1. Introduction

Water networks represent the most significant infrastructure objects of the water supply system, providing optimal and reliable water supply [

1,

2,

3]. This implies that the fundamental purpose of a water supply network is to foster social and economic prosperity while safeguarding public health [

4].

In addition to the global issue of water scarcity [

5], water supply system management faces significant challenges, notably the reduction of water losses within distribution networks [

6]. These challenges are particularly acute in less developed countries, as they result in reduced revenue for water utilities (when water losses imply water supply reductions, for limited water availability), compromise water quality, and escalate operational and maintenance costs [

5]. Water consumers expect uninterrupted access to water of appropriate quality and pressure, 24/7, 365 days a year [

7]. To meet these demands, various types of maintenance (corrective and preventive maintenance) are essential for water supply networks [

8]. Properly managing a water supply network requires not only the continuous operation of water supply facilities but also the restoration of their technical characteristics through defect repairs and the replacement of aging water pipes [

7,

9]. Furthermore, maintenance encompasses the replacement of infrastructure once it exceeds its expected lifespan. Typically, the estimated lifespan of water supply infrastructure is 50 years, necessitating an annual replacement rate of approximately 2%. In this regard, to ensure the longevity and efficiency of the water network, the management structure of water companies must develop plans for infrastructure restoration [

10].

Pipeline replacement serves as a critical strategy to uphold the service standards provided to consumers, primarily driven by the need to enhance water quality, maintain health and safety standards, address inadequate permeability, or respond to external factors impacting pipeline integrity. It’s important to note that pipeline replacement isn’t exclusively undertaken to reduce water losses; however, it plays a substantial role in mitigating water loss and can serve as an additional justification for pipeline replacement.

Technical solutions for water supply systems in Bosnia and Herzegovina and neighboring Western Balkan countries were primarily developed during the early and mid-20th century, when most of the present infrastructure was constructed. At that time, the primary objective of these systems was to meet the water demands of the population, as well as various sectors such as industry and the military. These systems were designed based on data available during that era. Subsequent expansions of water supply systems were carried out without a comprehensive and planned approach, often leading to inefficiencies. Many of these systems are characterized by overcapacity, inadequate maintenance, and continuous construction of new water abstraction facilities. This inefficiency results in high operational costs, making them economically unsustainable. Moreover, the pricing of water is typically a subject of political negotiation and doesn’t accurately reflect the actual costs incurred by water companies. This practice further exacerbates the challenge of maintaining these water systems regularly. Typically, interventions occur only in response to major issues, with each successive problem being more extensive than the previous one.

Recently water supply systems in Bosnia and Herzegovina and the Western Balkan have been shifting their focus away from constant expansion and the construction of new water supply catchment facilities. Instead, there is a growing emphasis on renovating older infrastructure, reducing water losses, and implementing initiatives aimed at raising consumer awareness about the value of water and the importance of its efficient use. Notably, thanks to funding and donations from EU programs in Bosnia and Herzegovina, there has been a discernible trend towards improving the situation regarding water loss reduction in water supply systems [

11]. However, it’s worth mentioning that there is relatively less attention paid to the strategic planning of replacing the aging water supply network, despite its importance in addressing the challenges faced by these systems.

In Bosnia and Herzegovina, local communities own and are responsible for managing the water supply network, with the primary obligation of overseeing its maintenance. Water companies, funded by LGs, are entrusted with the vital task of ensuring a consistent water supply to the population. To sustain optimal water supply conditions [

1], it becomes imperative to develop strategies for renovation of the water supply network through a combination of repair and replacement efforts [

4].

For the pipeline replacement decision-making and prioritization process greatly benefits from the application of multi-criteria optimization (MCO) methods. The relevance of MCO methods becomes evident when considering that pipeline replacement should not be pursued as an isolated objective but rather evaluated from a multifaceted perspective [

12,

13]. This entails the utilization of relevant criteria to determine priorities when making decisions about replacing segments of the water supply network [

14].

Research in water resources management has demonstrated the extensive utility of MCO methods, primarily in the domains of strategic planning and infrastructure management. These methods have been identified as instrumental across eight distinct applications [

12] encompassing watershed management, groundwater management, infrastructure selection, project evaluation, water allocation, water supply policy and planning, water quality management, and the management of protected marine areas. Commonly employed methods in these applications include compromise programming, AHP (Analytic Hierarchy Process), ELECTRE (ELimination Et Choice Translating REality), and PROMETHEE (Preference Ranking Organization METHod for Enrichment Evaluation). A recent analysis by [

15] categorized the application of VKO methods in water supply issues from 2000 to 2019 into several problem domains: water shortage-based problems, water use management-based problems, water quality-based problems, water environmental/ecosystem-based problems, flood-based problems, and combined water problems, such as those involving water shortage and water quality or water shortage and flood.

The aim of this paper is to contribute to the intricate decision-making process surrounding pipeline replacement within water systems. This contribution is achieved through the development of a methodology that is applicable in the context of water systems in less developed countries, particularly when faced with limited data availability.

2. Materials and methods

The main objective of this study is to efficiently plan the replacement of pipelines in water supply systems, especially in countries with limited data availability on their water supply networks. In this context, the study identifies the criteria for which data are typically accessible to the majority of water supply companies in less developed countries. Two methods were applied to the problem of choosing the optimal project for the rehabilitation of the pipeline system: the VIKOR method for the process of choosing the optimal project and the AHP method for the process of determining the weights of the criteria. Real data for calculating the criteria for the repair of the pipeline system were taken for the Vojkovići water supply system located in Bosnia and Herzegovina.

2.1. Choice of criteria for replacement of the water supply network

Criteria represent standards, rules, or tests on which decisions are based, that is, they represent a tool for evaluating and comparing potential alternatives. Each criterion should be measurable and not dependent on another criterion, i.e. the criteria should be: operational, applicable for measurements of alternatives, complete but not too many [

16].

The criteria can only be defined based on the determination of the goals that the appropriate water system should reach. Through a review of studies, numerous objectives of efficient management of the water supply system were identified (e.g. economic, public health, social, technical, sustainability, operational, financial, infrastructural, etc.) [

17,

18,

19,

20,

21,

22].

Since most papers only consider a subset of the criteria required for effective water supply management Salehi et al. (2017) [

23] aggregated all pertinent criteria, categorizing them into technical and non-technical categories. In total, there are 42 parameters for analysis that encompass both technical and non-technical criteria.

Subsequently Salehi et al. (2020) [

24] further classified these technical and non-technical criteria into eight distinct categories: Mechanical Criteria, Operational Criteria, Environmental Criteria, Economic Criteria, Hydraulic Criteria, Social Criteria, Physical Criteria, and Qualitative Criteria. This categorization resulted in a total of 48 criteria.

It was evident that comprehensive data necessary for all initially suggested criteria are often lacking in water supply companies in less developed countries. As a result, the criteria for which the majority of water supply companies in Bosnia and Herzegovina and the Western Balkans countries have precise data were singled out, as detailed in

Table 1. Consideration was carefully given to the selection of criteria that are really significant for addressing specific problems and for which exact data are readily available. Furthermore, to simplify calculations and avoid redundancy, certain individual criteria were consolidated into a single criterion (for example, criteria color, taste, residual chlorine, the smell of water, and so on are comprised into one criterion, i.e. water quality) [

25]. In addition to the 12 adopted criteria, an additional criterion was introduced, namely, ’flat-rate connection,’ representing consumers whose water consumption is not metered. This scenario is frequent in water supply companies throughout Bosnia and Herzegovina and the other Western Balkans countries.

It is important to emphasize that, for each criterion defined in

Table 1, data can be obtained in most water companies in less developed countries.

2.2. Evaluation of criteria

The evaluation of criteria and their evaluation method is presented in

Table 1. Quantitative criteria are those criteria characterized by numerical values that distinctly demonstrate variations in the value of each criterion. This group of criteria encompasses parameters such as average pressure, flow rate, pipe age, pipe length, pipe diameter, number of connections, number of flat connections, failure rate, and total investment.

In contrast to quantitative criteria, qualitative criteria cannot be quantified in the initial stage. This category of criteria comprises factors such as the ease of soil excavation around the pipe, water quality, and population density. The general descriptive treatment of qualitative criteria is as follows: H - high; M - medium and L - low. These labels, namely H - high, M – medium and L - low, serve to indicate the impact of an individual alternative on the qualitative criterion. Despite their lack of measurably, it is imperative that the evaluation criteria maintain logical consistency. To achieve such logical grading, each grade should possess clear definitions, that is, the boundaries of the constraints for each grade should be established. Each of the descriptive grades in the second stage can be assigned a numerical value, specifically: H – 1; M – 3 and L - 5.

The qualitative criterion of the ease of excavating the soil around the pipe implies the way of carrying out the works depending on the configuration of the terrain (the impossibility of carrying out the works with machines or the possibility of using modern technologies for the execution of the works), the type and installation of materials (the weight of the terrain for the installation of the materials, digging or under-drilling of roads, the existence of other installation on the route, etc.) and it is possible to evaluate the same in the design service and maintenance service of the water supply company (this criterion is always maximized). Limits for this criterion can be defined as follows:

H - High impact on the performance of works implies impassibility or the impossibility of performing works with machines, i.e. implies inaccessible and impassable terrain.

M – Medium impact implies moderate terrain pass-ability where less techniques can be used. A soil composed of crumbly and soft rocks can also be considered as having a medium impact. On some sections, interventions such as drilling the road, moving installations, etc. are needed.

L - Low impact on the execution of works implies that the route is accessible and passable, and modern equipment can be used on each section, that is, no additional interventions are needed on the section.

The qualitative criterion of water quality is an evaluation of the quality of water (this criterion is minimized) and can be characterized through three descriptive scales:

H - Signifying a high impact on the consumer, this corresponds to low-quality drinking water (which may exhibit impaired taste, smell, and color).

M - Denoting a medium impact on the consumer, this implies that the quality of drinking water is conditionally satisfactory (making it suitable for use as technical water), and

L - Representing a low impact on the consumer, this implies that the quality of drinking water conforms to the standards set out in the Rulebook on the hygienic correctness of drinking water.

Population density, as a qualitative criterion, encompasses factors related to the location of pipeline replacement, distinguishing between urban and rural areas. It takes into account variables such as population density, traffic volume, street congestion, the feasibility of diverting traffic, and more (this criterion is maximized). This criterion can be characterized through three descriptive scales:

H - Signifying an urban area with high population density, frequent traffic, the necessity of prolonged traffic stoppages, presence in tourist zones, and significant disruption to everyday life. Extensive preparations are required for work execution in this zone.

M - Denoting a medium impact, this indicates that population density is not particularly high, and there may be occasional short-term disruptions in traffic. Nevertheless, these disruptions do not significantly affect the daily lives of citizens.

L - Representing a rural area with minimal traffic, no need for traffic stoppages, and no significant disruption to daily life. This zone typically requires fewer logistical preparations for work execution.

2.3. VIKOR method

The VIKOR method, which stands for Multi-Criteria Compromise Ranking (Serbian language –

VIšekriterijumsko

KOmpromisno

Rangiranje), is employed in this work to determine the optimal solution when faced with multiple criteria. This method was developed based on the idea of presenting a solution to decision-makers that strikes a compromise between their desires and the constraints, or represents a kind of compromise of the diverse interests of decision-making participants [

26].

As noted by Thakkr et al. (2021) [

27], the VIKOR method is a powerful tool applicable to a range of strategic decision-making scenarios across various domains, including social, technical, economic, and environmental contexts. The approach within the VIKOR method involves several steps: identifying different potential solutions for a given problem, establishing priorities among these solutions, ranking them in ascending order, and ultimately selecting the best solution [

27,

28,

29]. Consequently, the VIKOR method is well-suited for optimizing complex systems with multiple criteria that may be in conflict with each other. It aids in the selection of the most favorable solution from a set of available alternatives by taking into account these conflicting criteria and finding a compromise that aligns with the decision-makers’ objectives and constraints.

2.3.1. Steps of the VIKOR method

The VIKOR method is typically carried out through a series of steps to evaluate and select the optimal solution when dealing with conflicting criteria and multiple alternatives. Here are the six steps of the VIKOR method [

30,

31,

32]:

STEP 1: The initial step in the optimization process involves gathering information about all the criterion functions for each potential alternative. This requires knowing the values associated with each criterion for all possible alternatives. The problem is then formulated into an evaluation matrix, often in tabular format (

Table 2). In the

Table 2, the variable "(

,

, ...,

, ..., a)" represents a finite set of possible alternatives and

(.),

(.), ...,

(.), ...,

(.), a set of evaluation criteria. The VIKOR method assumes that all criteria should be maximized. However, there are situations where certain criteria need to be minimized. To align these minimized criteria with the VIKOR method’s requirement, they are adjusted by multiplying them by -1.

STEP 2: In the second step, the best

and the worst

value of all criteria i = 1, 2,... n are determined. When the evaluation matrix is formed, the maximum and minimum values are requested for each criterion:

STEP 3: In the third step, the values of

and

, where j = 1, 2, ..., J, corresponding to the norms

and L

∞, respectively, are calculated as follows:

Where the weights of the criteria, represented by , express their relative importance and reflect the decision maker’s preference.

STEP 4: The values of the compromise solution

, where j = 1, 2, ..., J, are calculated as follows:

the factors in the equation are as follows

STEP 5: In the fifth step, the alternatives are ranked by sorting the values of S, R, and Q in ascending order because the best alternative is the one with the lowest value. The ranking is determined by sorting the alternatives based on the measures QS, QR, and finally Q. The best alternative is the one with the minimum value in the measure and has the top position in the ranking list.

STEP 6: In the sixth step, a compromise solution (a′) is proposed, which ranks best according to the Q measure if two conditions are met, namely

where: is the second-placed alternative in the ranking list Q;

Advantage Threshold DQ = 1/(M - 1);

where M is number of alternatives.

Acceptable stability: Alternative a′ should also be the best-ranked S and/or R rank.

The VIKOR method is a six-step approach used to calculate compromise values and establish a ranking list of alternatives. It is known for its simplicity in application and versatility, making it suitable for a wide range of criteria and alternatives. What distinguishes the VIKOR method from others are the two essential conditions that a solution must satisfy: acceptable advantage and solution stability. In essence, the obtained result is considered valid only if it meets these two crucial conditions.

3. Case study East Sarajevo

3.1. Analysis of the water supply area

In the subsequent sections of this study, the analysis is focused on the district metering area (DMA) of the water supply system in Vojkovići, which is managed by the Communal Company "Vodovod i Kanalizacija" a.d. in East Sarajevo. DMA Vojkovići, as informed by data obtained from the municipality of East Ilidža, supplies with water approximately 4,300 inhabitants. This region is predominantly composed of individual residential buildings and is situated in the rural part of the city of East Sarajevo. The precise number of connections to the water supply network is 1257.

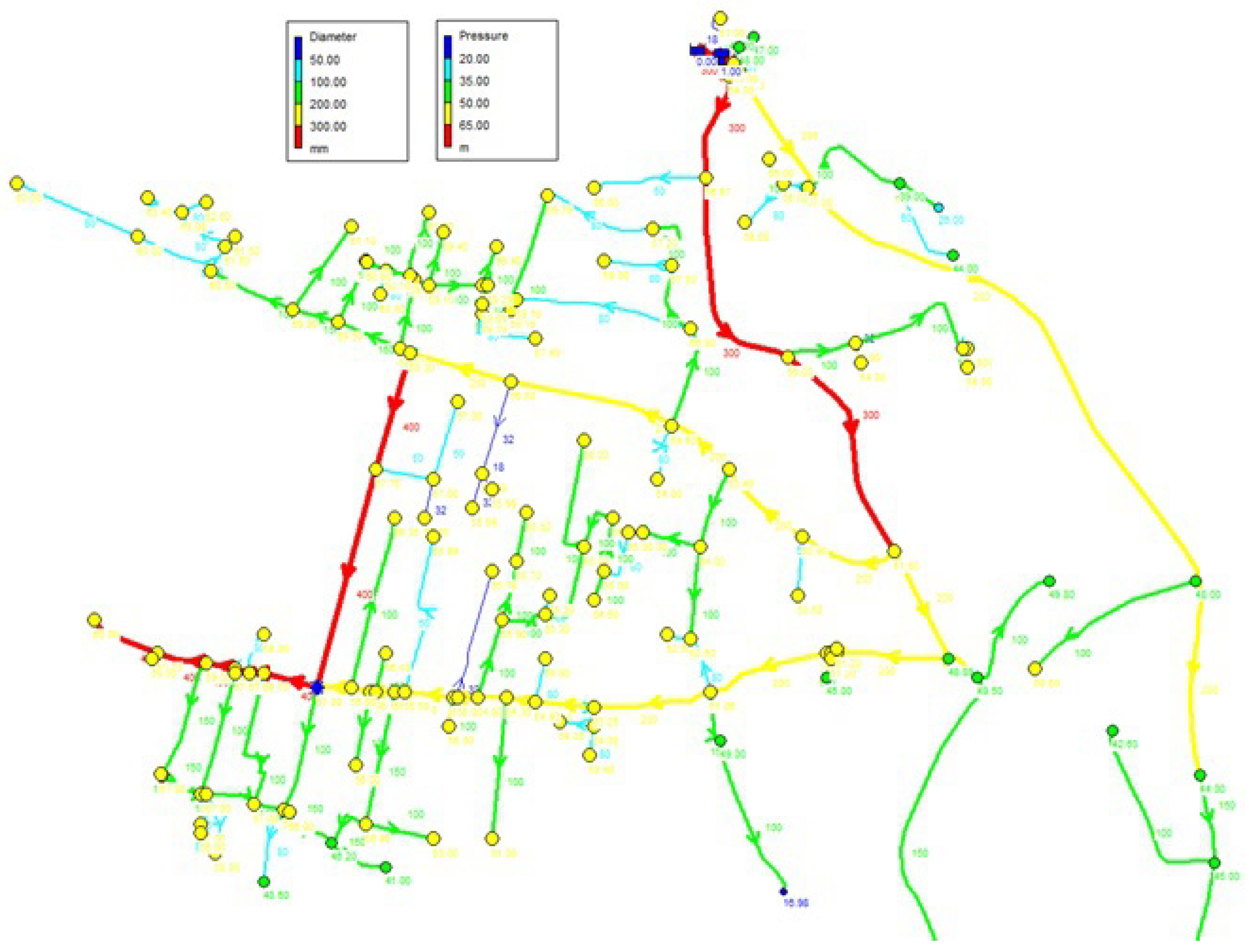

Water supply companies, to varying degrees, utilize free software such as EPANET 2.0 or EPANET 2.2 for hydraulic analysis and optimization of their water supply networks [

33,

34,

35,

36]. For the purpose of creating the hydraulic model of the Vojkovići water supply system within the EPANET 2.2 software, data concerning the existing types and materials of pipelines were gathered. It was determined that the water supply network in the Vojkovići DMA spans 25 kilometers, featuring pipe diameters ranging from DN 50 to DN 400 mm. Various pipeline materials are in use, including polyethylene, cast iron, and asbestos cement pipelines. Upon analyzing the materials in use, it can be inferred that the water supply network includes pipelines that are over 40 years old, installed using the technology and knowledge available at that time. The expansion of the pipeline network occurred without a comprehensive planning approach and a holistic assessment of the system’s deficiencies.

By developing a hydraulic model for the water supply network illustrated in

Figure 1, presuming no leaks in the water supply network, it was determined that certain sections of the pipeline have exceptionally low water flow rates and flows, indicating that these segments are oversized for the current and future water demands of the local population. The pressures in the junctions are largely satisfactory from the point of view of the hydraulic model, however, for the purposes of applying the pipeline replacement methodology, they were checked in the field. It was found that in some places pressure is significantly lower compared to the calculated pressures within the hydraulic model. This observation suggests the presence of leaks or losses within the water supply network. Also, it was established that the need for water in DMA is on average about 14 l/s, and at the inflow to the system this amount is significantly higher and ranges to 35 l/s.

An assessment of the failures that occurred over the past 5 years was conducted, revealing a total of 507 work orders issued for interventions on the water supply network within the Vojkovići measuring area. Following a comprehensive analysis and optimization of the water supply network using the hydraulic model developed in the EPANET software, 8 projects for the replacement of the primary pipelines were identified. These project selections also took into account plans for the construction of new residences and potential commercial entities. The chosen projects are presented with

Table 3.

3.2. Results and discussion

The aim of the paper is to present and test the methodology for choosing the optimal solution for the restoration of the water supply network. As outlined in the paper, a list of pertinent criteria has been established as the basis for the analysis and evaluation of all planned projects, with each project being assessed against these criteria.

Table 4 illustrates the evaluations of criteria for each of the individual projects.

In the subsequent step, all qualitative criteria are assigned values as described in previous chapter (

Table 5).

Table 4. and

Table 5 show that there isn’t a single project that excels in all criteria values. Furthermore, it’s evident that criteria C2, C11, and C12 should be minimized, while criteria C1, C3, C4, C5, C6, C7, C8, C9, C10, and C13 should be maximized. To achieve this consistency, a simple transformation of the criteria that need minimization (by multiplying by -1) is applied, resulting in all criterion functions being reformulated to maximize them. Since, depending on the criteria category, there are different units of measure, and also no project is the best according to all criteria, the values of the criteria are normalized. The normalization of criteria values is presented in

Table 6.

After normalizing the values, weight coefficients must be assigned to all criteria. Determining the weight of each criterion is one of the key problems that occurs in multi-criteria optimization models. There is no unique way of determining the weights of the criteria and they are usually determined subjectively. Since the weights of the criteria can significantly affect the result, it is necessary to pay attention to the objectivity of the weights of the criteria. For problems that involve a set of criteria with a mixed structure, including both quantitative and qualitative aspects, the authors have opted for the Analytical Hierarchical Process (AHP) method. This method, initially formulated by Saaty and further detailed in works such as [

37,

38,

39,

40,

41], facilitates the systematic evaluation of criteria one by one. Through pairwise comparisons of criteria and assessing the consistency of the results obtained,

Table 7 displays the weight values assigned to each criterion.

After evaluating the projects according to the criteria and determining the weight coefficients, the values of S, R and Q are calculated, which are shown in the steps of the VIKOR method. A ranking list of projects is obtained for the weight of the strategy, which is v=0.5. The ranking of the projects is shown in

Table 8.

The ranking list indicates that the top-ranked project for pipeline replacement is Project P6, followed by Project P5 in the second position. Once the ranking of projects has been determined, it is essential to establish the criteria for acceptable advantage and acceptable stability.

The difference between the rankings of the first and second projects is 0.161, while the DQ (DQ is often used to denote the difference between the maximum and minimum values in VIKOR) is 0.143, indicating that the condition of acceptable advantage has been met. Additionally, Project P6 ranks highest in the R ranking, satisfying the condition of acceptable stability.

As the VIKOR method typically considers the best alternative to be the one with the lowest value, which is not always welcome by real decision makers, alternative is to normalize the values within the range of 0 to 100 so that the best alternative receives the highest value, and the worst receives the lowest. The normalization of the ranked alternatives is achieved using the following expression:

where is

the value of the individual project rank shown in the

Table 8.,

– the minimal value of the projects rank shown in

Table 8,

– maximal value of the projects rank shown in Table 8. By following this approach, the best alternative will be assigned a value of 100, while the worst alternative will have a value of 0. The final ranking list is depicted in

Table 9.

Through an analysis of the obtained results, it is evident that, considering the actual conditions in the water supply system, both Project 6 and Project 5 are top priorities for replacement. These pipelines are characterized by being oversized, resulting in water stagnation and very low flow rates, which in turn lead to frequent consumer complaints about water quality and the need for frequent pipeline desalting. While there may be some pressure drop in these pipelines, it is not significantly pronounced compared to other projects, and the number of flat-rate connections is also relatively low.

4. Conclusions:

In less developed countries, water supply systems often find themselves dealing with limited data compared to their counterparts in developed countries. Criteria and a method for their evaluation, complete with clearly established boundaries, were defined based on the available data in these water supply systems. In this paper, a methodology was developed with the aim of determining optimal solutions for pipeline replacement in water supply systems constrained by limited data. The research has demonstrated that the application of the VIKOR method for multi-criteria optimization can significantly assist in making informed decisions regarding pipeline replacement in water supply systems. The VIKOR method stands out for its simplicity in application and its capacity to handle a substantial number of criteria and alternatives. What distinguishes the VIKOR method from other approaches are the two crucial conditions that must be met for a solution to be deemed valid: the requirement of an acceptable advantage and the need for solution stability. The result obtained through the VIKOR method is considered valid only if it satisfies these two conditions. In summary, it can be concluded that the VIKOR method serves as a valuable tool for decision-makers, providing them with a realistic perspective on the situation and aiding in making informed decisions when planning the replacement of pipelines in the water supply system.

The AHP method for multi-criteria optimization was employed to determine the weights of individual criteria. Notably, criteria such as water quality, investment value, frequency of failures, and pipe flow velocity were found to carry greater weight compared to other criteria. These criteria encompassed both the regularity of water supply and the quality of water for consumers, as well as the financial aspect of project implementation. However, it is possible for individual water supply systems to omit certain criteria they deem less important, adjust the model according to system specifics, assign different weights to individual criteria when selecting the appropriate project, or even allocate the same weight to each criterion.

The results obtained in this research can be of value not only to water supply companies but also to technical professionals involved in determining the necessary parameters for pipeline replacement. During this study, other challenges faced by water supply companies were also observed, including pressure drops among consumers, reduced flow, and network leaks. In the future, one potential research direction for hydraulic models of water supply systems could involve the development of an algorithm for predicting potential leaks in the water supply network.

Author Contributions

All authors conceived, designed, and performed the experiments, and all authors analyzed the data. All authors contributed to writing the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Da Silva, W.; Souza, M. A decision support model to Baid the management of crises in urban water supply systems (the uwc-model). Urban Water J. 2017, 14, 612–620. [Google Scholar] [CrossRef]

- Kabir, G.; Tesfamariam, S.; Francisque, A.; Sadiq, R. Evaluating risk of water mains failure using a Bayesian belief network model. Eur. J. Oper. Res. 2015, 240, 220–234. [Google Scholar] [CrossRef]

- Loucks, D.; Van Beek, E. Water Resource Systems Planning and Management, An Introduction to Methods, Models, and Applications. Springer 2017, pp. 527–565. [CrossRef]

- Nunes, R.; Arraut, E.; Pimente, M. Risk Assessment Model for the Renewal of Water Distribution Networks: A Practical Approach. Water 2023, 15, 3947–3969. [Google Scholar] [CrossRef]

- Kadenge, M.; Masanja, V.G.; Mkandawile, M. Optimisation of Water Loss Management Strategies: Multi-Criteria Decision Analysis Approaches. J. Math. Inform. 2020, 1. [Google Scholar] [CrossRef]

- Aschilean, I.; Giurca, I. Choosing a Water Distribution Pipe Rehabilitation Solution Using the Analytical Network Process Method. Water 2018, 484, 305–318. [Google Scholar] [CrossRef]

- Romaniuk, M. Optimization of maintenance costs of a pipeline for a V-shaped hazard rate of malfunction intensities. Eksploatacja i Niezawodnosc – Maintenance and Reliability 2018 2018, 20, 46–56. [Google Scholar] [CrossRef]

- Romaniuk, M.; Hryniewicz, O. Estimation of maintenance costs of a pipeline for a U-shaped hazard rate function in the imprecise setting. Eksploatacja i Niezawodnosc – Maintenance and Reliability 2020 2020, 22, 352–362. [Google Scholar] [CrossRef]

- Piegdoń, I.; Tchórzewska-Cieślak, B.; Eid, M. Managing the risk of failure of the water supply network using the mass service system. Eksploatacja i Niezawodnosc – Maintenance and Reliability 2018 2018, 20, 284–291. [Google Scholar] [CrossRef]

- Soldi, D.; Candelieri, A.; Archetti, F. Resilience and vulnerability in urban water distribution networks through network theory and hydraulic simulation. Procedia Eng. 2015 2015, 17, 1259–1268. [Google Scholar] [CrossRef]

- Serdarević, A.; Hadžiahmetović, A.; Džubur, A.; Hotić, K. Improvements to the water supply system - case study reconstruction of the water supply network of the city of Visoko (Unapređenja sistema za vodosnabdijevanje – case study rekonstrukcija vodovodne mreže grada Visoko). VODOPRIVREDA 0350-0519 2020, 17, 249–258. [Google Scholar]

- Hajkowicz, S.; Collins, K. A review of multiple criteria analysis for water recource planning and management. Water Resour. Manage. 2007, 21, 1553–1566. [Google Scholar] [CrossRef]

- Lade, O.; Oloke, D.; Chinyio, E.; Fullen, M. Use of Multi-criteria Decision Analysis Methods for Water Supply Problems: A Framework for Improved Rainwater Harvesting. J. Environ. Sci. Eng. A1 2012, pp. 909–917. [CrossRef]

- Morais, D.; Almeida, A. Water supply system decision making using multicriteria analysis. Water SA 2006, 32, 229–236. [Google Scholar] [CrossRef]

- Gebre, S.; Cattrysse, D.; Van Orshoven, J. Multi-Criteria Decision-Making Methods to Address Water Allocation Problems: A Systematic Review. Water 2021, 13, 612–620. [Google Scholar] [CrossRef]

- Baker, D.; Bridges, D.; Hunter, R.; Johnson, G.; Krupa, J.; Murphy, J.; Sorenson, K. Guidebook to decision-making methods. US Department of Energy 2001.

- Abrishamchi, A.; Ebranimimian, A.; Tajrishi, M.; Marino, M.; Asce, H.M. Case Study: Application of Multicriteria Decision Making to Urban Water Supply. J. Water Resour. Plan. Manage. 2005, 131, 326–335. [Google Scholar] [CrossRef]

- Afshar, A.; Marino, M.; Saadatpour, M.; Afshar, A. Fuzzy TOPSIS Multicriteria Decision Analysis Applied to Karun reservoir System. Water Resour. Manage. 2011, 25, 545–563. [Google Scholar] [CrossRef]

- Al-Barqawi, H.; Zayed, T. Infrastructure Management: Integrated AHP/ANN Model to Evaluate Municipal Water Mains’ Performance. J. Infrastruct. Syst. 2008, pp. 305–318. [CrossRef]

- Mutikanga, H.; Sharma, S.; Vairavamoorthy, K. Multi-criteria decision analysis: A Strategic Planning Tool for Water Loss Management. Water Resour. Manage. 2011, 25, 3947–3969. [Google Scholar] [CrossRef]

- Okeola, O.; Sule, B. Evaluation of management alternatives for urban water supply system using Multicriteria decision Analysis. J. King Saud University – Eng. Sci. 2023, 24, 9–24. [Google Scholar] [CrossRef]

- Orašanin, G.; Vučijak, B. Multi-criteria optimization in planning water supply (Višekriterijumska optimizacija u planiranju vodosnabdijevanja). TEHNIKA 2013 2013, 68, 768–774. [Google Scholar]

- Salehi, S.; Ghazizadeh, M.; Tabesh, M. A comprehensive criteria-based multi-attribute decision-making model for rehabilitation of water distribution systems. Struct. Infrastruct. Eng. 2017, 14, 1–23. [Google Scholar] [CrossRef]

- Salehi, S.; Ghazizadeh, M.; Tabesh, M.; Valadi, S.; S.P.S., N. A risk component-based model to determine pipes renewal strategies in water distribution networks. Struct. Infrastruct. Eng. 2020, 17, 1338–1359. [Google Scholar] [CrossRef]

- Orašanin, G.; Simić, S.; Blagojević, J. adn Milić, D. Analysis of effective criteria and the method of their evaluation in the water network renewal planning (Analiza efektivnih kriterijuma i način njihovog vrednovanja u planiranju obnove vodovodne mreže). 44. International conference Water supply and sewerage (44. Međunardna konferencija Vodovod i kanalizacija 23) 2023, pp. 98–106.

- Opricović, S. Multicriteria optimization of systems in construction (Višekriterijumska optimizacija sistema u građevinarstvu); Faculty of Civil Engineering, University of Belgrade (Građevinski fakultet Univerziteta u Beogradu): Belgrade, 1998. [Google Scholar]

- Thakkar, J. VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR). In: Multi-Criteria Decision Making. Studies in Systems, Decision and Control, 2021, Springer 2021, 336. [CrossRef]

- Kabir, G.; Sadiq, R.; Tesfamariam, S. A review of multi-criteria decision-making methods for infrastructure management. Struct. Infrastruct. Eng. 2013, 10, 1176–1210. [Google Scholar] [CrossRef]

- Opricović, S. Compromise in cooperative game and the VIKOR method. Yug.. J. Oper. Res. 19 2009, 2, 225–238. [Google Scholar] [CrossRef]

- Kang, D.; Park, Y. Review-based measurement of customer satisfaction in mobile service: Sentiment analysis and VIKOR approach. Exp. Syst. with Appl. 2013, 41, 1041–1050. [Google Scholar] [CrossRef]

- Opricović, S.; Tzeng, G. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 156 2004, pp. 445–455. [CrossRef]

- Opricović, S.; Tzeng, G. Extended VIKOR method in comparision with outranking methods. Eur. J. Oper. Res. 178 2007, pp. 514–529. [CrossRef]

- Gheibi, M.; Emrani, N.; Eftekhari, M.; Behzadian, K.; Mohtasham, M.; Abdollahi, J. Assessing the failures in water distribution networks using a combination of Geographic Information System, EPANET 2, and descriptive statistical analysis: a case study. Sustain. Water Resour. Manage. 2022, 8, 612–620. [Google Scholar] [CrossRef]

- Gorev, N.; 2013., K.I. Noniterative Implementation of Pressure-Dependent Demands Using the Hydraulic Analysis Engine of EPANET 2. Water Resour. Manage. 2022, 27, 3623–3630. [CrossRef]

- Košarac, A.; Romić, D.; Orašanin, G.; Blagojević, J. Optimization of Water Supply System Using Software EPANET 2.0. In: Karabegović, I. (eds) New Technologies, Development and Application. NT 2018. Lecture Notes in Networks and Systems. 2019. [CrossRef]

- Widiarti, W.; Wahyuni, S.; Wiyono, R.; Hidayah, E.; Halik, G.; Sisinggih, D. Evaluation of pipe network distribution system using EPANET 2.0 (a case study of the city of Jember). IOP Conf. Series: Earth and Environmental Science 437 2020. [CrossRef]

- Saaty, R. The Analytic Hierarchy Process—what it is and how it is used. Mathematical Modelling 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Saaty, T. How to make a decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Salo, A.; Hamalainen, R. On the Measurement of Preferences in the Analytic Hierarchy Process. J. MCDA 6 1997, pp. 309–319. [CrossRef]

- Saaty, T. Basic theory of the Analytic Hierarchy Process: How to make a decision. Rev. R. Acad. Cienc. Exact. Fis. Nat. (Esp) 1999, 93, 395–423. [Google Scholar]

- Saaty, T. Decision making with the Analytic Hierarchy Process. Int. J. Services Sci. 1 2008, p. 83 – 98. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).