Submitted:

20 February 2024

Posted:

23 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials

2.1. Matrix

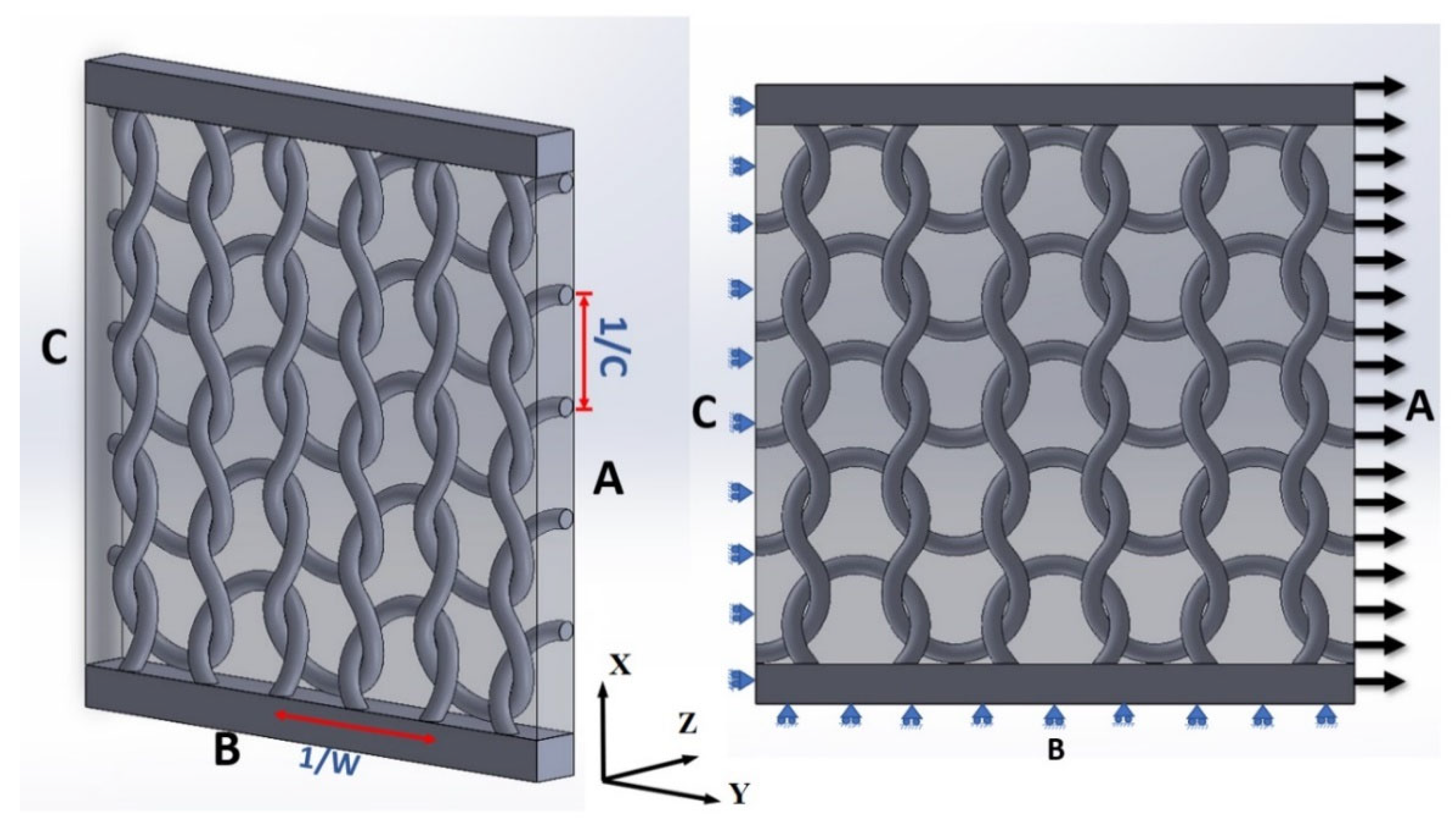

2.2. Textile

3. Numerical Damage Accumulation Modeling in Composite Plate Reinforced by Knitted Fabric

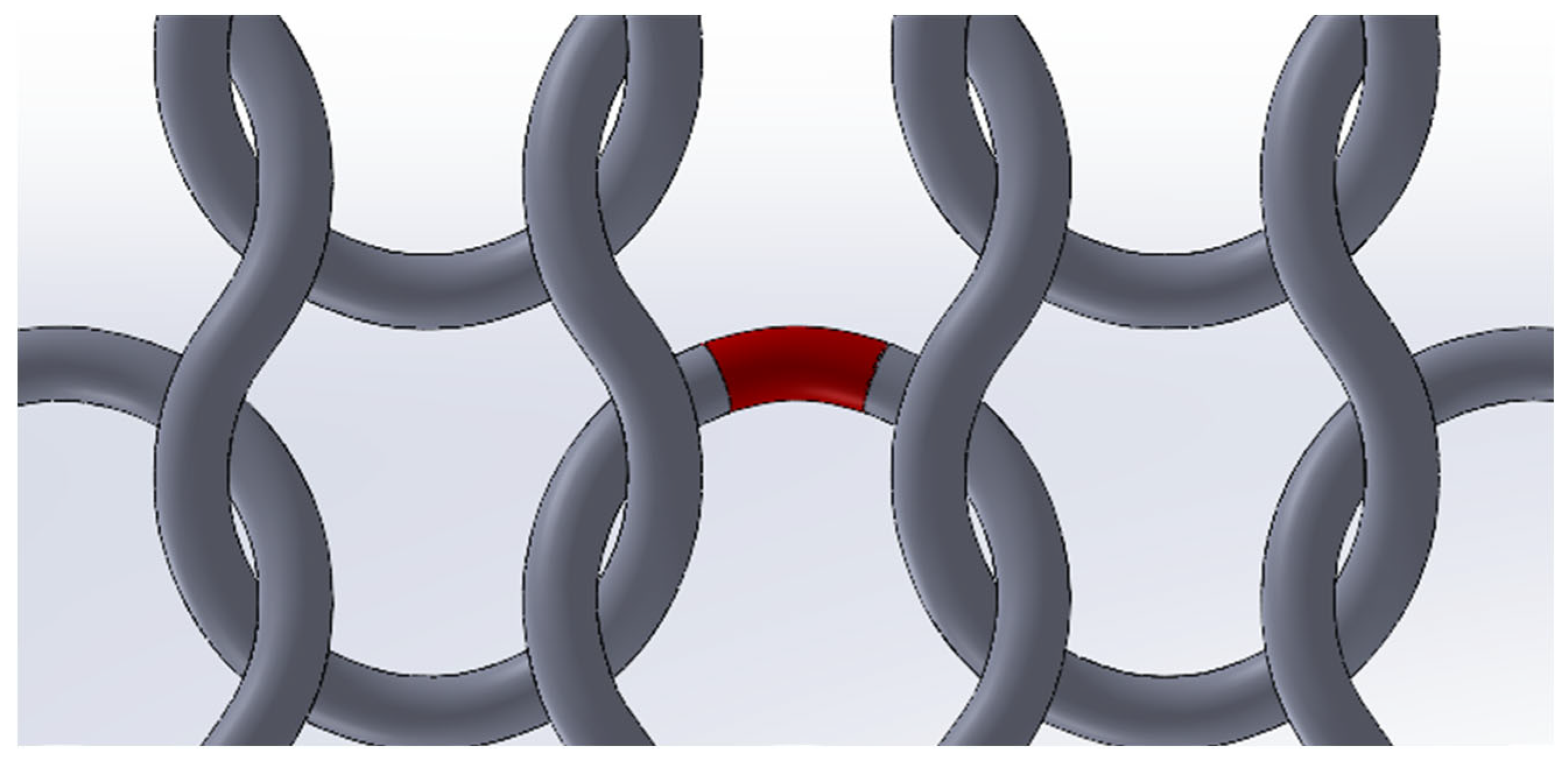

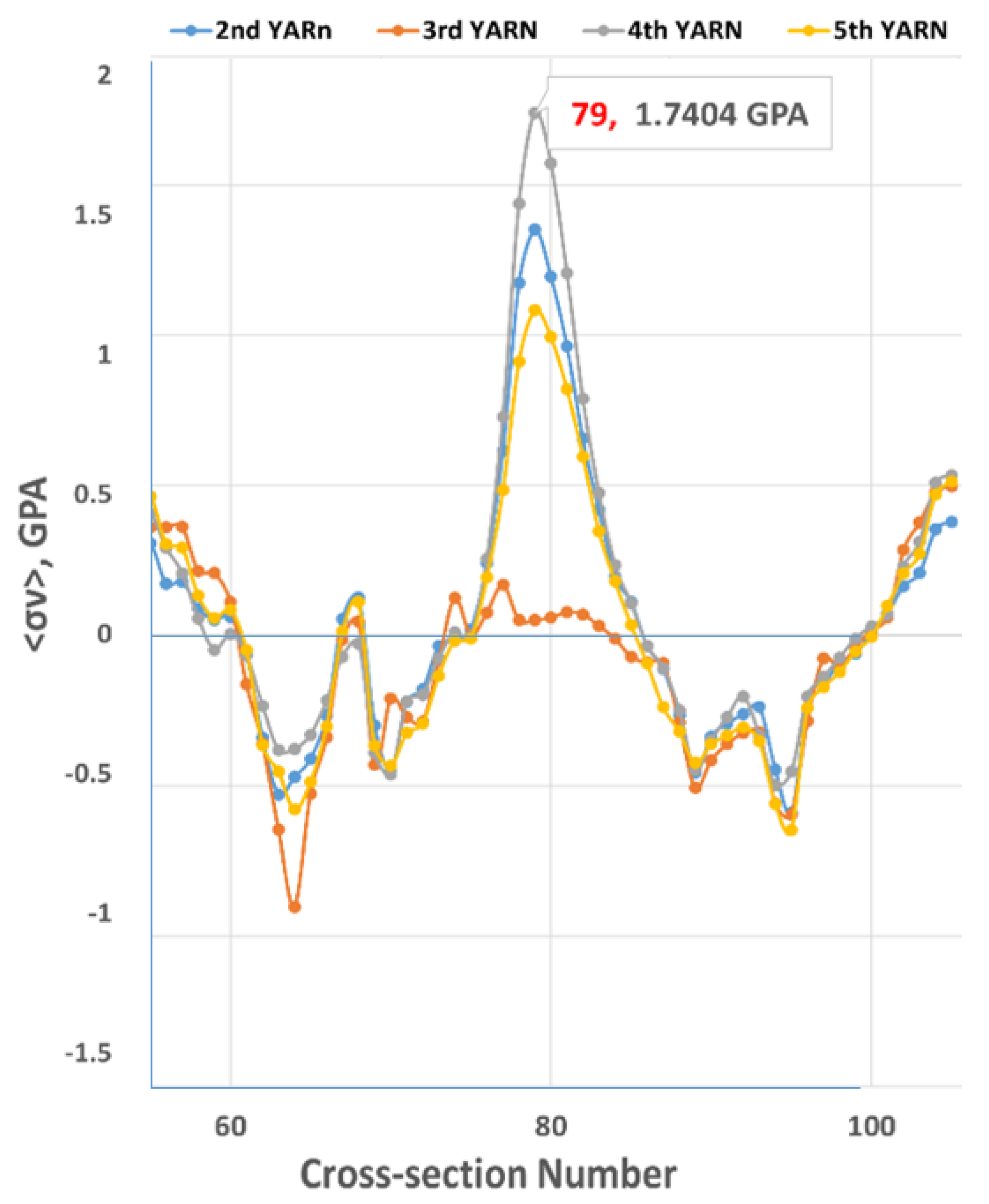

3.1. Stress Distribution in the CMHR. Assumptions

| Matrix with epoxy resin and 0% (weight) OSA | Macrofiber- basalt fiber thread impregnated by epoxy resin and 0% (weight) OSA | |

| Density ρ (g/cm3) | 1.19 | 1.74 |

| Young’s modulus E (GPa) | 3.15 | 63.4 |

| Poisson’s ratio ν | 0.35 | 0.3 |

| Matrix with epoxy resin and 10% (weight) OSA | Macrofiber- basalt fiber thread impregnated by epoxy resin and 10% (weight) OSA | |

| Density ρ (g/cm3) | 1.26 | 1.89 |

| Young’s modulus E (GPa) | 3.28 | 63.5 |

| Poisson’s ratio ν | 0.34 | 0.29 |

| Matrix with epoxy resin and 20% (weight) OSA | Reinforcement with basalt fiber thread in epoxy resin and 20% (weight) OSA | |

| Density ρ (g/cm3) | 1.34 | 2.07 |

| Young’s modulus E (GPa) | 3.62 | 64.1 |

| Poisson‘s ratio ν | 0.33 | 0.28 |

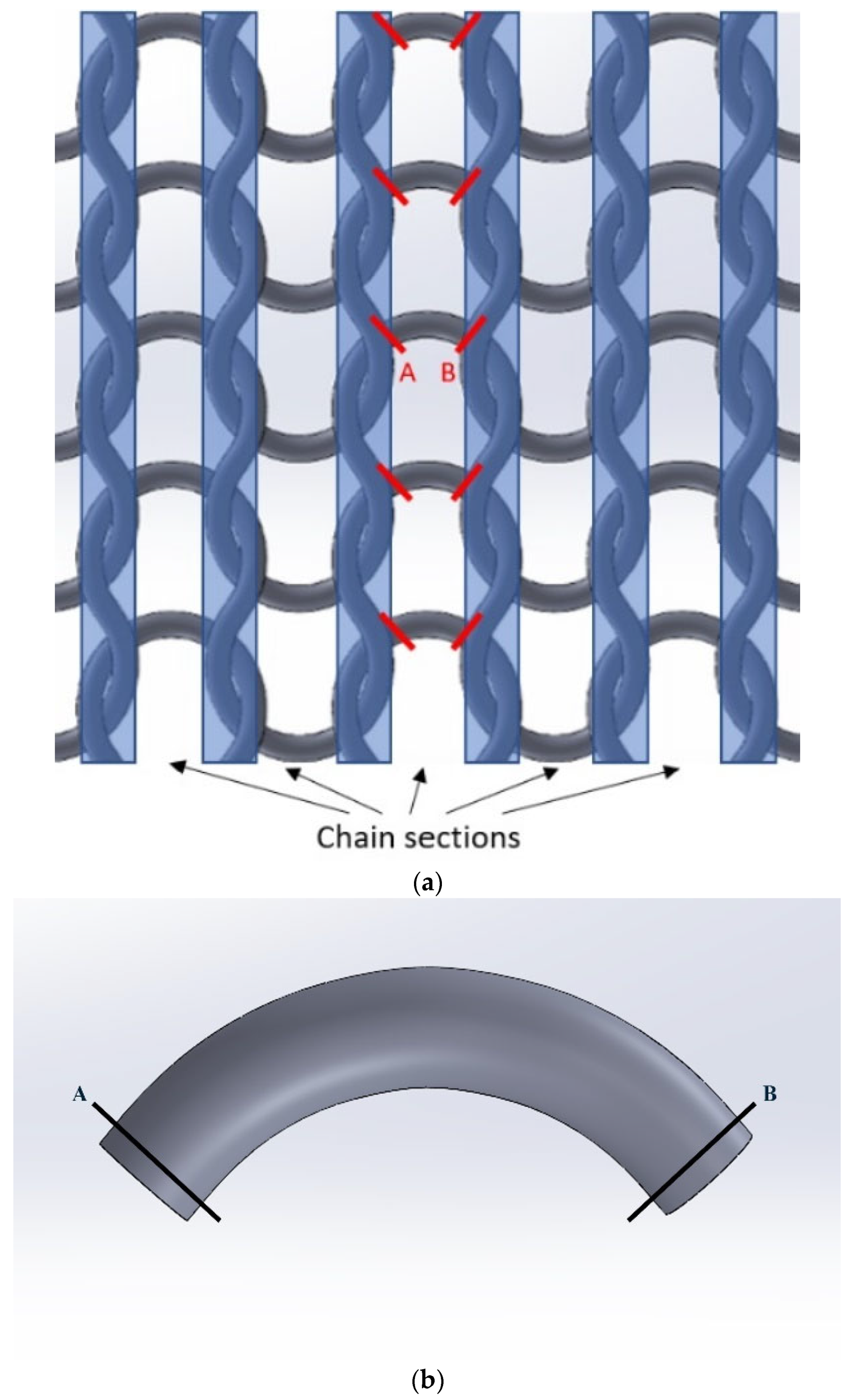

3.2. Calculations Using Model with a Frame

4. Model of Damage Accumulation in the CMHR

4.1. Material Failure Probability Modeling

4.2. Damage Accumulation

5. Numerical Example

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations:

| Symbol | Notation |

| j | defect size (number of adjacent broken macrofibers) |

| σν | stress in the internal point of the macrofiber, acting along the normal vector to current crossection |

| <σν> | Stress parameter - average, across the cross-section’s area, stretching stress value normal to the current cross-section’s plane |

| Random variable – cluster’s size | |

| P{J ≥ i} | probability to find cluster in one bundle, consisting of at leasti adjacent broken macrofibers |

| Terminology | Explanation |

| OSA | oil shale ash |

| HCM | hybrid composite material - epoxy+OSA+textile reinforcement |

| microfiber | Basalt microfiber 13-16 µm in diameter |

| yarn, thread | group of microfibers (250 microfibers) |

| Macrofiber (MF) | group of slightly twisted microfibers (250 microfibers) impregnated with epoxy resin with OSA particles. Approx. diameter 0.55 mm -1mm |

| bundle | series of adjacent macrofibers parts (impregnated yarns) in the plane orthogonal to loading direction. MF parts belongs to different loops in the textile. Length of different MF part in the bundle is the same for all MF parts (belonging to different loops) and depends on stretching stress distribution in loops |

| cluster | Group of broken adjacent MF |

References

- Hardaker M. and Richardson M. O. W. Trends in Hybrid Composite Technology, Polymer-Plastics Technology and Engineering (1980) - Issue 2K., 15:2, 169-182. [CrossRef]

- Jerzynska A. and Egner H. Energy Equivalence Based Estimation of Hybrid Composites Mechanical Properties, Materials (2023), 16, 4215. [CrossRef]

- Atmakuri A., Palevicius A., Vilkauskas A. and Janusas G. Review of Hybrid Fiber Based Composites with Nano Particles—Material Properties and Applications, Polymers (2020), 12, 2088. [CrossRef]

- Aveston J. and Sillwood J. M. Synergistic fibre strengthening in hybrid composites, Journal of Materials Science, 11, 1877–1883 (1976). [CrossRef]

- Radulović J. Hybrid Filament-wound Materials: Tensile Characteristics of (Aramid Fiber/Glass Fiber)-Epoxy Resins Composite and (Carbon Fibers/Glass Fiber)-Epoxy Resins Composites, Scientific Technical Review, (2020), Vol.70, No.1, pp.36-46. [CrossRef]

- Sim J., Kang Y., Kim B. J., Park Y. H. and Lee Y. C. Preparation of Fly Ash/Epoxy Composites and Its Effects on Mechanical Properties, Polymers 2020, 12(1), 79. [CrossRef]

- Kononova, O.; Krasnikovs, A.; Kharkova, G.; Zalesky, J.; Machanovsky, E. Mechanical Properties Characterization by Inverse Technique for Composite Reinforced by Knitted Fabric. Part 1. Material Modeling and Direct Experimental Mechanical Properties Evaluation. Journal of Vibroengineering 2012, 14, 681–690. [Google Scholar]

- Ogin, S. Textile-reinforced composite materials. Technology & Engineering. In Handbook of Technical Textiles; Horrocks, A.R., Ed.; Subhash C. Anand, 2000; Chapter 11; pp. 265–280. [Google Scholar]

- Mobasher, B. Mechanics of Fiber and Textile Reinforced Cement Composites; CRC Press; 473p, ISBN 1439806608.

- Katerelos, D.T.G.; Krasnikovs, A.; Varna, J. Variational models for shear modulus of symmetric and balanced laminates with cracks in 90-layer International. Journal of Solids and Structures 2015, 71, 169–179. [Google Scholar] [CrossRef]

- Pakkam Gabriel, V.R.; Loukil, M.S.; Varna, J. Analysis of intralaminar cracking in 90-plies of GF/EP laminates with distributed ply strength. Journal of composite materials 2021, 55, 3925–3942. [Google Scholar] [CrossRef]

- Varna, J.; Berglund, L.A.; Krasnikovs, A.; Chihalenko, A. Crack opening geometry in cracked composite laminates. International Journal of Damage Mechanics 1997, 6, 96–118. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Kreikemeier, J.; Wille, T. Review and benchmark study on the analysis of low-velocity impact on composite laminates. Engineering Failure Analysis 2018, 86, 72–99. [Google Scholar] [CrossRef]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Composite Structures 2019, 224, 111007. [Google Scholar] [CrossRef]

- Pandita, S.D.; Falconet, D.; Verpoest, I. Impact properties of weft knitted fabric reinforced composites. Composites Science and Technology 2002, 62, 1113–1123. [Google Scholar] [CrossRef]

- Krasnikovs, A.; Kononova, O.; Machanovskis, A.; Zaharevskis, V.; Akishins, P.; Ruchevskis, S. Mechanical Properties Characterization for Composite Reinforced by Knitted Fabric using Inverse Technique. Part 2. Mechanical properties experimental evaluation by frequency eigenvalues method. Journal of Vibroengineering 2012, 14, 691–698. [Google Scholar]

- Lee, M., Mata-Falcón, J. & Kaufmann, W. Load-deformation behaviour of weft-knitted textile reinforced concrete in uniaxial tension. Mater Struct 54, 210 (2021). [CrossRef]

- Jacobsen, A.J.; Luo, J.J.; Daniel, I.M. Characterization of constitutive behavior of satinweave fabric composite. J. Composite Materials 2004, 38, 555–565. [Google Scholar] [CrossRef]

- Abot, J.L.; Yasmin, A.; Jacobsen, A.J.; Daniel, I.M. In-plane mechanical, thermal, and viscoelastic properties of a satin fabric carbon/epoxy composite. Composites Science and Technology 2004, 64, 263–268. [Google Scholar] [CrossRef]

- Mallick, P. Composites Engineering Handbook. Marcel Dekker, Inc.: New York, 1997. [Google Scholar]

- Kononova, O.; Krasnikovs, A.; Dzelzitis, K.; Kharkova, G.; Vagel, A.; Eiduks, M. Mechanical properties modeling and experimental verification for cotton knitted fabric composites. Estonian Journal of Engineering 2011, 17, 39–50. [Google Scholar] [CrossRef]

- Znoaga, M.; Tanasa, F. Complex textile structures as reinforcement for advanced composite materials. In International conference of scientific paper; AFASES, 2014. [Google Scholar]

- Morgan, P. (2005). Carbon Fibers and Their Composites (1st ed.). CRC Press. [CrossRef]

- Hu, J. Introduction to three-dimensional fibrous assemblies. In J. Hu, 3-D fibrous assemblies Properties, applications and modelling of three-dimensional textile structures; Woodhead Publishing: Cambridge, 2008. [Google Scholar]

- Huang, Z.; Zhang, Y.; Ramakrishna, S. Modeling of the progressive failure behavior of multilayer knitted fabric-reinforced composite laminates. Composite Science and Technology 2001, 61, 2033–2046. [Google Scholar] [CrossRef]

- Ramakrishna S. Tensile Properties of Plain Weft Knitted Glass Fiber Fabric Reinforced Epoxy Composites, Journal of Reinforced Plastics and Composites, July 1997 vol. 16 no. 10 946-966. [CrossRef]

- Rios C.R., Ogin S.L., Lekakou C. and Leong K.H. The Relationship Between Fibre Architecture and Cracking Damage in a Knitted Fabric Reinforced Composite. Available online: http://www.iccm-central.org/Proceedings/ICCM12proceedings/site/papers/pap1035.pdf.

- Hansen A. The Three Extreme Value Distributions: An Introductory Review, Frontiers in Physics, 10 Dec. 2020, Sec. Interdisciplinary Physics,Vol. 8 – 2020. [CrossRef]

- Engelbrecht-Wiggans AE, Phoenix SL. Comparison of maximum likelihood approaches for analysis of composite stress rupture data. J Mater Sci. (2016), 51:6639–61. [CrossRef]

- Mahesh S, Phoenix SL, Beyerelin IJ. Strength distributions and size effects for 2D and 3D composites with Weibull fibers in an elastic matrix. Int. J Fract. (2002) 115:41–85. [CrossRef]

- Sutherland L. S. and Guedes Soares C. Review of probabilistic models of the strength of composite materials. Reliability Engineering and System Safety 56 (1997) 183-196, 1997 Elsevier. [CrossRef]

- Korabelnikov, Y.G.; Tamuzh, V.P.; Siluyanov, O.F.; Bondarenko, V.M.; Azarova, M.T. Scale effect of the strength of fibers and properties of unidirectional composites based on them. Mechanics of Composite Materials 1984, 20, 129–134. [Google Scholar] [CrossRef]

- Gutans, J.; Tamuzh, V. Scale Effect of the Weibull Distribution of Fibre Strength. Mechanics of Composite Materials 1984, 6, 1107–1109. [Google Scholar]

- Kaw, A.K. Mechanics of composite materials; Taylor & Francis, 2006; Mechanical engineering series; 457p, ISBN 0-8493-1343-0. [Google Scholar]

| Break number | Stress parameter (normal stress) <σi> |

Calculation without the frame (MPa), epoxy matrix resin with 0% OSA | Calculation without the frame (MPa), epoxy matrix resin with 20% OSA | Calculation with the frame (MPa), epoxy matrix resin with 0% OSA | Calculation with the frame (MPa), epoxy matrix resin with 20% OSA |

|---|---|---|---|---|---|

| Virgin material | σ0 | 1755.9 | 1761.0 | 1672.2 | 1.679.0 |

| 1 break | σ1 | 2354.5 | 2370.1 | 1740.0 | 1748.9 |

| 2 breaks | σ2 | 2646.0 | 2690.1 | 1670.9 | 1679.1 |

| 3 breaks | σ3 | 2642.5 | 2687.2 | 1365.7 | 1369.2 |

| 4 breaks | σ4 | 1700.3 | 1820.1 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).