Introduction

Carbon fiber foam core structure had high specific strength and specific stiffness, good stability, corrosion resistance, structural designability and other excellent properties. It was widely used in the industrial sector [

1,

2,

3]. However, in the daily use and maintenance process, it was often subjected to low-energy impacts from various external objects such as hailstones and maintenance tools, resulting in damage and causing significant performance degradation [

4]. Therefore, it was very necessary to study the damage of carbon fiber foam core structure after low-speed impact.

Domestic and foreign scholars had done considerable research on low-energy impact of composite foam sandwich structures. Azimpour-Shishevan F et al. [

5] added graphene nanosheets to the composite material, reducing rebound by increasing contact force, thereby enhancing the ability of the composite material to resist low-speed impact. Zhang Wenping et al. [

6] conducted a mechanical analysis of the dynamic response characteristics of a new bionic honeycomb sandwich structure under low-speed oblique impact by establishing a finite element model. With the increase of the impact angle, the peak value of the load and the damage area decreased. Li Jing [

7] analyzed and studied the pollution in the production of composite honeycomb sandwich structure. The research showed that oil pollution and other pollution of the honeycomb cannot be inspected by non-destructive testing, and it will lead to debonding defects and expansion of sandwich structure. Gao Chunyun et al. [

8] studied the low-velocity impact response of symmetrical sandwich structures. The results showed that when the total thickness of the upper and lower panels is constant, increasing the thickness ratio of the upper and lower panels is helpful to improve the low-velocity impact resistance of the sandwich structure. Zhou Chunhua et al. [

9] effectively extracted the impact time domain signal and obtained the impact energy cloud diagram. The experimental results showed that any sensor in the sensing network can detect four damage locations. Yang Kang et al. [

10] studied the influence of foam sandwich thickness on the impact performance of composite sandwich panels. The results indicated that the larger the thickness, the stronger the span wise guidance energy of the impact energy, and the smaller the damage depth. Luo Wei [

11] provided a system of second-order nonlinear differential equations, which can be applied to the rapid prediction of low-speed impact response of corrugated core material hybrid sandwich structures using this approximate calculation method. Mohan et al. [

12] conducted an impact response analysis of foam aluminum with different panel materials through experiments. The results showed that the impact resistance of the material can be improved by changing the panel material, panel thickness, and foam core size. Sun Ziheng and J. Zhou [

13,

14,

15,

16,

17,

18,

19,

20,

21] studied the impact damage of composite sandwich structures from different stacking methods, different impact methods and different fiber layers, trying to find a structure with high impact resistance. Luo Zhiqiang et al. [

22,

23,

24,

25] through the study of stitched foam sandwich structure technology, effectively improved the impact resistance of the structure. Duan Youshe [

26] studied the low-velocity impact damage properties of Z-direction reinforced composite structures. The results indicated that when the reinforcing material is carbon fiber, the compressive strength and CAI strength are improved.

In this paper, the finite element equivalent model of low-velocity impact of carbon fiber foam sandwich panel was established based on Hashin failure criterion. The experimental results were compared with the finite element numerical simulation results to prove the effectiveness of the impact equivalent model. The impact damage of other carbon fiber foam sandwich panels with different ply structures was predicted. It provided theoretical basis and data support for the design of foam sandwich structure.

1. Experimental

1.1. Preparation of Specimen

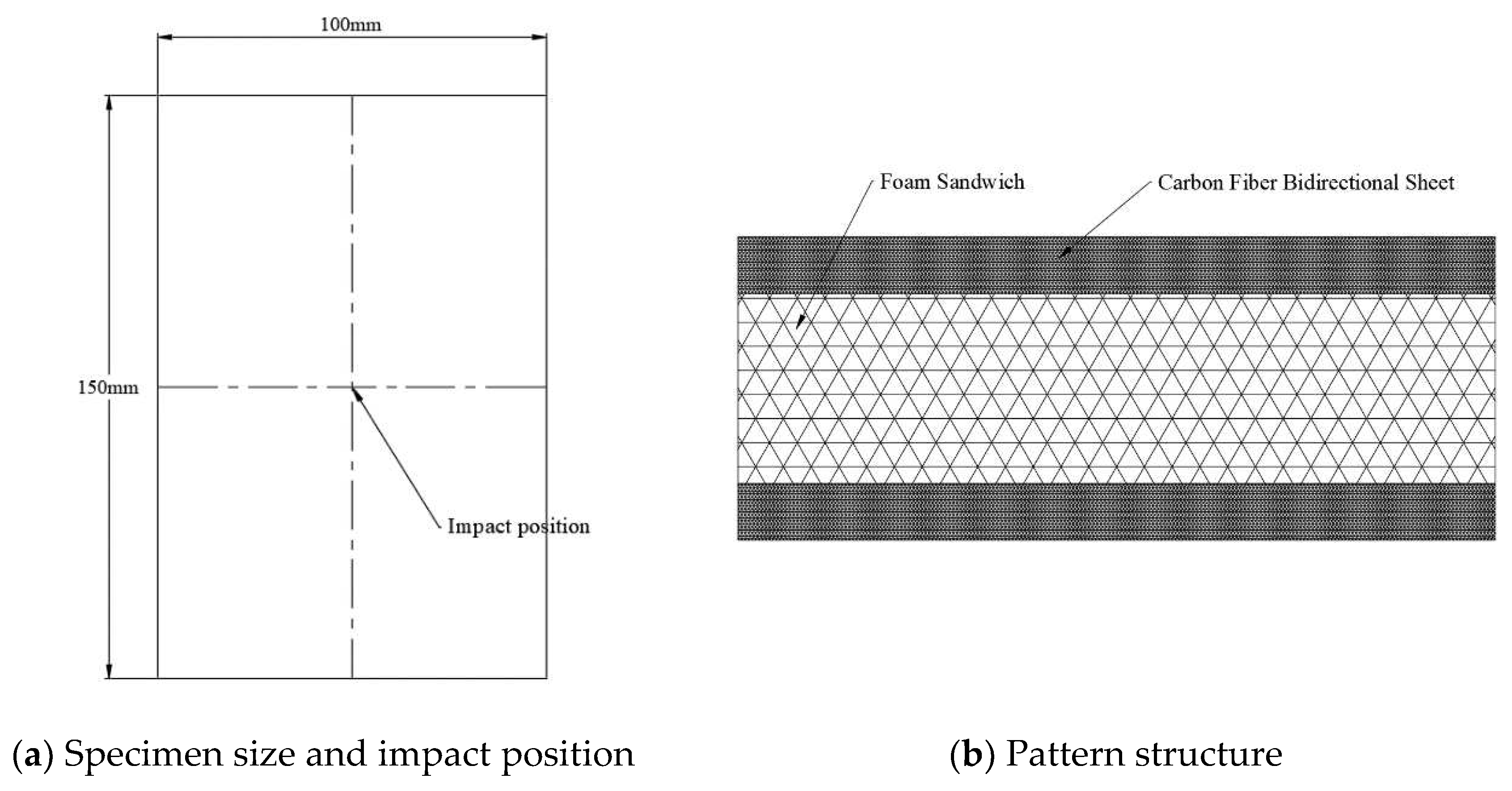

The structure of the specimen in this test was carbon fiber composite foam sandwich structure. Carbon fiber woven fabric grade W-3021FF and foam material grade H60. The specimen was processed by hand paste vacuum bag pressing process. The ply direction of carbon fiber reinforced fiber material was [±45°/±45°/ (core) /±45°/±45°], and the thickness of foam sandwich foam was 4mm. The formed test pieces were cut into 150mm×100mm standard test pieces by water cutting machine, as was shown in

Figure 1.

1.2. Test Method

This test was carried out according to ASTM D7136 standard. The impact hammer was used to impact the test specimen, and the impact damage effect was obtained. The impact energy was set to 10.58J, 21.17J, 31.75J, and 42.34J in the test, and the corresponding test numbers were San-A01, San-A02, San-A03, and San-A04. Four specimens were tested in each group to reduce the test error, and the results were averaged. The method of microscope C-scan was used to show the damage characteristics after impact.

2. Test Result

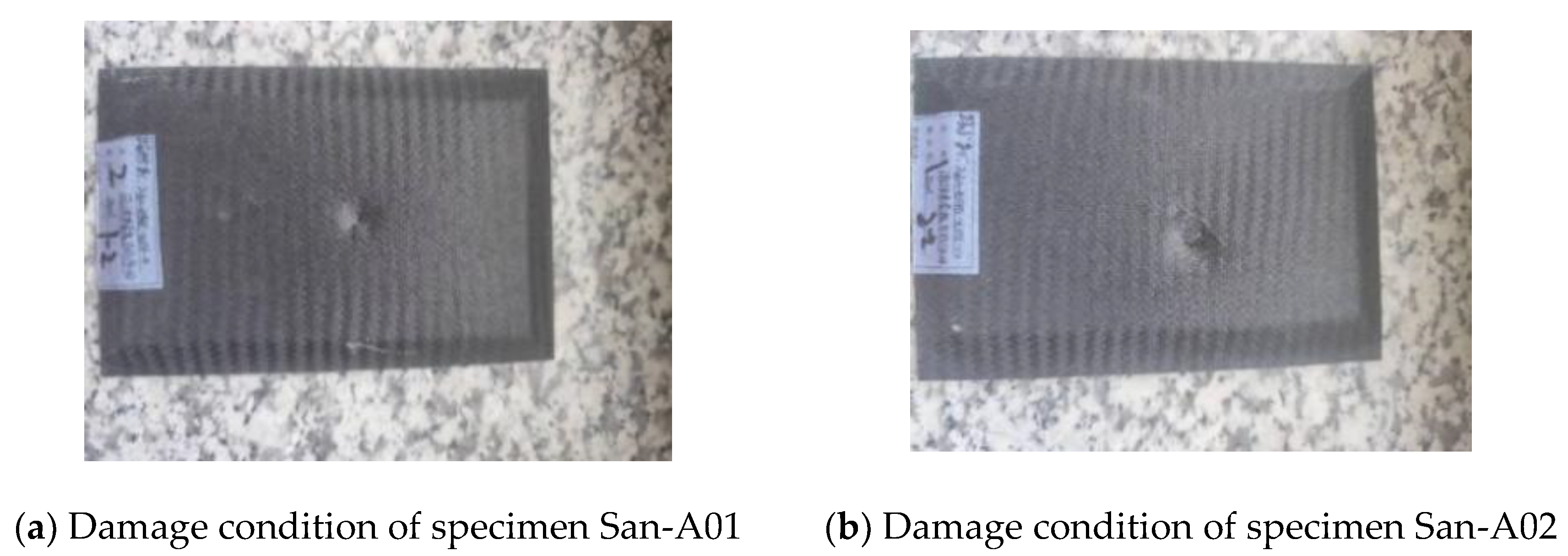

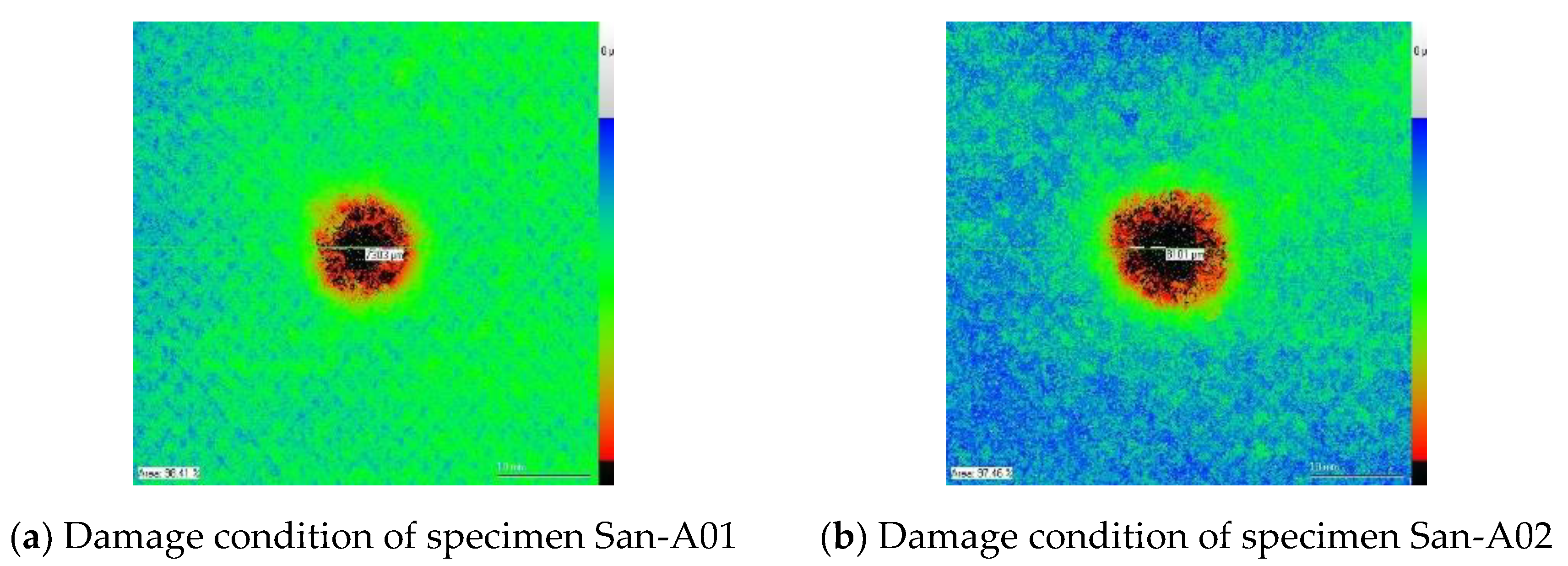

The impact damage of the specimen was shown in

Figure 2. With the increase of impact energy, the surface damage of the specimen was increasing. The specimen was completely penetrated when the energy increases to 42.34J, and the foam crushed by the impact can be observed. The upper panel had X-shaped damage marks, and fiber cracks can be observed along the 45° direction at the impact location.

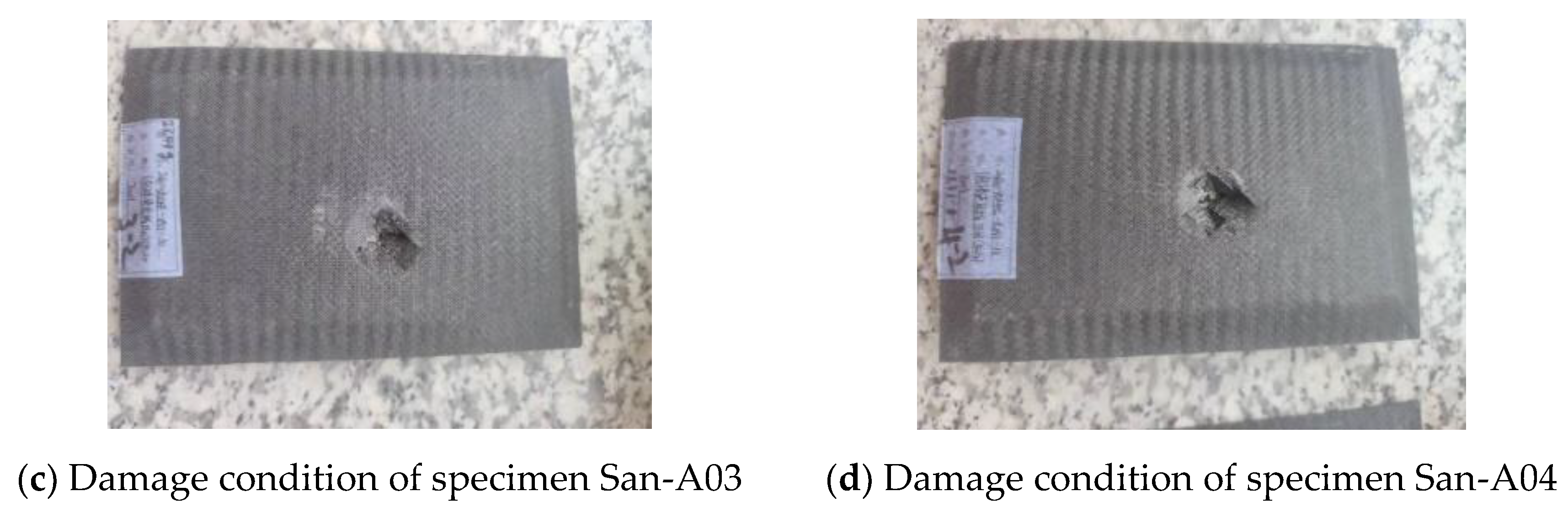

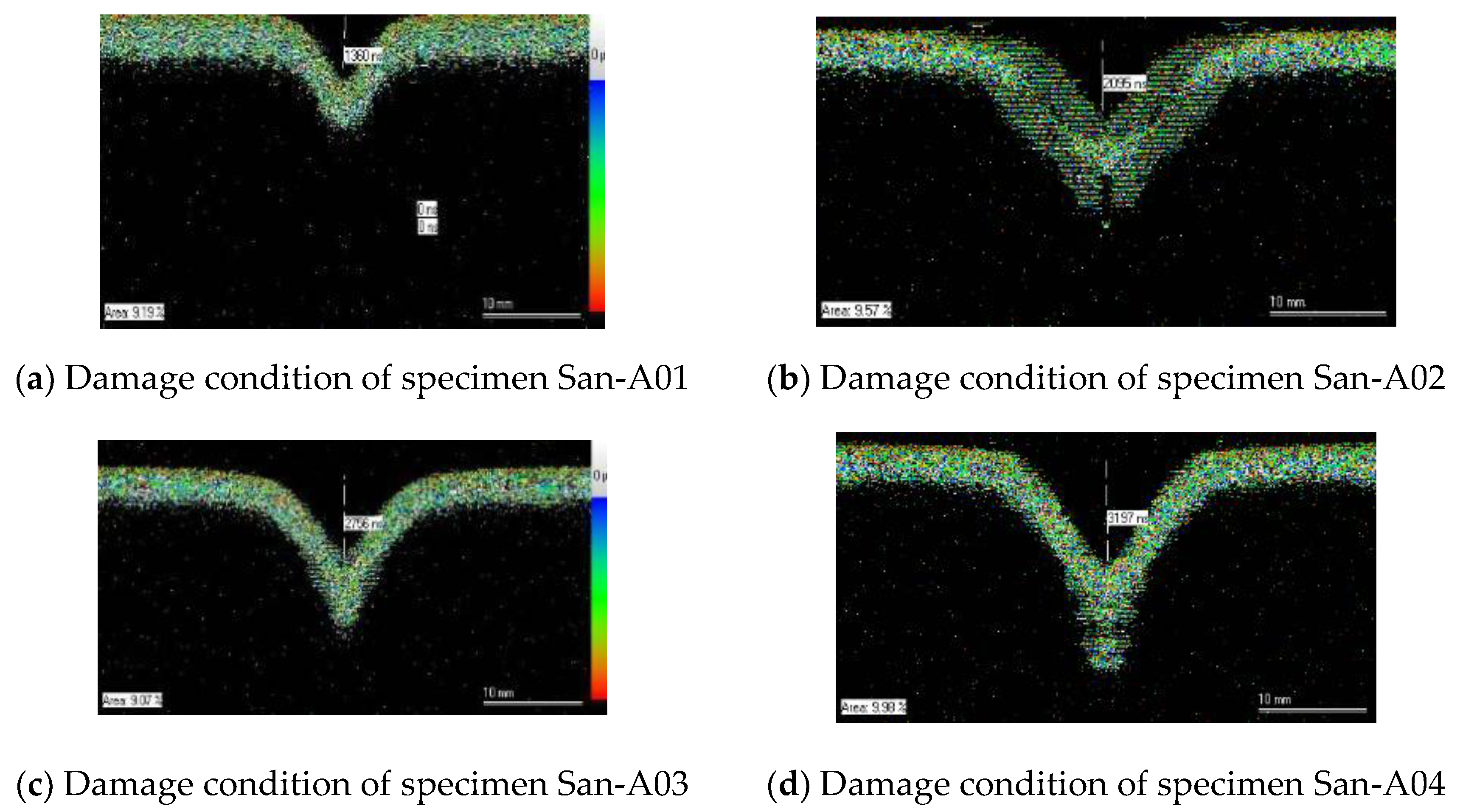

The damage characteristics of the specimen after impact obtained by microscope C-scan were shown in

Figure 3 and

Figure 4. The variation of the depth and size of the impact damage area of each group of test specimens under different impact energy was the same. With the increase of impact energy, the depth and diameter of the impact damage area of the test specimen gradually increased.

3. Finite Element Simulation and Comparative Analysis

3.1. Result of Impact Simulation

The same ply mode and size data as the test specimen of the impact test were used in the finite element numerical simulation. The impact simulation model was built in Abaqus. The impact position was the center of the model, and the thickness of the foam core was 4mm. The failure model of carbon fiber panel adopted two-dimensional Hashin failure model, and the elastic parameter type of carbon fiber material was Lamina model.

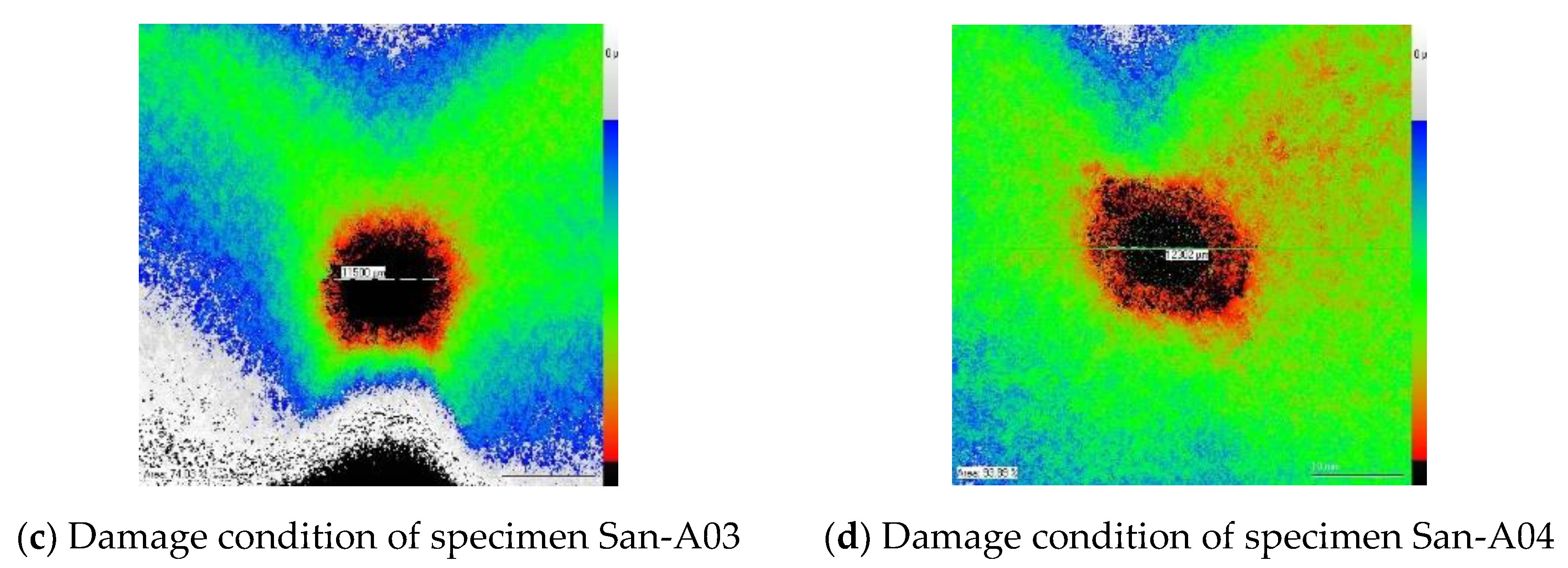

The simulation type was EXPLICIT display analysis. The upper and lower panels of the model used the universal continuous shell element SC8R in the 8-node quadrilateral plane to simulate the carbon fiber panel, to effectively reduce the hourglass integration. The foam core material was defined as isotropic material, and the eight-node hexahedron C3D8R solid element of linear reduced integral element was used for modeling. The impact head was set as a rigid body, the elastic modulus was 210 GPa, the Poisson's ratio was 0.3, the mass was set to 5.5kg by adjusting the density, and the unit type was C3D8R solid unit. The impact height of the drop hammer was equivalently replaced by the dynamic formula. The initial velocity of the punch was 2.775m/s, which corresponds to the corresponding impact energy of 21.17J, and the corresponding test specimen number was San-A02. The finite element numerical simulation results of the San-A02 specimen were compared with the damage of the upper panel of the impact test. As shown in

Figure 5, the damage shapes of both were nearly X-shaped, and the fibers were broken along the punch to the periphery. The damage can be obviously seen in upper panel, and the damage areas of both are consistent.

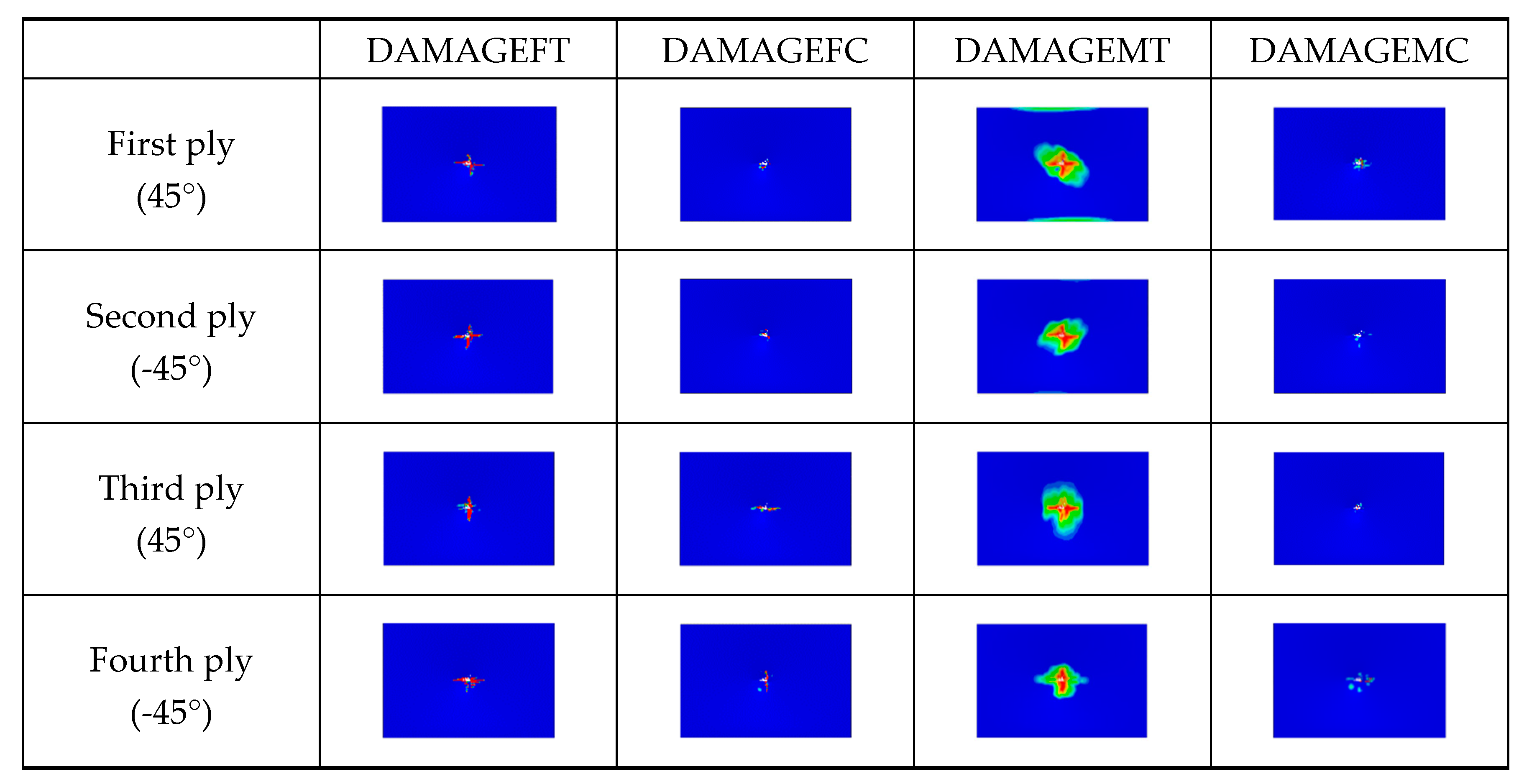

Four damage failure modes of composites were defined based on the Hashin failure criterion: Fiber tensile failure (DAMAGEFT), fiber compression failure (DAMAGEFC), matrix tensile failure (DAMAGEMT) and matrix compression failure (DAMAGEMC). In this paper, ABAQUS / EXPLICT was used to simulate the damage process of typical foam sandwich panels under low-speed impact. The panel failure area is red in the post-processing if the damage effect of each layer of the upper and lower panels of the carbon fiber foam sandwich panel meets the failure criterion. At the same time, the unit deletion function was set up in the modeling process: the unit will be automatically deleted if only the four failure conditions are satisfied in a single layer.

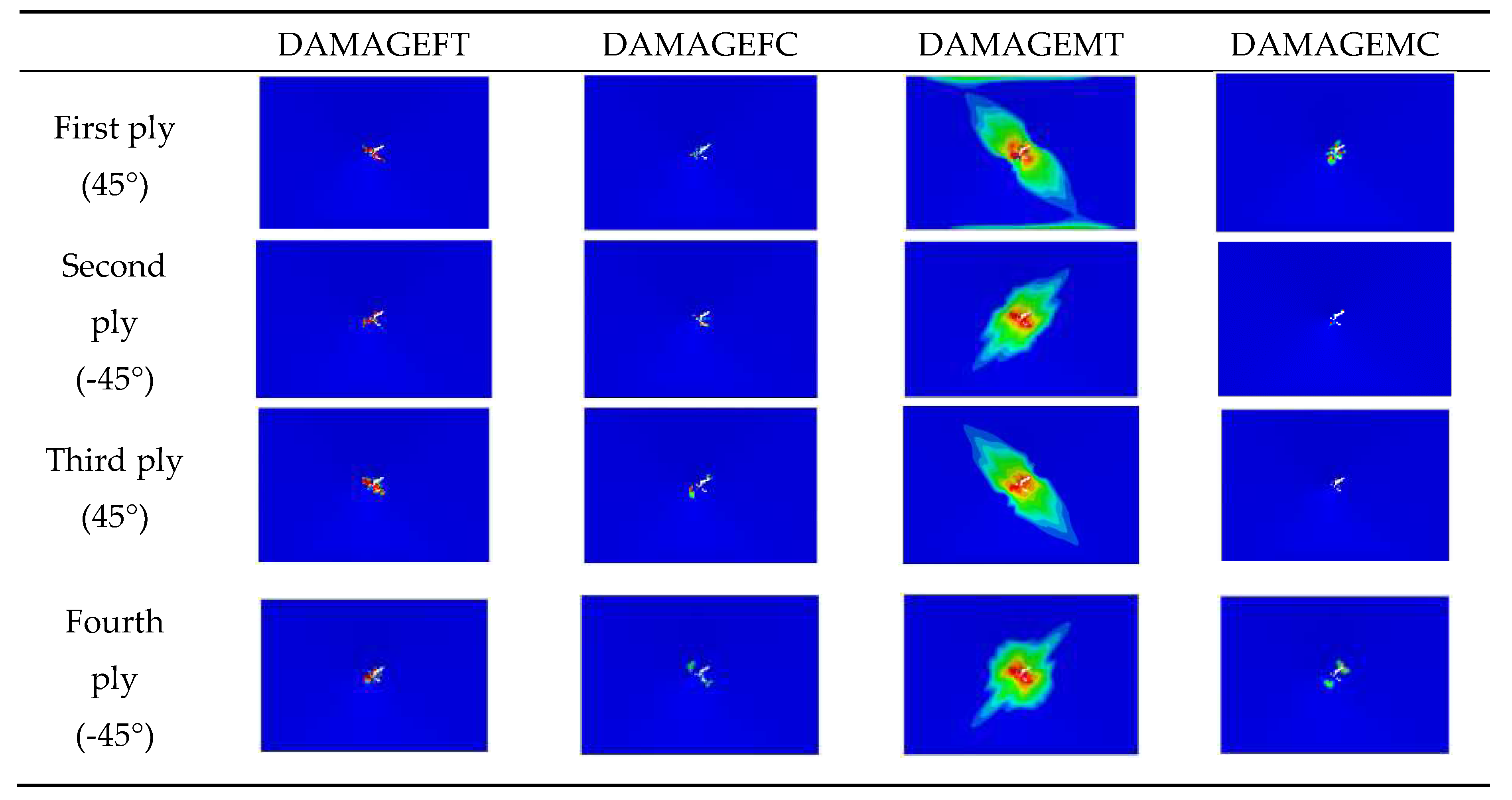

The material damage condition of each layer of San-A02 under the impact energy of 21.17J was shown in

Table 1. The failure part in the table was mainly the area affected by the impact. The most areas where the failure occurred was mainly affected by the impact. It can be seen that the layer unit was deleted, indicating that the carbon fiber of upper panel of the San-A02 was damaged under 21.17J, and the remaining red areas indicated that the carbon fiber or the matrix material failed in each failure mode. The results of the finite element simulation showed that the failure mode of the upper panel of the sandwich panel was mainly the tensile failure of the carbon fiber and the tensile failure of the matrix, and the failure in compression was rare, and the direction of the tensile failure of the carbon fiber was consistent with the direction of the panel ply structure.

3.2. Comparative Analysis of Low-Velocity Impact Response

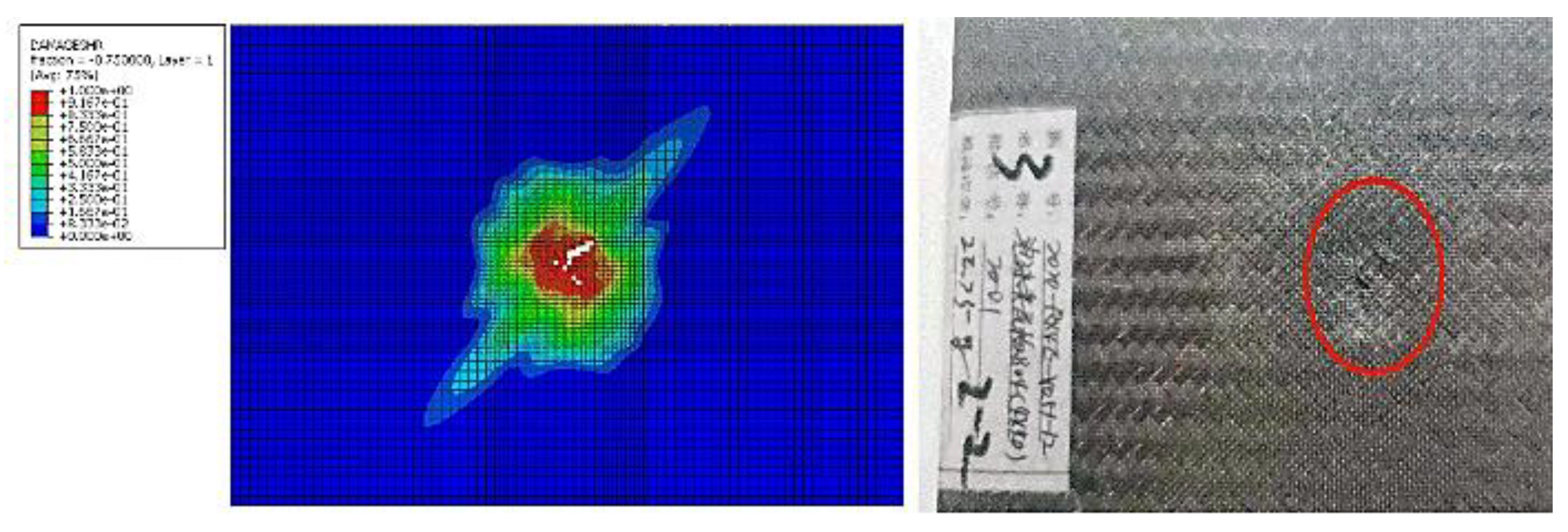

The damage depth and surface damage diameter measured by microscope C-scan were compared with the result of finite element numerical simulation to verify the effectiveness of the model in forecasting the low-velocity impact response and impact loss of carbon fiber composite foam sandwich panels. The finite element simulation process started as the punch contacts the panel, and the speed dropped to zero and then to the sandwich panel rebound punch until the specimen was stable.

Considering the elastic properties of the foam, the impact force on the panel was taken as the target for analysis, and the deformation of the overall model when the impact force changes from low to high and then to zero was taken as the target to reflect the real damage. The comparison between the damage area of finite element simulation and the C-scan was shown in

Figure 6. The direct contact position of the punch was the damage position. The upper panel of carbon fiber composite was directly impacted in the finite element numerical simulation, and the panel damage was only in the local area near the impact position. The comparison between the test values and the predicted values of finite element model simulation of San-A01~04 was shown in

Table 2. The test and simulation had good consistency since the error between the test values and the predicted values was less than 10%, and it proved that the composite sandwich plate model and the compressible foam model theory used in this paper can effectively simulate the damage process of carbon fiber composite foam plate under low-speed impact.

4. Impact Damage Prediction of Foam Sandwich Plate under Different Ply Forms

4.1. Analysis of Damage Condition of Each Layer

The finite element numerical analysis of three different sandwich panels was carried out. The numbers were San-A, San-B and San-C respectively. The ply of the panel was shown in

Table 3, and the impact energy was set to 21.17J.

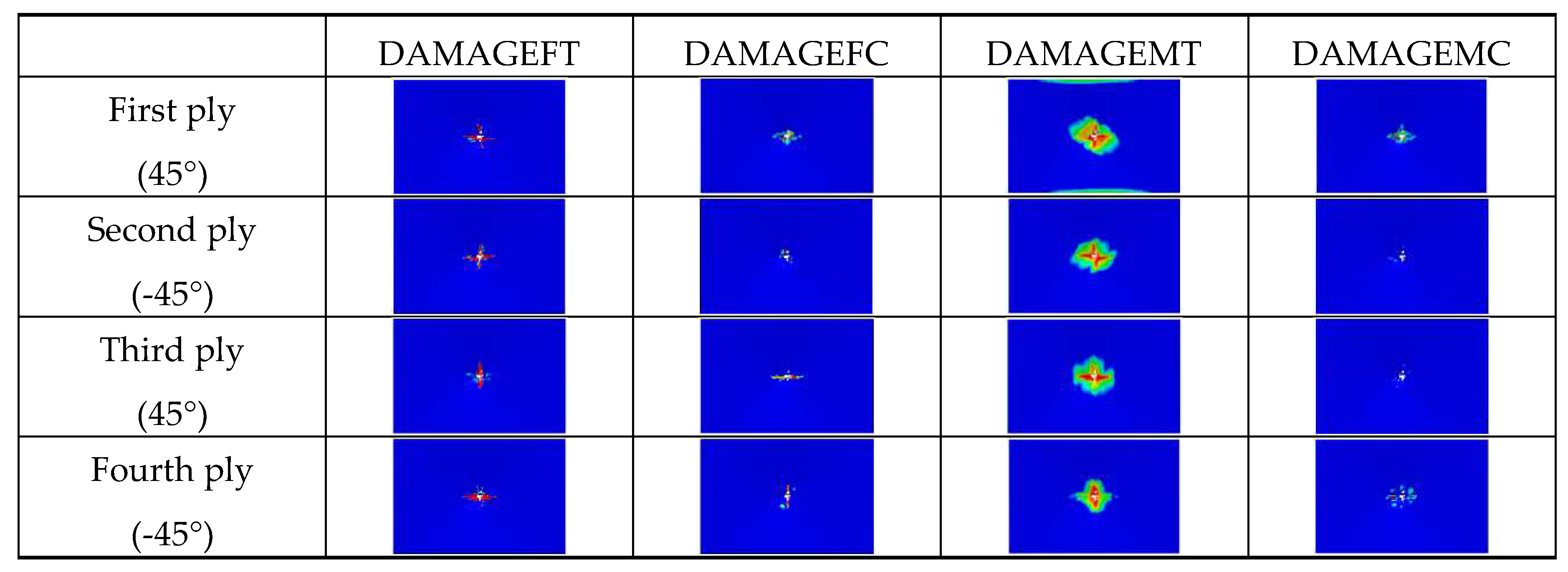

The damage of the upper and lower surfaces of the San-B was shown in

Table 4. Compared with San-A02, the depth of the two was similar, but the surface damage diameter and the matrix damage of the upper and lower panels of San-B were greater than San-A02, and the fiber breakage was also more obvious than the latter. Since the different thickness of the layer, the damage along the compression direction can be seen in the lower panel of San-B, while this phenomenon was almost invisible in the San-A02 lower panel. In summary, the increase of the proportion of [± 45°] direction layer in the carbon fiber composite plate can improve the impact resistance of the carbon fiber composite foam sandwich plate.

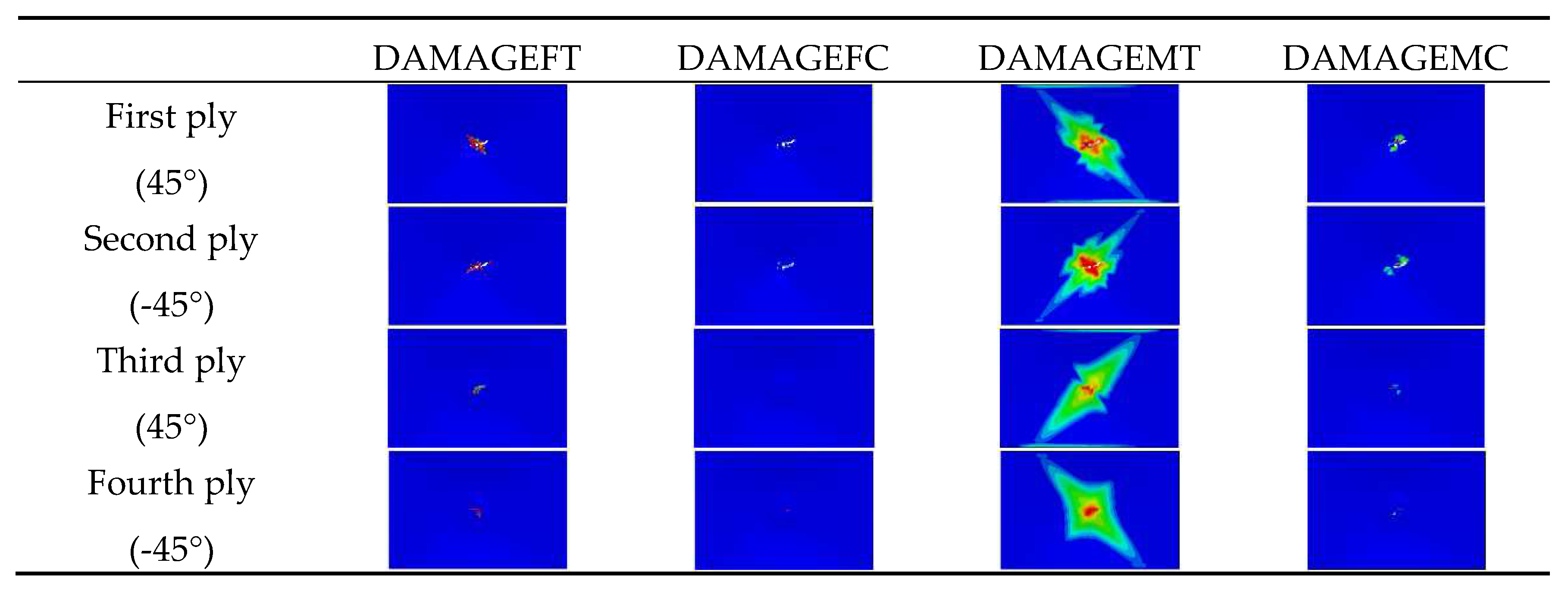

The Damage of each layer of carbon fiber in San-C and San-D under the 21.17J were respectively shown in

Table 5 and

Table 6. Under the same impact energy, due to the small number of carbon fiber layers, the thermal expansion between the layers of the asymmetric layer structure San-C was not uniform, so that the sandwich panel was formed into an arch. Under the action of impact energy, the anti-stratification ability of the panel was weakened, and the impact force continues to expand outward at the impact point, so the surface damage area diameter was relatively large. The number of layers of San-D carbon fiber in the symmetrical ply structure was more, which guided the impact force to transfer between more ply layers and effectively curbs the damage to the periphery. Therefore, the depth was deeper, and the surface damage area diameter was smaller than that of San-C.

Comparing the damage of San-C and San-D in

Table 5 and

Table 6, it can be found that the increase of [(0°, 90°)] ply order in the San-C upper panel ply structure increased the tensile fracture of the fiber and the damage area was wider, which aggravated the damage of the whole sandwich panel. The upper and lower panels of San-D increased the [(0°, 90°)] layer structure, which further aggravated the deep damage. Therefore, adding the proportion of [(0°, 90°)] ply structure to the carbon fiber composite material will reduce the impact resistance of the entire sandwich panel.

4.2. Analysis of Impact Response

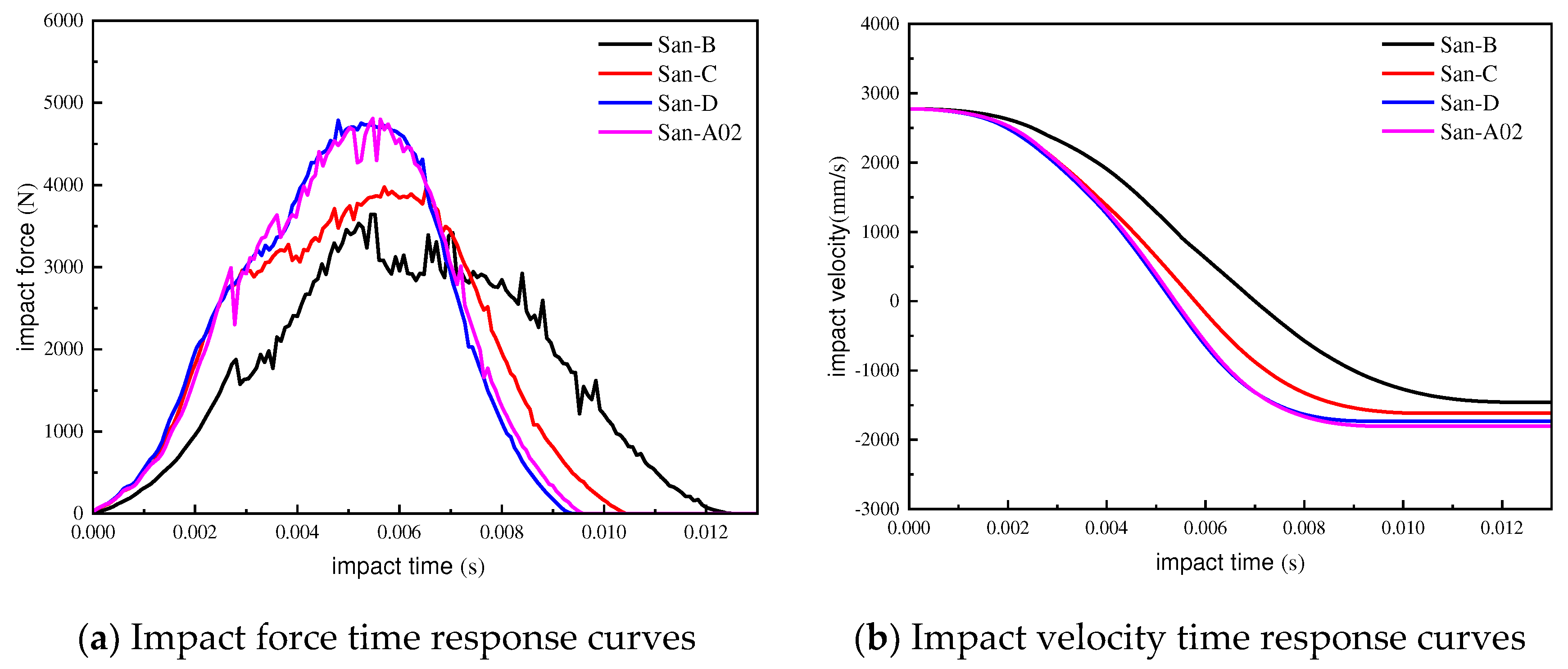

It can be seen in the impact force response curve of

Figure 7a, with the increase of impact energy, the surface of the upper panel of the sandwich panel of the San-A began to damage, which was consistent with the damage of the upper panel of the San-A group during the test. The reason for the phenomenon of constant oscillation of impact force was the friction between the punch and the panel or sandwich material during the impact process, or the failure of the carbon fiber and the matrix on the surface of the upper panel. The thickness of San-B was half of the thickness of the other three groups of ply schemes, so the impact force required for the failure of the upper panel was relatively low. The impact force at the time of failure was 3639 N, corresponding to the inflection point of the rising stage of the impact force on the curve. The local stiffness of the specimen currently became larger, and the contact force between the impact head and the sandwich foam of the test piece rose rapidly. After reaching the maximum value, the contact force was weakened, and the impact force began to decrease, corresponding to the falling section of the second half of the curve. At the same time, the foam sandwich of the San-B group began to resist the impact of the punch very early, and the response time was longer than that of the other three groups. The ply structures of San-C and San-D specimens were the same as [± 45° / (0°, 90°)], but the lower panel layup of San-C specimens was one group less [(0°, 90°)] than San-D, and the thickness was only half of San-D, so the overall impact resistance was also smaller. The maximum impact force on the panel was 3890 N, which was much smaller than the 4752 N of the San-D and the 4820 N of the San-A. The thicker of the composite panel, the stronger of the impact resistance.

According to the speed-time response curve of the punch in

Figure 7b, the response time of San-B was longer. Due to the long action time of the sandwich foam and the excessive impact resistance, the rebound speed was the lowest among the four groups of specimens. The thickness of the San-A and San-D specimens was the same, and the impact force was not much different. Under the impact energy of 21.17J, the velocity of the punch before and after the impact was not much different.

5. Conclusions

By studying the impact damage of carbon fiber foam sandwich structure based on Hashin failure criterion, the influence of different impact energy and different ply structure on the impact resistance of sandwich panel was analyzed, and the equivalent numerical simulation was carried out in the finite element software, and the impact response and panel ply damage were analyzed in detail. The main conclusions are summarized as follows:

(1) The impact damage of sandwich panels with different ply structures under different impact energy was different. From the perspective of impact energy, the damage of the upper panel directly contacting the punch was obvious, and most of the damage shapes were X-shaped. The lower panel bore less impact load, and the damage was not obvious. The pit depth and surface diameter of the upper panel of the four ply structures increased with the increase of impact energy. From the perspective of the layer structure, the thicker the layer thickness, the smaller the damage size of the surface diameter of the panel; the symmetrical layer structure of the upper and lower panels can also reduce the size of the diameter damage. At the same time, the increase of [± 45°] in the layer can greatly improve the impact performance of the sandwich panel.

(2) Comparing the finite element numerical simulation results with the experimental results, the errors were within a reasonable range, indicating that the finite element method used in this paper was reasonable. The curves of impact force, impact velocity and impact energy response of the equivalent model in the impact process were listed. Under the same ply structure, the greater the impact energy, the greater the impact force of the sandwich plate, and the shorter the time to reach the maximum impact force, the more the energy absorbed by the whole, and the maximum speed change during rebound. The response of different ply structures under the same impact energy was different. The damage types of the upper panel of the sandwich panel were mainly matrix tensile fracture and fiber tensile fracture. The fracture direction was along the ply angle direction and was symmetrically distributed in the impact area. The thicker the ply thickness, the smaller the damage range. The increase of the number of [± 45°] ply structures can greatly reduce the damage size.

(3) The increase of [± 45°] ply structures can improve the bearing capacity of the sandwich panel and reduce the energy absorbed by the sandwich panel.

Author Contributions

YANG Kang: Writing – original draft, Writing – review & editing, Resources, Formal Analysis; ZAHNG Yunpeng: Writing – original draft, Formal Analysis, Visualization, Project administration; YANG Yong: Data curation; WANG Ji: Supervision; LV Zan: Formal Analysis; HE Dongqing: Investigation.

Funding

This work was supported by a grant from the project of Liaoning Provincial Department of Education (LJKMZ20220563).

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Conflict of Interest

Authors state no conflict of interest.

References

- Vlach J, Doubrava R, Růžek R, Raška J, Horňas J, Kadlec M. Strain-Field Modifications in the Surroundings of Impact Damage of Carbon/Epoxy Laminate. Polymers (Basel). 2022 Aug 9, 14(16):3243. [CrossRef]

- Hu C, Huang G, Li C. Experimental and Numerical Study of Low-Velocity Impact and Tensile after Impact for CFRP Laminates Single-Lap Joints Adhesively Bonded Structure. Materials (Basel). 2021 Feb 21, 14(4):1016. [CrossRef]

- ZHANG Yaqian, LIU Yixuan, WU Yongfu, et al. Nonlinear post-buckling analysis of composite laminates with antisymmetric angle-ply[J]. Chinese journal of applied mechanics, 2023, 40(04):778-787 (in Chinese).

- Zhu, Y.; Sun, Y. Low-Velocity Impact Response of Multilayer Foam Core Sandwich Panels with Composite Face Sheets. Int. J. Mech. Sci. 2021, 209, 106704. [CrossRef]

- Azimpour-Shishevan F, Mohtadi-Bonab MA, Akbulut H, Rahmatinejad B. Low velocity impact behavior of twill basalt/epoxy composites modified by graphene nanoparticles. Journal of Composite Materials. 2023: 57(8):1379-1394. [CrossRef]

- ZHANG Wenping, KONG Xiangqing1, ZHANG Huiling1, ZHANG Wenjiao1, LI Ruonan1, FU Ying. Numerical investigation on dynamic response of bio-inspired honeycomb sandwich beams under oblique impact loading[J].. Composites science and engineering. 2023 (10):17-22+31. ( in Chinese).

- LI Jing. Study on performance of honeycomb sandwich structure caused by manufacturing pollution[J]. China science and technology information, 2023(10): 103-105. ( in Chinese).

- Gao Chunyun,Chen Qihui,Du Ruikui,et al. Low-velocity impact response of asymmetric honeycomb sandwich structure [J]. Engineering Plastics Application, 2023, 51(3):113−120. ( in Chinese).

- Zhou Chunhua,Ye Zilong,Lu Jiyun,et al. Damage monitoring on satellite’ s typical composite honeycomb structure panel based on impact energy gradients[J]. Science Technology and Engineering, 2020, 20(12): 4718-4722 (in Chinese).

- Yang Kang, Zhang Ziao, Yang Li, Geng Hao, Ding Yining. Influence of foam core thickness on impact performance of carbon fiber composite sandwich pane [J]. Materials reports, 2021,35(S2):579-582 (in Chinese).

- Luo Wei, Investigation of low-velocity and residual bending strength characteristics of hybrid sandwich structures [D]. China Ship Research and Development Academy, 2018. ( in Chinese).

- Mohan K, Yip T H, Idapalapati S, Chen Z. Impact response of aluminum foam core sandwich structures. Materials Science and Engineering: A 2011; 529:94–101. [CrossRef]

- Sun Ziheng, Wang Jihui, Ni Aiqing, Cheng Hongda. Study on the low-speed impact performance and residual strength after impact of composite sandwich structure with different layup [J]. Composites science and engineering, 2020(11):102-110. ( in Chinese).

- MAO L W, ZHU X M, HUANG Z X, et al. Impact response of composite lattice sandwich plate structure subjected to underwater explosion [J]. Chinese Journal of Ship Research, 2022, 17(3): 253–263. ( in Chinese).

- Xue Pu, Qin Xuguo, Su Wei, Gong Xin, Deng Jian. Damage behavior and energy absorption mechanisms of composite honeycomb sandwich structures under local impacts [J]. Missiles and space vehicles, 2022(05):126-131. (in Chinese).

- Besant T, Davies G A O, Hitchings D. Finite element modelling of low velocity impact of composite sandwich panels [J]. Composites Part A: Applied science and manufacturing, 2001, 32(9): 1189-1196. [CrossRef]

- Samlal S, Santhanakrishnan R. Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets [J]. Polymers, 2022, 14(5): 1060. [CrossRef]

- Huo X, Liu H, Luo Q, et al. On low-velocity impact response of foam-core sandwich panels [J]. International Journal of Mechanical Sciences, 2020, 181: 10°5681. [CrossRef]

- Zhou J, Guan Z W, Cantwell W J. The impact response of graded foam sandwich structures [J]. Composite Structures, 2013, 97(2):370-377. [CrossRef]

- Sun G, Wang E, Wang H, et al. Low-velocity impact behavior of sandwich panels with homogeneous and stepwise graded foam cores [J]. Materials & Design, 2018, 160: 1117-1136. [CrossRef]

- WU Xiaodong, XIA Fan, WU Xiaoqing. Work on low-velocity impact properties of foam sandwich composites with various face sheets [J]. Fiber composites, 2010, 27(04):8-11. (in Chinese).

- Luo Zhiqiang, Lai Jiamei, Huang Zhichao, Mo Mingzhi, Li Meiyan. Study on repeated low velocity impact properties of stitched carbon fiber foam sandwich composites [J]. Materials reports, 2022, 36(19) :218-225. (in Chinese).

- MAO L H, GENG H H, YIN C H, et al. Flat compression properties and numerical simulation of stitched foam sandwich composites [J]. Journal of Tiangong University, 2022, 41(6): 36-42 (in Chinese).

- WANG Ke. Analysis of resin filling for stitched foam core sandwich structure composites by VARTM process[D]. Nanchang University. 2017 (in Chinese).

- YANG Jinshui, LIANG Wei, ZENG Jingcheng, YIN Changping. Fabrication and properties of stitching reinforced foam sandwich composites [J]. Fiber composites, 2020,37(04):43-50. (in Chinese).

- Duan Youshe, Guo Shuliang, Wu Gang, et al. Impact damage and post-impact compressive properties of Z-direction reinforced foam sandwich composites [J]. Composite Journal, 2012,29 (02): 180-185. ( in Chinese).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).