3. Results

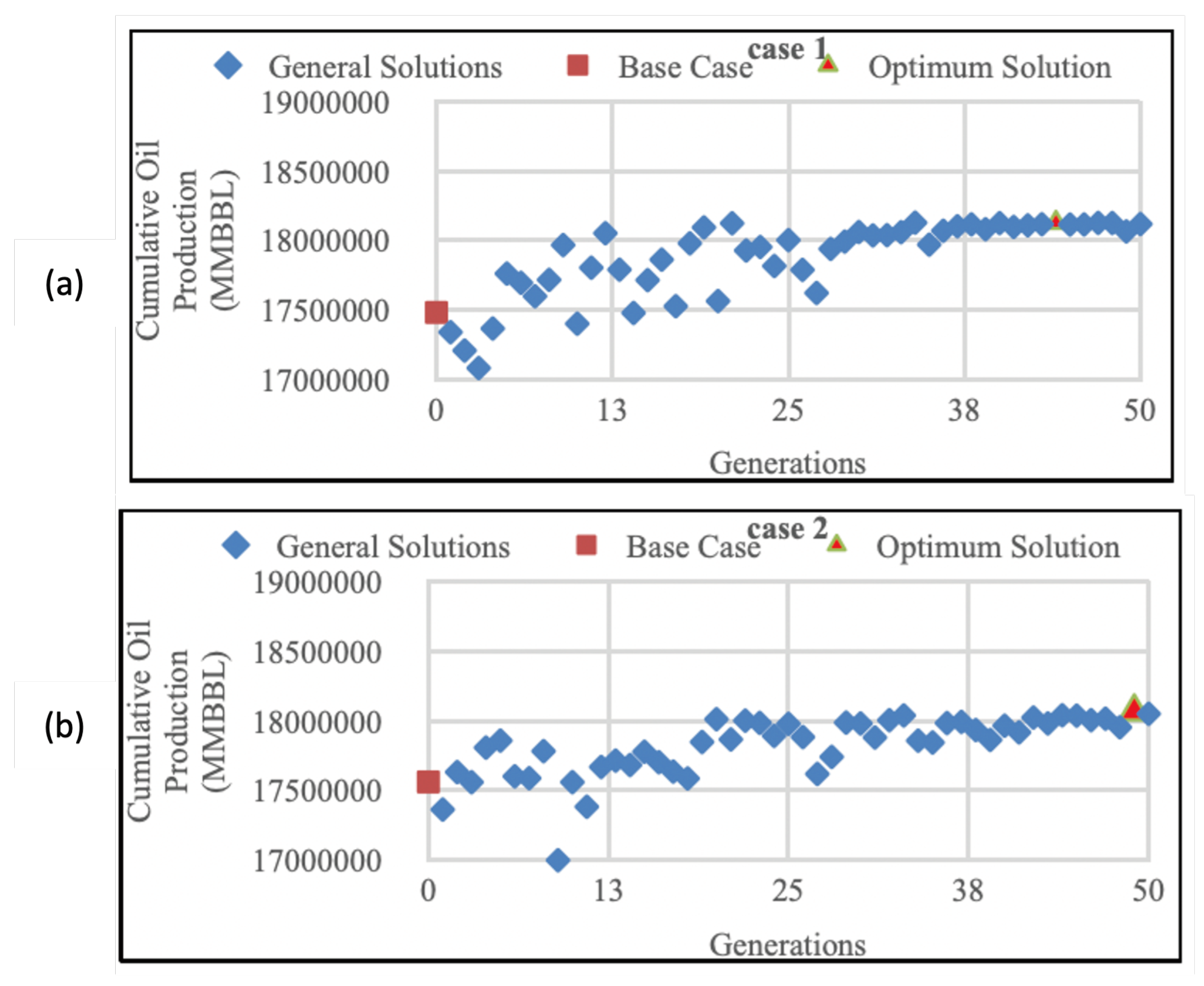

From the result obtained in

Figure 2a, the base case cumulative oil production for Case 1 was 17484 MBBL, and it reached its optimum solution at the 44th generation with 18130 MBBL of cumulative oil production. The cumulative oil production has increased by 3.6% compared to the initial cumulative oil production before optimization.

Figure 2b shows that Case 2 initially had 17562 MBBL of cumulative oil production, which increased by 2.88% to the optimum value of 18068 MBBL at the 49th generation.

However, the difference between the optimized value of Case 1 and 2 was only 0.81%. This indicates that the different initial well placement distribution did not have a significant impact on GA performance and the cumulative oil produced over 50 generations. The assumption for this result was because of GA’s stochastic nature of randomly searching for random solutions and hence initial well placement distribution did not significantly have an impact on the cumulative oil produced.

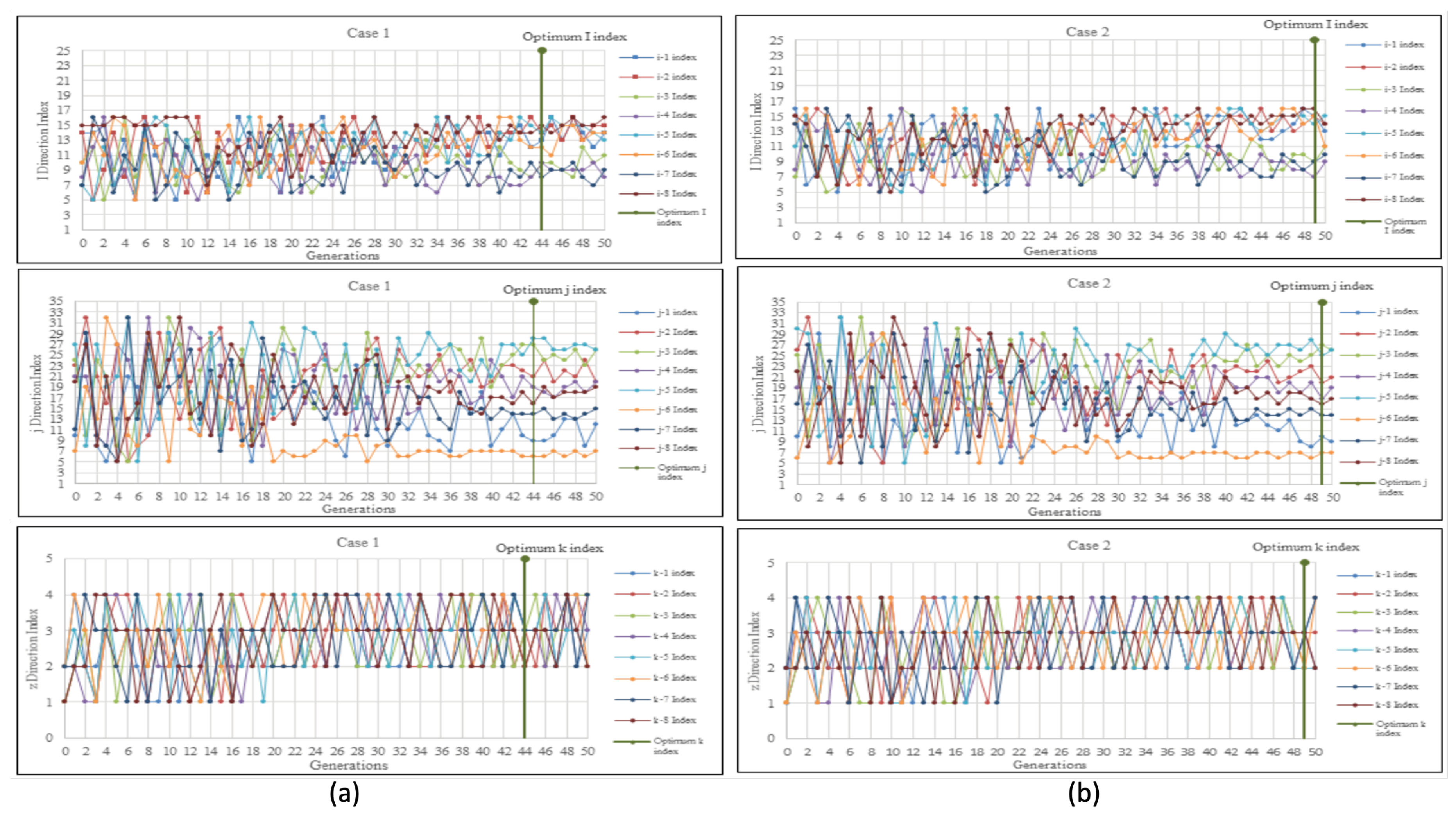

In Case 1,

Figure 3a (i) illustrates the optimization of the i-direction index for all 8 producers. The range of index values considered for optimization was between 5 and 16, in order to reduce the number of cells that needed evaluation. Initially, the i-direction indexes were dispersed randomly across the first 10 generations, ranging from a minimum of 5 indexes to a maximum of 16 indexes. However, as the generations progressed, these values gradually decreased. By the 40th generation, a more consistent pattern emerged, with the optimum i-direction indexes observed at the 44th generation, coinciding with the peak cumulative oil production.

In

Figure 3a (j), the optimization of the j-direction index for all 8 producers is depicted. Similarly, the index values for the j-direction were optimized within the range of 5 to 32, in order to limit the number of cells to be evaluated. In the initial 20 generations, the j-direction indexes were scattered randomly, with a minimum of 5 indexes and a maximum of 32 indexes involved. Gradually, the intervals of decrease became smaller as the generations progressed, peaking at the 50th generation. From the 42nd generation onward, there was a noticeable trend in the graph pattern, with the j indexes displaying greater consistency. The optimal j indexes were observed at the 44th generation, coinciding with the achievement of the optimal cumulative oil production.

In

Figure 3a (k), the optimization of the k-direction index for all 8 producers in Case 1 is depicted. Since the synthetic reservoir model consisted of only 4 layers, the k-direction indexes for the 8 producers were optimized within the range of indexes 1 to 4. Initially, in the first 20 generations, the graph showed a random scattering of k indexes, with a minimum of 1 and a maximum of 4 k-direction indexes. However, starting from the 20th generation, the graph pattern indicated a growing consistency in the k indexes. The optimal k indexes were achieved at the 44th generation, aligning with the attainment of the optimal cumulative oil production.

In Case 2,

Figure 3b (i) illustrates the optimization of the i-direction index for all 8 producers. The range of optimization falls between index 5 and 16, effectively reducing the number of cells to be evaluated. Initially, the i-direction indexes were scattered randomly in the first 10 generations, ranging from a minimum of 5 to a maximum of 16. However, as the generations progressed up to a maximum of 50, these indexes gradually decreased at intervals. Notably, by the 40th generation, the graph pattern indicated a greater consistency in the I indexes, with the optimal indexes observed at the 49th generation coinciding with the optimal cumulative oil production.

Similarly,

Figure 3b (j) demonstrates the optimization of the j-direction index for all 8 producers in Case 2. The optimization range for the j-direction indexes spans from index 5 to 32, effectively limiting the number of cells to be evaluated. In the initial 20 generations, the j-direction indexes were scattered randomly, ranging from a minimum of 5 to a maximum of 32.

The generations saw a gradual decrease in intervals, with a maximum of 50 generations. At the 40th generation, the graph displayed a more consistent pattern for the j indexes, reaching optimal values at the 49th generation when the cumulative oil production was at its peak.

In

Figure 3b (k), the optimization of the k-direction index for all 8 producers is depicted for Case 2. As the synthetic reservoir model consisted of only 4 layers, the k-direction indexes for the 8 producers were optimized within the range of 1 to 4. Initially, the graph showed a random scattering of k indexes for the first 20 generations, ranging from a minimum of 1 to a maximum of 4. However, starting from the 21st generation, the k indexes became more consistent, reaching their optimal values at the 49th generation when the cumulative oil production was at its peak.

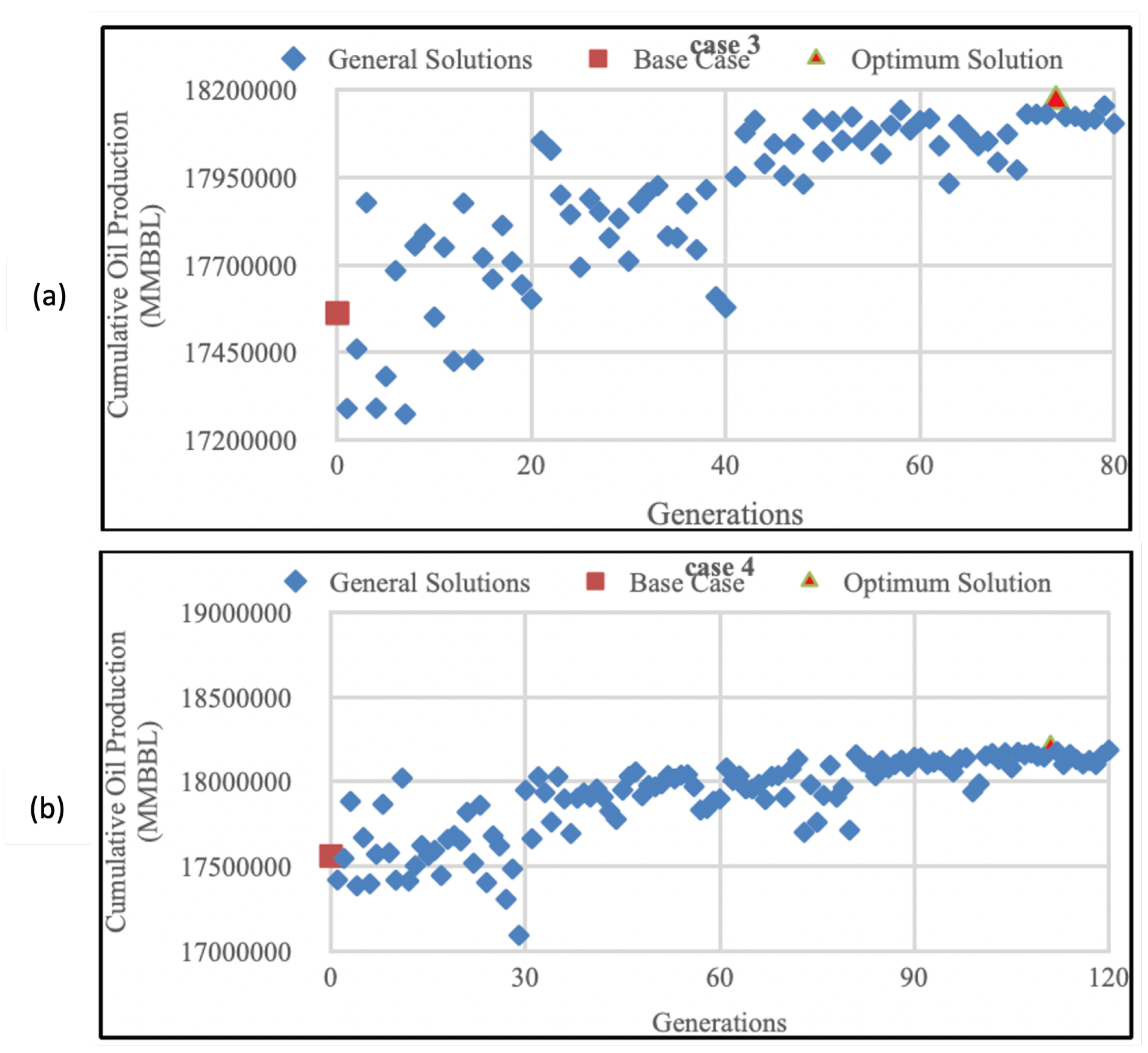

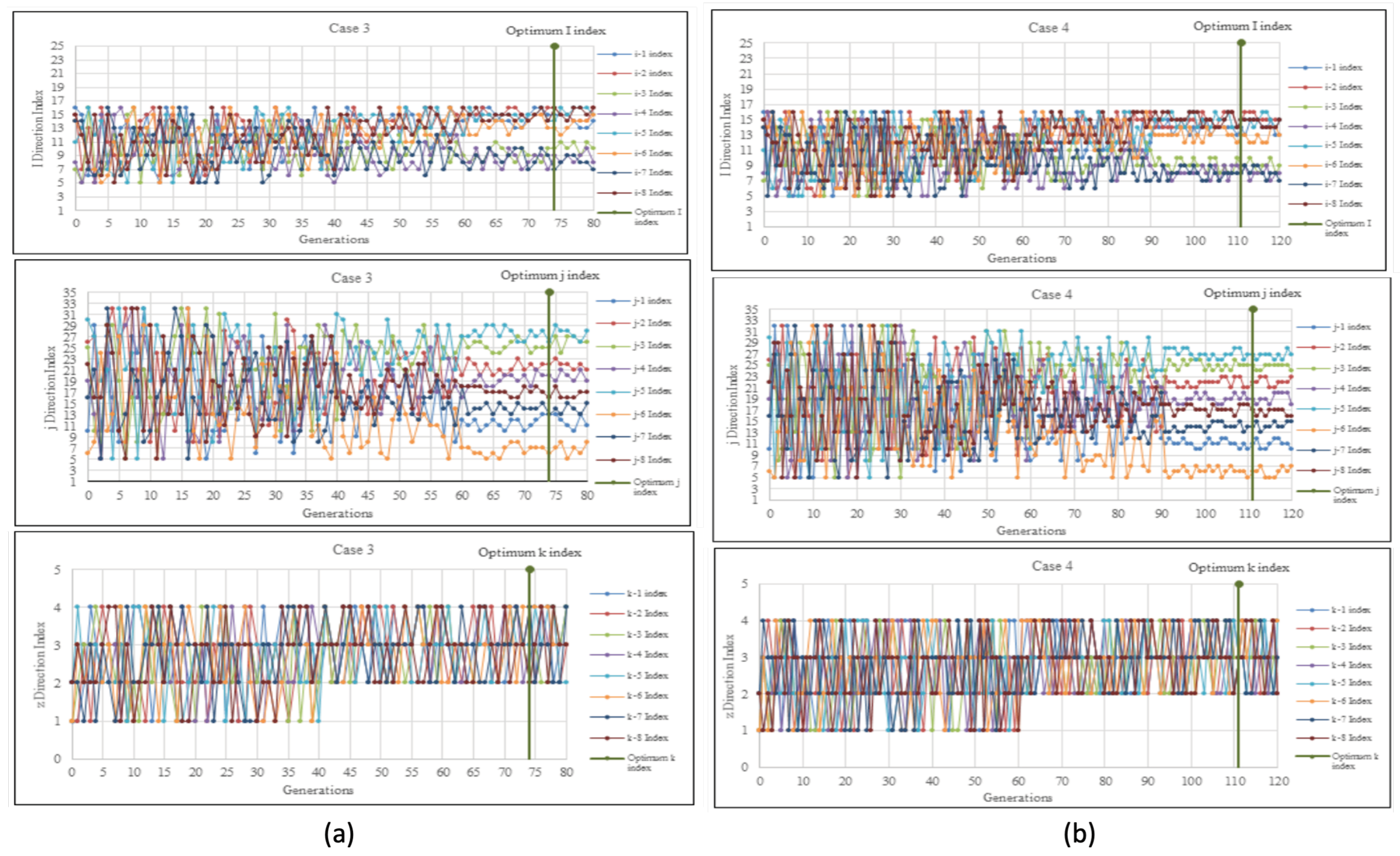

In

Figure 4a, it was observed that Case 3 achieved the optimal solution after 74 generations, resulting in a cumulative oil production of 18169 MBBL. This represents a 3.46% increase compared to the initial cumulative oil production before optimization.

Moving on to Case 4,

Figure 4b illustrated that the cumulative oil production increased by 3.63% to reach a value of 18200 MBBL at the optimum point. This was achieved after 111 generations. Comparing Case 4 to Case 3, there was a slight improvement of 0.17

These findings suggest that increasing the number of potential well placement solutions leads to a greater genetic richness, which in turn increases the likelihood of converging towards the optimal cumulative oil production. However, it is important to note that a larger number of random solutions requires more iterations or generations, as seen in Cases 3 and 4. Specifically, Case 3 reached the optimum solution in just 74 generations, while Case 4 required 111 generations. In conclusion, employing a larger number of random solutions enhances the probability of reaching the optimal solution, albeit at the cost of additional generations. The optimized well placements for Cases 3 and 4 can be observed in

Figure 4a,b, respectively.

For Case 3, the optimisation of each of the eight manufacturers’ i-direction index is displayed in

Figure 5a (i). To reduce the number of cells that need to be assessed, all eight producers’ i-direction indexes were optimised in the range between index 5 and index 16. The graph demonstrated how, over the first 22 generations, the direction I indices were dispersed at random, with a minimum of 5 and a maximum of 16 i-direction index. Even yet, they steadily dropped off as the generations increased to a maximum of 80. The graph pattern demonstrated that the I indexes started to become more consistent at generation 55. As the optimum cumulative oil production achieved an optimal solution, generation 74 saw the observation of the optimum I indexes.

The optimisation of the j-direction index for Case 3 across all 8 producers is displayed in

Figure 5a (j). To reduce the number of cells to be assessed, all eight manufacturers’ j-direction indexes were optimised between index 5 and index 32. With a minimum of 5 and a maximum of 32 j-direction indices involved, the graph demonstrated how the direction j indexes were randomly dispersing throughout the first 20 generations. Even Nevertheless, when the generations increased to a maximum of 80, they progressively reduced at intervals. The j indexes started to become more consistent at the 60th generation, according to the graph pattern, and the optimum j indexes were found to be at the 74th generation when the optimum cumulative oil production achieved an optimal solution.

The optimisation of each of the eight producers’ k-direction index for Case 3 is displayed in

Figure 5a (k). Since the artificial reservoir model was limited to four layers, all k-direction indices for eight producers were optimised in the range between indexes 1 and 4. The graph demonstrated how, over the first 40 generations, the direction k indices were randomly dispersed, with a minimum of 1 k-direction index and a maximum of 4 k-direction indexes. The graph pattern indicated that the k indexes started to become consistent at generation 41, and the optimum k indexes were found to be at generation 74 when the optimum cumulative oil production achieved an optimal solution.

Figure 5b (i) shows the optimization of the i-direction index of all 8 producers for Case 4. All i-direction indexes for 8 producers were optimized in the interval between index 5 to 16 to limit the number of cells to be evaluated. The graph showed the direction I indexes were scattered randomly in the first 50 generations with a minimum of 5 i-direction index and a maximum of 16 i-direction index. Still, they gradually decreased in intervals as the generations reached a maximum generation of 120. Starting at the 80th generation, the graph pattern showed that the I indexes began to be more consistent and the optimum I indexes were observed to be at the 111th generation as the optimum cumulative oil production reached an optimal solution.

Figure 5b (j) shows the optimization of the j-direction index of all 8 producers for Case 4. All j-direction indexes for 8 producers were optimized in the interval of between index 5 to 32 to limit the number of cells to be evaluated. The graph showed the direction j indexes were scattering randomly in the first 30 generations with a minimum of 5 j-direction index and a maximum of 32 j-direction index. Still, they gradually decreased in intervals as the generations reached a maximum generation of 120. Starting at the 90th generation, the graph pattern showed that the j indexes began to be more consistent and the optimum j indexes were observed to be at the 111th generation as the optimum cumulative oil production reached an optimal solution.

Figure 5b (k) shows the optimization of the k-direction index of all 8 producers for Case 4. All k-direction indexes for 8 producers were optimized in the interval between indexes 1 to 4 because the synthetic reservoir model was only a 4-layered model. The graph showed the direction k indexes were scattering randomly in the first 60 generations with a minimum of 1 k-direction index and a maximum of 4 k-direction index. Starting at the 61st generation, the graph pattern showed that the k indexes began to be consistent and the optimum k indexes were observed to be at the 111th generation as the optimum cumulative oil production reached an optimal solution.

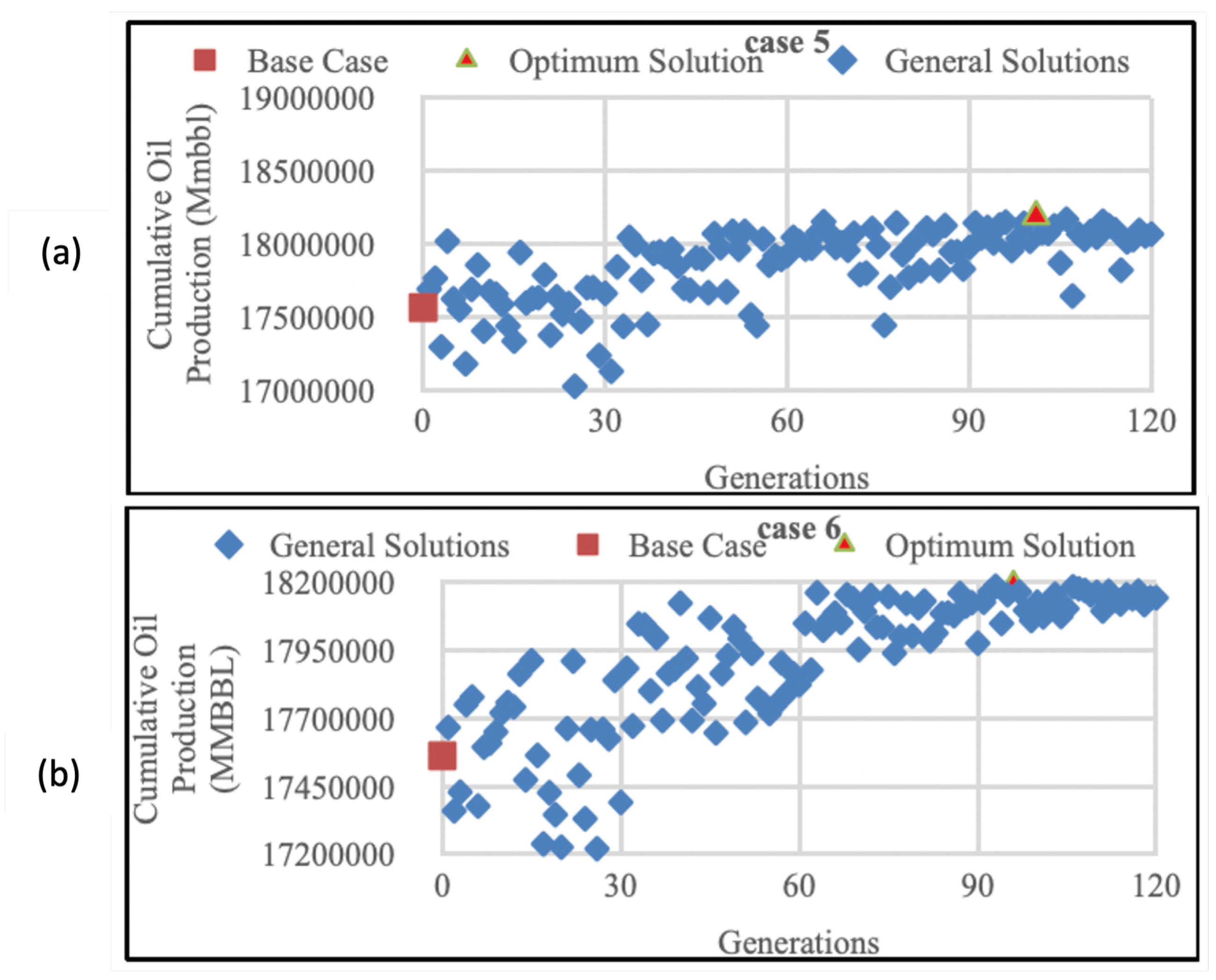

From the result obtained in

Figure 6a, Case 5 reached the optimum solution at the 101st generation with 18189 MBBL of cumulative oil production. The cumulative oil production has increased by 3.57% compared to the initial cumulative oil production before optimization. For Case 6, cumulative oil production increased also by 3.57% at an optimum value of 18188 MBBL with 96 generations, as shown in

Figure 6b.

The findings demonstrated that, despite using various crossover rates, Cases 5 and 6 did not differ significantly in terms of the total amount of oil produced. According to theory, a higher crossover rate causes generations or iterations to continue, increasing the likelihood that they will converge to global optima. Even still, Case 6’s 0.9 crossover rate resulted in less cumulative oil production than Case 4’s 0.8 crossover rate.

Figure 6a,b display the optimised well placement that was achieved for Cases 5 and 6.

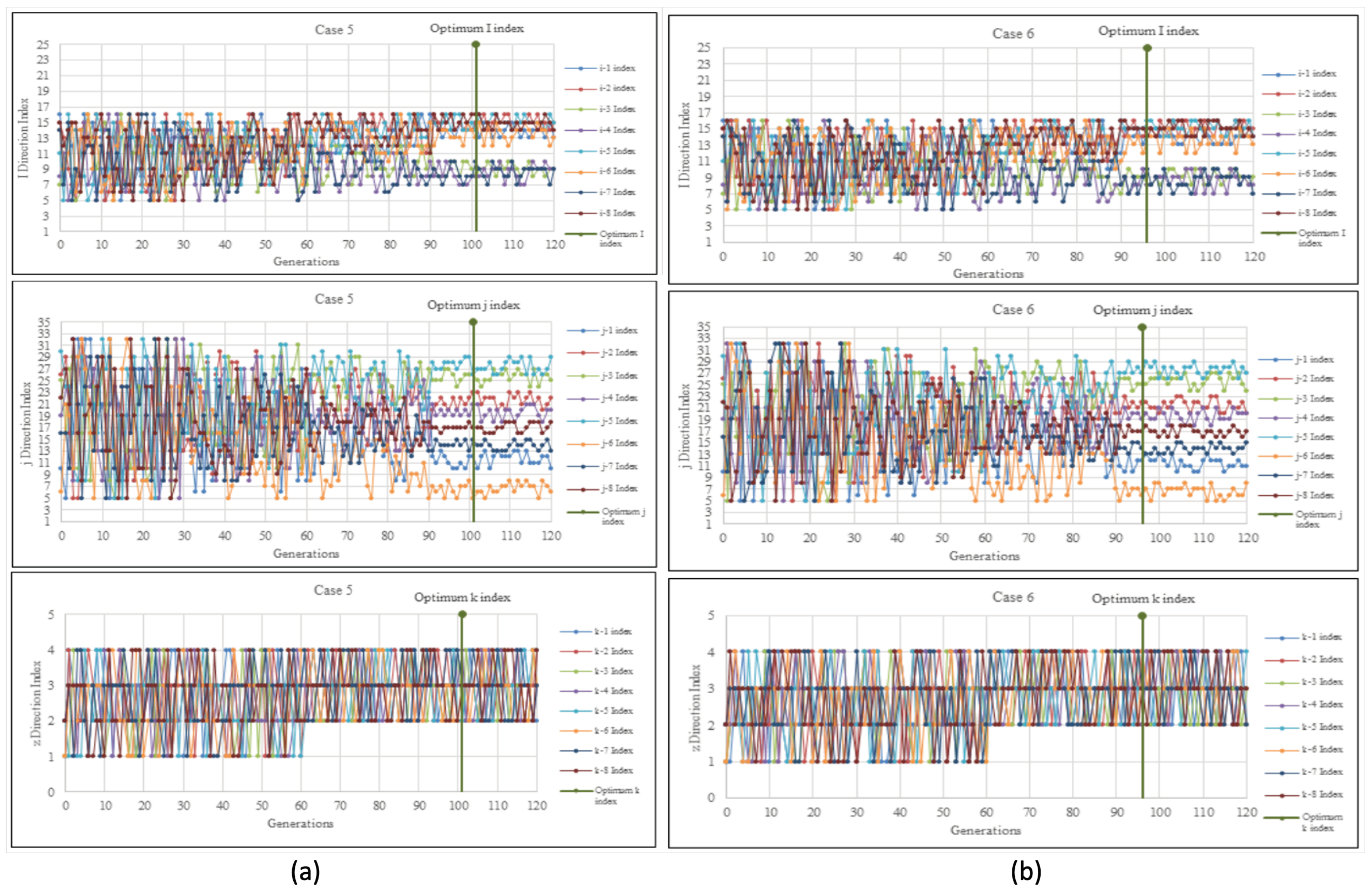

Figure 7a (i) shows the optimization of the i-direction index of all 8 producers for Case 5. All i-direction indexes for 8 producers were optimized in the interval between index 5 and 16 to limit the number of cells to be evaluated. The graph showed the direction I indexes were scattered randomly in the first 40 generations with a minimum of 5 i-direction index and a maximum of 16 i-direction index. Still, they gradually decreased in intervals as the generations reached a maximum generation of 120. Starting at the 90th generation, the graph pattern showed that the I indexes began to be more consistent, and the optimum I indexes were observed to be at the 101st generation as the optimum cumulative oil production reached an optimal solution.

Figure 7a (j) shows the optimization of the j-direction index of all 8 producers for Case 5. All j-direction indexes for 8 producers were optimized in the interval between index 5 and 32 to limit the number of cells to be evaluated. The graph showed the direction j indexes were scattering randomly in the first 30 generations, with a minimum of 5 j-direction index and a maximum of 32 j-direction index. Still, they gradually decreased in intervals as the generations reached a maximum generation of 120. Starting at the 90th generation, the graph pattern showed that the j indexes began to be more consistent, and the optimum j indexes were observed to be at the 101st generation as the optimum cumulative oil production reached an optimal solution.

Table 1.

Case Comparative Analysis for Cumulative Oil Production.

Table 1.

Case Comparative Analysis for Cumulative Oil Production.

| |

Cumulative Oil Production |

|

| Cases |

Base, (MBBL) |

Optimum, (MBBL) |

Production Increment |

Case Change |

Case 1

4th generations |

17484 |

18130 |

3.69 % |

0.81% |

Case 2

49th generations |

17562 |

18068 |

2.88 % |

|

Case 3

74th generations |

17561 |

18169 |

3.46 % |

0.17% |

Case 4

111st generations |

17562 |

18200 |

3.63 % |

|

Case 5

101st generations |

17562 |

18189 |

3.57 % |

0% |

Case 6

96th generations |

17561 |

18188 |

3.57 % |

|

Figure 7a (k) shows the optimization of the k-direction index of all 8 producers Case 5. All k-direction indexes for 8 producers were optimized in the interval between indexes 1 and 4 because the synthetic reservoir model was only a 4-layered model. The graph showed the direction k indexes were scattering randomly in the first 60 generations, with a minimum of 1 k-direction index and a maximum of 4 k-direction index involved. Starting at the 61st generation, the graph pattern showed that the k indexes began to be consistent, and the optimum k indexes were observed to be at the 101st generation as the optimum cumulative oil production reached an optimal solution.

Figure 7b (i) shows the optimization of the i-direction index of all 8 producers for Case 6. All i-direction indexes for 8 producers were optimized in the interval between index 5 to 16 to limit the number of cells to be evaluated. The graph showed the direction I indexes were scattered randomly in the first 50 generations, with a minimum of 5 i-direction index and a maximum of 16 i-direction index. Still, they gradually decreased in the interval as the generations reached a maximum generation of 120. Starting at the 90th generation, the graph pattern showed that the I indexes began to be more consistent, and the optimum I indexes were observed to be at the 96th generation as the optimum cumulative oil production reached an optimal solution.

Figure 7b (j) shows the optimization of the j-direction index of all 8 producers for Case 6. All j-direction indexes for 8 producers were optimized in the interval between index 5 and 32 to limit the number of cells to be evaluated. The graph showed the direction j indexes were scattering randomly in the first 30 generations, with a minimum of 5 j-direction index and a maximum of 32 j-direction index. Still, they gradually decreased in intervals as the generations reached a maximum generation of 120. Starting at the 90th generation, the graph pattern showed that the j indexes began to be more consistent, and the optimum j indexes were observed to be at the 96th generation as the optimum cumulative oil production reached an optimal solution.

Figure 7b (k) shows the optimization of the k-direction index of all 8 producers for Case 6. All k-direction indexes for 8 producers were optimized in the interval between indexes 1 and 4 because the synthetic reservoir model was only a 4-layered model. The graph showed the direction k indexes were scattering randomly in the first 60 generations, with a minimum of 1 k-direction index and a maximum of 4 k-direction index involved. Starting at the 61st generation, the graph pattern showed that the k indexes began to be consistent, and the optimum k indexes were observed to be at the 96th generation as the optimum cumulative oil production reached an optimal solution.