1. Introduction

High-pressure water jet commonly known as waterjet, is a kind of water as an energy carrier, through the liquid pressurization equipment to supercharge the water flow, at the nozzle through the shrinkage surface to form a high-energy beam of a technology, since the 80s of the 20th century with the emergence of a variety of new water jets, water jet technology have been rapidly developed. With its advantages of high efficiency and environmental protection, it is widely used in cleaning, paint and rust removal, cutting, crushing, descaling and other fields. The nozzle is the core component of the high-pressure water jet, which sprays the water through the fine aperture of the nozzle to form a high-speed jet. Good nozzle structure can improve the energy conversion efficiency of water jet and obtain better spray performance. The development of high-pressure water jets is inseparable from the study of jet nozzles [

1,

2]. Dr. Norman Franz is recognized as the father of water jets. In 1950, Dr. Franz first placed a very heavy object on top of a column of water, forcing water to eject from a tiny hole. This method can be used to obtain a very high pressure water flow and use it to cut wood and other materials .

According to the size of the jet pressure, the water jet can be divided into three categories: low-pressure water jet, high-pressure water jet and ultra-high-pressure water jet: low-pressure water jet usually refers to a water jet with a pressure of less than 10Mpa, which is generally used for domestic cleaning, coal mining, etc., mainly generated by low-pressure reciprocating pumps or centrifugal pump. High-pressure water jet usually refers to water jet with a pressure between 10Mpa and 100Mpa, which is generally used for industrial cleaning, mining, crushing and cutting of soft materials, mainly generated by high-pressure reciprocating pumps. Ultra-high pressure water jets are generally water jets with pressures above 100Mpa and are typically used in industrial cutting or other machining, mainly by boosters or ultra-high pressure reciprocating pumps. People's application of water jet starts from low pressure and gradually expands to ultra-high pressure, of course, this is also determined by the level of development of science and technology [

3].

The nozzle jet performance plays a decisive role in the effect of water jet, and this paper reviews the types and characteristics of water jet, the simulation and experiment of high-pressure water jet nozzle, and the application of water jet.

2. Characteristics and classification of water jets

High-pressure water jet technology is a cold working technology that overcomes rigidity with softness, which has the following characteristics and irreplaceable advantages compared with other processing methods:

Wide processing range, can process various metal materials and a huge part of non-metallic materials: such as glass, marble, etc.

It has good processing accuracy and processing quality, and the processing incision is smooth and burr-free.

Because waterjet technology is a cold processing technology, there will be no heat generation (or only a very small part of heat generation), no thermal deformation, and can be used to process materials that are sensitive to heat influence, such as: titanium.

The processing technology has no pollution to the environment, generally composed of water and abrasives, which can be directly discharged.

It can be processed at any position of any object without prior opening.

No need to change the tool, one nozzle can process any shape of material, which can save time and cost.

The high-pressure waterjet system supports third-party software, so the shape to be machined can be generated by third-party software, and the machining program is generated by the waterjet system. It is also possible to import the program generated by other software directly into the water cutting machine to achieve automatic and fast processing.

The processed medium is water as the main processing medium, which is rich in resources, and the abrasive adopts quartz sand, etc., which is cheap and low cost [

4,

5].

There are various methods of water jet classification, and according to the .different working pressure of the jet, the water jet is divided into low pressure, high pressure, and ultra-high pressure water jet. Low-pressure water jet is mainly used in domestic cleaning, coal mining, etc. High-pressure water jet is mainly used in industrial cleaning, rust removal, mining, crushing, etc. Ultra-high pressure water jet is mainly used in industrial cutting, drilling and other mechanical processing, generally also known as high-pressure water jet. According to the composition of the jet, water jets are divided into liquid, gas-liquid and solid-liquid jets. Liquid jets are formed from pure water or other liquids. Gas-liquid jet is a gas-liquid two-phase jet formed by mixing air or other gases into a water jet. Solid-liquid jets are formed by mixing solid particles and liquids. According to the different media around the jet, water jets are divided into non-submerged, semi-submerged and submerged jets. The surrounding medium of the non-submerged jet is air, and the surrounding medium of the submerged jet is water or other liquid or gas. The classification of water jets is commonly based on their technical characteristics, which fall into four categories: pure water jet, abrasive water jet, pulsed water jet, and cavitation water jet.[

6].

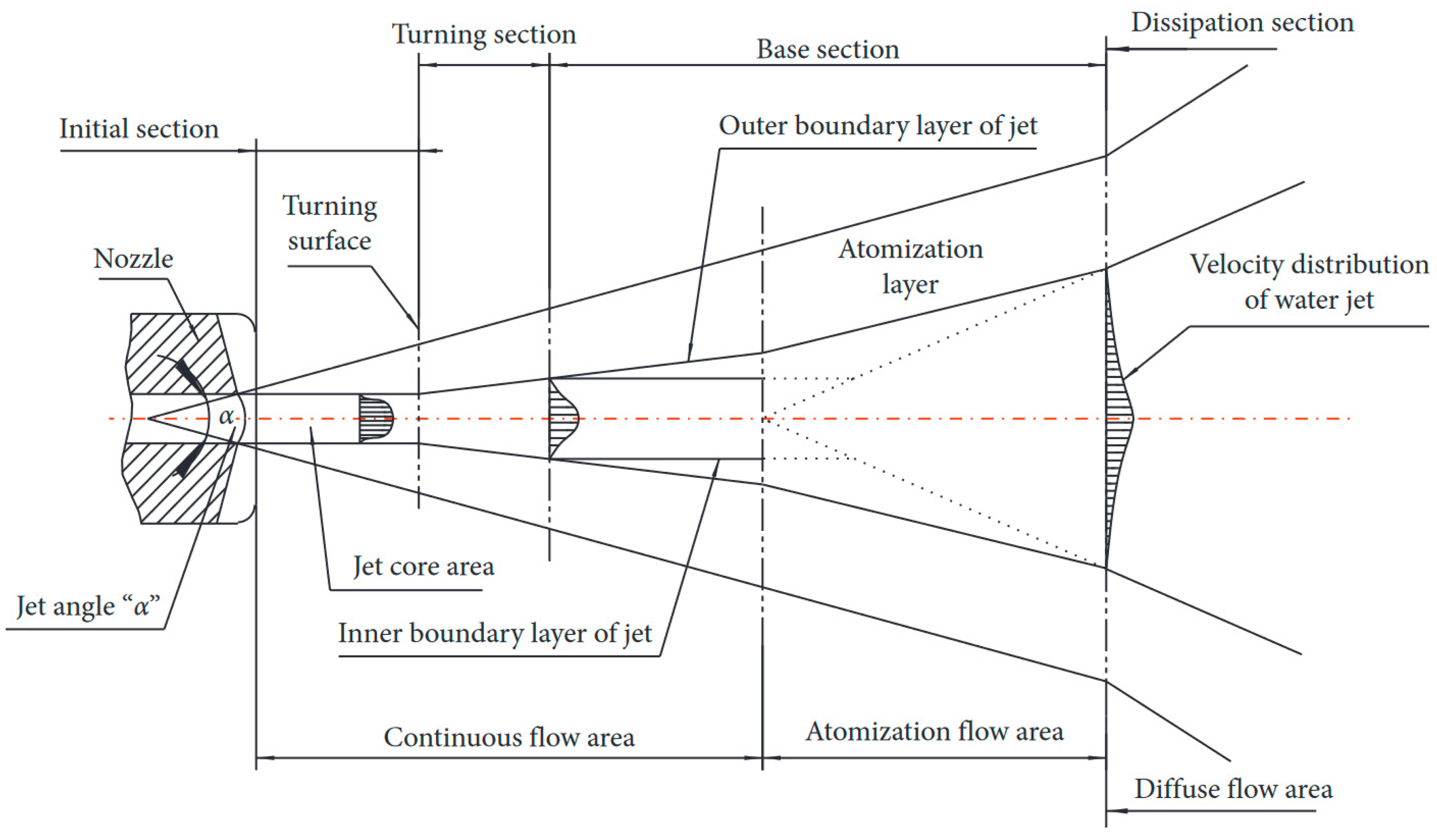

Kou [

7] and Zhao Huihe [

8] analyzed the water jet structure. According to the distance from the nozzle outlet, the nozzle jet is divided into core area, basic area and divergence area. The length of the core area is very short, the water flow is basically not mixed with the air, the rate of fire is very high, and the dynamic pressure is basically the same as the outlet dynamic pressure, which is generally used for material cutting. The base zone is significantly longer than the core zone. As a result, the water flow mixes with the air, causing a gradual decrease in flow rate and dynamic pressure. The area where the jet is working is generally referred to as the working area. In the divergence area, the water flow is atomized, resulting in a significant reduction in striking force and dynamic pressure. Therefore, it is not suitable for high-pressure jet work. This area can be used for cooling and dusting purposes.

Figure 1.

Water jet structure diagram [

7].

Figure 1.

Water jet structure diagram [

7].

2.1. Pure water jet

The pure water jet is mainly based on pure water without adding abrasives and other substances as the working medium, and the high-pressure water jet is used to obtain high-speed kinetic energy through the nozzle to strike the action surface to carry out cleaning, cutting, crushing, descaling and other operations. Although its cutting ability is poor, it still has a lot of energy, so the pure water jet has a good effect on the rust layer removal of the surface of the plate material, and is also suitable for the cutting of non-metallic materials such as rock, paper, cloth, wood, leather, and plastic [

9].

Pure water jet is the traditional high-pressure water jet, as the core component of the pure water jet nozzle research earlier, with the rise of high-pressure water jet technology, pure water jet nozzle also appeared for various occasions high-pressure pure water jet nozzle. The internal structure of the pure water jet nozzle is different, and the purpose will be different. According to the different nozzle jet outlet shapes, it can be divided into two types of nozzles: round nozzles and fan nozzles [

10].

By changing the length and structure of each section of the circular nozzle, various types of circular nozzles can be obtained. It is divided into three categories: cylindrical nozzles, conical nozzles, and streamlined nozzles. The cross-section of the cylindrical nozzle outlet is beneficial to improving the speed of the water jet. Both conical and streamline nozzles have good jet performance. The overall performance of the conical nozzle is good, with a larger nozzle contraction angle and a smaller jet flow rate. There is more research on mining crushing and pipeline descaling.

A fan-shaped nozzle formed by combining the internal structural parameters of a circular nozzle with a special outlet end. The fan-shaped nozzle is different in structure from ordinary axisymmetric cylindrical nozzles, and its structure is divided into two types: axial fan-shaped nozzle and guide plate fan-shaped nozzle. The guide plate fan-shaped nozzle has a greater impact force than the axial fan-shaped nozzle, and is suitable for cleaning petroleum drill pipes and oil pipes.

2.2. Abrasive water jet

A large number of practices have proved that adding a certain number of abrasive particles to the pure water jet can improve the cutting effect and work efficiency of the water jet. The main reason is that the density of the abrasive is large, and the flow energy can be concentrated, and the stagnant pressure erosion of the water quality in the original pure water jet is changed into the impact dynamic erosion of the abrasive, which enhances the grinding effect and impact effect on the target material, which in turn leads to a larger cutting depth of the abrasive jet and improves the quality and efficiency of the jet. The outlet end structure of the abrasive waterjet nozzle is similar to that of the pure waterjet nozzle, so the abrasive waterjet nozzle can be roughly divided into two nozzles: round nozzle and fan-shaped nozzle [

11,

12].

Abrasive water jet is essentially a liquid-solid two-phase jet mixed with a certain number of abrasive particles with a certain quality and hardness in a high-pressure water jet. Generally, according to the different positions of abrasive addition, it can be divided into pre-mixing type and post-mixing type. The abrasive particles of the pre-mixing system are fully mixed with high-pressure water in the mixing chamber, which has the advantages of strong cutting ability and repeated recycling of abrasives, but the wear of the system pipeline and nozzle is large. The post-mixing system is to first form a high-pressure water jet and then add abrasives, at this time in the pure water jet nozzle to add a sand mixing head, you can make the abrasive particles and high-pressure water mixed at the nozzle, with simple structure, wide range of abrasive application and small wear of pipelines and nozzles. However, compared with the pre-mixing type, its abrasive mixing efficiency is lower and the abrasive cannot be recycled twice.

2.3. Pulsed water jet

A pulsed water jet is a discontinuous water jet. Using special equipment, the water jet is hit on the target surface in the form of pulses through the nozzle to carry out cleaning, crushing and other operations. The discontinuous water column generated by the pulsed jet acts on the target surface much more than the continuous jet continuously acts on the target surface, thereby improving the jet performance. Pulsed water jet nozzles can be divided into excitation pulsed water jet nozzles and extruded pulsed water jet nozzles according to their form. Among them, self-excited oscillating pulsed water jet nozzles are the most commonly used.

Researchers have used high-speed cameras to capture the flow state of pulsed water jets outside the pipe, and have found that pulsed water jets usually begin to appear as mushroom shaped jets with lateral expansion at the outlet of the pipe. However, the reason for this mushroom shaped jet phenomenon has not yet been explored [

13]. D. Rockwell and E Naudasche [

14] analyzed the pressure characteristics inside the nozzle and briefly explained the mechanism by which the nozzle device generates pulse effects on the jet. Liao Zhenfang et al. [

15] proposed that the pulse jet is generated by the fluid's self-vibration, and established the theoretical analysis model of the self-vibration pulse jet nozzle. Then the team made a comparative analysis of the erosion performance of the self-oscillating pulse jet and the continuous jet.

2.4. Cavitation water jets

Cavitation jet is a new and efficient jet technology that combines water jet technology with cavitation phenomena, with simple operation and promising development prospects. It enhances the effectiveness of the jet by utilizing the strong impact force generated when a bubble ruptures, and solves engineering problems by utilizing the "cavitation effect" caused by bubble collapse. Practice has proved that cavitation jet has better cleaning and cutting effects than ordinary pure water jet under the premise of consistent flow rate and pumping pressure, and has been applied to deep water cutting, nuclear reactor cleaning and aerospace fields[

16]. Cavitation nozzles are divided into shear type and oscillating type. The common oscillation type cavitation nozzles are mainly divided into two types: organ tube structure cavitation nozzles and self-excited oscillation pulse cavitation nozzles.

Ma Wenliang [

17] used high-speed photography and image processing to record the flow in the transparent aspirated self-excited oscillation nozzle chamber under submerged conditions at different times, providing a visual mean for subsequent research. Cui Cong [

18] studied the effects of three different structures of nozzles, namely organ tube cavitation nozzle, shear type nozzle, and self-excited oscillation pulse cavitation nozzle, on the cavitation jet effect.

This section describes the characteristics of high-pressure water jets, how the four types of water jets work, and their commonly used nozzles.

3. High pressure water jet nozzle simulation and experimentation

High pressure water jet is widely used and has a wide variety of types. Many scholars at home and abroad have conducted simulations and experiments on different types of water jet nozzles to improve performance and improve the efficiency of jets.

After verification, the streamlined nozzle has better jet strength and stability. Yang Yousheng [

19] et al. found that the closer the contour of the nozzle inner wall is to the streamline, the smaller the characteristic energy loss. Cai Yi [

20,

21] designed a streamlined nozzle with a contraction section, a transition section, and a flat section by analyzing existing linear nozzles. By analyzing and calculating the water jet flow pressure, flow velocity, and turbulence distribution patterns with different transition ratios, the optimal transition ratio of the streamlined nozzle was obtained. Some scholars have compared and found suitable turbulence models for nozzle simulation. Wang Yanfen [

22] found that RNG k- ɛ It can more realistically reflect the characteristics of the circular nozzle jet flow field. Guo, Lin [

23] et al. established a three-dimensional mathematical model of the internal flow field of the fan nozzle by using CFD software. The internal flow fields of different fan nozzles are numerically simulated by using the standard K-turbulent model.

Many scholars have designed simulation and comparative experiments to study the effects of nozzle main structural parameters such as shrinking Angle (nozzle inlet diameter), nozzle length-diameter ratio, V-shaped grooving Angle and inlet pressure on jet performance.

Table 1.

Influence of nozzle structure parameters on jet performance.

Table 1.

Influence of nozzle structure parameters on jet performance.

| Structure Parameters |

Impact on Jet |

References |

| Cone contraction angle, nozzle outlet diameter, nozzle length, and aspect ratio of cylindrical nozzles |

When the contraction angle of the conical section is between 12-16 °, the axis velocity of the jet is the highest. The larger the outlet diameter value, the slower the attenuation of nozzle axis velocity. The change in nozzle length has no significant impact on the external flow field of the jet nozzle. The change in the aspect ratio of cylindrical nozzles has no significant effect on the axis velocity. |

[4] |

| V-groove offset, V-groove angle, inlet pressure |

The flow rate increases with the increase of the half angle and inlet pressure of the V-shaped groove, and decreases with the increase of the depth of the V-shaped groove. The impact force increases with the increase of the half angle of the V-shaped groove and the inlet pressure, and decreases with the increase of the V-shaped groove offset. The influence of nozzle outlet length-diameter ratio on flow rate and impact force is negligible. |

[24] |

| Inlet shape, inner channel aspect ratio, outlet angle |

The flow rate and impact force of the conical inlet structure is greater than those of the flat bottom type. When the aspect ratio is between 2-4, the jet velocity and flow rate are inversely proportional to the aspect ratio. The nozzle flow rate and jet strike force are directly proportional to the outlet angle. |

[25] |

| Contraction angle, length to diameter ratio of jet outlet section, V-shaped groove angle |

The optimal aspect ratio is 2-4 for a contraction angle of 13-15 °. The cutting half angle has a good jet velocity at 30-45 °. |

[26] |

| Outlet expansion angle, cone depth, inlet contraction angle |

An increase in the outlet expansion angle will increase the jet flow rate, velocity, and impact force of the nozzle. Increasing the depth of the cone hole can improve the jet performance. An increase in the contraction angle will weaken the jet performance of the nozzle. |

[27] |

| Inlet pressure, contraction angle, and V-groove half angle |

Increasing the inlet pressure can significantly increase the velocity of the jet impacting the water in the core area. Increasing the half angle of the V-shaped groove increases the flow velocity of water in the core area of the jet. The contraction angle significantly changes the flow characteristics inside the nozzle. |

[28] |

| Inlet diameter, inlet section length, contraction section length, outlet diameter, outlet section length, V-groove angle, and groove offset |

The outlet diameter and V-groove angle is positively correlated with changes in jet velocity, nozzle flow rate, and impact force, while the groove offset is negatively correlated with jet velocity. As the length of the contraction section increases, the jet velocity slightly increases, the jet impact force first increases and then decreases, and the nozzle flow rate gradually increases. When the length to diameter ratio of the outlet section is 2, the impact force is the most affected. The changes in diameter and length of the inlet section have little impact on the jet. |

[29] |

For abrasive jet nozzles, nozzle wear is the main reason for their short lifespan. Studying their wear principle, searching for new wear-resistant materials, and improving nozzle smoothness and uniformity are key factors in improving the service life and jet performance of abrasive jet nozzles.

Based on the analysis of the jet structure, Miao Xiaojin studied the distribution of jet velocity in the radial and axial directions, as well as the distribution of abrasive particles in the jet, and obtained the distribution of jet energy. Ding Xiangqing [

30] found through research that the larger the inlet to outlet ratio of the nozzle, the greater the jet outlet velocity, and the greater the particle phase velocity. The angle of abrasive inlet also has a certain impact on the velocity of abrasive particles. Guo Zihao [

31,

32] combined the volume fraction of abrasive near the inner wall of the mixing chamber to obtain the optimal abrasive inlet position, and proposed improvement measures to reduce the wall wear of high-pressure abrasive jet nozzles using numerical simulation methods. Guan Jinfa [

33] believes that from the perspective of reducing the wear on the inner surface of the nozzle, the flow rate and volume fraction of abrasive water jet should not be too large. Liu Yuxiang [

34] mainly studied the wear mechanism and form of nozzles, as well as the main factors affecting the wear of high-pressure water jet nozzles, and proposed strategies to reduce abrasive water nozzle wear and improve its service life.

Table 2.

The problem and solution of abrasive jet nozzle.

Table 2.

The problem and solution of abrasive jet nozzle.

| Problem |

Solution |

References |

| The nozzle has a short lifespan and is prone to wear and tear |

A new type of nozzle made of tungsten carbide based material, while using porous lubrication nozzles to prevent nozzle wear |

[35] |

| Uneven flow field of post mixed abrasive nozzle |

Adding a conical baffle structure to improve the uniformity and spraying stability of abrasive and water mixing |

[36] |

| Uneven mixing of abrasive slurry and high-speed water flow |

Design a new type of abrasive water jet fan nozzle, with abrasive entering from the middle and high-pressure water entering from the side. The high-pressure water in the mixing chamber changes from a traditional single stream water flow to a four stream water flow, and a high-speed abrasive jet is formed at the outlet |

[37] |

The research on pulse jet and cavitation jet nozzles mainly focuses on the nozzle structure.

Wang Tianyu [

38] studied the straight nozzle structure based on the high-pressure gas driven water jet experiment conducted by Shi Honghui. In order to further optimize the hydrodynamic characteristics of pulse water jets, two different nozzle structures were designed: a conical gradually shrinking nozzle and a conical gradually expanding nozzle, and the simulation results of the three types of nozzles were compared and analyzed. Leach [

39] et al. conducted research and tested various shapes of nozzles, and found that conical and conical straight nozzles can significantly improve jet kinetic energy.

Wang Jiasheng [

40] studied three different shapes of contraction nozzles, namely conical, streamline, and organ tube, and found that streamline nozzles have high stability, spraying performance, and significant cavitation effects. Zhang Junyao [

41] found that the shape of the expansion structure of the scaled cavitation water jet nozzle can affect the ability of the nozzle to induce cavitation. Zhang Fenghua [

42] conducted cavitation water jet experiments on self-designed ordinary nozzles, gradually converging suddenly expanding nozzles, and gradually converging gradually expanding nozzles, indicating that the jet erosion ability of gradually converging suddenly expanding nozzles and gradually converging gradually expanding nozzles is significantly better than that of ordinary nozzles. Liu Luxing [

43] studied the cavitation regions of three different inlet shapes of center body nozzles, conical inlet nozzles and streamline inlet nozzles, which has a wider range and more significant cavitation effect compared to cylindrical inlet nozzles. Liao Song [

44] et al. conducted experiments on the erosion performance of four types of submerged cavitation water jet nozzles, and compared the results to show that streamlined nozzles have better erosion ability and jet stability.

This section summarizes and introduces the simulation and experiments of four types of jet nozzles conducted by predecessors.

4. Application of high-pressure water jet

The above article introduced the characteristics of high-pressure water jet, which is widely used in social production and daily life. The following will introduce the practical application of high-pressure water jet from four aspects.

4.1. Water jet cutting

High pressure water jet cutting technology, as an efficient and green processing technology, has a broad application prospect, including food and medical, aerospace, construction, Marine, oil and gas engineering and other fields. High pressure water jet cutting can be divided into continuous water jet cutting and pulse water jet cutting based on continuity. Continuous jet refers to the continuous supply of stable high-pressure water during the cutting process, which continuously acts on the material. The characteristic of continuous jet is that the pressure during the cutting process is continuously stable, and the effect on the target material is continuous. The water hammer pressure generated by the intermittent jet of pulsed water jet during high-speed injection far exceeds the pressure generated by continuous jet. Therefore, under the same supply pressure, the destructive effect of pulsed jet is greater than that of continuous jet, and the cutting ability is stronger and the cutting effect is obvious [

45,

46].

Geng Pengfei [

47] proposed a new optimization method for abrasive water jet cutting process parameters based on hybrid strategy through experimental research to improve the efficiency and quality of water jet cutting. Yu Ruilong [

48] proposed a method of water jet assisted laser composite processing, which continuously impacts the surface of the workpiece to reduce surface temperature and wash away slag, reducing thermal damage in laser processing.

4.2. Water jet cleaning

With the increasing understanding and research on fouling issues, high-pressure water jet cleaning technology (i.e. high-pressure water jet cleaning technology) applied to cleaning and descaling has rapidly developed in multiple industries. So far, the high pressure water jet cleaning technology has been widely used in the cleaning operations of automobiles, chemical heat exchangers and storage tanks, and has the advantages of low cost, energy saving and environmental protection, high efficiency and so on, and is favored by countries all over the world.

Yang Yu [

49] et al. conducted numerical simulation analysis of the jet flow field of guide plate fan-shaped nozzles with different diversion distances, inclination angles of diversion surfaces, and cleaning distances. Wang Liping [

50] et al. built an experimental platform for high-pressure water jet cleaning and tested the effects of different target distances and incidence angles on the jet striking force. Zhang Yue [

51] conducted simulation analysis on the corresponding relationship between high-pressure water jet parameters and cleaning efficiency to optimize the impact of high-pressure water jet parameters on water jet cleaning efficiency, and conducted cleaning experiments using the same jet parameters as the simulation for verification.

4.3. Water jet descaling

High pressure water jet descaling technology, as an emerging technology, is receiving increasing attention. Compared with the traditional descaling method, the high pressure water jet descaling technology has the advantages of strong adaptability, high efficiency, low cost, good quality, energy saving and environmental protection, and has achieved good application results in the field of descaling.

The impact force of the nozzle jet is a direct factor affecting the phosphorus removal effect. Shen Juan [

52] analyzed the impact of jet impact on the descaling effect in a high-pressure water descaling system based on engineering practice, and comprehensively studied the effects of jet pressure, nozzle flow rate, jet angle and distance, as well as the arrangement of nozzles on jet characteristics. Chen Peng [

53] studied the outflow field characteristics of descaling nozzles with different penetration depths, different shrinking orifice forms and different grooving forms. The influence of the above variables on the jet performance of the nozzle is studied with the same target distance as the line length, the total dynamic pressure of the outlet and the mass flow as the main indexes.

4.4. Water jet rock breaking

In the late 1960s and early 1970s, the US NSF funded a massive research project aimed at finding an efficient method for rock cutting. There are 25 new methods were proposed and tested, such as high-pressure water jet, electric pulse, plasma, laser, microwave, flame, etc. Finally, it was unanimously recognized that the most feasible and effective method was high-pressure water jet rock breaking [

54].

Han Weifeng [

55] believes that high-pressure water jets not only have the function of erosion of rock slag and powder by medium and low pressure water jets, but also can directly cut rocks to create free surfaces and improve rock breaking efficiency. In order to obtain the structural parameters of the high-pressure water jet flow field, optimize the nozzle structure, and study the rock failure characteristics, Ma Wentao [

56,

57] studied the flow field structure, core zone length, and velocity distribution of the high-pressure pure water jet, and used the ALE method to study the rock failure characteristics of the high-pressure water jet. Liu Fanyong [

58,

59,

60] et al. established a high-pressure water jet rock breaking test platform and conducted research on rock fragmentation performance and rock crack propagation mechanism under different media conditions such as pure water jet, abrasive jet, and slurry jet under jet impact conditions.

5. Conclusion and outlook

High pressure water jet technology has been widely concerned and applied because of its high efficiency and environmental protection. The high pressure water jet nozzle is the core component, and the study of the high pressure water jet nozzle is beneficial to improve the performance and efficiency of the jet. In this paper, the main types of high-pressure water jets are summarized and the theoretical analysis and experiments of previous nozzles are summarized, and the following conclusions are obtained.

(1) At present, research on the jet characteristics and performance of the internal and external flow fields of nozzles mainly uses fluid simulation software for numerical simulation analysis. New detection technologies should be introduced to monitor the jet characteristics and water jet performance of the internal and external flow fields of nozzles.

(2) The development of various new types of high-pressure water jets is beneficial to the research of high-pressure water jet nozzles. The diversification of jet characteristics and the improvement of jet performance will promote research on various aspects of jet nozzles.

(3) Continuously expanding the application range of high-pressure water jets, with the research on new types of water jets and jet nozzles, high-pressure water jet nozzles have deeper applications in industries such as petrochemical, mining, medical, shipbuilding, steel, processing and manufacturing. The study of various nozzle water jet characteristics has increasingly highlighted the advantages of water jet technology, and jet nozzles are bound to be more and more widely used.

(4) With the development of artificial intelligence, high-pressure water jet technology should develop towards intelligence and full automation, achieving the transformation of operating processes from two-dimensional to three-dimensional, and adaptive processing of process parameters based on materials.

(5) Developing towards safer, more economical, environmentally friendly, and more efficient reuse. After the completion of jet technology treatment, harmless treatment and recycling of waste materials should be carried out, and available waste materials should be converted into civilian products through secondary treatment.

I believe that with the continuous deepening of people's understanding of high-pressure water jet and the continuous optimization of related technologies, its application prospects will be even broader.

Author Contributions

Article frame construction: H.J. Article Writing: Y.T. Theoretical guidance: Y.F. Comments on the first draft of the article: G.Y. Assist in gathering information: D.Y. and Y.Y. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The article is supported by the following projects: The Scientific Research Center of North China Aerospace Research Institute funded by the doctoral Entrepreneurship project Engineering (bky-2021-05), Langfang Science and Technology Research and Development plan self-funded project 2021011072 and Undergraduate Teaching Research and Reform Project JY-2022-15.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lei, K. High pressure abrasive water sprays a huge mouth how many shapes and Buddha properties research. Yanshan University, academic profound.2015.

- Xiaojin, M. Research on the Mechanism and Quality Improvement Methods of Abrasive Water Jet Cutting. Jiangnan University, 2020.

- Yinglei, X. Exploration of an ultra-high pressure water jet cutting machine. Science and Technology Wind, 2014 (03): 16.

- Wenhui, Z. Numerical simulation study on the internal and external flow fields of high-pressure water jet nozzles. Lanzhou University of Technology. 2008.

- Juan, S. Design and Structural Optimization of High Pressure Water Jet Nozzles. Suzhou University. 2014.

- Peixing, Z. Research on the process of abrasive water jet cutting zirconia ceramic materials. Jiangnan University. 2022.

- Baofu, K. Pengliang, H. Xiaohua, H. Research on the Influence of External Parameters of Fan-Type Nozzle on Water Jet Performance. Shock and Vibration, 2020, 2020. [CrossRef]

- Huihe, Z. Research on the Performance of Abrasive Water Jet Rotating Cutting Hard Rock. China University of Mining and Technology, 2022.

- Xiaorui, C. Shuyan, Z. Liangliang, M. Yutong, T. Application Status and Development Prospects of High Pressure Water Jet Technology. Hydraulic, Pneumatic and Sealing, 2019, 39 (08): 1-6.

- Jiangnan, Z. Zeyong, L. Lin, Z. Zhewen, Z. Research progress on high-pressure water jet nozzles. Clean World, 2023, 39 (01): 45-48.

- Kun, D. Research on Injection Parameters of High Pressure Water Jet Cylindrical Nozzles. Dalian Jiaotong University, 2017.

- Wenjie, L. Xiaoyang, C. Optimization simulation study of high-pressure water jet nozzle based on Fluent. Energy and Environmental Protection, 2020, 42 (05): 14-18.

- Fu-yong, S. Wen, Z. Hydraulic experiment on mushroom head in bottom-blown smelting furnace. Journal of Iron and Steel Research International, 2017, 24(5). [CrossRef]

- Rockwell, D. Naudascher, E. Self-Sustained Oscillations of Impinging Free Shear Layers. Annual Review of Fluid Mechanics, 1979, 11(1). [CrossRef]

- Zhenfang, L. Chuanlin, T. Fenghua, Z. Experimental study on self-excited oscillating pulse jet nozzle. Journal of Chongqing University (Natural Science Edition), 2002 (02): 28-32.

- Fan, Y. Research on rock breaking characteristics and nozzle structure design of self-excited oscillating pulse water jet. Hebei University of Engineering, 2021.

- Wenliang, M. Research on the pulsating pressure characteristics of self-excited suction pulse jet. North China University of Water Resources and Hydropower, 2016.

- Cong, C. Gongxue, Z. Kai, H. Analysis of the influence of nozzle structure on cavitation jet. Modern Machinery, 2021 (05): 64-67.

- Yousheng, Y. Jianping, Z. Songlin, N. Research on Energy Loss of Water Jet Nozzles. Journal of Mechanical Engineering, 2013, 49 (02): 139-145.

- Yi, C. Guobing, S. Design and finite element analysis of high-pressure water jet nozzles. Mechanical Design and Research, 2017, 33 (06): 163-167+171.

- Yi, C. Guobing, S. Orthogonal experiment and simulation study of high-pressure water jet streamlined nozzle. Coal Technology, 2017, 36 (12): 299-302.

- Yanfen, W. Yanfang, Y. Huibo, M. Feng, W. Jianhua, W. Optimization selection of simulation method for circular nozzle jet characteristics. Journal of Shenyang University of Chemical Technology, 2016, 30 (01): 55-59.

- Renning, G. Lin, X. Qi, S. Xiaoyan, L. Study of Influence on Internal Flow Field in Geometry of Fan-shaped Nozzles with Water Jet Cleaning. Energy Procedia, 2011, 13. [CrossRef]

- Song, C. Design of Power System and Study on Fan shaped Nozzles for Self driving Cleaning Vehicle Equipment. Anhui University of Science and Technology, 2019.

- Liang, C. Simulation analysis of internal and external flow fields of high-pressure water jet fan-shaped nozzles. Lanzhou University of Technology, 2010.

- Xinming, Z. Qing, L. Guang, H. Ya, L. Numerical simulation of the influence of structural parameters of high-pressure water fan-shaped nozzles on internal flow field. Thermal Power Engineering, 2012, 27 (03): 301-306+390-391.

- Bojian, L. Dianrong, G. The influence of structural parameters of high-pressure water descaling nozzles on nozzle jet performance. China Mechanical Engineering, 2018, 29 (24): 2939-2946.

- Bowen, J. Siqi, M. Xin, L. Zhuang, L. Fengrui, J. Huanyang, L. Numerical simulation study on jet behavior of fan-shaped nozzles. Industrial Heating, 2021, 50 (06): 26-32.

- Hengfan, L. Simulation study on high-pressure water jet fan-shaped nozzle based on licorice cleaning. Lanzhou University of Technology, 2016.

- Xiangqing, D. Optimization design of abrasive water jet nozzle structure. Modular Machine Tool and Automation Processing Technology, 2016 (11): 115-118.

- Zihao, G. Research on Structural Improvement and Boosting System Characteristics of High Pressure Abrasive Water Jet Cutting Nozzles. Wuhan University of Science and Technology, 2021.

- Zihao, G. Liandong, F. Flow field analysis and structural optimization of high-pressure abrasive jet nozzles based on numerical simulation. Journal of Wuhan University of Science and Technology, 2020, 43 (03): 201-207.

- Jinfa, G. Songsheng, D. Jianlin, W. Dan, S. Numerical simulation of wear law of premixed abrasive water jet nozzle. Journal of Chongqing University of Technology (Natural Science), 2016, 30 (12): 48-54.

- Yuxiang, L. Research on the causes and countermeasures of wear of high-pressure water jet nozzles. Henan Science and Technology, 2022, 41 (13): 44-47.

- Syazwani, H. Mebrahitom, G. Azmir, A. A review on nozzle wear in abrasive water jet machining application. IOP Conference Series: Materials Science and Engineering, 2016, 114(1). [CrossRef]

- Guoyong, L. Yang, Y. Haiyang, X. Dongmei, Z. Analysis of flow field uniformity of a new type of post mixed abrasive water jet nozzle. Journal of Hunan University (Natural Science Edition), 2020, 47 (10): 56-67.

- Wei, W. Yong, T. Shuo, Y. Wenbo, L. Qinyuan, T. Bitu, L. Numerical simulation and experimental research on the internal and external flow field of a new type of abrasive jet descaling nozzle. Modern Manufacturing Engineering, 2022 (10): 101-106.

- Tianyu, W. Optimization of nozzle structure for high-pressure pulse water jet. Zhejiang University of Technology, 2020.

- Leach S. J. Walker G. L. Smith A. V. Farmer I. W. Taylor Geoffrey. Some Aspects of Rock Cutting by High Speed Water Jets [and Discussion]. Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences (1934-1990), 1966, 260(1110).

- Jiasheng, W. Yuefeng, Y,. Fei, X. Numerical simulation study of negative pressure cavitation jet nozzle. Coal Mine Machinery, 2022, 43 (08): 73-76.

- Junyao, Z. Research on the influence of nozzle structure on water jet velocity and cavitation ability. China University of Petroleum, 2019.

- Fenghua, Z. Yong, W. Gu, C. The influence of nozzle structure on the erosion ability of cavitation water jet. Journal of Hunan University of Technology, 2021, 35 (02): 30-37.

- Luxing, L. Songsheng, D. Jinfa, G. Su, Y. Guodong, L. Xiaochen, C. Simulation of Cavitation Induced by Centroid Nozzles with Different Entrance Shapes. Coal Mining Machinery, 2018, 39 (12): 47-49.

- Song, L. Songsheng, D. Liang, L. Chuanchao, L. Experimental study on submerged cavitation water jet nozzle for cleaning and rust removal. Natural Gas and Petroleum, 2018, 36 (04): 47-53.

- Haiqing, L. Zhiwen, W. Ming, C. Development and Application Status of High Pressure Water Jet Cutting Technology. Machine Tool and Hydraulic, 2018, 46 (21): 173-179.

- Yongjun, G. Research Status and Development Trends of Abrasive Water Jet Cutting Technology. Hydraulic and Pneumatic, 2016 (10): 1-5.

- Pengfei, G. Research on Process Parameters of High Pressure Water Jet Cutting. Yanshan University, 2012.

- Ruilong, Y. Yuan, Y. Shuai, F. Design of a new cutting head structure for laser/water jet cutting technology. Applied Laser, 2022, 42 (12): 66-75.

- Yu, Y. Tao, Q. Numerical simulation of cleaning jet flow field with guide plate fan-shaped nozzle. Journal of Drainage and Irrigation Machinery Engineering, 2017, 35 (03): 243-247.

- Liping, W. Xiaojun, C. Yantao, D. Experimental Study on High Pressure Water Jet Cleaning Parameters. Laboratory Research and Exploration, 2017, 36 (08): 48-51.

- Yue, Z. Yupeng, C. Hua, L. Experimental and simulation of high-pressure water jet cleaning on ship surfaces. Ship and Sea Engineering, 2020, 49 (04): 86-89.

- Juan, S. Research on Performance Testing System for High Pressure Water Descaling Nozzles. Wuhan University of Science and Technology, 2008.

- Peng, C. Analysis and optimization of the influence of structure and parameters on the performance of high-pressure water descaling nozzles. Yanshan University, 2018.

- Songyong, L. Hongsheng, L. Hongxiang, J. Research progress on coal rock fragmentation methods in mines. Journal of Coal Science: 1-21.2023-07-03.

- Weifeng, H. Experimental study on rock breaking with TBM roller cutter assisted by high-pressure water jet front cutting seam. Railway Standard Design, 2023, 67 (04): 130-135.

- Wentao, M. Junfeng, P. Numerical simulation of water jet flow field and rock breaking characteristics with different nozzle structures. Coal Mine Machinery, 2019, 40 (09): 17-20.

- Wentao, M. Numerical simulation of continuous high-pressure water jet rock breaking based on ALE algorithm. Coal Engineering, 2022, 54 (12): 164-169.

- Hongxiang, J,. Zenghui, L. Kuidong, G. Numerical simulation on rock fragmentation by discontinuous water-jet using coupled SPH/FEA method. Powder Technology, 2017, 312.

- Hongxiang, J. Huihe, Z. Songyong, L. Hongsheng, L. Analysis of factors affecting the performance of abrasive jet impact cutting rock. Vibration. Testing and Diagnosis, 2022, 42 (03): 564-571+621-622.

- Songyong, L. Song, C. Hongsheng, L. Fangyue, Z. Baolong, X. Yang, H. Impact characteristics of rock breaking using a conical pick assisted with abrasive slurry jet. Engineering Fracture Mechanics, 2022, 271.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).