Introduction

In different countries of the Mediterranean region, solar drying is still considered as a practical method that can be used for the preservation of products such as fruits, vegetables and grains. Even though, the direct effect on the physical and chemical properties, the application of this process for aromatic and medicinal herbs is progressively attracting the attention of researchers and scientists. Nurhaslina et al. (2022) presented an extensive review related to the effect of drying process on essential oil yield and bioactive compounds of several medicinal herbs. The following were particularly reviewed: antioxidant, aromatic, antimicrobial compounds and color. The authors described the most important drying methods, such as sun drying, shade drying and convective drying, keeping the objective of making the final product as a marketable product. They pointed that temperature and drying time are two important parameters that play essential role on the quality of the final product. They presented the antibacterial activity of several herbal extract bioactive compounds, such as Citronella and Curcuma. Moreover, the authors showed that for leaves freeze drying is the most favorable drying method, with a less degree solar drying is also favorable, however sun drying is the less favorable drying method. The authors focused in their review on giving general information without going into details with the technical side, such as the design of the dryer. Pise et al. (2024) presented important information about aromatic plants and the classification of herbs, spices and medicinal plants, which was based on its usage, chemical composition or the time life of the product. The authors mentioned the importance of having controlled drying conditions, in particular the temperature of the air, and its effect on the quality of the final product. Ndukwu et al. (2021) discussed the solar drying experience in Africa including Mediterranean countries such as Algeria, Egypt, Tunisia, and Morocco. In this review, the authors focused on the technical side of the process with the description of several solar dryers that has been used. The authors made a classification of the published research papers based on the country and the tested plant. Indeed, in Algeria researchers investigated recently drying of henna, spearmint leaves, colocynth gourd and bay leave. In Morocco, they focused on eucalyptus, rosemary leave, some kind of flowers, citrus leave and other plants. The authors of this review discussed via the published studies the impact of solar drying on essential oils of the plants, as well as the physical appearance and microbial activities. It was clearly stated that drying conditions (i.e. temperature of the heated air, its velocity and humidity) have a direct effect on the quality of the final product. Finally, the authors and based on the published papers, gave an idea about the optimum drying conditions that were used for the different tested plants.

Henna is one of the valuable traditional plants that is regularly consumed in Algeria. Labed et al. (2016) stated that the average production of henna in Algeria in the last decade was around 3000 tons per year. As described by Bennaceur et al. (2021), this plant, and due to its richness with natural components, is widely used in cosmetic and pharmaceutical fields. It is also used to prevent from several skin and eye diseases. The authors stated that the most important component that we can find in henna leave extracts is: Lawsone. Hosseiny et al. (2023) found that the harvesting date and the climate conditions is this period, as well as the genotype are two important factors that influence the concentration of the bioactive compounds and minerals in henna, pointing in particular: lawsone, flavonoid and phenol. It was concluded in this research that the best results were obtained when henna harvesting was performed in periods with low humidity and low rainfalls, around the month of July. In addition to the benefits of henna mentioned by Bennaceur et al. (2021), Semwal et al. (2014) declared that henna is used against fungal pathogens and even in digestive disorder treatments. In this review, the authors discussed the phytochemistry and the different phenolic compounds in particular lawsone, which has been used in several pharmacological industries.

Bennaceur et al. (2021) explored the effect of drying on the lawsone component. It was found that adding ultrasound to the traditional convective drying helped to reduce drying time and consequently the increase of the extraction yield of lawsone. Labed et al. (2016, 2015) studied solar drying of henna using a forced convective air dryer. The study focused on the design and the behavior of the solar dryer by presenting the variation of the drying kinetics and drying curves with the operating conditions (i.e. temperature, humidity and velocity of the heated air), which vary with the weather conditions. Unfortunately, there was no evaluation of the final quality of the product, which is an important part that should be taken into consideration. Hassanain (2010) tested three different solar drying methods: unglazed transpired dryer, direct open sun drying and in a shaded house. Similarly, to the previous studies, the author focused on the effect of the weather conditions of three medicinal plants including henna. It was found that the unglazed transpired dryer gave better results as more oil was extracted from these plants. Boubeghal and Chaker (2018) investigated the drying process of henna in the south region of Algeria. The used dryer was an indirect natural convection dryer, usually the drying time for this kind of dryers is longer than the ones using forced convection. For this case, between 20 and 22 hours were necessary to dry the product. In this study and similarly to the other presented publications, the authors focused on the design of the dryer and the effect of the weather conditions on the variation of the moisture of henna without studying the effect of this process on the physio-chemical properties of the product and its final quality.

The aim of the research is to study the behavior of henna leaves during drying forced convection drying. The evaluation of the performances of this process was determined through the variation of the moisture content of the henna leaves, as well as the efficiency of the solar collector. The second axe of this study focused on the quality of the final product in terms of assessing the effect of open solar drying and the convective solar drying on bioactivities (total polyphenol content, total flavonoid content, antioxidant activity).

Material and methods

Convective solar drier

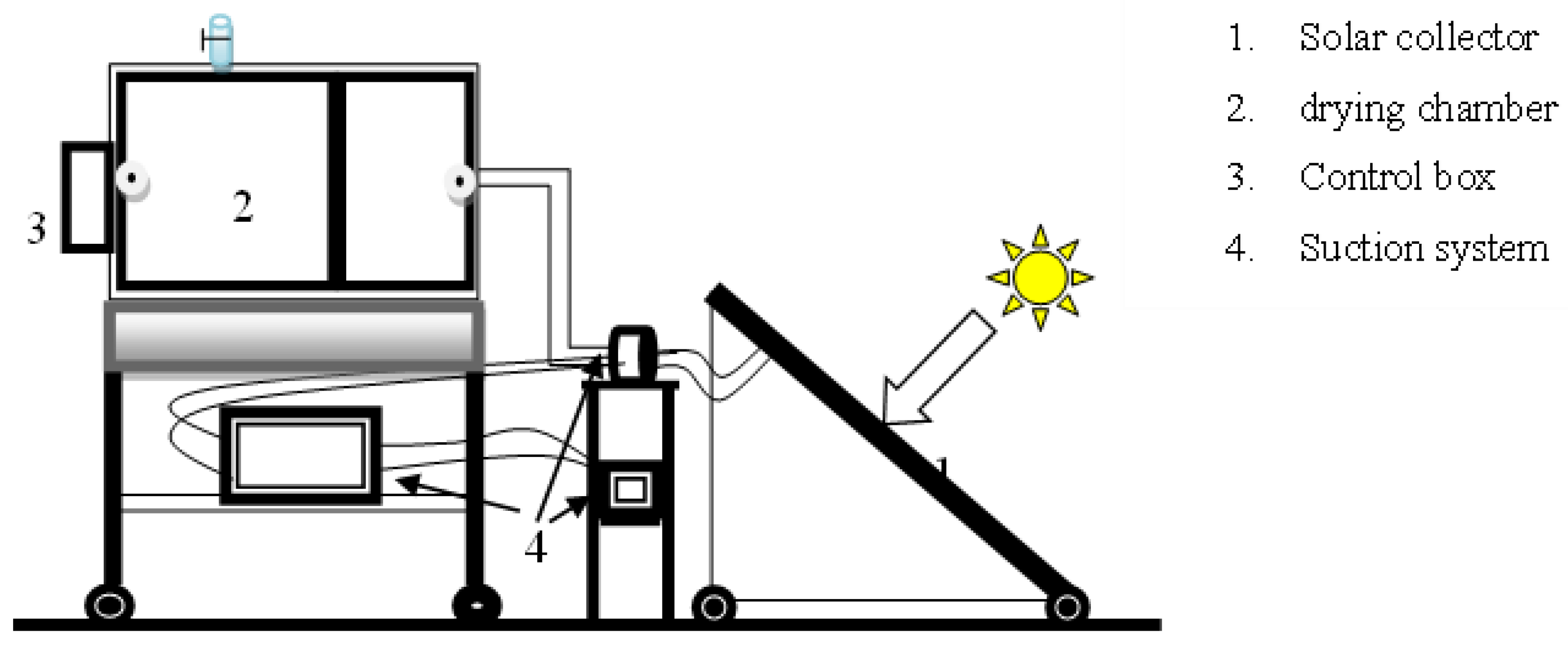

A solar drier that uses forced convection was utilized for this study. The main components of this dryer are a flat air collector and a drying chamber. The dryer was built with the objective of using inexpensive and available local materials. Indeed, the frame of the flat collector and the drying chamber was wood. The dimensions of the solar collector are: 1.24m × 0.9m. The collector is installed with an inclination of 31° from the horizontal. A sheet of iron is used as an absorber and polystyrene is used as insulator. The external dimensions of the drying chamber are: 0.94m × 0.63m × 0.61m, however the internal dimensions are: 0.48m × 0.52m × 0.47m. Similarly, to the solar collector, the insulation is insured using polystyrene. The drying system contains a thermostat that adjusts the temperature of the heated air using an auxiliary source of heat in case the temperature of the air coming from the solar collector does not reach the required temperature. Moreover, the velocity of the air is measured using an anemometer and controlled using a suction system and velocity variator.

Figure 1 shows a schema of the solar dryer used in this study.

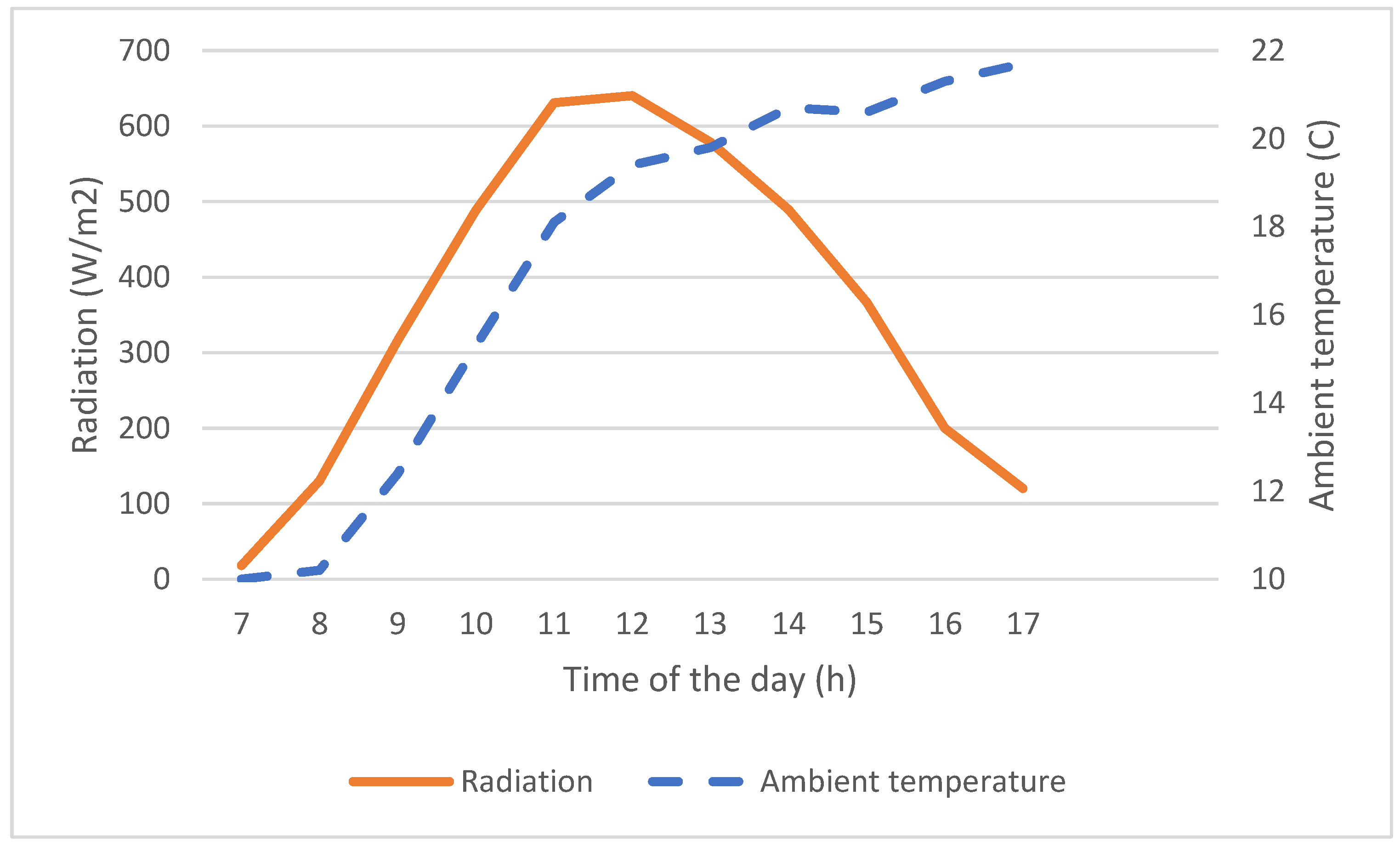

The experiment is performed in the month of November. Solar drying is directly affected by the weather conditions, in particular the ambient temperature of the air and the radiation.

Figure 2 shows the variation of these two parameters in the region of Béchar, where the experiment is executed.

Indeed,

Figure 2 shows that the solar radiation starts increasing from 7 a.m. and reaches the maximum between 11 a.m. and 1 p.m. then it decreases until reaching low radiations, about 100 W/m

2, at 5 p.m. As mentioned by (Bennamoun and Li, 2018), solar radiation has a direct effect on the solar collector and its outlet temperature, this effect will be discussed later in this study. Moreover,

Figure 2 shows the variation of the ambient temperature and its continuous increase from 7 a.m. to 5 p.m. this increase is less important after 1 p.m. The ambient temperature changed from 10°C to 22°C.

Preparation of the samples

Lawsonia inermis leaves were collected in November 2021 from cultivated farm from area of Béchar, located in South-West of Algerian desert (Latitude: 31°37′00″ North Longitude: 2°13′00″ West).

The process began by cleaning the leaves from impurities. After that, the leaves have been spread in a thin layer and exposed to two different types of drying open solar drying (with no control of the weather conditions, in particular the temperature) and convective solar drying under constant temperature of 50°C and air velocity of about 3.4 m/s. After the drying process, the samples were delivered to Mentouri University, Constantine to begin the study of the bioactive properties and its extraction.

The initial moisture of the leaves was determined using the standard gravimetric method at 105 °C for 24 h, the measurements were taken until there was no changes in the mass of the samples. Each measurement was performed in triplicate (Bennamoun et al., 2020).

Determination of the bioactivity

Total Phenol Content (TPC)

The total phenol content of the extracts was assessed according to Muller et al. (2010) method, using a spectrophotometer and Folin Ciocalteu reagent. First, 20 µl of the samples were added to 100 µl of Folin Ciocalteu reagent diluted to (1:10) and 75 µl of sodium carbonate (Na2CO3) (7.5%). The resulting mixtures were incubated in dark condition at room temperature for 2h before the absorption was measured at 765 nm.

To calculate sample concentration, the gallic acid (y = 0.0034x + 0.22, R2 =0.9624) calibration curve was used as the standard. The values are expressed in grams of gallic acid equivalent /100 g extract.

Total Flavonoid Content (TFC)

The estimation of total flavonoid content (TFC) is based on the formation of a complex between and flavonoids extract (Topçu et al., 2007). A volume of 50 μL of each diluted extract was added to 130 μL of methanol, 10 μL of potassium acetate, and 10 μL of aluminum nitrate. The reaction mixture was incubated for 40 min in the dark at room temperature. Before the absorbance of the reaction mixture was read at 415 nm. Quercetin is used as a calibration curve (y= 0.0026x + 0.1824, R2= 0.9738). Flavonoid content was expressed as μg of Quercetin equivalent (QE)/mg of extract.

Antioxidant activities

The extracts were assessed for their antioxidant activity by using three different methodologies which are: Free radical scavenging (DPPH), Radical cation trapping (ABTS) and reducing power (FRAP).

DPPH radical scavenging activity

One of the most popular techniques to evaluate the antioxidant capacity is the method employing 2,2’-diphenyl-1-picrylhydrazyl DPPH. The free radical scavenging activity was evaluated spectrophotometrically using the method described by Bendjabeur et al. (2018) with slight modification. Briefly, 40 µl of sample solution was mixed with 160 µl of DPPH solution. The reaction mixture was incubated for 30 min in the dark at room temperature. The absorbance was measured at 517 nm. Trolox and ascorbic acid were utilized as standards. The radical scavenging activity was calculated using as follows:

The results are expressed as IC50 value (µg/ml).

ABTS radical scavenging assay

The ABTS scavenging activity was measured using the method outlined in the protocol described by Re et al. 1999 with slight modifications. Different extract concentrations were mixed with ABTS solution: mix 160 µl (ABTS+) with 40 µl (extract), incubating 10 min in the dark, and measure the absorbance at 734 nm. The results are presented with different IC50 concentrations. The radical scavenging activity was calculated using Equation (2)

Ferric reducing ability assay

Reducing power activity is measured using the Oyaizu (1986) explained method, with slight modification. Substances with the ability to undergo reduction react with potassium ferricyanide (Fe3+) to create potassium ferrocyanide (Fe2+). This compound then reacts with ferric chloride, ultimately forming a cyan-blue ferrous complex with maximum absorption at 700 nm which is measured using microplate spectrophotometer, and results are expressed by A0.50, which corresponds to the concentration producing 0.50 absorbance. The absorbance was spectrophotometrically measured at 700nm. Butylatedhydroxytoluene (BHT) was used as a positive reference compound. The results were given as A0.50, which corresponds to the concentration producing 0.50 absorbance. The same Equation (2) was also used for the calculation.

Statistical analysis

Results are reported as mean value ± SD of three measurements (p < 0.05); the IC50 and A0.50 values were calculated by linear regression analysis.

Results and discussion

As it was confirmed in the introduction, most of the published studies dealing with solar drying of herbs and medicinal plans do not take in consideration the quality of the final product, which is crucial to determine the appropriate drying conditions. Accordingly, two main axes are presented in this study: results related to the solar dryer and its design and then results related to the quality of the final product in terms of the antioxidant properties of the final product.

Solar drying results

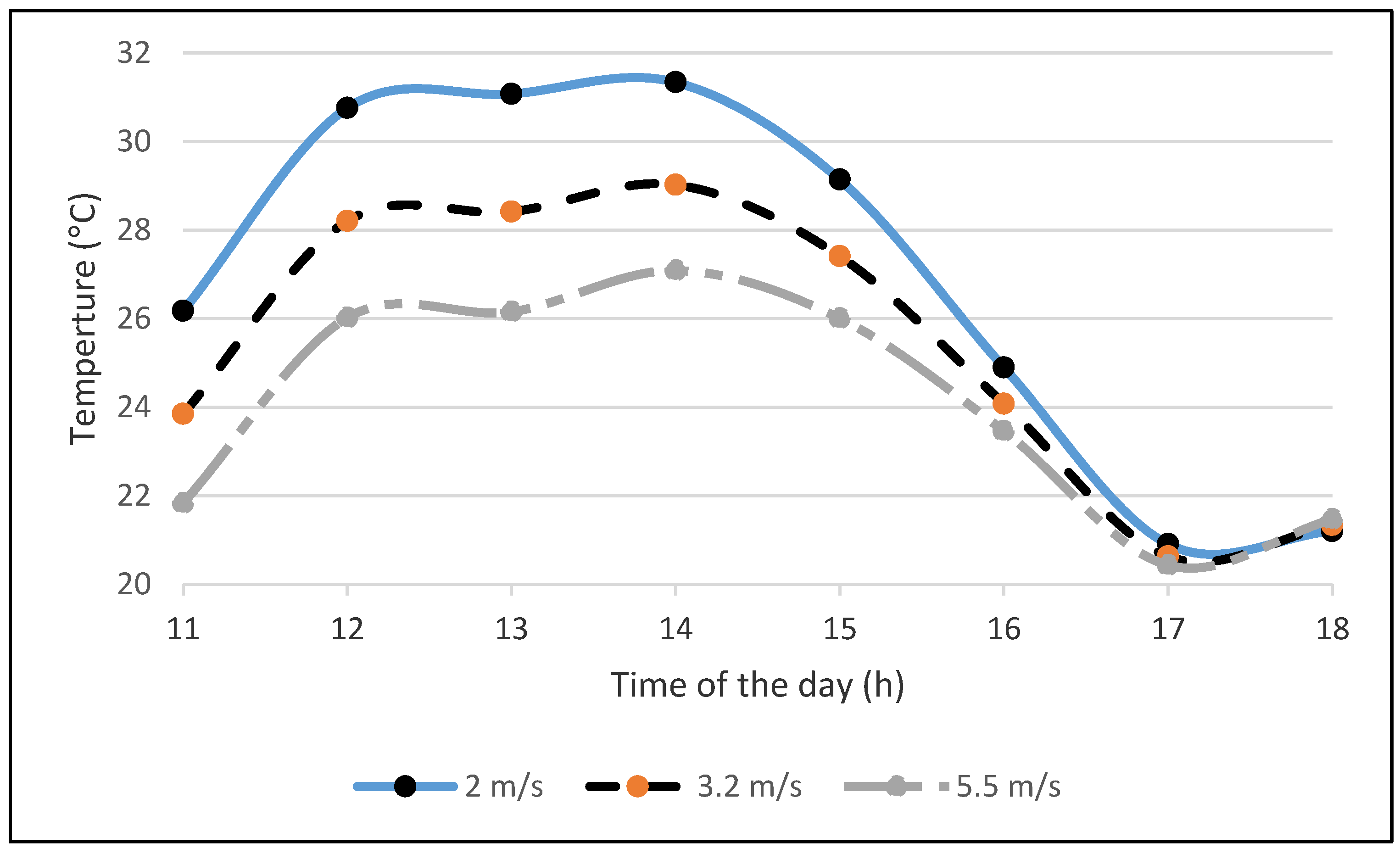

Figure 3 represents the effect of the air velocity on the outlet temperature of the solar collector. The general shape of the three curves of the figure is quite similar to the radiation presented in

Figure 2, as the temperature of the collector increases with the increase of the radiation and decreases with its decrease. This allows saying that radiation could be the most important parameter that has influence on the temperature of the collector. It is important to note that the maximum values of the exit temperature of the solar collector was obtained between 12 p.m. and 14 p.m., compared to the maximum radiations shown in

Figure 2 (between 11 a.m. and 1 p.m.), it can be deduced that there is a reaction time of 1 hour. Moreover, it was found that increasing the velocity of the air led to the decrease of the exit temperature of the solar collector, which means that the air velocity plays a role of dissipation of the thermal energy (temperature of the collector). These results are comparable with simulation and modeling results obtained by Bennamoun and Belhamri (2006), where they find the same effect of the air velocity on the outlet temperature of a solar collector. The authors (Bennamoun and Belhamri, 2006) have also find that there is a response time of about 1 hour between, as similar to our experimental study, the maximum value of the radiation was obtained around 12 p.m. and, however the maximum value of the outlet temperature was reached around 1 p.m. Accordingly, increasing the residence time of the ambient air using fins (Kharrafi et al., 2023). Bennamoun and Belhamri (2003) presented a detailed simulation and mathematical modeling of such convective solar drying system. The mathematical modeling was performed based on heat and mass transfer applied for each component of the drying system which are mainly: the solar collector and the drying chamber. The effect of the surface of the solar collector was also studied. The results confirm the effect of the radiation on the outlet temperature of the collector, as mentioned previously. Bennamoun et Belhamri (2003) found that increasing the surface leads to the increase of the outlet temperature. It is important to note that in this simulation, the study started at 5 a.m. and that the heat used from this time to 8 a.m. was used to heat-up the collector. Indeed, it was faster to heat-up a surface of 1 m

2 than 4 m

2, which means that in this lap of time the outlet temperature increased with the surface decrease then the tendence changes and the outlet temperature increases with the increase of the collector surface.

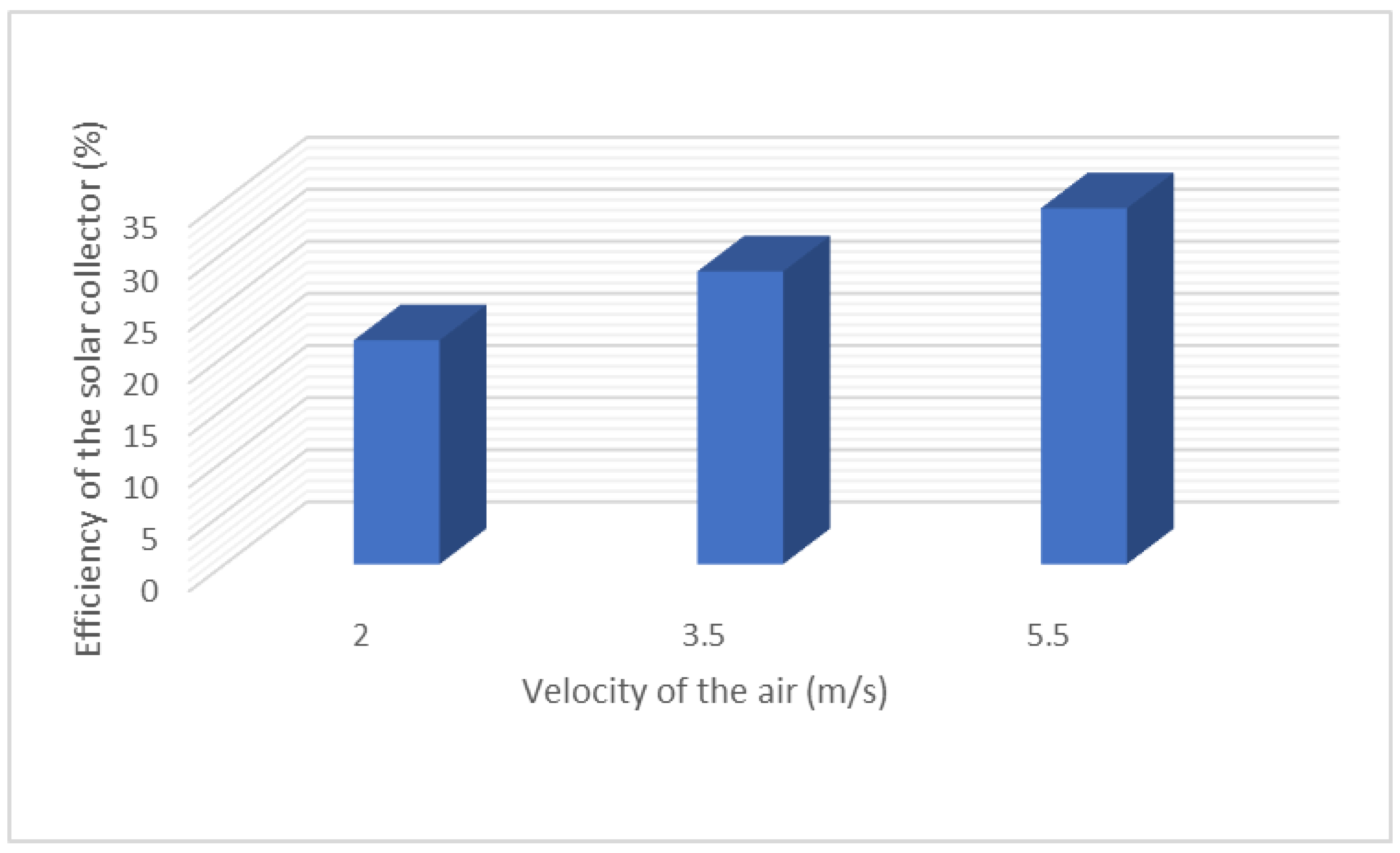

Figure 3 shows the variation of the average solar collector thermal efficiency with the velocity of the air entering the solar collector controlled using the suction system and velocity variator. We refer the reader to the study published by Amer et al. (2010). The instant thermal efficiency of the solar collector is also directly affected by the solar radiation with an increase with its increase and vis-versa.

Figure 3 shows that even increasing the air velocity leads to the decrease of the outlet temperature, the average thermal efficiency of the solar collector increases with the air velocity increase, as it is function of the flow rate of the air and the solar radiation. This observation is in agreement with the experimental results obtained by Tarminzi et al. (2021).

Figure 3.

Effect of the air velocity on the thermal efficiency of the solar collector.

Figure 3.

Effect of the air velocity on the thermal efficiency of the solar collector.

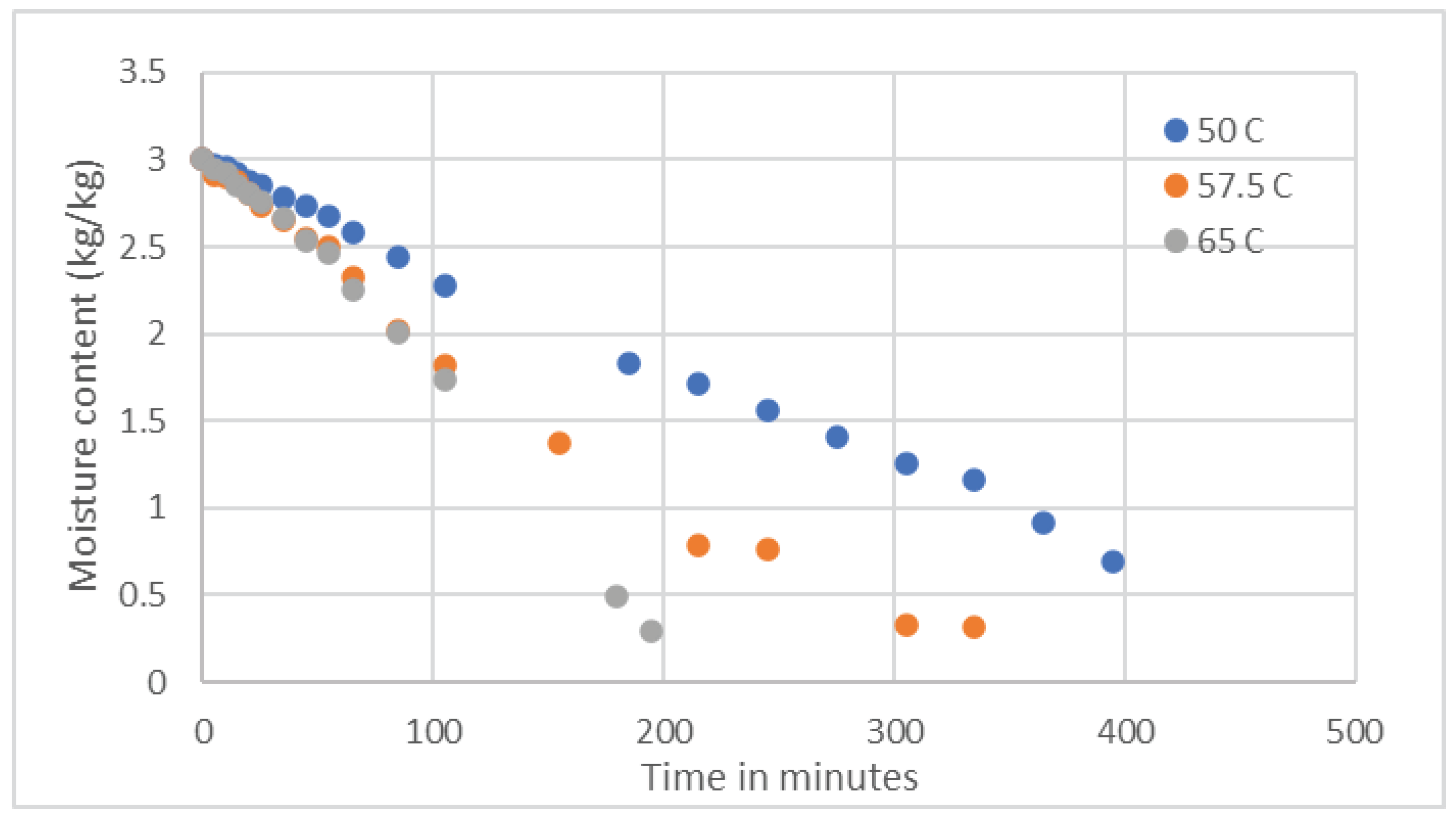

Figure 4 shows the variation of the moisture content with time and the effect of the drying air temperature for henna leaves. The curves of this figure show that the moisture content of the leaves decreases with time until reaching the equilibrium moisture content. The drying time varies from 200 minutes to 400 minutes depending on the applied temperature. It is important to note that and as shown in

Figure 3, the maximum outlet temperature from the solar collector, entering the drying chamber, did not reach the required drying temperature, which was 50 °C, 57.5 °C or 65 °C. This situation means that the auxiliary source of heat was working during the whole process, giving a similar situation of drying at constant drying temperature.

Figure 4 shows the important of the temperature parameter and its important influence of the drying time. Similar modeling and simulation results were obtained by Bennamoun et al. (2003 and 2006), as it was found that increasing the drying temperature allows reducing drying time. Furthermore, drying without an auxiliary source of energy or controlled temperature may show a completely different tendency of the drying curves with no regularities in the curve. As an example of this behavior, the study published by Babar et al. (2020), which was applied for agricultural products. Moreover, it was found in this study that the acquired energy or heat coming from the solar collector will serve in decreasing the moisture content of the product, but also in increasing its temperature until reaching the temperature of the drying air at the end of the process. Similar results were also obtained by Bennamoun and Belhamri (2003) at the completion of their modeling and simulation work applied for agriculture product.

Quality of the final product

Total bioactive content (TPC and TFC)

In the present study, the yield of extraction, TPC and TFC were influenced by the method of drying of

Lawsonia inermis samples (

Table 1). The yield of

Lawsonia inermis ethanolic extracts showed that the highest yield was obtained by the CSD sample.

The highest amounts of TPC (867.82 ± 6.39 μg GAE/mg E) and TFC (407.47 ± 33.53 μg QE/mg E) were recorded with CSD. Whereas the lowest amounts were found in FL sample.

Phenolic compounds are generally polar and ethanol solvent appears to play a significant role in their extraction. The solvent is available to penetrate the plant matrix, allowing bioactive compounds to dissolve and, in turn, increasing the recovery yield (Naseem et al., 2022).

Furthermore, ethanol was used as a solvent because it has the advantage of being a non-polluting, cheaper and non-toxic polar solvent (polarity of 5.2) compared to other solvents such as methanol (Jokić et al., 2010). Also, it is known for its greater efficiency in extracting maximum quantities of bioactive components (Bourgou et al., 2016).

Previous investigations on Tunisian L. inermis revealed that the butanolic fraction of leaves has strong antioxidant activities, and these activities were attributed to phenolic glycosides including 1,2,4 trihydroxynaphthalene-1-O-_-d-glucopyranoside (Hsouna et al., 2011).

Phenolic and flavonoids are bioactive compounds that shown considerable antioxidant and protective characteristics (Naseem et al., 2020). In the current study, the phenolic levels of Lawsonia inermis extracts ranged from 429.77 ± 22.76 to 867.82 ± 6.39 μg GAE/mg E. Such results were higher than those obtained by Elansary et al., 2020, who studied methanolic exctracts of Lawsonia inermis from natural populations growing in Northern of Saudi Arabia and found phenolic content of 81± 13.2 GAE/g E.

Regarding the flavonoid contents, our findings were higher than the Tunisian (20.5 ± 1.4 mg QE / g MS) (Enneb et al., 2015).

Among the drying methods the convective solar drying allows the preservation or even the increase of phenolic and flavonoids compounds.

The drying operation conditions applied shows that high temperatures 55°C are conducive to rapid heating, which inactivates oxidative enzymes and contributes to better preservation of polyphenols and flavonoids (Casto et al., 2023). On the other hand, the maximum TPC was obtained with mid-range temperatures and air velocities.

Antioxidants activities

Antioxidant activity cannot be unequivocally determined with only one method, as plant raw materials have complex chemical composition, and the components may interact with each other Wojdylo et al. (2020). For these reasons, the antioxidant capacity of fresh and dried

Lawsonia inermis was determined using three assays based on different mechanisms. Scavenging activity, ABTS radical action, and ferric reducing capacity. The findings from these tests are shown in

Table 2. The antioxidant activity of different extracts was evaluated using the A

0.5 and IC

50 indices. The results showing that all sample extracts displayed potent antioxidant activity with regards to all tested methods.

Table 2 shows significant effects of different drying on antioxidant activities on dried extracts of

Lawsonia inermis. For DPPH and ABTS radical scavenging activities, OSD had the highest to trap DPPH with IC

50 value (35.86±0.42 μg/ml). Whereas CSD exerted the most potent scavenging activity for ABTS with IC

50 values of 9.54±0.51 μg/ml. The strong antiradical potential of OSD and CSD could be linked to their TPC an TFC.

Our results were coherent with those of literature that indicated different ranges of DPPH, ABTS radicals scavenging effects. In DPPH scavenging activity, Ling et al. (2013) indicated IC50 value 1.26±5.55 mg/ml of ethanolic extract from Malaysian plant.

Again, the strongest activity showed by ABTS method was observed in CSD sample (9.54±0.51 µg/ml) but lower activity was observed in FL. the study by Al-Snafi (2019) on the ethanolic extract of Lawsonia inermis Linn showed a very low IC50 of 6.9±0.1 mg/l compared to our results.

In the other hand, the antioxidant capacity determined by FRAP assay increased in OSD and CSD depending on the drying method.

Interestingly, our results showed that antioxidants in Lawsonia inermis extracts were well preserved during convective solar drying at 50 °C and Open solar drying, thus indicating that mild heat treatment processes were promising drying methods to obtain antioxidants from Lawsonia inermis plant.

As reported in the literature (Haminiuk et al., 2012; Oancea, 2021), phenolics are the major contributors to the antioxidant potential of plants. A strong correlation between TPC and antioxidant capacities was reported (Sirichai et al., 2022), concurring with our results and indicating that TPC and antioxidant activities of open solar drying and convective solar drying followed the same trend. In various scientific findings, milder heat conditions during processing have demonstrated mitigative effects on the structural degradation of bioactive components. Interestingly, our results showed that antioxidants in henna plant were well preserved during hot-air drying at 50 °C, thus indicating that mild heat treatment processes were promising drying methods to obtain antioxidants from henna plant.

Conclusions

Herbal medicine is a true legacy of human knowledge and use. In recent years, their importance in the field of public health has expanded dramatically due to the therapies they provide.

The two primary causes of this growing interest are the desire for a better pharmaceutical with a gentler therapy that has no side effects and the fact that medicinal plants are a limitless source of bioactive natural chemicals and molecules.

Our research aims to optimize the effects of various drying techniques, such as open solar drying, and convective solar drying, in relation to fresh plants.

Solar drying technology offers an alternative that can process the plants, vegetables and fruits in clean, hygienic, and sanitary conditions to national and international standard.

Convective drying was applied to obtain dehydrated henna. The obtained results in this study indicates that the use of convective solar drying average temperature of 50°C and air velocities and a thinner thickness are related to low drying times and are favourable conditions to avoid higher antioxidant capacity determined by the DPPH, ABTS and FRAP methods.

CSD is one of the drying techniques that preserves or even improves antioxidant activity extracts from most studied species, as indicated by a decrease in IC50.

When compared to fresh extract, the spectrophotometric analysis of polyphenols and flavonoids showed the abundance of henna in various drying modes.

Reduced IC50 values indicate that even higher antioxidant activity tested extracts can be preserved by solar drying and convective solar drying. We may infer from the various outcomes that the processes solar drying appear to be the most preserving of the phenolic components and have the highest antioxidant activity of all the extracts that were studied.

Author Contributions

Conceptualization, Le.B., S.B. and Ly.B.; methodology, Le.B., S.D., S.B. and Ly.B.; validation, Le.B., S.D., S.B., M.M. R.B. and Ly.B.; formal analysis, S.B., M.M., R.B.; investigation, Le.B., S.B., M.M., R.B.; resources, Le.B., S.D., S.B., A.A.K., T.N.; data curation, Le.B., S.B, M.M. and R.B.; writing—original draft preparation, Le.B. and Ly.B.; writing—review and editing, Le.B., S.D.,A.A.K. and Ly.B.; visualization, Le.B., S.D, and Ly.B.; supervision, S.D. and T.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

the authors declare that there is no conflict of interest.

References

- Al-Snafi, A. A review on Lawsonia inermis: a potential medicinal plant. Int. J. Curr. Pharm. Res. 2019, 11, 1–13. [CrossRef]

- Amer, B.M.A.; Hossain, M.A.; Gottschalk, K. Design and performance evaluation of a new hybrid solar dryer for banana. Energy Conversion and Management 2010, 51, 813–820. [CrossRef]

- Babar, O.A., Tarafdar, A., Malakar, S., Arora, V.K., Nema, P.K. Design and performance evaluation of a passive flat plate collector solar dryer for agricultural products. Journal of Food Process Engineering 2020, 43, e13484. [CrossRef]

- Bendjabeur, S.; Benchabane, O.; Bensouici, C.; Hazzit, M.; Baaliouamer, A.; Bitam, A. Antioxidant and anticholinesterase activity of essential oils and ethanol extracts of Thymus algeriensis and Teucrium polium from Algeria. Journal of Food Measurement and Characterization 2018, 12, 2278–2288. [CrossRef]

- Bennaceur, S.; Berreghioua, A.; Bennamoun, L.; Mulet, A.; Draoui, B.; Abid, M.; Carcel, J.A. Effect of Ultrasound on Henna Leaves Drying and Extraction of Lawsone: Experimental and Modeling Study. Energies 2021, 14, 1329. [Google Scholar] [CrossRef]

- Bennamoun, L.; Simo-Tagne, M.; Ndukwu, M.C. Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties. Energies 2020, 13, 2544. [Google Scholar] [CrossRef]

- Bennamoun, L., Li. J. Drying Process of Food: Fundamental Aspects and Mathematical Modeling, In Alexandru Mihai Grumezescu, Alina Maria Holban,(eds) Handbook of Food Bioengineering, Natural and Artificial Flavoring Agents and Food Dyes, 2018, Chapter 2. Academic Press, 29-82.

- Bennamoun, L.; Belhamri, A. Numerical simulation of drying under variable external conditions: Application to solar drying of seedless grapes. Journal of Food Engineering 2006, 76, 179–187. [Google Scholar] [CrossRef]

- Bennamoun, L.; Belhamri, A. Design and simulation of a solar dryer for agriculture products. Journal of Food Engineering 2003, 59, 259–266. [CrossRef]

- Boubeghal, A.; Chaker, A. Design and experimental studies of an indirect-mode natural convection solar dryer for henna leaves (Lawsonia inermis). World Review of Science, Technology and Sustainable Development 2018, 14, 344–358. [CrossRef]

- Bourgou, S.; Serairi Beji, R.; Medini, F.; Ksouri, R. Effet du solvant et de la méthode d’extraction sur la teneur en composés phénoliques et les potentialités antioxydantes d’Euphorbia helioscopia. Journal of New Sciences 2016, 28, 1649–1655. [Google Scholar]

- Boutaghane, N.; Voutquenne-Nazabadioco, L.; Harakat, D.; Simon, A.; Kabouche, Z. Triterpene saponins of Genista ulcina Spach. Phytochemistry 2013, 93, 176–181. [Google Scholar] [CrossRef]

- Castro, A.M.; Díaz, L.E.; Quintanilla-Carvajal, M.X.; Mayorga, E.Y.; Moreno, F.L. Convective drying of feijoa (Acca sellowiana Berg): A study on bioactivity, quality, and drying parameters. LWT - Food Science and Technology 2023, 186, 115209. [CrossRef]

- Elansary, H.O.; Szopa, A.; Kubica, P.; Ekiert, H.; Al-Mana, F.A.; El-Yafrsi, M.A. Antioxidant and Biological Activities of Acacia saligna and Lawsonia inermis Natural Population. Plants 2020, 9, 908. [Google Scholar] [CrossRef] [PubMed]

- Enneb, H.; Belkadhi, A.; Cheour, F.; Ferchichi, A. Comparaison des composés phénoliques et du pouvoir antioxydant de la plante de henné (Lawsonia inermis L.). Journal of New Sciences 2015, 20, 788–793. [Google Scholar]

- Haminiuk, C. W. I.; Maciel, G. M.; Plata-Oviedo, M. S. V.; Peralta, R. M. Phenolic compounds in fruits – an overview. International Journal of Food Science & Technology 2012, 47, 2023–2044.

- Hassanain, A.A. Unglazed Transpired Solar Dryers for Medicinal Plants. Drying Technology 2010, 28, 240–248. [CrossRef]

- Hosseiny, Z.; Meftahizadeh, H.; Ghorbanpour, M.; Gholamnejad, J.; Zareshahi, R. Influence of harvesting dates and genotypes on secondary metabolites status and antioxidant activity in Lawsonia inermis L. (Henna). Acta Ecologica Sinica 2023, 43, 891–898. [CrossRef]

- Hsouna, A.; Trigui, M.; Culioli, G.; Blache, Y.; Jaoua, S. Antioxidant constituents from Lawsonia inermis leaves: Isolation, structure elucidation and antioxidative capacity. Food Chem. 2011, 125, 193–200. [CrossRef]

- Jokić, S. ; Velić, D. ; Bilić, M. ; Bucić-Kojić, A. ; Plan inić, M. ; Srećko, T. Modelling of the process of solid-liquid extraction of total polyphenols from Soybeans. Czech J.Food Sci. 2010, 28, 206–212. [CrossRef]

- Kherrafi, M.A.; Benseddik, A.; Saim, R.; Bouregueba, A.; Badji, A.; Nettari, C.; Mansouri, S.M.; Lahreche, A.; Bensaha,H. Performance enhancement of indirect solar dryer with offset strip fins: Experimental investigation and comparative analysis. Solar Energy 2023, 266, 112158. [CrossRef]

- Labed, A., Moummi, N., Zellouf, M., Aoues, K., Rouag, A. Effect of Different Parameters on the Solar Drying of Henna; Experimental Investigation in the Region of Biskra (Algeria). In: Dincer, I., Colpan, C., Kizilkan, O., Ezan, M. (eds) Progress in Clean Energy, 2015, 2. Springer, 979-992.

- Labed, A.; Moummi, N.; Aoues, K.; Benchabane, A. Solar drying of henna (Lawsonia inermis) using different models of solar flat plate collectors: an experimental investigation in the region of Biskra (Algeria). Journal of Cleaner Production 2016, 112, 2545–2552. [CrossRef]

- Müller, L.; Gnoyke, S; Popken, A.M.; Böhm V. Antioxidant capacity and related parameters of different fruit formulations. LWT - Food Science and Technology 2010, 43, 992–999. [CrossRef]

- Naseem, Z. ; Hanif, M.A. ; Zahid, M. ; Tahir, S. ; Anjum, F. ; Bhatti, H.N. Ultrasound-assisted deep eutectic solvent–based extraction of phytochemicals from Mentha arvensis: optimization using Box-Behnken design. Biomass Convers. Biorefinery 2022, 12, 35–45. [CrossRef]

- Naseem, Z. ; Zahid, M. ; Hanif, M.A. ; Shahid, M. Environmentally friendly extraction of bioactive compounds from Mentha arvensis using deep eutectic solvent as green extraction media. Pol. J. Environ. Stud. 2020, 29, 3749–3757. [CrossRef]

- Ndukwu, M.C.; Simo-Tagne M.; Bennamoun L. Solar drying research of medicinal and aromatic plants: An African experience with assessment of the economic and environmental impact. African Journal of Science, Technology, Innovation and Development 2021, 13, 247–260. [CrossRef]

- Nurhaslina, C.R.; Bacho, S.A.; Mustapa, A.N. Review on drying methods for herbal plants. Materials Today: Proceedings 2022, 63, S122–S139. [CrossRef]

- Pise, V.H; Harlalka, R,; Thorat, B.N. Need for Systematic/ Controlled Dehydration of Aromatic Plants. In Advances in Drying Science and Technology, 1st ed.; A.S., Mujumdar, Ed.; CRC Press: Florida, U.S.A., 2024; pp. 33–41. [Google Scholar]

- Semwal, R.B.; Semwal, D.K.; Combrinck, S.; Cartwright-Jones, C.; Viljoen, A. Lawsonia inermis L. (henna): Ethnobotanical, phytochemical and pharmacological aspects. Journal of Ethnopharmacology 2014, 155, 80–103. [CrossRef]

- Tarminzi, M.A.S.M.; Razak, A.A.; Azmi, M.A.A.; Fazlizan, A.; Majid, Z.A.A.; Sopian, K. Comparative study on thermal performance of cross-matrix absorber solar collector with series and parallel configurations. Case Studies in Thermal Engineering 2021, 25, 100935. [CrossRef]

- Topçu, G.; Ay, A.; Bilici, A.; Sarıkürkcü, C.; Öztürk, M.; Ulubelen, A. A new flavone from antioxidant extracts of Pistacia terebinthus. Food Chemistry 2007, 103, 816–822. [CrossRef]

- Oancea, S. A review of the current knowledge of thermal stability of anthocyanins and approaches to their stabilization to heat. Antioxidants 2021, 10, 1337. [CrossRef] [PubMed]

- Oyaizu, M. Studies on products of browning reactions: antioxidative activities of browning reaction prepared from glucosamine. Japanese Journal of Nutrition 1986, 44, 307–315. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Bio. Med. 1999, 26, 1231–1237. [CrossRef] [PubMed]

- Sirichai, P.; Kittibunchakul, S.; Thangsiri, S.; On-Nom, N.; Chupeerach, C.; Temviriyanukul, P.; Inthachat, W.; Nuchuchua, O.; Aursalung, A.; Sahasakul, Y.; Charoenkiatkul, S.; Suttisansanee, U. Impact of drying processes on phenolics and in vitro Health-Related activities of Indigenous plants in Thailand. Plants 2022, 11, 294. [CrossRef]

- Wojdyło, A.; Lech, K.; Nowicka, P. Effects of different drying methods on the retention of bioactive compounds, on-line antioxidant capacity and color of the novel snack from red-fleshed apples. Molecules 2020, 25, 5521. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).