Submitted:

11 February 2024

Posted:

13 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

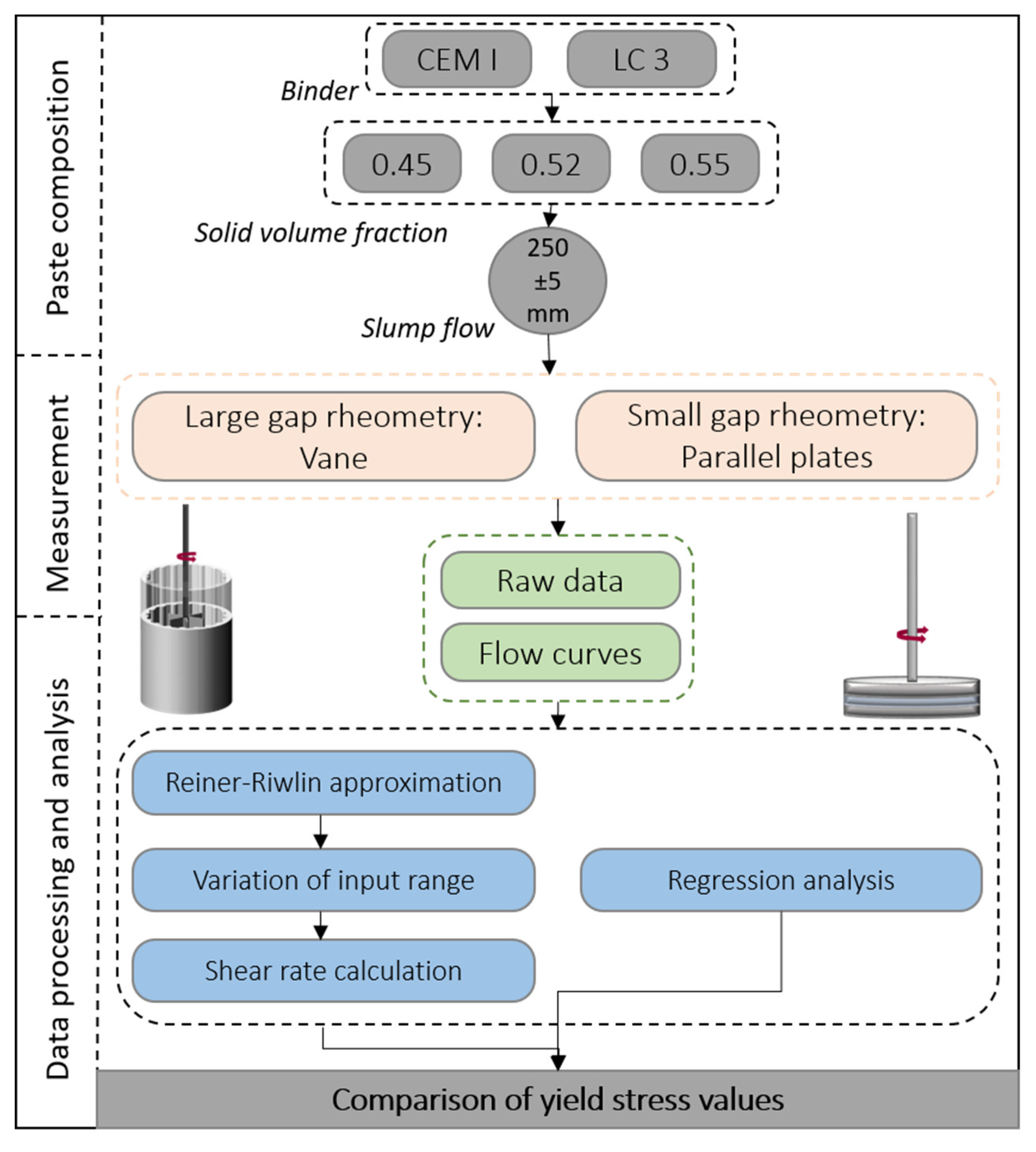

2.1. Concept of Investigation

2.2. Materials

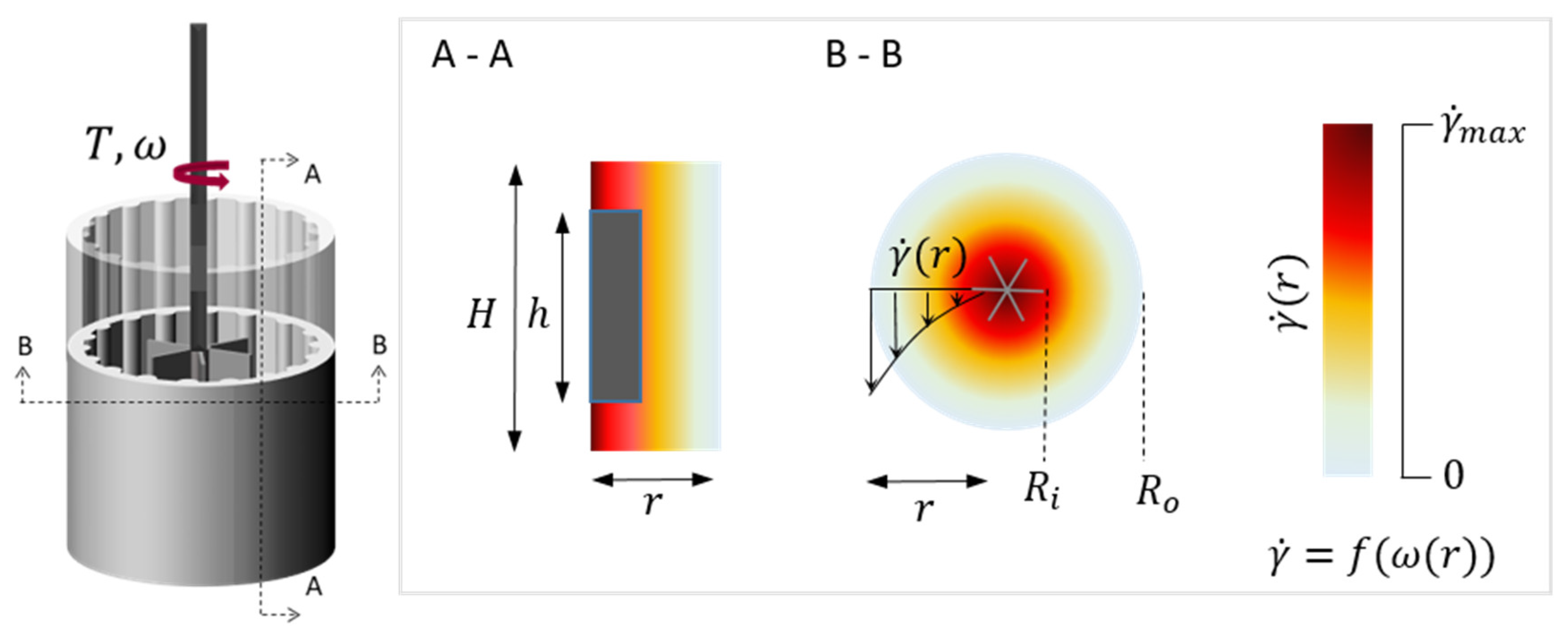

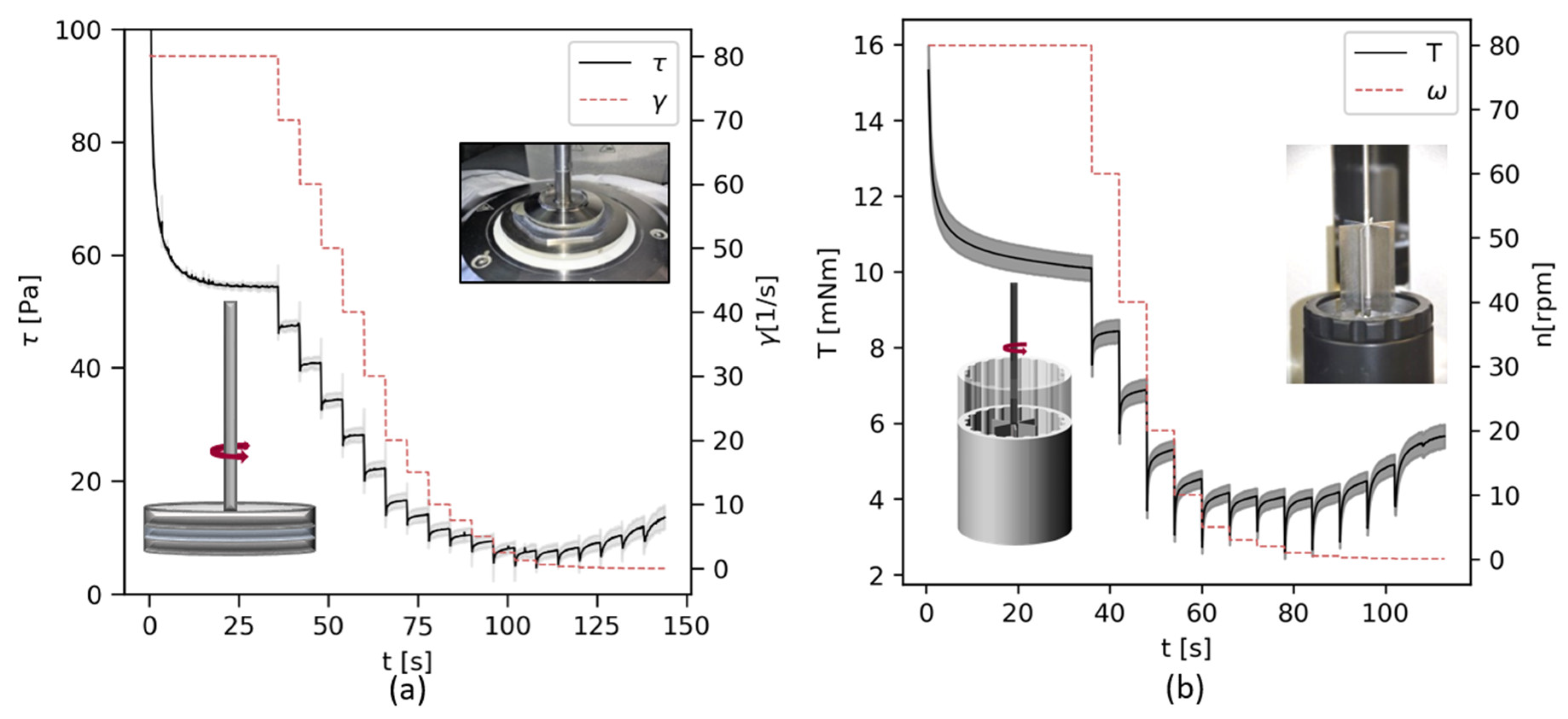

2.3. Methods and Data Handling

3. Results

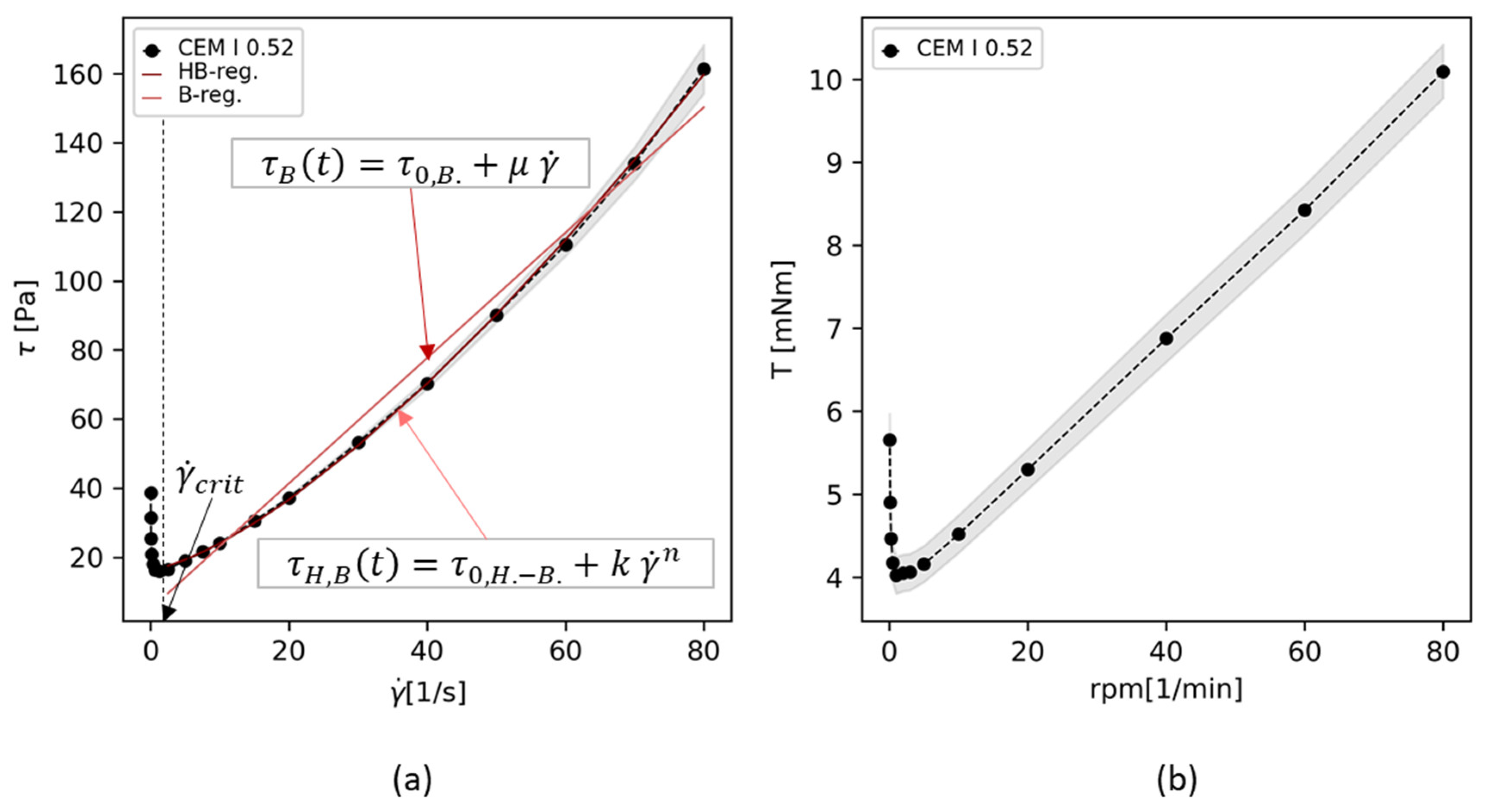

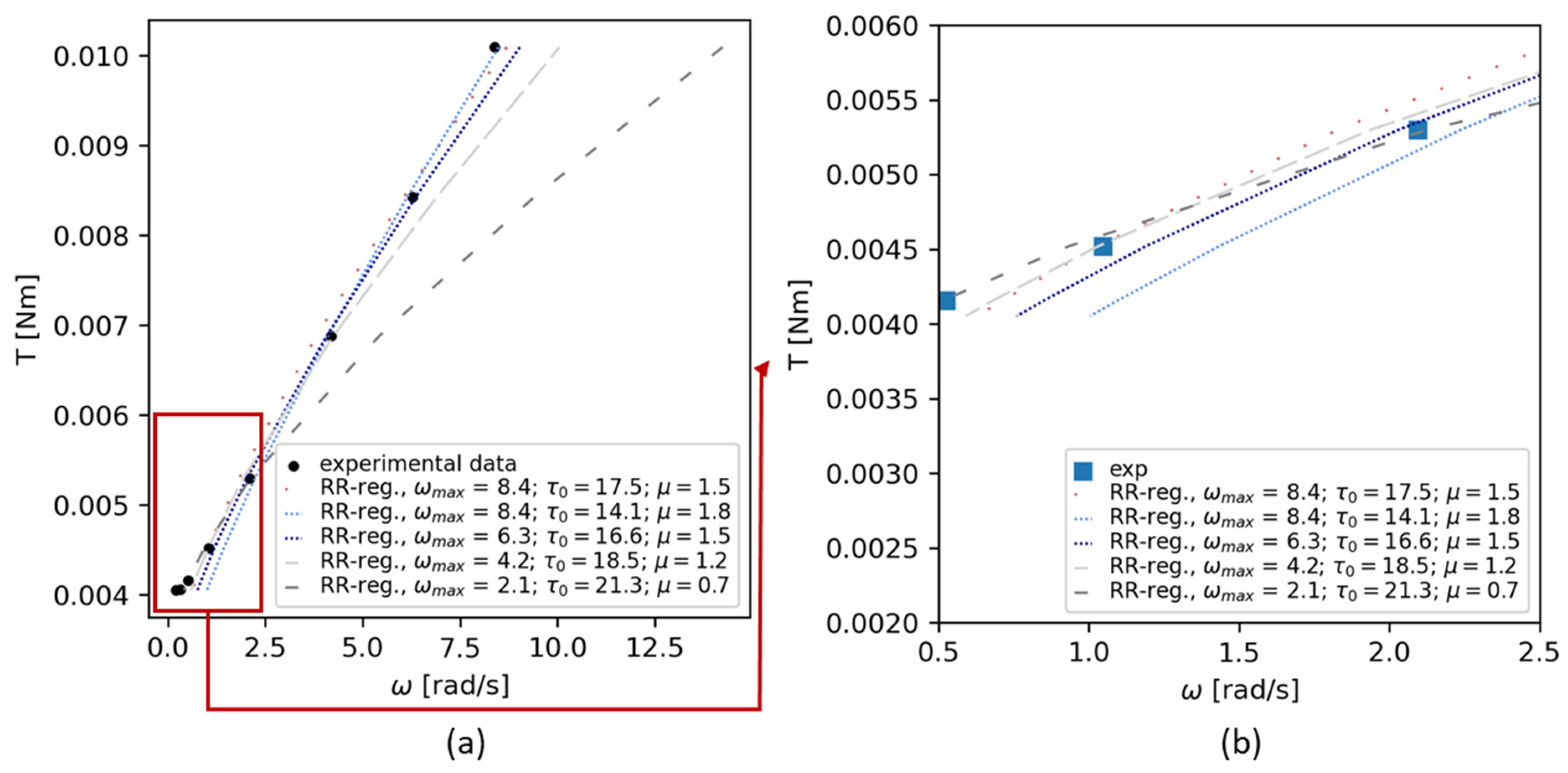

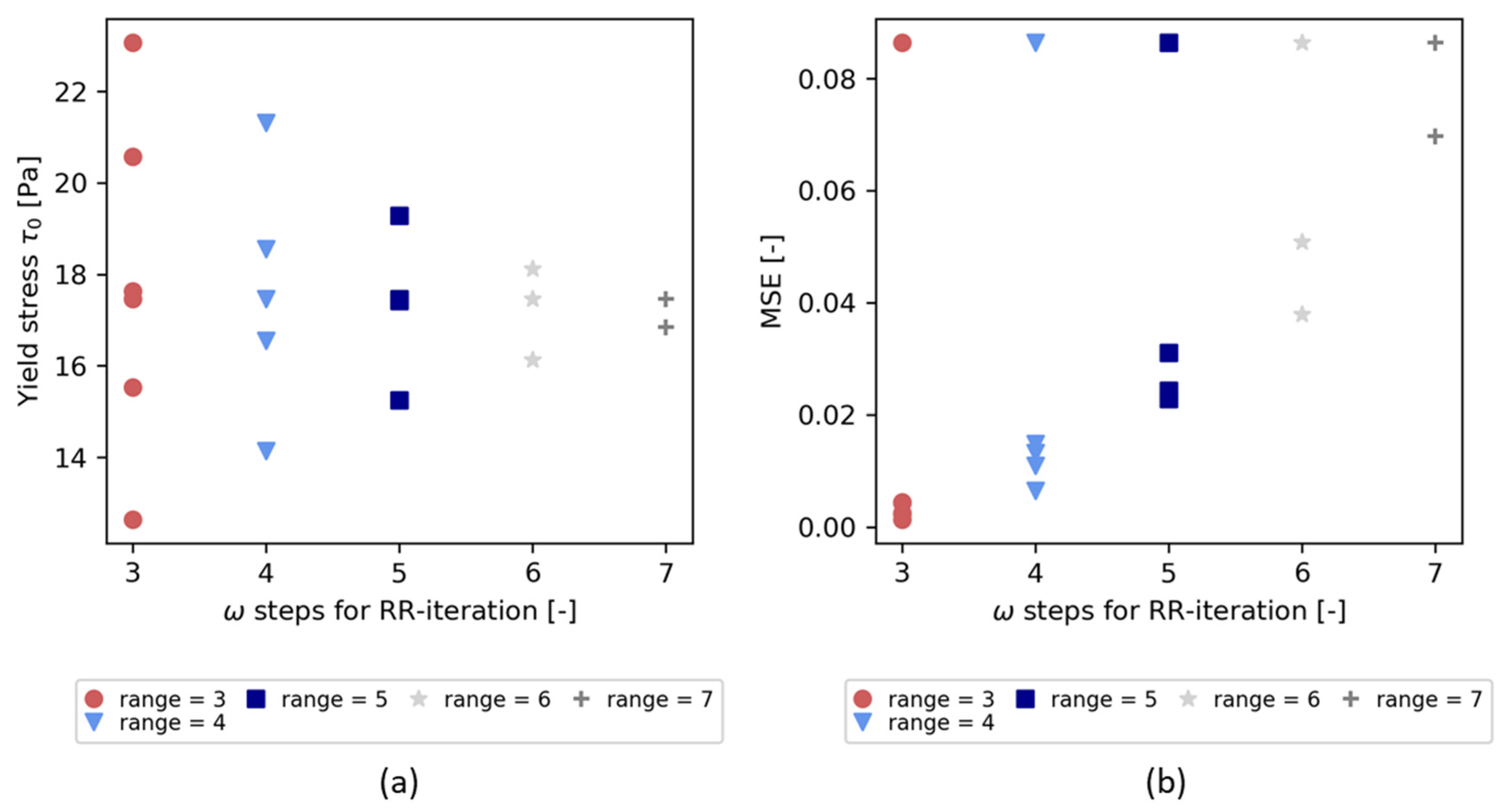

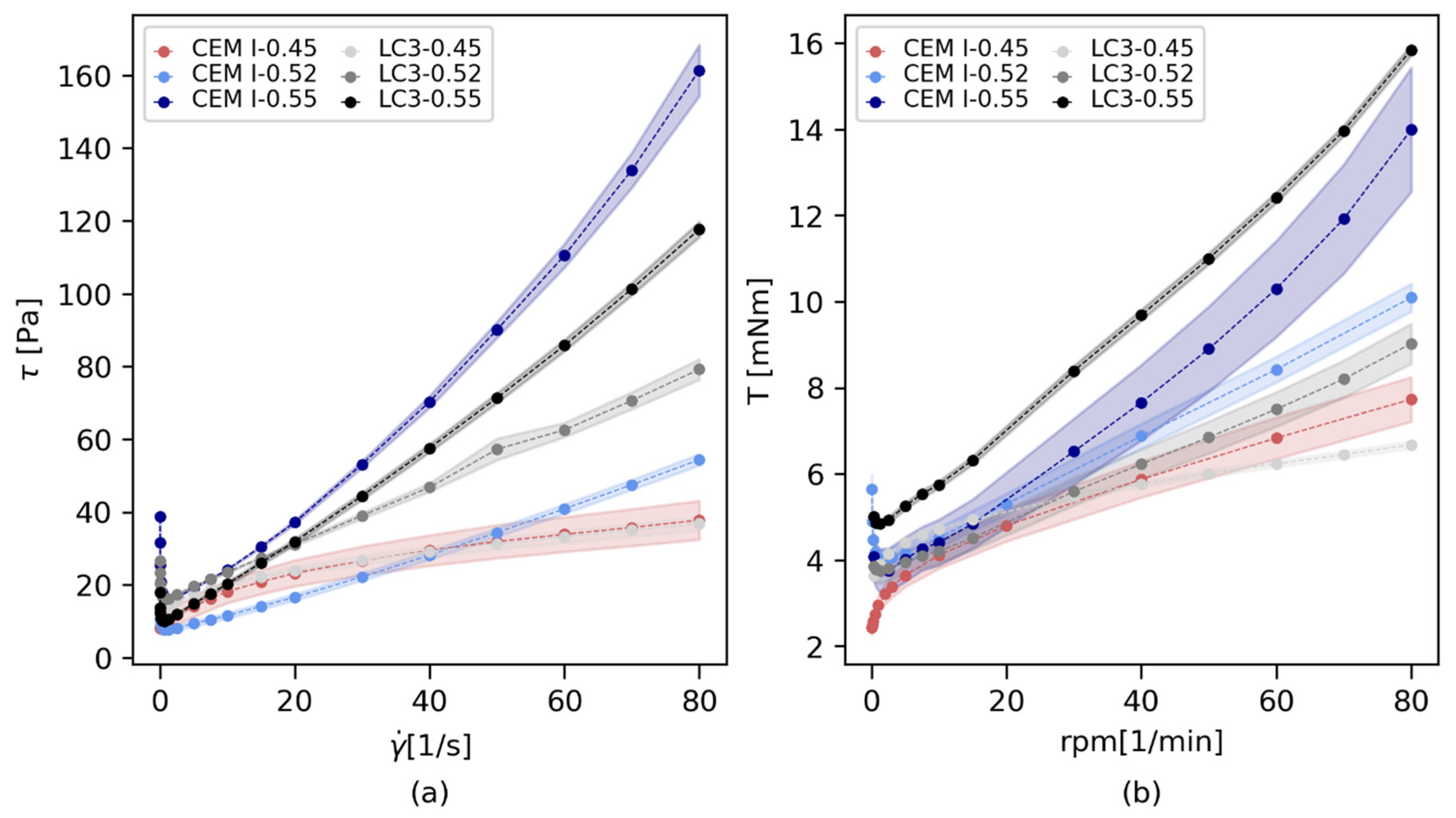

3.1. Flow Curves

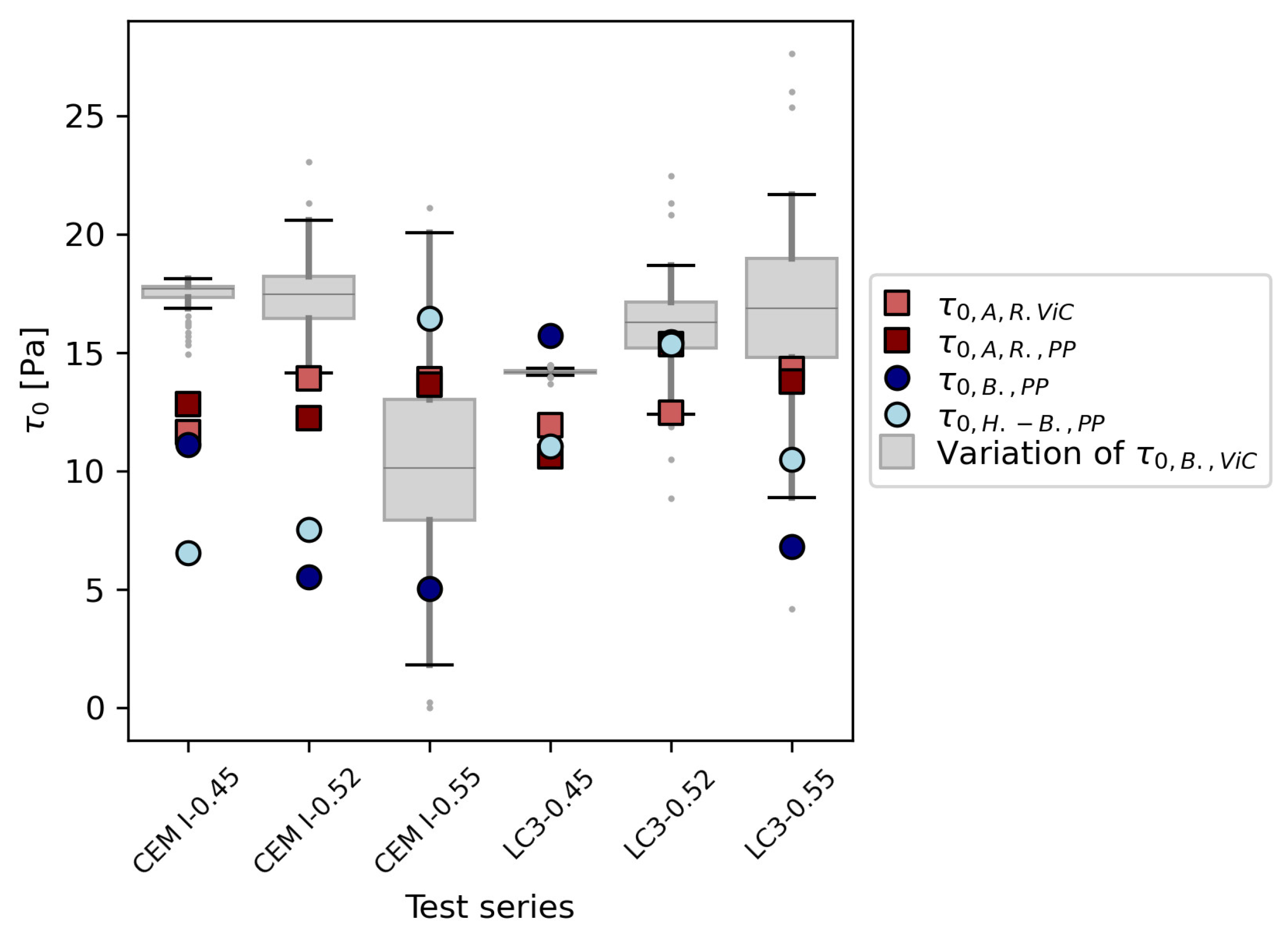

3.2. Rheological Parameter Comparison

4. Discussion and Outlook

Acknowledgments

References

- Roussel, N.; Stefani, C.; Leroy, R.: From Mini-Cone Test to Abrams Cone Test: Measurement of Cement-Based Materials Yield Stress Using Slump Tests. In: Cemcon 35 (2005), Nr. 5, S. 817–822. [CrossRef]

- Mezger, Thomas: Das Rheologie Handbuch: Für Anwender Von Rotations- Und Oszillations-Rheometern. 5., Vollständig Überarbeitete Auflage: Hannover: Vincentz, 2016.

- Thiedeitz, Mareike; Kränkel, Thomas; Gehlen, Christoph: Viscoelastoplastic Classification of Cementitious Suspensions: Transient and Non-Linear Flow Analysis in Rotational and Oscillatory Shear Flows. In: Rheologica Acta 61 (2022), 8-9, S. 549–570. [CrossRef]

- Haist, Michael; Link, Julian; Et Alr: Interlaboratory Study on Rheological Properties of Cement Pastes and Reference Substances: Comparability of Measurements Performed with Different Rheometers and Measurement Geometries. In: Materials and Structures 53 (2020), Nr. 4. [CrossRef]

- Reiner, Markus; Eyring, Henry: Deformation and Flow. An Elementary Introduction to Theoretical Rheology. In: Physics Today 3 (1950), Nr. 4, S. 35–36. [CrossRef]

- Krieger, Irvin M.; Elrod, Harold: Direct Determination of The Flow Curves of Non-Newtonian Fluids. Ii. Shearing Rate in The Concentric Cylinder Viscometer. In: Jour. of Appl. Physics 24 (1953), Nr. 2, S. 134–136. [CrossRef]

- Krieger, Irvin M.: Shear Rate in Couette Viscometer. In: Trans. Soc. of Rheology 12 (1968), Nr. 1, S. 5–11. [CrossRef]

- Wallevik, Olafur H.; Feys, Dimitri; Et Al: Avoiding Inaccurate Interpretations of Rheological Measurements for Cement-Based Materials. In: Cement and Concrete Research 78 (2015), S. 100–109. [CrossRef]

- Baravian, C.; Lalante, A.; Parker, A.: Vane Rheometry with A Large, Finite Gap. 2015. [CrossRef]

- Nguyen, Q. Dzuy; Boger, D. V.: Direct Yield Stress Measurement with The Vane Method. In: Journal of Rheology 29 (1985), Nr. 3, S. 335–347. [CrossRef]

- Haist, Michael: Zur Rheologie Und Den Physikalischen Wechselwirkungen Bei Zementsuspensionen. Karlsruhe, Universität Karlsruhe (Th), Institut Für Massivbau Und Baustofftechnologie. Dissertation. 2009.

- Feys, Dimitri; Wallevik, Jon E.; Yahia, Ammar; Khayat, Kamal H.; Wallevik, Olafur H.: Extension of The Reiner–Riwlin Equation to Determine Modified Bingham Parameters Measured in Coaxial Cylinders Rheometers. In: Materials and Structures 46 (2013), 1-2, S. 289–311. [CrossRef]

- Din En 12350-8:2019-09, Prüfung Von Frischbeton_- Teil_8: Selbstverdichtender Beton_- Setzfließversuch; Deutsche Fassung En_12350-8:2019.

- Lu, Z. C.; Haist, M.; Ivanov, D.; Et Al: Characterization Data of Reference Cement Cem I 42.5 R Used for Priority Program Dfg Spp 2005 "Opus Fluidum Futurum - Rheology of Reactive, Multiscale, Multiphase Construction Materials". In: Data in Brief 27 (2019). [CrossRef]

- Pott, U.; Crasselt, C.; Et Al.: Characterization Data of Reference Materials Used for Phase Ii of The Priority Program Dfg Spp 2005 "Opus Fluidum Futurum - Rheology of Reactive, Multiscale, Multiphase Construction Materials". In: Data in Brief 47 (2023), S. 108902. [CrossRef]

- Lei, L.; Chomyn, C.; Schmid, M.; Plank, J.: Characterization Data of Reference Industrial Polycarboxylate Superplasticizers Used within Priority Program Dfg Spp 2005 "Opus Fluidum Futurum - Rheology of Reactive, Multiscale, Multiphase Construction Materials". In: Data in Brief 31 (2020), S. 106026. [CrossRef]

- Zhang, Lin; Li, Ran; Lei, Lei; Plank, Johann: Characterization Data of Reference Industrial Polycarboxylate Superplasticizer Vp 2020/15.2 Used for Priority Program Dfg Spp 2005 "Opus Fluidum Futurum ". In: Data in Brief 39 (2021),Pp S. 107657. [CrossRef]

| Sample name | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | TiO2 |

|---|---|---|---|---|---|---|---|---|

| [%] | [%] | [%] | [%] | [%] | [%] | [%] | [%] | |

| OPC | 62.90 | 19.63 | 5.23 | 2.60 | 1.54 | 0.24 | 0.80 | 3.32 |

| LC3 | 42.53 | 28.12 | 9.43 | 3.47 | 1.43 | 0.18 | 1.31 | 0.43 |

| Sample name | Blaine SSA | BET SSA | d50 | ||

|---|---|---|---|---|---|

| [g/cm³] | [cm²/g] | [m²/g] | [µm] | [-] | |

| OPC | 3.11 | 4300 | 1.24 | 13.80 | 0.27 |

| LC3 | 2.89 | 6528 | 2.65 | 9.99 | 0.25 |

| Mixture | w/c ratio | Binder | Water | PCE | |

|---|---|---|---|---|---|

| [-] | [-] | [kg/m³] | [kg/m³] | [% bwoc] | |

| OPC-0.45 | 0.45 | 0.39 | 1399.5 | 550.0 | 0.24 |

| OPC-0.52 | 0.52 | 0.30 | 1617.2 | 480.0 | 0.85 |

| OPC-0.55 | 0.55 | 0.26 | 1710.5 | 450.0 | 1.40 |

| LC3-0.45 | 0.45 | 0.42 | 1295.1 | 550.0 | 0.22 |

| LC3-0.52 | 0.52 | 0.32 | 1496.6 | 480.0 | 0.75 |

| LC3-0.55 | 0.55 | 0.28 | 1582.9 | 450.0 | 1.07 |

| Mixture | ||||||

|---|---|---|---|---|---|---|

| [1/s] | [Pa] | [Pa*s] | [Pa] | [Pa*sn] | [-] | |

| OPC-0.45 | 0.02 | 11.13 | 0.38 | 6.53 | 3.69 | 0.49 |

| OPC-0.52 | 1.25 | 5.53 | 0.59 | 7.53 | 0.26 | 1.18 |

| OPC-0.55 | 1.25 | 5.00 | 1.82 | 16.45 | 0.29 | 1.41 |

| LC3-0.45 | 0.16 | 15.71 | 0.29 | 11.05 | 2.86 | 0.50 |

| LC3-0.52 | 0.63 | 15.47 | 0.80 | 15.35 | 0.82 | 0.99 |

| LC3-0.55 | 0.63 | 6.79 | 1.34 | 10.50 | 0.63 | 1.17 |

| Mixture |

, ViC |

ViC |

, PP |

PP |

ViC |

PP |

PP |

|---|---|---|---|---|---|---|---|

| [mm] | [Pa] | [mm] | [Pa] | [Pa] | [Pa] | [Pa] | |

| OPC-0.45 | 257 | 11.6 | 251 | 12.8 | 17.7 | 11.1 | 6.5 |

| OPC-0.52 | 251 | 13.9 | 255 | 12.2 | 17.5 | 5.5 | 7.5 |

| OPC-0.55 | 253 | 13.9 | 254 | 13.7 | 10.1 | 5.0 | 16.5 |

| LC3-0.45 | 252 | 11.9 | 258 | 10.6 | 14.2 | 15.7 | 11.1 |

| LC3-0.52 | 254 | 12.5 | 243 | 15.4 | 16.3 | 15.5 | 15.4 |

| LC3-0.55 | 245 | 14.3 | 250 | 13.8 | 16.9 | 6.8 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).