Submitted:

05 February 2024

Posted:

06 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

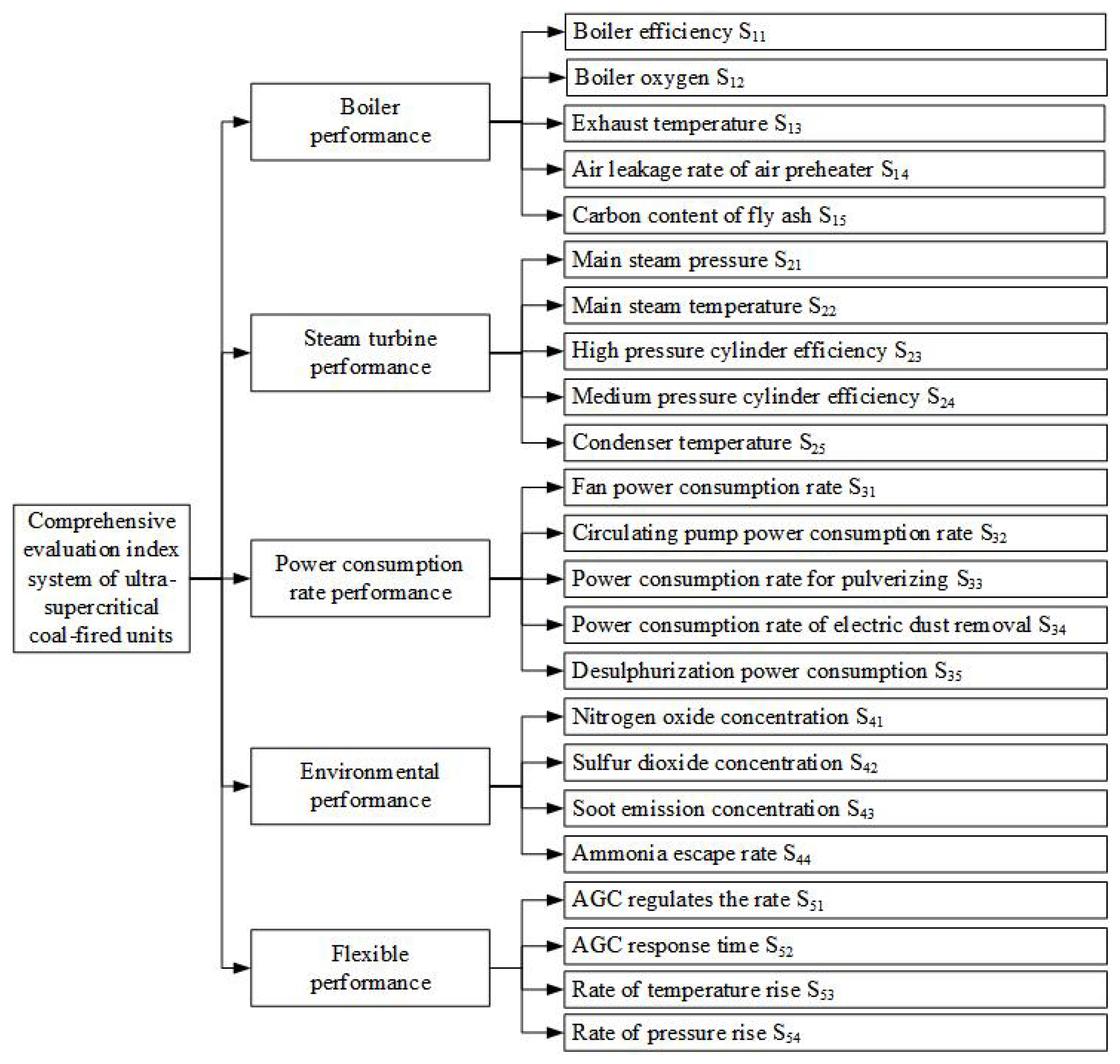

2. The Construction of Index System

2.1. Principle of Index System Construction

2.2. Index System of Coal-Fired Units

This is an example of a quote.

3. Methods

3.1. Improve CRITIC Method

3.2. Entropy Weight Method

3.3. Combinatorial Weighting

3.4. Aggregation Operator

3.4.1. TOWA Operator

3.4.2. TOWGA Operator

3.4.3. TOWA-TOWGA Hybrid Model

3.5. Determination of Time Weight

4. Results and discussion

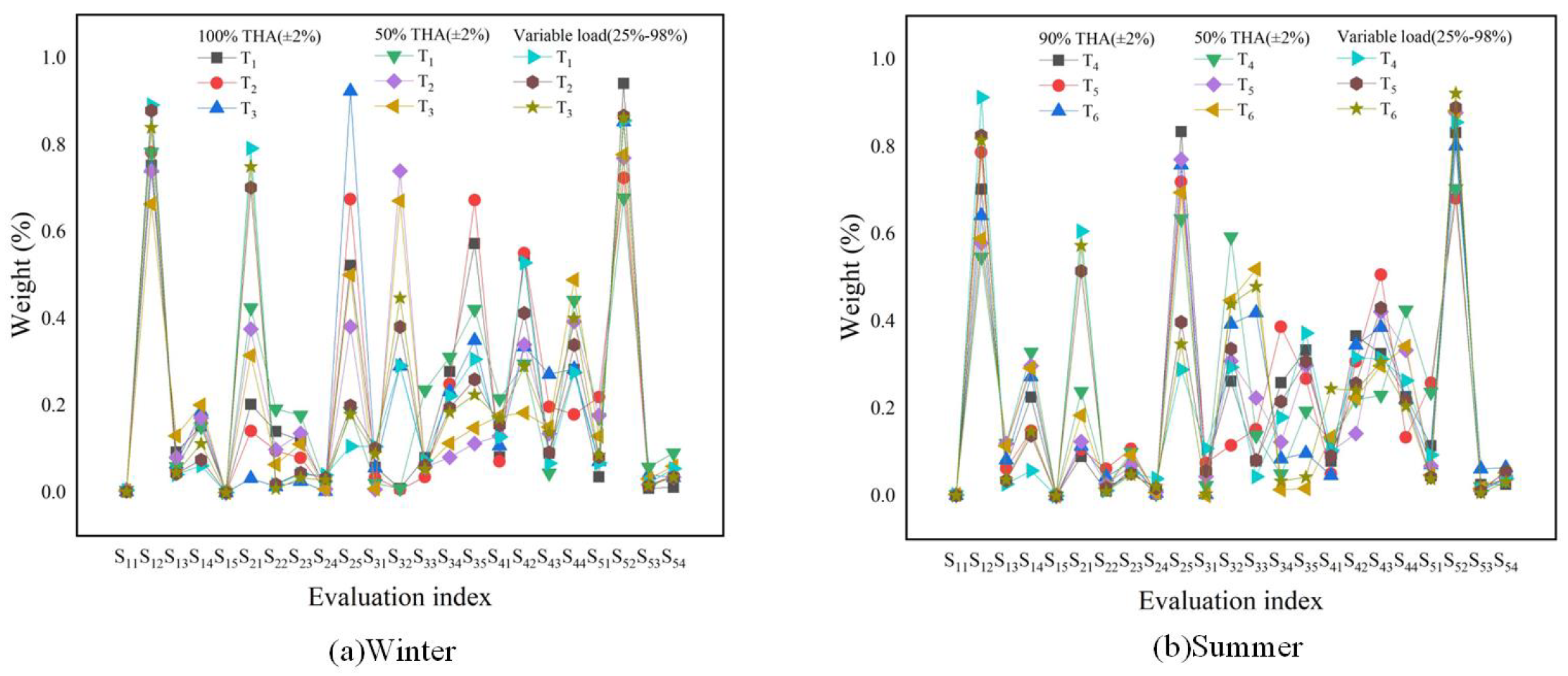

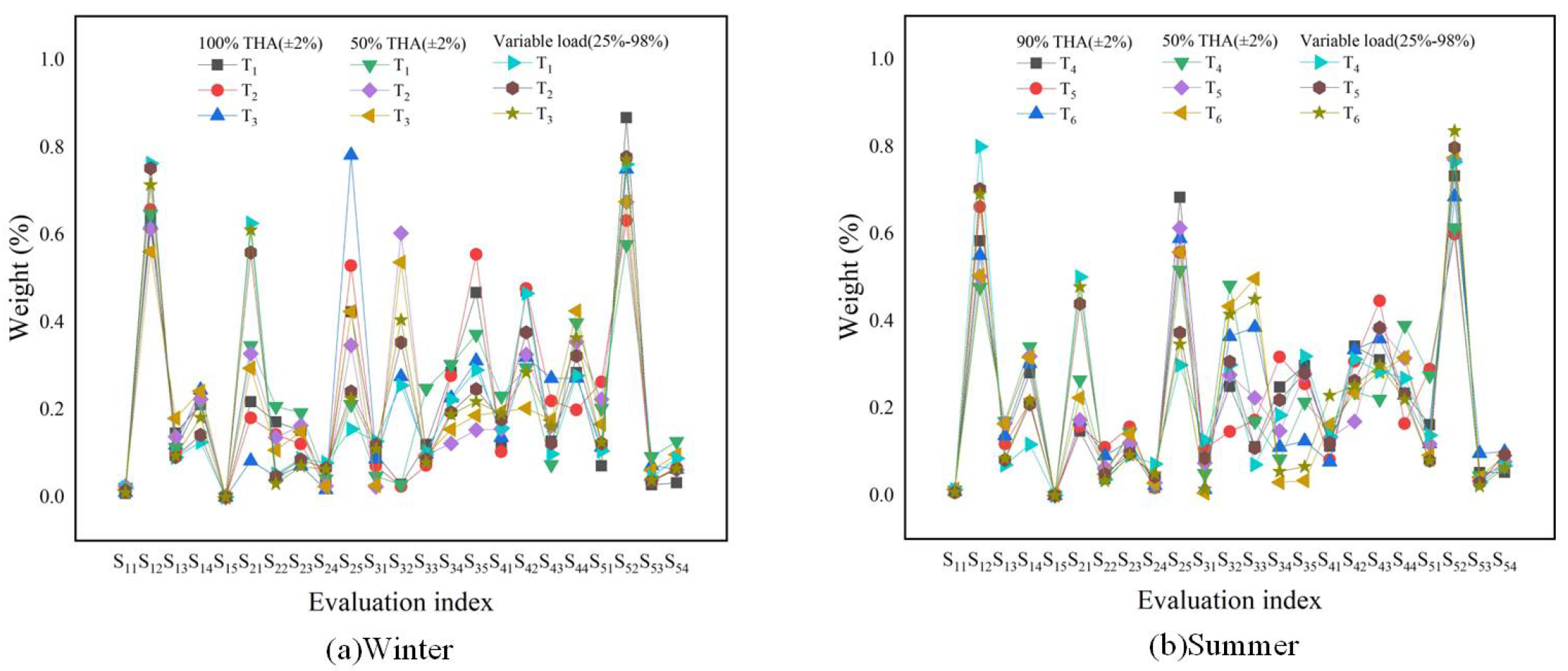

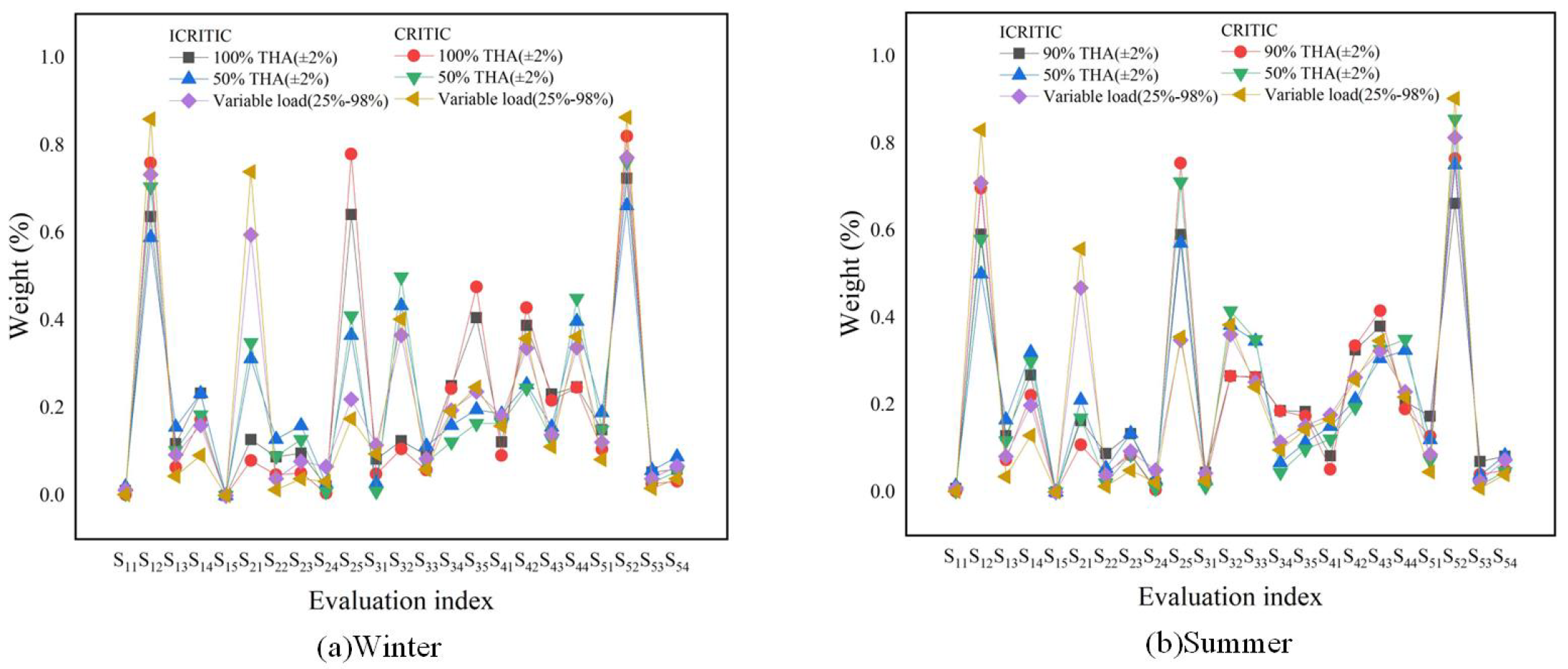

4.1. Determination of Combinatorial Weights

4.2. Determination of Combinatorial Weights

5. Conclusions

- 1.

- First item; This paper proposes a dynamic comprehensive evaluation model based on ICRITIC-EWM. The model aims to make the static weights of each evaluation index more objective, enabling efficient and accurate determination of the static weight parameters of coal-fired units.

- 2.

- Based on the actual running data of the power plant and the power plant performance assessment model in this paper, and analyzes the five comprehensive performances of the object power plant. Figure 4 and Table 4 show the different factors that affect the performance level of a power plant. shows the different factors that can affect the performance level of a power plant. These include the air leakage rate of the air preheater, condenser temperature, desulfurization power consumption rate, circulating pump power consumption rate, SO2 concentration, dust emission concentration, ammonia escape rate, and AGC response time. It is important for the operator of the power plant to consider these factors when aiming to improve the plant’s performance.

- 3.

- Most power plants do not conduct a comprehensive performance analysis for variable load conditions due to the lack of resources or expertise. Thus, this paper proposes using a dynamic and comprehensive evaluation model based on ICRITIC-EWM to obtain power plant operating state evaluation results at variable load. Furthermore, it is essential to conduct additional research on how to integrate the control system to establish a closed-loop regulation in the practical application of the power plant. This will enable the power plant to be automatically adjusted to achieve optimal operating conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chang, S.; Zhuo, J.; Meng, S. Clean coal technologies in China: current status and future perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Lyu, J. Eliminating Outdated Capacity to Promote Energy Conservation in China’s Coal-Fired Power Industry. Engineering 2019, 5, 194–196. [Google Scholar] [CrossRef]

- Tontu, M.; Sahin, B.; Bilgili, M. Analysis and performance assessment of coal-fired based integrated energy system for multigeneration. Energy Sources Part A: Recovery Util. Environ. Eff. 2023, 45, 6131–6149. [Google Scholar] [CrossRef]

- Zhang, X.; He, N. Study on Classification and Applicability of Comprehensive Evaluation Methods. Stat. Decis. 2022, 8, 31–36. [Google Scholar]

- Ma, T.; Li, M.J.; Xue, X.D. Study of Peak-load regulation characteristics of a 1000MWe S-CO2 Coal-fired power plant and a comprehensive evaluation method for dynamic performance. Appl. Therm. Eng. Des. Process. Equip. Econ. 2023, 221, 119892. [Google Scholar] [CrossRef]

- Chen, C.; Yan, X.Y.; Qi, H.R.; Kang, Y.L. An evaluation method of a roof photovoltaic access distribution network based on the weight of FAHP-improvement CRITIC combination. Power Syst. Prot. Control. 2023, 51, 97–108. [Google Scholar]

- Wang, Z.J.; Chen, W.; Zhu, X.X. Comprehensive Evaluation Method for Thermal Power Unit Flexibility Based on Data-driven and its Application. Mod. Electr. Power 2021. [Google Scholar]

- Huang, Z.; Zhou, H.; Miao, Z. Life-Cycle Carbon Emissions (LCCE) of Buildings: Implications, Calculations, and Reductionss. Engineering 2024. [Google Scholar] [CrossRef]

- Wang, S. Near-zero air pollutant emission technologies and applications for clean coal-fired power. Engineering 2020, 6, 1408–1422. [Google Scholar] [CrossRef]

- Ma, L.; Wang, R.; Fan, J. Index and evaluation method of source-network-load interaction for low-carbon development of coal-fired power plants. In 2022 4th International Conference on Electrical Engineering and Control Technologies (CEECT); IEEE: Piscataway, NJ, USA, 2022; pp. 1049–1053. [Google Scholar]

- Zhang, F.M. Dynamic comprehensive evaluation method and its applicatio; Beijing: Science Press, China, 2018. [Google Scholar]

- Zhou, Y.F.; Hu, W.; Min, Y. Dynamic Comprehensive Evaluation Method of Power Industry Development Level Based on Provincial Data. Autom. Electr. Power Syst. 2016, 40, 76–83. [Google Scholar]

- Guo, Y.J.; Yao, Y.; Yi, P.T. A Method and Application of Dynamic Comprehensive Evaluation. Syst. Eng. -Theory Pract. 2007, 10, 154–158. [Google Scholar] [CrossRef]

- Li, M.J.; Yuan, N.; Xu, L.M. ynamic Evaluation Method Based on Vertical Projection Methos. Chin. J. Manag. Sci. 2020, 28, 208–219. [Google Scholar]

- Wang, D.; Fang, X.Y.; Chen, X.G. CDynamic comprehensive evaluation of power grid emergency capability based on fuzzy-two-stage super efficiency SBM. Control. Decis. 2021, 36, 1333–1341. [Google Scholar]

- Zhang, Q.; Fang, Z.G. Research on the dynamic comprehensive evaluation model of multi-Source uncertain indexes based on the generalized grey incentive factors. Syst. Eng. Electron. 2019, 41, 586–593. [Google Scholar]

- Yang, S. Research on Technical and Economic Evaluation of Thermal Power Flexibility Modification Project; North China Electric Power University: Beijing, China, 2022. [Google Scholar]

- Wu, D.F. General Energy Consumption Evaluation Methods of Large Coal-Fired Power Generation Units; North China Electric Power University: Beijing, China, 2020. [Google Scholar]

- Chen, H.H.; Sun, W.F.; Zou, X.X. Evaluation method of power source reaching service term based on Fuzzy Analytical Hierar-chy Process and the Entropy Weight Method. J. Power Supply 2022. [Google Scholar]

- Feldman, Y.; Gulberg, Y. An extension of the immersed boundary method based on the distributed Lagrange multiplier approach. J. Comput. Phys. 2016, 322, 248–266. [Google Scholar] [CrossRef]

- Mokhtar, M.A.; Darpe, A.K.; Gupta, K. Investigations on bending-torsional vibrations of rotor during rotor-stator rub using Lagrange multiplier method. J. Sound Vib. 2017, 401, 94–113. [Google Scholar] [CrossRef]

- Yager, R.R. On ordered weighted averaging aggregation operators in multicriteria decision makin. IEEE Trans. Syst. Man Cybern. 1988, 18, 183–190. [Google Scholar] [CrossRef]

- Yager, R.R.; Filev, D.P. Induced Ordered Weighted Averaging Operators. IEEE Trans. Syst. Man Cybern. Part B 1999, 29, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.J.; Wan, Z.; Chen, J.H. Dynamic comprehensive evaluation on governance effect of regional maritime accidents. J. Saf. Environ. 2023. [Google Scholar]

| Significance | |

|---|---|

| 0.1 | Great emphasis on recent data |

| 0.3 | Pay more attention to recent data |

| 0.5 | Also focus on period data |

| 0.7 | Pay more attention to the forward data |

| 0.9 | Great emphasis on forward data |

| 0.2, 0.4, 0.6, 0.8 | The intermediate case corresponding to the above two adjacent judgments |

| Index | 100%THA(±2%) | 50%THA(±2%) | Variable load(25%-98%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.0080 | 0.0122 | 0.0111 | 0.0226 | 0.0254 | 0.0161 | 0.0205 | 0.0144 | 0.0099 | |

| 0.6344 | 0.6577 | 0.6244 | 0.6474 | 0.6134 | 0.5613 | 0.7631 | 0.7522 | 0.7143 | |

| 0.1462 | 0.1058 | 0.1195 | 0.1131 | 0.1376 | 0.1803 | 0.0908 | 0.0915 | 0.0943 | |

| 0.2113 | 0.2243 | 0.2449 | 0.2169 | 0.2236 | 0.2423 | 0.1256 | 0.1420 | 0.1816 | |

| 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | |

| 0.2178 | 0.1807 | 0.0830 | 0.3461 | 0.3281 | 0.2949 | 0.6262 | 0.5593 | 0.6110 | |

| 0.1716 | 0.1429 | 0.0471 | 0.2073 | 0.1359 | 0.1073 | 0.0524 | 0.0474 | 0.0302 | |

| 0.1518 | 0.1213 | 0.0710 | 0.1932 | 0.1636 | 0.1493 | 0.0882 | 0.0859 | 0.0708 | |

| 0.0350 | 0.0256 | 0.0168 | 0.0417 | 0.0249 | 0.0240 | 0.0781 | 0.0662 | 0.0632 | |

| 0.4237 | 0.5295 | 0.7821 | 0.2117 | 0.3475 | 0.4244 | 0.1552 | 0.2412 | 0.2248 | |

| 0.0976 | 0.0713 | 0.0870 | 0.0472 | 0.0231 | 0.0264 | 0.1275 | 0.1198 | 0.1096 | |

| 0.0292 | 0.0240 | 0.2759 | 0.0282 | 0.6038 | 0.5370 | 0.2553 | 0.3535 | 0.4052 | |

| 0.1199 | 0.0725 | 0.0982 | 0.2486 | 0.0969 | 0.0953 | 0.1034 | 0.0862 | 0.0782 | |

| 0.2855 | 0.2772 | 0.2270 | 0.3037 | 0.1224 | 0.1547 | 0.2230 | 0.1937 | 0.1885 | |

| 0.4677 | 0.5551 | 0.3119 | 0.3723 | 0.1537 | 0.1866 | 0.2908 | 0.2468 | 0.2185 | |

| 0.1166 | 0.1037 | 0.1366 | 0.2312 | 0.1556 | 0.1950 | 0.1580 | 0.1775 | 0.1903 | |

| 0.4714 | 0.4768 | 0.3200 | 0.2962 | 0.3261 | 0.2028 | 0.4656 | 0.3767 | 0.2849 | |

| 0.1274 | 0.2200 | 0.2714 | 0.0740 | 0.1633 | 0.1767 | 0.0983 | 0.1230 | 0.1615 | |

| 0.2846 | 0.1995 | 0.2720 | 0.3986 | 0.3550 | 0.4255 | 0.2780 | 0.3228 | 0.3634 | |

| 0.0715 | 0.2632 | 0.1142 | 0.2029 | 0.2231 | 0.1665 | 0.1055 | 0.1226 | 0.1252 | |

| 0.8677 | 0.6324 | 0.7506 | 0.5780 | 0.6750 | 0.6754 | 0.7611 | 0.7779 | 0.7718 | |

| 0.0280 | 0.0375 | 0.0718 | 0.0921 | 0.0392 | 0.0613 | 0.0452 | 0.0359 | 0.0384 | |

| 0.0328 | 0.0669 | 0.0635 | 0.1270 | 0.0628 | 0.0968 | 0.0882 | 0.0635 | 0.0646 | |

| Index | 90%THA(±2%) | 50%THA(±2%) | Variable load(25%-98%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.0094 | 0.0063 | 0.0094 | 0.0124 | 0.0130 | 0.0142 | 0.0126 | 0.0071 | 0.0073 | |

| 0.5838 | 0.6621 | 0.5509 | 0.4771 | 0.5025 | 0.5046 | 0.8002 | 0.7027 | 0.6911 | |

| 0.1255 | 0.1180 | 0.1371 | 0.1695 | 0.1651 | 0.1645 | 0.0701 | 0.0813 | 0.0848 | |

| 0.2813 | 0.2135 | 0.3026 | 0.3410 | 0.3194 | 0.3167 | 0.1170 | 0.2089 | 0.2169 | |

| 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | |

| 0.1477 | 0.1583 | 0.1712 | 0.2646 | 0.1734 | 0.2239 | 0.5009 | 0.4394 | 0.4787 | |

| 0.0388 | 0.1104 | 0.0909 | 0.0519 | 0.0640 | 0.0488 | 0.0365 | 0.0485 | 0.0332 | |

| 0.1113 | 0.1569 | 0.1253 | 0.1448 | 0.1203 | 0.1415 | 0.0920 | 0.0957 | 0.0921 | |

| 0.0183 | 0.0174 | 0.0229 | 0.0216 | 0.0285 | 0.0276 | 0.0717 | 0.0432 | 0.0495 | |

| 0.6839 | 0.5571 | 0.5897 | 0.5171 | 0.6138 | 0.5582 | 0.2988 | 0.3732 | 0.3464 | |

| 0.0920 | 0.1074 | 0.0135 | 0.0501 | 0.0741 | 0.0054 | 0.1269 | 0.0853 | 0.0138 | |

| 0.2497 | 0.1461 | 0.3647 | 0.4825 | 0.2762 | 0.4340 | 0.2992 | 0.3067 | 0.4155 | |

| 0.1117 | 0.1728 | 0.3859 | 0.1700 | 0.2238 | 0.4969 | 0.0704 | 0.1087 | 0.4496 | |

| 0.2487 | 0.3178 | 0.1110 | 0.0833 | 0.1474 | 0.0298 | 0.1841 | 0.2189 | 0.0549 | |

| 0.2979 | 0.2558 | 0.1249 | 0.2142 | 0.2785 | 0.0340 | 0.3194 | 0.2803 | 0.0662 | |

| 0.1127 | 0.0819 | 0.0767 | 0.1517 | 0.1315 | 0.1628 | 0.1354 | 0.1211 | 0.2295 | |

| 0.3424 | 0.3073 | 0.3340 | 0.2378 | 0.1697 | 0.2359 | 0.3122 | 0.2631 | 0.2521 | |

| 0.3108 | 0.4462 | 0.3592 | 0.2205 | 0.3837 | 0.2845 | 0.2837 | 0.3846 | 0.2985 | |

| 0.2342 | 0.1647 | 0.2300 | 0.3900 | 0.3151 | 0.3168 | 0.2687 | 0.2312 | 0.2199 | |

| 0.1622 | 0.2897 | 0.1186 | 0.2748 | 0.1181 | 0.0921 | 0.1380 | 0.0795 | 0.0795 | |

| 0.7328 | 0.5992 | 0.6849 | 0.6139 | 0.7710 | 0.7752 | 0.7646 | 0.7977 | 0.8362 | |

| 0.0522 | 0.0420 | 0.0965 | 0.0445 | 0.0331 | 0.0411 | 0.0295 | 0.0294 | 0.0211 | |

| 0.0528 | 0.0691 | 0.1001 | 0.0669 | 0.0777 | 0.0915 | 0.0680 | 0.0935 | 0.0632 | |

| Index | Winter | Summer | ||||

|---|---|---|---|---|---|---|

| 100%THA (±2%) | 50%THA (±2%) | Variable load (25%-98%) | 90%THA (±2%) | 50%THA (±2%) | Variable load (25%-98%) | |

| 0.0110 | 0.0198 | 0.0126 | 0.0083 | 0.0136 | 0.0079 | |

| 0.6367 | 0.5897 | 0.7333 | 0.5913 | 0.5002 | 0.7091 | |

| 0.1182 | 0.1560 | 0.0929 | 0.1290 | 0.1654 | 0.0816 | |

| 0.2334 | 0.2326 | 0.1601 | 0.2684 | 0.3208 | 0.1991 | |

| 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | |

| 0.1279 | 0.3125 | 0.5955 | 0.1637 | 0.2114 | 0.4683 | |

| 0.0883 | 0.1285 | 0.0383 | 0.0885 | 0.0541 | 0.0384 | |

| 0.0962 | 0.1596 | 0.0780 | 0.1335 | 0.1347 | 0.0933 | |

| 0.0217 | 0.0264 | 0.0661 | 0.0204 | 0.0270 | 0.0500 | |

| 0.6415 | 0.3661 | 0.2200 | 0.5908 | 0.5708 | 0.3486 | |

| 0.0829 | 0.0277 | 0.1153 | 0.0450 | 0.0258 | 0.0434 | |

| 0.1248 | 0.4342 | 0.3660 | 0.2661 | 0.3832 | 0.3616 | |

| 0.0918 | 0.1126 | 0.0840 | 0.2643 | 0.3462 | 0.2521 | |

| 0.2508 | 0.1602 | 0.1947 | 0.1869 | 0.0672 | 0.1145 | |

| 0.4063 | 0.1961 | 0.2370 | 0.1849 | 0.1136 | 0.1517 | |

| 0.1225 | 0.1859 | 0.1816 | 0.0829 | 0.1505 | 0.1768 | |

| 0.3887 | 0.2531 | 0.3367 | 0.3261 | 0.2128 | 0.2634 | |

| 0.2319 | 0.1559 | 0.1391 | 0.3802 | 0.3064 | 0.3239 | |

| 0.2481 | 0.3978 | 0.3378 | 0.2075 | 0.3256 | 0.2299 | |

| 0.1499 | 0.1893 | 0.1216 | 0.1740 | 0.1204 | 0.0864 | |

| 0.7248 | 0.6618 | 0.7724 | 0.6619 | 0.7512 | 0.8136 | |

| 0.0528 | 0.0569 | 0.0384 | 0.0699 | 0.0388 | 0.0248 | |

| 0.0599 | 0.0882 | 0.0672 | 0.0823 | 0.0834 | 0.0733 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).