Submitted:

27 February 2024

Posted:

28 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

| Variable | Digital Supply Chain | Supply Chain Sustainability | Supply Chain Resilience | Supply Chain Dynamism |

|---|---|---|---|---|

| Digital Supply chain | 0.714 | |||

| Supply Chain Sustainability | 0.580 | 0.854 | ||

| Supply Chain Resilience | 0.636 | 0.661 | 0.842 | |

| Supply Chain Dynamism | 0.504 | 0.510 | 0.452 | 0.788 |

4. Discussion

5. Conclusions

Funding

Acknowledgments

References

- Hatamlah, H.; Allahham, M.; Abu-AlSondos, I.A.; Al-junaidi, A.; Al-Anati, G.M.; Al-Shaikh, and M. The Role of Business Intelligence Adoption as a Mediator of Big Data Analytics in the Management of Outsourced Reverse Supply Chain Operations. Appl. Math. Inf. Sci. 2023, 17, 897–903. [CrossRef]

- Ali, A.; Ismail, I.H.M.; Abulehia, A. Supply Chain Resilience and Information Technology Alignment on Firm Performance. 2023. [Google Scholar]

- Jazairy, A.; von Haartman, R. Analysing the Institutional Pressures on Shippers and Logistics Service Providers to Implement Green Supply Chain Management Practices. Int. J. Logist. Res. Appl. 2020, 23, 44–84. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, Y.; Guan, X.; Xu, M.; Wang, L.; Wang, H.; Liu, Y. Collaborative Two-Echelon Multicenter Vehicle Routing Optimization Based on State–Space–Time Network Representation. J. Clean. Prod. 2020, 258. [Google Scholar] [CrossRef]

- De Boeck, K.; Besiou, M.; Decouttere, C.; Rafter, S.; Vandaele, N.; Van Wassenhove, L.N.; Yadav, P. Data, Analytical Techniques and Collaboration between Researchers and Practitioners in Humanitarian Health Supply Chains: A Challenging but Necessary Way Forward. J. Humanit. Logist. Supply Chain Manag. 2023, 13, 237–248. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing Supply Chain Digitalization and Unphysicalization to Enhance Supply Chain Performance: A Conceptual Framework; 2023; Volume 53, ISBN 0620220201. [Google Scholar]

- Ivanov, D. Digital Supply Chain Management and Technology to Enhance Resilience by Building and Using End-to-End Visibility During the COVID-19 Pandemic. IEEE Trans. Eng. Manag. 2021. [Google Scholar] [CrossRef]

- Shqair, M.I.; Altarazi, S.A. Evaluating the Status of SMEs in Jordan with Respect to Industry 4.0: A Pilot Study. Logistics 2022, 6. [Google Scholar] [CrossRef]

- Seepma, A.P.; de Blok, C.; Van Donk, D.P. Designing Digital Public Service Supply Chains: Four Country-Based Cases in Criminal Justice. Supply Chain Manag. 2020, 26, 418–446. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as Enabler for a Sustainable Development: A Qualitative Assessment of Its Ecological and Social Potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Abdul, S.; Khan, R.; Zhang, Y.; Nathaniel, S. LogForum. 2020, 16, 141–159.

- Hatamlah, H.; Allan, M.; Abu-Alsondos, I.; Shehadeh, M.; Allahham, M. The Role of Artificial Intelligence in Supply Chain Analytics during the Pandemic. Uncertain Supply Chain Manag. 2023, 11, 1175–1186. [Google Scholar] [CrossRef]

- Allahham, M.; Ahmad, A.Y.B. AI-Induced Anxiety in the Assessment of Factors Influencing the Adoption of Mobile Payment Services in Supply Chain Firms: A Mental Accounting Perspective. Int. J. Data Netw. Sci. 2024, 8, 505–514. [Google Scholar] [CrossRef]

- Alazab, M. Industry 4 . 0 Innovation : A Systematic Literature Review on the Role of Blockchain Technology in Creating Smart and Sustainable Manufacturing Facilities. 2024.

- Rossini, M.; Powell, D.J.; Kundu, K. Lean Supply Chain Management and Industry 4.0: A Systematic Literature Review. Int. J. Lean Six Sigma 2023, 14, 253–276. [Google Scholar] [CrossRef]

- Baycik, N.O.; Gowda, S. Digitalization of Operations and Supply Chains: Insights from Survey and Case Studies. Digit. Transform. Soc. 2023. [Google Scholar] [CrossRef]

- Sharabati, A.A.; Allahham, M.; Yahiya, A.; Ahmad, B.; Sabra, S. EFFECTS OF ARTIFICIAL INTEGRATION AND BIG DATA ANALYSIS ON ECONOMIC VIABILITY OF SOLAR MICROGRIDS : MEDIATING ROLE OF COST BENEFIT ANALYSIS. 2023, 6, 360–379.

- Shahzad, A.; Zhang, K.; Gherbi, A. Intuitive Development to Examine Collaborative Iot Supply Chain System Underlying Privacy and Security Levels and Perspective Powering through Proactive Blockchain. Sensors (Switzerland) 2020, 20, 1–27. [Google Scholar] [CrossRef]

- Srai, J.S.; Graham, G.; Van Hoek, R.; Joglekar, N.; Lorentz, H. Impact Pathways: Unhooking Supply Chains from Conflict Zones—Reconfiguration and Fragmentation Lessons from the Ukraine–Russia War. Int. J. Oper. Prod. Manag. 2023, 43, 289–301. [Google Scholar] [CrossRef]

- Lai, P.L.; Su, D.T.; Tai, H.H.; Yang, C.C. The Impact of Collaborative Decision-Making on Logistics Service Performance for Container Shipping Services. Marit. Bus. Rev. 2020, 5, 175–191. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K. Blockchain and Supply Chain Sustainability. Logforum 2020, 16, 363–372. [Google Scholar] [CrossRef]

- Trivellas, P.; Malindretos, G.; Reklitis, P. Implications of Green Logistics Management on Sustainable Business and Supply Chain Performance: Evidence from a Survey in the Greek Agri-Food Sector. Sustain. 2020, 12, 1–29. [Google Scholar] [CrossRef]

- Bahrami, M.; Shokouhyar, S.; Seifian, A. Big Data Analytics Capability and Supply Chain Performance: The Mediating Roles of Supply Chain Resilience and Innovation. Mod. Supply Chain Res. Appl. 2022, 4, 62–84. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R. Supply Chain Sustainability during Turbulent Environment: Examining the Role of Firm Capabilities and Government Regulation. Oper. Manag. Res. 2022, 15, 1081–1095. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Determining the Antecedents of Dynamic Supply Chain Capabilities. Supply Chain Manag. 2020, 25, 427–442. [Google Scholar] [CrossRef]

- Norrman, A.; Wieland, A. The Development of Supply Chain Risk Management over Time: Revisiting Ericsson. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 641–666. [Google Scholar] [CrossRef]

- Roque Júnior, L.C.; Frederico, G.F.; Costa, M.L.N. Maturity and Resilience in Supply Chains: A Systematic Review of the Literature. Int. J. Ind. Eng. Oper. Manag. 2023, 5, 1–25. [Google Scholar] [CrossRef]

- Elijah, O.; Rahman, T.A.; Orikumhi, I.; Leow, C.Y.; Hindia, M.N. An Overview of Internet of Things (IoT) and Data Analytics in Agriculture: Benefits and Challenges. IEEE Internet Things J. 2018, 5, 3758–3773. [Google Scholar] [CrossRef]

- Markus, S.; Buijs, P. Beyond the Hype: How Blockchain Affects Supply Chain Performance. Supply Chain Manag. 2022, 27, 177–193. [Google Scholar] [CrossRef]

- Hallikas, J.; Immonen, M.; Brax, S. Digitalizing Procurement: The Impact of Data Analytics on Supply Chain Performance. Supply Chain Manag. 2021, 26, 629–646. [Google Scholar] [CrossRef]

- Thakur, S.; Breslin, J.G. Scalable and Secure Product Serialization for Multi-Party Perishable Good Supply Chains Using Blockchain. Internet of Things (Netherlands) 2020, 11, 100253. [Google Scholar] [CrossRef]

- Valashiya, M.C.; Luke, R. Enhancing Supply Chain Information Sharing with Third Party Logistics Service Providers. Int. J. Logist. Manag. 2023, 34, 1523–1542. [Google Scholar] [CrossRef]

- Jia, F.; Peng, S.; Green, J.; Koh, L.; Chen, X. Soybean Supply Chain Management and Sustainability: A Systematic Literature Review. J. Clean. Prod. 2020, 255. [Google Scholar] [CrossRef]

- Zhou, J.; (Peggy) Chen, S.L.; Shi, W. (Wendy) The Concept of the Cruise Supply Chain and Its Characteristics: An Empirical Study of China’s Cruise Industry. Marit. Bus. Rev. 2022, 7, 196–221. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of Intertwined Supply Networks: Extending the Supply Chain Resilience Angles towards Survivability. A Position Paper Motivated by COVID-19 Outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Herold, D.M.; Nowicka, K.; Pluta-Zaremba, A.; Kummer, S. COVID-19 and the Pursuit of Supply Chain Resilience: Reactions and “Lessons Learned” from Logistics Service Providers (LSPs). Supply Chain Manag. 2021, 26, 702–714. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. A Review of Literature on Implementation and Operational Dimensions of Supply Chain Digitalization: Framework Development and Future Research Directions. Int. J. Inf. Manag. Data Insights 2023, 3, 100156. [Google Scholar] [CrossRef]

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial Intelligence-Driven Innovation for Enhancing Supply Chain Resilience and Performance under the Effect of Supply Chain Dynamism: An Empirical Investigation. Ann. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Alfalla-Luque, R.; Luján García, D.E.; Marin-Garcia, J.A. Supply Chain Agility and Performance: Evidence from a Meta-Analysis. Int. J. Oper. Prod. Manag. 2023, 43, 1587–1633. [Google Scholar] [CrossRef]

- Rahman, M.S.; Gani, M.O.; Fatema, B.; Takahashi, Y. B2B Firms’ Supply Chain Resilience Orientation in Achieving Sustainable Supply Chain Performance. Sustain. Manuf. Serv. Econ. 2023, 2, 100011. [Google Scholar] [CrossRef]

- Nwagwu, U.; Niaz, M.; Chukwu, M.U.; Saddique, F. The Influence of Artificial Intelligence to Enhancing Supply Chain Performance Under the Mediating Significance of Supply Chain Collaboration in Manufacturing and Logistics Organizations in Pakistan under the Creative Common Attribution Non-Commercial 4.0. 2023, 01, 29–40. [Google Scholar]

- Sarkar, A.; Routroy, S.; Sultan, F.A. The Impact of Co-Creation and Co-Invention in Supply Chains: A Bibliometric Review. Arab Gulf J. Sci. Res. 2022, 40, 364–391. [Google Scholar] [CrossRef]

- Bischoff, O.; Seuring, S. Opportunities and Limitations of Public Blockchain-Based Supply Chain Traceability. Mod. Supply Chain Res. Appl. 2021, 3, 226–243. [Google Scholar] [CrossRef]

- Jawabreh, O.; Baadhem, A.M.; Ali, B.J.A.; Atta, A.A.B.; Ali, A.; Al-Hosaini, F.F.; Allahham, M. The Influence of Supply Chain Management Strategies on Organizational Performance in Hospitality Industry. Appl. Math. Inf. Sci. 2023, 17, 851–858. [Google Scholar] [CrossRef]

- Ivanov, D. Viable Supply Chain Model: Integrating Agility, Resilience and Sustainability Perspectives—Lessons from and Thinking beyond the COVID-19 Pandemic. Ann. Oper. Res. 2022, 319, 1411–1431. [Google Scholar] [CrossRef]

- Hossan Chowdhury, M.M.; Quaddus, M.A. Supply Chain Sustainability Practices and Governance for Mitigating Sustainability Risk and Improving Market Performance: A Dynamic Capability Perspective. J. Clean. Prod. 2021, 278, 123521. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Since January 2020 Elsevier Has Created a COVID-19 Resource Centre with Free Information in English and Mandarin on the Novel Coronavirus COVID- 19 . The COVID-19 Resource Centre Is Hosted on Elsevier Connect , the Company ’ s Public News and Information . 2020.

- Nandi, M.L.; Nandi, S.; Moya, H.; Kaynak, H. Blockchain Technology-Enabled Supply Chain Systems and Supply Chain Performance: A Resource-Based View. Supply Chain Manag. 2020, 25, 841–862. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Knowl. Strateg. 2009, 18, 77–116. [Google Scholar] [CrossRef]

- Nakabuye, Z.; Mayanja, J.; Bimbona, S.; Wassermann, M. Technology Orientation and Export Performance: The Moderating Role of Supply Chain Agility. Mod. Supply Chain Res. Appl. 2023, 5, 230–264. [Google Scholar] [CrossRef]

- Bell, D.R.; Gallino, S.; Moreno, A. Offline Showrooms in Omnichannel Retail: Demand and Operational Benefits. Manage. Sci. 2018, 64, 1629–1651. [Google Scholar] [CrossRef]

- Roy, S.; Das, M.; Ali, S.M.; Raihan, A.S.; Paul, S.K.; Kabir, G. Evaluating Strategies for Environmental Sustainability in a Supply Chain of an Emerging Economy. J. Clean. Prod. 2020, 262. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and Supply Chain Sustainability: Framework and Future Research Directions. Benchmarking 2018, 28, 1410–1450. [Google Scholar] [CrossRef]

- Walker, H.; Preuss, L. Fostering Sustainability through Sourcing from Small Businesses: Public Sector Perspectives. J. Clean. Prod. 2008, 16, 1600–1609. [Google Scholar] [CrossRef]

- Končar, J.; Grubor, A.; Marić, R.; Vučenović, S.; Vukmirović, G. Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic. Sustain. 2020, 12. [Google Scholar] [CrossRef]

- de Vass, T.; Shee, H.; Miah, S.J. Iot in Supply Chain Management: A Narrative on Retail Sector Sustainability. Int. J. Logist. Res. Appl. 2021, 24, 605–624. [Google Scholar] [CrossRef]

- Dzwigol, H.; Kwilinski, A.; Trushkina, N. Green Logistics as a Sustainable Development Concept of Logistics Systems in a Circular Economy. Proc. 37th … 2021.

- Mohsen, B.M. Developments of Digital Technologies Related to Supply Chain Management. Procedia Comput. Sci. 2023, 220, 788–795. [Google Scholar] [CrossRef]

- Weerabahu, W.M.S.K.; Samaranayake, P.; Nakandala, D.; Hurriyet, H. Digital Supply Chain Research Trends: A Systematic Review and a Maturity Model for Adoption. Benchmarking 2023, 30, 3040–3066. [Google Scholar] [CrossRef]

- Zavala-Alcívar, A.; Verdecho, M.J.; Alfaro-Saiz, J.J. A Conceptual Framework to Manage Resilience and Increase Sustainability in the Supply Chain. Sustain. 2020, 12, 1–38. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustain. 2021, 13, 1–18. [Google Scholar] [CrossRef]

- Dubey, R.; Singh, T.; Gupta, O.K. Impact of Agility, Adaptability and Alignment on Humanitarian Logistics Performance: Mediating Effect of Leadership. Glob. Bus. Rev. 2015, 16, 812–831. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital Supply Chain Model in Industry 4.0. J. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Ali, A.A.A.; Udin, Z.B.M.; Abualrejal, H.M.E. The Impact of Artificial Intelligence and Supply Chain Resilience on the Companies Supply Chains Performance: The Moderating Role of Supply Chain Dynamism BT - International Conference on Information Systems and Intelligent Applications.; Al-Emran, M., Al-Sharafi, M.A., Shaalan, K., Eds.; Springer International Publishing: Cham, 2023; pp. 17–28. [Google Scholar]

- Yu, W.; Jacobs, M.A.; Chavez, R.; Yang, J. Dynamism, Disruption Orientation, and Resilience in the Supply Chain and the Impacts on Financial Performance: A Dynamic Capabilities Perspective. Int. J. Prod. Econ. 2019, 218, 352–362. [Google Scholar] [CrossRef]

- Olan, F.; Liu, S.; Suklan, J.; Jayawickrama, U.; Arakpogun, E. The Role of Artificial Intelligence Networks in Sustainable Supply Chain Finance for Food and Drink Industry. Int. J. Prod. Res. 2021, 0, 1–16. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, N. The Impact of Blockchain Technology Application on Supply Chain Partnership and Performance. Sustain. 2019, 11. [Google Scholar] [CrossRef]

- Alzoubi, H.M.; Alshurideh, M.; El, M.; Dawood, M. Uncertain Supply Chain Management Navigating the Interplay between Innovation Orientation, Dynamic Capabilities, and Digital Supply Chain Optimization : Empirical Insights from SMEs. 2024, 12, 649–658. [Google Scholar] [CrossRef]

- Kassa, A.; Kitaw, D.; Stache, U.; Beshah, B.; Degefu, G. Artificial Intelligence Techniques for Enhancing Supply Chain Resilience: A Systematic Literature Review, Holistic Framework, and Future Research. Comput. Ind. Eng. 2023, 186, 109714. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating Sustainability and Resilience in the Supply Chain: A Systematic Literature Review and a Research Agenda. Bus. Strateg. Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Oubrahim, I.; Sefiani, N.; Happonen, A. The Influence of Digital Transformation and Supply Chain Integration on Overall Sustainable Supply Chain Performance: An Empirical Analysis from Manufacturing Companies in Morocco. Energies 2023, 16. [Google Scholar] [CrossRef]

- Salamah, E.; Alzubi, A.; Yinal, A. Unveiling the Impact of Digitalization on Supply Chain Performance in the Post-COVID-19 Era: The Mediating Role of Supply Chain Integration and Efficiency. Sustainability 2023, 16, 304. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Gunasekaran, A.; Bag, S. Dynamic Capabilities and Institutional Theories for Industry 4.0 and Digital Supply Chain. Supply Chain Forum 2020, 21, 139–157. [Google Scholar] [CrossRef]

- Etemadi, N.; Borbon-Galvez, Y.; Strozzi, F.; Etemadi, T. Supply Chain Disruption Risk Management with Blockchain: A Dynamic Literature Review. Inf. 2021, 12, 1–25. [Google Scholar] [CrossRef]

- Purnomo, H.; Okarda, B.; Dermawan, A.; Ilham, Q.P.; Pacheco, P.; Nurfatriani, F.; Suhendang, E. Reconciling Oil Palm Economic Development and Environmental Conservation in Indonesia: A Value Chain Dynamic Approach. For. Policy Econ. 2020, 111, 102089. [Google Scholar] [CrossRef]

- Xiang, Z.; Xu, M. Dynamic Game Strategies of a Two-Stage Remanufacturing Closed-Loop Supply Chain Considering Big Data Marketing, Technological Innovation and Overconfidence. Comput. Ind. Eng. 2020, 145, 106538. [Google Scholar] [CrossRef]

- Anser, M.K.; Khan, M.A.; Awan, U.; Batool, R.; Zaman, K.; Imran, M.; Sasmoko; Indrianti, Y.; Khan, A.; Bakar, Z.A. The Role of Technological Innovation in a Dynamic Model of the Environmental Supply Chain Curve: Evidence from a Panel of 102 Countries. Processes 2020, 8. [Google Scholar] [CrossRef]

- Alkhatib, S.F.; Momani, R.A. Supply Chain Resilience and Operational Performance: The Role of Digital Technologies in Jordanian Manufacturing Firms. Adm. Sci. 2023, 13. [Google Scholar] [CrossRef]

- Adem, S. Al; Childerhouse, P.; Egbelakin, T.; Wang, B.; Teerlink, M.; Tabassum, R.; Fogarty, S.T.; Bag, S.; Gupta, S.; Kumar, A.; et al. Big Data Analytics and Artificial Intelligence Pathway to Operational Performance under the Effects of Entrepreneurial Orientation and Environmental Dynamism: A Study of Manufacturing Organisations. Ind. Mark. Manag. 2018, 226, 3–5. [Google Scholar] [CrossRef]

- Kunz, N.; Gold, S. Sustainable Humanitarian Supply Chain Management–Exploring New Theory. Int. J. Logist. Res. Appl. 2017, 20, 85–104. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM). Sage Publications. Eur. J. Tour. Res. 2014, 6, 211–213. [Google Scholar]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10 Exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

| Constructs | Items | Factor loadings | Cronbach's Alpha | CR | (AVE) |

|---|---|---|---|---|---|

| Supply Chain Sustainability | SCS-1 | 0.850 | 0.877 | 0.915 | 0.730 |

| SCS -2 | 0.830 | ||||

| SCS -3 | 0.861 | ||||

| SCS -4 | 0.871 | ||||

| Digital Supply chain | DSC-1 | 0.638 | 0.812 | 0.861 | 0.511 |

| DSC -2 | 0.800 | ||||

| DSC -3 | 0.709 | ||||

| DSC -4 | 0.742 | ||||

| DSC -5 | 0.685 | ||||

| DSC -6 | 0.700 | ||||

| Supply chain Resilience | SCR-1 | 0.838 | 0.889 | 0.922 | 0.710 |

| SCR -2 | 0.825 | ||||

| SCR -3 | 0.865 | ||||

| SCR -4 | 0.837 | ||||

| SCR -5 | 0.840 | ||||

| Supply Chain Dynamism | SCD-1 | 0.716 | 0.801 | 0.869 | 0.624 |

| SCD -2 | 0.752 | ||||

| SCD -3 | 0.818 | ||||

| SCD -4 | 0.759 |

| Characteristic | Frequency | Percentage |

|---|---|---|

| Gender | ||

| Male | 229 | 76 % |

| Female | 71 | 24% |

| Age | ||

| less than 27 | 30 | 10% |

| 27-less than 35 | 51 | 17% |

| 35-less than 45 | 135 | 45% |

| 45 and above | 84 | 28% |

| Education | ||

| Diploma | 33 | 11% |

| Undergraduate degree | 180 | 60% |

| Postgraduate degree (Master/PhD) | 87 | 29% |

| Experience | ||

| less than 10 | 33 | 11% |

| 10-less than 15 | 57 | 19% |

| 15-less than 20 | 102 | 33% |

| 20-less than 25 | 69 | 24% |

| 25 and above | 39 | 14% |

| Specialization | ||

| Business Administration | 165 | 55% |

| Accounting | 67 | 22% |

| Social sciences | 52 | 17% |

| Other | 15 | 5% |

| Variable | Digital Supply chain | Supply Chain Sustainability | Supply Chain Resilience |

|---|---|---|---|

| Digital Supply chain | |||

| Supply Chain Sustainability | 0.631 | ||

| Supply Chain Resilience | 0.674 | 0.733 | |

| Supply Chain Dynamism | 0.625 | 0.594 | 0.530 |

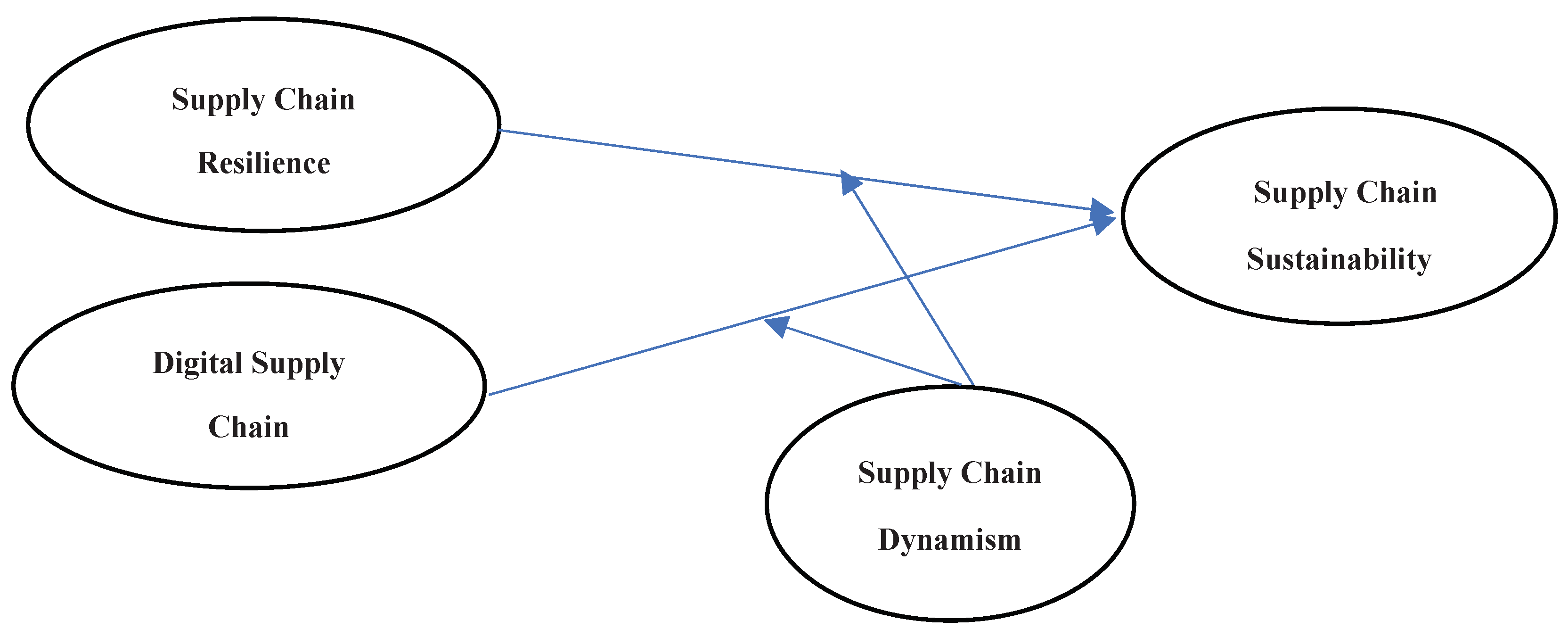

| Hypo | Relationships | Std. Beta | Std. Error | T-Value | P-Values | Decision |

|---|---|---|---|---|---|---|

| H1 | Digital Supply Chain -> Supply Chain Sustainability | 0.191 | 0.040 | 4.512 | 0.000 | Supported |

| H2 | Supply chain Resilience -> supply chain Sustainability | 0.411 | 0.051 | 7.805 | 0.000 | Supported |

| H3 | Supply Chain Dynamism -> Supply Chain Sustainability | 0.221 | 0.051 | 4.464 | 0.000 | Supported |

| H4 | Digital Supply chain -> Supply Chain Dynamism -> Supply chain Sustainability | 0.238 | 0.045 | 5.350 | 0.000 | Supported |

| H5 | Supply Chain Resilience -> Supply Chain dynamism -> Supply chain Sustainability | -0.083 | 0.057 | 1.460 | 0.144 | Rejected |

| Variable | R2 | R2 Adjusted |

| Supply Chain Sustainability | 0.556 | 0.550 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).