Submitted:

14 January 2024

Posted:

15 January 2024

You are already at the latest version

Abstract

Keywords:

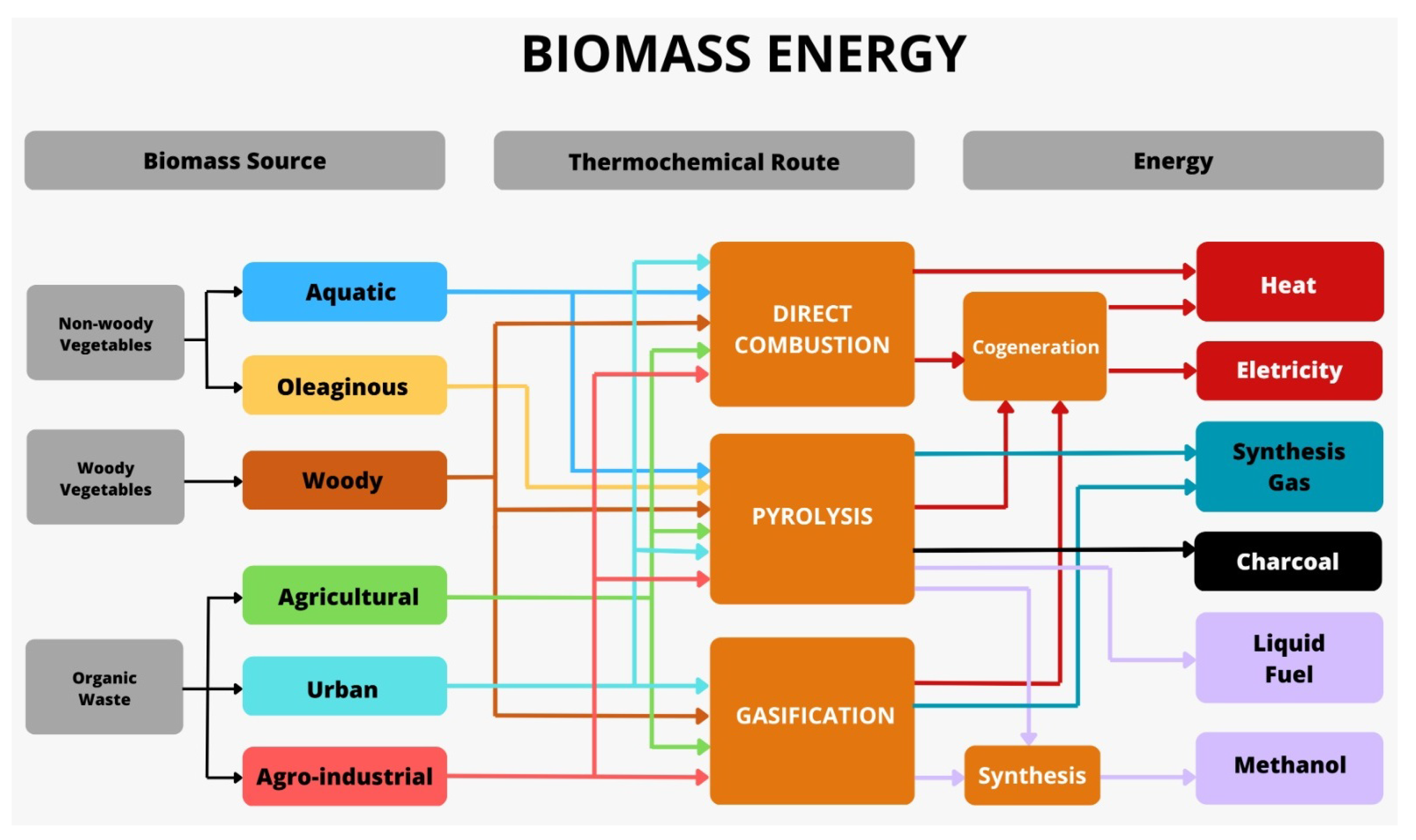

1. Introduction

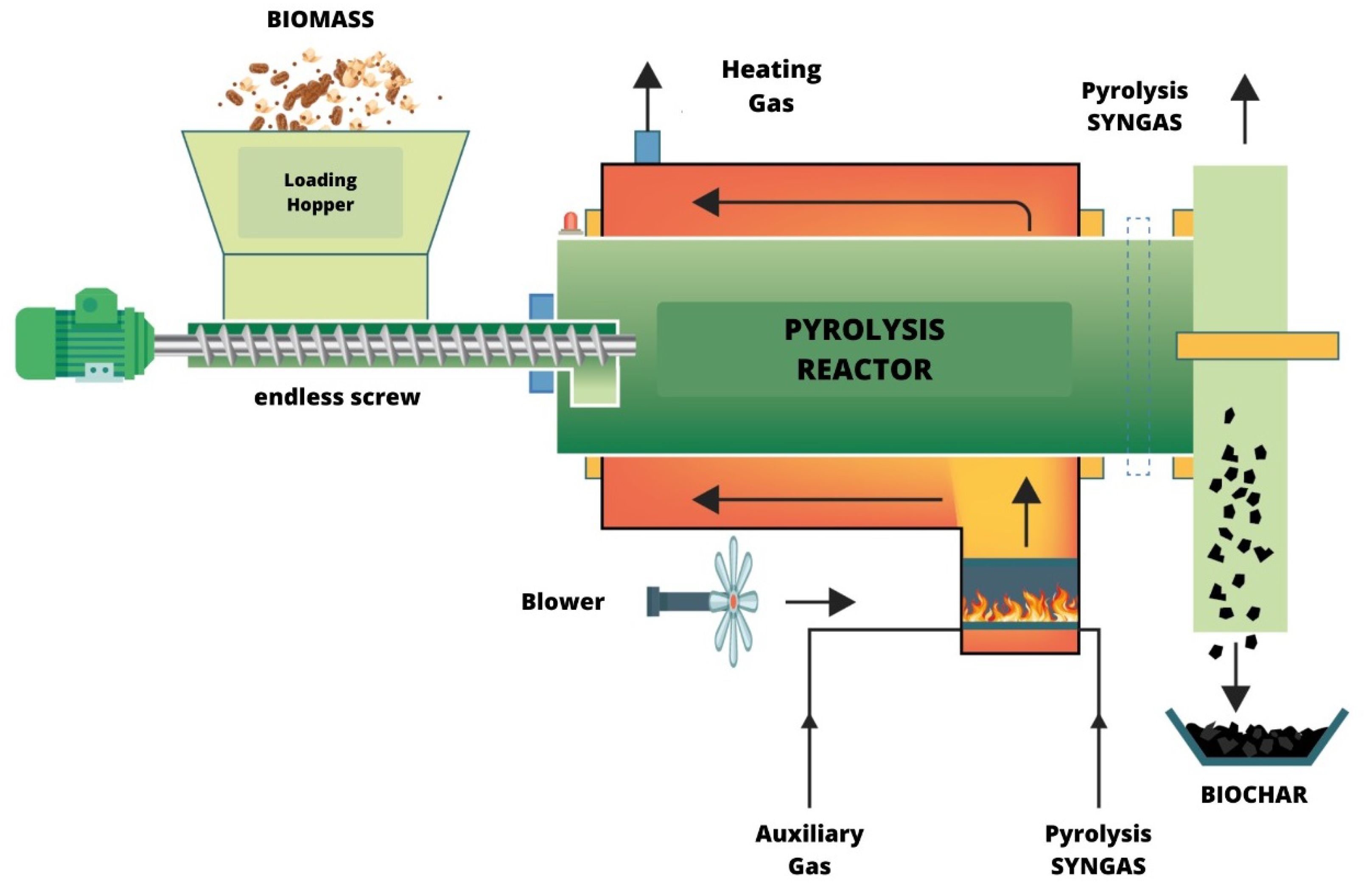

2. Pyrolysis

3. Gasification

4. Important Features for Thermal of Power Generation

4.1. Temperature Influence

4.2. Pressure Factors

4.3. Heating Rate Dependence

4.4. Residence Time Importance

5. Power Plant Control and Automation

5.1. Artificial Intelligence Applications

6. Final Remarks

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nandhini, R.; Berslin, D.; Sivaprakash, B.; Rajamohan, N.; Vo, D.V.N. Thermochemical conversion of municipal solid waste into energy and hydrogen: a review. Environmental Chemistry Letters 2022, 20, 1645–1669. [Google Scholar] [CrossRef] [PubMed]

- Ledón, Y.C.; González, P.; Concha, S.; Zaror, C.A.; Arteaga-Pérez, L.E. Exergoeconomic valuation of a waste-based integrated combined cycle (WICC) for heat and power production. Energy 2016, 114, 239–252. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renewable and sustainable energy reviews 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Sharma, A.; Pareek, V.; Zhang, D. Biomass pyrolysis—A review of modelling, process parameters and catalytic studies. Renewable and sustainable energy reviews 2015, 50, 1081–1096. [Google Scholar] [CrossRef]

- Sharma, S.; Celebi, A.D.; Maréchal, F. Robust multi-objective optimization of gasifier and solid oxide fuel cell plant for electricity production using wood. Energy 2017, 137, 811–822. [Google Scholar] [CrossRef]

- Darmawan, A.; Ajiwibowo, M.W.; Yoshikawa, K.; Aziz, M.; Tokimatsu, K. Energy-efficient recovery of black liquor through gasification and syngas chemical looping. Applied Energy 2018, 219, 290–298. [Google Scholar] [CrossRef]

- dos Santos, I.F.S.; Vieira, N.D.B.; de Nóbrega, L.G.B.; Barros, R.M.; Tiago Filho, G.L. Assessment of potential biogas production from multiple organic wastes in Brazil: Impact on energy generation, use, and emissions abatement. Resources, Conservation and Recycling 2018, 131, 54–63. [Google Scholar] [CrossRef]

- Piñas, J.A.V.; Venturini, O.J.; Lora, E.E.S.; Roalcaba, O.D.C. Technical assessment of mono-digestion and co-digestion systems for the production of biogas from anaerobic digestion in Brazil. Renewable Energy 2018, 117, 447–458. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Antoniou, N.; Barakat, A.; Zabaniotou, A. A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process. Applied Energy 2015, 148, 32–38. [Google Scholar] [CrossRef]

- Cao, Y.; Pawłowski, A. Sewage sludge-to-energy approaches based on anaerobic digestion and pyrolysis: Brief overview and energy efficiency assessment. Renewable and Sustainable Energy Reviews 2012, 16, 1657–1665. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste management 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Bayat, R.; Hosseinzadeh-Bandbafha, H.; Afrasyabi, H.; Chau, K.w. Modeling of energy consumption and environmental life cycle assessment for incineration and landfill systems of municipal solid waste management-A case study in Tehran Metropolis of Iran. Journal of cleaner production 2017, 148, 427–440. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—a technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Lédé, J. Biomass fast pyrolysis reactors: a review of a few scientific challenges and of related recommended research topics. Oil & Gas Science and Technology–Revue d’IFP Energies nouvelles 2013, 68, 801–814. [Google Scholar]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste management 2015, 37, 104–115. [Google Scholar] [CrossRef]

- Barsali, S.; De Marco, A.; Giglioli, R.; Ludovici, G.; Possenti, A. Dynamic modelling of biomass power plant using micro gas turbine. Renewable Energy 2015, 80, 806–818. [Google Scholar] [CrossRef]

- Sadegh-Vaziri, R.; Babler, M.U. Modeling of slow pyrolysis of various biomass feedstock in a rotary drum using TGA data. Chemical Engineering and Processing-Process Intensification 2018, 129, 95–102. [Google Scholar] [CrossRef]

- Benato, A.; Bracco, S.; Stoppato, A.; Mirandola, A. Dynamic simulation of combined cycle power plant cycling in the electricity market. Energy conversion and management 2016, 107, 76–85. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; Van Den Broek, R.; Berndes, G.; Gielen, D.; Turkenburg, W. Exploration of the ranges of the global potential of biomass for energy. Biomass and bioenergy 2003, 25, 119–133. [Google Scholar] [CrossRef]

- Silveira, A.R.R.; Nadaleti, W.C.; Przybyla, G.; Belli Filho, P. Potential use of methane and syngas from residues generated in rice industries of Pelotas, Rio Grande do Sul: Thermal and electrical energy. Renewable energy 2019, 134, 1003–1016. [Google Scholar] [CrossRef]

- Babler, M.U.; Phounglamcheik, A.; Amovic, M.; Ljunggren, R.; Engvall, K. Modeling and pilot plant runs of slow biomass pyrolysis in a rotary kiln. Applied energy 2017, 207, 123–133. [Google Scholar] [CrossRef]

- Gómez, N.; Rosas, J.G.; Cara, J.; Martínez, O.; Alburquerque, J.A.; Sánchez, M.E. Slow pyrolysis of relevant biomasses in the Mediterranean basin. Part 1. Effect of temperature on process performance on a pilot scale. Journal of cleaner production 2016, 120, 181–190. [Google Scholar] [CrossRef]

- Aboughaly, M.; Fattah, I.R. Environmental Analysis, Monitoring, and Process Control Strategy for Reduction of Greenhouse Gaseous Emissions in Thermochemical Reactions. Atmosphere 2023, 14, 655. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Computers & Chemical Engineering 2014, 66, 36–56. [Google Scholar]

- Cerda-Flores, S.C.; Rojas-Punzo, A.A.; Nápoles-Rivera, F. Applications of multi-objective optimization to industrial processes: a literature review. Processes 2022, 10, 133. [Google Scholar] [CrossRef]

- Malode, S.J.; Shanbhag, M.M.; Kumari, R.; Dkhar, D.S.; Chandra, P.; Shetti, N.P. Biomass-derived carbon nanomaterials for sensor applications. Journal of Pharmaceutical and Biomedical Analysis 2023, 222, 115102. [Google Scholar] [CrossRef] [PubMed]

- Desai, F.J.; Uddin, M.N.; Rahman, M.M.; Asmatulu, R. A critical review on improving hydrogen storage properties of metal hydride via nanostructuring and integrating carbonaceous materials. International Journal of Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Mphahlele, K.; Matjie, R.H.; Osifo, P.O. Thermodynamics, kinetics and thermal decomposition characteristics of sewage sludge during slow pyrolysis. Journal of Environmental Management 2021, 284, 112006. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.; Xu, D.; Hao, B.; Liu, L.; Wang, S.; Wu, Z. Thermochemical methods for the treatment of municipal sludge. Journal of Cleaner Production 2021, 311, 127811. [Google Scholar] [CrossRef]

- Sun, Y.; Dong, B.; Wang, L.; Li, H.; Thorin, E. Technology selection for capturing CO2 from wood pyrolysis. Energy Conversion and Management 2022, 266, 115835. [Google Scholar] [CrossRef]

- Gouws, S.M.; Carrier, M.; Bunt, J.R.; Neomagus, H.W. Co-pyrolysis of coal and raw/torrefied biomass: A review on chemistry, kinetics and implementation. Renewable and Sustainable Energy Reviews 2021, 135, 110189. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass pyrolysis technologies for value-added products: a state-of-the-art review. Environment, Development and Sustainability 2021, 1–55. [Google Scholar] [CrossRef]

- Ketov, A.; Sliusar, N.; Tsybina, A.; Ketov, I.; Chudinov, S.; Krasnovskikh, M.; Bosnic, V. Plant Biomass Conversion to Vehicle Liquid Fuel as a Path to Sustainability. Resources 2022, 11, 75. [Google Scholar] [CrossRef]

- Das, A.; Peu, S.D. A comprehensive review on recent advancements in thermochemical processes for clean hydrogen production to decarbonize the energy sector. Sustainability 2022, 14, 11206. [Google Scholar] [CrossRef]

- Callegari, A.; Capodaglio, A.G. Properties and beneficial uses of (bio) chars, with special attention to products from sewage sludge pyrolysis. Resources 2018, 7, 20. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, S.; Duan, Y.; Chen, W.; Li, Z.; Li, Y. Thermodynamic assessment of hydrothermal combustion assisted fossil fuel in-situ gasification in the context of sustainable development. Fuel 2023, 335, 127053. [Google Scholar] [CrossRef]

- Fozer, D.; Volanti, M.; Passarini, F.; Varbanov, P.S.; Klemeš, J.J.; Mizsey, P. Bioenergy with carbon emissions capture and utilisation towards GHG neutrality: Power-to-Gas storage via hydrothermal gasification. Applied Energy 2020, 280, 115923. [Google Scholar] [CrossRef]

- Santos, N.D.S.A.; Roso, V.R.; Malaquias, A.C.T.; Baeta, J.G.C. Internal combustion engines and biofuels: Examining why this robust combination should not be ignored for future sustainable transportation. Renewable and Sustainable Energy Reviews 2021, 148, 111292. [Google Scholar]

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Liu, Q. A critical review of technologies, costs, and projects for production of carbon-neutral liquid e-fuels from hydrogen and captured CO 2. Energy Advances 2022, 1, 580–605. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Badur, J.; Pawlak-Kruczek, H.; Stasiak, K.; Amiri, M.; Niedzwiecki, L.; Krochmalny, K.; Mularski, J.; Madejski, P.; Mikielewicz, D. Mathematical modelling of gasification process of sewage sludge in reactor of negative CO2 emission power plant. Energy 2022, 244, 122601. [Google Scholar] [CrossRef]

- Ayol, A.; Yurdakos, O.T.; Gurgen, A. Investigation of municipal sludge gasification potential: Gasification characteristics of dried sludge in a pilot-scale downdraft fixed bed gasifier. International Journal of Hydrogen Energy 2019, 44, 17397–17410. [Google Scholar] [CrossRef]

- Alves, O.; Calado, L.; Panizio, R.M.; Gonçalves, M.; Monteiro, E.; Brito, P. Techno-economic study for a gasification plant processing residues of sewage sludge and solid recovered fuels. Waste Management 2021, 131, 148–162. [Google Scholar] [CrossRef] [PubMed]

- Bisinella, V.; Hulgaard, T.; Riber, C.; Damgaard, A.; Christensen, T.H. Environmental assessment of carbon capture and storage (CCS) as a post-treatment technology in waste incineration. Waste Management 2021, 128, 99–113. [Google Scholar] [CrossRef] [PubMed]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow III, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Applied energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Islam, K.N. Municipal solid waste to energy generation: An approach for enhancing climate co-benefits in the urban areas of Bangladesh. Renewable and Sustainable Energy Reviews 2018, 81, 2472–2486. [Google Scholar] [CrossRef]

- Wienchol, P.; Szlęk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture–Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Alves, O.; Garcia, B.; Rijo, B.; Lourinho, G.; Nobre, C. Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies 2022, 15, 6600. [Google Scholar] [CrossRef]

- Samolada, M.; Zabaniotou, A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste management 2014, 34, 411–420. [Google Scholar] [CrossRef]

- Schnell, M.; Horst, T.; Quicker, P. Thermal treatment of sewage sludge in Germany: A review. Journal of environmental management 2020, 263, 110367. [Google Scholar] [CrossRef]

- Huttenhuis, P.; Roeloffzen, A.; Versteeg, G. CO2 capture and re-use at a waste incinerator. Energy Procedia 2016, 86, 47–55. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, F.; Mei, Z.; Lv, L.; Chi, Y. Status and development of sludge incineration in China. Waste and Biomass Valorization 2021, 12, 3541–3574. [Google Scholar] [CrossRef]

- Yang, J.; Wang, S.; Li, Y.; Zhang, Y.; Xu, D. Novel design concept for a commercial-scale plant for supercritical water oxidation of industrial and sewage sludge. Journal of environmental management 2019, 233, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Ma, R.; Huang, X.; Sun, S.; Wang, H. Bio-fuels generation and the heat conversion mechanisms in different microwave pyrolysis modes of sludge. Applied energy 2020, 266, 114855. [Google Scholar] [CrossRef]

- Pietrelli, L.; Ferro, S.; Reverberi, A.P.; Vocciante, M. Removal and recovery of heavy metals from tannery sludge subjected to plasma pyro-gasification process. Journal of Cleaner Production 2020, 273, 123166. [Google Scholar] [CrossRef]

- Qian, L.; Wang, S.; Wang, S.; Zhao, S.; Zhang, B. Supercritical water gasification and partial oxidation of municipal sewage sludge: An experimental and thermodynamic study. International Journal of Hydrogen Energy 2021, 46, 89–99. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Wang, X.; Zhang, Q. Microwave-assisted pyrolysis of sewage sludge: A review. Fuel processing technology 2019, 187, 84–104. [Google Scholar] [CrossRef]

- Khamies, M.; Kamel, S.; Hassan, M.H.; Elnaggar, M.F. A Developed Frequency Control Strategy for Hybrid Two-Area Power System with Renewable Energy Sources Based on an Improved Social Network Search Algorithm. Mathematics 2022, 10, 1584. [Google Scholar] [CrossRef]

- Materazzi, M.; Foscolo, P.U. The role of waste and renewable gas to decarbonize the energy sector. In Substitute natural gas from waste; Elsevier, 2019; pp. 1–19.

- Raza, M.; Inayat, A.; Ahmed, A.; Jamil, F.; Ghenai, C.; Naqvi, S.R.; Shanableh, A.; Ayoub, M.; Waris, A.; Park, Y.K. Progress of the pyrolyzer reactors and advanced technologies for biomass pyrolysis processing. Sustainability 2021, 13, 11061. [Google Scholar] [CrossRef]

- Atsonios, K.; Nesiadis, A.; Detsios, N.; Koutita, K.; Nikolopoulos, N.; Grammelis, P. Review on dynamic process modeling of gasification based biorefineries and bio-based heat & power plants. Fuel Processing Technology 2020, 197, 106188. [Google Scholar]

- Krochmalny, K.; Niedzwiecki, L.; Pelińska-Olko, E.; Wnukowski, M.; Czajka, K.; Tkaczuk-Serafin, M.; Pawlak-Kruczek, H. Determination of the marker for automation of torrefaction and slow pyrolysis processes–A case study of spherical wood particles. Renewable Energy 2020, 161, 350–360. [Google Scholar] [CrossRef]

- De Leeuw, M.; Koelemeijer, R. Decarbonisation options for the Dutch waste incineration industry, 2022.

- Lu, C.; Zhang, H.; Zhang, Q.; Chu, C.y.; Tahir, N.; Ge, X.; Jing, Y.; Hu, J.; Li, Y.; Zhang, Y.; et al. An automated control system for pilot-scale biohydrogen production: design, operation and validation. International Journal of Hydrogen Energy 2020, 45, 3795–3806. [Google Scholar] [CrossRef]

- Kabugo, J.C.; Jämsä-Jounela, S.L.; Schiemann, R.; Binder, C. Industry 4.0 based process data analytics platform: A waste-to-energy plant case study. International journal of electrical power & energy systems 2020, 115, 105508. [Google Scholar]

- Lozano Avilés, A.B.; del Cerro Velázquez, F.; Llorens Pascual del Riquelme, M. Methodology for energy optimization in wastewater treatment plants. Phase I: Control of the best operating conditions. Sustainability 2019, 11, 3919. [Google Scholar] [CrossRef]

- Grobelak, A.; Czerwińska, K.; Murtaś, A. General considerations on sludge disposal, industrial and municipal sludge. In Industrial and municipal sludge; Elsevier, 2019; pp. 135–153.

- Montagnaro, F.; Tregambi, C.; Salatino, P.; Senneca, O.; Solimene, R. Modelling oxy-pyrolysis of sewage sludge in a rotary kiln reactor. Fuel 2018, 231, 468–478. [Google Scholar] [CrossRef]

- La Villetta, M.; Costa, M.; Cirillo, D.; Massarotti, N.; Vanoli, L. Performance analysis of a biomass powered micro-cogeneration system based on gasification and syngas conversion in a reciprocating engine. Energy conversion and management 2018, 175, 33–48. [Google Scholar] [CrossRef]

- Nnabuife, S.G.; Ugbeh-Johnson, J.; Okeke, N.E.; Ogbonnaya, C. Present and projected developments in hydrogen production: A technological review⁎. Carbon Capture Science & Technology 2022, 3, 100042. [Google Scholar]

- Buss, W.; Wurzer, C.; Manning, D.A.; Rohling, E.J.; Borevitz, J.; Mašek, O. Mineral-enriched biochar delivers enhanced nutrient recovery and carbon dioxide removal. Communications Earth & Environment 2022, 3, 67. [Google Scholar]

- He, X.; Lima, F.V. Development and implementation of advanced control strategies for power plant cycling with carbon capture. Computers & Chemical Engineering 2019, 121, 497–509. [Google Scholar]

- Ren, Z.J.; Pagilla, K. Pathways to Water Sector Decarbonization, Carbon Capture and Utilization; IWA Publishing, 2022.

- Poblete, I.B.S.; Araujo, O.d.Q.F.; de Medeiros, J.L. Sewage-Water treatment and Sewage-Sludge management with power production as bioenergy with carbon capture system: A review. Processes 2022, 10, 788. [Google Scholar] [CrossRef]

- Luo, F.; Lei, S.; Liao, W. Research on Controlling Dewatering Ratio Based on Fuzzy PID in Sludge Process.

- Wu, B.; Dai, X.; Chai, X. Critical review on dewatering of sewage sludge: Influential mechanism, conditioning technologies and implications to sludge re-utilizations. Water research 2020, 180, 115912. [Google Scholar] [CrossRef]

- Wang, S.; Wen, Y.; Shi, Z.; Zaini, I.N.; Jönsson, P.G.; Yang, W. Novel carbon-negative methane production via integrating anaerobic digestion and pyrolysis of organic fraction of municipal solid waste. Energy Conversion and Management 2022, 252, 115042. [Google Scholar] [CrossRef]

- Kılkış, Ş.; Krajačić, G.; Duić, N.; Rosen, M.A.; et al. Advancements in sustainable development of energy, water and environment systems, 2018.

- Dhoke, C.; Zaabout, A.; Cloete, S.; Amini, S. Review on reactor configurations for adsorption-based CO2 capture. Industrial & Engineering Chemistry Research 2021, 60, 3779–3798. [Google Scholar]

- Cormos, A.M.; Dragan, S.; Cormos, C.C. Techno-economic and environmental assessment of flexible operation for decarbonized super-critical power plants using reactive gas–liquid absorption. Applied Thermal Engineering 2021, 197, 117354. [Google Scholar] [CrossRef]

- Liang, H. Electrical and Thermal Load Matching of Thermoelectric Power Generation Systems. Journal of Electronic Materials 2022, 51, 3950–3957. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Li, K.; Du, W.; Lu, K.; Zhang, Y. Thermal interaction analysis of isolated hemicellulose and cellulose by kinetic parameters during biomass pyrolysis. Energy 2020, 195, 117010. [Google Scholar] [CrossRef]

- Cheng, F.; Luo, H.; Colosi, L.M. Slow pyrolysis as a platform for negative emissions technology: An integration of machine learning models, life cycle assessment, and economic analysis. Energy Conversion and Management 2020, 223, 113258. [Google Scholar] [CrossRef]

- Shahbeig, H.; Nosrati, M. Pyrolysis of municipal sewage sludge for bioenergy production: Thermo-kinetic studies, evolved gas analysis, and techno-socio-economic assessment. Renewable and Sustainable Energy Reviews 2020, 119, 109567. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Thermal energy storage in district heating and cooling systems: A review. Applied Energy 2019, 252, 113474. [Google Scholar] [CrossRef]

- Trabelsi, A.B.H.; Zaafouri, K.; Friaa, A.; Abidi, S.; Naoui, S.; Jamaaoui, F. Municipal sewage sludge energetic conversion as a tool for environmental sustainability: production of innovative biofuels and biochar. Environmental Science and Pollution Research 2021, 28, 9777–9791. [Google Scholar] [CrossRef]

- Xu, T.; Zheng, X.; Xu, J.; Wu, Y. Hydrogen-rich gas production from two-stage catalytic pyrolysis of pine sawdust with nano-NiO/Al2O3 catalyst. Catalysts 2022, 12, 256. [Google Scholar] [CrossRef]

- Hossain, M.K.; Strezov, V.; Chan, K.Y.; Ziolkowski, A.; Nelson, P.F. Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. Journal of environmental management 2011, 92, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Xin, C.; Addy, M.M.; Zhao, J.; Cheng, Y.; Ma, Y.; Liu, S.; Mu, D.; Liu, Y.; Chen, P.; Ruan, R. Waste-to-biofuel integrated system and its comprehensive techno-economic assessment in wastewater treatment plants. Bioresource Technology 2018, 250, 523–531. [Google Scholar] [CrossRef]

- Brown, R.C. The role of pyrolysis and gasification in a carbon negative economy. Processes 2021, 9, 882. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Sorniotti, A.; Karci, A.E.; Di Palo, R. Review of thermal management of catalytic converters to decrease engine emissions during cold start and warm up. Applied Thermal Engineering 2019, 147, 177–187. [Google Scholar] [CrossRef]

- Rezaeimozafar, M.; Monaghan, R.F.; Barrett, E.; Duffy, M. A review of behind-the-meter energy storage systems in smart grids. Renewable and Sustainable Energy Reviews 2022, 164, 112573. [Google Scholar] [CrossRef]

- Gopikumar, S.; Banu, J.R.; Robinson, Y.H.; Shanmuganathan, V.; Kadry, S.; Rho, S. Novel framework of GIS based automated monitoring process on environmental biodegradability and risk analysis using Internet of Things. Environmental Research 2021, 194, 110621. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Oh, J.I.; Lee, J.; Kwon, E.E. Valorization of sewage sludge via a pyrolytic platform using carbon dioxide as a reactive gas medium. Energy 2019, 179, 163–172. [Google Scholar] [CrossRef]

- Zimmer, T.; Rudi, A.; Glöser-Chahoud, S.; Schultmann, F. Techno-economic analysis of intermediate pyrolysis with solar drying: a chilean case study. Energies 2022, 15, 2272. [Google Scholar] [CrossRef]

- Ögren, Y.; Sepman, A.; Fooladgar, E.; Weiland, F.; Wiinikka, H. Development and evaluation of a vision driven sensor for estimating fuel feeding rates in combustion and gasification processes. Energy and AI 2024, 15, 100316. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Wnukowski, M.; Niedzwiecki, L.; Czerep, M.; Kowal, M.; Krochmalny, K.; Zgóra, J.; Ostrycharczyk, M.; Baranowski, M.; Tic, W.J.; et al. Torrefaction as a valorization method used prior to the gasification of sewage sludge. Energies 2019, 12, 175. [Google Scholar] [CrossRef]

- Pulka, J.; Manczarski, P.; Stępień, P.; Styczyńska, M.; Koziel, J.A.; Białowiec, A. Waste-to-carbon: is the torrefied sewage sludge with high ash content a better fuel or fertilizer? Materials 2020, 13, 954. [Google Scholar] [CrossRef]

- Zheng, A.; Li, L.; Tippayawong, N.; Huang, Z.; Zhao, K.; Wei, G.; Zhao, Z.; Li, H. Reducing emission of NOx and SOx precursors while enhancing char production from pyrolysis of sewage sludge by torrefaction pretreatment. Energy 2020, 192, 116620. [Google Scholar] [CrossRef]

- Ronda, A.; Gómez-Barea, A.; Haro, P.; de Almeida, V.; Salinero, J. Elements partitioning during thermal conversion of sewage sludge. Fuel Processing Technology 2019, 186, 156–166. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Stasiak, K.; Amiri, M.; Mikielewicz, D. Negative carbon dioxide gas power plant integrated with gasification of sewage sludge. Energy 2023, 262, 125496. [Google Scholar] [CrossRef]

- Di Fraia, S.; Massarotti, N.; Uddin, M.R.; Vanoli, L. Conversion of Sewage Sludge to combined heat and power: Modeling and optimization. Smart Energy 2022, 5, 100061. [Google Scholar] [CrossRef]

- Vargas-Salgado, C.; Montuori, L.; Alcázar-Ortega, M. Experimental analysis of a bubbling fluidized bed gasification plant fed by biomass: Design, implementation and validation of the control system. In Proceedings of the E3S Web of Conferences; EDP Sciences, 2021; Vol. 239, p. 00007. [Google Scholar]

- Costa, M.; Di Blasio, G.; Prati, M.; Costagliola, M.; Cirillo, D.; La Villetta, M.; Caputo, C.; Martoriello, G. Multi-objective optimization of a syngas powered reciprocating engine equipping a combined heat and power unit. Applied Energy 2020, 275, 115418. [Google Scholar] [CrossRef]

- Chataut, R.; Phoummalayvane, A.; Akl, R. Unleashing the power of IoT: A comprehensive review of IoT applications and future prospects in healthcare, agriculture, smart homes, smart cities, and industry 4.0. Sensors 2023, 23, 7194. [Google Scholar] [CrossRef] [PubMed]

- Kondratenko, Y.; Kozlov, O.; Gerasin, O.; Topalov, A.; Korobko, O. Automation of control processes in specialized pyrolysis complexes based on web SCADA systems. In Proceedings of the 2017 9th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS). IEEE, 2017, Vol. 1, pp. 107–112.

- Zhang, H.; Ju, S.; Jin, X.; Yuan, Y.; Wu, Y.; Nadda, A.K.; Pugazhendhi, A.; Cai, L.; Xia, C. A review of sensor applications towards precise control of pyrolysis of solid waste and biomasses. Renewable and Sustainable Energy Reviews 2022, 169, 112915. [Google Scholar] [CrossRef]

- Arakelyan, E.; Kosoy, A.; Mezin, S.; Pashchenko, F.F. Application of the basic principles of" Industry 4.0" in the intellectualization of automated control systems of modern thermal power plants. Procedia Computer Science 2021, 184, 865–870. [Google Scholar] [CrossRef]

- Vargas-Salgado, C.; Aguila-Leon, J.; Chiñas-Palacios, C.; Hurtado-Perez, E. Low-cost web-based Supervisory Control and Data Acquisition system for a microgrid testbed: A case study in design and implementation for academic and research applications. Heliyon 2019, 5. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Cristoforetti, M.; Cimatti, A. Towards Automatic Digitalization of Railway Engineering Schematics. In Proceedings of the AIxIA 2023 – Advances in Artificial Intelligence; Springer Nature: Rome, Italy, 2023; Vol. 22, pp. 453–466. [Google Scholar] [CrossRef]

- Safarian, S.; Saryazdi, S.M.E.; Unnthorsson, R.; Richter, C. Artificial neural network integrated with thermodynamic equilibrium modeling of downdraft biomass gasification-power production plant. Energy 2020, 213, 118800. [Google Scholar] [CrossRef]

- Saini, V.K.; Kumar, R.; Al-Sumaiti, A.S.; Sujil, A.; Heydarian-Forushani, E. Learning based short term wind speed forecasting models for smart grid applications: An extensive review and case study. Electric Power Systems Research 2023, 222, 109502. [Google Scholar] [CrossRef]

- Corso, M.P.; Stefenon, S.F.; Singh, G.; Matsuo, M.V.; Perez, F.L.; Leithardt, V.R.Q. Evaluation of visible contamination on power grid insulators using convolutional neural networks. Electrical Engineering 2023, 105, 3881–3894. [Google Scholar] [CrossRef]

- Wilbert, H.J.; Hoppe, A.F.; Sartori, A.; Stefenon, S.F.; Silva, L.A. Recency, Frequency, Monetary Value, Clustering, and Internal and External Indices for Customer Segmentation from Retail Data. Algorithms 2023, 16, 396. [Google Scholar] [CrossRef]

- Yamasaki, M.; Freire, R.Z.; Seman, L.O.; Stefenon, S.F.; Mariani, V.C.; dos Santos Coelho, L. Optimized hybrid ensemble learning approaches applied to very short-term load forecasting. International Journal of Electrical Power & Energy Systems 2024, 155, 109579. [Google Scholar] [CrossRef]

- Westarb, G.; Stefenon, S.F.; Hoppe, A.F.; Sartori, A.; Klaar, A.C.R.; Leithardt, V.R.Q. Complex graph neural networks for medication interaction verification. Journal of Intelligent & Fuzzy Systems 2023, 44, 10383–10395. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Singh, G.; Souza, B.J.; Freire, R.Z.; Yow, K.C. Optimized hybrid YOLOu-Quasi-ProtoPNet for insulators classification. IET Generation, Transmission & Distribution 2023, 17, 3501–3511. [Google Scholar] [CrossRef]

- Glasenapp, L.A.; Hoppe, A.F.; Wisintainer, M.A.; Sartori, A.; Stefenon, S.F. OCR applied for identification of vehicles with irregular documentation using IoT. Electronics 2023, 12, 1083. [Google Scholar] [CrossRef]

- Surek, G.A.S.; Seman, L.O.; Stefenon, S.F.; Mariani, V.C.; Coelho, L.S. Video-based human activity recognition using deep learning approaches. Sensors 2023, 23, 6384. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Ribeiro, M.H.D.M.; Nied, A.; Mariani, V.C.; Coelho, L.S.; Leithardt, V.R.Q.; Silva, L.A.; Seman, L.O. Hybrid wavelet stacking ensemble model for insulators contamination forecasting. IEEE Access 2021, 9, 66387–66397. [Google Scholar] [CrossRef]

- Olafasakin, O.; Chang, Y.; Passalacqua, A.; Subramaniam, S.; Brown, R.C.; Mba Wright, M. Machine learning reduced order model for cost and emission assessment of a pyrolysis system. Energy & Fuels 2021, 35, 9950–9960. [Google Scholar]

- Branco, N.W.; Cavalca, M.S.M.; Stefenon, S.F.; Leithardt, V.R.Q. Wavelet LSTM for fault forecasting in electrical power grids. Sensors 2022, 22, 8323. [Google Scholar] [CrossRef] [PubMed]

- García-Nieto, P.J.; García-Gonzalo, E.; Paredes-Sánchez, B.M.; Paredes-Sánchez, J.P. Modelling hydrogen production from biomass pyrolysis for energy systems using machine learning techniques. Environmental Science and Pollution Research 2023, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Tai, X.Y.; Ocone, R.; Christie, S.D.; Xuan, J. Multi-objective optimisation with hybrid machine learning strategy for complex catalytic processes. Energy and AI 2022, 7, 100134. [Google Scholar] [CrossRef]

- Culaba, A.B.; Mayol, A.P.; San Juan, J.L.G.; Vinoya, C.L.; Concepcion II, R.S.; Bandala, A.A.; Vicerra, R.R.P.; Ubando, A.T.; Chen, W.H.; Chang, J.S. Smart sustainable biorefineries for lignocellulosic biomass. Bioresource technology 2022, 344, 126215. [Google Scholar] [CrossRef] [PubMed]

- Klaar, A.C.R.; Stefenon, S.F.; Seman, L.O.; Mariani, V.C.; Coelho, L.S. Optimized EWT-Seq2Seq-LSTM with attention mechanism to insulators fault prediction. Sensors 2023, 23, 3202. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Mariani, V.C.; Coelho, L.d.S. Aggregating Prophet and Seasonal Trend Decomposition for Time Series Forecasting of Italian Electricity Spot Prices. Energies 2023, 16, 1371. [Google Scholar] [CrossRef]

- Klaar, A.C.R.; Stefenon, S.F.; Seman, L.O.; Mariani, V.C.; Coelho, L.S. Structure optimization of ensemble learning methods and seasonal decomposition approaches to energy price forecasting in Latin America: A case study about Mexico. Energies 2023, 16, 3184. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Aquino, L.S.; dos Santos Coelho, L. Wavelet-Seq2Seq-LSTM with attention for time series forecasting of level of dams in hydroelectric power plants. Energy 2023, 274, 127350. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Sopelsa Neto, N.F.; Meyer, L.H.; Mariani, V.C.; Coelho, L.d.S. Group method of data handling using Christiano-Fitzgerald random walk filter for insulator fault prediction. Sensors 2023, 23, 6118. [Google Scholar] [CrossRef]

- Seman, L.O.; Stefenon, S.F.; Mariani, V.C.; Coelho, L.S. Ensemble learning methods using the Hodrick–Prescott filter for fault forecasting in insulators of the electrical power grids. International Journal of Electrical Power & Energy Systems 2023, 152, 109269. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Ullah, Z.; Taqvi, S.A.A.; Khan, M.N.A.; Farooq, W.; Mehran, M.T.; Juchelková, D.; Štěpanec, L.; et al. Applications of machine learning in thermochemical conversion of biomass-A review. Fuel 2023, 332, 126055. [Google Scholar]

- Starke, L.; Hoppe, A.F.; Sartori, A.; Stefenon, S.F.; Santana, J.F.D.P.; Leithardt, V.R.Q. Interference recommendation for the pump sizing process in progressive cavity pumps using graph neural networks. Scientific Reports 2023, 13, 16884. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic process automation and artificial intelligence in industry 4.0–a literature review. Procedia Computer Science 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Himeur, Y.; Elnour, M.; Fadli, F.; Meskin, N.; Petri, I.; Rezgui, Y.; Bensaali, F.; Amira, A. AI-big data analytics for building automation and management systems: a survey, actual challenges and future perspectives. Artificial Intelligence Review 2023, 56, 4929–5021. [Google Scholar] [CrossRef] [PubMed]

- Mukhopadhyay, S.C.; Tyagi, S.K.S.; Suryadevara, N.K.; Piuri, V.; Scotti, F.; Zeadally, S. Artificial Intelligence-Based Sensors for Next Generation IoT Applications: A Review. IEEE Sensors Journal 2021, 21, 24920–24932. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Kasburg, C.; Freire, R.Z.; Silva Ferreira, F.C.; Bertol, D.W.; Nied, A. Photovoltaic power forecasting using wavelet Neuro-Fuzzy for active solar trackers. Journal of Intelligent & Fuzzy Systems 2021, 40, 1083–1096. [Google Scholar] [CrossRef]

- Jarrett, A.; Choo, K.K.R. The impact of automation and artificial intelligence on digital forensics. Wiley Interdisciplinary Reviews: Forensic Science 2021, 3, e1418. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).