1. Introduction

A counter-rotating output transmission system, which adopts a power shunt when transmitting power, can meet the requirements of high-speed and heavy-duty working conditions with a small volume and mass, and this system is widely used in helicopters, torpedoes, underwater unmanned boats and aviation. For redundancy and safety, multiple inputs and multiple branch shunt convergence drives are generally used. However, due to the inevitable manufacturing and installation errors of the gear system, as well as the influence of factors such as the deformation of the moving components, the gap size between each branch and the output gear is inconsistent, resulting in uneven distribution of the load transmitted by each branch, which seriously affects the power density and reliability of the transmission system. The size of the torsional stiffness of each branch is also an important factor affecting the load distribution. Therefore, it is important to study the matching relationship between the clearance and torsional stiffness of each branch gear and optimize the corresponding parameters to reduce the unevenness of the load distribution of each branch and improve the reliability of the transmission system.

To determine how to allocate the side clearance of the gearbox with the stiffness of each branch to obtain a reasonable load distribution coefficient, scholars around the world have performed a large amount of research in this area:

- (1)

Calculation of load distribution based on hydrostatic gear split-torsion transmission

Krantz [

1,

2] et al. conducted a theoretical analysis and experimental study on the load distribution of a gear split-torsion transmission system under a static load using a synchronous angular load equalization design method without any load equalization device. Yuriy Gmirya, and Leslie Leigh [

3,

4] conducted a hydrostatic study on the equal load problem of multi-branch power shunt reducers and derived equal load coefficients satisfying the prevailing manufacturing and installation conditions. Dong Hao [

5] et al. investigated the static mean load characteristics of gear shunt drive wheel systems with different structures based on deformation coordination conditions using concentrated parameter theory. Zhibin Li and Guanghu Jin [

7,

8,

9] investigated the effects of the error, torsional stiffness, and standoff stiffness on the static load matching performance of multi-branch gearing systems.

- (2)

Optimization of the load-equalization performance of a gear split-torsion transmission system based on a flexible shaft device

Isabelle [

10] et al. proposed the use of elastic devices such as elastic torsion shafts and rectangular elastic pads to optimize the load distribution in gear shunt transmission systems. White [

11] proposed the design method of nesting a flexible shaft inside a duplex shaft, which resulted in better load equalization performance of the system.Gmirya [

12,

13] et al. used a flexible shaft device in a multi-branch gear shunt transmission system and conducted a static and dynamic experimental study on the load equalization performance of the multi-branch transmission system. Yongfang Gui [

14] et al.studied the equal-load characteristics of the elastic torsion shaft system for a dual-input gear split transmission system and proposed a calculation method for the torsional stiffness of the elastic torsion shaft and the transmission error of the system.Zehua Hu [

15] studied the equal-load characteristics of a dual-branch gear transmission system and proposed optimization measures for the flexibility of the wheel spokes and the support shaft.

- (3)

Analysis of gearbox backlash based on three-dimensional tolerance

The three-dimensional tolerance analysis model of Jacobian-Torsor takes the backlash at the output end of the gearbox as the demand dimension and the other errors affecting the backlash as the constituent ring dimensions, which are calculated with the matrix method to avoid the complex derivation of geometric relationships. Desrochers [

16] et al. proposed a three-dimensional tolerance analysis model based on small displacement torsor (SDT)theory and Jacobian matrix for characterizing the dimensional and form tolerances in geometries. Min Zhang [

17] et al. established a transmission error prediction model for complex multi-stage gear reducers based on design tolerances. L. Laperrière [

18,

19] et al. developed a Jacobian-Torsor volume tolerance analysis model based on the interval algorithm, which could perform tolerance analysis based on the extreme value method and statistical methods. XiaoYan Zuo [

20] developed an error propagation model based on the Jacobian-Torsor theory. Weihua N, Rivire, Bruyere, and Dantan [

21,

22,

23] proposed a contact analysis method for the rapid determination of gear drive clearance based on the Jacobian-Torsor model and the Monte Carlo simulation technique.

The existence of local parallel chains in the process of gear backlash analysis affects the accuracy of backlash analysis. Zeng et al [

24] compared the analytical results of spiral bevel gearboxes with and without partial parallel chains and proved that the effect of partial parallelism on the resolution accuracy was not negligible. Yang, Hussain, et al, [

25,

26,

27,

28,

29] studied linear construction and parallel construction methods and proposed a probabilistic approach using a connected assembly model without considering partial parallel effects. Sun Jin et al [

30] studied a method to solve the partial parallel chain problem caused by deterministic deviations and established a generalized deviation propagation formulation for n-level component assembly. Chen, H [

31,

32,

33] et al. proposed the spin measure model to transform parallel chains into serial chain tolerances with complex algebraic operations. Wenhui Zeng [

34] proposed the use of the geometric structure leverage effect and combined the advantages of CLIC (an acronym for “localization tolerancing with contact influence”)method and analytical line method to generate new serial chain tolerances.

Current methods for calculating load distribution based on static and elastic shaft structures do not take into account the effect of tolerance zones on gear backlash distribution or three-dimensional tolerance analysis for parallel shafts, and there has been less research on multi-branch split-torsion transmission. The dual input counter-rotating drive system has a complex structure and many factors affect the load distribution. In this research, we consider the effects of the backlash and elastic shaft torsional stiffness on the equal load performance at the output of two branches of the dual-input-to-rotation transmission system, and we establish a three-dimensional tolerance Monte Carlo analysis model of gear backlash based on the small displacement torsor theory and Jacobian matrix. The method of local parallel chain theory of gearbox meshing tooth pairs is proposed, and the calculation method of an elastic deflection angle and an equal load coefficient of the gearbox is combined with the theory of the elastic torsional deformation of the shaft system. The side clearance and the range of the equal load coefficient are calculated for the dual-input counter-rotating gearbox, and then verified through tests and proposed measures to optimize the equal load performance of the system.

2. Calculation Method of Gear Backlash Based on Jacobian-Torsor Theory

2.1. Analytical Model of Jacobian-Torsor Based on SDT Theory

The basic concept of SDT theory is to consider the geometric defects of features as a result of the motion of a three-dimensional Euclidean space point set and to represent the spatial motion of points with tiny vectors. As a tolerance expression model, SDT theory characterizes the actual variation of the key geometric features of a part with respect to the ideal posture using three translational components and three rotational components, and the theory can also characterize the variation of the gap between the key geometric features of a part in an assembly. The tolerance expression is as follows:

where

are the ideal geometric features of the translation along the X, Y, and Z coordinate axes respectively,

are the rotation of the ideal geometric features along the X, Y, and Z coordinate axes, respectively.

A detailed list of SDT models with various characteristics is given in the literature [

34].

The Jacobian model can accurately transfer the robot’s joint variations to the end, and the 3D deviation of the actual features in the assembly from the ideal position can be perfectly transferred to the functional requirements (FR) of the assembly with the help of the Jacobian model. With the help of SDT to represent each characteristic deviation, the Jacobian matrix is introduced into the tolerance transfer model to establish the Jacobian-Torsor model for three-dimensional tolerance analysis, whose expression is shown in Equation 2. Each functional element of the part layer in the Jacobian-Torsor model has a corresponding coordinate system: 0 is the closed-loop element, i denotes the i-th functional element in the tolerance transfer chain, (i =1, 2,..., n)and n is the last functional element.

where,

is the Jacobian matrix of tolerances,

is the small displacement torsor of the functional requirements elements, and

is the amount of small displacement torsor associated with the i-th functional element.

According to SDT theory, the tolerance band can be expressed in a matrix form as follows:

When the constituent tolerance zone is skewed with respect to the direction of tolerance analysis, it is necessary to project this tolerance zone in the direction of tolerance analysis, whose axis direction must coincide with or be parallel to the reference coordinate axis. To obtain a projection of the tolerance band, the change in the tilt of the tolerance band with respect to the basic reference system must be applied to the translational and rotational torsor of the tolerance band.

denotes the translational small displacement torsor, and

denotes the rotational small displacement torsor. The expressions for the projected torsor of the tolerance band are as follows:

where

denotes the inconsistency coefficient of the tolerance analysis direction with respect to the i-coordinate system, with the columns

respectively designating the unit vectors along axes Xi, Yi, and Zi, respectively, for the tolerance zone tilted according to the direction to be analyzed in reference mark i. The final expression of the small displacement torsor associated with the i-th functional element is as follows:

The Jacobian matrix

represents the transformation relationship between the requirement elements of the assembly and the functional elements of the part level, given by

where

is the directional transformation matrix between coordinate systems,

is the transformation matrix of the positions between coordinate systems, and

is the matrix that is corrected for the spatial location to overcome the leverage effect.

represents the directional change of the i-coordinate system with respect to the zero-coordinate system, and its expression is as follows:

where

are the direction vectors of the axes

, respectively, in the 0th coordinate system.

is the change in position of the n-coordinate system relative to the i-coordinate system, given by

where,

and

are the x-values,

and

are the y-values,

and

are the z-values, of the origin of the i, n coordinate system in the 0 coordinate system.

2.2. Three-Dimensional Tolerance Analysis Parallel Chain Serialization Method

Two or more assembly positioning nodes exist for inter-part assembly positioning, which constitutes a parallel chain. According to the type of benchmark, parallel chains can be divided into two categories: multiple benchmarks and common benchmarks. Multiple datums and common datums are used as criteria for classifying parallel chains. Multiple datums are based on the spatial degree of freedom restrictions on the part features from mutually independent coordinate systems, while common datums are based on spatial degrees of freedom restrictions on part features from mutually coupled coordinate systems.

Multi-basis parallel chains are commonly found in contact pairs formed between two surfaces, where cylindrical nodes combined with planar nodes are the most common type. When a key connection or a clearance fit is used between the gear and the shaft, a chain of parallel tolerances similar to the hole-pin is formed, and the partial parallel chain is calculated with the parallel or intersection operation [

31].

The parallel dimensional chain with the geometric tolerance datum in the dimensional chain is the common datum. The tolerance of the two contact surfaces can no longer take the serial chain operation method due to the existence of the leverage effect, and to eliminate the influence of the geometric structure leverage effect on part of the parallel chain, the advantages of the CLIC method and the analytical line method are integrated to transform the parallel chain into the new serial chain tolerance [

24].

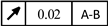

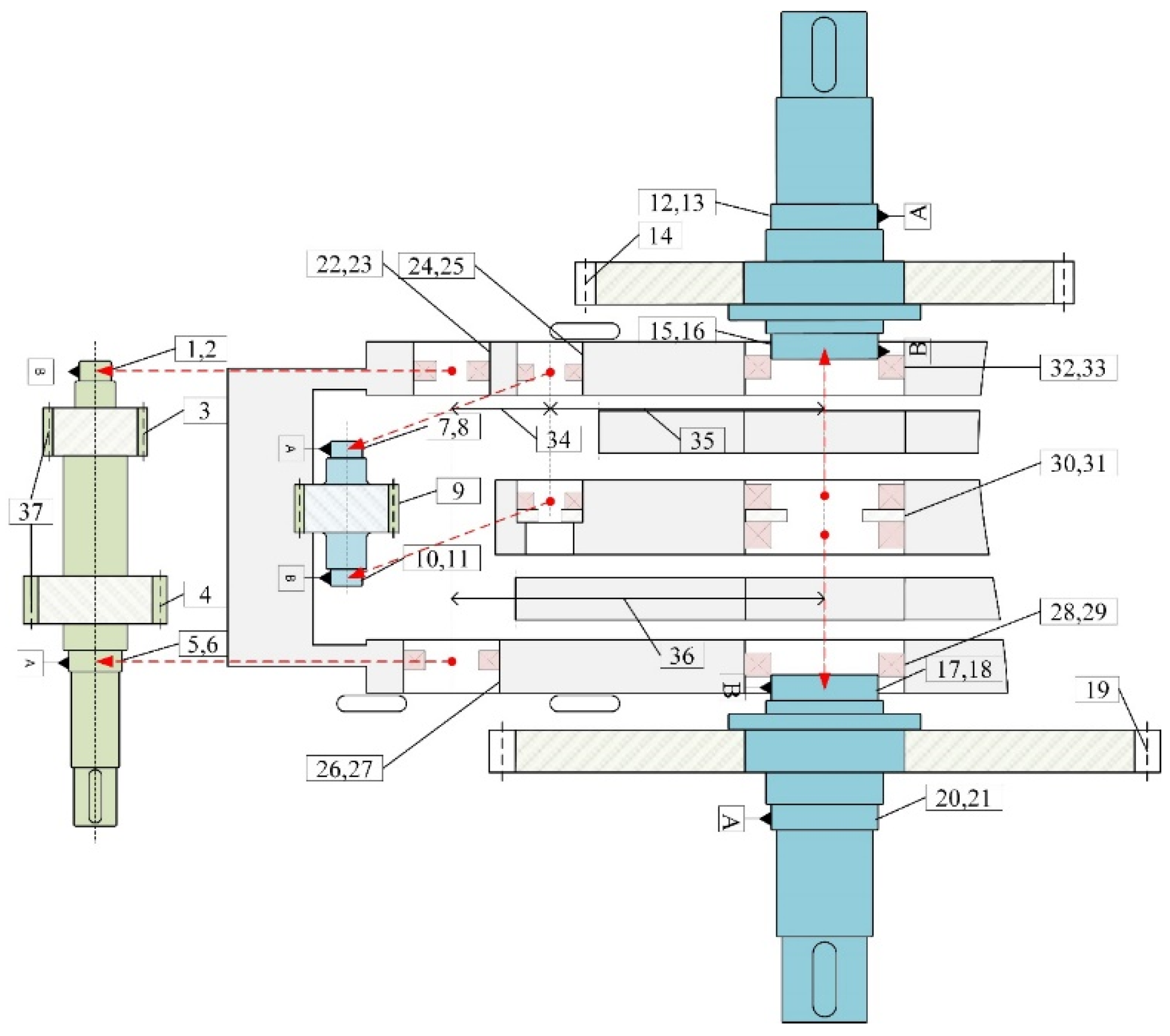

When a pair of gears meshes, with the active shaft axis as the positioning reference, there is a relative offset between the drive shaft axis and the active shaft axis, and the offset of the center distance tolerance causes the gears on the shaft to also be offset, The offset makes the gears misaligned, there is a local parallel chain between the main serial chain and the center distance tolerance, and the dimensional chain is shown in

Figure 1 Directly superimposing the center distance tolerance on the gear tolerance will increase the error. The center distance tolerance can be equated to the gear tooth thickness manufacturing deviation through the geometric relationship, which is shown in.

Figure 1.

IFE3 in

Figure 1 represents the tooth thickness deviation of gear 2, given by

CFE5 indicates the center distance deviation of the two gears, given by

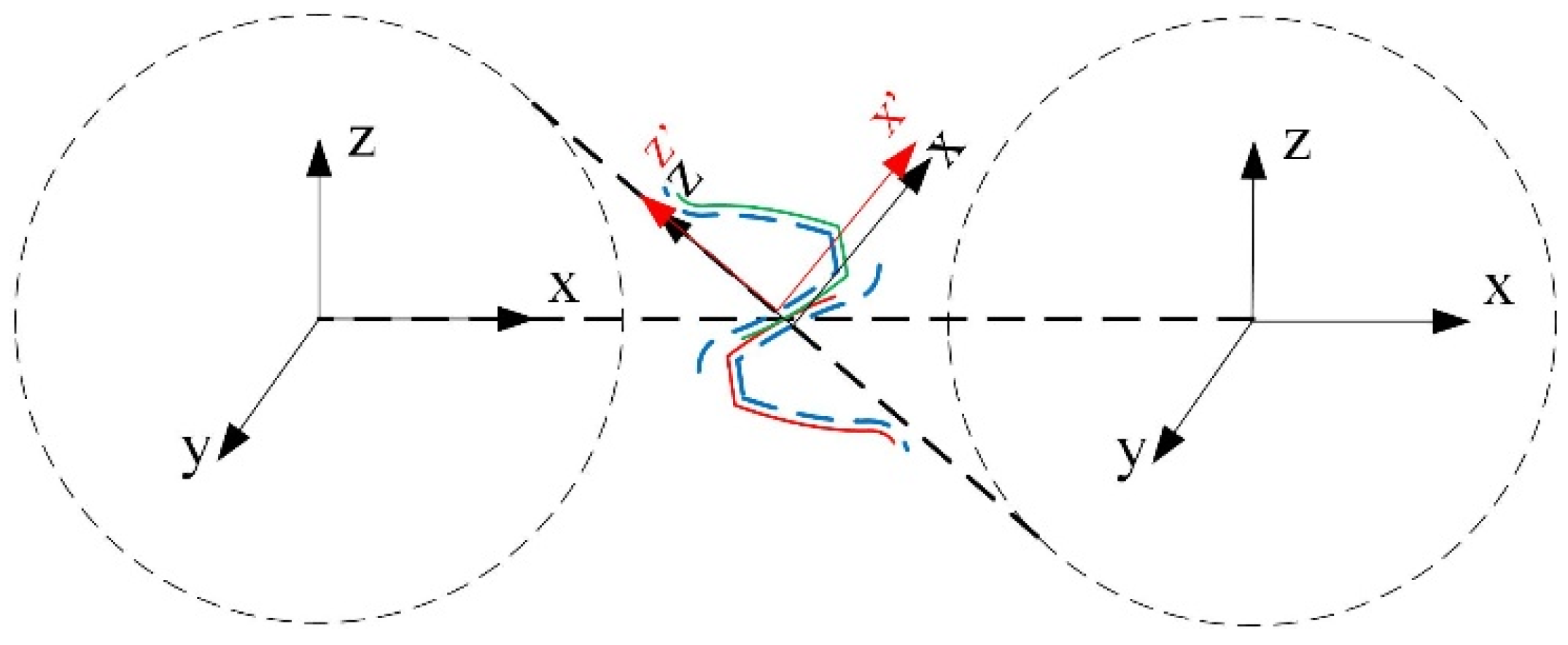

In

Figure 2 t is the center distance deviation,

and

are the displacement components of the center distance deviation,

and are the displacement components of the center distance deviation at the point of engagement,

and

are the displacement components of the center distance deviation on the engagement line,

and

are the rotational components of the center distance deviation. O

1O

3 is the length of the pitch circle radius of gear 1, which is denoted by

, and O

2O

3 is the length of the pitch circle radius of gear 2, which is denoted by

, The length of O

1O

2 is the central distance and is denoted by

, and

θ is the mesh angle of the two gears, which can be expressed by the radius of the base circle

and the radius of the indexing circle

of gear 1.

The deviation of the center distance of the two gears is in the same direction as the rotational component of the tooth thickness deviation of gear 2 and can be algebraically superimposed. The displacement component of the center distance deviation needs to be translated to the meshing line with the geometric relationship and then algebraically superimposed with the displacement component of the gear 2 tooth thickness deviation.For

and

as shown in Equations 12 and 13, after converting the center distance deviation to the gear 2 tooth thickness deviation, the tolerance torsor is IFE3' as shown in Equation 14.

After the transformation, the center distance deviation CFE5 and the tooth thickness deviation IFE3 form a new tolerance torsor IFE3', the coordinates of which coincide with those of IFE3.

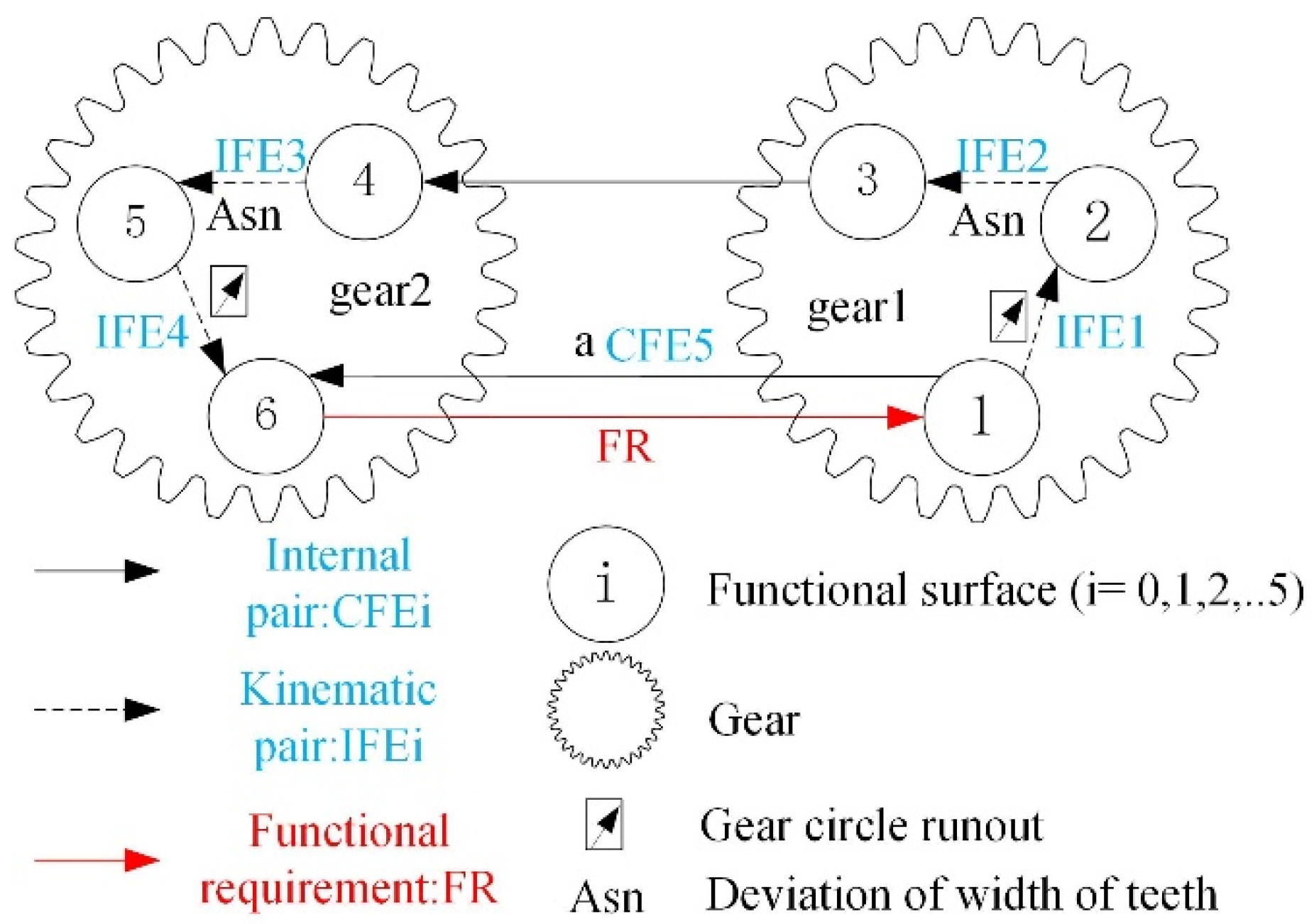

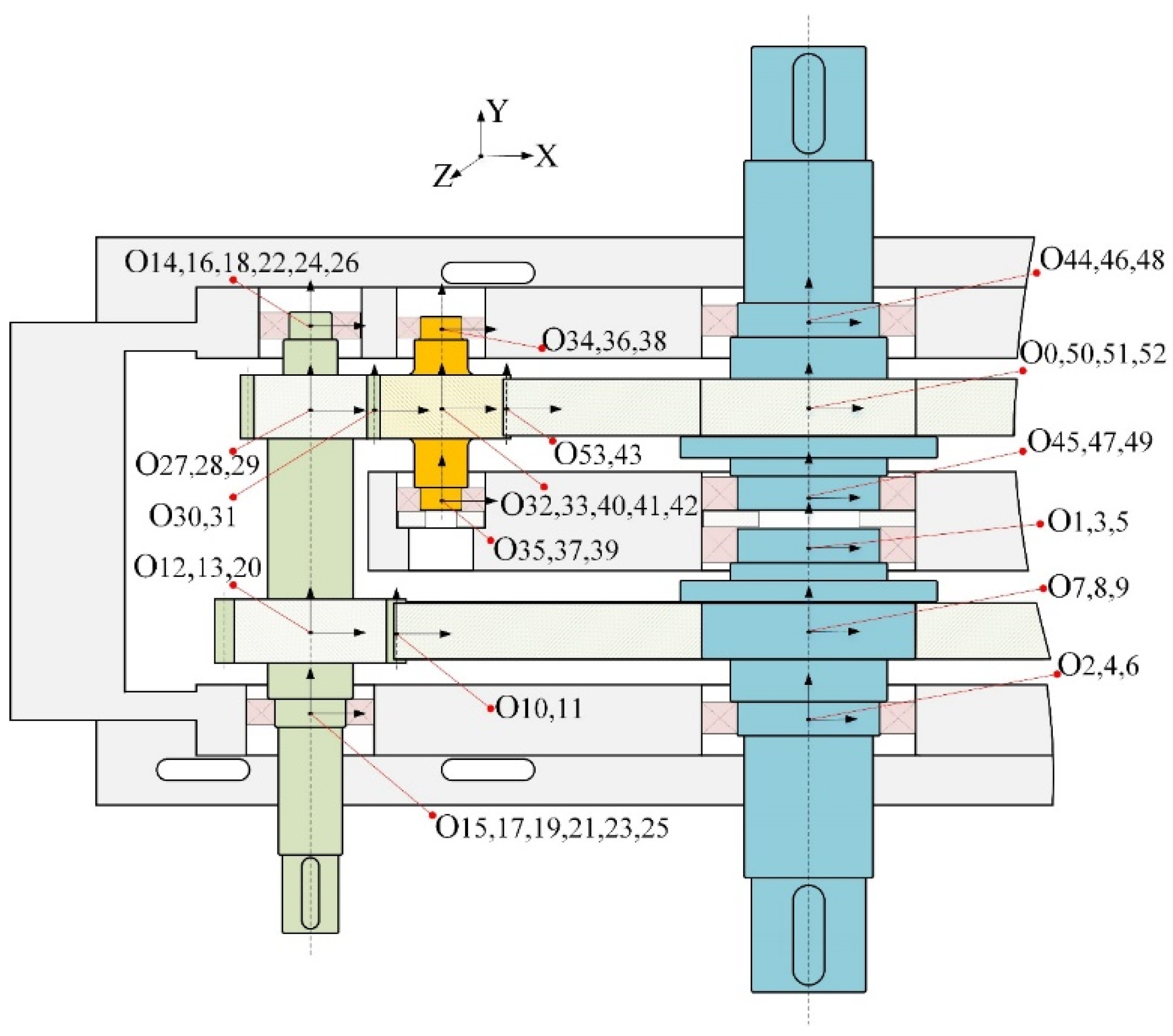

The gearbox is composed of main parts such as the drive shaft, gear, bearing and box. For a gear transmission system with a known transmission structure, the three-dimensional tolerance analysis of the gearbox backlash is as shown in

Figure 3.

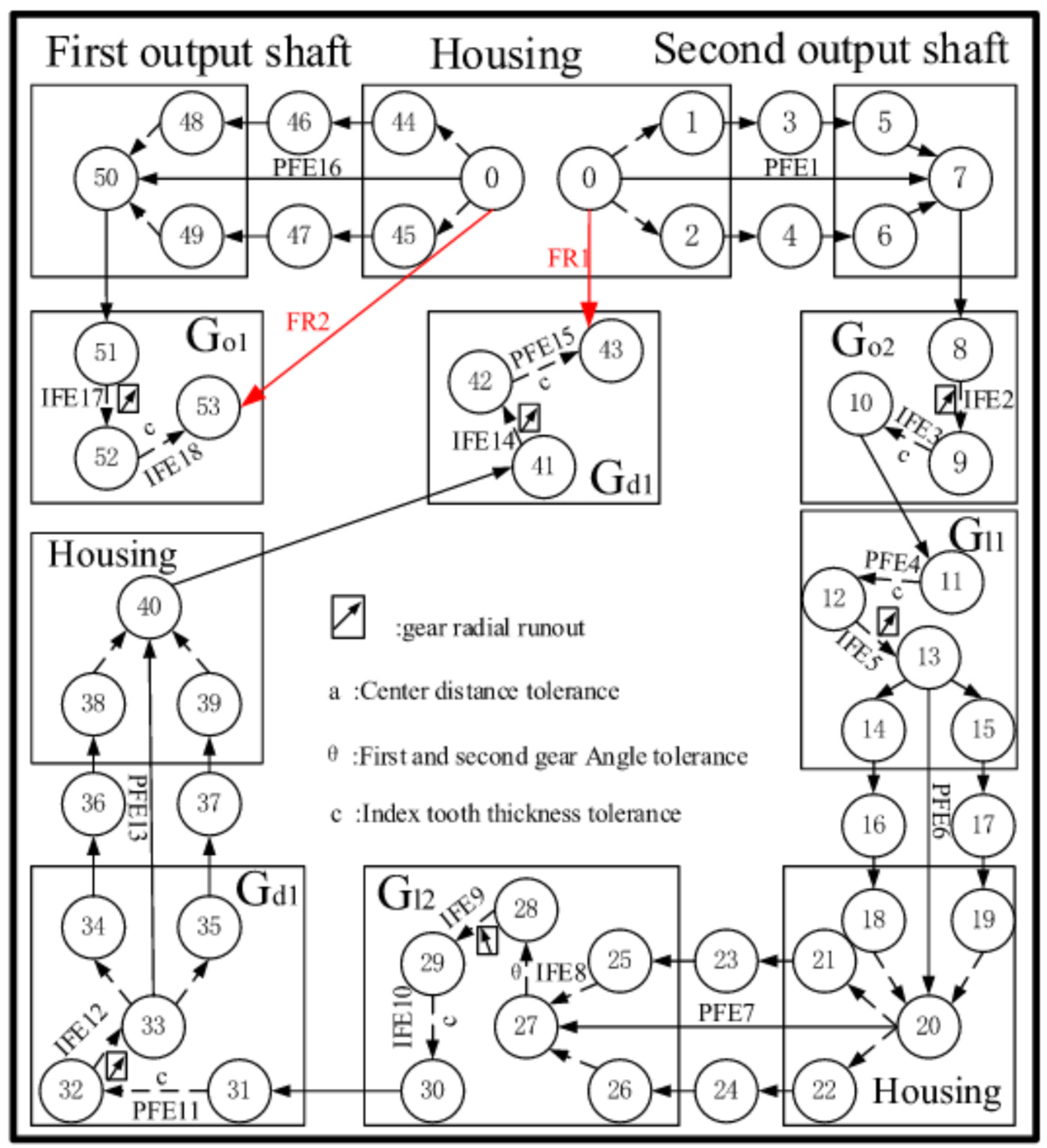

3. Condition of Backlash Distribution of Dual Input Counter-Rotating Gearbox

The dual-input counter-rotating gearbox is symmetrical from left to right. The parameters are shown in

Table 1. Taking the bearing seat axis of output shaft 1 as the positioning reference, and the backlash between G

d1,G

d2, and G

o1 as the functional requirement

FRi and each element tolerance torsor as

FEi, serializing the parallel chain is established, the Jacobian-Torsor model of the gearbox, and calculating the distribution of the gearbox is established, and the distribution of the gearbox backlash is calculated.

The tooth thickness deviation parameter shows that the theoretical backlash at the engagement of Gd1 and Gd2 with Go1 is 0.2443 mm.

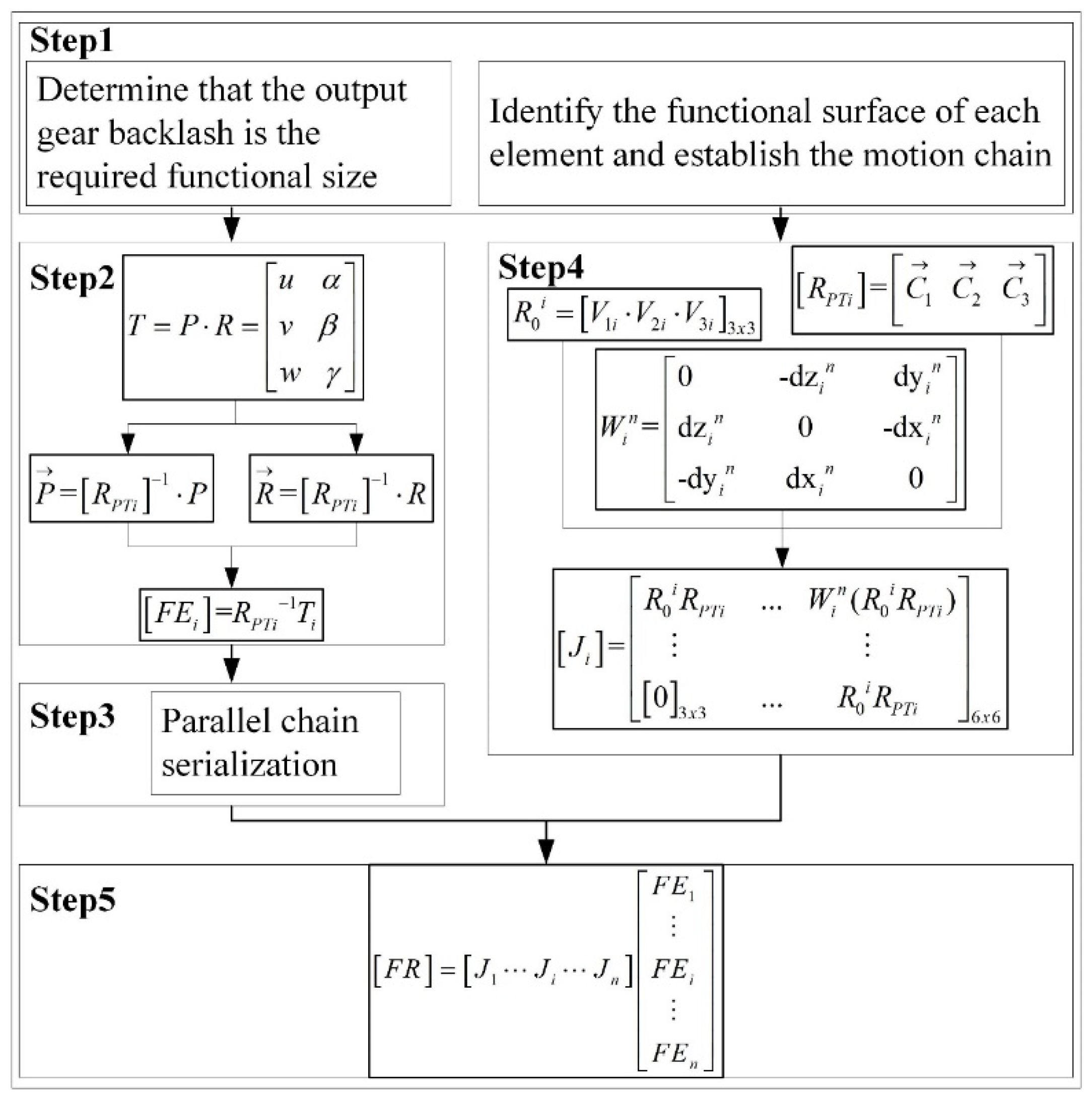

3.1. Structural Analysis of Dual Input Counter-Rotating Gearbox

A multi-branch shunt drive system adopts the method of a fixed shaft drive to achieve a power shunt, and multi-branch input, so that the load of each branch is only part of the original load, thus greatly reducing the volume and weight of the wheel. A multi -branch drive system has certain a fault tolerance. When one of the branches is damaged, the other branches can still maintain the normal operation of the system, which improves the reliability of the drive system.

Due to the existence of these errors, the backlashs between the multi-branch gears and the output gears are not equal, resulting in an uneven distribution of the system’s load. To study the system’s load equalization performance, the backlash distribution of each branch is calculated with the system errors, and thus the system load equalization factor is calculated.

The three-dimensional tolerance analysis model based on a Jacobian-Torsor can consider the coupling of various errors in gearboxes well, avoiding the derivation of complex geometric relationships. The small displacement torsor and matrix are used to represent the tolerance of each element, and combined with the Monte Carlo analysis method to calculate the distribution of the backlash at the output end.

Due to the difficulty of processing and cost limitations, the test is carried out using a double-input counter-rotating gearbox for theoretical calculation and experimental verification. The gearbox has synchronized inputs on the left and right branches and counter-rotating outputs on the two output shafts, and its transmission structure sketch is shown in

Figure 4.

3.2. Tolerance Specifications for Gearing Systems

Based on the new generation GPS standard system, the main parts of the gear transmission system include the case, shaft, bearing and gear. The bearing clearance is not considered here. G

o1, G

o2, and the output shaft are hot-mounted without considering assembly clearance. The tolerance specification of each part is shown in

Figure 5, and the tolerance dimensions are shown in

Table A1 in

Appendix A.

3.3. Modeling of the Jacobian-Torsor Model of the Gearing System

The gearbox is symmetrical from left to right and can be modeled on one side. The left side of the gearbox is modeled with the output shaft 1 as the positioning reference and the backlash between Gd1 and Go1 as the closed ring.

In the gear transmission system, choosing a reasonable working backlash is beneficial for improving transmission accuracy. The intersection of the two gear axis lines and the gear mesh line is the origin of the characteristic coordinate system on the two gear tooth profiles, and the backlash is the minimum distance between the two tooth profiles. The schematic diagram of the two gears meshing is shown in

Figure 6.

In accordance with the gearbox assembly relationship and the tolerance specification of each part, the coordinate system shown in

Figure 7 is established with the gearbox bearing bond surface as the reference. The housing bore is machined based on a uniform datum, so the output shaft 1 and output shaft 2 mounting bores are common datum. Considering the gear tooth thickness deviation and center distance tolerance, the Jacobian spin volume model is established with each part manufacturing error and assembly error as the constituent ring and the output gear backlash

as the closed ring. Three-dimensional tolerance calculations are usually performed in the closed-loop tolerance direction. However, the direction of the constituent ring tolerance is mostly inconsistent with the backlash direction, so the output shaft reference hole is used as the tolerance analysis direction, and finally

is calculated with angular conversion to the closed ring coordinate system direction. The dimensional chain of the gearbox assembly is shown schematically in

Figure 8.

As shown in

Figure 8,

FRi is the output gear backlash tolerance torsor, IFE is the internal part tolerance torsor, CFE is the inter-part tolerance torsor, and the PFE parallel tolerance torsor can be solved as described in

Section 2.2

The calculation of

in the

Table A1 is as follows:

where

is the base circle radius of G

o2,and

is the reference circle radius of G

o2.

3.4. Three-Dimensional Tolerance Analysis of Output Gear Backlash of Gearbox

Three-dimensional tolerance analysis mainly has an extreme value method and a statistical method. The backlash calculated with the extreme value method is large. In this research, we use the Monte Carlo method in the statistical method for the tolerance analysis of the backlash.

Monte Carlo simulation is a numerical method for solving approximate solutions to mathematical, physical and engineering technology problems through stochastic simulations and statistical experiments. The method is computationally accurate and consistent with the actual generation, and it is suitable for the solution of assembly functions with nonlinear expressions.

The dimensional and shape tolerances of the gearbox follow the principle of independence, and the tolerance zones of their dimensional and shape tolerances are symmetrically distributed and obey a normal distribution. The symmetrically distributed tolerances, regardless of whether they are defined as increasing or decreasing rings, have the same effect on the closed ring. Therefore, in the process of tolerance analysis, the tolerance of each component ring is expressed as (t is the tolerance of the component ring).

The closed-loop samples

FR1 and

FR2 conform to a normal distribution, for which the tolerance can be calculated as follows:

where

and

are the mean and the variance of

FR, respectively. The confidence level at 99.73% probability is used, and

Z is taken as 3.

The backlash

value is calculated as follows:

where

is the upper deviation of the z-directional translation of closed dimensional chain 1,

is the lower deviation of the z-directional translation of closed dimensional chain 2,

is the upper deviation of the z-directional rotation of closed dimensional chain 1,

is the lower deviation of the z-directional rotation of closed dimensional chain 2, and

is the angle of engagement of G

d1 and G

d2 with G

o1.

The results of the

calculation are shown in

Table 2.

The theoretical value of 0.2443 mm is used as the lower limit of the backlash, and the value calculated with the Monte Carlo method, 0.4150 mm, is used as the upper limit of the backlash. The actual measurement of the backlash should be distributed in this range.

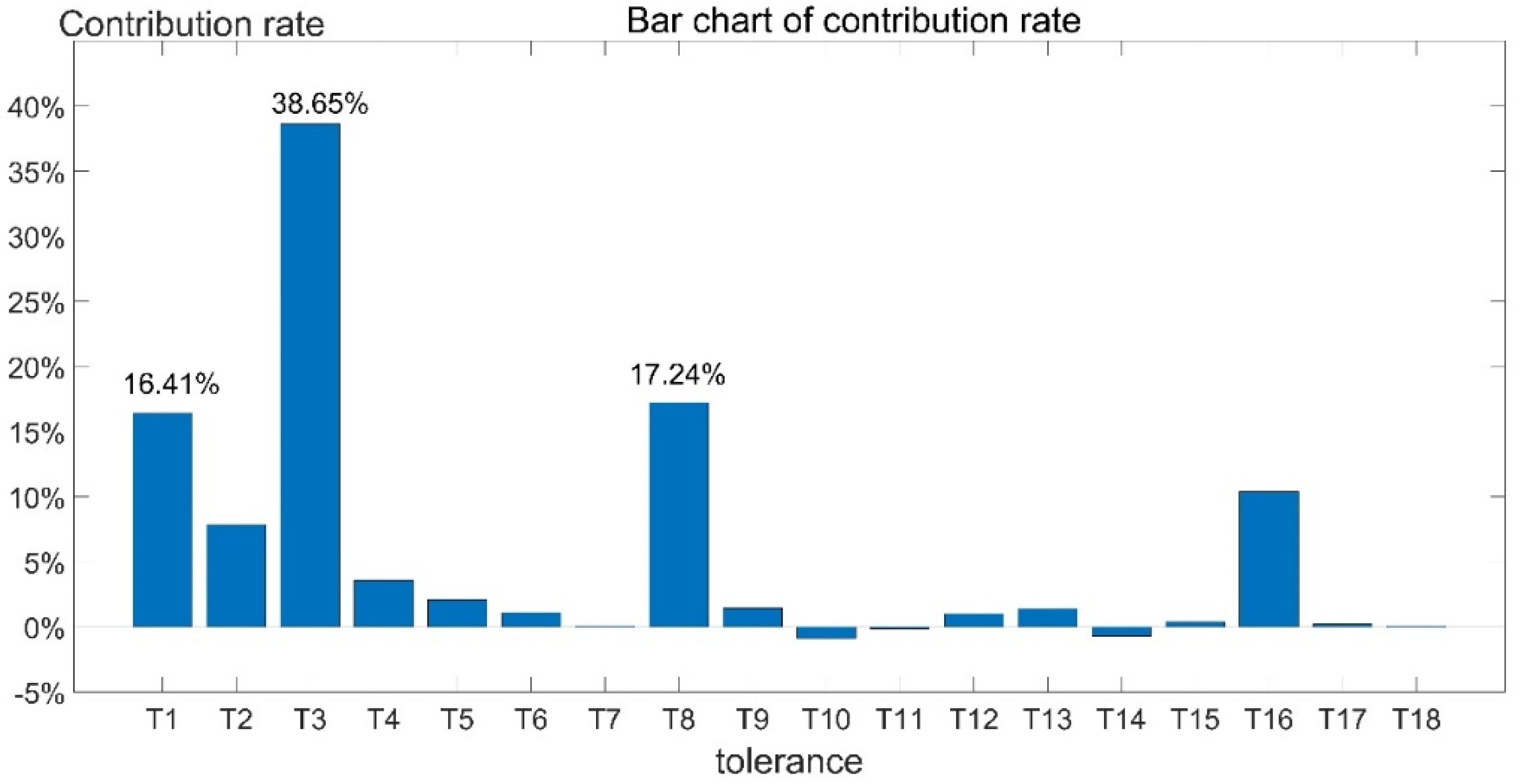

The contribution of each dimensional tolerance to the backlash closure ring is shown in

Figure 9.

As can be seen from

Figure 9, the tolerance

T3 has the highest contribution to the backlash at 38.65%, followed by the tolerances

T8, and

T1, at 17.24%, and 16.41%, respectively.

4. Calculation Method of Equal Load Factor for Dual Input Counter-Rotating Gearbox

4.1. Calculation of the Elastic Deflection Angle of the Gear Shaft System

For the dual-input counter-rotating transmission system, when the two input torques are the same, the load difference between Gl1, Gr1, and Go2 is neglected because the cumulative error between Gl1, Gr1, and Go2 is small and the two gears are very close to the input motor and the deformation of the shaft system is small. During the loading process, one of the two idler pulleys enters into engagement first. Due to the influence of manufacturing and installation errors, there is a gap between the idler pulley that enters into engagement later and Go1, and with the increase of the input torque T, the gap is gradually eliminated through the elastic deformation of the engagement sub and input shaft system. Then all idler pulleys enter into engagement. The rotation angle of Gl1 and Gr1 is . The rotation angles of Gl2 and Gr2 is , respectively. Go1 and Go2 rotation angles are , respectively. The left and right input shaft torsion angles are , respectively.

The gear meshing deformation and rotation angle are calculated as shown in Equation 18. The torsion angle formed by the torsional deformation of the shaft is calculated as shown in Equation 19. The equations for the static balance of the input shaft, idler shaft, and output shaft 1 are shown in Equation 20. The theoretical normal backlash can be converted into a circumferential backlash with equation 21.

where

i is the transmission ratio,

is the average meshing stiffness of gears G

o2 and G

l1, and

is the average meshing stiffness of gears G

o1 and G

l2.

is the torque applied to gear G

l1, and

is the radius of the base circle of the gear

is the torque applied to gear G

l2 and

is the radius of the base circle of the G

l2.

is the torque applied to gear G

r1, and

is the radius of the base circle of gear G

r1.

is the torque applied to gear G

r2 and

is the radius of the base circle of gear G

r2.

is the torque applied to gear G

o1, and

is the torque applied to gear G

o2.

is the base helix angle of gear G

o1,

is the gear G

o1 engagement angle,

is the input shaft length,

is the input shaft diameter, and

is the input shaft modulus of elasticity.

In Equation 18 and 21, the torsional deformation of the input shaft is solved according to material mechanics, the average meshing stiffness of the gear is calculated according to GB/T 3480-1997, and the meshing angle is calculated by referring to ISO/TR10064-2:1996.

When the input torques are equal to 200 N m, the calculated deformation of the system under a load, Gd1 turns at an angle of 0.007 rad with respect to Go1. The previous theoretical backlash value of 0.2443 mm is the normal backlash, and the rotation angle corresponding to the Gd1 circumferential backlash is 0.006 rad. If the manufacturing and assembly errors of the system are not considered, the theoretical equal load performance of the system is good.

4.2. Analysis and Calculation of the Uniform Load Factor

In fact, the dual input counter-rotating gearbox has manufacturing and assembly errors, and the two branches are not loaded in the same way. It is then assumed that the left branch backlash is the theoretical value of 0.2443 mm and the right branch backlash value is the upper limit of 0.4150 mm, and the elastic deformation of the two branches can compensate for the backlash. The torque values of gears G

l2 and G

r2 are calculated according to Equations 18 and 19, and the equal load factor is defined as follows:

where,

is the torque value of gear G

l2 and G

r2, respectively.

From the previous calculations of backlash and torque values, it can be seen that the uniform load coefficient of the dual input counter-rotating gearbox ranges from 1 to 1.259.

5. Experimental Verification of Load Distribution Characteristics of Dual Input Counter-Rotating Gearbox

The range of the G

d1, G

d2 and G

o1 backlash calculated by with the three-dimensional tolerance discussed in

Section 3.3 shows that when the input torque of the two branches is equal, the backlash of G

l2, G

r2 and the value of the torque applied are not equal.

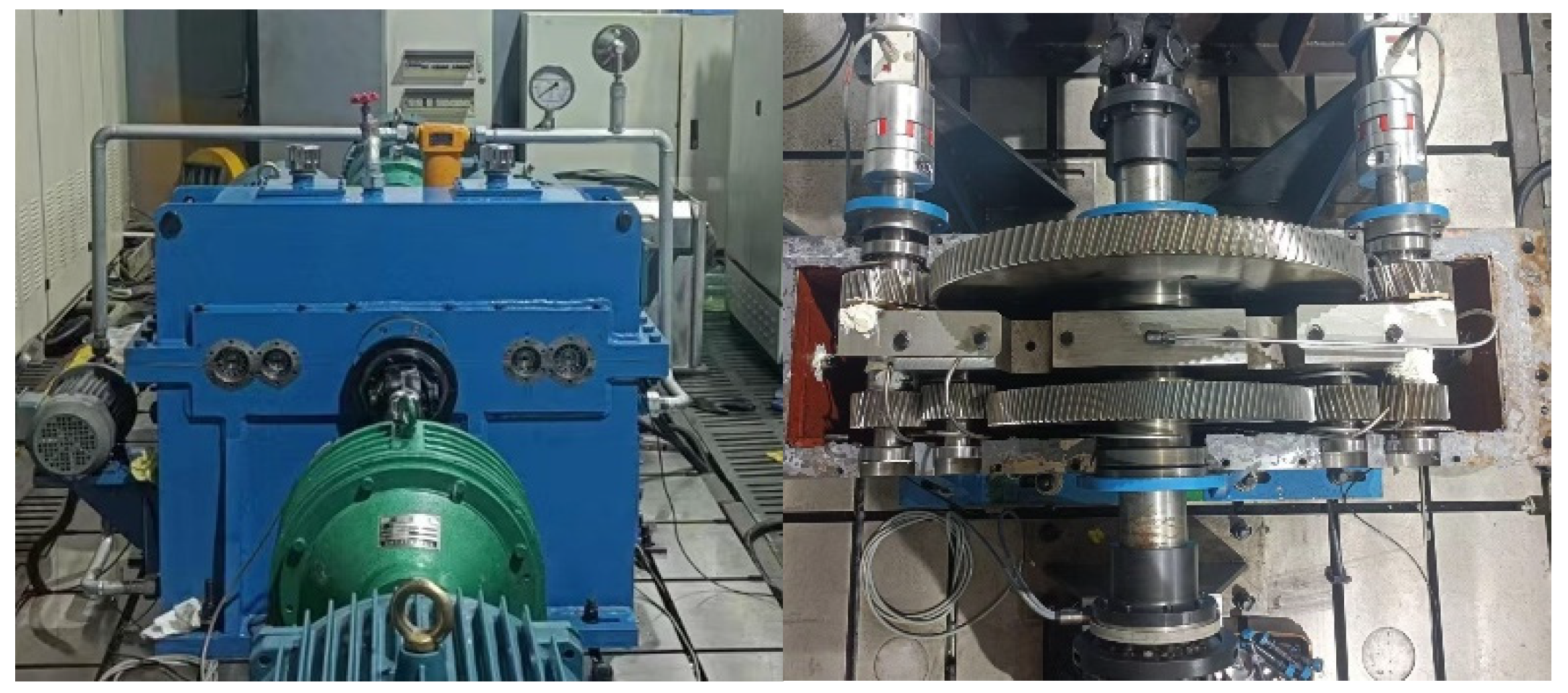

The previous calculation shows that theG

d1, G

d2 and G

o1 backlash range is 0.2443-0.4150 mm, and the system’s uniform load coefficient range is 1-1.259. To verify the reasonableness of the previous calculation method, a test rig is built for testing. The test rig for the dual input counter-rotating gearbox is shown in

Figure 10.

5.1. Backlash Test Verification

The G

d1, G

d2 and G

o1 backlash is measured using a dial gauge. When measuring the side clearance, the input shaft and output shaft 1 positions are fixed, and the dial gauge is located at the G

d1 and G

d2 indexing circle. Then G

d1 and G

d2 are turned, and the dial gauge reading is the backlash value. The actual measurement method is shown in

Figure 11.

When measuring, the input shaft is rotated four times with the output shaft 1 position, and the backlash is taken as the average of eight measurements. The measurement data are shown in

Table 3.

The actual measured Gd1 and Go1 backlash value is 0.251 mm and the Gd2 and Go1 backlash value is 0.410 mm. The actual measured backlash is within the theoretical calculated backlash range of 0.2443-0.4150 mm, and the three-dimensional tolerance analysis plays a more important role in the study of the system’s even-load performance.

With the actual measured backlash values, the two branch torques are calculated as 86.736 N m and 141.680 N m using Equations 18, 19, 20and 21, and the uniform load coefficient is calculated as 1.241 according to the definition of the uniform load coefficient Equation 22.

5.2. Uniform Load Performance Test

The uniform load coefficient is calculated to be 1.241 according to the backlash, and the gear G

l2 and G

r2 torque values are then measured using a stress-torque sensor with strain gauges applied to the two input shafts at the corresponding two measurement points. The measurement principle is shown in

Figure 12.

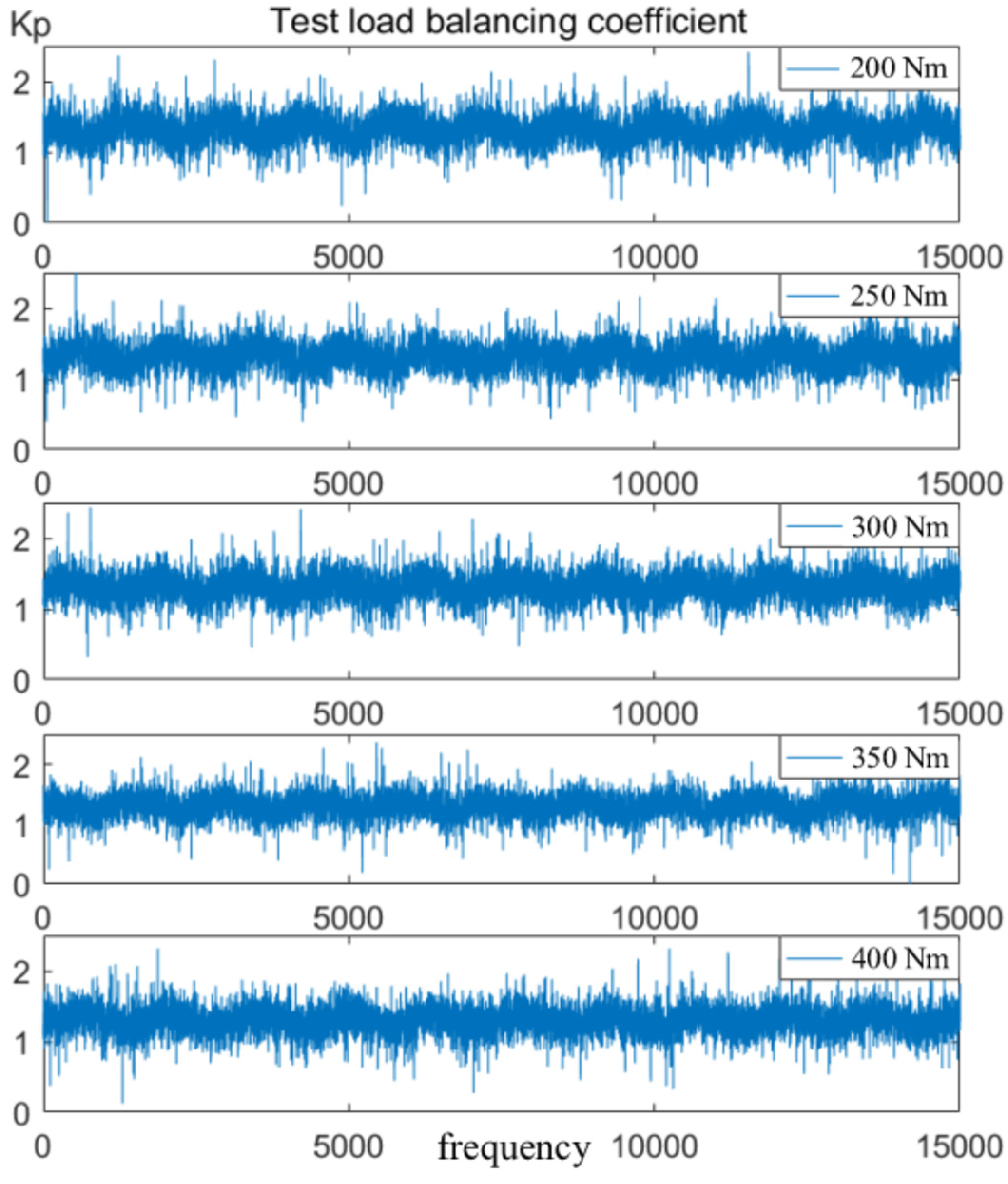

The results of the torque measurement at measurement point 1 and measurement point 2 for various input conditions are shown in

Table 4.

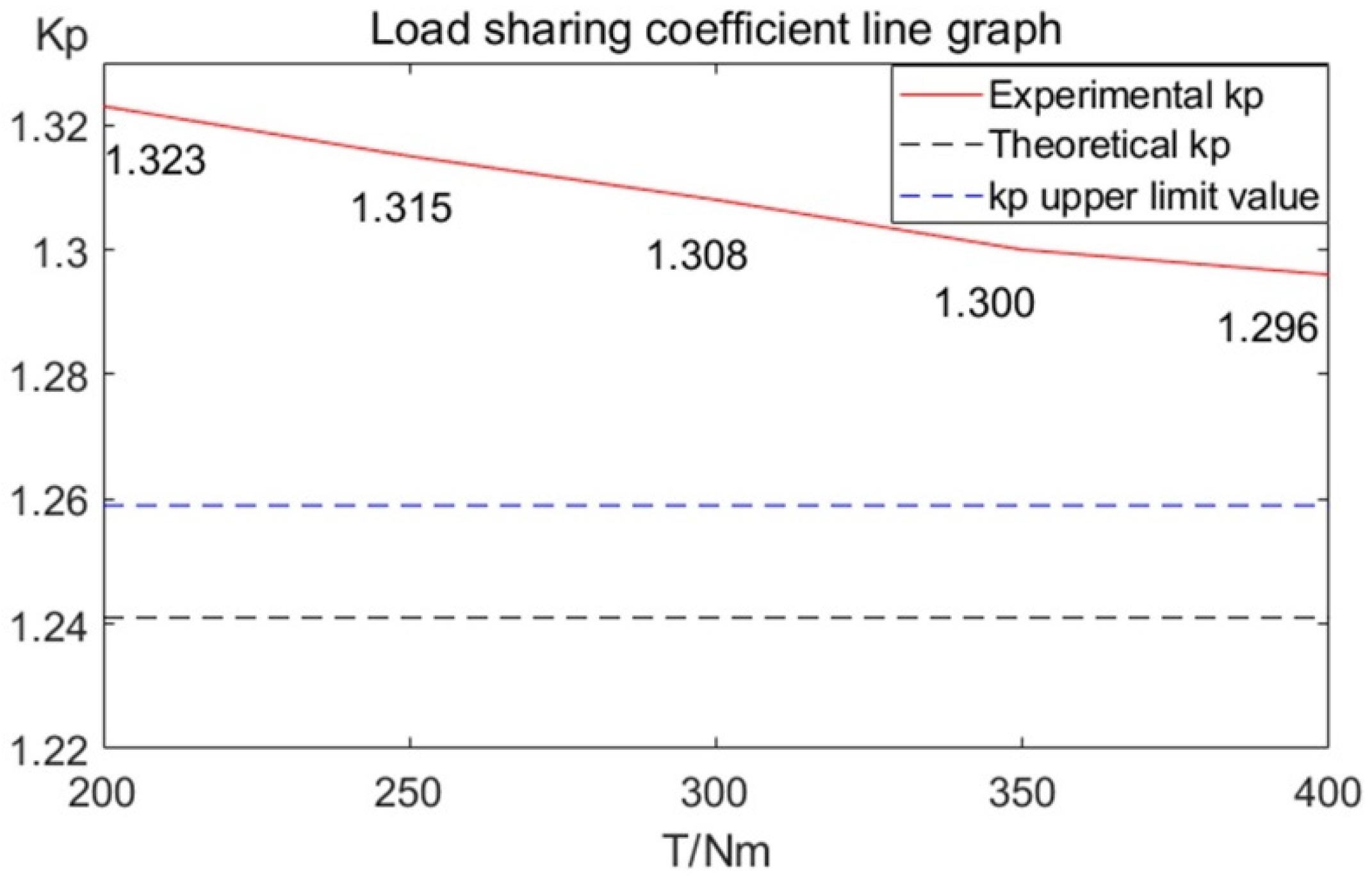

The uniform load coefficient test data are shown in

Figure 13, and the relationship between the input torque and the average value of the uniform load coefficient is shown in

Figure 14.

From

Figure 14, it can be seen that the maximum system uniform load coefficient is 1.323, which exceeds the theoretical uniform load coefficient of 0.064, and the-test measured uniform load coefficient exceeds the theoretical value by 5.08%. The error is 6.61% compared to the uniform load coefficient calculated from the measured backlash. According to the experimental data, it can be seen that the larger the input torque is, the lower the equal load coefficient is. The difference between the elastic deflection angles of the two branches decreases as the torque increases, resulting in a more uniform load distribution of the system. Due to the input torque limitation, the system load equalization performance can be improved by reducing the elastic shaft torsional stiffness of the branch with a large backlash.

6. Conclusions

- (1)

From the tolerance contribution degree, it can be seen that T3 is the output shaft 2 large gear tooth thickness deviation, and T8 is the input shaft 1 two gear phase angle deviation. These two tolerances have the greatest influence on the backlash. These two design tolerances can be reduced appropriately in the theoretical design stage to obtain a more reasonable equal load factor.

- (2)

The three-dimensional tolerance analysis method is used to derive the law of backlash distribution, and the torsional stiffness of the elastic shaft of the branch with a larger backlash is reduced to improve the system’s load equalization performance.

- (3)

The three-dimensional tolerance theory analysis method can calculate the backlash range more accurately, and utilize the backlash range to calculate the uniform load coefficient range. The test measured uniform load coefficient exceeds the theoretical range by 5.08%. The error is 6.61% compared to the uniform load coefficient calculated from the measured backlash. This method of calculating the uniform load coefficient has a greater reference value.

Author Contributions

He Yu collected and organized the data, conceived and designed the analysis, and conceived and wrote the paper, Wankai Shi collected and organized the data, and revised the paper, Zhenhao Su contributed in writing and revision. All authors have read and agreed to the published version of the manuscript

Funding

The author declares that no funds, grants, or other support were received during the preparation of this manuscript.

Acknowledgments

The authors would like to thank Shi Wankai and Zhenhao Su of Chongqing University. Thank them for their contribution to this work.

Replication of results

Both the backlash results and the mean load factor results in this paper can be reproduced as results from the data and equations in the research.

Appendix A

Table A1.

Tolerance dimensions of each part.

Table A1.

Tolerance dimensions of each part.

| Component |

Serial number |

Dimensional tolerance |

Position tolerance |

| First input shaft |

1, 2 |

|

|

| 3 |

/ |

|

| 5, 6 |

|

|

| 37 |

|

/ |

| Left idler shaft |

7, 8, 10, 11 |

|

|

| 9 |

/ |

|

| First output shaft |

12, 13, 15, 16 |

|

|

| 14 |

/ |

|

| Second output shaft |

17, 18, 20, 21 |

|

|

| 19 |

/ |

|

| Housing |

22, 23 |

|

|

| 24, 25 |

|

|

| 26, 27 |

|

|

| 28, 29, 32, 33 |

|

|

| 30, 31 |

|

|

| 34, 35, 36 |

|

/ |

Table A2.

Housing and shaft parallel chain conversion to serial chain parameters.

Table A2.

Housing and shaft parallel chain conversion to serial chain parameters.

| |

/mm |

/mm |

/mm |

/mm |

/mm |

/mm |

|

74 |

121.5 |

24 |

145.5 |

0.051 |

0.046 |

|

224.5 |

273 |

19 |

292 |

0.043 |

0.039 |

|

66.5 |

273 |

19 |

292 |

0.043 |

0.039 |

|

63.5 |

120.5 |

16 |

136.5 |

0.0415 |

0.039 |

|

74 |

121.5 |

24 |

145.5 |

0.051 |

0.046 |

Table A3.

SDT for each tolerance of the gearbox.

Table A3.

SDT for each tolerance of the gearbox.

| Tolerance |

Type |

Small displacement torsor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table A4.

Jacobian matrix for each tolerance.

Table A4.

Jacobian matrix for each tolerance.

| |

|

|

|

|

|

|

0→7

0→9 |

|

|

|

|

|

0→10

0→11 |

|

|

|

|

|

0→13

0→20 |

|

|

|

|

|

0→27

0→28

0→29 |

|

|

|

|

|

0→30

0→31 |

|

|

|

|

|

0→32

0→33

0→42 |

|

|

|

|

0→43 |

|

|

|

|

|

0→50

0→52 |

|

|

|

|

0→53 |

|

|

|

References

- Timothy L Krantz. A method to analyze and optimize the load sharing of split path transmissions. Technical report, 1996.

- Timothy L Krantz and Irebert R Delgado. Experimental study of splitpath transmission load sharing. In International Power Transmission and Gearing Conference, number E-10187, 1996.

- Yuriy Gmirya. Multi-path rotary wing aircraft gearbox, April 5 2011. US Patent 7,918,146.

- Gmirya Yuriy, He Shulin, and Buzel Gregory. Leighleslie load sharing test of the ch-53k split torque main gearbox. In The American Helicopter Society 65th Annual Forum, pages 977–986, 2009.

- Hao Dong, Zong-De Fang, Bao-Bin Wang, and Jin-Fu Du. Load-sharing characteristics of gear train with dual power split based on deflection compatibility. Journal of South China University of Technology 2012, 40, 18–23.

- H.Dong, Z.Fang, and J.Du. Static load sharing characteristics analysis for power split transmission system. J. Harbin Inst. Technol. 2013.

- Jin Guanghu, Ren Wei, and Zhu Rupeng. Influence of torsional stiffness on load sharing characteristics of power split transmission system. J. Aerosp. Power 2019.

- Y. F. Gui, R. P. Zhu, G. H. Jin, and Z. J. Li. Dynamic and load sharing characteristic analysis of a nonlinear cylindrical gear split-torque transmission system with backlash. Journal of Vibration and Shock, 2014.

- Li, Z.; Wang, S.; Li, F.; Peng, Q.; Li, J. Research on matching conditions of coaxial six-branch split-torsion herringbone gear transmission system. Xibei Gongye Daxue Xuebao/J. Northwestern Polytech. Univ. 2021, 39, 341–349. [Google Scholar] [CrossRef]

- Charles J. Isabelle, Jules G. Kish, and Robert A. Stone. Elastomeric load sharing device.

- G and White. Design study of a split-torque helicopter transmission. Proceedings of the Institution of Mechanical Engineers Part G Journal of Aerospace Engineering, 1998.

- Yuriy Gmirya. Split torque gearbox for rotary wing aircraft with translational thrust system. 2006.

- Yuriy Gmirya, Sikorsky Aircraft Corporation, Matthew Alulis, Sikorsky Aircraft Corporation, Peter Palcic, Sikorsky Aircraft Corporation, Leslie Leigh, and H. Q. Navairsyscom. Baseline configuration of the ch-53k drive system. 2011.

- Y. F. Gui, R. P. Y. F. Gui, R. P. Zhu, B. B. Fu, H. F. Li, and Z. J. Li. Impact of torsional stiffness on dynamic load sharing coefficient of two-input cylindrical gear split-torque transmission system. Hangkong Dongli Xuebao/Journal of Aerospace Power 2014, 29, 2264–2272. [Google Scholar]

- Hu, Z.; Tang, J.; Wang, Q.; Chen, S.; Qian, L. Investigation of nonlinear dynamics and load sharing characteristics of a two-path split torque transmission system. Mech. Mach. Theory 2020, 152, 103955. [Google Scholar] [CrossRef]

- Desrochers, A.; Ghie, W.; Laperrie`re, L. Application of a Unified Jacobian—Torsor Model for Tolerance Analysis. J. Comput. Inf. Sci. Eng. 2003, 3, 2–14. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Z.; Shi, L.; Gao, P.; Zhang, J.; Zhang, W. A new assembly error modeling and calculating method of complex multi-stage gear transmission system for a large space manipulator. Mech. Mach. Theory 2020, 153, 103982. [Google Scholar] [CrossRef]

- Laperrière, L.; Ghie, W.; Desrochers, A. Statistical and Deterministic Tolerance Analysis and Synthesis Using a Unified Jacobian-Torsor Model. CIRP Ann. 2002, 51, 417–420. [Google Scholar] [CrossRef]

- Laperrière, L.; ElMaraghy, H.A. Tolerance Analysis and Synthesis Using Jacobian Transforms. CIRP Ann. 2000, 49, 359–362. [Google Scholar] [CrossRef]

- Zuo, X.; Li, B.; Yang, J.; Jiang, X. Application of the Jacobian–torsor theory into error propagation analysis for machining processes. Int. J. Adv. Manuf. Technol. 2013, 69, 1557–1568. [Google Scholar] [CrossRef]

- Weihua, N.; Zhenqiang, Y. Integrating cylindricity error into tolerance analysis of precision rotary assemblies using Jacobian–Torsor model. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2013, 227, 2517–2530. [Google Scholar] [CrossRef]

- Desrochers, A.; Rivière, A. A matrix approach to the representation of tolerance zones and clearances. Int. J. Adv. Manuf. Technol. 1997, 13, 630–636. [Google Scholar] [CrossRef]

- Bruyere, J.; Dantan, J.-Y.; R´egis Bigot; Martin, P. Statistical tolerance analysis of bevel gear by tooth contact analysis and monte carlo simulation. Mech. Mach. Theory 2007, 42, 1326–1351. [CrossRef]

- Zeng, W.; Rao, Y.; Wang, P.; Yi, W. A solution of worst-case tolerance analysis for partial parallel chains based on the Unified Jacobian-Torsor model. Precis. Eng. 2017, 47, 276–291. [Google Scholar] [CrossRef]

- Z Yang, T Hussian, AA Popov, and S McWilliam. A comparison of different optimization techniques for variation propagation control in mechanical assembly. In IOP Conference Series: Materials Science and Engineering, volume 26, page 012017. IOP Publishing, 2011.

- Yang, Z.; Hussain, T.; A Popov, A.; McWilliam, S. Novel Optimization Technique for Variation Propagation Control in An Aero-Engine Assembly. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 225, 100–111. [Google Scholar] [CrossRef]

- Yang, Z.; Popov, A.; McWilliam, S. Variation propagation control in mechanical assembly of cylindrical components. J. Manuf. Syst. 2012, 31, 162–176. [Google Scholar] [CrossRef]

- Hussain, T.; McWilliam, S.; A Popov, A.; Yang, Z. Geometric error reduction in the assembly of axi-symmetric rigid components: a two-dimensional case study. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2012, 226, 1259–1274. [Google Scholar] [CrossRef]

- Yang, Z.; McWilliam, S.; Popov, A.A.; Hussain, T. A probabilistic approach to variation propagation control for straight build in mechanical assembly. Int. J. Adv. Manuf. Technol. 2012, 64, 1029–1047. [Google Scholar] [CrossRef]

- Jin, S.; Ding, S.; Li, Z.; Yang, F.; Ma, X. Point-based solution using Jacobian-Torsor theory into partial parallel chains for revolving components assembly. J. Manuf. Syst. 2018, 46, 46–58. [Google Scholar] [CrossRef]

- Chen, H.; Jin, S.; Li, Z.; Lai, X. A modified method of the unified Jacobian-Torsor model for tolerance analysis and allocation. Int. J. Precis. Eng. Manuf. 2015, 16, 1789–1800. [Google Scholar] [CrossRef]

- Chen, H.; Jin, S.; Li, Z.; Lai, X. A solution of partial parallel connections for the unified Jacobian–Torsor model. Mech. Mach. Theory 2015, 91, 39–49. [Google Scholar] [CrossRef]

- Chen, H.; Jin, S.; Li, Z.; Lai, X. A comprehensive study of three dimensional tolerance analysis methods. Comput. Des. 2014, 53, 1–13. [Google Scholar] [CrossRef]

- Cheng Binbin, Huang Meifa, Wang Zhiyue, Feng Jianguo, and W. U. Changlin. Research of assembly tolerance modeling method based on actual working condition. Machine Tool Hydraulics, 2016.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).