1. Introduction

New industrial technology has increased noticeably in the last few years. The digital factory and its components are among them [9]. The digital factory and its instruments are now the main means of locating and resolving issues with industrial processes and systems [12,13]. In the manufacturing industry, case studies and their solutions are becoming a vital resource for businesses looking to manage processes [14].

The phrase "digital factory" refers to a virtual representation of actual production [18,19]. Virtual reality takes the role of reality. It is feasible to validate conflicting scenarios and suggest the best course of action even before a solution is put into practice by using Digital Factory [20].

Production and assembly technology, time analyses, processing production and assembly procedures, production system design, robotization, production layout creation, ergonomic analyses, simulation of own production, and internal logistics are all covered by the digital enterprise [10].

Research on the design of production halls, digital factories, material flows, and digital twins is bringing several significant trends and topics to light [22].

The production hall's design is primarily concerned with investigating effective spatial utilization and streamlining the facility's operations [24]. The Internet of Things, contemporary technology for boosting manufacturing efficiency, and the application of automation are the key trends in this field. The design of workstations with an emphasis on sustainability and ergonomics is also included in this research [26].

The digital enterprise is a prominent area of study, with research mostly concentrating on the incorporation of digital technologies throughout the organization [27]. The digital enterprise also leverages tools such as cloud computing, big data analysis, and artificial intelligence, which are yet far from explored [28].

The concept of a digital twin is closely associated with the digital enterprise, which is primarily concerned with the analysis, modeling, and optimization of production processes [29]. The use of improved sensors, simulation technologies, and simulations to produce more precise and efficient production operation execution is a topic of ongoing discussion in this field [11].

In terms of material flows, most of the research in this field focuses on streamlining the flow of materials to minimize warehouse space and guarantee seamless material movement throughout the production process [23]. RFID technology, real-time material tracking, and data analysis are utilized in research to enhance the tracking, management, and monitoring of material flows [25].

It can be claimed that research in these fields is connected to the ongoing transition to intelligent production systems, where innovation and the transformation of digitalization play a significant role. These elements already fit within Industry 5.0 today [21].

This research aims to suggest a process for creating a production workspace within an organization. Regarding the business, it is a privately held engineering firm based in Slovakia that manufactures cranes, crane tracks, and related goods.

Clarifying the production planning issue and describing the production system are the goals of the work's introduction. The subject of software environments and digital enterprises is then discussed. The examination of the company's current situation, which addresses the problem of workplace arrangement during beam production, forms the basis of the work. A strategy for designing the ideal office layout was suggested based on the investigation. Within the Digital Factory, the digitization of the workplace is aided by the software application visTABLE.

2. Literature review

The following literature review presents the variety of interests that need to be considered in this matter.

The production system is made up of production and auxiliary means (machines, tools, preparations, energy, etc.) and production forces, which are interconnected by material and information flow and perform production operations on production objects (materials, raw materials, parts). Current production systems can be characterized by many elements (machines, warehouses, transport systems, control equipment, people), among which there are many complex deterministic and stochastic links. When designing such systems, there are strict requirements for their functional and operational capability, short project time, flexibility, simplicity and safety of operation, low investment, and operating costs [

1].

The authors' study focuses on the state-of-the-art development of the digital factory, which combines digital twins, sensing devices, laser additive manufacturing, and manufacturing processes in general. The studies highlight the shortcomings and perspectives of the digital factory. According to the study, a digital factory should include state-of-the-art manufacturing equipment that uses innovative technologies, including automation, artificial intelligence, the Internet of Things, and additive manufacturing. The study presents a new perspective on the development of the digital factory. The main objective of this study is to point out the aspects of the digital factory and its development using existing techniques, as there are still many companies that do not use the concepts of the digital factory. The finding of this study was the lack of complete standardization techniques and also problems in cooperation between man and machine or robot. The article also presents a proposal for a digital factory, which effectively fills the gaps by introducing the digital factory and its aspects into the production process. The design, which includes the use of a digital twin, sensing devices, laser additive manufacturing, and other innovative technologies within the manufacturing process, facilitates more sophisticated data analysis and algorithms, predictive maintenance, quality control, and optimal resource allocation. In general, this study and its overview help to create a comprehensive approach to the development of the digital factory using individual technologies and provide current progress in this field [

2].

The relationship between control systems and robot operating systems is the subject of Micieta et al.'s studies. A portion of the contribution is devoted to theoretical understanding concerning the most recent developments in the subject. While it's important to focus on the relationship between robotic operating systems and control systems at the enterprise process level, the study also describes how cobots based on operating systems are implemented in production systems. An algorithm with appropriate, well-defined phases is suggested in the article's research section for the effective integration of cobots into holonic production processes. The final piece in the chain of commercial applications of the newest developments in the field of robotic systems across the board is the development of a proposal for the realization of a collaborative robot working alongside a human. The establishment of a communication channel between cobots and programmable logic controllers, as well as the experimental validation of the suggested approach for integrating a collaborative robot and human in a production system in a lab, are the primary contributions of this work. The development of a novel process for risk analysis of cooperative robots and multifunctional autonomous devices is another advantage of this work. Since society does not currently use this kind of technology, the discovery of new trends in the automation and robotics fields is what brought attention to this topic. It will be feasible to identify areas of concentration within the context of human-robot cooperation and to concentrate on emerging trends in the field thanks to the study [

3].

A paperless checklist for confirming the procedure and production readiness for usage in the industry is covered in studies by Cosme et al. The essay discusses the benefits of the digital enterprise. The authors claim that the digital enterprise facilitates communication across workstations as well as processing, visualization, and simulations. Additionally, the studios' digital enterprise enables the collection of production data and a set of equipment using physical sensors built into the machinery. To handle equipment information and monitoring and restart production, this study suggests a paperless checklist. The suitability of the suggested solution is assessed in an actual industrial setting by contrasting it with the current paper-based information logging method. The findings demonstrate that the paperless checklist has benefits over the existing method since it permits numerous viewings and loggings and keeps a digital record of procedure modifications for further examination. The studios were given special attention because the hall arrangement has changed in this studio. As a result, the study will assist me in gathering data regarding the disruption and the hall's subsequent restart, which ought to occur as quickly and error-free as feasible [

4].

The writers of studies by Lee et al. concentrate on the digital twin and its simulations to guarantee the flow optimization of industrial processes. The authors of the paper stress the value of implementing a digital twin in a manufacturing organization since it guarantees that small and medium-sized production facilities will become more intelligent and autonomous. The construction and development of digital twin models for the simulation and optimization of manufacturing process flows is the article's primary objective. In the investigations, a multi-agent simulation model was first created. Additionally, a statistical meta-modeling method for creating trials for process optimization is suggested. Thirdly, two novel graph models, the task flow graph, and the automated guided vehicle movement graph are constructed to track and monitor the performance of production workplaces in real time. Experimental experiments are conducted to test and validate the suggested simulation-enabled digital twin approach in representing an actual manufacturing plant. The outcomes of the experiments demonstrate that the suggested approach successfully converts the production workshop, with the aid of a digital twin, into a new class of smart factories. The sequential design of experiments efficiently decreases the computing overhead of expensive simulations and at the same time optimally plans the autonomous guided vehicle to achieve production capacity cost-effectively. It is highly promised that this research will assist small and medium-sized manufacturing factories in making the most of digital twins and big data technologies to obtain a competitive edge in the global market. The layout solution in this study, which took place in the setting of a digital firm, attracted attention to the studies [

5].

The projection of production systems is a crucial component of the literature review since it plays a major role in resolving workplace layout issues. You can see which of the studies in this issue received attention in the lines that follow.

The goal of Baron et al.'s study is to use computer software in digital factories to meet production order deadlines. The use of computer simulation tools for the production system to confirm the scheduled dates of production orders in a production company is explained in the article. The creation of a computer model of the assembly hall and the subsequent simulation of the three prohibitions' production flow were mandated by the contractual authority. The distribution of material to the assembly hall, either already created internally or acquired from vendors, marks the start of the material flow. Three computer models built within the Witness Horizon 21 environment were used for simulation tests. The trials verified that the suggested implementation timelines for two monitored orders were implausible. The production layout solution's capacity, the transport and storage system's functionality, the information flow, and the management system's performance may all be assessed by computer simulation [

6].

The techniques for creating the production layout of the chosen company are covered in the article by Kováč et al. In situations where it's required to integrate a new machine swiftly and flexibly into the current layout and prevent collisions even before the actual machine is installed in production, the study focuses on the application of mixed reality in production system design, as well as changes made to it during expansion or technological advancements in production. The Vumark design approach is used to implement it; it was tested and validated in the production setting of the Innovation and Prototyping Center at the Technical University of Kosice's Mechanical Engineering Faculty. The post's separate sections cover the steps involved in implementing Vumark in a production environment as well as the hardware and software tools available to users. For the experiment, three production machines and one robotic device were chosen from the Factory design software database. The selected approach makes it possible to quickly identify the ideal location for the machines in the layout solution by verifying multiple machine placement options during the trial. The experiment demonstrated that the selected approach is workable in real-world scenarios and results in time, money, and energy savings—particularly when modifying the production hall's architecture or machine [

7].

In their study, authors Kralik et al. concentrate on improving the arrangement of machinery and equipment in a particular company's output. The optimization of the current production hall layout solution at a particular component-producing firm is the topic of this contribution. The objective is to create a layout solution through product portfolio analysis, capacity calculation implementation, and machine and equipment design optimized configuration. A few optimization calculations were performed utilizing simulation for this purpose. A comprehensive plan with 3D visualization is the end product [

8].

Overall, the review of the literature leads to the conclusion that research in the fields of material flows, digital factories, smart factory design, and production hall design demonstrates a continuous movement towards more intelligent and effective production systems, where technological advancements and digital transformation are critical to gaining a competitive edge [30].

3. Materials and Methods

The main objective of this study is to propose an improvement of the workplace layout and production flow in the company concerning Industry 4.0 in the digital factory environment.

The sub-objectives of the case study include:

To examine the company from the manufacturing sector and to examine the scope of activities and services provided by the company;

To analyse the current state of the selected company in which the case study is carried out, in the field of production systems design and the level of digitization.

A production process is a set of activities of people, means of production, and physical processes that require one or more types of inputs and form an output that has value for the customer. These are activities using which the material is transformed into a product or an order into customer service [15].

To ensure the effective functioning of the production system, this case study researched specific elements of the production process, especially the company's flow production and layout. The aim was to streamline the conversion of inputs into valuable outputs for the customer. Given that customers typically have limited visibility into the realization of these outputs, their primary concern lies in the product or service [16].

3.1. Unveiling the Examined Company: In-Depth Company Description

The company, based in Slovakia, was founded in 1994 as a limited liability company specializing in engineering production. The company currently has 27 employees and is classified as a small business. The company is engaged in the production of cranes and crane tracks. He then assembles the cranes and puts them into operation with all the obligations of the supplier.

The staff members of the organization are highly experienced in their fields. The group of workers can meet the needs of the client. For their operations, they have access to a manufacturing hall, assembly cars, measuring tools, and STN standards. The business possesses the licenses and certifications required to produce goods in compliance with applicable regulations and technical specifications. ISO 9001 certifies the company's developed quality management system. The organization certifies that it has put in place and is using a quality management system in producing, assembling, and repairing lifting and electrical equipment after receiving a quality management system certificate from an outside organization.

3.2. Subject of the company's activity

Since its inception, the company has been operating activities focused on the production and assembly of cranes and crane tracks. These activities were specified in more detail based on a personal interview with a competent employee. These are the following activities:

Production, assembly, reconstruction, repair and maintenance, professional inspections, and professional tests of lifting equipment;

Production, assembly, repair and maintenance, professional inspections and professional tests of electrical equipment;

Design of dedicated electrical equipment;

Production, installation, and repair of electrical machines and devices;

Production, assembly, and repair of consumer electronics products and devices;

Installation and repair of measuring and control equipment;

Electrical installation;

Intermediary activity in the scope of free trades;

Retail in the scope of free trades;

Wholesale in the scope of free trades;

Business consulting;

Consulting activity – technical area;

Welding works;

Advertising activities;

Education and training in the field of labor protection focused on load binders.

The company follows the necessary standards in the production and assembly of cranes.

3.3. Unveiling the Product Portfolio: A Glimpse into the Company's Offerings

The company has a relatively wide portfolio of products, which can be classified into the following categories:

Crane technology;

Engineering production for the construction industry;

Engineering production for the food industry;

Engineering production for advertising;

Production of electrical switchboards.

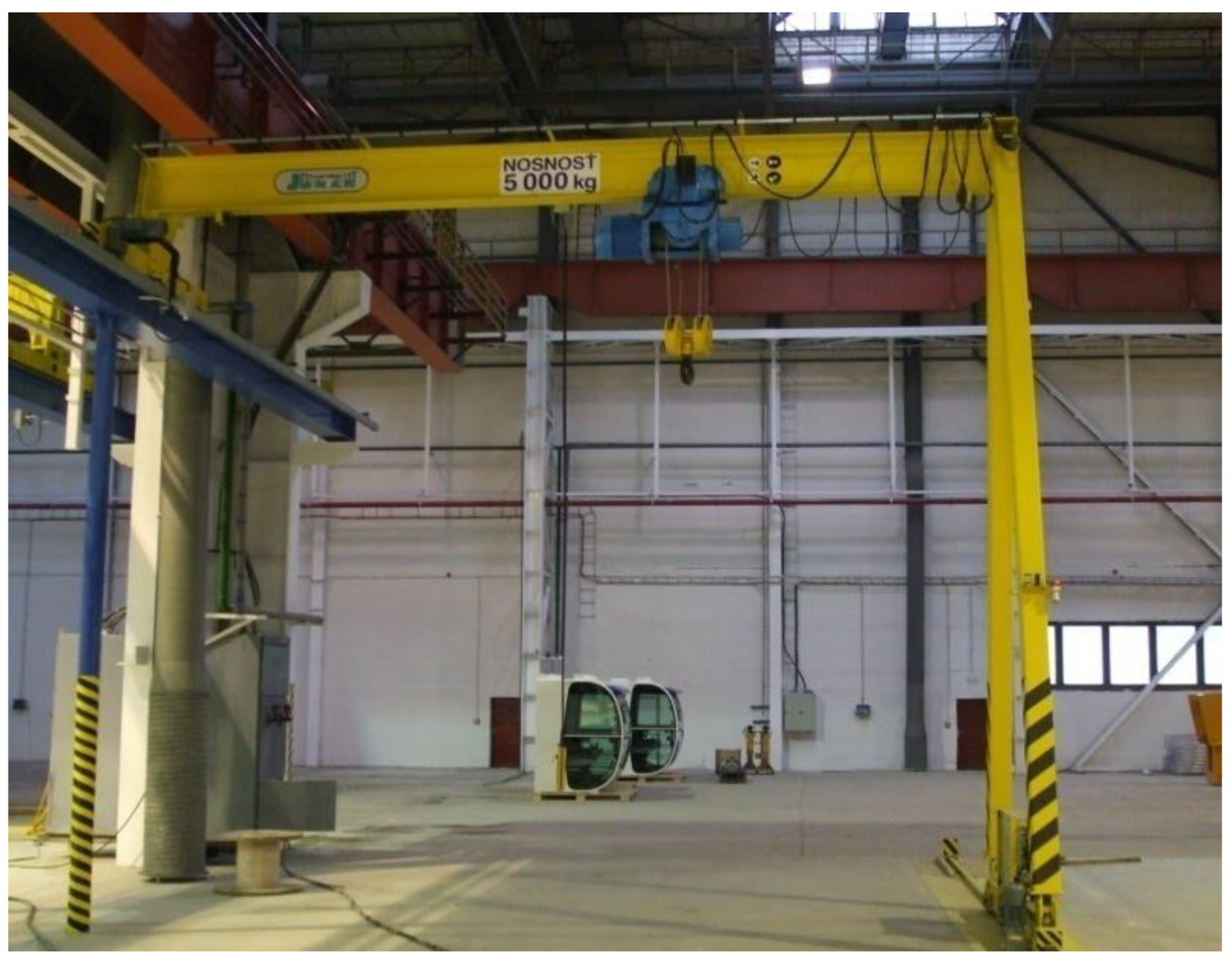

Within crane technology, it can be products such as single and double girder cranes, gantry cranes, cantilever cranes, or various other types of cranes. As part of crane technology, they also manufacture various preparatory equipment for transporting and lifting products or offer assembly and refurbishing of crane cabins or service and maintenance of crane tracks.

As part of engineering production for the construction industry, they can produce, for example, beams and brackets for the construction industry, constructions of transitions and overpasses, bridges for cars and pedestrians, or the production of steps and ladders from metal, fencing, or brackets for connecting wooden structures.

As for engineering production for the food industry, within this section, the company is engaged in the production of engineering products from stainless steel according to customer requirements. As part of engineering production for advertising, companies provide production of machined constructions for billboards or tower constructions for billboards.

The last section of the production of electrical switchboards is devoted to the production and installation of electricity meter switchboards, single-tariff, two-tariff, multiple connection points, production of connection switchboards, production of switchboards according to customer requirements, and installation and service.

The following

Figure 1 shows an example of a special welding technique produced by the company.

3.4. Evaluating the Current Work Environment: A Comprehensive Review

This section established a study of the workplace as it exists currently, which includes gathering, processing, and analyzing the relevant data. The information and analytical findings will be used to identify inefficiencies and opportunities for enhancing the chosen work environments, and they will also serve as the foundation for recommendations for potential solutions.

3.4.1. Analysis of the company areas

In this design phase, it is a detailed mapping of all in-house areas that are available for the next design stage. A business that has enough areas at its disposal may not be successful unless it can use these areas efficiently and purposefully.

The procedure for analyzing the surfaces was established through the following steps:

Mapping of spaces (video sequences, photo documentation);

Measurement of areas: directly in the plant (manual method or digital method) or using drawing documentation;

Drawing construction and energy restrictions into the existing drawing documentation according to the actual state;

Correction of drawing documentation due to its out-of-dates.

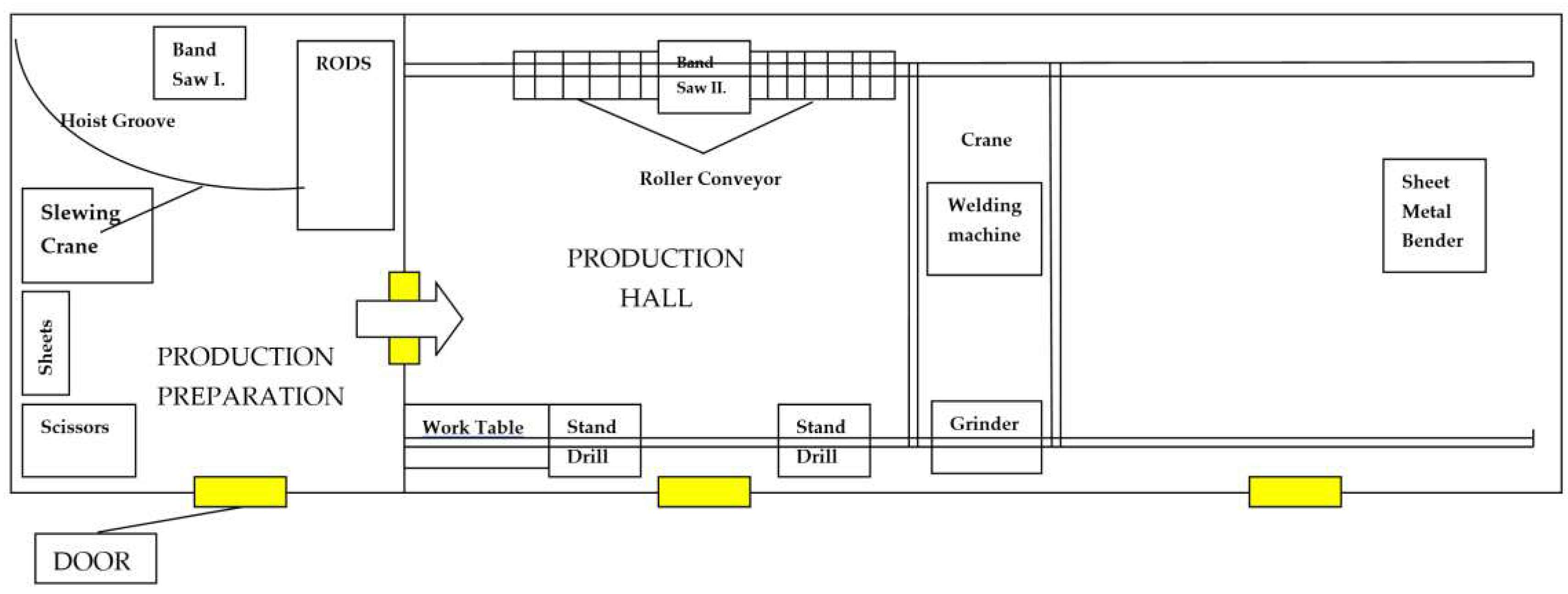

The production hall's workplace layout can be seen in the following

Figure 2. In

Figure 2, in the left part of the picture, the production preparation is taking place. In addition, in this part, there are material and individual machines, that are necessary for the production process itself. In this part, some rods are divided using a band saw. A slewing crane with a Hoist Groove is also located in this area. In the lower part, there is a door, and, in this part, it is possible to see sheets that are cut using scissors. In the middle part of the picture, you can see the production hall, where production processes occur. In the upper part is a band saw and a roller conveyor. In the lower part, there are two stand drills with a worktable and then a grinder. There are cranes, which are necessary for handling the material. A sheet metal bender can be seen in the right part of the picture.

The analysis of business areas was carried out directly in production. The sizes of individual areas were manually measured and processed in

Table 1. The areas were divided into production, storage, auxiliary, and transport areas.

Table 1 shows individual surfaces.

It can be seen from

Table 1 that the total measuring area is 723 m

2. Production areas occupy 546 m

2, storage areas 19 m

2, auxiliary areas occupy 30 m

2, and transport roads occupy 128 m

2.

The following

Figure 3 shows the percentage of individual areas. It is clear from

Figure 3 that the production areas occupy 75% of the total areas of the enterprise. Transport communication occupies 18% of the total areas of the enterprise, auxiliary areas occupy 4% of the total areas of the enterprise, and only 3% of the total areas are occupied by warehouse areas. From the area ratio in %, the company uses its areas as production areas as much as possible.

3.4.2. Analysis of the production process

The key issue in solving the spatial structure of the production process is the relationship between the production layout and material handling. It does not matter whether the problem to be solved is the redesign of an existing production layout or the design of a new one, but to move material as economically and efficiently as possible in both cases. Therefore, there is an inextricable link between production layout and material handling. Any complete analysis of material movement is linked to the production layout. In the next part, the beam manufacturing process will be analysed. This beam can be seen in the following

Figure 4.

In the beginning, basic data collection was carried out. The input data represented a simplified technological procedure, the duration of individual operations, predecessors of operations, and the number of workers on individual technological operations. This information is divided into two tables for better clarity and visibility.

Table 2 describes the operation number, operation description, number of workers, and duration time. Operation 1 requires one worker and takes four hours to complete. Operation 2 requires one worker and takes four hours to complete. Operation 3 requires a single worker and takes three hours to complete. It takes two hours and two workers to complete Operation 4. Operation 5 takes four hours to complete and requires one person. Operation 6 takes eight hours and needs one person. It takes 30 minutes and two people to complete Operations 7 and 10. Operation 8 takes one hour and needs one person. One worker is needed for Operation 9, which takes two and a half hours to complete.

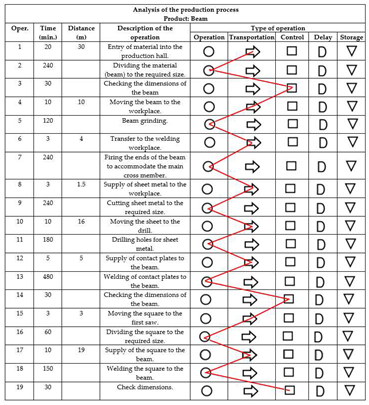

3.4.3. Analysis of the production process

In the case of detailed design, it is advantageous to use instead of a classic diagram of the production process, a production progress table, which represents a more detailed record of individual activities with the product in the process of its processing (operation number, type of operation, description, duration, distance). The analysis of the production process is a good starting point for the analysis of the production process from the point of view of the creation of added value. The production progress table can be seen in the following

Table 3.

Table 3 shows the analysis of the production process and material flow. In addition to the main operations that can be seen in

Table 2. This table also shows the intermediate operations, their time duration, and the distance traveled. In addition to these indicators, it is also possible to see a graphic representation of the material flow by indicating the type of operations. Their graphic explanation is in the lower part of

Table 3.

It can be seen from

Table 3 that during operation 1, during which the material enters the production hall, 30 meters are traveled, and the duration of this operation is 20 minutes. Operation 4 takes 10 minutes, and the distance traveled is 10 meters, while this operation involves moving the beam to the workplace. During operation 6, transfer to the welding workplace, while the duration of this operation is 3 minutes, and the distance covered is 4 meters. In operation 8, where sheet metal is supplied to the workplace, the duration is 3 minutes, and the distance traveled is 1.5 meters. During operation 10, the sheet metal is moved to the drill, while the time for this operation is 10 minutes, and the distance traveled is 16 meters. During operation 12, the contact plates are fed to the beam, while the duration of this operation is 5 minutes, and the distance covered is 5 meters. Operation 15 takes 3 minutes, and the distance traveled is 3 meters, while this operation involves moving the square to the first saw. During operation 17, the square is fed to the beam, while the duration is 10 minutes, and the distance traveled is 19 meters. The other operations that are described in Table 4 were specified in more detail in the previous

Table 2 and

Table 3.

3.4.4. Analysis of the intensity of material flows

In this section, there is a table of traffic relations between individual workplaces. Using this tool, the intensity of material flows between individual workplaces is determined. Workplaces between which the intensity of the material flow is the highest are located as close as possible to each other. The table is divided into squares, in which the amount of transported material between individual workplaces is entered. The workplaces that send the relevant material are listed vertically, and the workplaces as recipients of the relevant material are listed horizontally. Table 4 shows data on material relations between individual workplaces in kilograms per month.

In

Table 5, for a closer understanding, the individual numbers represent workplaces in the production section during the production of the beam. Number 1 represents the profile warehouse, number 2 represents the sheet metal warehouse, number 3 represents the bar warehouse, number 4 represents the first saw, number 5 represents the second saw, number 6 represents the cutting workplace, number 7 represents the drilling workplace, number 8 represents the grinding workplace, and number 9 represents the welding workplace.

It is also evident from

Table 5 that 20,000 kilograms of material are moved from the saw II profile warehouse. From the sheet metal warehouse to the cutting area, 400 kilograms of material are moved. The bar warehouse ships 1,500 kilograms of material to sawmill I. From sawmill I, 1,200 kilograms of material are moved to the welding workspace. Nineteen thousand kilograms of material are brought to the grinding facility from sawmill II. From the cutting workspace to the drilling workspace, 300 kilograms of material are moved. From the drilling site to the welding site, 240 kilograms of material are moved. From the grinding area to the welding area, 19,000 kilograms of material are moved. This is the transport of material in one month.

In conclusion, sawmill I process 1,500 kilograms of material every month. Workplace saw II: 20,000 kilograms of material are passed there each month. Every month, 400 kilograms of material go through the cutting workspace. Every month, 300 kilograms of material go through the drilling site. Every month, 19,000 kilograms of material go through the grinding area. Every month, 20,440 kilograms of material go through the welding workspace. It follows that the welding workplace will see the highest monthly volume of material flow through it. The kilogram is 20,440.

In

Table 6, it is possible to see a table of distances between individual workplaces for the current state. Between the profile warehouse and the band saw II. is a distance of 30 meters. There is a distance of 1.5 meters between the sheet metal warehouse and the cutting area. There is a distance of 3 meters between the bar warehouse and the band saw I. There is a distance of 19 meters between Bandsaw I. and the welding workplace. Between band saw II. and the grinding workplace is 10 meters away. There is a distance of 16 meters between the cutting and drilling workplace. The distance between drilling and grinding is 5 meters. The distance between grinding and welding is 4 meters.

In

Table 7 it is possible to see the transport performance between workplaces in meters. The following mathematical formula is required to calculate the transport performance:

In the mathematical formula, it means P – transmission performance (piece*meter/month), i – intensity (kg), d – distance between workplaces (meters).

It follows from

Table 7 that the transport performance between the profile warehouse and the band saw II. is 60,000. The transport capacity between sheet metal warehouse and cutting is 600. Transport capacity between the bar warehouse and band saw I. is 4,500. The transport capacity between band saw I and welding is 22,800. Transport capacity between band saw II. and grinding is 19,000. The transportation capacity between cutting and drilling is 4,800. The transportation capacity between drilling and welding is 1,200. The transportation capacity between grinding and welding is 76,000. The total transportation capacity is 899,900 pieces*meter/month.

In

Table 8, it is possible to see the cost of transporting one piece of product. The product cost of one piece of product is €1.5 per meter. It is an internal data provided by the company. The following mathematical formula expresses the calculation of transport costs:

In the mathematical formula, it means N – total transport costs (€), i – intensity (kg), n – transport costs of one piece per one meter (€).

The cost of transportation between the profile warehouse and the band saw I is €900,000. The cost of transportation between the sheet metal warehouse and cutting is €900. The cost of transportation between the bar warehouse and band saw I is €6,750. The cost of transportation between band saw I and welding is €34,200. Transportation costs between the band saw II. and grinding is €285,000. The cost of transportation between cutting and drilling is €7,200. The cost of transportation between drilling and welding is €1,800. The cost of transportation between grinding and welding is €114,000. The total cost of the original layout of the workplaces came to €1,349,850.

4. Results

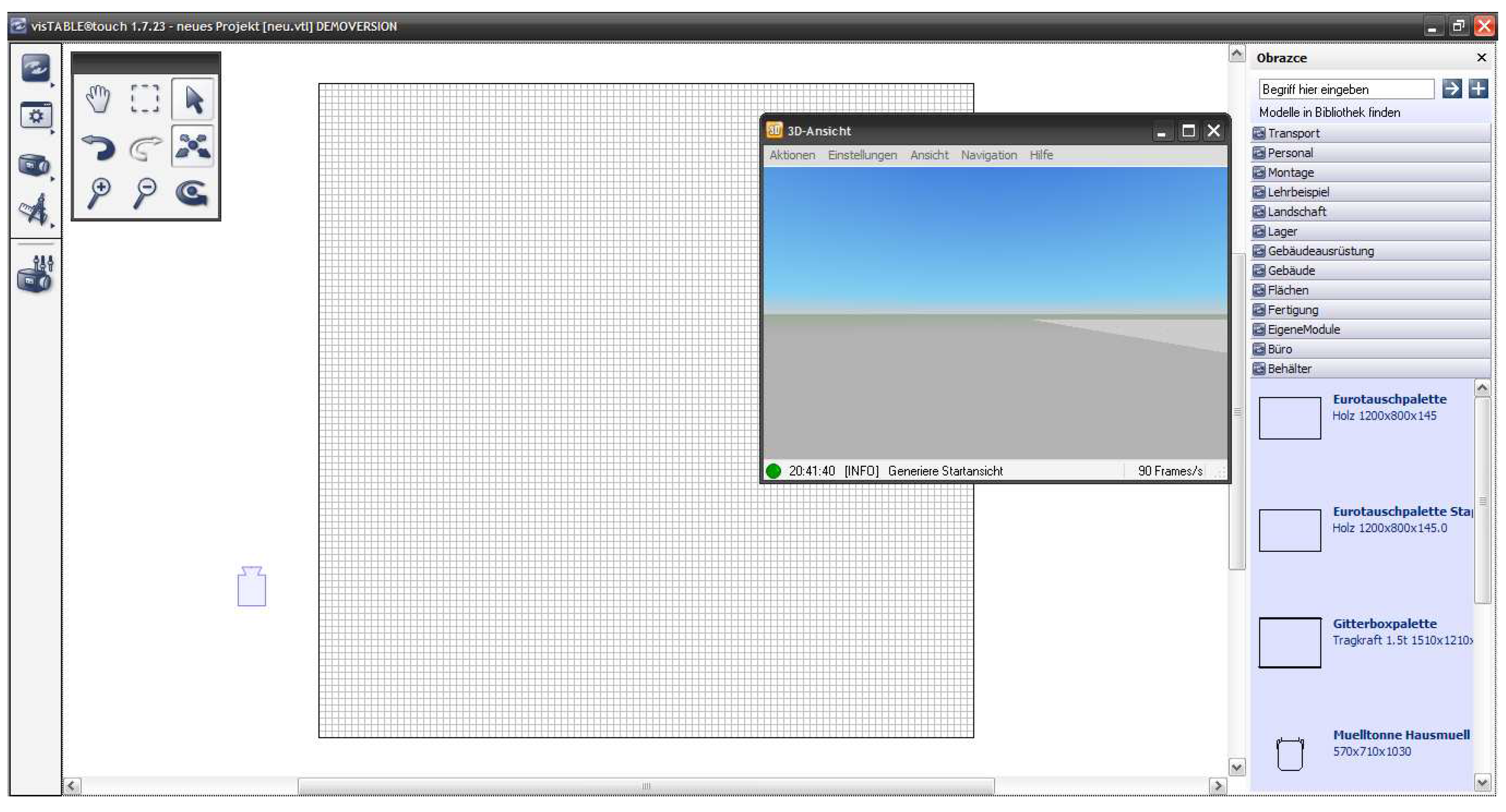

This section of the study includes a workspace design for a digital factory. It will specifically deal with creating the workspace in the visTABLE software's Digital Factory environment. The visTable tool serves as a supporting application for the static design of production systems. It will entail designing a workspace layout based on an assessment of the existing situation.

4.1. Developing an Effective Workplace Layout

Depending on the production concept, the workspace layout can be created automatically, or you can design your layout by adding your workspace components as needed. As previously indicated, the layout was designed using the VisTable application, whose working environment is depicted in

Figure 5 below.

The visTABLE tool serves as a supporting application for the static design of production systems. The software contains applications that facilitate the designer's work and decision-making when designing the layout of the workplace and the entire production layout. The following activities are primarily supported in the visTABLE application:

Interactive layout design in the project team;

Creating material flow analyses;

Flexible adaptation of production to commercial and innovative changes;

Team elaboration of detailed designs of spatial structures;

Checking and observing minimum distances;

Evaluation of the layout solution.

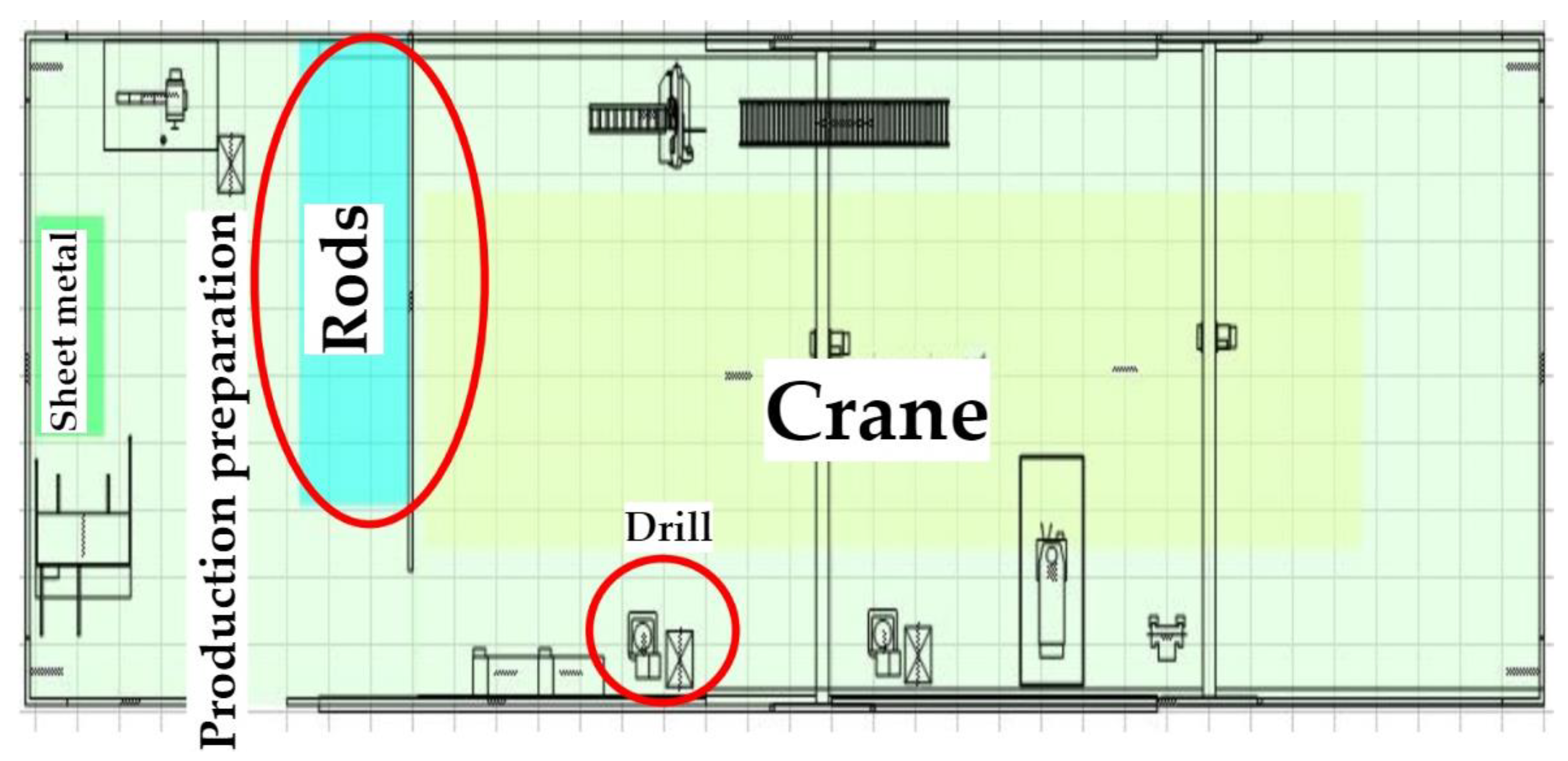

The present state of each machine's layout was likewise analysed in visTABLE. It is depicted in

Figure 6 below.

The visTABLE environment's current situation in the workplace is depicted in

Figure 6. The sole distinction between this arrangement and the one in

Figure 2 is that this layout was made in a digital setting.

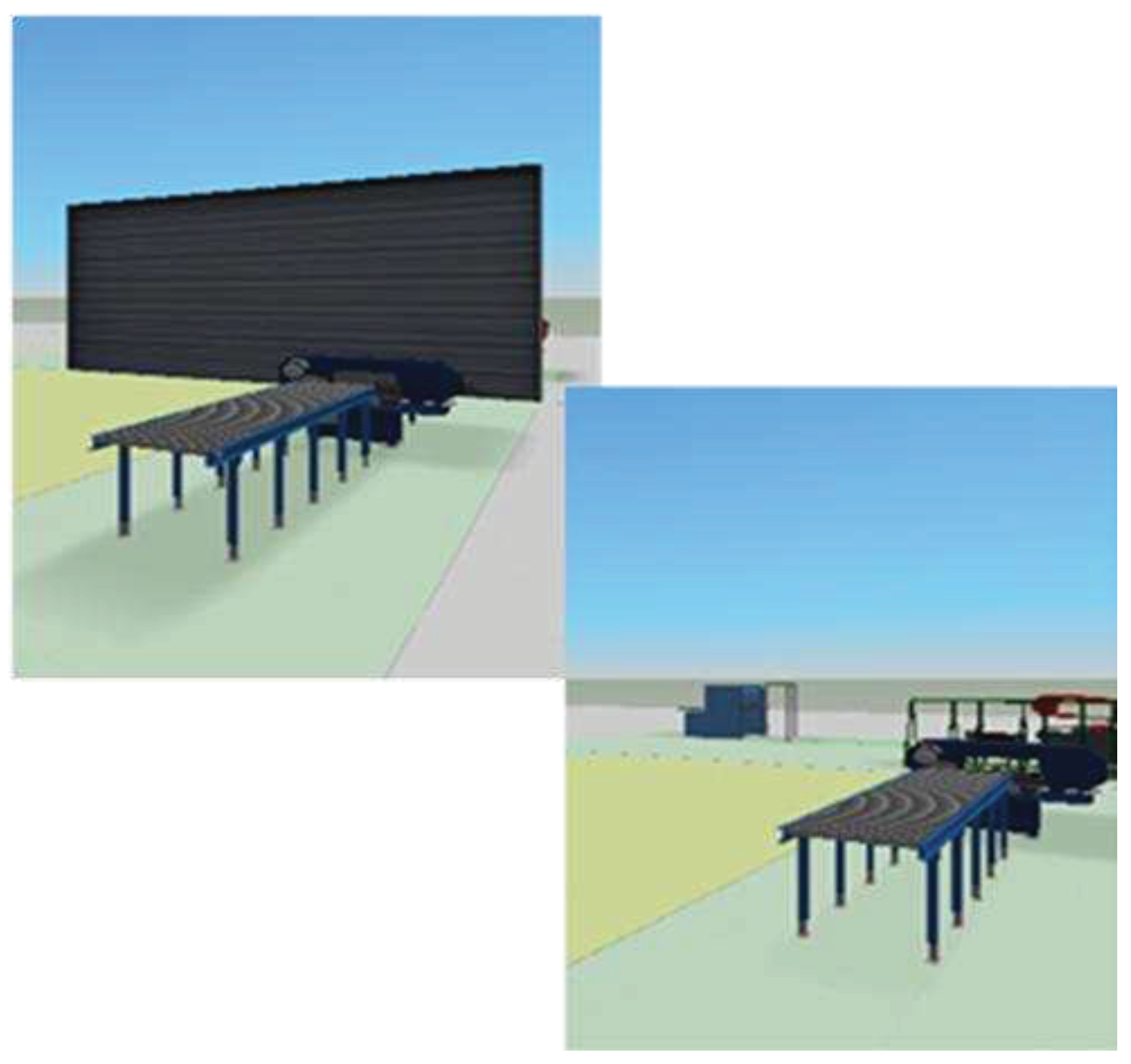

The basic design of the new workplace layout is shown in

Figure 7.

The sheet metal wall in this arrangement is suggested to be removed to expand the surface area and streamline the material flow between the production preparation area and the production hall. The production hall's core region cannot be changed since welding surfaces are required. Moving the standing drill closer to the shears and sheets was another suggestion in the plan, which would shorten the time it takes to transport the sheets from the shears to the standing drill. It is advised to keep the bars in a stacker for safety concerns and to conserve storage space. To guarantee worker safety and reduce handling and tool search time, additional recommendations include establishing workplace standards.

5. Discussion

This section presents a comparison of the current state with the design state as well as an assessment of the solution's benefits and outcomes.

This study's primary objective was to suggest the best beam manufacturing workstation layout based on an examination of the existing situation.

Figure 7 illustrates the new workstation configuration that was created using the visTABLE application. The next photographs also show specific designs in three dimensions.

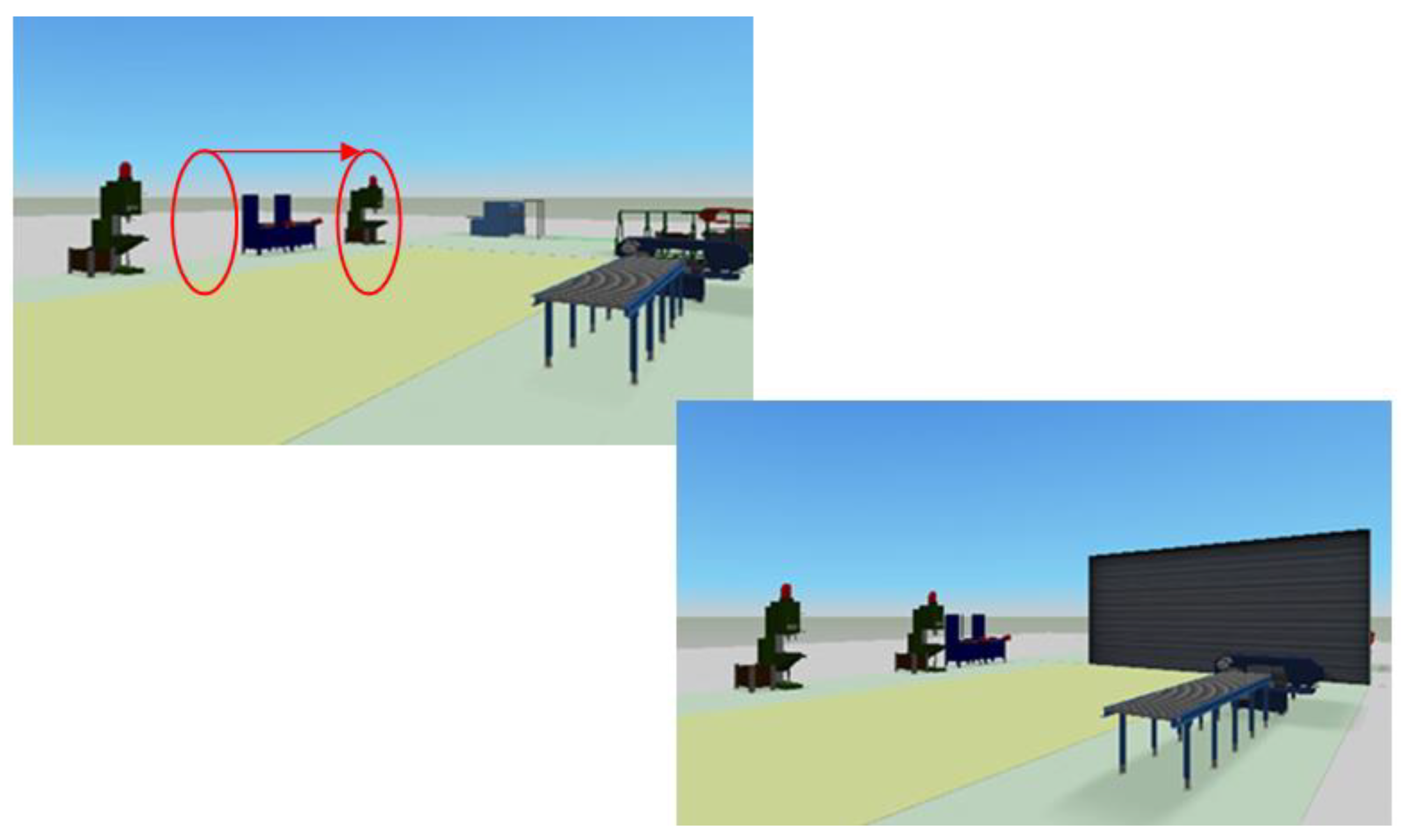

An illustration of the removal of a sheet metal wall from the production hall in a virtual setting is shown in

Figure 8.

Figure 8 shows the state before the removal of the sheet metal wall and after the removal of the sheet metal wall that separated the production preparation from the production hall. From the point of view of material handling and maximum use of areas there, it was unnecessary. The design state is shown on the right, while the present state is shown on the left.

Another point of the proposal was the relocation of the stand drill closer to the sheet metal cutting workplace. The main reason was the direct flow of material from the scissors to the standing drill, which reduced the handling time and material flow. The current state is displayed on the left, while the design state is displayed on the right in

Figure 9.

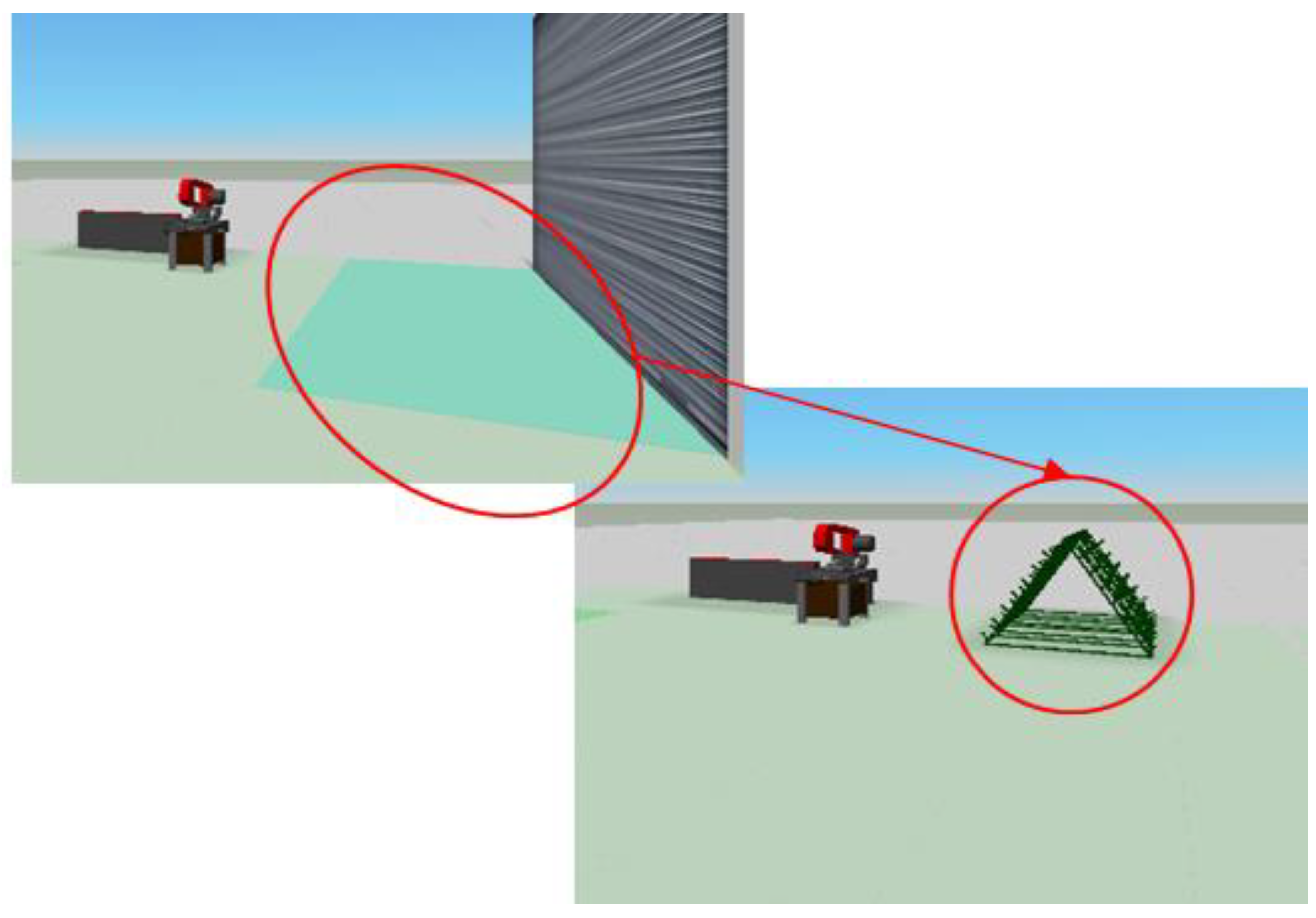

In preparation for production, a new stacker for rods is placed due to their free storage on the floor. The previous location was not suitable for handling and safety.

Figure 10 shows the placement of the stacker on the rod material.

Table 9, which calculates the differences between the existing and the proposed condition, provides a comparison of the current situation and the suggested solution.

Based on the comparison of the current (C) and the design (D) variant, it was found that the company can reduce the production of the beam from 1,864 minutes to 1,854 minutes. So, the beam production time would be reduced by 10 minutes. Time reduction is possible in the following operations: Moving the sheet to the drill, Supply of contact plates to the beam, and Supply of the square to the beam. The main benefit of the work is the shortening of the material flow by 15 meters from the original 88.5 meters to 73.5 meters.

Another proposal for the company was the introduction of workplace standards, specifically visualization of processes and 5S. After the introduction of individual standards, the expected benefits are:

Reducing the time spent searching for work aids by 50%;

Reduction of assembly operations by 30%;

Transparency and simplification of workplace processes;

Increasing safety at the workplace;

Increasing work discipline.

Process visualization ensures simplification and transparency of workplace processes and is used to prevent people from making unnecessary mistakes. This will also improve communication in the workplace. Other recommendations for the company are:

Color marking of assembly components;

Signs for storing tools;

Markers for storing materials;

Pictorial assembly or production procedures;

Think about the introduction of robots in the workplace in the future and pay attention to the development of the relationship between the employee and the robot.

5. Conclusions

Finding the best option for a workplace's layout was the main goal of this inquiry. The research was carried out in a Slovak Republic-based company. The suggested remedy was formulated after a thorough analysis of the company's current situation and served as the foundation for several assessments. The examinations focused on the beam's manufacturing procedure, the movement of materials, and the layout of the business's facilities. The welding process has been identified as a particularly difficult feature of the work environment since it takes up the largest amount of space in the production area and is stationary. It became necessary, therefore, to imagine the best possible approach that would maintain this essential component.

In

Table 10 a summary of the key indicators addressed in this case study can be seen. The distance has decreased from the original 88.5 meters to 73.5 meters, while it is a difference of 15 meters, converted to % it is 16.95%. Production time decreased from 1864 minutes to 1854 minutes, a difference of 10 minutes and 0.54% in %. The transport capacity of the original solution was 899,900 pcs*m, while the transport capacity of the proposed solution is 890,060 pcs*m, which is a difference of 9,840 pcs*m and in % this difference is 1.09%. The last indicator of transport costs per piece within the current state was 1,349,850, while the design state of this indicator is 1,335,090, representing a difference of 14,760 and that is in percentage 1.09%.

VisTable was used as an add-on tool for the static design of production systems, helping to visualize the layout and digitize the workspace. A proposal was then put forth that aimed to move the stand drill specifically. To optimize the material flow, this advice was made about the components that were going into the beam. An additional recommended action was to remove the sheet metal wall, which would also help to decrease material flow and improve material handling effectiveness.

The overarching recommendation for the company is to implement workplace standards aimed at diminishing handling times and enhancing workplace safety. Additionally, it is advised to contemplate the potential integration of robots into the work environment in the future, with careful consideration of the evolving dynamics between employees and robotic entities. The envisaged and executed solutions anticipate several advantages, including the reduction of material flow, decreased production time, heightened workplace safety, increased work productivity, and a consequential decrease in costs associated with the waiting times for individual components.

Author Contributions

Conceptualization, J.Z. and B.F.; methodology, L.D and S.K..; software, B.F.; validation, J.Z., L.D. and B.F.; formal analysis, J.Z. and S.K.; investigation, B.F.; resources, B.F.; data curation, J.Z.; writing—original draft preparation, J.Z.; writing—review and editing, L.D.; visualization, B.F and S.K..; supervision, L.D.; project administration, J.Z.; funding acquisition, L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under contract No. APVV-19-0305.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Buckova, M. , Krajcovic, M., & Jerman, B. (2017). Impact of digital factory tools on designing of warehouses. Journal of Applied Engineering Science, 15(2), 173–180. Scopus. [CrossRef]

- Tariq, U. , Joy, R., Wu, S.-H., Mahmood, M. A., Malik, A. W., & Liou, F. (2023). A state-of-the-art digital factory integrating digital twins for laser additive and subtractive manufacturing processes. Rapid Prototyping Journal, 29(10), 2061–2097. Scopus. [CrossRef]

- Micieta, B. , Binasova, V., Marcan, P., & Gaso, M. (2023). Interfacing the Control Systems of Enterprise-Level Process Equipment with a Robot Operating System. Electronics (Switzerland), 12(18). Scopus. [CrossRef]

- Cosme, J. , Pinto, T., Ribeiro, A., Filipe, V., Amorim, E. V., & Pinto, R. (2023). Paperless Checklist for Process Validation and Production Readiness: An Industrial Use Case. 95–103. Scopus. [CrossRef]

- Lee, H. , & Yang, H. (2023). DIGITAL TWIN SIMULATION AND OPTIMIZATION OF MANUFACTURING PROCESS FLOWS. 2. Scopus. [CrossRef]

- Baron, P. , Kočiško, M., & Hlavatá, S. (2023). Verification of Term Fulfillment of Production Orders with Computer Simulation Tools. 2976(1). Scopus. [CrossRef]

- Kováč, J. , Malega, P., Rudy, V., & Svetlík, J. (2023). Vumark’s Method of Production Layout Designing. Applied Sciences (Switzerland), 13(3). Scopus. [CrossRef]

- Králik, M. , Jerz, V., & Paštéka, M. (2020). Optimization of the Machine and Device Layout Solution in a Specific Company Production. Lecture Notes in Mechanical Engineering, 91–103. Scopus. [CrossRef]

- Bestvinova, V. , Praj, F., & Cambal, M. (2022). IDENTIFICATION OF SUSTAINABILITY RISKS AND THEIR QUANTIFICATION IN THE CONDITIONS OF SMALL AND MEDIUM-SIZED INDUSTRIAL ENTERPRISES. MM Science Journal, 2022-November. Scopus. [CrossRef]

- Grznár, P. , Burganová, N., Mozol, Š., & Mozolová, L. (2023). A Comprehensive Digital Model Approach for Adaptive Manufacturing Systems. Applied Sciences (Switzerland), 13(19). Scopus. [CrossRef]

- Micieta, B. , Staszewska, J., Kovalsky, M., Krajcovic, M., Binasova, V., Papanek, L., & Antoniuk, I. (2021). Innovative system for scheduling production using a combination of parametric simulation models. Sustainability (Switzerland), 13(17). Scopus. [CrossRef]

- Pekarcíková, M. , Trebuna, P., Kliment, M., Král, S., & Dic, M. (2021). Modelling and simulation the value stream mapping—Case study. Management and Production Engineering Review, 12(2), 107–114. Scopus. [CrossRef]

- Pekarčíková, M. , Trebuna, P., Kliment, M., Trojan, J., Kopec, J., Dic, M., & Kronová, J. (2023). Case Study: Testing the Overall Efficiency of Equipment in the Production Process in TX Plant Simulation Software. Management and Production Engineering Review, 14(1), 34–42. Scopus. [CrossRef]

- Plinta, D. , & Radwan, K. (2023). Implementation of Technological Innovation in a Manufacturing Company. Applied Sciences (Switzerland), 13(10). Scopus. [CrossRef]

- Plura, J. , Vykydal, D., Tošenovský, F., & Klaput, P. (2023). Graphical Tools for Increasing the Effectiveness of Gage Repeatability and Reproducibility Analysis. Processes, 11(1). Scopus. [CrossRef]

- Rakyta, M. , Bubenik, P., Binasova, V., Micieta, B., & Staffenova, K. (2022). Advanced Logistics Strategy of a Company to Create Sustainable Development in the Industrial Area. Sustainability (Switzerland), 14(19). Scopus. [CrossRef]

- Szabó, P. , Mĺkva, M., Marková, P., Samáková, J., & Janík, S. (2023). Change of Competences in the Context of Industry 4.0 Implementation. Applied Sciences (Switzerland), 13(14). Scopus. [CrossRef]

- Vavrík, V. , Gregor, M., Grznár, P., Mozol, S., Schickerle, M., Ďurica, L., Marschall, M., & Bielik, T. (2020). Design of manufacturing lines using the reconfigurability principle. Mathematics, 8(8). Scopus. [CrossRef]

- Wiȩcek, D. , Wiȩcek, D., & Kuric, I. (2019). Cost estimation methods of machine elements at the design stage in unit and small lot production conditions. Management Systems in Production Engineering, 27(1), 12–17. Scopus. [CrossRef]

- Pekarcíková, M. , Trebuňa, P., & Markovič, J. (2014). Case study of modelling the logistics chain in production. 96, 355–361. Scopus. [CrossRef]

- Kliment, M. , Trebuna, P., Pekarcikova, M., Straka, M., Trojan, J., & Duda, R. (2020). Production efficiency evaluation and products’ quality improvement using simulation. International Journal of Simulation Modelling, 19(3), 470–481. Scopus. [CrossRef]

- Gregor, M. , Grznár, P., Gregor, M., Mozolová, L., & Mozol, Š. (2023). SIMULATION META-MODEL OF ASSEMBLY LINE WITH CONWIP CONTROL. International Journal of Industrial Engineering: Theory Applications and Practice, 30(6), 1594–1615. Scopus. [CrossRef]

- Luu, T. V. , Chromjaková, F., & Nguyen, H. Q. (2023). A model of industry 4.0 and a circular economy for green logistics and a sustainable supply chain. Business Strategy and Development, 6(4), 897–920. Scopus. [CrossRef]

- Chromjakova, F. (2023). Production Planning Process Based on the Work Psychology of a Collaborative Workplace with Humans and Robots. Machines, 11(2). Scopus. [CrossRef]

- Chromjakova, F. , Trentesaux, D., & Kwarteng, M. A. (2021). Human and cobot cooperation ethics: The process management concept of the production workplace. Journal of Competitiveness, 13(3), 21–38. Scopus. [CrossRef]

- Stankalla, R. , Koval, O., & Chromjakova, F. (2018). A review of critical success factors for the successful implementation of Lean Six Sigma and Six Sigma in manufacturing small and medium sized enterprises. Quality Engineering, 30(3), 453–468. Scopus. [CrossRef]

- Mozolova, L. , Grznar, P., Mozol, S., & Krajcovic, M. (2023). Streamlining utilisation of the assembly line using computer simulation. Acta Logistica, 10(2), 165–173. Scopus. [CrossRef]

- Mesarosova, J. , Martinovicova, K., Fidlerova, H., Chovanova, H. H., Babcanova, D., & Samakova, J. (2022). IMPROVING THE LEVEL OF PREDICTIVE MAINTENANCE MATURITY MATRIX IN INDUSTRIAL ENTERPRISE. Acta Logistica, 9(2), 183–193. Scopus. [CrossRef]

- Kubisova, E. , Grajzova, L., Cambal, M., & Babcanova, D. (2022). Implementation of elements of the Industry 4.0 concept and its impact on employees in line with Human Resource Management in industrial organisations in Slovakia. 352–357. Scopus. [CrossRef]

- Lorincová, S. , Čambál, M., Miklošík, A., Balážová, Z., Babel’ová, Z. G., & Hitka, M. (2020). Sustainability in business process management as an important strategic challenge in human resource management. Sustainability (Switzerland), 12(15). Scopus. [CrossRef]

Figure 1.

Special crane technology produced in the company.

Figure 1.

Special crane technology produced in the company.

Figure 2.

Workplace layout in the company.

Figure 2.

Workplace layout in the company.

Figure 3.

Analysis of company areas in %.

Figure 3.

Analysis of company areas in %.

Figure 4.

Representation of the analysed beam.

Figure 4.

Representation of the analysed beam.

Figure 5.

The working environment of the visTABLE program.

Figure 5.

The working environment of the visTABLE program.

Figure 6.

Workplace layout of the current state created in visTABLE.

Figure 6.

Workplace layout of the current state created in visTABLE.

Figure 7.

Workplace layout of the design state created in visTABLE.

Figure 7.

Workplace layout of the design state created in visTABLE.

Figure 8.

A demonstration of the removal of a sheet metal wall from the production hall.

Figure 8.

A demonstration of the removal of a sheet metal wall from the production hall.

Figure 9.

The current and design status of the stand drill.

Figure 9.

The current and design status of the stand drill.

Figure 10.

Placement of the stacker for rod material in the production preparation area.

Figure 10.

Placement of the stacker for rod material in the production preparation area.

Table 1.

Overview of the analysis of areas in the company.

Table 1.

Overview of the analysis of areas in the company.

| Area |

Surface (m²) |

Note |

| Production areas |

546 |

The area of the production hall |

| Warehouse areas |

19 |

Sheet metal and rods |

| Auxiliary surfaces |

30 |

Unpacking, waste sorting |

| Transport communications |

128 |

Traffic roads |

Table 2.

Duration and number of workers in the technological procedure of beam production.

Table 2.

Duration and number of workers in the technological procedure of beam production.

| Operation number |

Description of the operation |

Number of workers (pcs) |

Duration time (hours) |

| 1 |

Dividing the material (beam) to the required size. |

1.0 |

4.0 |

| 2 |

Sheet metal cutting - contact plates. |

1.0 |

4.0 |

| 3 |

Drilling holes for sheet metal. |

1.0 |

3.0 |

| 4 |

Grinding of material (beam). |

2.0 |

2.0 |

| 5 |

Firing the ends of the beam to accommodate the main cross member. |

1.0 |

4.0 |

| 6 |

Welding of contact plates to the beam. |

1.0 |

8.0 |

| 7 |

Checking the dimensions of the beam. |

2.0 |

0.3 |

| 8 |

Dividing the square (rail) to the required size. |

1.0 |

1.0 |

| 9 |

Welding the square to the beam. |

1.0 |

2.3 |

| 10 |

Check dimensions. |

2.0 |

0.3 |

Table 3.

Production progress table – analysis of production and material flow.

Table 3.

Production progress table – analysis of production and material flow.

Table 5.

Intensity of material flows between workplaces – current state.

Table 5.

Intensity of material flows between workplaces – current state.

| |

Receiver |

| Sender |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Σ |

| 1 |

|

|

|

|

20,000 |

|

|

|

|

20,000 |

| 2 |

|

|

|

|

|

400 |

|

|

|

400 |

| 3 |

|

|

|

1,500 |

|

|

|

|

|

1,500 |

| 4 |

|

|

|

|

|

|

|

|

1,200 |

1,200 |

| 5 |

|

|

|

|

|

|

|

19,000 |

|

19,000 |

| 6 |

|

|

|

|

|

|

300 |

|

|

300 |

| 7 |

|

|

|

|

|

|

|

|

240 |

240 |

| 8 |

|

|

|

|

|

|

|

|

19,000 |

19,000 |

| 9 |

|

|

|

|

|

|

|

|

|

- |

| Σ |

- |

- |

- |

1,500 |

20,000 |

400 |

300 |

19,000 |

20,440 |

61,640 |

Table 6.

Distance between workplaces in meters – current state.

Table 6.

Distance between workplaces in meters – current state.

| |

Receiver |

| Sender |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 1 |

|

|

|

|

30.0 |

|

|

|

|

| 2 |

|

|

|

|

|

1.5 |

|

|

|

| 3 |

|

|

|

3.0 |

|

|

|

|

|

| 4 |

|

|

|

|

|

|

|

|

19.0 |

| 5 |

|

|

|

|

|

|

|

10.0 |

|

| 6 |

|

|

|

|

|

|

16.0 |

|

|

| 7 |

|

|

|

|

|

|

|

|

5.0 |

| 8 |

|

|

|

|

|

|

|

|

4.0 |

| 9 |

|

|

|

|

|

|

|

|

|

Table 7.

Transport performance between workplaces – current state.

Table 7.

Transport performance between workplaces – current state.

| |

Receiver |

| Sender |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Σ |

| 1 |

|

|

|

|

60,000 |

|

|

|

|

60,000 |

| 2 |

|

|

|

|

|

600 |

|

|

|

600 |

| 3 |

|

|

|

4,500 |

|

|

|

|

|

4,500 |

| 4 |

|

|

|

|

|

|

|

|

22,800 |

22,800 |

| 5 |

|

|

|

|

|

|

|

19,000 |

|

19,000 |

| 6 |

|

|

|

|

|

|

4,800 |

|

|

4,800 |

| 7 |

|

|

|

|

|

|

|

|

1,200 |

1,200 |

| 8 |

|

|

|

|

|

|

|

|

76,000 |

76,000 |

| 9 |

|

|

|

|

|

|

|

|

|

- |

| Σ |

- |

- |

- |

4,500 |

60,000 |

600 |

4,800 |

19,000 |

100,000 |

899,900 |

Table 8.

The cost of transporting one piece of beam – current state.

Table 8.

The cost of transporting one piece of beam – current state.

| |

Receiver |

| Sender |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Σ |

| 1 |

|

|

|

|

900,000 |

|

|

|

|

900,000 |

| 2 |

|

|

|

|

|

900 |

|

|

|

900 |

| 3 |

|

|

|

6,750 |

|

|

|

|

|

6,750 |

| 4 |

|

|

|

|

|

|

|

|

34,200 |

34,200 |

| 5 |

|

|

|

|

|

|

|

285,000 |

|

285,000 |

| 6 |

|

|

|

|

|

|

7,200 |

|

|

7,200 |

| 7 |

|

|

|

|

|

|

|

|

1,800 |

1,800 |

| 8 |

|

|

|

|

|

|

|

|

114,000 |

114,000 |

| 9 |

|

|

|

|

|

|

|

|

|

- |

| Σ |

- |

- |

- |

6,750 |

900,000 |

900 |

7,200 |

285,000 |

150,000 |

1,349,850 |

Table 9.

Comparison of the current (C) and design solution (D).

Table 9.

Comparison of the current (C) and design solution (D).

| Oper. |

Duration (min.) |

Distance*/- (m) |

Description of the operation |

| C |

D |

C |

D |

| 1 |

20 |

20 |

30 |

30 |

17Entry of material into the production hall. |

| 2 |

240 |

240 |

|

|

Dividing the material (beam) to the required size. |

| 3 |

30 |

30 |

|

|

Checking the dimensions of the beam. |

| 4 |

10 |

10 |

10 |

10 |

Moving the beam to the workplace. |

| 5 |

120 |

120 |

|

|

Beam grinding. |

| 6 |

3 |

3 |

4 |

4 |

Transfer to the welding workplace. |

| 7 |

240 |

240 |

|

|

Firing the ends of the beam to accommodate the main cross member. |

| 8 |

3 |

3 |

1.5 |

1.5 |

Supply of sheet metal to the workplace. |

| 9 |

240 |

240 |

|

|

Cutting sheet metal to the required size. |

| 10 |

10 |

4 |

16 |

8 |

Moving the sheet to the drill. |

| 11 |

180 |

180 |

|

|

Drilling holes for sheet metal. |

| 12 |

5 |

4 |

5 |

4 |

Supply of contact plates to the beam. |

| 13 |

480 |

480 |

|

|

Welding of contact plates to the beam. |

| 14 |

30 |

30 |

|

|

Checking the dimensions of the beam. |

| 15 |

3 |

3 |

3 |

3 |

Moving the square to the first saw. |

| 16 |

60 |

60 |

|

|

Dividing the square to the required size. |

| 17 |

10 |

7 |

19 |

13 |

Supply of the square to the beam. |

| 18 |

150 |

150 |

|

|

Welding the square to the beam. |

| 19 |

30 |

30 |

|

|

Check dimensions. |

Table 10.

Summary of key indicators.

Table 10.

Summary of key indicators.

| Indicator |

Current solution |

Design solution |

Difference |

% difference |

| Distance (m) |

88.5 |

73.5 |

15 |

16.95 |

| Duration (min.) |

1,864 |

1,854 |

10 |

0.54 |

| Transport performance (pcs*m) |

899,900 |

890,060 |

9,840 |

1.09 |

| Transport costs per piece (€) |

1,349,850 |

1,335,090 |

14,760 |

1.09 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).