1. Introduction

Development and increased economic activity have steadily increased the demand for energy over the last two centuries. Much of this energy is sourced from the combustion of fossil fuels. According to one estimate, 84% of global energy demand came from fossil fuels [

1]. The combustion of fossil fuels adds greenhouse gases (GHGs) to the atmosphere which are exacerbating the climate crisis.

The manufacturing industry has played a key role in economic development [

2,

3,

4], but this sector has also been a major consumer of energy. For instance, in the European Union manufacturing accounted for 26% of final energy consumption in 2020 [

5]. Globally, it is estimated that the manufacturing industry is responsible for about a fifth of the total carbon emissions [

6]. Therefore, improving the energy efficiency of manufacturing is the need of the hour. The United Nations have identified

sustainable consumption and production patterns1 as one of the 17 Sustainable Development Goals. Furthermore, rising energy costs, increased government regulations, and climate-conscious consumers are adding to the urgency of implementing sustainable energy solutions and reducing environmental impact in the manufacturing industry.

An important step towards energy efficiency in manufacturing is to accurately model the energy consumption of manufacturing processes and tools [

7]. This topic has received a lot of attention from the industry as well as the scientific community. Various types of mathematical models are already being used to optimise each and every stage of the manufacturing process. Energy consumption models can be used to control the processes so that their energy efficiency is optimised. These models can also aid in the fault detection as well as maintenance of machine tools [

8,

9]. In this paper we undertake the task of reviewing and categorising the literature on energy modelling with the dual purpose of simplifying the theoretical discussion as well as providing practical guidelines for choosing the appropriate modelling approach.

1.1. Motivation for the work

This paper is primarily motivated by the fact that modelling machine tools and manufacturing processes is a highly complex task for several reasons with some of these outlined below:

Complex systems: the systems under study are themselves very complex. We are dealing with large, distributed and highly interconnected systems spanning multiple physical domains. These systems are controlled by software and they also interact with their environment in complex ways.

Complex procedure: system modelling a cyclic and iterative procedure. It begins with a well-defined objective and initial data, but may involve redefining objectives and acquiring more data. Furthermore, an effective model is expected to serve additional purposes beyond initial specifications, accommodating data that may not have been included in the original sample.

Multidisciplinarity: modelling a system requires understanding the underlying physics, knowledge of operational details as well as data analysis. Focusing on only one aspect without considering others can result in an ineffective model.

Multitude of options: there is a vast range of modelling techniques, data analysis methods and metrics for evaluating model performance. The choice is not straightforward as it depends on multiple factors. As the cliche goes, “modelling is as much an art as a science” [

10].

Data related issues: System modelling within complex industrial settings faces additional challenges related to data. The most prevalent issues are are referred to as the 3B problems: bad, broken and background [

11]. These include missing values, incorrect data, and incomplete data. In addition to these, there are issues around data integration from multiple sources and its interoperability. Furthermore, confidentiality and data security can restrict the scope of the modelling activities.

There is already an enormous amount of literature on modelling applied to the prediction and optimisation of energy consumption in manufacturing. There are also several reviews on this subject which attempt to theoretically classify the individual studies. However, there are several gaps in the current literature. Most of these literature reviews, being bibliometric in nature, have only glossed over the subject. Some recent ones have attempted to lay down theoretical frameworks, but they have several drawbacks. Furthermore, they provide very little practical utility to system modellers. Our framework aims to address these drawbacks.

1.2. Novel Contributions

The main contributions of this paper are

A simple but logical framework, grounded in system modelling theory, is discussed in the context of energy modelling in the manufacturing industry

A critical review of several illustrative articles is presented. These articles are chosen so that they are representative of their respective categories.

Practical aspects including the advantages and disadvantages, as well as associated costs of the different modelling approaches are highlighted.

Four real world case studies are discussed, which serve to underscore the importance of adopting a systematic modelling framework in addressing the challenges involved in modelling real-world industrial problems.

The rest of this paper is organised as follows.

Section 2 gives a detailed account of the related work on this subject. A detailed summary of the literature reviews is presented and some of their drawbacks and the gaps in the current literature are discussed. Next, we discuss some illustrative examples of the distinct approaches to energy modelling in

Section 3 in order to draw out their defining characteristics. This discussion leads to

Section 4, which then describes the framework.

Section 5 discusses four real world case studies from the DENiM [

12] project. These examples highlight the challenges encountered in industrial data analytics problems and also explain the rationale behind choosing a particular modelling approach at each of the project’s pilot sites.

2. Related Work

The topic of energy consumption modelling has received a lot of importance from the manufacturing industry as well as academia. This is evidenced by the huge number of articles published in the last few decades. Furthermore, multiple review articles have been published on this subject. However, the focus of these reviews has shifted away from the practical aspects of modelling approaches. Some of these research endeavours also attempt to lay down theoretical frameworks in the form of taxonomical schemes. However, they use tailor-made categorisations that are not grounded in established theory, which diminishes the generalisability of these frameworks and their applicability to broader contexts. In the following discussion, we present a summary of some recent literature reviews and highlight some of these drawbacks and gaps.

One early review [

13] categorises modelling approaches into theoretical and experimental. However, some empirical models which depend on experimental data are also misclassified as theoretical approaches. In [

14], the authors have restricted their review on empirical models. They also discuss approaches to optimising the energy consumption.

Several other early reviews used simple classification schemes to categorise the various modelling approaches. For instance, in [

15] the authors use model complexity to classify the literature into three categories. A simple classification scheme consisting of three categories is also used in [

16] where the system boundary of the models is used as the main criterion to divide the modelling approaches.

Recently, the trend has been to use very complex multi-dimensional classification schemes. The dimensions define a particular aspect of an energy prediction model, each of which are further divided into sub-categories. A four-dimensional classification scheme was used by [

17] whereas [

7] used six dimensions and [

18] used a seven-dimensional classification scheme. The details of these review articles are summarised in

Table 1.

A number of drawbacks are immediately apparent from the summary of reviews in

Table 1.

The classification schemes have become increasingly complex over time

The focus of reviews has shifted from technical description to bibliometric analysis

There is a lack of clarity in the terminology used

Some of the categories overlap with one another

Some of the categories have no relation with practical aspects of modelling

Besides these issues, there are others drawbacks which limit the practical utility of these frameworks. For instance, they do not attempt to explain the underlying rationale for choosing a particular solution from a plethora of modelling approaches. Any given system can be modelled in multiple different ways. The best choice for the modelling approach is not system-specific, but rather depends on the objectives as well as the data available. However, these reviews have not addressed the data dimension. As a result, these frameworks and classification schemes have limited practical utility for a system modeller working on a real-world industrial problem.

Therefore, there are several gaps in the literature in this field. In particular, there is an urgent need for standardising as well as simplifying the discussion surrounding modelling in the manufacturing industry. The framework proposed in this article attempts to bridge these gaps.

It is worth mentioning the impact of systematic taxonomical frameworks in another closely related strand of literature namely that of Fault Detection and Diagnosis (FDD). Katipamula et. al. in their seminal work [

20] in 2005 proposed a classification scheme to categorise various model-based methods. This framework has not only become part of the standard theory of FDD, but also provided a practical means to compare the various approaches as evidenced by its relevance in the recent articles [

21,

22].

3. Literature Review on Energy Consumption Modelling

In this section we present our analysis of the literature on energy consumption modelling in the manufacturing industry. We look at the various aspects of different approaches to energy modelling.

3.1. Detailed Physics Based Models

Bi and Wang, 2012 [23]: the focus of this study is a parallel kinematic machine which is typically used to carry out sizeable manufacturing operations. A detailed physics-based which considers multi-body kinematics as well as dynamics is used to derive a complex function for the energy consumption. This function can compute the energy consumption for a given set of process parameters and tool orientation. The model is calibrated using the manufacturer’s specifications.

The results of the case study are not validated with real data, and no considerations about the accuracy of the models are presented. The main application of this model is to simulate the energy consumption for a variety of scenarios. The authors use this to present a theoretical optimal configuration for a case study. In relation to other modelling approaches, the authors make the interesting argument that empirical or data-driven models are specific to a particular machine or process, and they cannot be generalised.

Avram and Xirouchakis [24]: in this work the authors have developed a simulation tool that computes the energy consumption by interpreting the machine code. They use a complex physics based model with incorporating the kinematics, dynamics and cutting force components. The authors compare the power consumption predicted by the model to the actual for few tests. The results show that the model is reasonably accurate for low speeds but has poor accuracy for high speed machining.

3.2. Discrete Event Models

Dietmair and Verl, 2009 [25]: this work uses a discrete event formulation which uses a digraph as the basic model structure. The nodes represent operational states of the machine and the edges the transitions between them. Furthermore, each state is characterised by an energy consumption profile. Mathematically, the model is given by:

where are the operational states, is the optimal parameter vector consisting of optimal settings of the control parameters. The aggregate machine energy consumption in a particular state is represented by which consists of the individual energy consumption of the components denoted by . These parameters can be obtained from simple measurements or from machine specifications.

The model was tested at three different complexity levels on a roughing operation. The model takes the sequence of operations as input and outputs the energy consumption profile. The authors report that the overall energy prediction is within 5% of the actual.

While this model was very accurate for the test carried out, one major drawback is that the power consumption of the machine is fixed for each operational state, which is an unrealistic assumption. Moreover, the model is heavily dependent on the energy consumption related parameters provided by the user. The sensitivity of the model to these parameters would be a major concern when applying this model to real-world use cases.

Larek et al., 2011 [26]: the model used in this work includes representations of all the relevant subsystems that contribute to the overall power consumption. Additionally, a workpiece model is also included which keeps track of the geometry and cutting parameters. The subcomponent models have multiple states which enable a finer representation of energy consumption. The model also contains a load calculation subsystem which can interpret the numerical codes and set the individual components into the appropriate states.

The model is validated on a two-axis turning operation in a CNC machine. It can be seen that the simulation underestimates the power consumption and does not account for some of the variations. The authors do not report the numerical accuracy.

Jia et al. [27] – Therblig-Based Model: in this work, Therbligs - a technique used in motion study - is used to represent a basic energy demand unit. One or more Therbligs make up a machining state which in turn corresponds to machining activities. The authors identify two types of Therbligs based on whether they are directly related to the machining or not. For the indirect Therbligs, the power consumption is considered to be constant during operation and it is obtained by averaging a number of measurements. The authors describe simple analytical models for each of the Therbligs directly related to machining.

The authors present a case study on a turning process using a CNC machine. The activities, machine states and therbligs are identified using expert knowledge, and the model parameters are set on the basis of a few measurements. The model is then used to predict the overall energy consumption for manufacturing a stepped shaft which involves multiple cuts on the same workpiece. An accuracy of almost 95% was reported.

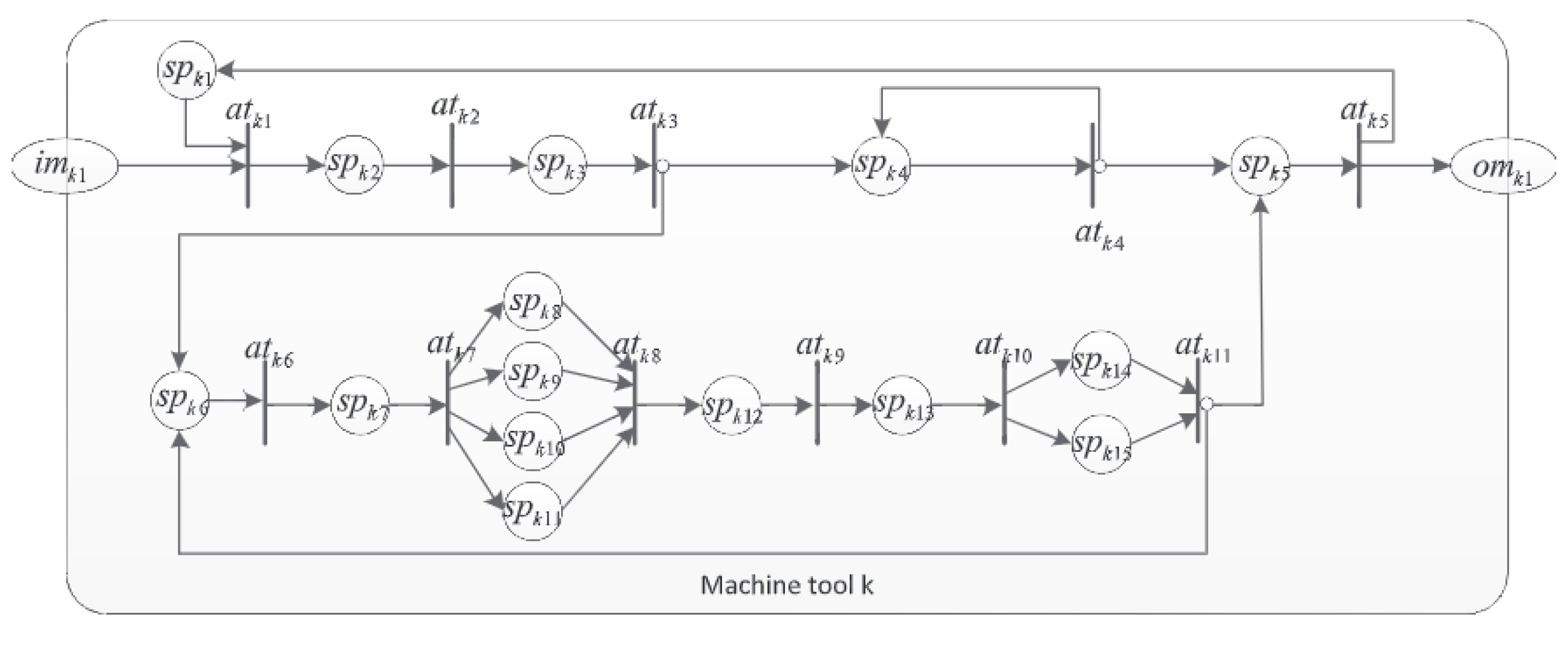

Li et al. [28] – Petri-Nets: in this work the authors present a Coloured Timed Object-Oriented Petri Net (CTOPN) to model the operation of manufacturing machine tools. Utilising the features of the petri-nets a wide range of behaviours can be modelled. The model captures four types of energy consumption behaviours related to the structure of the machine tool, the operational states, the process and the assignment of batches to different working tools. The formalism used here can be described mathematically as follows:

where

is the set of object places corresponding to the subcomponents of the machine tool,

R is the set of transitions,

C is the set of coloured tokens,

T is the set of time-delay attributes,

correspond to the inputs and output functions. Finally,

P is the set of power consumption attributes for each of the object places. An example of a petri-net representing a machine tool, its subcomponents and transitions is shown in

Figure 1

The model parameters are set using measurements or machine specifications. The authors carry out the validation on a series of machining operations in an experimental facility. The overall energy consumption is reported for two operations and the error is about 10%.

3.3. Statistical Models

Bhinge et al. [29]: in this work the authors have used Gaussian Process Regression to develop an energy prediction model. Gaussian process regression is a non-parametric technique which aims to build a distribution of the input-output response, i.e., the energy prediction is given by a mean and covariance function obtained from historical data, which enable the prediction of energy for the new input. The authors not only considered certain cutting parameters, but also the cutting direction and strategy as input features. This enables them to optimise toolpaths and cutting strategies.

The model was trained using data obtained from the machining of eighteen parts. Data from three other parts were used for testing the model. The errors for individual machining operations and production of the whole parts were below 16% and 6% respectively.

3.4. Machine Learning Models

He et al. [30]: in this work the authors have documented the results of a systematic study on various statistical and machine learning methods to predict energy consumption of milling and grinding processes. They compare Support Vector Regression, Gaussian Process Regression with neural networks and Deep Learning. The performance of such methods heavily depends on the features that are fed as inputs. To that end, the authors have also considered various methods of feature generation. They report that the combination of the features generated by convolutional neural networks (CNN) and deep learning gave the most accurate predictions.

Kant et al. [31]: in this work the authors compare a neural network model against support vector regression to predict the energy consumption of milling of medium carbon steel. The input variables are spindle speed, feed-rate, cutting depth and cutting width. They use the Taguchi experimental design method to obtain sixteen data samples, 80% of which are used for training. The results show that the neural network is accurate over all of the the tests. On the other hand, the SVR achieves decent accuracy for some samples, but has a large error for some of the tests. Nevertheless, it must be pointed out that the authors are using a very limited amount of data which may not be entirely representative of the process. Typically, neural networks are trained on the basis of large amounts of historical data.

3.5. Empirical Models

Gutowski et al. [32]: in this seminal paper using empirical modelling, the authors propose a simple, but effective and highly generalisable model for describing a variety of manufacturing processes including subtractive, net-shape and additive. The authors identify that modern manufacturing machines consist of several subsystems which perform auxiliary tasks such as lubrication, cooling, chip removal, tool change and break detection. They cite an example where these tasks account for over 85% of the actual energy so that only 15% goes toward material processing. Furthermore, the power consumption of these tasks is constant with respect to the material processing rate which is the only parameter considered in the model. Therefore, their model can mathematically described as:

where,

P is the overall power consumption comprised of a fixed part

and the variable part depending on the material processing rate

.

The authors have compiled data from various sources and tested the model on various machining process types such as milling, grinding, injection molding and vapor deposition to name a few. This was indeed a seminal paper - as their model is simple yet so widely applicable, their work was used and/or improved in several following studies [

33,

34]

Budinoff et al. [35]: this paper is a good illustration of the flexibility of the grey-box modelling approach. Gutowski’s model given in eqn. (

3) is used as a baseline which only considers the material processing rate. The authors of this paper argue that chip thickness is an important factor in determining the specific energy consumption. They report that the exact reason for this dependence is unknown. However, based on operational knowledge of the domain, the authors propose an improvement to Gutowski’s model as follows:

where h and are the chip thickness and a normalising chip thickness factor and a is a parameter to be determined from the data.

The authors then present the results of a couple of experiments where the models were compared. The modified model (

4) was more accurate for all the tests than Gutowski’s original

3. This paper perfectly captures the essence of the grey-box modelling methodology. Firstly, we start (or create) a baseline model. If it is found to be inadequate, domain-knowledge is leveraged to improve the model by adding more parameters. Experiments are carried out to determine the mathematical relationship that best fits the data. In this process, visual analysis of the data is also used to draw important conclusions e.g., if the relationship is linear or exponential, whether to use a single or piecewise function etc. Numerical analysis is then used to determine the best-fit parameters. Thus, this methodology combines expert knowledge and data driven modelling.

Al Hazza et al. [36]: in this work the authors compare a grey-box model against a neural network for the energy consumption prediction of a high speed turning process. For the grey-box model the Box-Behnken experimental design methodology was used with the parameters cutting speed, rake angle, feed-rate and cutting depth. The authors report that the grey-box model performed slightly better than the neural network model.

4. Framework

Section 2 identified the main drawbacks in the classification schemes used in recent literature on system modelling. In short, the schemes are highly complex with unclear terminology and overlapping categories, thereby limiting their practical utility. In

Section 3 we gave a comprehensive yet concise review of exemplary articles representing the diverse modelling approaches. An interesting observation is that the role of data in the models is an important distinguishing feature. It was seen that some approaches such as physics-based models [

23,

24] as well as models within the discrete event formalism [

25,

26,

27,

28] do not use operational data in building the model. In the latter category, the models predict fixed energy consumption for various states of the machine. On the other hand, statistical and machine learning methods are based on data and typically disregard any domain knowledge. Empirical models make use of first principles, domain knowledge as well as operational details in obtaining the structure of the model. The model parameters, however, are tuned from experimental data.

In this section we develop the proposed framework to serve as a practical guide to professionals in the energy modelling field. We also aim for the framework’s adaptability so that it can extend to generic modelling applications. In order to accomplish these objectives two design principles were used:

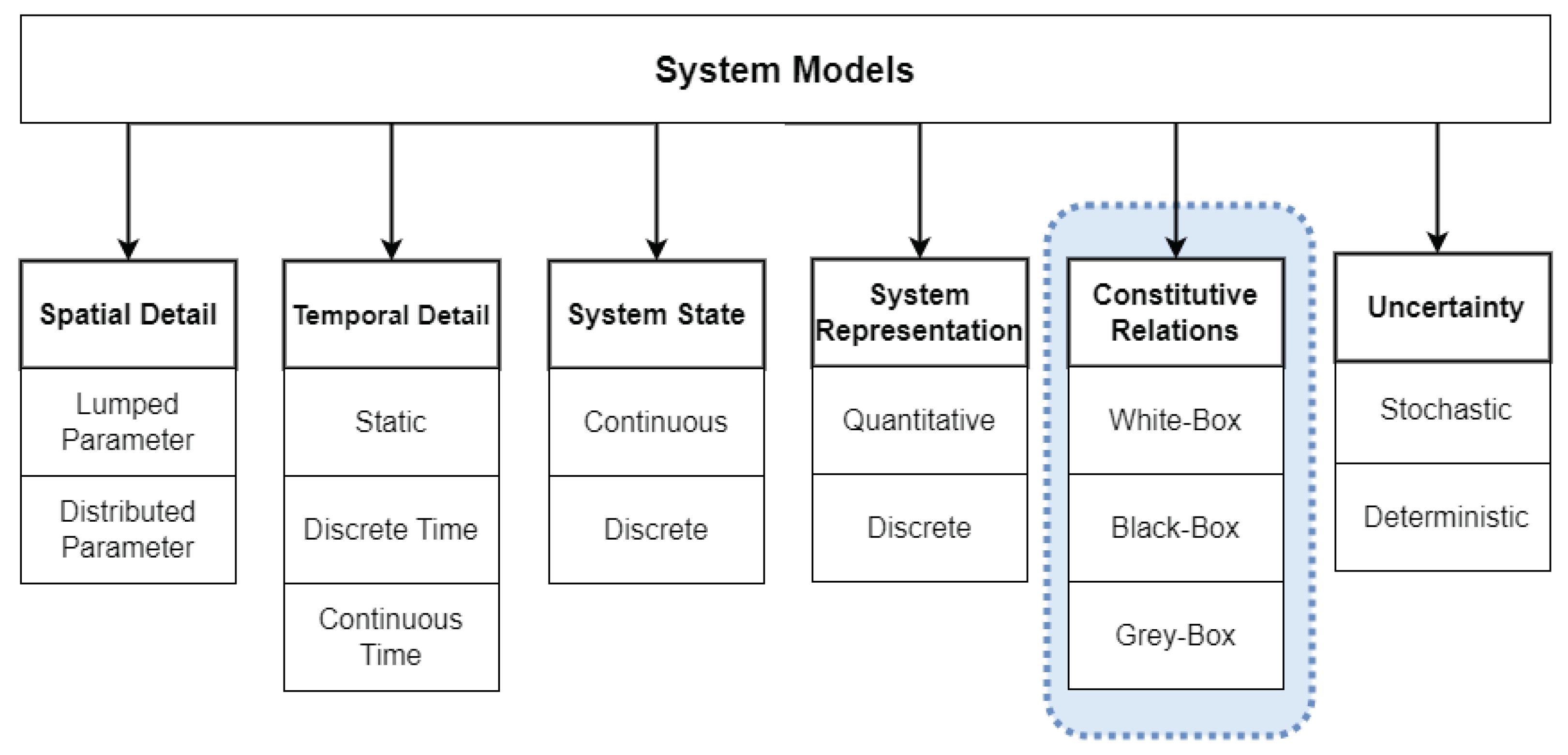

To start our discussion, it’s essential to recognise the various ways of categorising system models (see

Figure 2). However, the most important practical consideration lies in how the model’s constituent relations are derived. This is because these categories—white-box, black-box, and grey-box—essentially depict how data is incorporated into the model. This was also seen to be one of the main differentiating characteristics of the approaches discussed in

Section 3.

Table 2 presents our proposed framework, which enumerates the different aspects of the three modelling approaches. The framework is grounded in classical system modelling theory, but also very compact and practical. Instead of using a multi-dimensional classification scheme only one criterion is used to enumerate the different practical aspects of model development, which are described in detail below:

-

Data Requirements: this is the defining characteristic on the basis of which models are classified.

White-box: these models are entirely based on prior knowledge. Measurements, manufacturer’s specifications, operational parameters etc. may be used, but the constituent relations are based on prior knowledge.

Black-box: in this category the models are derived entirely from the data. Large amount of historical data is typically required.

Grey-box: these models are a mix of white-box and grey-box models. The models are typically developed using the design of experiments approach. However, historical data can also be used, if available.

-

Applications: this aspect discusses the main application areas of each of the three model categories, although some models can also be used in other applications in some situations

White-box: the main application area is simulation. These models are useful in understanding system behaviour in various conditions.

Black-box: the main application of these models is predictive analytics, which makes them useful in decision support tools.

Grey-box: like black-box models are used in predictive analytics and decision support. However, their compact size gives them additional scope such as embedded control systems and fault diagnostic tools

-

Accuracy: note that this is not a comparison across the categories, but the key factors that determine accuracy are presented

White-box: accuracy depends on modelling assumptions. There is a trade-off between model complexity and accuracy.

Black-box: the accuracy strongly depends on data availability quality

Grey-box: by combining expert knowledge as well as experimental data, these models have the potential to reach high accuracy levels even with simple models

-

Development Costs: this aspect highlights the requirements in terms of personnel and computational resources.

White-box: domain experts are required to develop these models. Additionally, commercial modelling software may be necessary.

Black-box: creating and maintaining these models requires data engineers, and machine learning experts. Setting up the data infrastructure and pipelines also adds to the cost.

Grey-box: requires collaboration between domain experts as well as data analysts. If using experimental design, the equipment must be reserved for a portion of time during which it is unavailable for production.

-

Computational Costs:

White-box: depends on model fidelity. As mentioned above, there is a trade-off between model accuracy and computational cost.

Black-box: primarily depends on the type of model chosen. Additionally, one must also consider the computational cost in data pre-processing.

Grey-box: these models typically take the form of algebraic relations between a few key parameters. Therefore, these models have low computational costs.

-

Customisability:

White-box: as they’re based on first principles, these models have a low customisability.

Black-box: there is a wide range of models – from simple statistical models to deep neural nets. However, there is a limited choice in terms of the model parameters.

Grey-box: this is the hallmark of this category. In the development cycle, modellers can start from a baseline model and continuously improve it by considering additional parameters and exploring various mathematical relationships to capture their impact on the process.

-

Explainability:

White-box: as these models encode first principles and system understanding, the model outputs are easy to interpret.

Black-box: as the name suggests, the input-output relationships are somewhat obscure in this class.

Grey-box: with a limited number of parameters and simple relations, grey-box models also provide a high degree of explainability.

-

Uncertainty:

White-box: these models do not account for uncertainty as they are based on fixed values of parameters.

Black-box: these models directly or indirectly take into account the statistical distribution of the data they are trained on. Thus, they can quantify the uncertainty associated with any prediction.

Grey-box: as they are trained from data, this category of models can also quantify the uncertainty in predictions.

-

Dense Output: in describing this aspect, which determines whether a model can provide results beyond its intended purposes, we borrow the terminology from numerical analysis.

White-box: these models can be simulated to understand system behaviour under various conditions. They can be used to calculate any auxiliary parameters of the system.

Black-box: when training these models, the input-output relationship is fixed. The models cannot provide any other information about the system.

Grey-box: like black-box models, these models are also trained with specific input-output relationships in mind. However, thanks to the first principles and domain knowledge that is incorporated, they can provide some additional information as well.

5. Case Studies

This section presents four system modelling case studies within the DENiM [

12] project whose overarching aim is to develop an interoperable digital intelligence platform. The platform provides an integrated toolchain for advanced digital services such as secure edge connectivity, data analytics, energy modelling, fault detection and diagnosis. The project consortium consists of several academic institutions as well as four industry partners where the DENiM platform was implemented, and at the time of writing is under further development. The project recognises the importance of and places a major thrust on energy modelling as a means to achieve energy efficiency. The below sections give a description of the energy modelling tasks carried out at the four pilot sites. A detailed description of each of the pilot sites is beyond the scope of this article. Instead, emphasis will be placed on explaining:

Modelling objectives: the specific business objectives at each of the pilot sites for which the modelling task is carried out

Data: a brief description of the data is provided, highlighting the challenges

Modelling approach: this describes the rationale behind choosing a specific approach which achieves the objectives while overcoming the data-related and other challenges

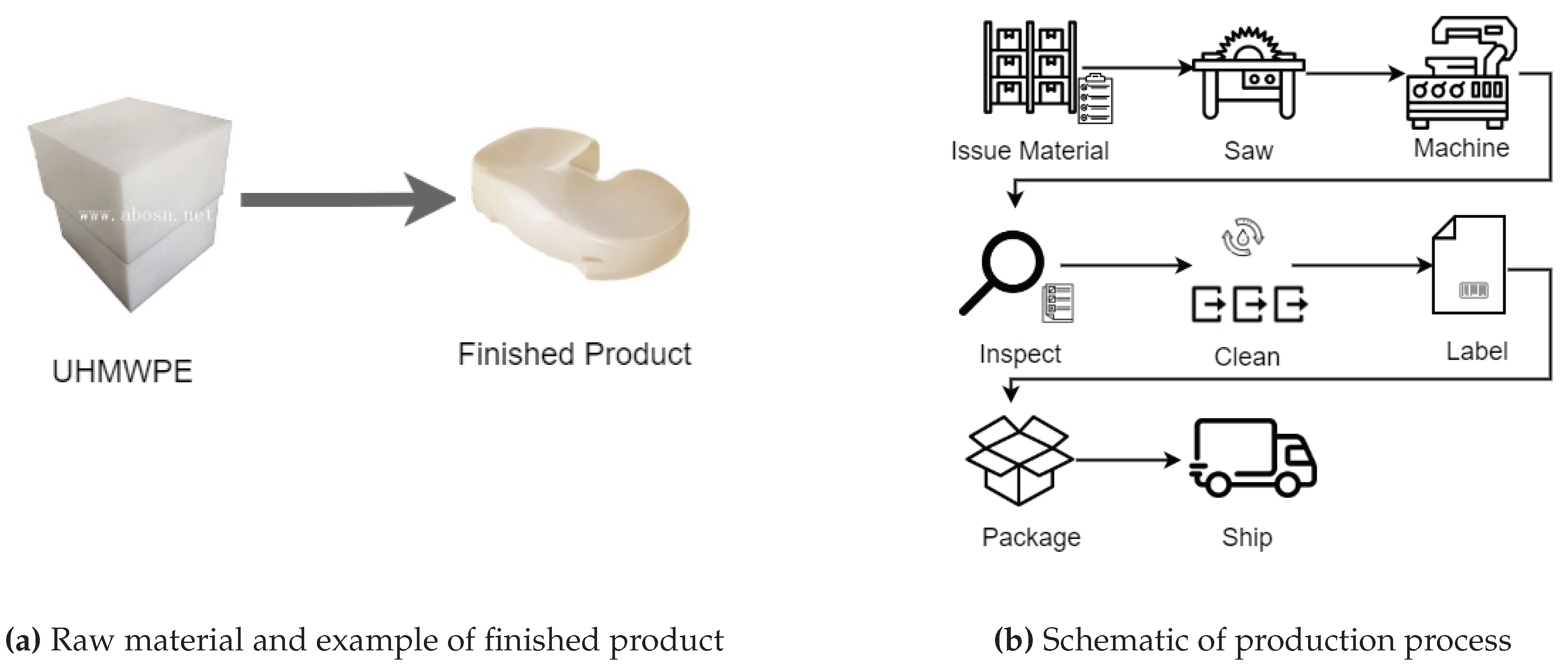

5.1. Pilot 1 – Medical Devices Manufacturing

Pilot 1 is a global medical devices manufacturing company, with a large production facility located in Cork, Ireland, employing over a thousand people. The facility, which is split over two buildings, produces many types of medical devices and orthopaedic implants. The production process is depicted in

Figure 3. Most of these products are manufactured by machining Ultra High Molecular Weight Polyethylene. Except for a few minor variations, the manufacturing process for most products consists of the eight steps illustrated in

Figure 3a.

Many of these product types are medical implants manufactured from UHMWPE. Although there are variations across each product, the overall production process can be boiled down to the eight steps shown in

Figure 3b and described below:

Issue Material: the raw material is allocated to each of the product families. Operators use printers and barcode scanners to enable tracking.

Saw: The material undergoes processing in machine saws to obtain blocks of the required size for each product family.

Machine: The individual blocks are processed using CNC machines to obtain the finished product.

Inspect: The products are inspected for compliance and defective ones are scrapped. A coordinate measuring machine (CMM) is used during this stage.

Clean: The products are cleaned and sterilised in a multi-stage cleanline. The stages include water-baths as well as air-dryers. The parameters such as temperature, flow-rate, pH etc. are tightly controlled.

Label: Each product is assigned labels.

Package: The products are sealed and packaged.

Ship: The products are shipped from the facility.

The significant energy users (SEUs) were defined as any asset with a power rating of more than 3 kW. Thus, the production assets falling under this category are 1.) Electric saws, 2.) CNC Machines, and 3.) Multi-stage Cleanlines.

5.1.1. Modelling Objectives

The main objectives of the modelling are three-fold:

Energy efficiency: by monitoring and analysing energy consumption trends, the model can provide insights for improving energy efficiency

Production planning: the model should be able to predict the energy consumption for a given number of units produced as an input. The model should consider different product types.

Anomaly Detection: The model should also be capable of flagging abnormal energy consumption patterns.

5.1.2. Data

The grey-box modelling approach is the most popular in the literature for predicting the energy consumption of CNC machines. The typical variables used in these approaches are spindle speed, feedrate, cutting depth, material removal rate etc., which are obtained from the PLC of the machines. However, at this site these datapoints were not available. The only data available was the energy consumed and production throughput. Furthermore, these datapoints were sampled at different rates – while the energy data are available at one minute intervals, the production data are manually recorded by the operators at the end of a production batch. Thus, the analysis was based on shift-wise aggregates of energy consumption and production. Each different product type would have different energy requirements. Production operatives provided input indicating that saws and cleanlines were utilised for multiple product types, whereas CNC lathes were dedicated to specific products. Thus, the cleanlines and saws had to be excluded from analysis, which would now focus on product specific energy consumption models for the lathes.

5.1.3. Modelling approach

Due to the limited availability of data the choices for the modelling approach are limited. In the white-box approach, the model would take the form of a process model that predicts a constant energy consumption for each unit of a given product type. However, this approach was rejected as the data showed a significant variance in the energy consumption values. Furthermore, getting even a limited number of accurate measurements was not possible as it would disrupt the daily production targets. Therefore, we settled on the black-box approach by developing a simple linear regression model. This also helps to meet the third objective, i.e., anomaly detection. The prediction intervals of the model were used taken as a threshold for normal operation. Energy consumption for any particular shift which lies beyond the prediction interval is flagged as anomalous and the operators are instructed to inspect the machine to determine the cause for excess energy consumption.

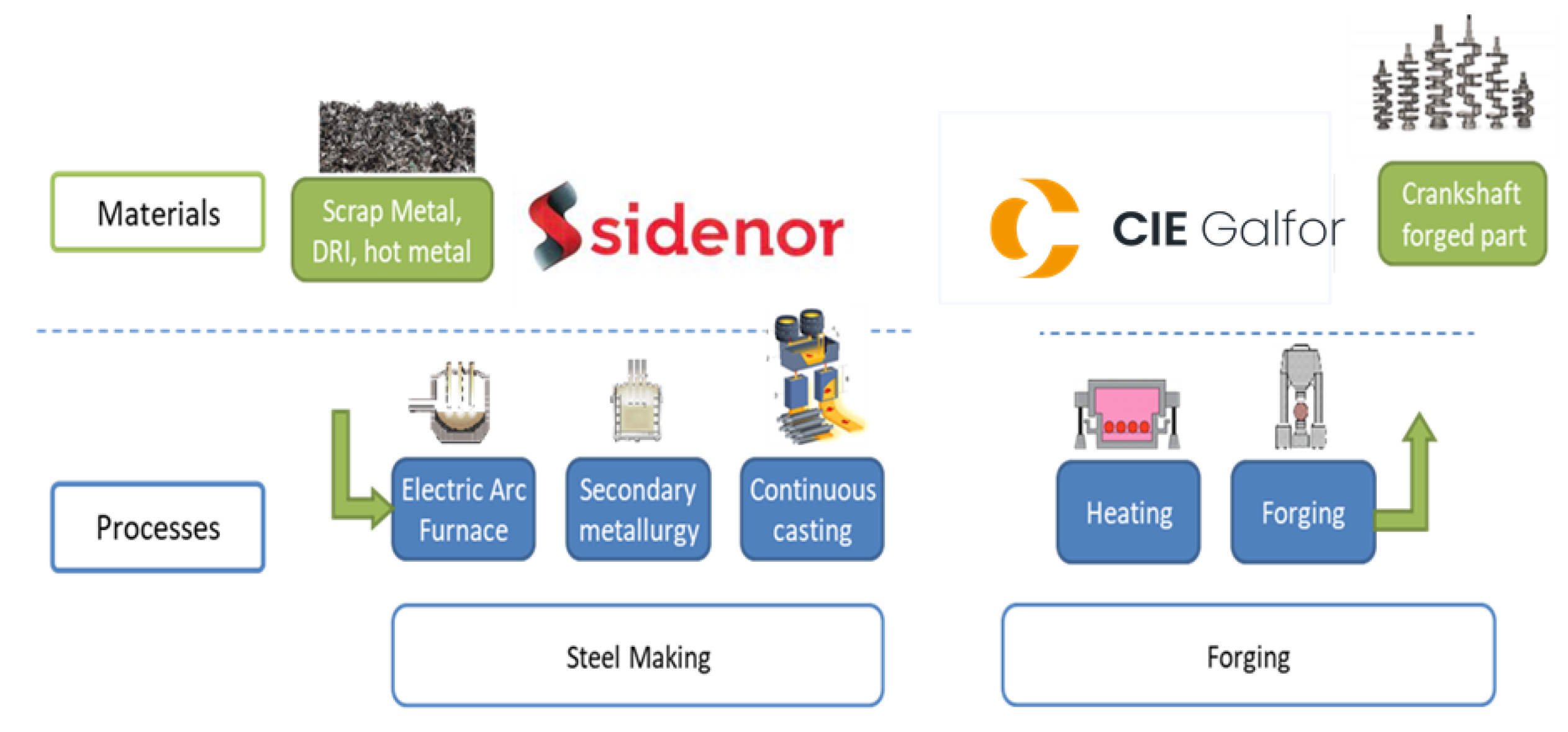

5.2. Pilot 2 – Steel Crankshaft Production

The processes involved at this pilot comprise steelmaking and forging which is shown in figure The main objective is to reduce the energy consumption and environmental impact of the crankshaft production process, taking into account the value chain and ensuring a good performance of the processes.

The process comprises of the following steps

Electric Arc Furnace (EAF): The process starts with the melting of steel scrap by using electrical power as well as chemical energy in the form of natural gas and carbon.

Secondary Metallurgy (SM): This is carried out in two different equipment – Ladle Furnace (LF) and Vacuum Degasser. The aim is to achieve a homogenous composition of steel with low content of sulphur, gases and other impurities.

Continuous Casting: In this step, molten steel is solidified into a billet by means of water-cooled open mold, secondary cooling by water and air sprays, electromagnetic stirring. The product is also cut into the desired size.

Induction Furnace Heating: The main function is to heat the billet to the forging temperature.

Forging Press: This is the step where the heat cylindrical billet is transformed into a crankshaft.

5.2.1. Modelling Objectives:

The main objective of the modelling is to minimise the energy consumption and environmental impact of the production process while still ensuring adequate quality of the final product. The models should be capable of accurately predicting the energy consumption based on the different process parameters. By integrating them with a suitable optimisation algorithm, these models are also used as a decision support tool to find the optimal values of the parameters that minimise the energy consumption.

5.2.2. Data

For each process, the needed data were categorised into different types. The data related to the SM process are categorised in seven types: heat general data, data from EAF process, ladle information, additions during the process, stirring parameters, electric energy information and process control measurements (compositions and temperatures at different points of the process). On the other hand, the data related to the induction furnace process (CIE GALFOR) are classified in four types: batch general data, production process data, electrical parameters and process measurements (temperatures of the billet at the exit).

5.2.3. Modelling Approach

This is a complex manufacturing process consisting of various steps, each of which involves different parameters. Due to this complexity, a purely white-box approach was ruled out as the modelling would be expensive as well as time-consuming. As process data is available, the black-box modelling approach was chosen, within which different modelling methods were tested. The modelling methods included Neural Networks, Gradient Boosting and Random Forests. Feature engineering was also carried out to determine the appropriate set of input variables to include in the models. For instance, in the modelling of the electric arc furnace (EAF), the raw material consists of different types of scrap and it can be input in two ways – absolute quantities in kgs or percentages of the overall scrap basket. Moreover, there are various data points that impact the process such as fume extraction, cooling etc., however, they may not have a significant impact on the accuracy of the models. The final set of variables selected are as follows:

general heat data such as the number of the heating step in the cycle, and the programme being used

data about the hotheel (molten steel remaining from previous step) such as amount, temperature, oxygen and phosphorus content etc.

total quantities of the different types of scrap and additions such as slag formers and carburisers.

information about other additions such as oxygen, natural gas, coal etc. at different stages of the process

information of the material after the melting (temperature, Oxygen and Phosphorous content).

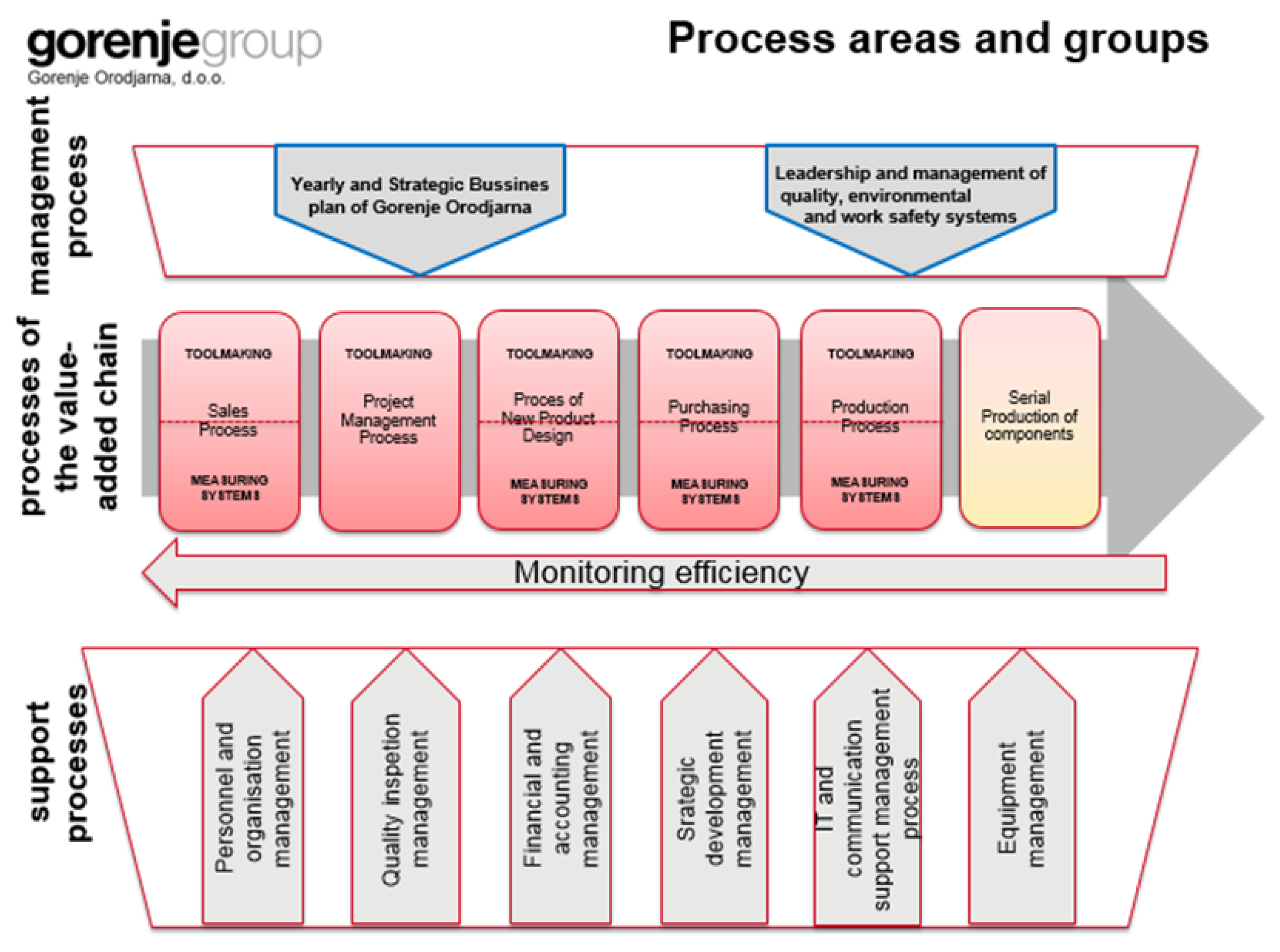

5.3. Pilot 3 – Tool manufacturing

GORENJE ORODJARNA, d.o.o. is a major tool making company in Slovenia. The company specialises in development, manufacturing, marketing and maintenance of a variety of tools for sheet metal processing, progressive and transfer tools and injection moulding tools.There are various machining steps involved in tool making including milling, grinding, drilling, turning, electric discharge machining and laser processing.

Owing to the fact that the process is continuously changing, focus is placed on manufacturing routes rather than focusing on individual assets. Nevertheless, the flexible and continuously changing production means that it is still a challenge to select a specific optimisation target. For this reason, sample manufacturing routes are modelled, and the developed models and optimisation tools, need to adapt seamlessly to the new operational restrictions of every new product. Some of the key manufacturing processes are shown in

Figure 5.

5.3.1. Modelling Objectives

The main objectives are

Informed decision making for operation managers to improve energy efficiency enabled by energy monitoring.

Optimal production planning in terms of the manufacturing route and the set of machines involved.

5.3.2. Data

There were no energy sensors available on any of the machines at the beginning of the project. Power meters were installed to measure parameters such as the voltage, current, power etc. to perform energy analysis and modelling. These data are recorded at one-minute intervals. Real-time data from the sensors is not sufficient, the models also need operational data and process parameters of the current step being executed. The most straightforward way is through connection to the machine controllers or through the enterprise level management software. However, similar to Pilot 1, none of these were available due to technical or data confidentiality constraints. To circumvent this, a customised software called the Gorenje Operations Logger (GOL) was developed. This enables the machine operators to manually register logs for the operations along with some process parameter values. The following parameters are obtained:

order number: this is a unique identifier for the operations within a manufacturing route

process type: records the type of process such as grinding, milling, pressing etc.

sub process: details of the sub-process where applicable

machine: identifies the specific machine involved at any step within the manufacturing route

material: identifies the specific material among a set of choices

start and end times: the time at which any step starts and ends

process parameters: depending on the particular process, various process parameters, such as cutting parameters, spindle speed etc. are recorded

Again, similar to Pilot 1, the production data are logged only at the end of a production batch.

5.3.3. Modelling Approach

Due to the complexity of the overall production and the variety of individual processes, the white-box modelling approach was rejected as it would be too time-consuming. The same would apply to the grey-box modelling procedure, and therefore, the black-box modelling approach was selected. Within this approach, various modelling methods as well as synthetic data generation was used to obtain the final set of models as described below:

Linear regression: being the simplest method in the black-box approach, linear regression was applied first. However, it was found that the process variables do not exhibit sufficient correlation with the energy consumption. The mean squared error (MSE) of the model was of the same order of magnitude as the energy consumption. Therefore, this method was rejected.

Neural network: in this step, neural networks with different structures and various settings of the hyper-parameters were tested while trying to find a balance between the training time and accuracy of predictions. While, the MSE was reduced in comparison to linear regression, it is still not satisfactory.

Synthetic data: to improve the accuracy of the models, one avenue explored was that of synthetic data generation. A Gaussian approach was used to obtain synthetic data that is statistically similar to the original dataset. The new dataset was reused in training the linear regression as well as the neural networks. The results showed some improvements, but were still not acceptable.

XGBoost regression: The new dataset consisting of real and synthetic data was used with XGBoost regression. This method provided the most satisfactory results as the MSE was one-fifth of the one for the first step i.e., linear regression.

5.4. Pilot 4 – Plastics Processing

MET is a dynamic enterprise located in Northern Italy which specialises in mechanics and packaging-processing machines for the food, beverage and pharmaceutical industry. Its main activity focuses on plastics, aluminium and composites processing for the production of tailored components for industrial machinery. Some of the products manufactured at MET are shown in

Figure 6

Each component is typically made-to-order and generally produced with lot size one, making the company a highly specialised player in customised production for very demanding industrial customers. The production takes place in two buildings hosting different CNC machines for different operations ranging from milling and turning to waterjet and laser cutting. No standard production processes exist in MET due to the quick response required by the continuously changing customer’s needs. The whole production plan is daily defined relying completely on the operators’ experience.

5.4.1. Modelling Objectives

Through the energy models implementation, the company aims to achieve the following:

Predict the energy required by the manufacturing of each single product, in order to enable energy-based optimisations and accurately quote each order.

Introduce the energy consumption as optimisation variable in the choice of the optimal production set up and schedule, improving the overall efficiency of the plant.

Evaluate quantitatively the convenience of the installation of renewable energy sources and energy storage systems.

5.4.2. Data

Initially no energy related data was available in MET, so different sensors have been installed to monitor the energy consumption at machine and plant level. Furthermore, the control software of selected machines has been modified in order to be able to continuously monitor and export the machine state together with all relevant operating parameters.

5.4.3. Modelling Approach

There are various considerations that went into choosing the modelling approach for this pilot site. Firstly, the continuously varying production process meant that there is limited product-specific historical data available for analysis. This also means that the model should be generic and be able to model each individual machine’s processes, rather than the overall energy required for specific products. In view of that as well as some of the research literature on this subject, white-box physics-based models were considered as the first choice. This approach would meet the the primary objective of optimisation. The developed model would enable the simulation of several what-if scenarios to obtain optimal parameter values and settings. However, several unforeseen operational difficulties arose during the project, primarily surrounding data access, which made it difficult to obtain even those physics related parameters required by the white-box models. The black-box approach was ruled out due to limited data. Therefore, the grey-box approach was used for models of the CNC machines. These models depend on some process parameters and a limited amount of data, but achieve an accuracy adequate for the requirements. Nevertheless, white-box modelling is the only approach viable for the simulation of renewable energy sources and energy storage systems (i.e. photovoltaic panels and batteries), since such systems are not currently present on the plant and therefore no data are available. State of the art mathematical formulation have been utilised for such physic-based models relying on datasheets, parameters and weather forecasts provided by a web service. The models will be used within the cost-benefit analysis for the installation of renewable energy and energy storage systems.

6. Conclusions

In this article we present a practical modelling framework based on our analysis of the literature on energy consumption modelling in the manufacturing industry. Several illustrative research articles were critically analysed to identify differences as well as commonalities in the modelling approaches. The approaches are categorised according to the three-fold model classification, which includes white-box, black-box, and grey-box approaches, the basis for which is the use of data in deriving the constituent relationships. These approaches differ across various other aspects as well, which are encapsulated in the framework. Being grounded in this basic principle of system modelling theory, the framework can also be extended to other general applications beyond the manufacturing industry. Data availability and quality pose significant challenges in addressing real-world industrial problems. Insights gained from industry partners involved in the DENiM project, were addressed in the framework, which was proposed as a solution subsequently to the pilot partners, where it proved successful in guiding the implementation of the most suitable strategies. The realm of modelling is very vast due to the variety of approaches and methods available. Recent advancements in Data Science and machine learning have made black-box models very popular. However, it is important to consider alternative approaches. While model accuracy is the primary consideration, there are many other factors that need to be taken into account before settling on a particular approach. We hope that this framework will serve as an aid to navigate the complex landscape of modelling by highlighting the chief differences between the three different approaches.

Author Contributions

AR: conceptualisation, literature review, writing – original draft preparation (Introduction, Literature Review, Framework, Pilot 1); JIB: writing – original draft preparation (Pilot 2), reviewing and editing; LPB: writing – original draft preparation (Pilot 3); MG: writing – original draft preparation (Pilot 4); TG: writing, review and editing; JV: supervision, review and editing; AMcG: supervision, review and editing, funding acquisition; AH: project administration, review and editing; KB: supervision, review and editing.

Funding

The authors want to thank the European Commission for funding this work under Project DENiM. This project has received funding from the European Union‘s Horizon 2020 research and innovation programme under grant agreement No 958339.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rapier, R. Fossil Fuels Still Supply 84 Percent Of World Energy — And Other Eye Openers From BP’s Annual Review. Available online: https://www.forbes.com/sites/rrapier/2020/06/20/bp-review-new-highs-in-global-energy-consumption-and-carbon-emissions-in-2019/.

- Haraguchi, N.; Cheng, C.F.C.; Smeets, E. The importance of manufacturing in economic development: Has this changed? World Dev. 2017, 93, 293–315. [Google Scholar] [CrossRef]

- Higgins, S. Manufacturing in Ireland 2022. Available online: https://www.ibec.ie/-/media/ibec-manufacturing-report-2022.pdf.

- World Bank Data - Manufacturing, value added as percentage of GDP. Available online: https://data.worldbank.org/indicator/NV.IND.MANF.ZS.

- Final Energy Consumption in Industry - Detailed Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics.

- Reducing the carbon footprint of the manufacturing industry through data sharing. Available online: https://www.weforum.org/impact/carbon-footprint-manufacturing-industry/.

- Walther, J.; Weigold, M. A systematic review on predicting and forecasting the electrical energy consumption in the manufacturing industry. Energies 2021, 14. [Google Scholar] [CrossRef]

- Xia, T.; Shi, G.; Si, G.; Du, S.; Xi, L. Energy-oriented joint optimization of machine maintenance and tool replacement in sustainable manufacturing. J. Manuf. Syst. 2021, 59, 261–271. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tools. CIRP Ann. 2010, 59, 21–24. [Google Scholar] [CrossRef]

- Shannon, R.E. Introduction to the art and science of simulation. In Proceedings of the 1998 winter simulation conference. proceedings (cat. no. 98ch36274). IEEE, Vol. 1; 1998; pp. 7–14. [Google Scholar]

- Lee, J. Industrial AI; Springer Singapore, 2020. [CrossRef]

- Consortium, T.D. Consortium;, T.D. DENiM:Unlocking the Energy Saving Potential in Manufacturing Systems. Available online: https://denim-fof.eu/.

- Zhang, Y. Review of recent advances on energy efficiency of machine tools for sustainability. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2015, 229, 2095–2108. [Google Scholar] [CrossRef]

- Yoon, H.S.; Kim, E.S.; Kim, M.S.; Lee, J.Y.; Lee, G.B.; Ahn, S.H. Towards greener machine tools – A review on energy saving strategies and technologies. Renew. Sustain. Energy Rev. 2015, 48, 870–891. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy consumption model and energy efficiency of machine tools: A comprehensive literature review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Liu, Z.Y.; He, Y.; Cao, H.J.; Guo, Y.B. Energy consumption in machining: Classification, prediction, and reduction strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Reinhardt, H.; Bergmann, J.P.; Münnich, M.; Rein, D.; Putz, M. A survey on modeling and forecasting the energy consumption in discrete manufacturing. Procedia CIRP 2020, 90, 443–448. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. A systematic literature review on machine tool energy consumption. J. Clean. Prod. 2020, 275, 123125. [Google Scholar] [CrossRef]

- Moradnazhad, M.; Unver, H.O. Energy efficiency of machining operations: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1871–1889. [Google Scholar] [CrossRef]

- Katipamula, S.; Brambley, M.R. Methods for fault detection, diagnostics, and prognostics for building systems—a review, part I. Hvac&R Res. 2005, 11, 3–25. [Google Scholar]

- Chen, J.; Zhang, L.; Li, Y.; Shi, Y.; Gao, X.; Hu, Y. A review of computing-based automated fault detection and diagnosis of heating, ventilation and air conditioning systems. Renew. Sustain. Energy Rev. 2022, 161, 112395. [Google Scholar] [CrossRef]

- Nelson, W.; Culp, C. Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review. Energies 2022, 15, 5534. [Google Scholar] [CrossRef]

- Bi, Z.; Wang, L. Optimization of machining processes from the perspective of energy consumption: A case study. J. Manuf. Syst. 2012, 31, 420–428. [Google Scholar] [CrossRef]

- Avram, O.I.; Xirouchakis, P. Evaluating the use phase energy requirements of a machine tool system. J. Clean. Prod. 2011, 19, 699–711. [Google Scholar] [CrossRef]

- Dietmair, A.; Verl, A. A generic energy consumption model for decision making and energy efficiency optimisation in manufacturing. Int. J. Sustain. Eng. 2009, 2, 123–133. [Google Scholar] [CrossRef]

- Larek, R.; Brinksmeier, E.; Meyer, D.; Pawletta, T.; Hagendorf, O. A discrete-event simulation approach to predict power consumption in machining processes. Prod. Eng. 2011, 5, 575–579. [Google Scholar] [CrossRef]

- Jia, S.; Tang, R.; Lv, J. Therblig-based energy demand modeling methodology of machining process to support intelligent manufacturing. J. Intell. Manuf. 2014, 25, 913–931. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Wang, Y.; Wang, Y.; Yan, P.; Lin, S. A modeling method for hybrid energy behaviors in flexible machining systems. Energy 2015, 86, 164–174. [Google Scholar] [CrossRef]

- Bhinge, R.; Park, J.; Law, K.H.; Dornfeld, D.A.; Helu, M.; Rachuri, S. Toward a Generalized Energy Prediction Model for Machine Tools. J. Manuf. Sci. Eng. 2017, 139. [Google Scholar] [CrossRef]

- He, Y.; Wu, P.; Li, Y.; Wang, Y.; Tao, F.; Wang, Y. A generic energy prediction model of machine tools using deep learning algorithms. Appl. Energy 2020, 275, 115402. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Predictive Modeling for Power Consumption in Machining Using Artificial Intelligence Techniques. Procedia CIRP 2015, 26, 403–407. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. 2006.

- Rajemi, M.; Mativenga, P.; Aramcharoen, A. Sustainable machining: Selection of optimum turning conditions based on minimum energy considerations. J. Clean. Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Bányai, Á.; Bányai, T. Real-time maintenance policy optimization in manufacturing systems: An energy efficiency and emission-based approach. Sustainability 2022, 14, 10725. [Google Scholar] [CrossRef]

- Budinoff, H.; Bhinge, R.; Dornfeld, D. A material-general energy prediction model for milling machine tools. IEEE, 8 2016, pp. 161–164. [CrossRef]

- Al-H, M.H.F.; Adesta, E.Y.T.; Ali, A.M.; Agusman, D.; Supr, M.Y. Energy Cost Modeling for High Speed Hard Turning. J. Appl. Sci. 2011, 11, 2578–2584. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).