1. Introduction

In an increasingly competitive and resource-constrained world, organizations face the imperative to attain a competitive edge, stand out, and create value. Achieving sustainability across economic, social, and environmental dimensions is crucial in navigating the challenges posed by the digital age and resource scarcity. To strike an ideal balance, leveraging technology’s intrinsic advantages alongside sustainable practices emerges as a viable solution.

Procurement, once confined to acquiring goods and services, has evolved into a strategic element for value creation. It now significantly influences the end-to-end processes of a company. Procurement professionals are entrusted with managing relationships with clients, suppliers, and other internal departments, shaping the overall effectiveness of these functions. Individuals in procurement roles carry the responsibility for decisions that impact on the company’s supply and value chains. Therefore, agility in day-to-day operations and effective planning for short and long-term tasks are essential. Achieving agility necessitates a well-organized database and standardized processes, recognizing the uniqueness of each supplier and client. Documentation and regular updates of information related to them are imperative. This is where the role of information systems becomes pivotal, optimizing the management of information and knowledge, and facilitating rapid access to essential data for daily tasks and decision-making.

The Portuguese landscape in the realm of procurement is currently distant from the advancements embodied by Procurement 4.0. Despite global trends emphasizing digital transformation and innovation, the procurement practices in Portugal seem to lag. The adoption of cutting-edge technologies and the comprehensive integration of digital solutions within the procurement and supply chain management sector are yet to materialize fully in the Portuguese Small and Medium-sized Enterprises, SME context. There is a discernible gap between the current state of procurement practices in Portugal and the transformative potential offered by Procurement 4.0.

The creation of new products and market entry hinges on a company’s entire structure, with a spotlight on the pivotal role of procurement management and its interconnection with the Research and Development (R&D) department. However, the current macroeconomic uncertainty, coupled with soaring inflation, complicates market expectations management. Unpredictable consumer preferences and supplier availability make it challenging for companies to discern where to invest their focus in terms of markets, products, or services.

The input data for procurement is sourced from the Research and Development (R&D) department. This implies that the R&D department provides critical information and insights that guide the procurement process. The collaboration between these two departments underscores the interdependence of innovation and acquisition processes within the company. Most of the time, the communication between these two departments is made through a primary Excel spreadsheet, where all the needs and respective response timings of each raw or packaging material are exposed, as well as much other information, so it is very easy to lose the thread in the middle of dozens of projects, especially when it comes to the traceability of samples that have no information in the system.

Therefore, the research questions to be answered are briefly the following:

• How can information be stored, organized, and followed up more efficiently?

• In what way does a complete supplier qualification process contribute positively to the company’s strategy?

• How does the integration of Sustainable Procurement influence the creation of value for the company?

The primary objective of this work is to describe, from the procurement point of view, the way to assess and identify shortcomings in the current process of monitoring and controlling the delivery of requested samples. The overarching goal is to pave the way for the digitalization of this process. Additionally, it aims to contribute to the establishment of a comprehensive supplier portfolio specifically tailored for the development of new products.

2. Methodology

The bibliography on which this work is based was extracted only from SCOPUS, one of the most comprehensive and widely used databases. During the process of researching for an academic paper, it is common to encounter a vast quantity of papers about the subject matter. The keywords “Procurement”, “Digitalization” and “Industry 4.0” (TITLE-ABS-KEY (procurement) AND (Digitalization) AND (Industry 4.0)) were the main basis of this research (In our research, there were scrutinized a total of 26 papers, out of which only 15 were deemed pertinent to the specific research project. While it may appear imperative to incorporate all 26 papers in the examination, this could cause needless diversions and detract from the main focal point of the research.

By judiciously handpicking the most applicable papers, we were able to guarantee that this analysis was as directed and focused as possible, resulting in more significant and impactful research conclusions. It is crucial to acknowledge that excluding certain papers from the analysis is not a vulnerability, but instead a vital measure in ensuring that the research outcomes are comprehensive and pertinent to the research query.

According to [

1] a case study seeks to describe, comprehend, predict, and/or control the subject of investigation, which may encompass processes, individuals, groups, organizations, cultures, and more. Case studies find extensive application in organizational studies and the broader social sciences domain, progressively earning greater confidence and perceived rigor. They stand out as one of the most prevalent forms of qualitative research, although they may not be inherently qualitative [

2]. Conducting this type of research entails a comprehensive collection of information to ensure the most truthful construction of conclusions {3]. [

4] suggests that information collection methods can include interviews, observation, analysis of archived records, and examination of written documents, among others.

The following step involves the description of a case study based on on-site observation of the internship in the procurement department. In the context of this study, a unique Portuguese SME company was observed during an internship, representing a distinctive setting as only one company was the subject of investigation. The study meticulously analyzes the company’s processes and its relationships with stakeholders, with particular attention to suppliers. Data collection for this study primarily relied on examples mentioned by [

4], involving daily tasks, direct observations, and active engagement with company stakeholders. As an intern in the procurement department, active participation in the information flow process between procurement and R&D facilitated first-hand gathering of valuable information and insights.

The last section presents a summary of the whole internship, addressing the final key conclusions, highlighting what are the main limitations of the study, and making suggestions for future interventions, to give possible resolutions for the deepest issues of the studied processes.

3. Systematic Literature Review

A systematic literature review thoroughly identifies, evaluates, and synthesizes existing research, ensuring rigorous and unbiased analysis. This method reveals gaps, assesses study quality, generates hypotheses, and establishes an evidence-based foundation for theory development, study design, and decision-making in various fields.

The research field in the industry 4.0 domain has been growing exponentially in the last decade, and Procurement has been under the lens of the academic community lately since all the reviewed papers were published after 2018, showing interest in the topics regarding Procurement 4.0. In this segment, we will examine the current state of the literature, addressing topics such as the influence of the digital era on Procurement, its organizational significance, and the encountered obstacles.

Unlike past industrial shifts, Industry 4.0 relies on integrating diverse knowledge and expertise, [

5,

6]. Challenges in digital solutions demand innovative approaches for designing, customizing, evaluating, and implementing them in the supplier-customer dynamic. Suppliers now offer sophisticated product-service-software systems enabled by digital technology. Artificial intelligence solutions driven by data analytics recommend optimal ways to enhance individual equipment and entire production lines. This trend, termed digital "servitization," signifies the shift towards smart systems that create and capture value through autonomous function, optimization, monitoring, or control, [

7].

Digitalization’s increasing attention is due to its potential impact on sustainable development goals, fostering efficiency and waste reduction through digital communication and information sharing. Digital enablers are crucial for organizational transformation, facilitating integration, data collection, analysis, and ensuring compliance, [

8]. Distinguishing between digitization and digitalization is essential, as digitization involves replacing physical objects with digital versions, while digitalization creates new business models and transforms industries. The rapid development of digitalization has led industries to adopt digital technologies, enhancing supply chain and procurement processes. Academic research has focused on the potential of a more digital supply chain, emphasizing tools like the Internet of Things, artificial intelligence, cloud warehouses, big data, and blockchain technology to automate processes and add value, [

9,

10].

Procurement represents a very important part of the supply chain process since it has a direct impact on its entire performance, hence cautious management of this function results in a more fluid and effective transfer of information. Most times, procurement refers to the process of acquiring external supplies, services, or construction, which can include buying, leasing, renting, or any other method. This encompasses all the responsibilities of procurement managers, including identifying, sourcing, accessing, and negotiating with suppliers, and managing external resources to meet the company’s strategic objectives [

11].

However, according to [

10] the Procurement Cycle involved:

- 1)

Identifying the need for a good or service

- 2)

Gaining approval and forwarding documentation to procurement.

- 3)

Sending a Request for Quotation to Suppliers.

- 4)

Receiving supplier responses (with possible negotiation);

- 5)

Selecting a supplier and creating a Purchase Order (PO);

- 6)

Authorizing and sending the PO to the supplier.

- 7)

Delivering and inspecting the goods and services.

- 8)

Receiving the supplier’s invoice.

- 9)

Approving the invoice for payment (or pending);

- 10)

Conducting a post-contract review of the purchase.

To enhance strategic alignment in service procurement, the focus should shift from mere cost reduction to emphasizing value contribution. Evaluating potential suppliers during the contracting process based on alignment with the sourcing strategy, digital capabilities, and adherence to sustainability standards is a valuable approach, [

12].

Digital transformation necessitates essential connections, networks, and rapid innovation cycles [

4]. Procurement is set for substantial progress, evolving into a central focus for the entire firm by leveraging Industry 4.0 technologies and integrating creativity into the business model, thus raising questions about effective integration and strategic formulation [

7]. It provides an opportunity for procurement to enhance its standing within the company’s network. This shift is set to elevate the strategic importance of procurement, introducing Procurement 4.0 with real-time availability and digitalization. Growing interest in Industry 4.0 technologies signals leveraging tools like Big Data analysis, the Internet of Things, and blockchain to enhance procurement functions, fostering greater efficiency [

13].

Industry 4.0 yields benefits for procurement by enhancing inventory management, developing remote-control systems, and improving in-house communication. Online inventory management automates orders during low inventories, boosting efficiency and reducing costs through in-house communication. This leads to faster order processing, enhanced inventory management, and optimization, supported by virtual reality training. Industry 4.0 systems and the digital environment simplify raw material monitoring, enabling automatic briefings on inventory ratios [

11]. Addressing intangible and uncertain factors in digital solutions often demands alternative approaches in designing, customizing, evaluating, and implementing offerings within the supplier-customer relationship [

10]. Suppliers now provide sophisticated product-service-software systems enabled by digital technology, tailored for specific customer outcomes.

1) ERP Systems

According to [

13], an Enterprise Resource Planning (ERP) system holds a critical strategic role in centralizing an enterprise’s operational data and facilitating its use in decision-making processes. Nevertheless, granting external access to this internal system for data-sharing purposes may expose the enterprise to considerable information security risks. However, following the implementation of Blockchain, access to ERP system data and monitoring permissions can be restricted to authorized users only. This is one of the main-stream solutions for Supply Chains and Procurement processes [

6,

12].

2) AI

The term AI, a concept existing for six decades, refers to machines mimicking human behavior and communication, often associated with robots, and termed machine learning, [

10]. Particularly effective for precision and speed, AI, especially in the form of software robots, is gaining traction in procurement. IBM and Deloitte, for instance, utilize robotic process automation, redirecting focus from repetitive, time-critical, and rule-based tasks. Advanced techniques like text mining, data analysis, and interactive communication bots enhance supplier identification and selection, making processes more efficient and boosting the number of considered suppliers. Analyzing past quotations with AI streamlines the preparation of quotation requests [

15,

16].

3) Blockchain

The centralization of an enterprise’s operational data through an ERP system is crucial for informed decision-making but can pose information security issues when externally accessed for data sharing. Blockchain integration restricts ERP system data access to authorized users, enhancing security by monitoring access. However, recent research suggests limited information exchange through blockchain, emphasizing the continued use of email. It’s vital to recognize that blockchain is best used as a digital ledger for transaction-related information, while other data, like budgeting and service providers, should be stored separately. High personnel costs and upfront payments are barriers for SMEs adopting digital technologies, hindering progress due to limited spending on tangible investments and challenges in securing bank loans for digitalization initiatives compared to tangible asset investments [

6,

7,

13,

17].

4). Sustainability

The concepts of digital transformation and sustainability - encompassing environmental, economic, and social aspects - are interconnected and mutually beneficial, since it can make the implementation of a variety of sustainability initiatives easier, for example, the selection of environmentally friendly materials and components, and product design based on circular economy principles, to reduce waste and minimize the use of new resources [

17].

The ongoing discussion surrounding Industry 4.0 is compelling decision-makers to consider the necessary measures for aligning their procurement processes with sustainable and digitally driven competitive advantages since there has been a growing emphasis on "greenness" as a novel way for companies to enhance their competitiveness and performance, which involves adhering to new regulations and societal concerns surrounding environmental sustainability [

7]. Furthermore, digital technologies enable effective monitoring of raw materials and production facilities, resulting in substantial improvements in performance and resource consumption, as well as reductions in waste and CO2 emissions.

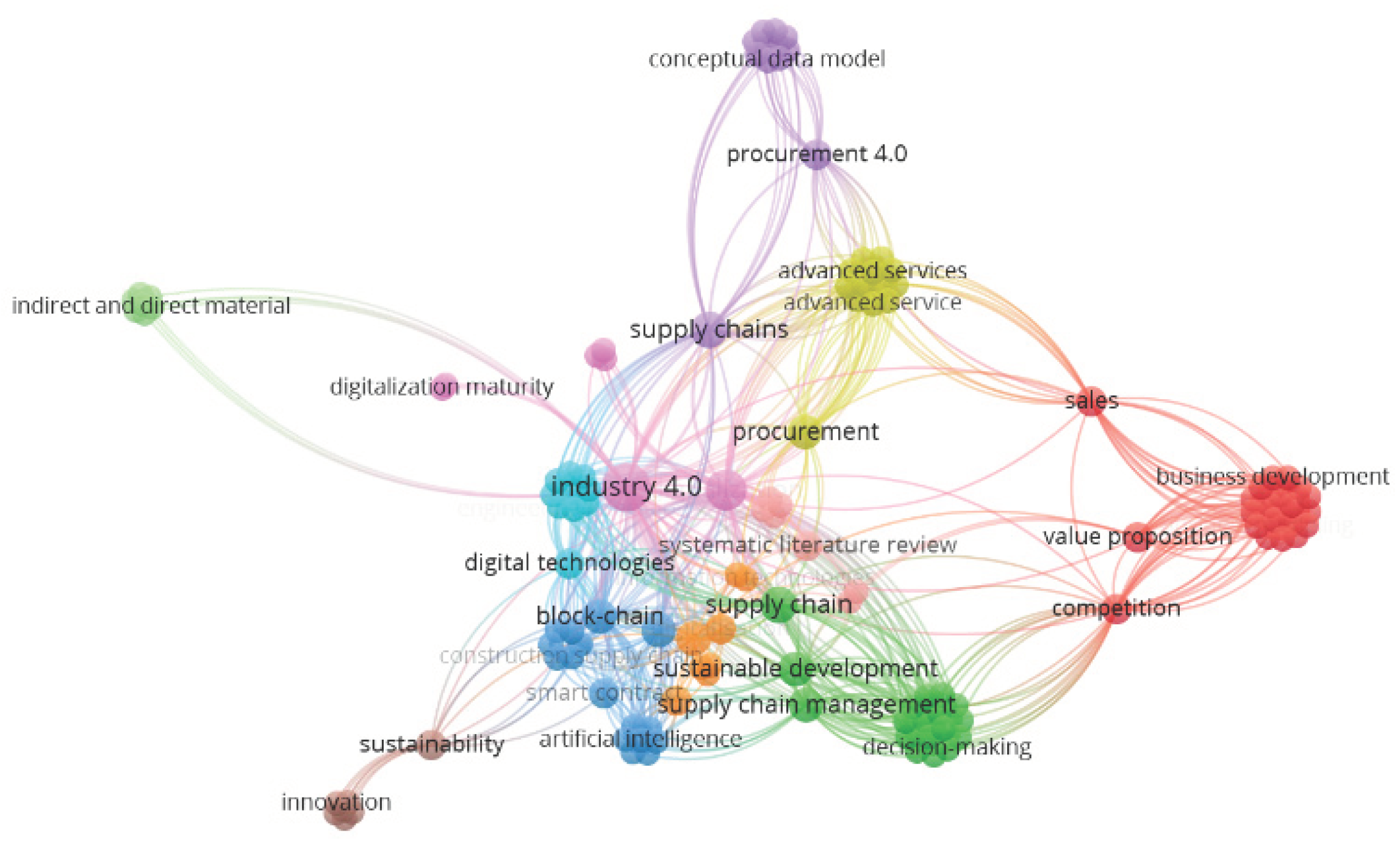

As part of our research, we delved into an analysis of keyword frequency. This was done to identify any anomalies and patterns within each area,

Figure 2. Our examination of pertinent keyword clusters was aided by the utilization of VOSviewer software. The main clusters and keywords of the present research are very clear “Industry 4.0”, “Supply Chain Management”, “Procurement”, “Procurement 4.0” and “digital technologies” are some of the most present keywords of this bibliographic analysis. However, the “indirect and direct material” can be considered an outlier of this database summary.

In essence, digitalization serves as a valuable tool for achieving sustainability goals across various domains.

4. Case Study

During an 8-month internship in the Procurement department, a distinctive Portuguese SME company became the sole focus of the investigation, offering a unique setting. The study meticulously examines the company’s processes and its interactions with stakeholders, emphasizing a special focus on suppliers’ evaluation methods, the maturity level of enterprise adoption and integration of digital technologies and practices into its operations, and the challenges to overcome to achieve the next level of digitalization.

To achieve these general objectives, first, it was identified the current information systems and digital tools for the workflow between research and development (R&D) and procurement. Then the analysis of the current supplier’s qualification process was done, making a practical application of a different decision-making method, studying the existing criteria in this filtering, and suggesting new approaches that could add value to the organization. These two processes are related, insofar as poor information management from the R&D department does not allow procurement to make considered and solid decisions.

It is relevant to clarify that (depending on the organization) procurement and purchasing might not be the same thing. In this company, procurement does not issue purchase orders (POs) due to a policy that separates the negotiation and approval roles. The procurement agent handles activities outlined in the “purchase requisition” stage, but other stages are not within the department’s responsibilities.

Most of the factory requirements are generated automatically by Material Requirements Planning (MRP), which means that usually no purchase requisitions are made since most of the POs are automated. In R&D it is different because the projects often involve unique or specialized requirements that cannot be standardized in the same way as materials and services for the main production process. This means that procurement must be proactive, think strategically, and be ready for last-call changes, which usually happen in R&D projects.

When all materials and documentation are gathered, the prototype of the final product is finally built, and submitted for approval. In case of approval, the project is added to the Innovative Product Solutions (IPS) projects folder in R&D’s share drive. The last phase is mainly for internal and external tests, and if everything goes well, industrial trials are made, and final production happens in the main factory plant.

It was not necessary to be in contact with this reality for very long to understand that there is a set of variables to consider when faced with the collaboration between R&D and procurement.

Firstly, there is a clear problem with the information management of R&D, since every need, report, and feedback, is done through a giant Excel spreadsheet. As the number of tasks and team members grows, this Excel file cannot handle large and complex projects since it is not scalable. Because improved cooperation, accuracy, visibility, and scalability are essential for successful project management, the adoption of other digital solutions are a preferable choice.

Secondly, on the procurement side, there is the responsibility to pre-qualify and carefully select the suppliers that will be contacted to supply the materials needed for R&D, considering that the needed quantities of both raw and packaging materials are small, meaning that the ideal is that the chosen suppliers should be open to supply small quantities, but should also have enough capacity to supply large quantities in case some project is approved and escalated to factory production. Therefore, it is necessary to understand the process of qualification and selection of suppliers, as well as the optimal supplier portfolio for R&D purposes.

This process would work perfectly if the requested sample flow were reduced. However, given the high volume of procurement requests, asked within a short period, it becomes challenging to properly handle each sample request. All the information is gathered from the Excel spreadsheet, and all follow-up is conducted via e-mail. Therefore, orders are occasionally forgotten, leading to delays and a lack of feedback from suppliers. Sometimes, samples arrive at the warehouse without sufficient information to identify their origin, which leads to delays in product development and raises questions to the suppliers regarding the shipment of the specific samples, creating a negative impression of the company, for lack of organization.

After carefully reviewing and correcting some data from the Excel spreadsheet used by R&D, it is possible to draw some conclusions about the main problems and their causes.

To be able to effectively summarize the measurable problems, some Key Performance Indicators (KPI) were chosen, based on the available information from the Excel Spreadsheet. The indicators should reflect, not totally but in some way, the inefficiency of the current sample order process. On the other hand, it also helps to visualize, for example, which suppliers collaborate more with the R&D team. Most KPIs are calculated only based on raw materials, to catch the main flaws of the actual tool, since packaging materials have fewer requests, and fewer people using the spreadsheet, which makes this category more manageable in terms of data.

Indicators show that, as foreseen before, the main gaps in the process mainly appear because of the poor information management tool, rushing project management, and a high volume of requests for the identified procurement categories.

5. Conclusions

One of the most important parts of supply chain management is, without any doubt, the process of Procurement, which has a direct impact on an organization’s profitability and competitiveness. In just over a decade, Industry 4.0 has been a subject of high attention, and nowadays the evolution of all processes relies on this concept, being Procurement 4.0 one of them. It appeared, and turned the old concept upside down, since new solutions like IoT, Big Data, AI, and Blockchain have the potential to transform the whole process, saving time and money (which in companies happens to be the same thing), and being capable to do the traceability of all data.

The internship experience for a young manager allowed understanding from a real sample request process, the tools and processes used by research and procurement departments in a real environment. The identified problems highlight the importance of information systems in streamlining high flows of information and improving overall efficiency.

Also, as suppliers are key to procurement, the qualification process was identified as a potential driver of value creation, being, therefore, carefully analyzed. For an ordered overview of the main topics, the initial three questions must be answered.

Some of the main issues that are common in a regular procurement process, mostly based on manual intervention, are inefficacy, lack of transparency, limited access to supplier data, and risk management. Most of these problems are resolved by auto-mated Procurement processes, centralized databases for many activities, and supplier information, as well as software that can identify risks among supply chain disruptions, compliance issues, and contracts. However, some barriers make these digital solutions not straightforwardly adopted, such as high costs, lack of technical expertise, and resistance to change. Also, to implement, e.g., Blockchain, one must be aware not only of its benefits but also its potential drawbacks, since it is a complex technology that requires high levels of expertise. In addition, it requires that customers and suppliers also adopt the same technology, so technology adoptions, like any other change in a company, must be well-studied regarding the business structure and context.

Something that also needs to be taken into consideration is that, unlike other operational departments from the Supply Chain (where digitalization can effectively replace almost all human intervention), Procurement deals directly with people, such as customers and suppliers, with whom it is beneficial to establish close, complicit, and cordial relationships. Therefore, it is necessary to find a balance between digital tools and human contact, which remains essential for the Procurement department.

The key to adding value to the procurement functions resides in the astute management and perpetual categorization of suppliers. Given that procurement chiefly collaborates with suppliers, the act of discerning the appropriate ones assumes paramount significance in amplifying the overall efficacy of the procurement journey.

Despite global trends emphasizing digital transformation and innovation, the procurement practices in Portugal seem to lag. The adoption of cutting-edge technologies and the comprehensive integration of digital solutions within the procurement and supply chain management sector are yet to materialize fully in the Portuguese SME context.

Author Contributions

Conceptualization, R.C.M. and M.A.; methodology, R.C.M. and M.A.; writing—original draft preparation, A.S., writing—review and editing, A.S., R.C.M. and M.A.; supervision, R.C.M. and M.A.; funding acquisition, R.C.M. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

s: This work was financially supported by the Research Unit on Governance, Competitiveness and Public Policies (UIDB/04058/2020) + (UIDP/04058/2020), funded by national funds through FCT - Fundação para a Ciência e a Tecnologia.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to General Data Protection Regulation (GDPR)..

Conflicts of Interest

The authors declare no conflict of interest.

References

- Woodside, A.G.; Wilson, E.J. Case study research methods for theory building. J. Bus. Ind. Mark. 2003, 18, 493–508. [Google Scholar] [CrossRef]

- Kohlbacher, F. (2006). The use of qualitative content analysis in case study research. In Forum Qualitative Sozialforschung/Forum: Qualitative Social Research (Vol. 7, No. 1, pp. 1-30). Institut für Qualitative Forschung. [CrossRef]

- Marczyk, G. R., DeMatteo, D., & Festinger, D. (2010). Essentials of research design and methodology (Vol. 2). John Wiley & Sons.

- Yin, R. K. (1994). Case study research: Design and methods. Newbury Park, CA: Sage. [CrossRef]

- Costa, J.; Matias, J.C.O. Open innovation 4.0 as an enhancer of sustainable innovation ecosystems. Sustainability 2020, 12, 8112. [Google Scholar] [CrossRef]

- Sjödin, D.; Kamalaldin, A.; Parida, V.; Islam, N. Procurement 4.0: How industrial customers transform procurement processes to capitalize on digital servitization. IEEE Trans. Eng. Manag. 2021, 70, 4175–4190. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green sourcing in the era of industry 4.0: towards green and digitalized competitive advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Gunasekara, H.G.; Sridarran, P.; Rajaratnam, D. Effective use of blockchain technology for facilities management procurement process. J. Facil. Manag. 2022, 20, 452–468. [Google Scholar] [CrossRef]

- Gavrila, S.G.; Ancillo, A.d.L. Spanish SMEs’ digitalization enablers: E-Receipt applications to the offline retail market. Technol. Forecast. Soc. Chang. 2021, 162, 120381. [Google Scholar] [CrossRef] [PubMed]

- Křenková, E.; Rieser, K.; Sato, A. How software robots can facilitate the procurement process? A case study of Siemens in the Czech Republic. Entrep. Bus. Econ. Rev. 2021, 9, 191–203. [Google Scholar] [CrossRef]

- Jahani, N.; Sepehri, A.; Vandchali, H.R.; Tirkolaee, E.B. Application of industry 4.0 in the procurement processes of supply chains: A systematic literature review. Sustainability 2021, 13, 7520. [Google Scholar] [CrossRef]

- Hofmann, E.; Brunner, J.H.; Holschbach, E. Research in business service purchasing: current status and directions for the future. Manag. Rev. Q. 2020, 70, 421–460. [Google Scholar] [CrossRef]

- Hacioglu, U. (Ed.) (2019). Digital business strategies in blockchain ecosystems: Transformational design and future of global business. Springer Nature. Hacioglu, U. [CrossRef]

- Yevu, S.K.; Yu, A.T.; Darko, A. Digitalization of construction supply chain and procurement in the built environment: Emerging technologies and opportunities for sustainable processes. J. Clean. Prod. 2021, 322, 129093. [Google Scholar] [CrossRef]

- Seyedghorban, Z.; Samson, D.; Tahernejad, H. Digitalization opportunities for the procurement function: pathways to maturity. Int. J. Oper. Prod. Manag. 2020, 40, 1685–1693. [Google Scholar] [CrossRef]

- Delke, V.; Schiele, H.; Buchholz, W. Differentiating between direct and indirect procurement: roles, skills, and Industry 4.0. Int. J. Procure. Manag. 2023, 16. [Google Scholar] [CrossRef]

- Bigliardi, B.; Filippelli, S.; Petroni, A.; Tagliente, L. The digitalization of supply chain: a review. Procedia Comput. Sci. 2022, 200, 1806–1815. [Google Scholar] [CrossRef]

- Pause, D., & Blum, M. (2018). Conceptual Design of a Digital Shadow for the Procurement of Stocked Products. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0: IFIP WG 5.7 International Conference, APMS 2018, Seoul, Korea, August 26-30, 2018, Proceedings, Part II (pp. 288-295). Springer International Publishing. 26 August. [CrossRef]

- Taghipour, A., Lu, X., Derradji, M., & Sow, A. D. (2022, July). The impact of digitalization on supply chain management: a literature review. In Proceedings of the 12th International Conference on Information Communication and Management (pp. 75-78). [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).