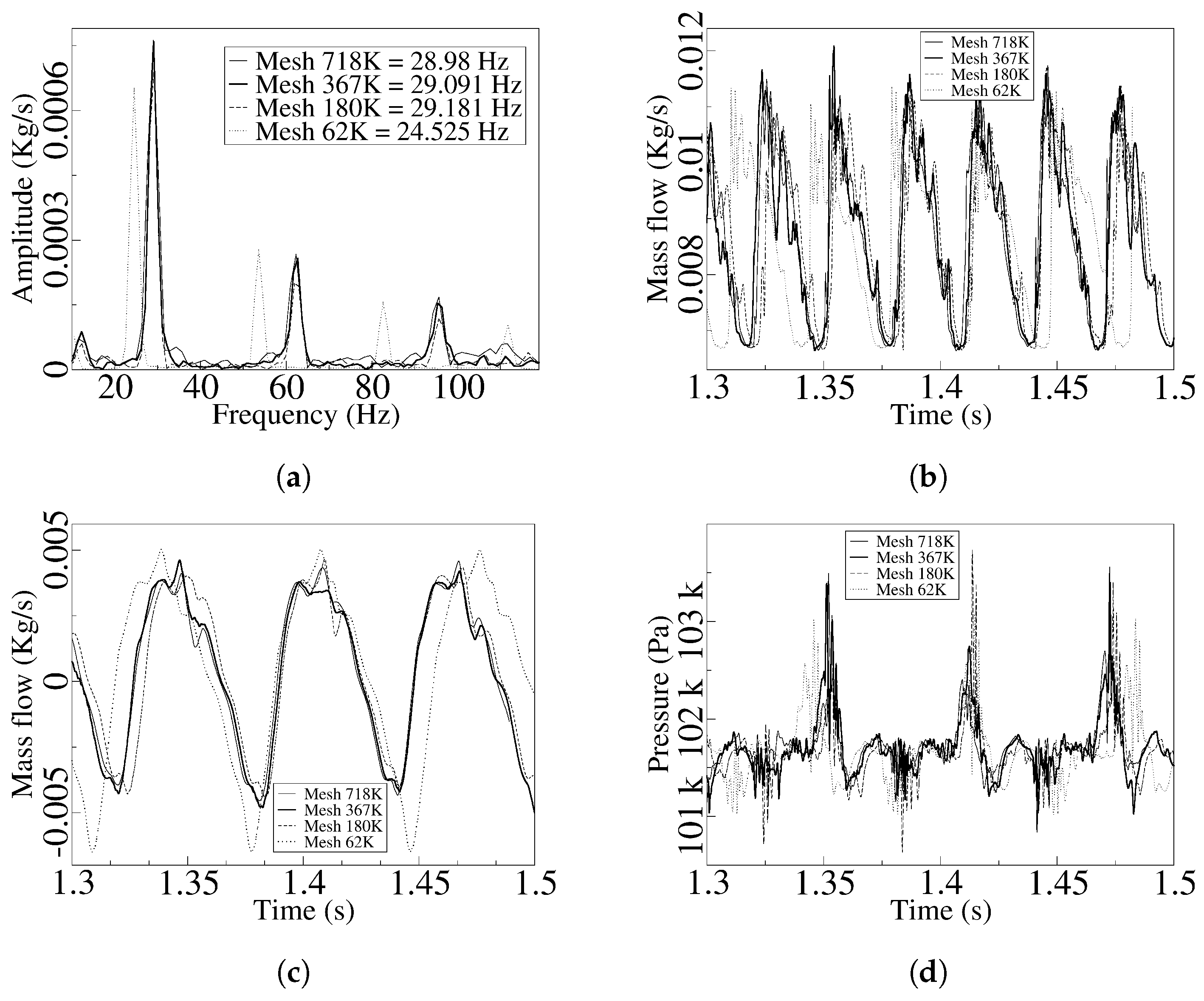

3. Mesh Assessment

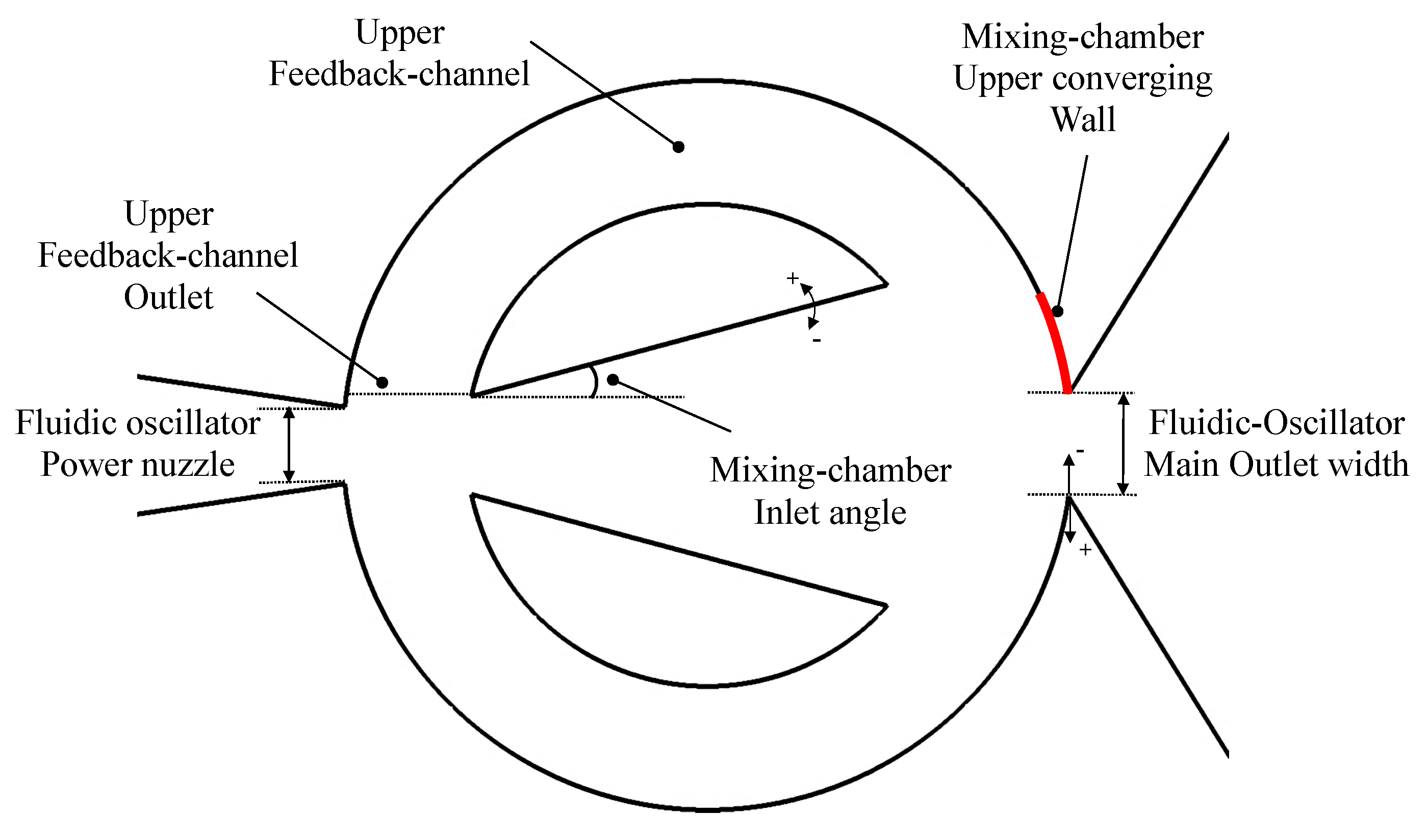

4. Geometrical Modifications Considered

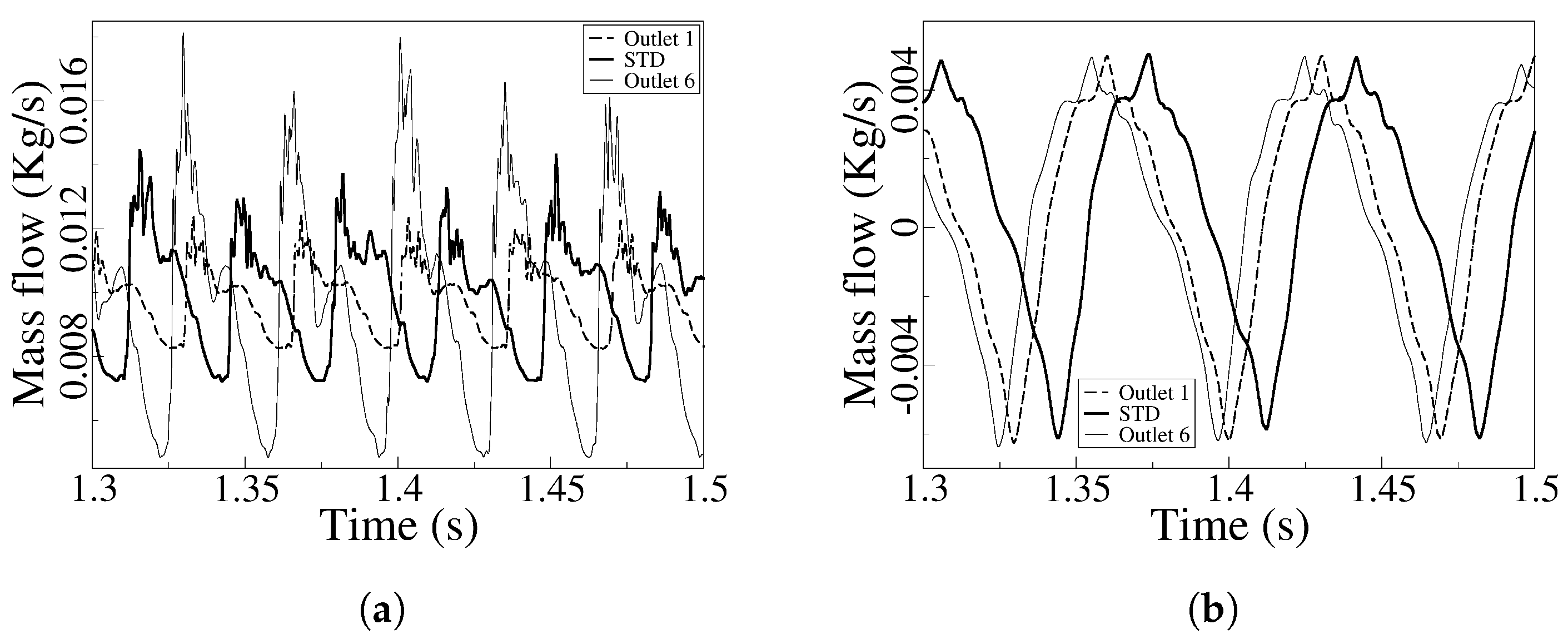

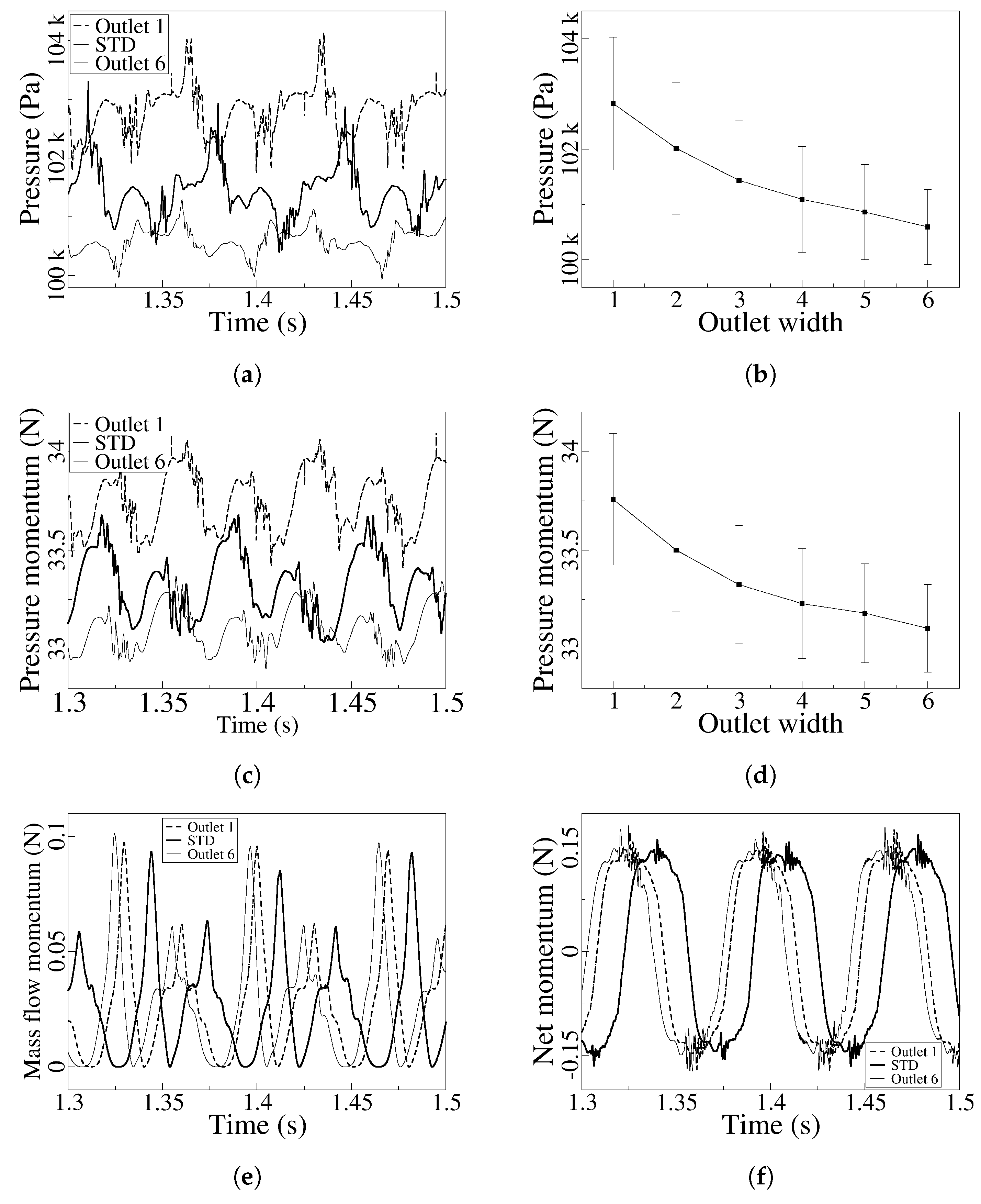

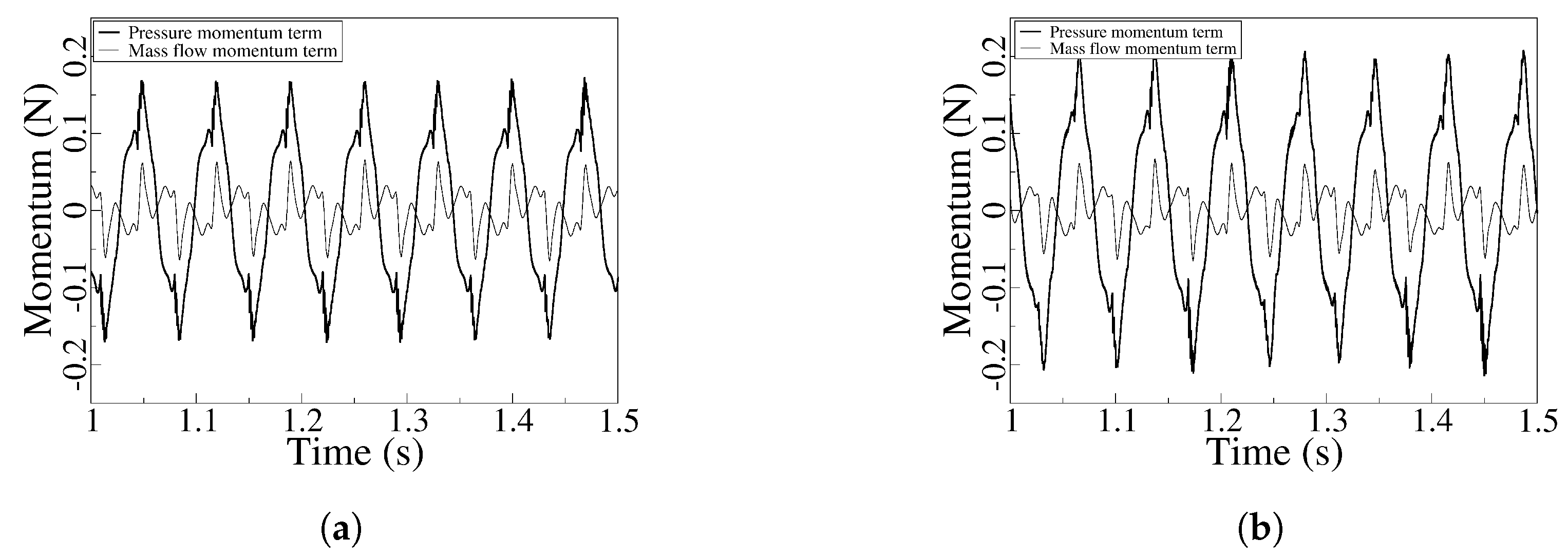

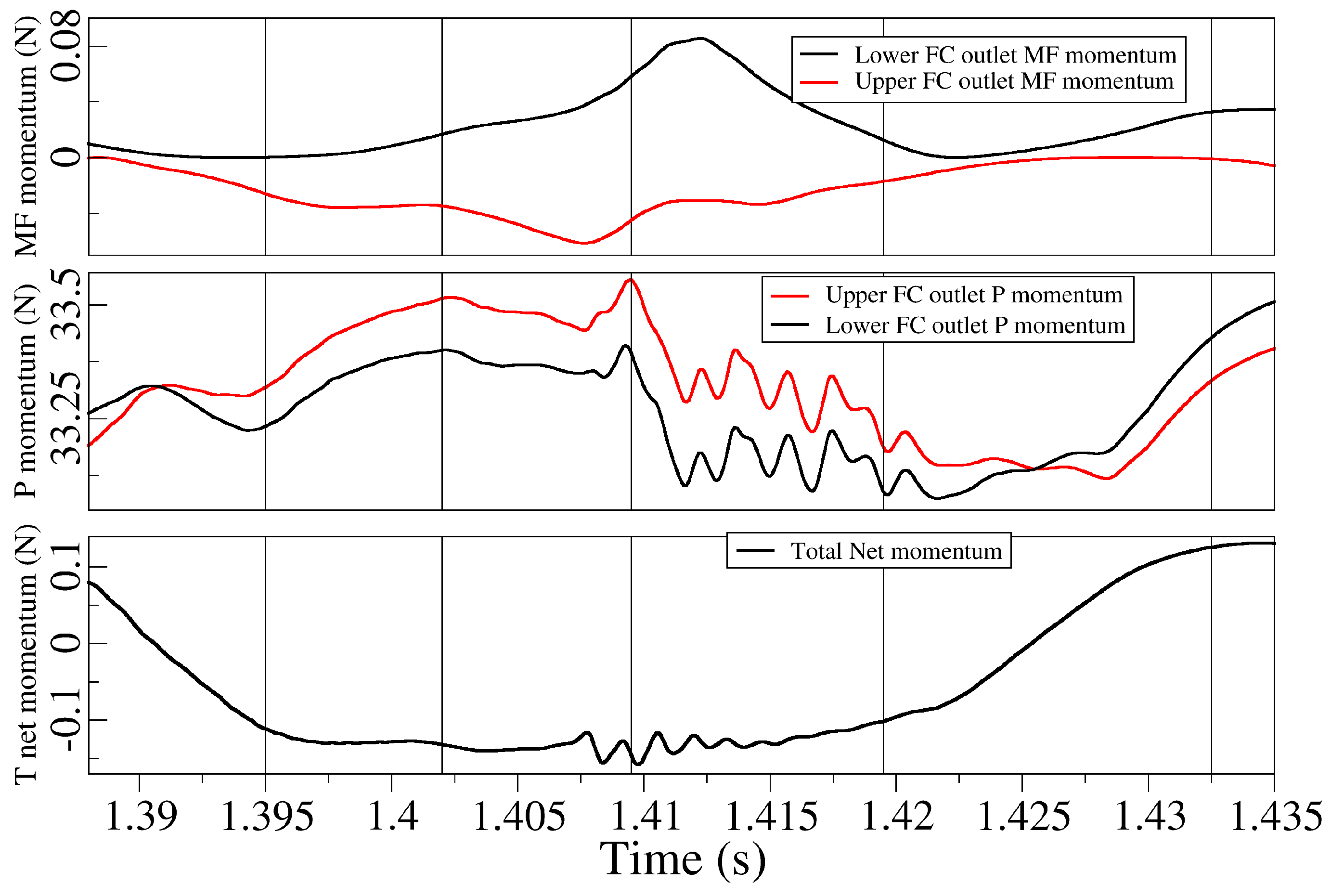

5. Concept of Momentum, Pressure and Mass Flow Terms, Acting on the Jet Entering the Mixing Chamber

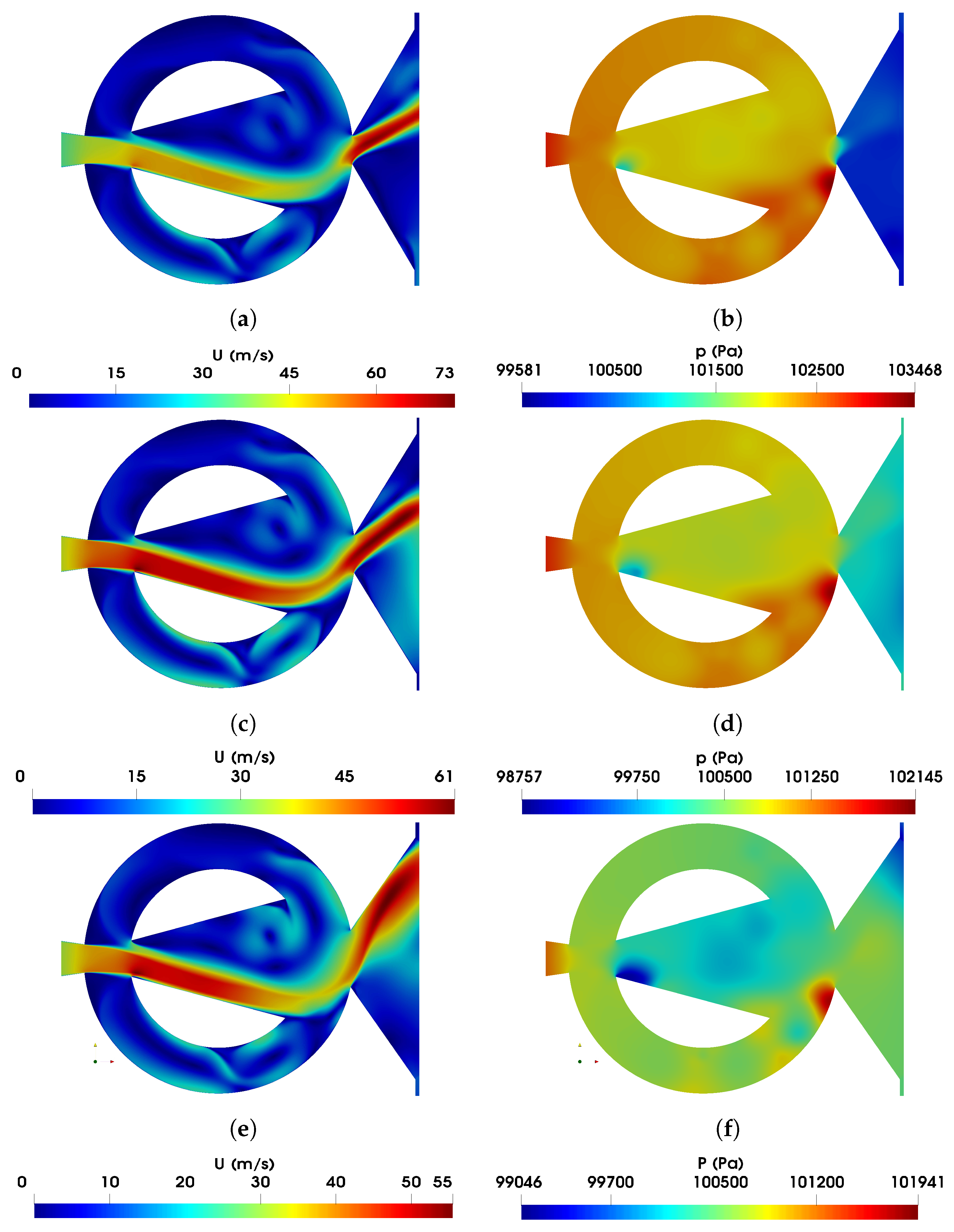

6. Results

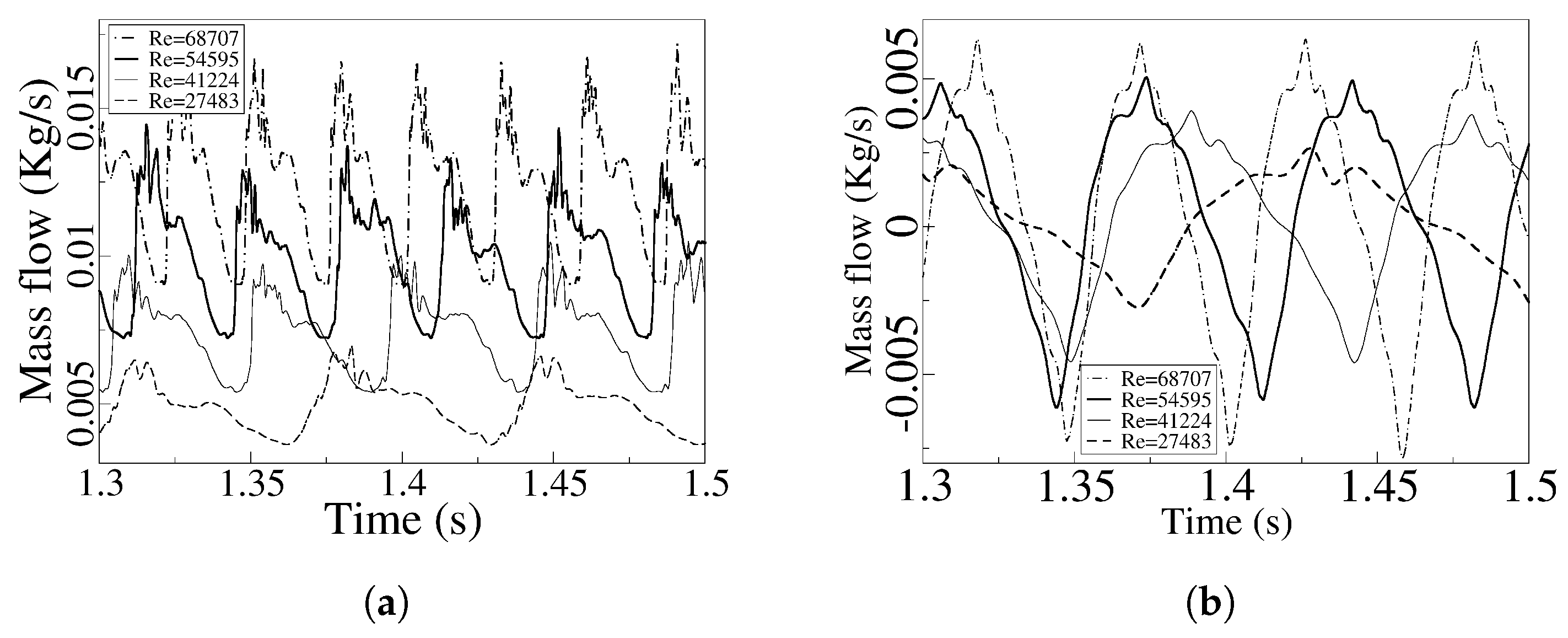

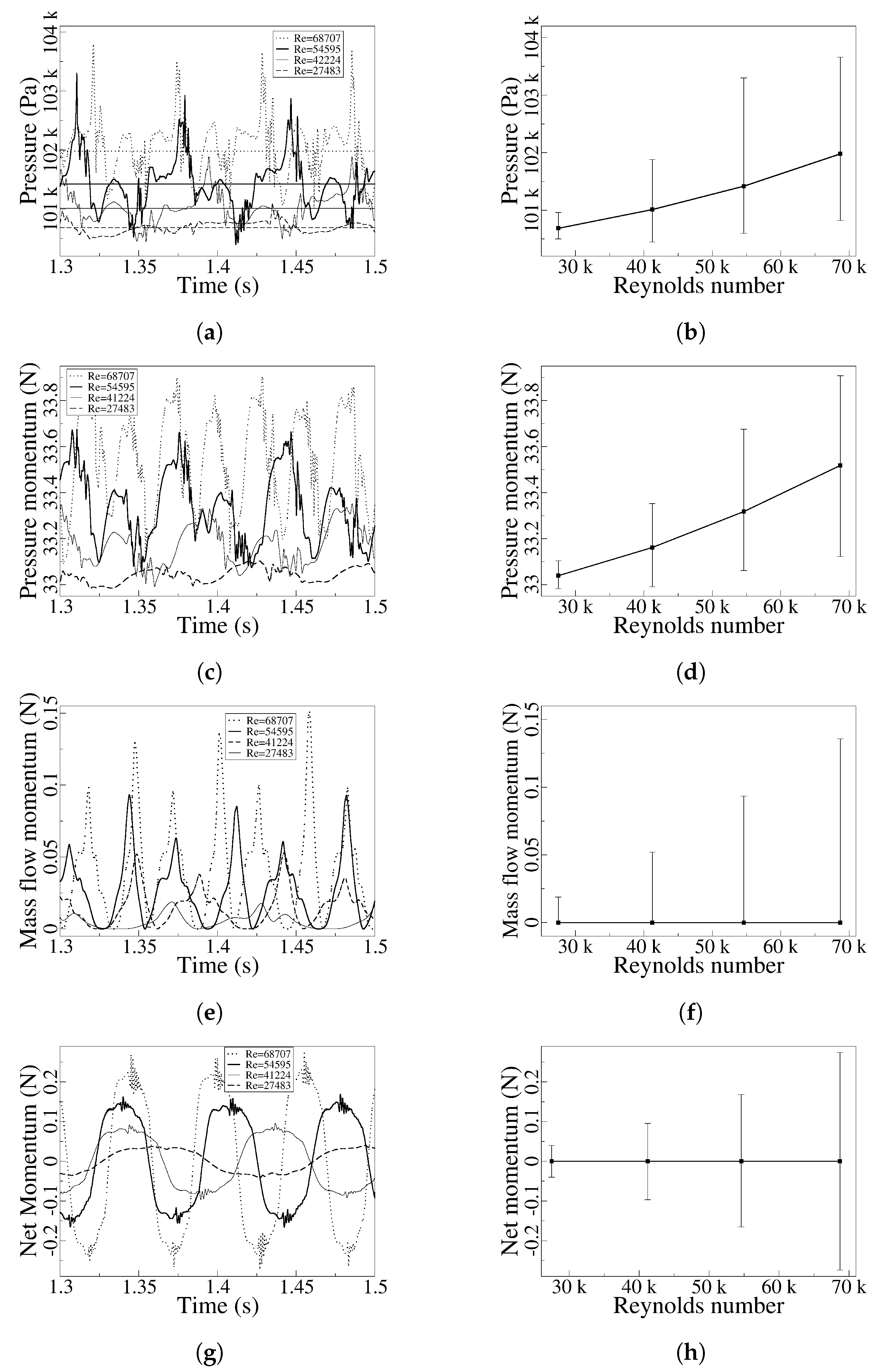

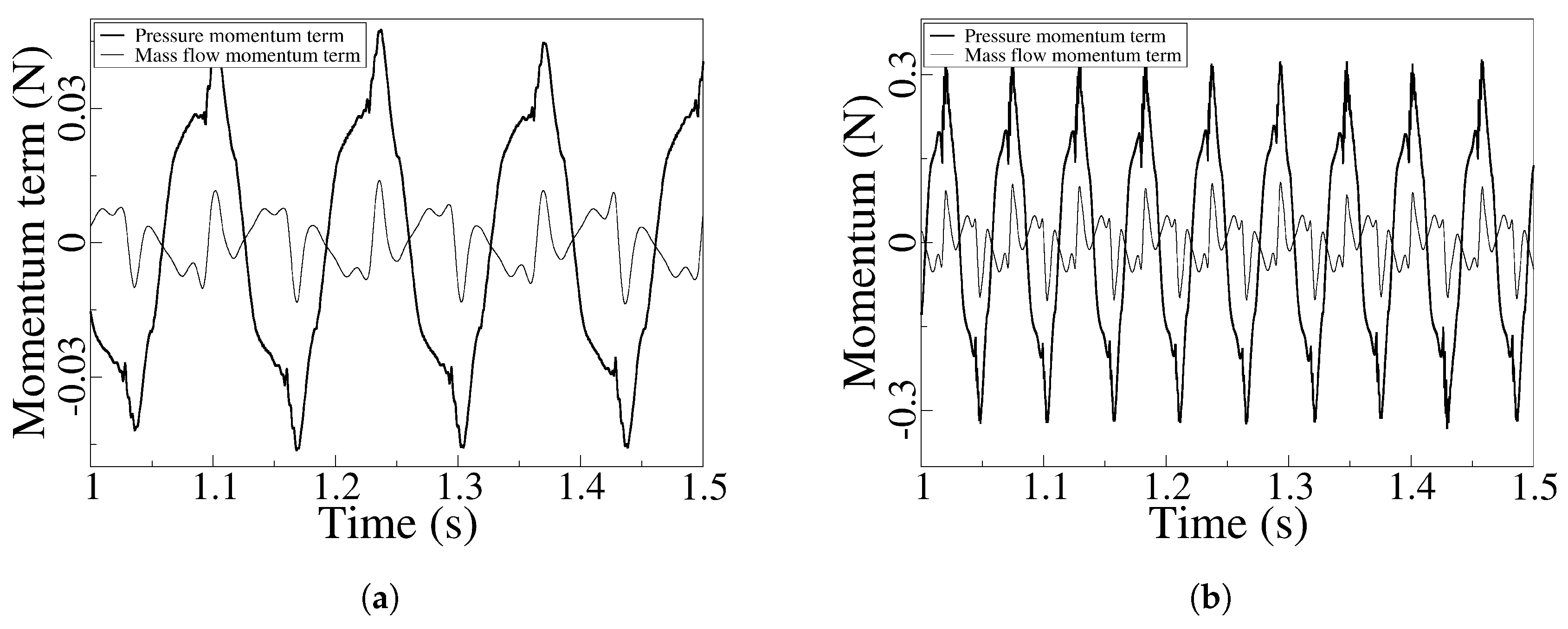

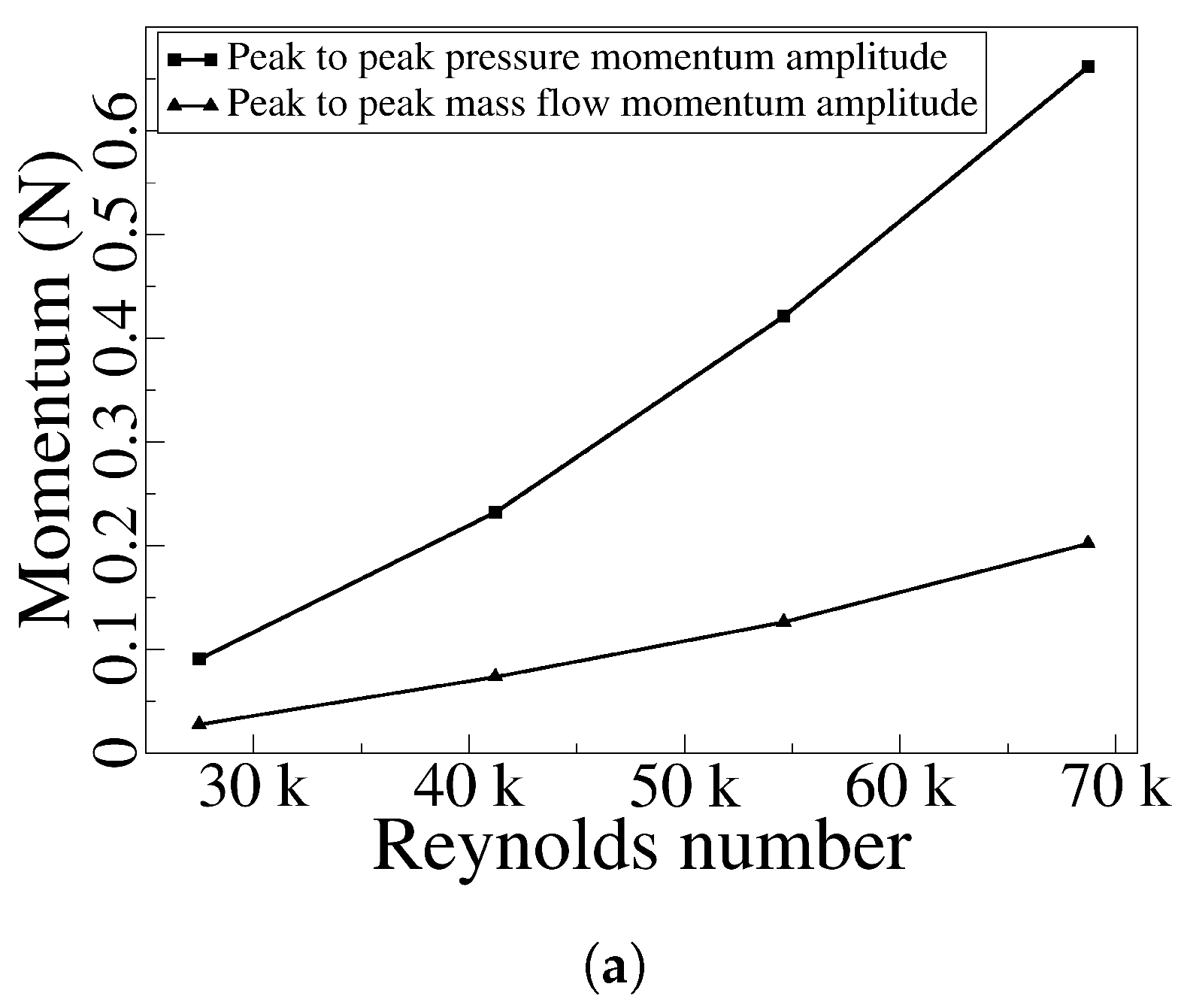

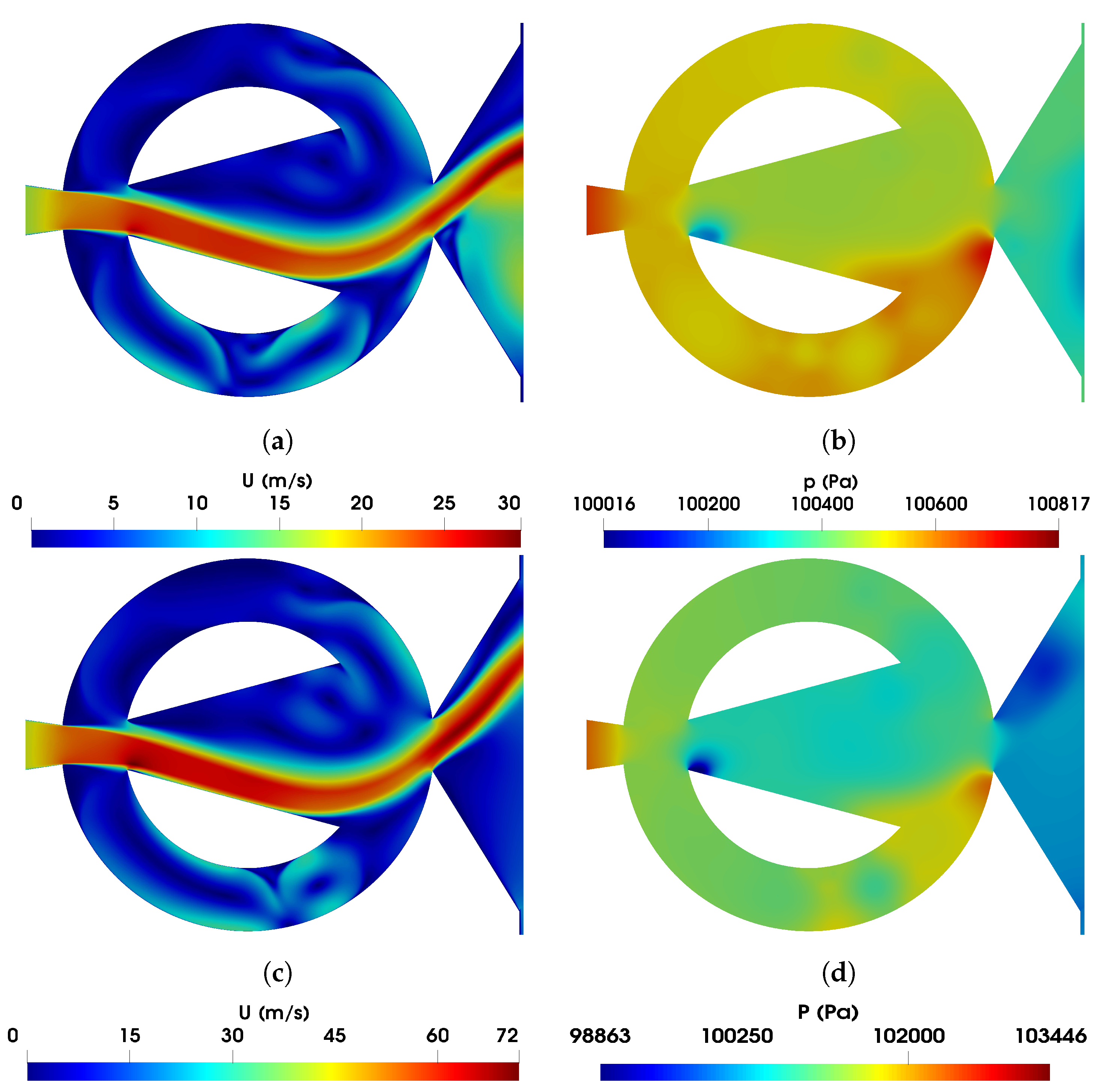

6.1. Reynolds Number Modification

6.2. Outlet width Modification

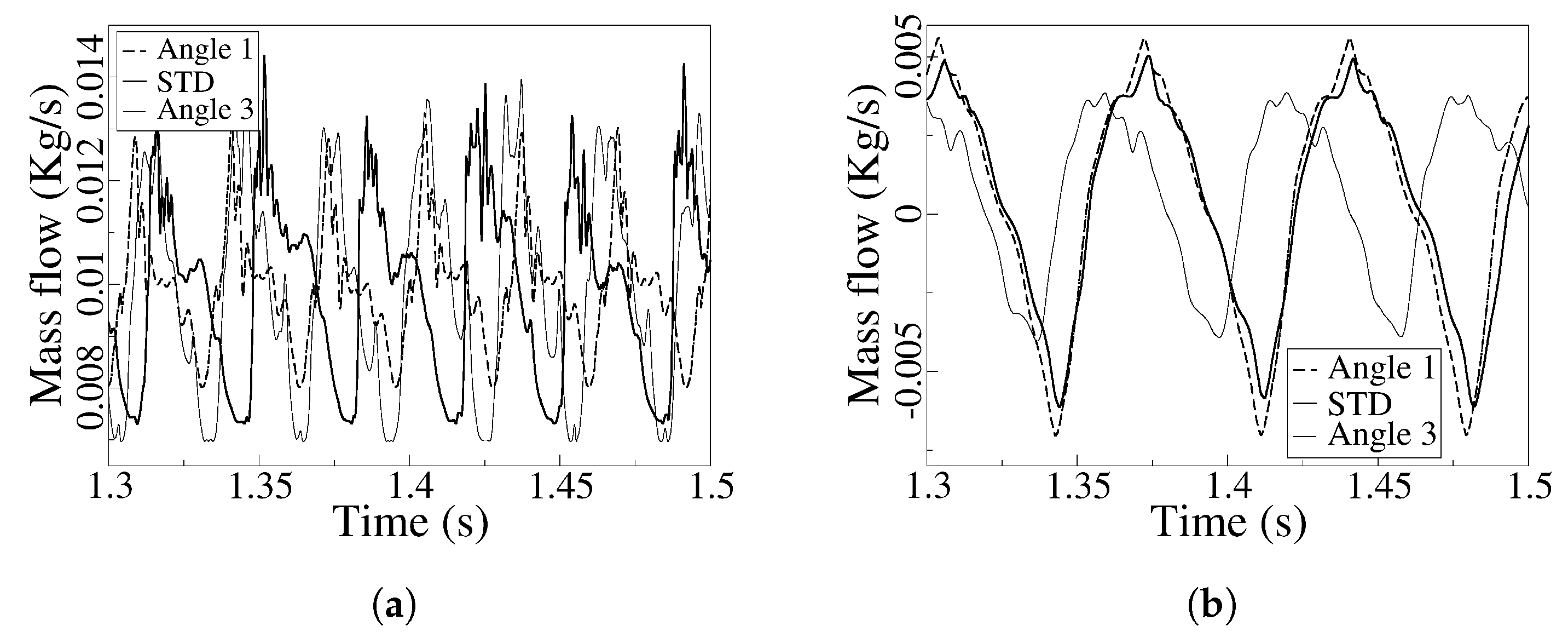

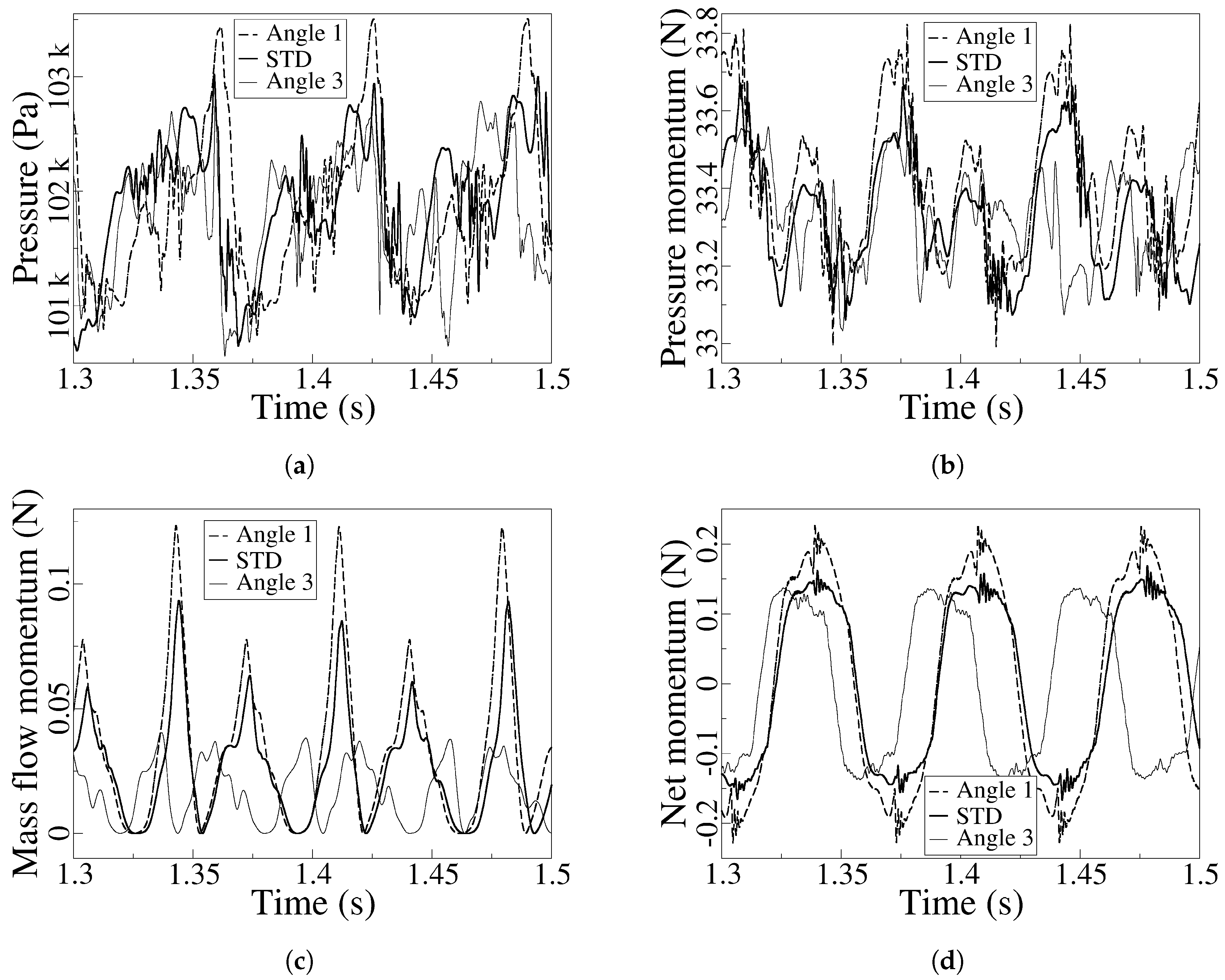

6.3. Mixing Chamber Internal Angle Modification

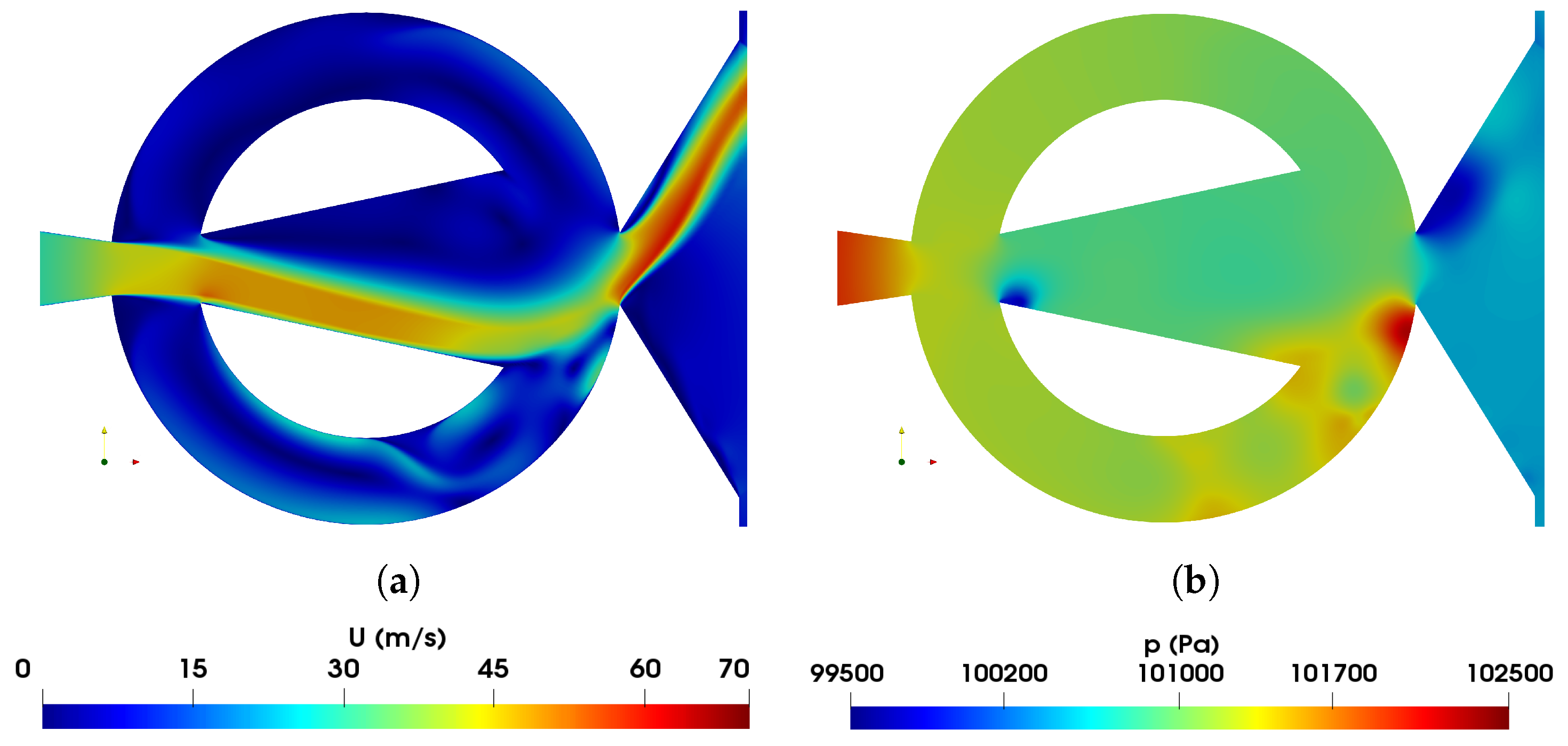

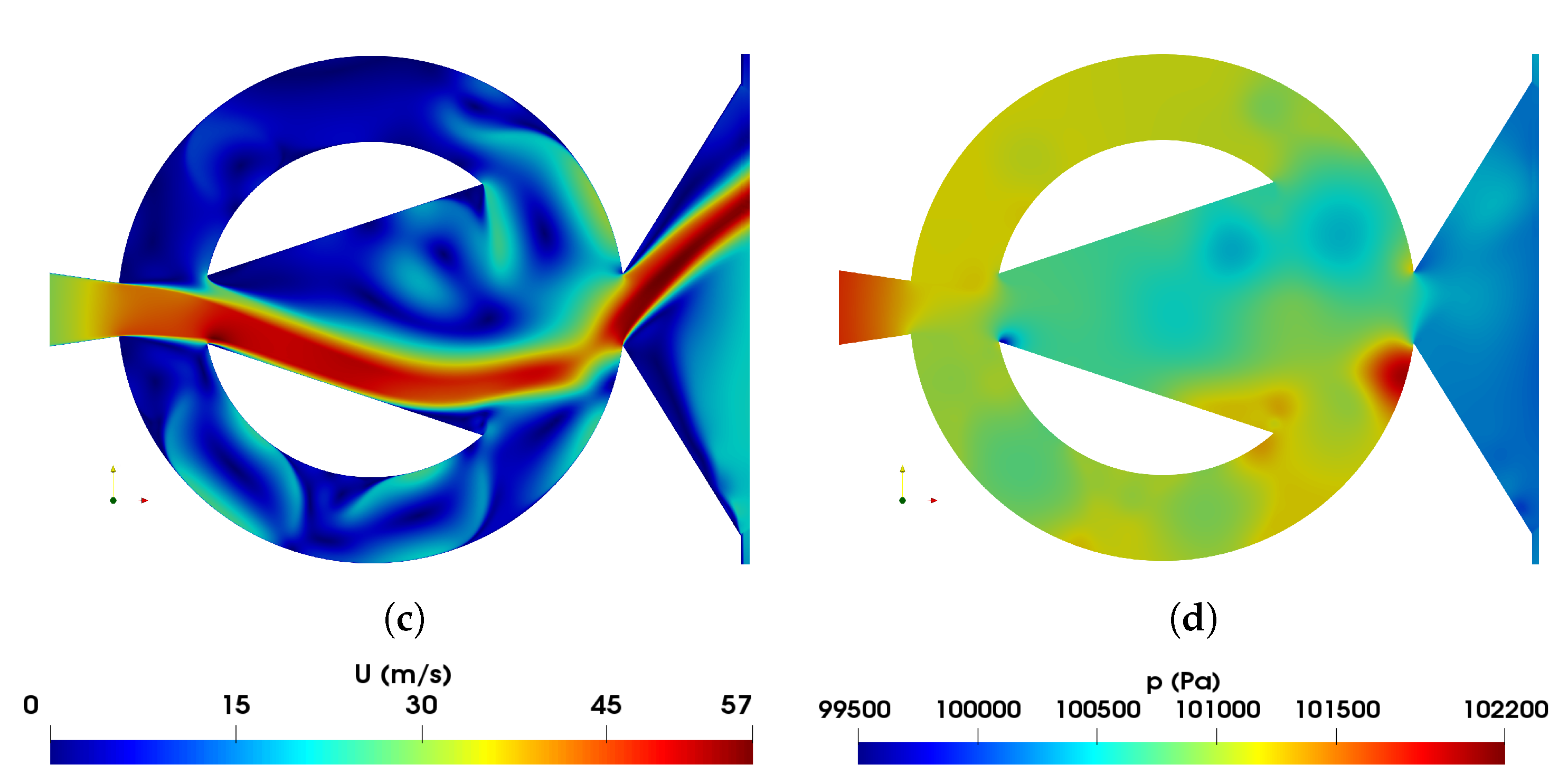

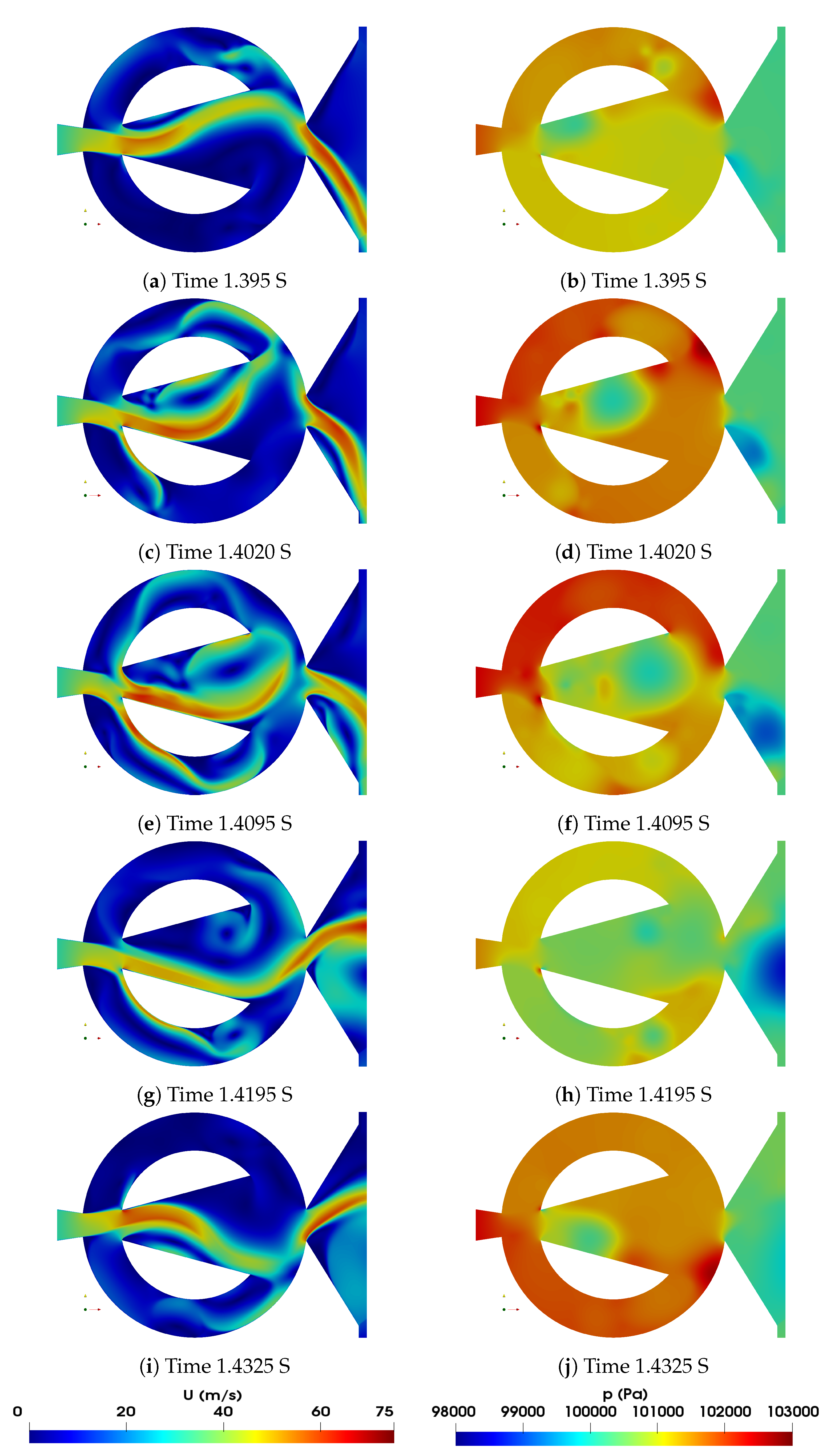

7. Discussion of the Results, Origin of the Self Sustained Oscillations

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ostermann, F.; Woszidlo, R.; Nayeri, C.N.; Paschereit, C.O. Properties of a sweeping jet emitted from a fluidic oscillator. Journal of Fluid Mechanics 2018, 857, 216–238. [Google Scholar] [CrossRef]

- Zeleke, D.S.; Huang, R.F.; Hsu, C.M. Effects of Reynolds number on flow and mixing characteristics of a self-sustained swinging jet. Journal of Turbulence 2020, 21, 434–462. [Google Scholar] [CrossRef]

- Kim, M.; Kim, D.; Yeom, E.; Kim, K.C. Experimental study on heat transfer and flow structures of feedback-free sweeping jet impinging on a flat surface. International Journal of Heat and Mass Transfer 2020, 159, 120085. [Google Scholar] [CrossRef]

- Mohammadshahi, S.; Samsam-Khayani, H.; Cai, T.; Nili-Ahmadabadi, M.; Kim, K.C. Experimental study on flow characteristics and heat transfer of an oscillating jet in a cross flow. International Journal of Heat and Mass Transfer 2021, 173, 121208. [Google Scholar] [CrossRef]

- Handa, T.; Fujimura, I. Fluidic oscillator actuated by a cavity at high frequencies. Sensors and Actuators A: Physical 2019, 300, 111676. [Google Scholar] [CrossRef]

- Suh, J.; Han, K.; Peterson, C.W.; Bahl, G. Invited Article: Real-time sensing of flowing nanoparticles with electro-opto-mechanics. APL photonics 2017, 2. [Google Scholar] [CrossRef]

- Guha, S.; Schmalz, K.; Wenger, C.; Herzel, F. Self-calibrating highly sensitive dynamic capacitance sensor: Towards rapid sensing and counting of particles in laminar flow systems. Analyst 2015, 140, 3262–3272. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kihm, K.D.; Thundat, T. Fluidic applications for atomic force microscopy (AFM) with microcantilever sensors. Experiments in fluids 2010, 48, 721–736. [Google Scholar] [CrossRef]

- Länge, K.; Blaess, G.; Voigt, A.; Götzen, R.; Rapp, M. Integration of a surface acoustic wave biosensor in a microfluidic polymer chip. Biosensors and Bioelectronics 2006, 22, 227–232. [Google Scholar] [CrossRef]

- Sakong, J.; Roh, H.; Roh, Y. Surface acoustic wave DNA sensor with micro-fluidic channels. Japanese Journal of Applied Physics 2007, 46, 4729. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, K.Y. Effects of installation location of fluidic oscillators on aerodynamic performance of an airfoil. Aerospace Science and Technology 2020, 99, 105735. [Google Scholar] [CrossRef]

- Cerretelli, C.; Wuerz, W.; Gharaibah, E. Unsteady separation control on wind turbine blades using fluidic oscillators. AIAA journal 2010, 48, 1302–1311. [Google Scholar] [CrossRef]

- Tousi, N.; Coma, M.; Bergadà, J.; Pons-Prats, J.; Mellibovsky, F.; Bugeda, G. Active flow control optimisation on SD7003 airfoil at pre and post-stall angles of attack using synthetic jets. Applied Mathematical Modelling 2021, 98, 435–464. [Google Scholar] [CrossRef]

- Bobusch, B.C.; Woszidlo, R.; Bergada, J.M.; Nayeri, C.N.; Paschereit, C.O. Experimental study of the internal flow structures inside a fluidic oscillator. Experiments in fluids 2013, 54, 1559. [Google Scholar] [CrossRef]

- Vatsa, V.; Koklu, M.; Wygnanski, I. Numerical simulation of fluidic actuators for flow control applications. 6th AIAA Flow Control Conference, 2012, p. 3239.

- Ostermann, F.; Woszidlo, R.; Nayeri, C.; Paschereit, C.O. Experimental comparison between the flow field of two common fluidic oscillator designs. 53rd AIAA Aerospace Sciences Meeting, 2015, p. 0781.

- Aram, S.; Lee, Y.T.; Shan, H.; Vargas, A. Computational Fluid Dynamic Analysis of Fluidic Actuator for Active Flow Control Applications. AIAA Journal.

- Woszidlo, R.; Ostermann, F.; Nayeri, C.; Paschereit, C. The time-resolved natural flow field of a fluidic oscillator. Experiments in Fluids 2015, 56, 125. [Google Scholar] [CrossRef]

- Gaertlein, S.; Woszidlo, R.; Ostermann, F.; Nayeri, C.; Paschereit, C.O. The time-resolved internal and external flow field properties of a fluidic oscillator. 52nd Aerospace Sciences Meeting, 2014, p. 1143.

- Slupski, B.Z.; Kara, K. Effects of Geometric Parameters on Performance of Sweeping Jet Actuator. 34th AIAA Applied Aerodynamics Conference, 2016, p. 3263.

- Wang, S.; Baldas, L.; Colin, S.; Orieux, S.; Kourta, A.; Mazellier, N. Experimental and numerical study of the frequency response of a fluidic oscillator for active flow control. 8th AIAA Flow Control Conference, 2016, p. 4234.

- Pandey, R.J.; Kim, K.Y. Numerical modeling of internal flow in a fluidic oscillator. Journal of Mechanical Science and Technology 2018, 32, 1041–1048. [Google Scholar] [CrossRef]

- Seo, J.; Zhu, C.; Mittal, R. Flow Physics and Frequency Scaling of Sweeping Jet Fluidic Oscillators. AIAA Journal.

- Bobusch, B.C.; Woszidlo, R.; Krüger, O.; Paschereit, C.O. Numerical Investigations on Geometric Parameters Affecting the Oscillation Properties of a Fluidic Oscillator. 21st AIAA Computational Fluid Dynamics Conference, 2013, p. 2709.

- Baghaei, M.; Bergada, J.M. Analysis of the Forces Driving the Oscillations in 3D Fluidic Oscillators. Energies 2019, 12, 4720. [Google Scholar] [CrossRef]

- Baghaei, M.; Bergada, J.M. Fluidic Oscillators, the Effect of Some Design Modifications. Applied Sciences 2020, 10, 2105. [Google Scholar] [CrossRef]

- Bergadà, J.M.; Baghaei, M.; Prakash, B.; Mellibovsky, F. Fluidic oscillators, feedback channel effect under compressible flow conditions. Sensors 2021, 21, 5768. [Google Scholar] [CrossRef] [PubMed]

- Sarwar, W.; Bergadà, J.M.; Mellibovsky, F. Onset of temporal dynamics within a low reynolds-number laminar fluidic oscillator. Applied Mathematical Modelling 2021, 95, 219–235. [Google Scholar] [CrossRef]

- Lee, S.; Roh, T.S.; Lee, H.J. Influence of jet parameters of fluidic oscillator-type fuel injector on the mixing performance in a supersonic flow field. Aerospace Science and Technology 2023, 134, 108154. [Google Scholar] [CrossRef]

- Tavakoli, M.; Nili-Ahmadabadi, M.; Joulaei, A.; Ha, M.Y. Enhancing subsonic ejector performance by incorporating a fluidic oscillator as the primary nozzle: a numerical investigation. International Journal of Thermofluids 2023, 20, 100429. [Google Scholar] [CrossRef]

- Menter, F. Zonal two equation kw turbulence models for aerodynamic flows. 23rd fluid dynamics, plasmadynamics, and lasers conference, 1993, p. 2906.

| Mesh assessment | |||||

|---|---|---|---|---|---|

| 2D mesh cells | Min y+ | Average y+ | Max y+ | Frequency (Hz) | Error % |

| 62143 cells | 0.007893928 | 5.255150 | 63.09918 | 24.525 Hz | 15.37% |

| 180065 cells | 0.5630300 | 1.616285 | 16.79723 | 29.181 Hz | 0.69% |

| 367720 cells | 0.2748158 | 0.9271403 | 8.044681 | 29.091 Hz | 0.38% |

| 718920 cells | 0.2741867 | 0.7549317 | 8.368831 | 28.98 Hz | - |

| Boundary conditions | |||||

|---|---|---|---|---|---|

| k | omega | nut | P (Pa) | U (m/s) | |

| inlet | zeroGradient | ||||

| outlet | zeroGradient | zeroGradient | zeroGradient | zeroGradient | |

| Top & Bottom | empty | empty | empty | empty | empty |

| walls | omegaWallFunction value |

nutLowReWallFunction value |

zeroGradient | 0 | |

| Outlet widths evaluated | |||||||

|---|---|---|---|---|---|---|---|

| Outlet width in % | |||||||

| Outlet width in (m) | |||||||

| Outlet section name | 1 | 2 | 3 | 4 | 5 | 6 | |

| Mixing chamber inlet angles | |||

|---|---|---|---|

| Inlet angle in % | |||

| Inlet angle in (degrees) | |||

| Reynolds number | Re=27483 | Re=41224 | Re=54595 | Re-68707 |

|---|---|---|---|---|

| Parameter | Main Frequency [Hz] | |||

| MC wall pressure | 11 | |||

| FC Pressure momentum | ||||

| FC Mass flow momentum | ||||

| Net momentum | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).