3.1. Analysis of Major Influencing Parameters on Performance of Borehole Heat Exchanger

Borehole heat exchanger (BHE) is the key component of the ground source heat pump system (GSHP) that delivers space heating and cooling of buildings. It determines the overall thermal performance of the GSHP system. In addition, the total cost of the GSHP system depends on the installation and drilling cost of the BHE.

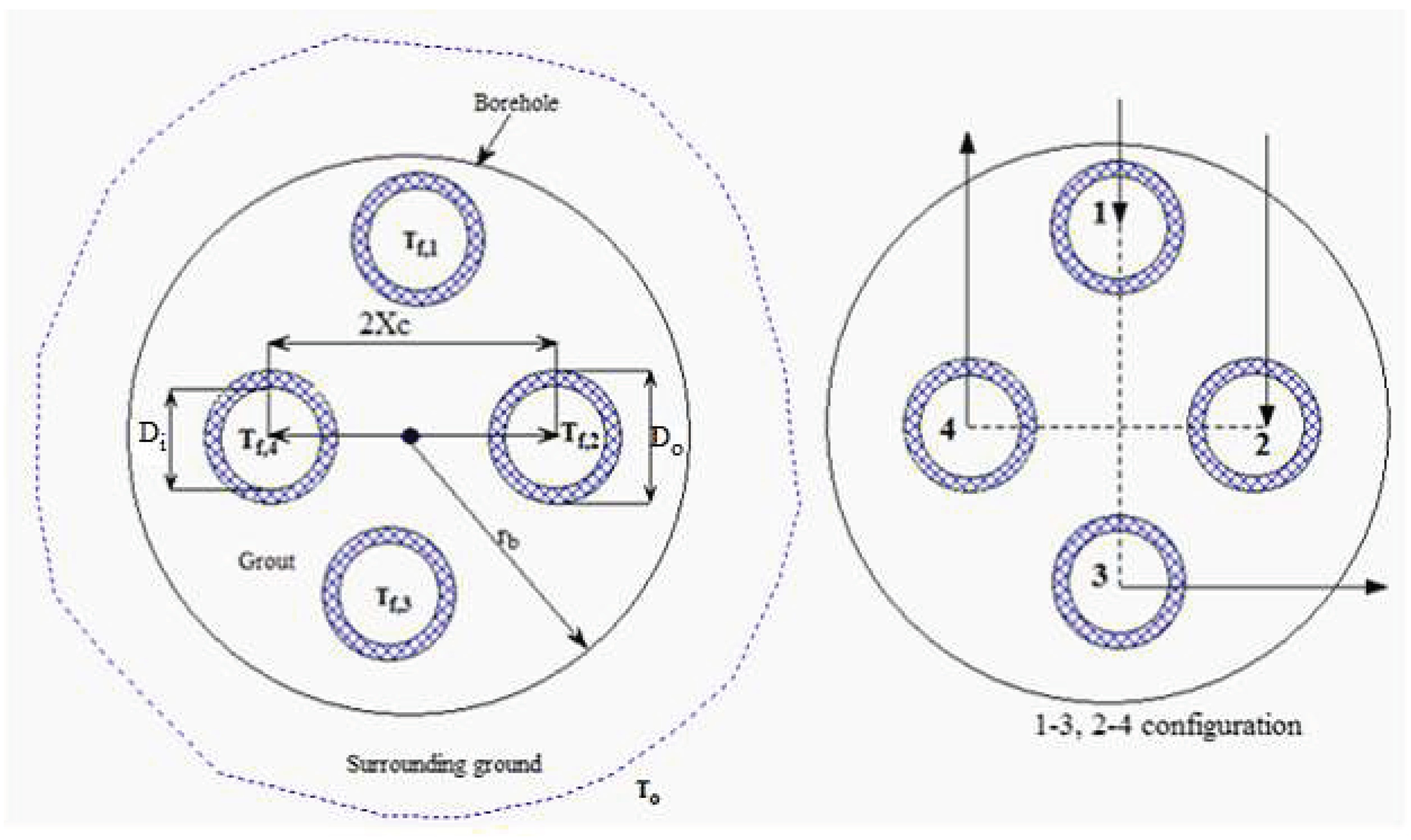

Due to the complex nature of heat transfer in the BHE, proper modelling and thermal design of BHE that meets the required demand is still challenging. In the design of BHE, thermal performance is an important parameter that determines the effective heat transfer between the soil and GSHP system. Moreover, thermal performance of BHE also determines effectiveness of the operational and running cost of the GSHP system. As a result, comprehensive investigation of BHE from the perspectives of the combined impact of different factors (borehole geometrical parameters and thermal properties) that affect its thermal performance is indispensable.

Heat transfer in the BHE is affected by various factors: geometrical, thermal, geological, and operational parameters. In this regard, investigation of combined effect of parameters in a systematic approach is important. Due to the complex nature of heat transfer in the BHE, presentation of this heat transfer in tabular/graphical form that enables one to conveniently and easily select the case that suits/fulfills the respective thermal design requirement (i.e., high heat transfer) is highly demanded. Such detailed investigation of the overall impact of various factors on heat transfer in the BHE is used as quick reference for the design and optimization of the BHE integrated with GSHP system. In this paper, combined effect of major influencing parameters that affect the performance of both single U-tube BHE (sBHE) and double U-tube BHE (dBHE) will be performed. For the sake of convenience, the combined impact of different parameters is included under the following four major cases (where each of them has nine different sub-cases shown in

Table 2):

- A)

Combined effect of borehole depth (H), borehole size (Db or rb) and shank spacing (Xc)

- B)

Combined effect of borehole depth (H), and soil (ks) and grout (kg) thermal conductivities

- C)

Combined effect of soil (ks) and grout (kg) thermal conductivities and borehole size (Db or rb)

- D)

Combined effect of soil thermal conductivity (ks), borehole size (Db or rb) and shank spacing (Xc)

The values of fixed borehole geometrical parameters and thermal properties considered under each case studies are listed in

Table 1.

Table 1.

Fixed input values of parameters and thermal properties used in the analysis.

Table 1.

Fixed input values of parameters and thermal properties used in the analysis.

| PARAMETERS |

VALUES |

REMARKS |

| Inner radius of the pipe |

0.014m |

Pipe thickness of 2mm |

| Outer radius of the pipe |

0.016m |

Pipe outer diameter 32mm |

| Thermal conductivity of the HDPE pipe |

0.4 W/m-K |

|

| Working Fluid Properties: |

|

|

| Fluid type |

Water |

|

| Specific heat capacity of fluid |

4183 J/kg-K |

|

| Density of circulating fluid |

997 kg/m3

|

|

| Thermal conductivity fluid |

0.5947 W/m-K |

|

| Dynamic viscosity of fluid |

0.8905x10-3 kg/m-s |

|

| Inlet fluid temperature |

40 °C |

|

| Grout thermal properties: |

|

|

| Specific heat capacity of the grout |

1850 J/kg-K |

|

| Density of grout |

2650 kg/m3

|

|

| Soil thermal properties |

|

|

| Specific heat capacity of the soil |

2016 J/kg-K |

|

| Density of the soil |

2650 kg/m3

|

|

| Undisturbed ground temperature |

10 °C |

|

Table 2.

The four major cases considered to investigate the combined effect of different parameters on performance of the sBHE and dBHE.

Table 2.

The four major cases considered to investigate the combined effect of different parameters on performance of the sBHE and dBHE.

|

A. Combined effect of borehole depth, borehole size and shank spacing |

B. Combined effect of borehole depth and thermal conductivity of grout and soil |

C. Combined effect of soil and grout thermal conductivity and borehole size |

D. Combined effect of soil thermal conductivity, borehole size and shank spacing |

| 1: Small borehole size |

1: Minimum soil thermal conductivity |

1: Minimum grout thermal conductivity |

1: Small (minimum) borehole size |

| Db = 100mm |

ks= 0.3 W/m.K |

kg = 0.5 W/m.K |

Db = 100mm |

| Xc = 0.034m (maximum) |

kg = 2.2 W/m.K (maximum) |

rb = 0.1m (maximum) |

Xc = 0.034m (maximum) |

| Xc = 0.025m (medium) |

kg = 1.5 W/m.K (medium) |

rb = 0.073m (medium) |

Xc = 0.025m (medium) |

| Xc = 0.016m (minimum) |

kg = 0.5 W/m.K (minimum) |

rb = 0.05m (minimum) |

Xc = 0.016m (minimum) |

| 2: Medium borehole size |

2: Average soil thermal conductivity |

2: Average grout thermal conductivity |

2: Medium borehole size |

| Db =146mm |

ks = 2.2 W/m.K |

kg = 1.5 W/m.K |

Db = 146mm |

| Xc = 0.057m (maximum) |

kg = 2.2 W/m.K (maximum) |

rb = 0.1m (maximum), |

Xc = 0.057m (maximum) |

| Xc = 0.037m (medium) |

kg = 1.5 W/m.K (medium) |

rb = 0.073m (medium), |

Xc = 0.037m (medium) |

| Xc = 0.016m (minimum) |

kg = 0.5 W/m.K (minimum) |

rb = 0.05m (minimum),Xc= 0.025m |

Xc = 0.016m (minimum) |

| 3: Large borehole size |

3: Maximum soil thermal conductivity |

3: Maximum grout thermal conductivity |

3: Large (maximum) borehole size |

| Db = 200mm |

ks = 4 W/m.K |

kg = 2.2 W/m.K |

Db = 200mm |

| Xc = 0.084m (maximum) |

kg = 2.2 W/m.K (maximum) |

rb = 0.1m (maximum) |

Xc = 0.084m (maximum) |

| Xc = 0.05m (medium) |

kg = 1.5 W/m.K (medium) |

rb = 0.073m (medium) |

Xc = 0.05m (medium) |

| Xc = 0.016m (minimum) |

kg = 0.5 W/m.K (minimum) |

rb = 0.05m (minimum) |

Xc = 0.016m (minimum) |

|

H varied from 50 to 275m

(With 9 different Cases of rb and Xc) |

ks varied from 0.3 to 4

(With 9 different cases of borehole depth (H) and Xc) |

ks varied from 0.3 to 4

(With 9 different cases of borehole depth (H) and kg) |

Table 3.

The nine sub-cases considered under each major cases of A to D.

Table 3.

The nine sub-cases considered under each major cases of A to D.

Cases

|

A. Combined effect of borehole depth, borehole size and shank spacing (with 9 different cases of kg and ks) |

B. Combined effect of borehole depth and thermal conductivity of soil and grout

(with 9 different Cases of rb and Xc) |

C. Combined effect of borehole size and thermal conductivity of soil and grout (with 9 different cases of borehole depth (H)) |

D. Combined effect of soil thermal conductivity, borehole size and shank spacing (with 9 different cases of kg and H) |

| 1 |

kg = 0.5 and ks = 0.3 W/m.K

(minimum-minimum) |

rb = 0.05m, Xc = 0.016m

(small BH, minimum Xc) |

H = 50m and allXc

(minimum) |

kg = 0.5W/m.K and

H = 50m

(min. kg & low H) |

| 2 |

kg = 0.5 and ks = 2.0 (W/m.K)

(minimum-average) |

rb = 0.05m, Xc = 0.025m

(small BH, average. Xc) |

H = 50m and allXc

(average) |

kg = 0.5W/m.K and

H = 100m

(min. kg, avg. H) |

| 3 |

kg = 0.5 and ks = 4 (W/m.K)

(minimum-maximum) |

rb = 0.05m, Xc = 0.034m

(small BH, maximum Xc) |

H = 50m and allXc

(maximum) |

kg = 0.5W/m.K and

H = 300m

(min. kg, high H) |

| 4 |

kg = 1.5 and ks =0.3 (W/m.K)

(average-minimum) |

rb = 0.073m, Xc = 0.016m

(medium BH, minimum Xc) |

H=100m and all

Xc (minimum) |

kg =1.5W/m.K and

H = 50m

(Avg.kg & low H) |

| 5 |

kg = 1.5 and ks = 2 (W/m.K)

(average-average) |

rb = 0.073m, Xc = 0.037m

(medium BH, average Xc) |

H = 100m and all

Xc (average) |

kg = 1.5W/m.K and

H = 100m

(avg. kg, avg. H) |

| 6 |

kg = 1.5 and ks = 4.0

(W/m.K)

(average-maximum) |

rb = 0.073m, Xc = 0.057m

(medium BH, maximum Xc) |

H = 100m and all

Xc (maximum) |

kg = 1.5W/m.K and

H = 300m

(avg. kg, high H) |

| 7 |

kg = 2.2 and ks = 0.3

(W/m.K)

(maximum-minimum) |

rb = 0.1m, Xc = 0.016m(

large BH, minimum Xc) |

H = 300m and all

Xc (minimum) |

kg = 2.2 W/m.K and

H = 50m

(max. kg & low H) |

| 8 |

kg = 2.2 and ks = 2.0

(W/m.K)

(maximum-average) |

rb = 0.1m, Xc = 0.05m

(large BH, average Xc) |

H = 300m and all

Xc (average) |

kg = 2.2W/m.K and

H = 100m

(max. kg, avg. H) |

| 9 |

kg = 2.2 and ks = 4

(W/m.K)

(maximum-maximum) |

rb = 0.1m, Xc = 0.084m

(large BH, maximum Xc) |

H = 300m and all

Xc (maximum) |

kg = 2.2 W/m.K and

H = 300m

(max. kg, high H) |

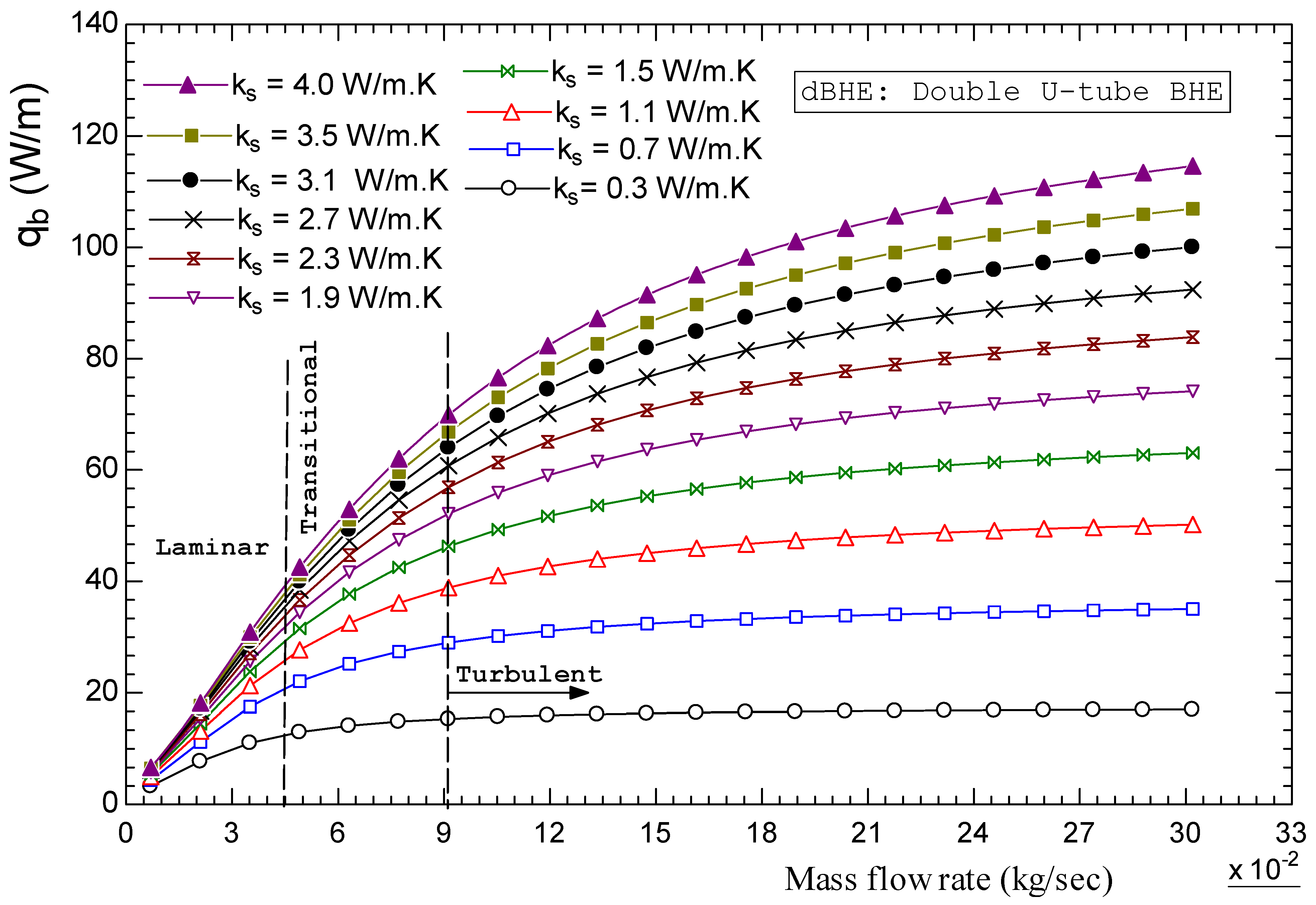

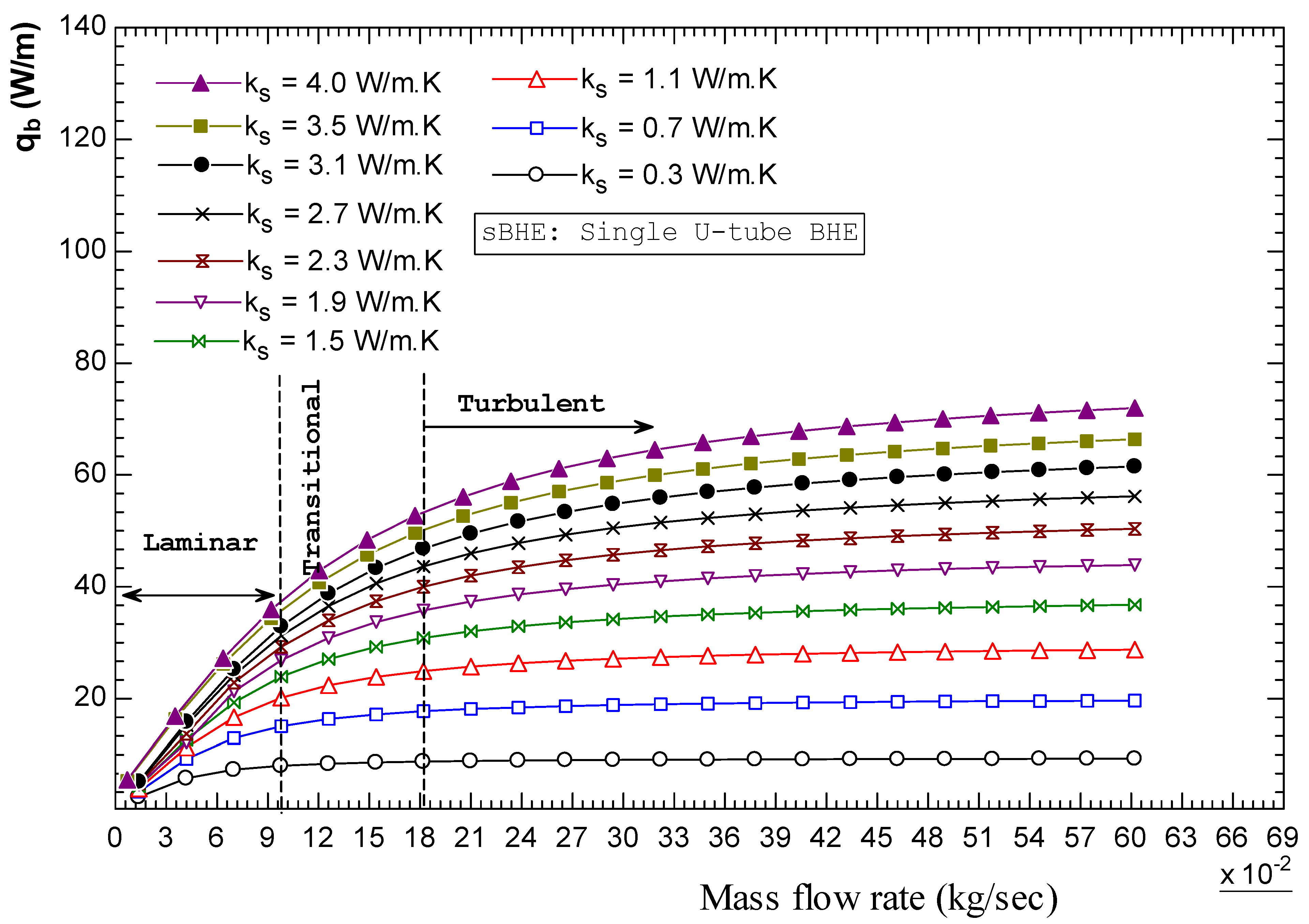

The optimal design of a borehole heat exchanger (BHE) for a ground source heat pump (GSHP) system depends on various factors such as geometrical parameters (borehole depth, borehole size (diameter), and shank spacing), soil thermal conductivity and others. Borehole depth is particularly important because it affects both the performance and cost of the BHE. Although deeper borehole depth may seem to increase the performance of BHE, it can also lead to thermal interaction between the legs of the BHE, which can reduce heat transfer between the working fluid and the ground. Furthermore, deeper boreholes are more expensive to drill. Various questions arise on BHEs. One question is whether a single or double U-tube BHE has lower thermal interaction between legs (thermal short-circuit) at deep borehole depths. Another question is whether it’s better to use a deep BHE with small or large shank spacing and with medium or high soil thermal conductivity; and it is important to determine which borehole configuration, sBHE or dBHE, is preferable in each scenario.

Borehole size (diameter) is another crucial geometrical parameter impacting heat transfer in the BHEs. While larger boreholes are generally preferred to enhance heat transfer between the working fluid and the surrounding ground, it is unclear whether small, medium or large boreholes are most effective for shallow or deep boreholes, as other parameters also play a significant role. Furthermore, increasing borehole size raises the cost of the BHE. Another geometrical parameter that affects the heat transfer in the BHE is the shank spacing, which is the center-to-center distance between U-tube legs of the BHE.

Overall, the heat transfer in the BHE is complex and depends on multiple factors, and hence, comprehensive sensitivity analysis that considers combined impact of all parameters should be done. Investigating a single impact of parameter on heat transfer in the BHE is inadequate to determine the variation of the total heat transfer in the BHE. Comprehensive investigation that involves combined effect of various parameters on heat transfer is highly needed for the design and optimization of the BHE. Therefore, presenting the variation of total heat transfer rate per unit borehole depth with different borehole parameters and thermal properties in a convenient way such as in tabular or graphical form becomes essential. Such series of heat transfer data in tables/graphs can be conveniently implemented during the thermal design of the BHE. In other words, when the results of such case studies of BHE with different options of various parameter is available, then BHE designers can utilize such result as a quick reference for the thermal design and optimization of BHE that can be integrated with GSHP system.

To fully assess such combined effect of parameters on total heat transfer per unit borehole depth, analysis involving the combined impact of borehole depth, borehole radius and shank spacing with different cases of soil and grout thermal conductivities will be performed in this section. The analysis of this subsection was done for both sBHE and dBHE with: small borehole size (D

b = 100 mm, and half shank spacing of X

c = 0.034 m (maximum), X

c = 0.025 m (medium) and X

c = 0.016 m (minimum)); medium borehole size with (D

b =146 mm, and half shank spacing of X

c = 0.057 m (maximum), X

c = 0.037 m (medium), X

c = 0.016 m (minimum)); and large borehole size with (D

b = 200 mm and half shank spacing of X

c = 0.084 m (maximum), X

c = 0.05 m (medium) and X

c = 0.016 m (minimum)). This case of combined effect of borehole depth, borehole size and shank spacing was done for nine different cases of combined values of grout and soil thermal conductivities (with minimum, medium, and maximum values) as shown in

Table 3. This case is important as a quick reference for the design of BHE with the given nine cases of thermal conductivities of grout and soil. Then one can select the case that provides the highest heat transfer among the various cases of sBHE and dBHE presented under column A of

Table 2. The results of these cases are presented in

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8. Various important information can be obtained from such results.

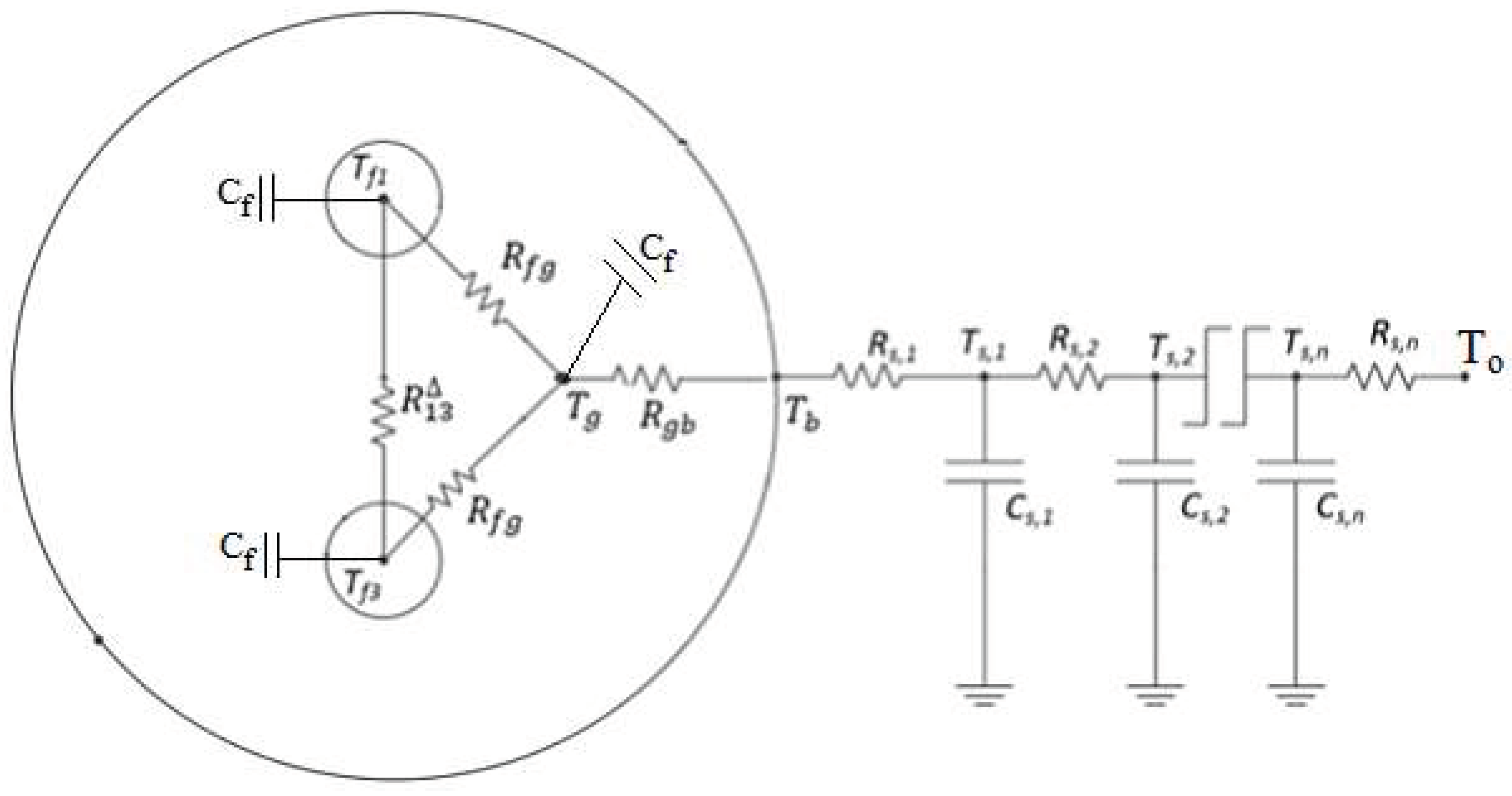

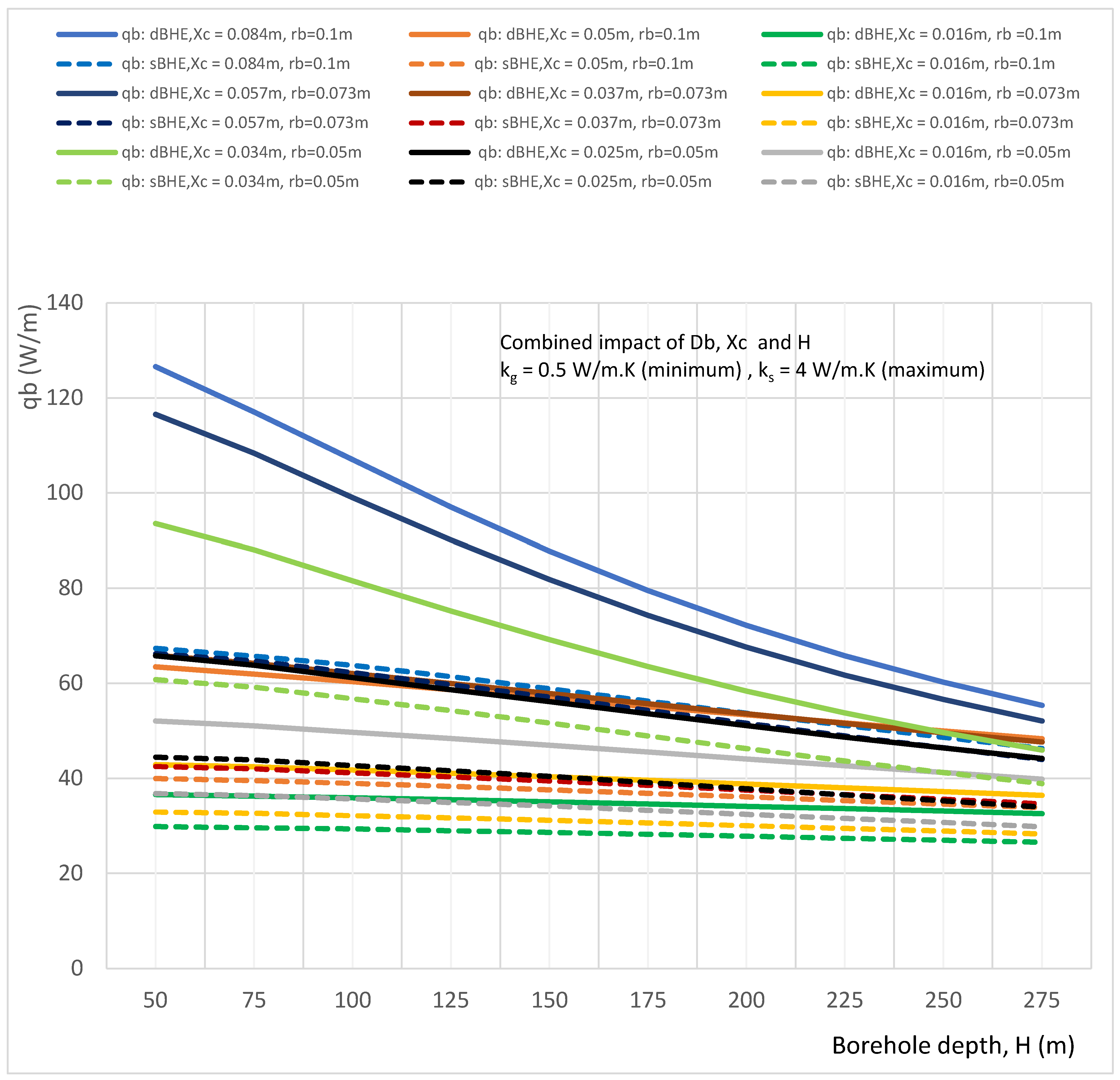

Figure 3,

Figure 4 and

Figure 5 illustrate combined impact of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth for minimum grout and soil thermal conductivity (k

g = 0.5, k

s = 0.3 W/m∙K), minimum grout and medium soil thermal conductivities (k

g = 0.5, k

s = 2.2 W/m∙K), minimum grout and maximum soil thermal conductivities (k

g = 0.5, k

s = 4 W/m∙K) respectively. Comparison of the results depicted in

Figure 3,

Figure 4 and

Figure 5 shows that the case with minimum grout and maximum soil thermal conductivity (shown in

Figure 5) provides the highest heat transfer rate per unit borehole depth than all other cases while the case with minimum grout and soil thermal conductivities (shown in

Figure 3) provides the lowest heat transfer rate. It is also interesting to note from

Figure 3 that when both grout and soil thermal conductivity values are minimum, the dBHE (due to its more surface area) transfers more heat than the sBHE. This is also seen in the other remaining cases. On the other hand, for the other cases of thermal conductivities, the sBHE becomes better to transfer more heat than dBHE particularly at deep borehole depth; for example, sBHE with large borehole size and maximum shank spacing (r

b = 0.1 m and X

c = 0.084 m) seem to provide more heat transfer than dBHE with large borehole size and minimum shank spacing (r

b = 0.1 m, X

c = 0.016 m). As you can see on the trends of

Figure 4 and

Figure 5, it seems that for the deep borehole depth, the sBHE transfers more heat than dBHE. The reason for this is that as the borehole depth increases, the short-thermal circuit (thermal interaction between the U-tube legs) increases, and its impact becomes more in dBHE than in sBHE. A close look at

Figure 4 and

Figure 5 also shows that (when grout conductivity is low and soil thermal conductivity is at average or high value), using BHE with maximum shank spacing is effective in the largest borehole size while using minimum shank spacing is more effective in BHE with the smallest borehole size. This could also be attributed to the phenomenon of thermal short-circuit.

Overall, the results depicted in

Figure 3,

Figure 4 and

Figure 5 reveal that the dBHE is preferable to transfer more heat when used in shallow borehole depth, while for the BHE with deep borehole depth, sBHE is better to exchange more heat between the working fluid and the ground that of dBHE.

Figure 3,

Figure 4 and

Figure 5 also show that in both sBHE and dBHE, BHE with large borehole size (r

b = 0.1 m) and maximum shank spacing (X

c = 0.084 m) provides the highest heat transfer. This could be due to the available more surface area for the heat transfer when borehole size is enlarged and U-tubes are widely spaced.

Figure 3.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout and soil thermal conductivities (kg = 0.5 W/m∙K, ks = 0.3 W/m∙K).

Figure 3.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout and soil thermal conductivities (kg = 0.5 W/m∙K, ks = 0.3 W/m∙K).

Figure 4.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout conductivity and average soil thermal conductivities (kg = 0.5 W/m.K, ks = 2.2 W/m.K).

Figure 4.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout conductivity and average soil thermal conductivities (kg = 0.5 W/m.K, ks = 2.2 W/m.K).

Figure 5.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout conductivity and maximum soil thermal conductivities (kg = 0.5W/m.K, ks = 4W/m.K).

Figure 5.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout conductivity and maximum soil thermal conductivities (kg = 0.5W/m.K, ks = 4W/m.K).

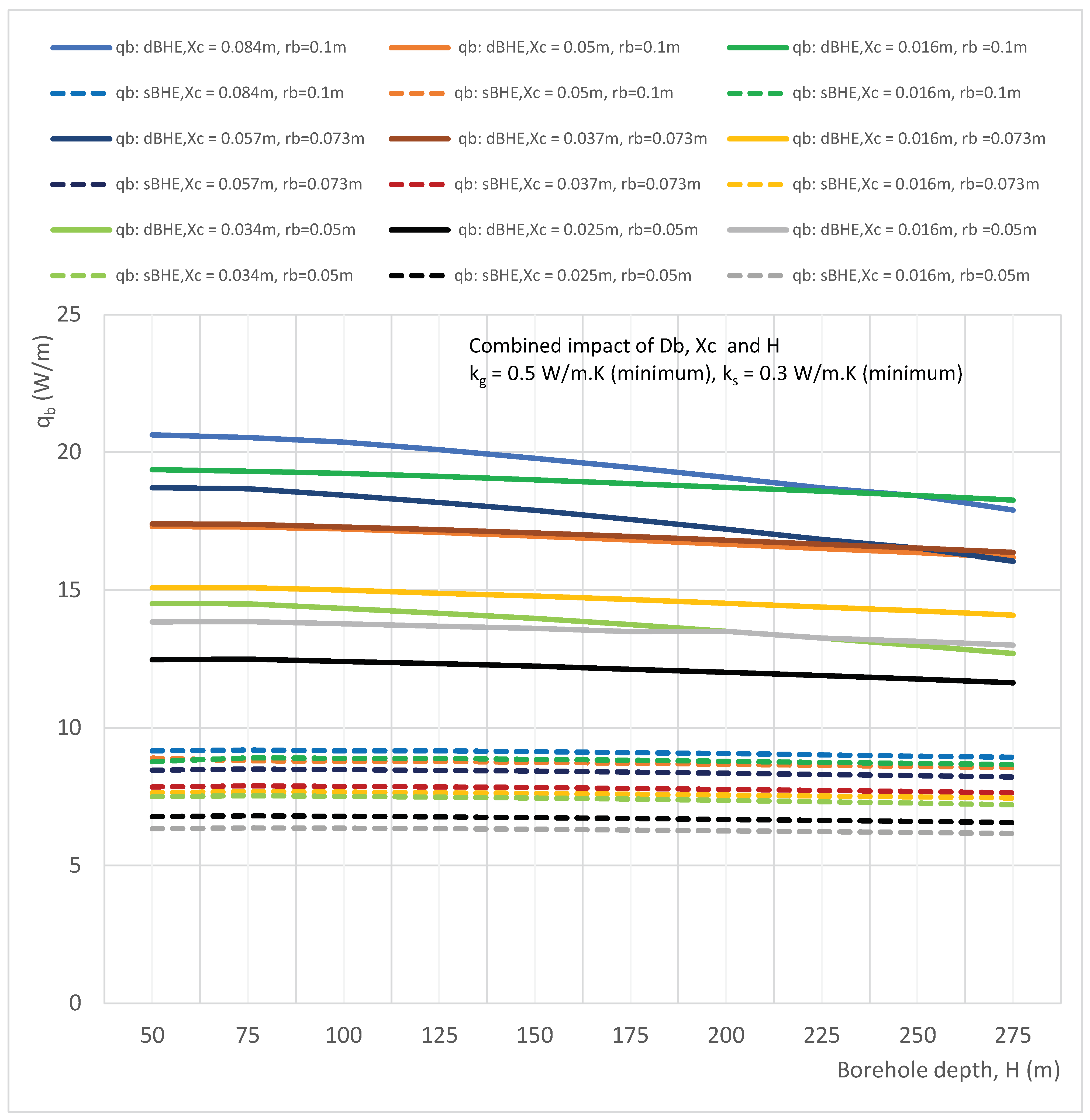

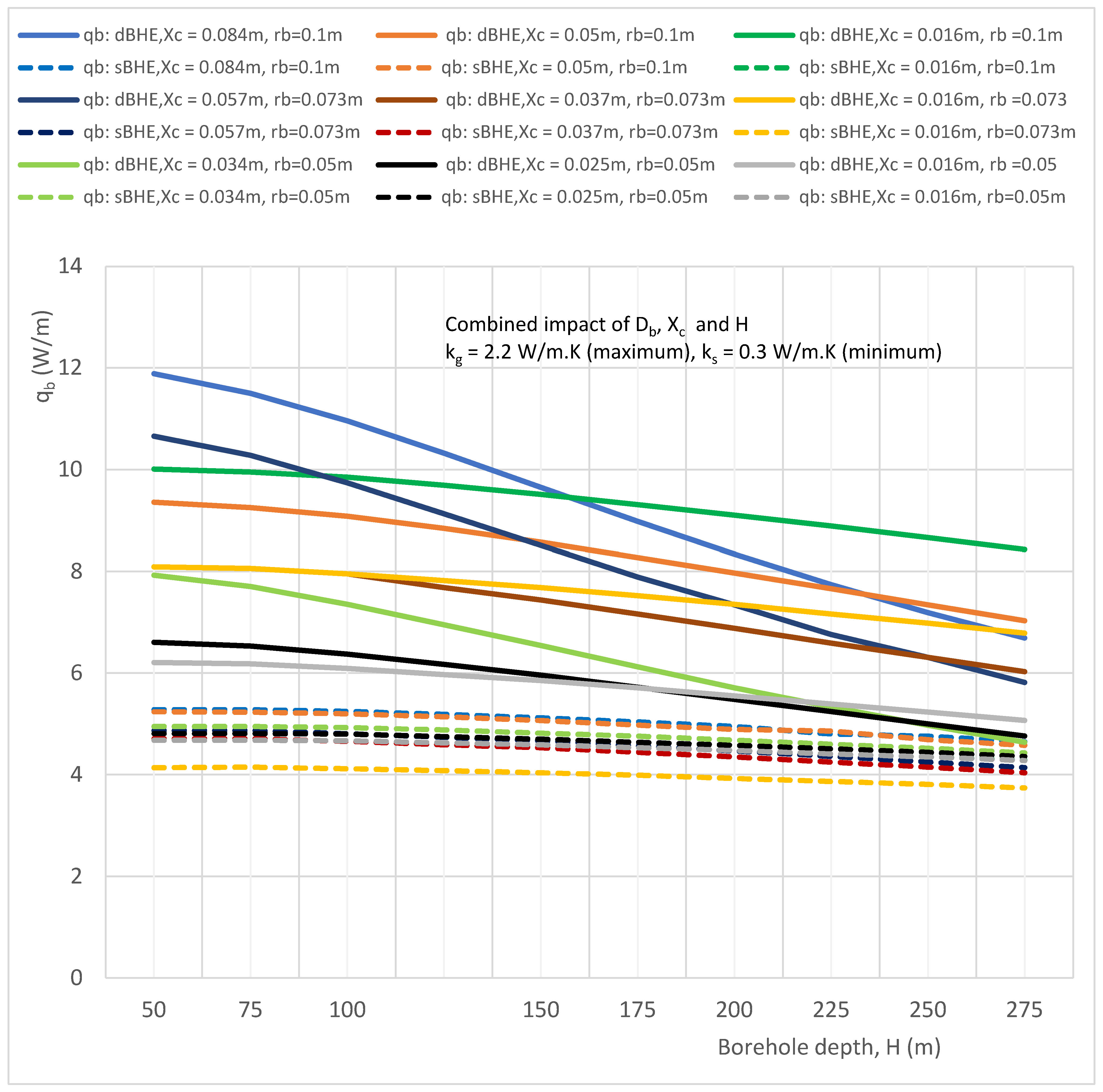

The results generated for the case of the average grout thermal conductivity is almost similar to the to the other results and hence not discussed here. The simulation result generated for the combined impact of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the cases of maximum grout thermal conductivity (k

g = 2.2 W/m.K) combined with minimum, average and maximum soil thermal conductivity is illustrated in

Figure 6,

Figure 7 and

Figure 8. Now, in these cases though the grout thermal conductivity is maximum, the heat transfer per unit borehole depth is lower than all other corresponding previously discussed cases (cases 1 to 6 in

Table 3) depicted in

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8. This is because employing excessive thermal conductivity of back-fill-material in the BHE may produce thermal interference (thermal short-circuit) between U-tube pipe legs leading to the reduced heat transfer, and hence, reduced BHE performance; and the phenomenon of short-thermal-circuit for the cases in

Figure 6,

Figure 7 and

Figure 8 could be more for dBHE with deep borehole depth than sBHE, and it is also relatively higher than the other previously discussed cases of this subsection.

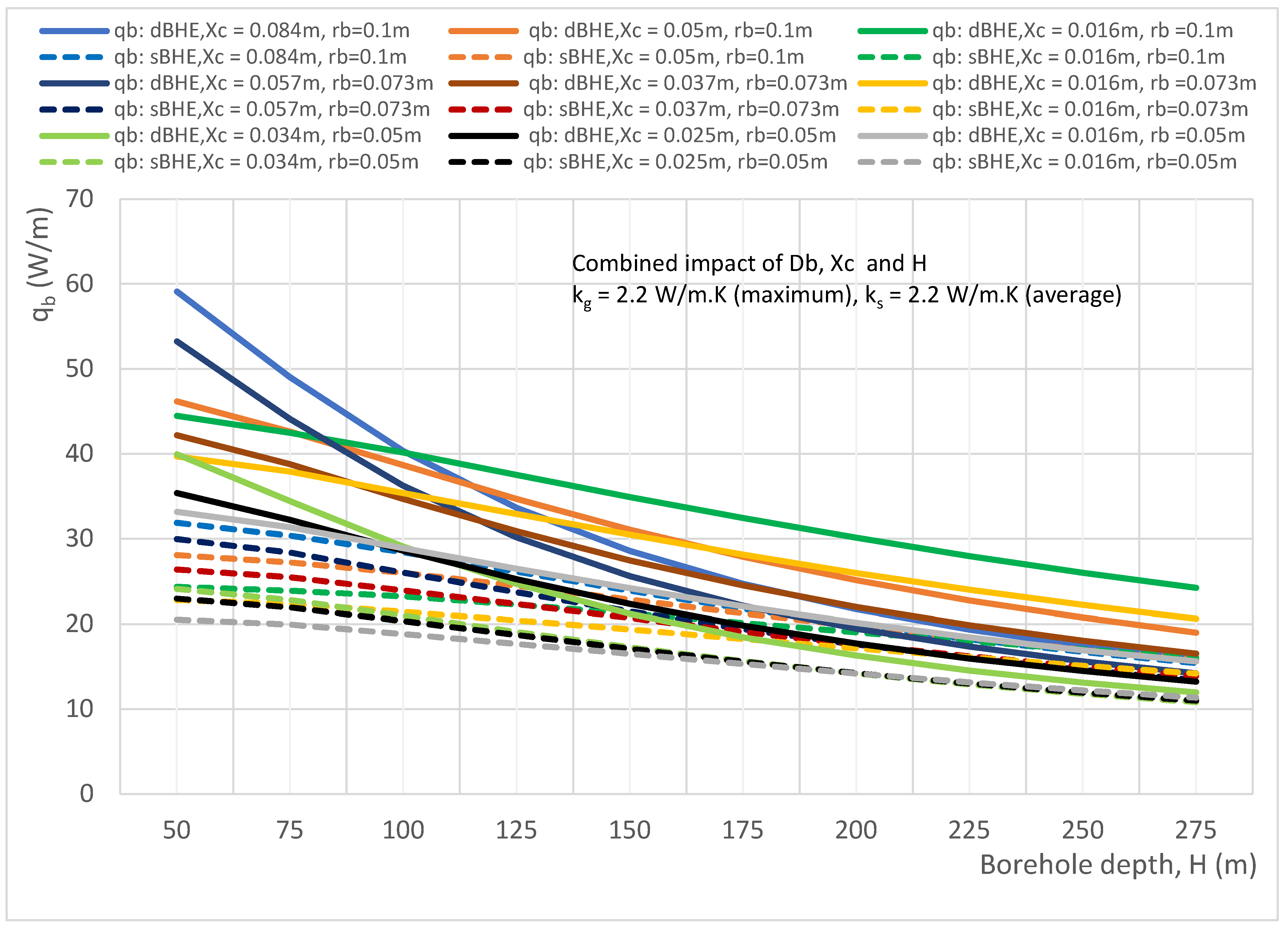

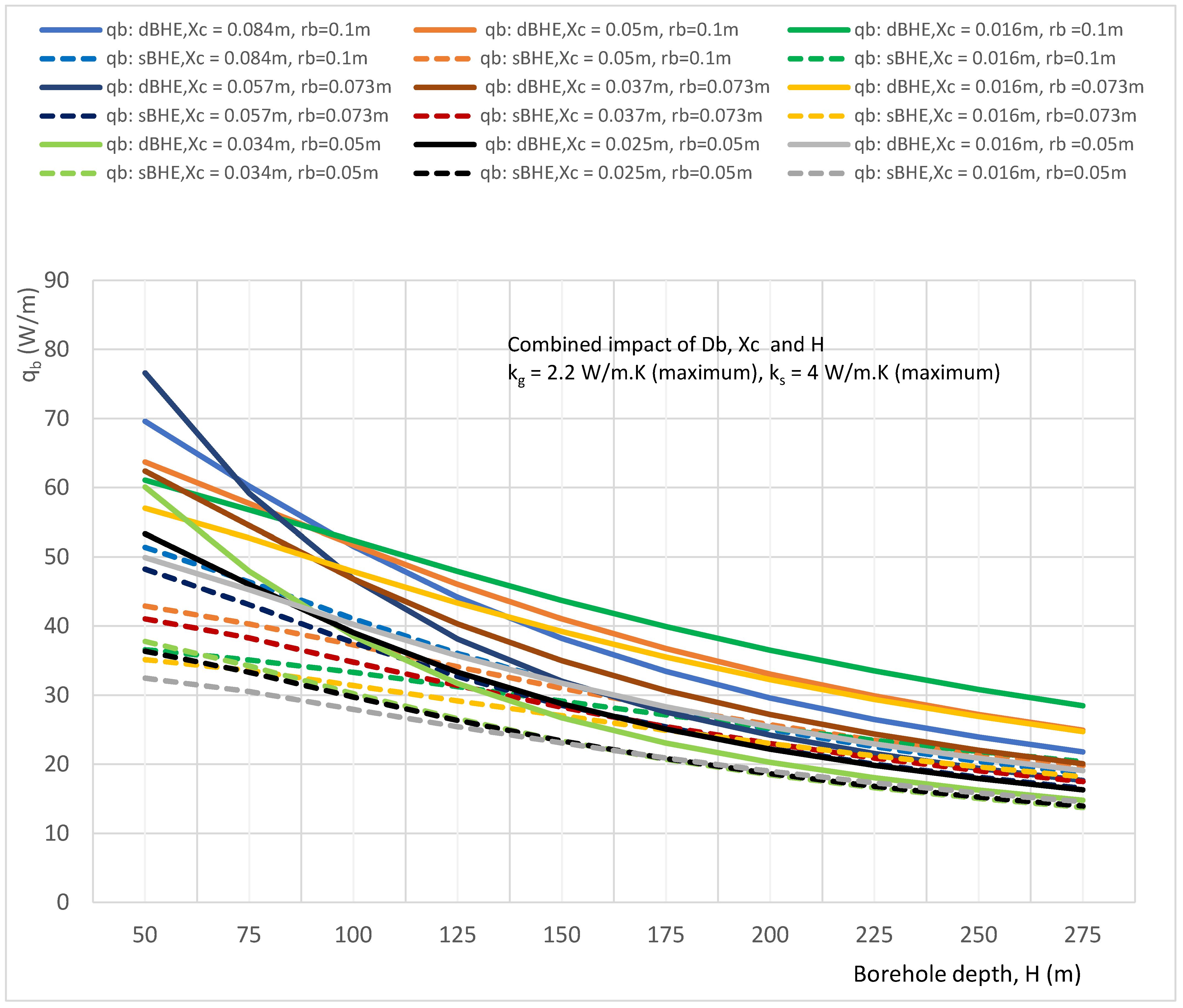

For case of low soil thermal conductivity (k

s = 0.3 W/m.K) shown in

Figure 6, all the considered dBHE cases transfer more heat than the corresponding sBHE. However, at deep borehole depth, sBHE (with large borehole size and high shank spacing) seems to transfer more heat than dBHE with small borehole size. This impact is more augmented for the other cases, shown in

Figure 10 and

Figure 11. That is at the deep borehole depth, the heat transferred by the dBHE with large borehole size (r

b = 0.1m) and maximum shank spacing (X

c = 0.084 m) is significantly reduced and becomes lower than that of the corresponding sBHE. In addition, as shown in

Figure 6,

Figure 7 and

Figure 8, dBHE with maximum shank spacing provides more heat transfer than all other cases when used in shorter borehole depth; while dBHE with minimum shank spacing is preferable to transfer more heat into the ground when applied in deeper borehole depth. Similarly, in sBHE, BHE with largest borehole size and maximum (highest) shank spacing is preferred to deliver more heat transfer into the ground when employed with shallow borehole depth (see

Figure 7 and

Figure 8).

Overall, among the 9 cases listed under the combined effect of borehole depth, borehole size and shank spacing depicted in

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8, increasing the borehole size and shank spacing is more effective to transfer more heat irrespective of borehole depth for case 3, and dBHE with large BH size and maximum shank spacing employed with low grout thermal conductivity and maximum soil thermal conductivity provides the highest heat transfer per unit borehole depth. On the other hand, the lowest heat transfer is obtained for case 7 where back-fill material with maximum thermal conductivity (k

g = 2.2 W/m.K) is used in the BHE installed at the ground with low soil thermal conductivity (0.3 W/m.K). The reason for this could be the thermal-short-circuit (thermal interference) associated with excessive thermal conductivity of the gout utilized in the BHE.

Figure 6.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity and minimum soil thermal conductivities (kg = 2.2 W/m.K, ks = 0.3 W/m.K).

Figure 6.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity and minimum soil thermal conductivities (kg = 2.2 W/m.K, ks = 0.3 W/m.K).

Figure 7.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity and average soil thermal conductivity (kg = 2.2 W/m∙K, ks = 2.2 W/m∙K).

Figure 7.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity and average soil thermal conductivity (kg = 2.2 W/m∙K, ks = 2.2 W/m∙K).

Figure 8.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout and soil thermal conductivities (kg = 2.2 W/m∙K, ks = 4.0 W/m∙K).

Figure 8.

Combined effect of borehole depth, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout and soil thermal conductivities (kg = 2.2 W/m∙K, ks = 4.0 W/m∙K).

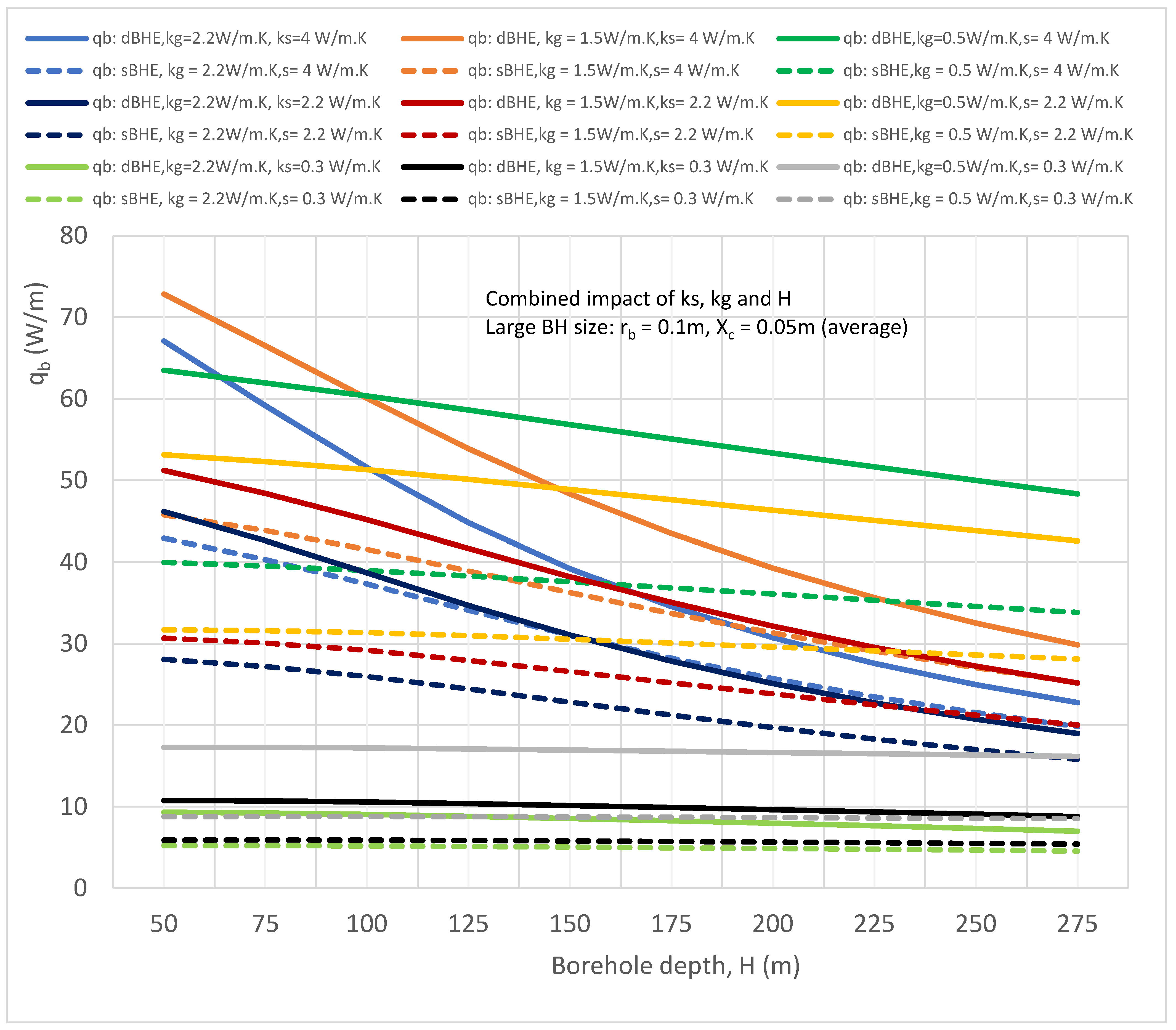

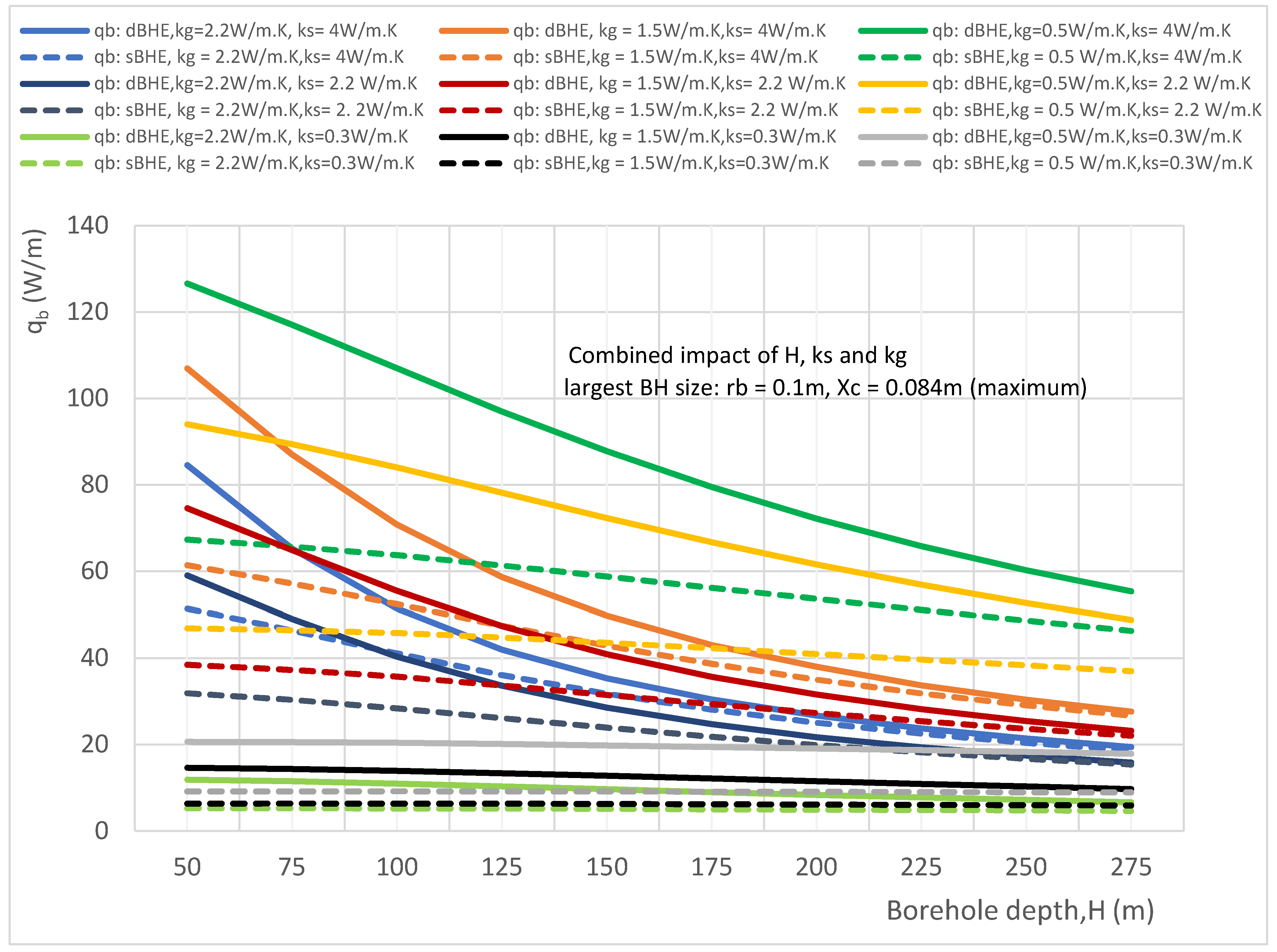

- B.

Combined Effect of Borehole Depth and Thermal Conductivities of Soil and Grout

In this section, analysis of combined impact of parameters (which includes borehole depth, soil and grout thermal conductivities) on total heat transfer per unit borehole depth with different cases of borehole size (radius) and half shank spacing (half center-to-center distance between U-tube pipe), will be performed. Specifically, the sensitivity analysis was done for minimum (low) soil thermal conductivity (k

s = 0.3 W/m∙K), average soil thermal conductivity (k

s = 2.2 W/m∙K) and maximum (high) soil thermal conductivity (k

s = 4 W/m∙K), where each value of the soil thermal conductivity was combined with minimum (k

g = 0.5 W/m∙K), average (k

g = 1.5 W/m∙K) and maximum (k

g = 2.2 W/m∙K) values of grout thermal conductivity. This is indicated in

Table 5-2 under column B. This case of combined effect of borehole depth, soil thermal conductivity and grout thermal conductivity was done for 9 different cases consisting of large borehole size/borehole radius (r

b = 0.1 m), average borehole size (r

b = 0.073 m) and small borehole size (r

b = 0.05 m) each with the corresponding minimum, medium, and maximum half shank spacing values as shown in

Table 3 under column B.

This case is important as a quick reference for the design of BHE with a given different cases of borehole size and shank spacing; that is, with the given borehole size and shank spacing, one can select the BHE case that provides highest heat transfer among the various cases of sBHE and dBHE presented under column B of

Table 2. The simulation result of the nine different cases considered in this section, shown under column B of

Table 3, is depicted in

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13 and

Figure 14. Various important information can be obtained from such results.

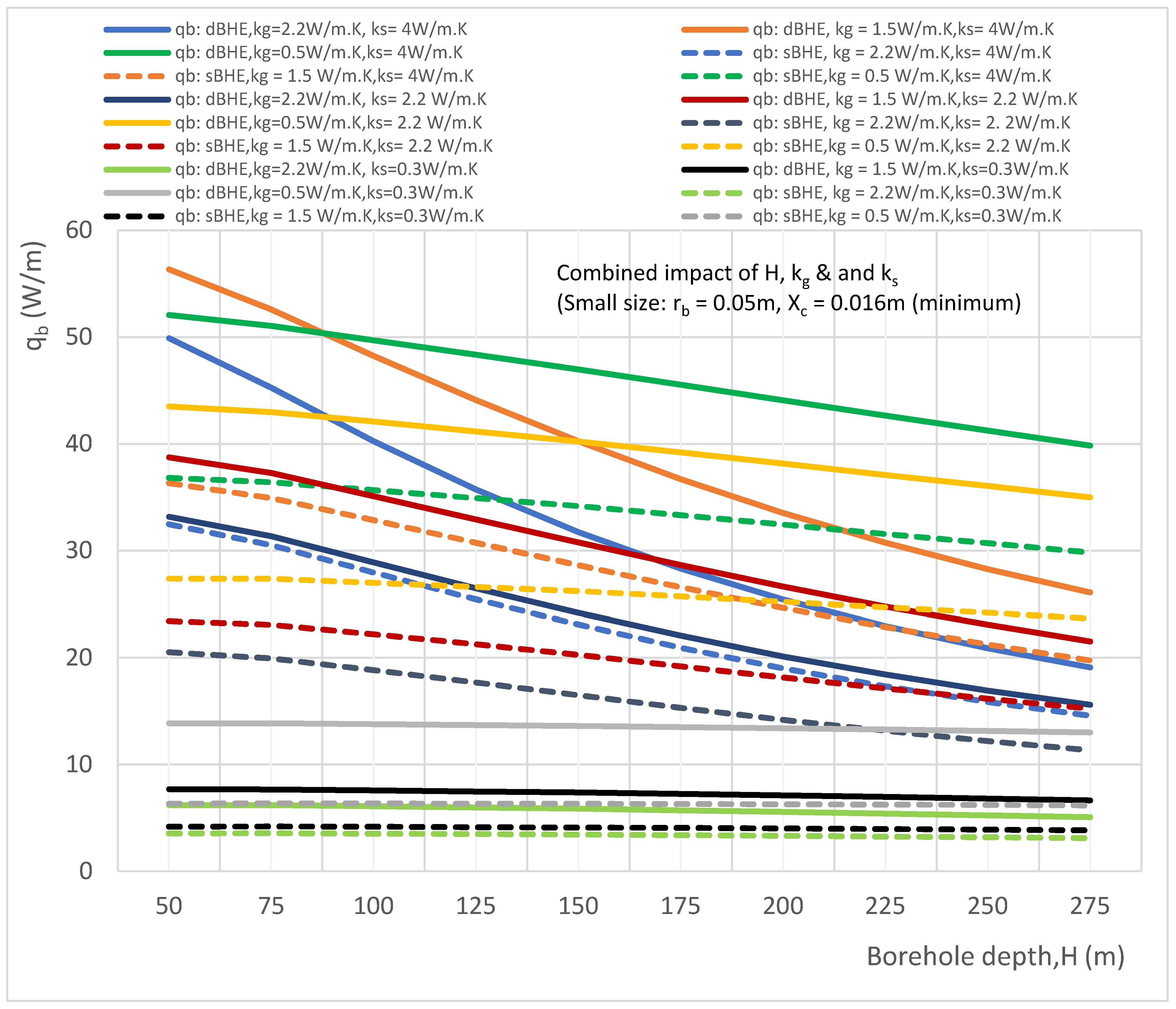

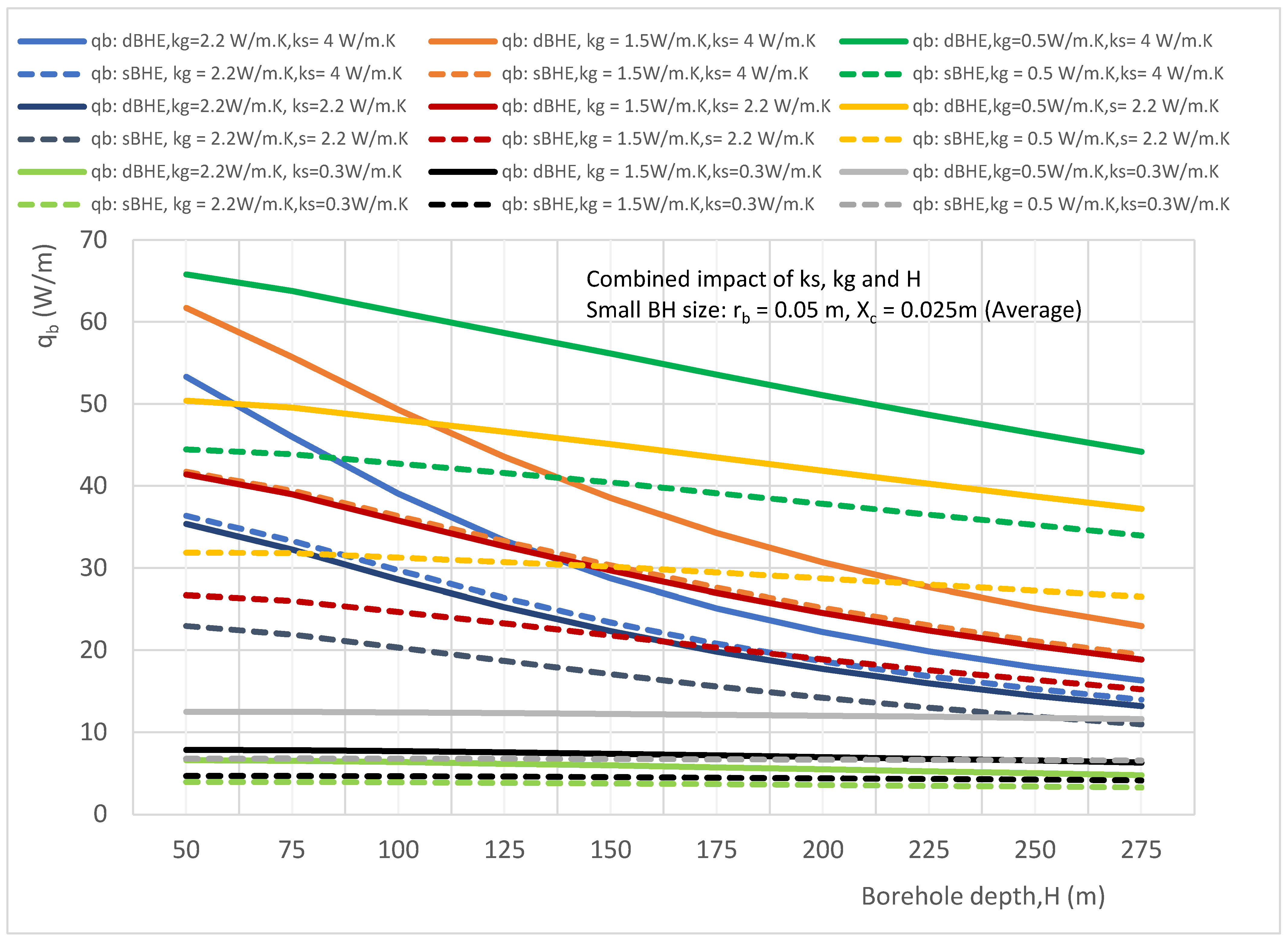

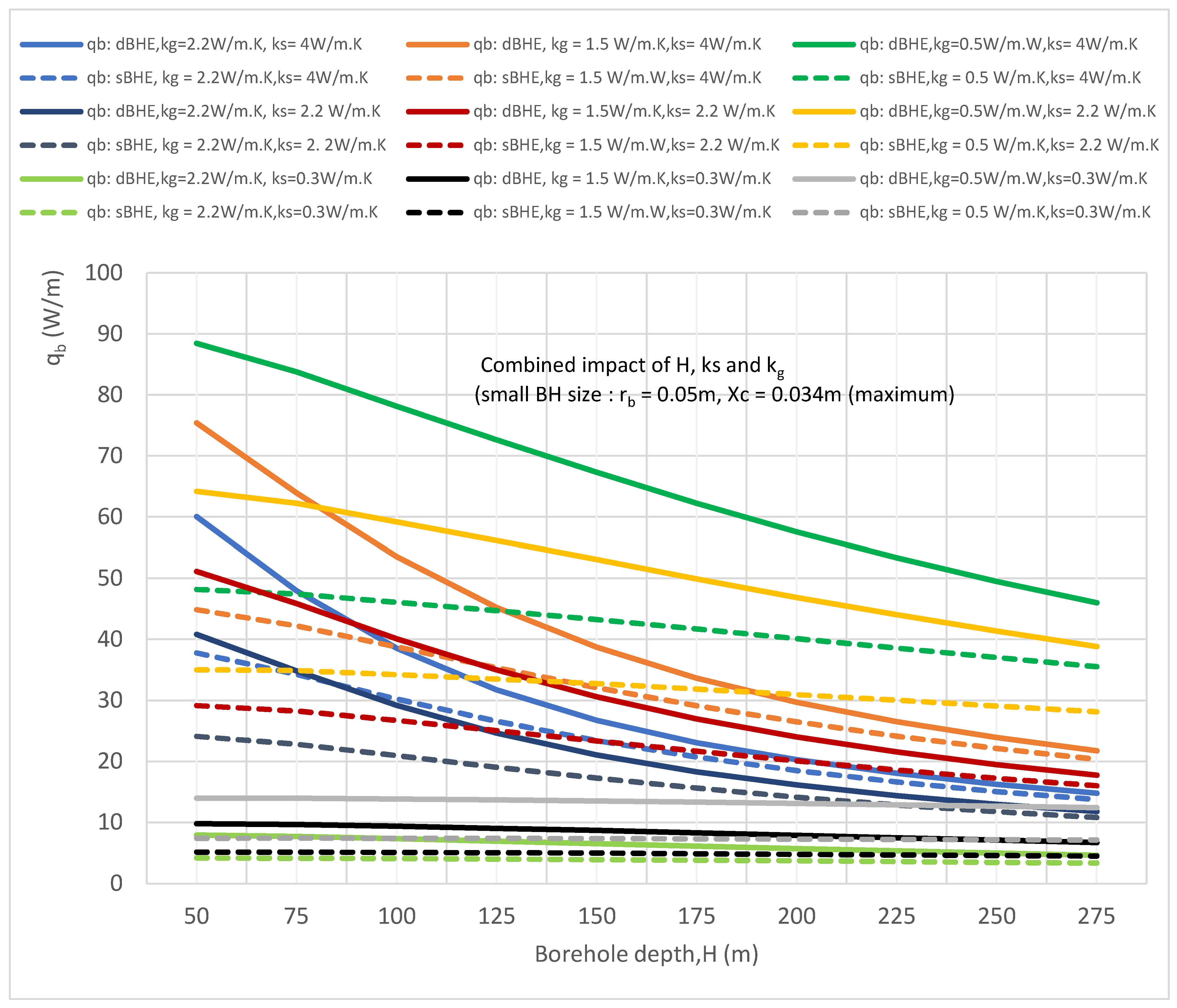

Figure 9,

Figure 10 and

Figure 11 illustrates combined impact of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in both sBHE and dBHE for the case of small borehole size (r

b = 0.05 m) with minimum half shank spacing (X

c = 0.016 m), average half shank spacing (X

c = 0.025 m), maximum half shank spacing (X

c = 0.034 m) respectively. It can be observed that the dBHE with minimum (low) grout thermal conductivity (k

g = 0.5 W/m∙K) and high soil thermal conductivity provides more heat transfer than all the three cases shown in

Figure 9,

Figure 10 and

Figure 11; and similar result is obtained for sBHE. Comparison among

Figure 9,

Figure 10 and

Figure 11 shows that more heat transfer is achieved by BHE with maximum shank spacing (X

c = 0.034 m) depicted in

Figure 9 (see case 3 column B of

Table 3). This is because when U-tube legs are widely spaced, the phenomenon of thermal short-circuit between the legs of the U-tube is reduced, and surface area is increased resulting in more heat transfer between working fluid in the BHE and the ground around the BHE. Furthermore, the results depicted in

Figure 9,

Figure 10 and

Figure 11 show that in some cases sBHE are preferable to transfer more heat than dBHE specially for deep borehole depth. For example, sBHE with minimum grout thermal conductivity (k

g = 0.5 W/m∙K) and maximum soil thermal conductivity (k

s = 4 W/m∙K) transfer more heat than for most of the cases of the dBHE. The reason for this is associated with the reduced thermal interference between the legs of the sBHE as compared to the dBHE, and low grout thermal conductivity resulting in more heat transfer to the ground. Therefore, low grout thermal conductivity and high soil thermal conductivity case is preferred to transfer more heat to the ground in the BHE. In the longer borehole depth, sBHE is better to transfer more heat than dBHE; while for BHE with shallow borehole depth, dBHE is effective to transfer more heat than sBHE.

Figure 9.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05 m) with minimum shank spacing (Xc = 0.016 m).

Figure 9.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05 m) with minimum shank spacing (Xc = 0.016 m).

Figure 10.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05m) with average shank spacing (Xc = 0.025m).

Figure 10.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05m) with average shank spacing (Xc = 0.025m).

Figure 11.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05m) with maximum shank spacing (Xc = 0.034m).

Figure 11.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of small borehole size (rb = 0.05m) with maximum shank spacing (Xc = 0.034m).

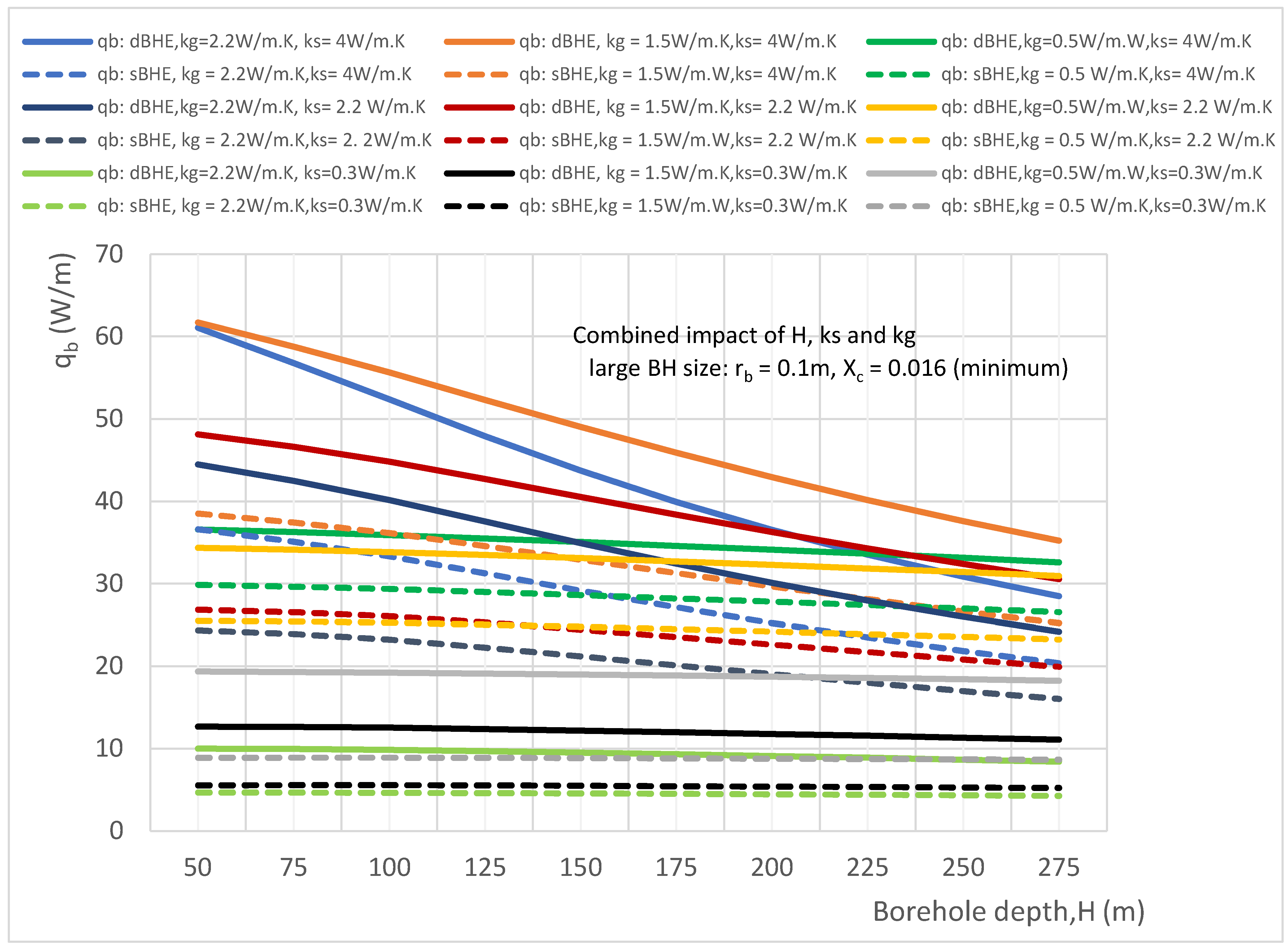

The results shown in

Figure 12,

Figure 13 and

Figure 14 illustrate the combined impact of borehole depth, grout, and soil thermal conductivity on heat transfer rate per unit borehole depth in sBHE and dBHE for large borehole size (r

b = 0.1 m) with minimum shank spacing (X

c = 0.016 m), average shank spacing (X

c = 0.05 m) and maximum shank spacing (X

c = 0.084 m) respectively. The result depicted in

Figure 12 illustrates the case for large borehole size with minimum shank spacing; it can be seen that dBHE filled with grout with k

g = 1.5 W/m∙K and installed at ground with high soil thermal conductivity (k

s = 4 W/m∙K) provides the highest heat transfer. However, for the longer borehole depth beyond 275 m, the dBHE with low grout thermal conductivity (k

g = 0.5 W/m∙K) and high soil thermal conductivity (k

s = 4 W/m∙K) seems to provide more heat transfer than other cases considered in

Figure 12. This is more clearly observed in

Figure 14 where the dBHE with maximum shank spacing, with k

g = 0.5 W/m∙K and k

s = 4 W/m∙K provides the highest heat transfer all along the borehole depth.

On the other hand,

Figure 13 shows that dBHE with average shank spacing, average grout thermal conductivity and high soil thermal conductivity provides the most heat transfer when used in shorter borehole depth; but dBHE filled with grout with minimum thermal conductivity and high soil thermal conductivity is preferable to transfer more heat into the ground when applied in deeper borehole depth. Similarly,

Figure 13 indicates that sBHE with average shank spacing, low (minimum) grout thermal conductivity and high soil thermal conductivity is preferred to deliver more heat transfer into the ground when applied in deep borehole depth.

Overall, comparison of the results depicted in

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13 and

Figure 14 shows that among the 9 cases listed under column B of

Table 3, case 9 (depicted in

Figure 14) provides the highest heat transfer per unit borehole depth; and of all the cases, dBHE with large borehole size, maximum shank spacing, low grout thermal conductivity and high soil thermal conductivity is the most effective to transfer more heat, especially for borehole with shallow borehole depth, than any other cases, and for borehole with deep borehole depth, sBHE with the same design condition is preferred. Similar important information that can be used as a quick reference for the design of the BHE can be deduced or obtained from the generated results depicted in other Figures

Figure 12.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with minimum shank spacing (Xc = 0.016m).

Figure 12.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with minimum shank spacing (Xc = 0.016m).

Figure 13.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with average/medium shank spacing (Xc = 0.05m).

Figure 13.

Combined effect of borehole depth, soil and grout thermal conductivities on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with average/medium shank spacing (Xc = 0.05m).

Figure 14.

Combined effect of borehole depth, soil, and grout thermal conductivity on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with minimum shank spacing (Xc = 0.084m).

Figure 14.

Combined effect of borehole depth, soil, and grout thermal conductivity on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of largest borehole size (rb = 0.1m) with minimum shank spacing (Xc = 0.084m).

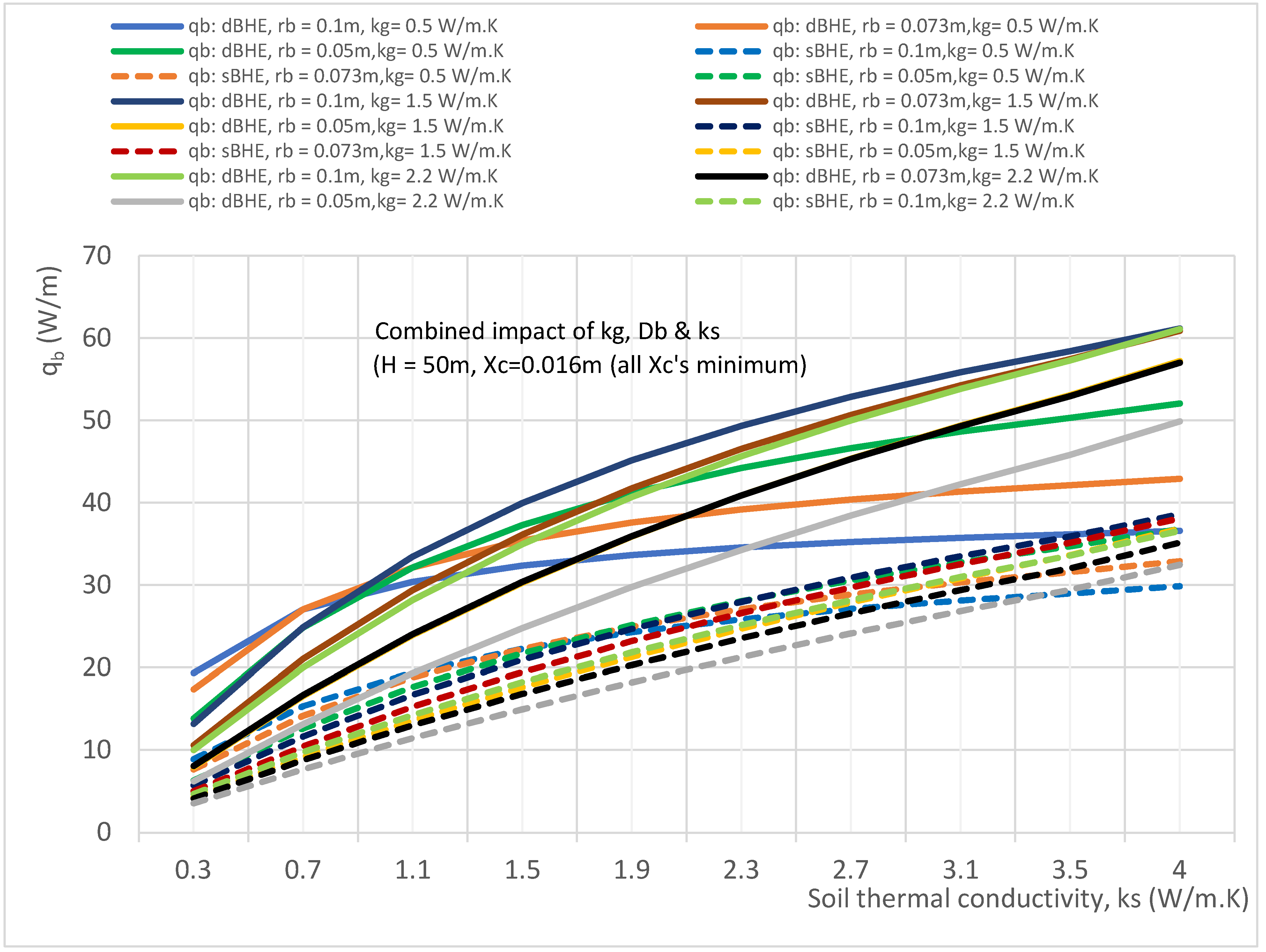

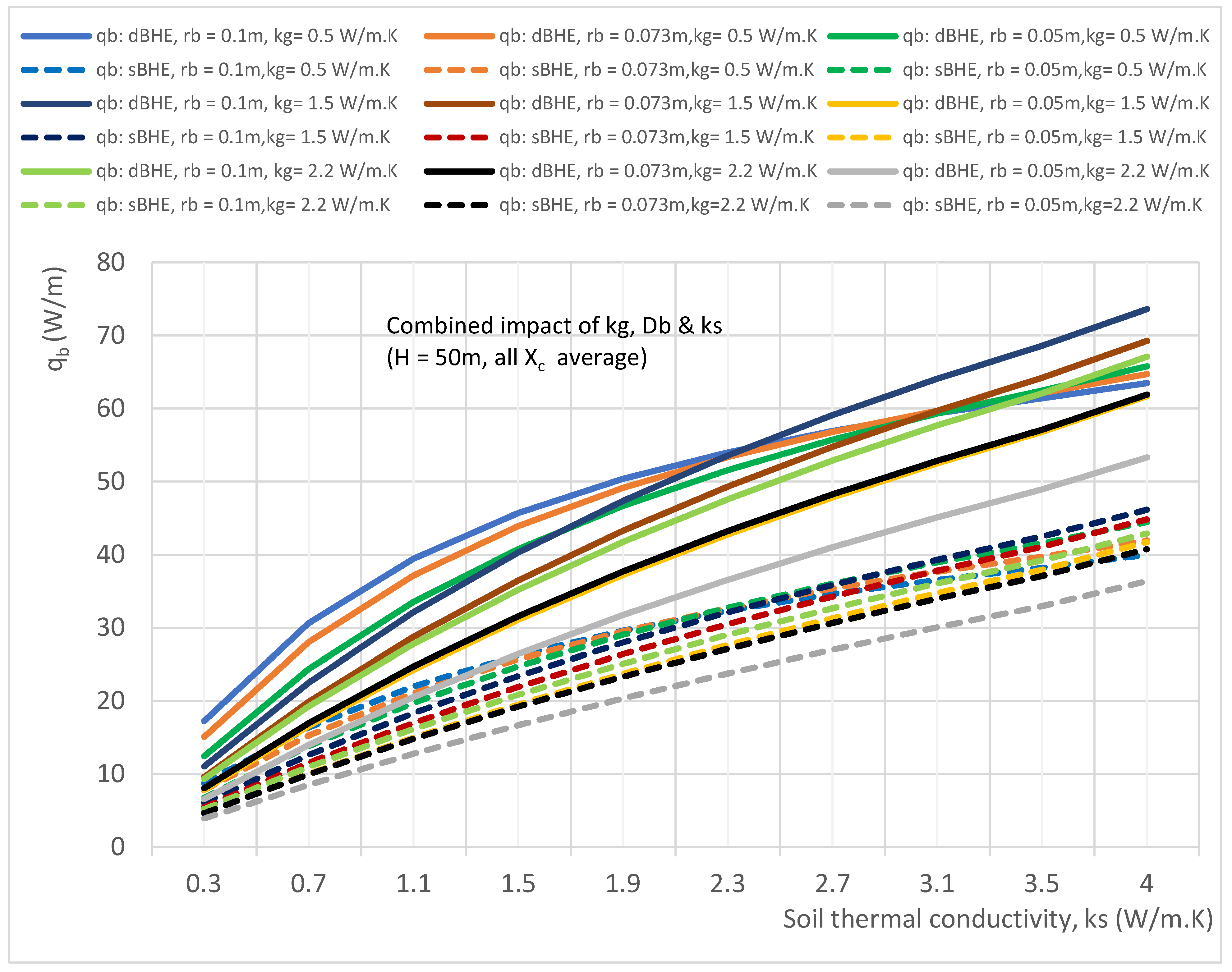

- C.

Combined Effect of Borehole Size and Thermal Conductivities of Soil and Grout

Thermal conductivity of the ground around the BHE and the back-fill material are among the parameters that affects the heat transfer in the BHE. The higher the soil thermal conductivity, the higher the heat transfer between the ground and the fluid that circulates in the loop between the BHE and the heat pump. This results in increased performance of the ground source heat pump system (GSHP), and hence, leads to the reduced total cost of the power consumed by the GSHP system. Grout thermal conductivity is another thermal parameter that impacts the heat transfer in the BHE. Back-fill material with high thermal conductivity is considered to enhance the heat transfer in the BHE, and hence improves the efficiency of the BHE. However, excessive thermal conductivity of grout may increase thermal short-circuit between U-tube pipes leading to the reduced thermal performance of the BHE. As seen in the previous cases of A and B, high grout thermal conductivity reduces the heat transfer in the BHE particularly for dBHE with deep borehole depth and small shank spacing.

Changing (increasing/reducing) one parameter alone cannot help to improve the thermal performance of the BHE. For example, increasing thermal conductivity of grout or soil alone may not help to improve the heat transfer in the BHE. Hence, sensitivity analysis consisting different combination of borehole parameters and thermal properties must be performed. That is, detailed investigation involving combined effect of parameters (for example, grout thermal conductivity with other parameters such as soil thermal conductivity and other borehole geometrical parameters) should be performed. Presenting such comprehensive sensitivity analysis in graphical/tabular form conveniently helps the BHE designer to select the case that provides the highest heat transfer. That is, such results can be used as a quick reference for the design and optimization of the BHE.

In this sub-section, combined impact of thermal conductivity of grout and soil as well as borehole size on heat transfer per unit borehole depth of sBHE and dBHE for different cases of borehole depth and shank spacing is discussed. This case is important as a quick reference for the design of the BHE with the given different cases borehole depth and shank spacing, and desired to be installed at the ground with known value of thermal conductivity. Then, one can select the BHE cases that provides highest heat transfer among the various cases of sBHE and dBHE presented under column C of

Table 2.

The simulation results of the nine different cases considered in this section, shown under column C of

Table 3, are depicted in

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20. Various important information can be obtained from such results. An essential BHE design information can be obtained from these simulation results. For example, if a BHE (with shallow/deep borehole depth and with a given shank spacing) that can transfer highest heat transfer is required to be installed at a ground with a certain thermal conductivity, then such information can be obtained from the results presented this section.

Nine different cases (listed in

Table 3 under column C) consisting of BHE with shallow borehole depth (H = 50 m) and deep borehole depth (H = 300 m) each with small, medium and large borehole sizes (diameters) with corresponding minimum, average and maximum shank spacing are analyzed. The simulation results of the combined impact of thermal conductivities of grout and soil as well as borehole size on heat transfer per unit borehole depth for sBHE and dBHE with different cases of borehole depth and shank spacing are shown in

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20. More specifically, the results presented in

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20 provide an important information on how to select the BHE that provides the highest heat transfer among the BHE design options (sBHE and dBHE with small, medium and large borehole sizes, and with minimum, average and maximum thermal conductivities of grout) for a given soil thermal conductivity, borehole depth (H = 50 m, and H = 300 m) and shank spacing. Note that each BHE is with the corresponding minimum, average and maximum shank spacing.

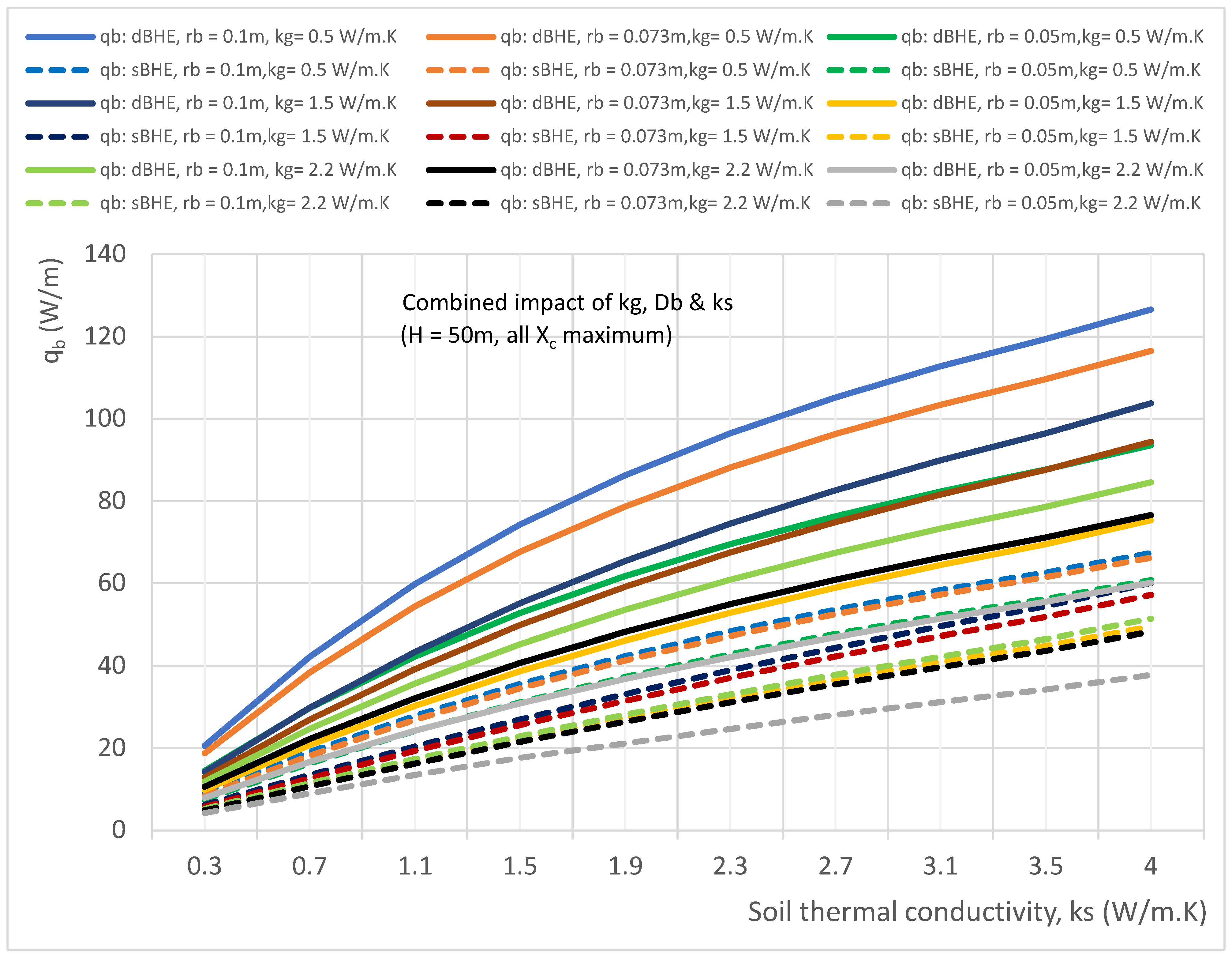

The result depicted in

Figure 15,

Figure 16 and

Figure 17 illustrates the result of the cases for the shallow borehole depth (H = 50 m) with all borehole sizes with the corresponding minimum shank spacing (r

b = 0.1 m with X

c = 0.016 m; r

b = 0.073 m with X

c = 0.016 m and r

b = 0.05 m with X

c = 0.016 m); all borehole sizes with corresponding average shank spacing (r

b = 0.1 m with X

c = 0.05 m; r

b = 0.073 m with X

c = 0.037 m and r

b = 0.05 m with X

c = 0.025 m); and all borehole sizes with the corresponding maximum shank spacing (r

b = 0.1 m with X

c = 0.084 m; r

b = 0.073 m with X

c = 0.057 m and r

b = 0.05 m with X

c = 0.034 m) respectively. It can be seen from

Figure 15 that dBHE with large borehole size (r

b = 0.1 m) and average grout thermal conductivity (k

g = 1.5 W/m∙K) provides the highest heat transfer when the soil thermal conductivity is higher than 1 W/m∙K. For thermal conductivity lower than about 1 W/m∙K, dBHE with large borehole size (r

b = 0.1 m) and low grout thermal conductivity (k

g = 0.5 W/m∙K) provides the highest heat transfer while its heat transfer for high soil thermal conductivity becomes lower than other cases (and lower than even some cases of sBHE). This could be attributed to the more thermal short-circuit associated with BHE with minimum shank spacing.

Figure 16 shows the combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (50 m) and all borehole sizes with the corresponding average shank spacing (r

b = 0.1 m with X

c = 0.05 m; r

b = 0.073 m with X

c = 0.037 m and r

b = 0.05 m with X

c = 0.025 m). For soil thermal conductivity lower than 2.3 W/m∙K, dBHE with large borehole size (r

b = 0.1 m) and low (minimum) grout thermal conductivity (k

g = 0.5 W/m∙K) provides the highest heat transfer while for soil thermal conductivity higher than 2.3 W/m∙K, dBHE with large borehole size (r

b = 0.1 m) filled with grout with average thermal conductivity (k

g = 1.5 W/m∙K) results in highest heat transfer of all cases presented in

Figure 16. It is also important to see that dBHE with r

b = 0.05 m and maximum grout thermal conductivity (k

g = 2.2 W/m∙K) provides the lowest heat transfer than all the cases of dBHE considered in

Figure 16. As depicted in

Figure 17, when BHE with corresponding maximum shank spacing is applied in each borehole size, it is observed that dBHE with large borehole size (r

b = 0.1 m) and low (minimum) grout thermal conductivity (k

g = 0.5 W/m∙K) provides the highest heat transfer for the whole range of soil thermal conductivity (0.3 to 4 W/m∙K) than other cases of BHE considered under this case. A close look at

Figure 17 also shows that dBHE with average borehole size (r

b = 0.073 m) and low grout thermal conductivity (k

g = 0.5 W/m∙K) delivers more heat transfer than even dBHE with large borehole size (r

b = 0.1 m) and average (k

g = 1.5 W/m∙K) as well as maximum grout thermal conductivity (k

g = 2.2 W/m∙K). This could be attributed to the more thermal short-circuit associated with high grout thermal conductivity. This indicates that more impact on heat transfer is observed with reduced grout thermal conductivity combined with increased borehole size than combined increase of borehole size and grout thermal conductivity. Therefore, when BHE with maximum shank spacing is used, more heat transfer can be achieved by combined increase of borehole size and reduced grout thermal conductivity. Finally, comparison among

Figure 15,

Figure 16 and

Figure 17 shows that more heat transfer is obtained for the case with maximum shank spacing (shown in

Figure 17), and in all the cases shown in these figures, dBHE is better to transfer more heat than the corresponding sBHE.

Figure 15.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with the corresponding minimum shank spacing (rb = 0.1 m with Xc = 0.016 m; rb = 0.073 m with Xc = 0.016 m and rb = 0.05 m with Xc = 0.016 m).

Figure 15.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with the corresponding minimum shank spacing (rb = 0.1 m with Xc = 0.016 m; rb = 0.073 m with Xc = 0.016 m and rb = 0.05 m with Xc = 0.016 m).

Figure 16.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with corresponding average shank spacing (rb = 0.1 m with Xc = 0.05 m; rb = 0.073 m with Xc = 0.037 m and rb = 0.05 m with Xc = 0.025 m).

Figure 16.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with corresponding average shank spacing (rb = 0.1 m with Xc = 0.05 m; rb = 0.073 m with Xc = 0.037 m and rb = 0.05 m with Xc = 0.025 m).

Figure 17.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with corresponding maximum shank spacing (rb = 0.1 m with Xc = 0.084 m; rb = 0.073 m with Xc = 0.057 m and rb = 0.05m with Xc = 0.034m).

Figure 17.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of shallow borehole depth (H = 50 m) and all borehole sizes with corresponding maximum shank spacing (rb = 0.1 m with Xc = 0.084 m; rb = 0.073 m with Xc = 0.057 m and rb = 0.05m with Xc = 0.034m).

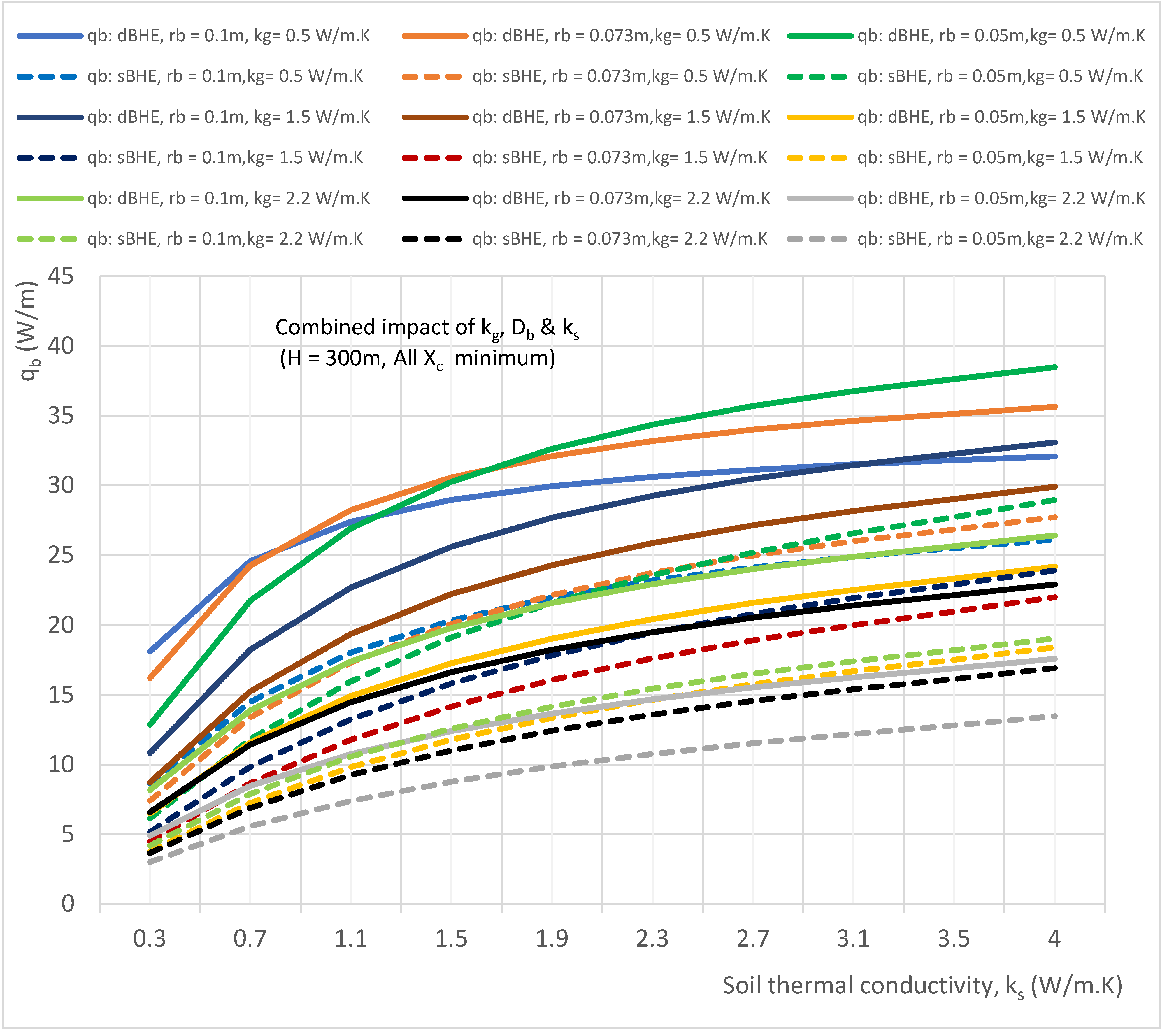

Further analysis was done for the case considered under column C in

Table 3 for the BHE with deep borehole depth (H = 300 m), and the simulation results obtained for this case are presented in

Figure 18,

Figure 19 and

Figure 20.

Figure 18 shows the combined impact of soil and grout thermal conductivities as well as borehole size on heat transfer per unit borehole depth for BHEs with corresponding minimum shank spacing, while

Figure 19 and

Figure 20 show the combined effect of parameters on heat transfer for the BHEs with the corresponding average and maximum shank spacing, respectively. It can be seen from

Figure 18 that for BHE with deep borehole depth and minimum shank spacing, the heat transferred by the dBHE with small borehole size (r

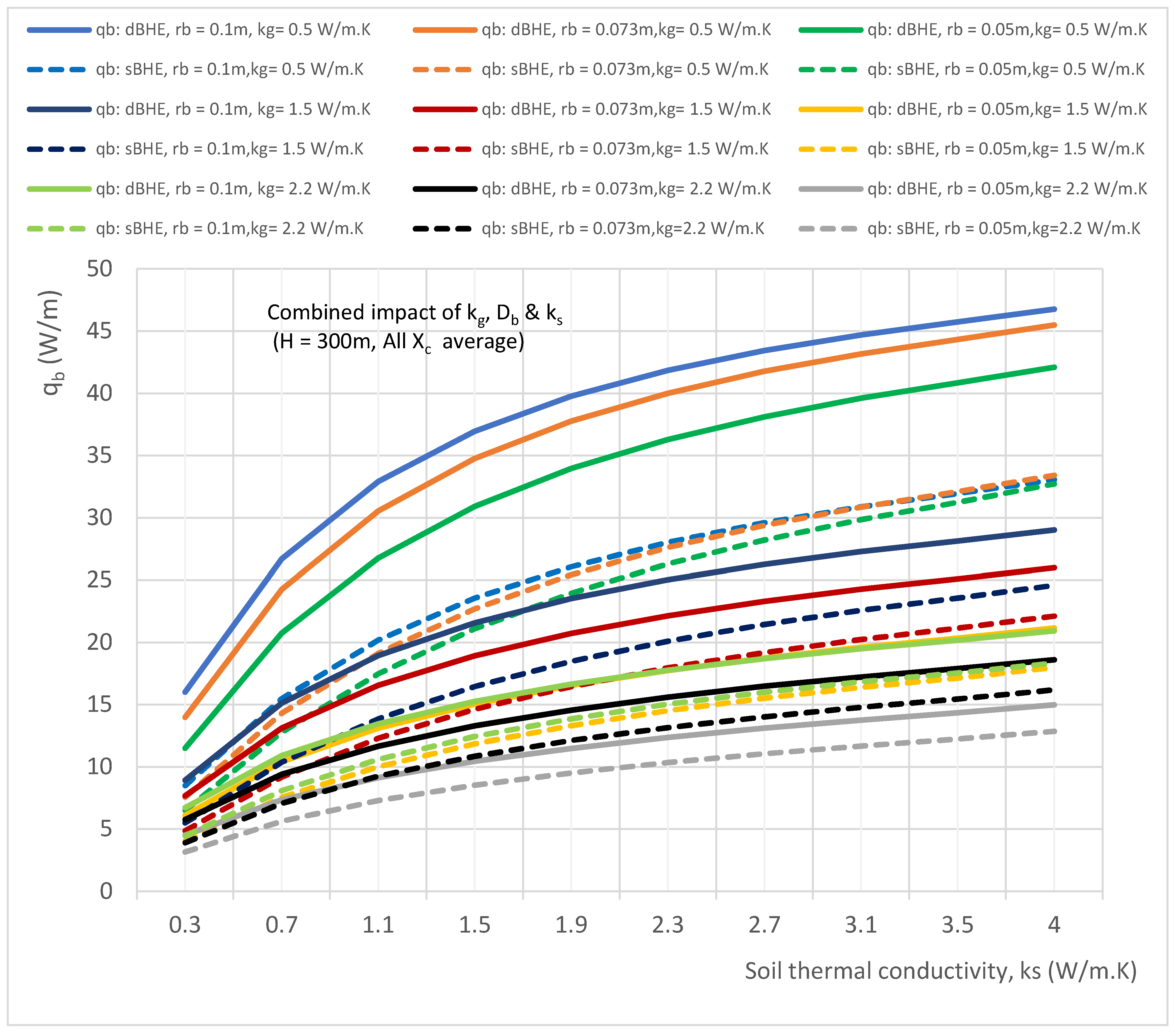

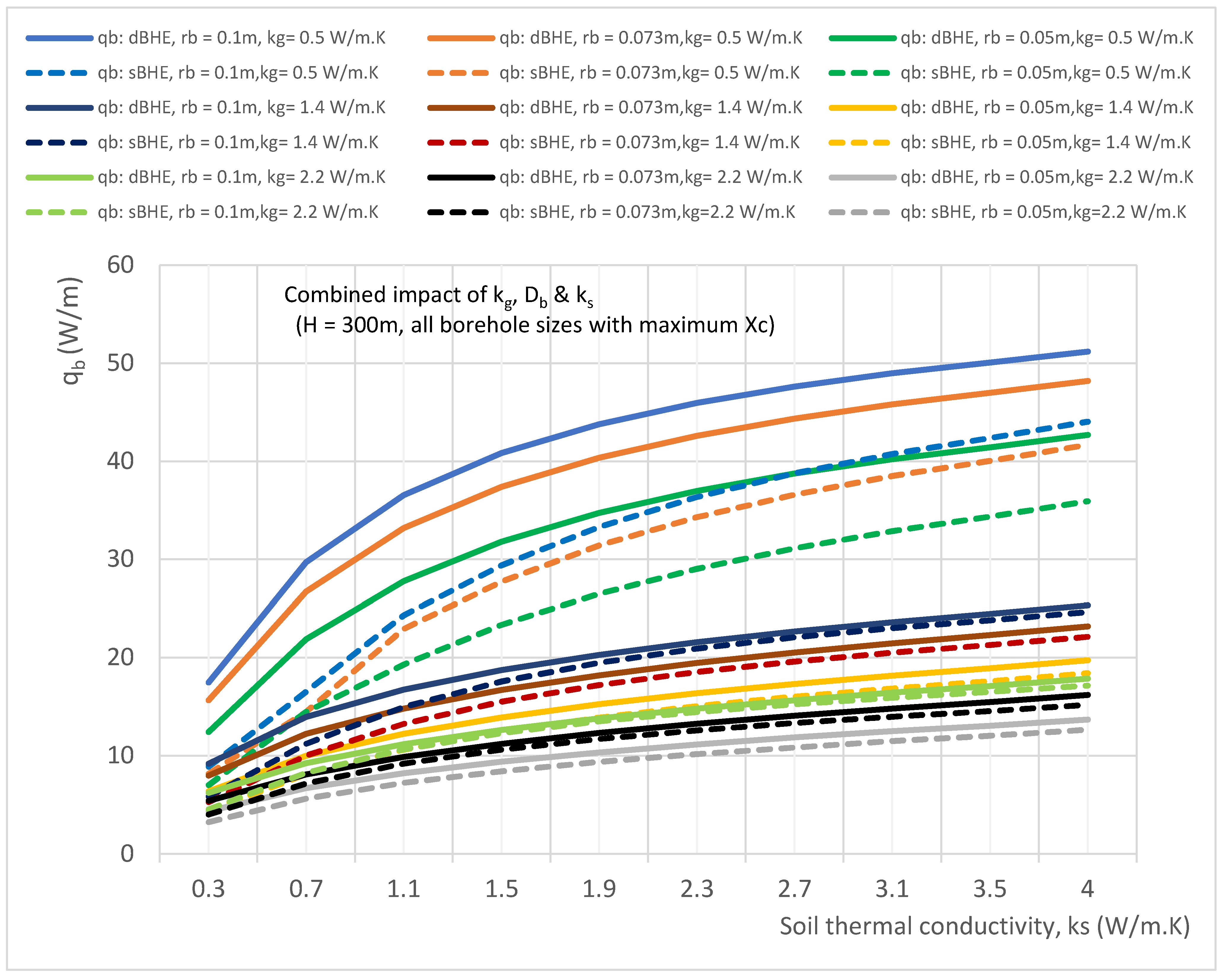

b = 0.05 m) and minimum grout thermal conductivity is the highest for the soil with thermal conductivity higher than 1.7 W/m∙K; and for soil thermal conductivity lower than 0.7 W/m∙K, dBHE with large borehole size and low grout thermal conductivity is preferred. This clearly indicates that for the BHE with minimum shank spacing and deep borehole depth, using BHE with large borehole size and with high gout and soil thermal conductivity is not preferred to transfer more heat between the working fluid and the ground around the BHE. This could be due to the augmented phenomenon of thermal short-circuit between the legs of the BHE designed with the minimum shank spacing, large borehole length and filled with grout that has high thermal conductivity. On the other hand, for borehole heat exchangers (BHEs) with corresponding average and maximum shank spacing (shown in

Figure 19 and

Figure 20 respectively), dBHE with large borehole size and low grout thermal conductivity provides the highest heat transfer for the whole range of soil thermal conductivity considered in this study (0.3 to 4 W/m∙K). This indicates that if a BHE with deep borehole depth is required to be designed to deliver the highest heat transfer rate per unit borehole depth, then dBHE with large borehole diameter, maximum shank spacing, and low grout thermal conductivity is preferred for all the range of the ground thermal conductivity. A close look at

Figure 20 indicates that for BHE designed with maximum shank spacing, deep borehole depth, low grout thermal conductivity, and high soil thermal conductivity, sBHE with large borehole size can provide more heat transfer than dBHE with small borehole size. Finally, comparison of the results presented in

Figure 18 and

Figure 20 indicates that for the same borehole depth, borehole size and grout thermal conductivity, the heat transferred by the BHE with high shank spacing is higher than that of the BHE with low shank spacing.

Overall, comparison among the nine cases (listed under column C of

Table 3 and depicted in

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20) shows that the third case (presented in

Figure 17) provided the highest heat transfer. Furthermore, the results presented in

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19 and

Figure 20 reveals that dBHE provides more heat transfer when used in shallow borehole depth while sBHE is preferred to transfer more heat when applied in deep borehole depth. The reason for this (as stated in the previous section) is due to more thermal interference in dBHE than in sBHE when applied in deep BHE; and to reduce the impact of the thermal loss (due to thermal short-circuit or thermal interference) associated with BHE with deep borehole depth, utilizing large borehole diameter and low grout thermal conductivity could be among the design options that can be considered.

Figure 18.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with the corresponding minimum shank spacing (rb = 0.1 m with Xc = 0.016 m; rb = 0.073 m with Xc = 0.016 m and rb = 0.05 m with Xc = 0.016 m).

Figure 18.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with the corresponding minimum shank spacing (rb = 0.1 m with Xc = 0.016 m; rb = 0.073 m with Xc = 0.016 m and rb = 0.05 m with Xc = 0.016 m).

Figure 19.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with corresponding average shank spacing (rb = 0.1 m with Xc = 0.05 m; rb = 0.073 m with Xc = 0.037 m and rb = 0.05 m with Xc = 0.025 m).

Figure 19.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with corresponding average shank spacing (rb = 0.1 m with Xc = 0.05 m; rb = 0.073 m with Xc = 0.037 m and rb = 0.05 m with Xc = 0.025 m).

Figure 20.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with corresponding maximum shank spacing (rb = 0.1 m with Xc = 0.084 m; rb = 0.073 m with Xc = 0.057 m and rb = 0.05 m with Xc = 0.034 m).

Figure 20.

Combined effect of soil thermal conductivity, grout thermal conductivity and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of deep borehole depth (H = 300 m) and all borehole sizes with corresponding maximum shank spacing (rb = 0.1 m with Xc = 0.084 m; rb = 0.073 m with Xc = 0.057 m and rb = 0.05 m with Xc = 0.034 m).

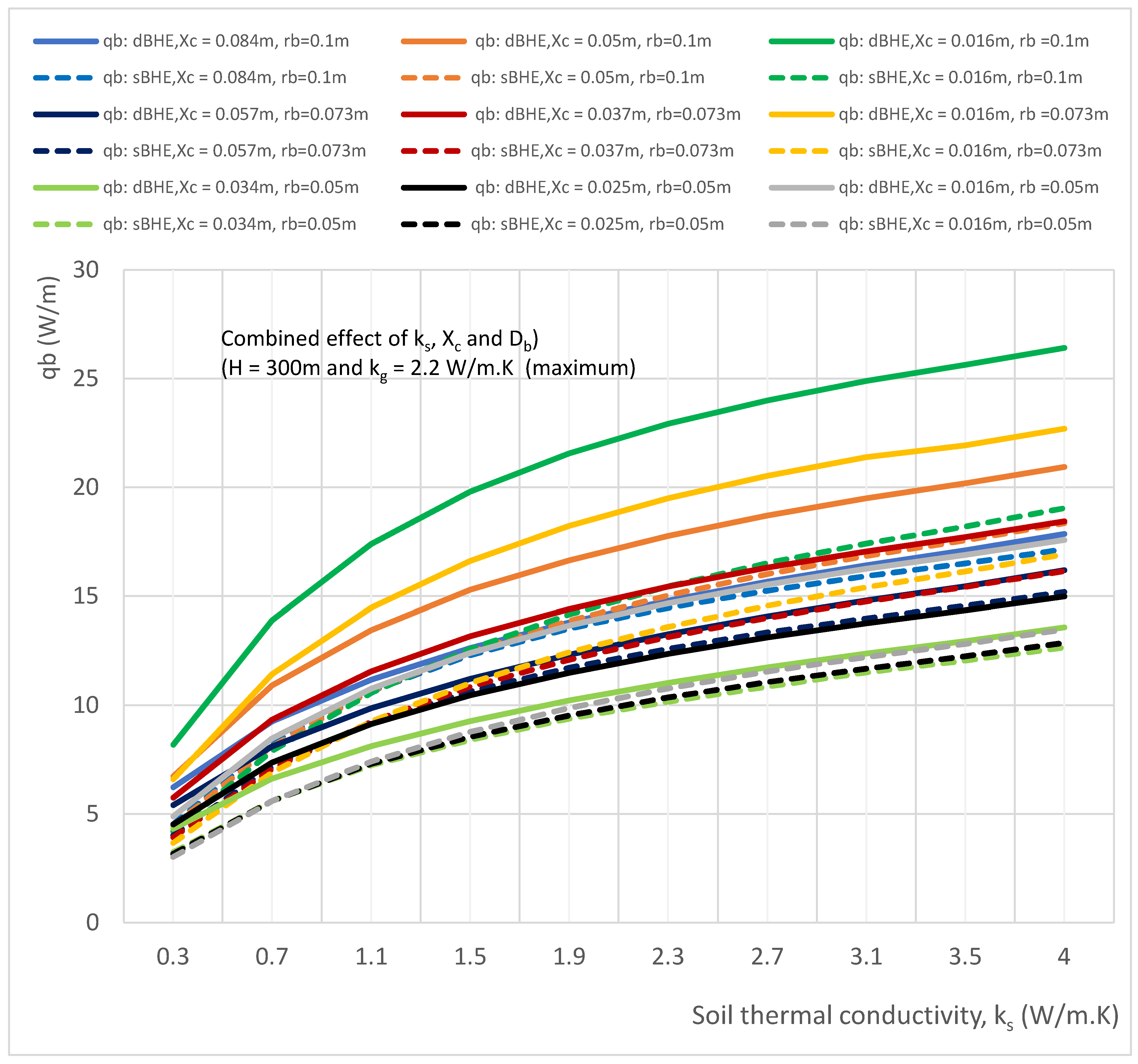

- D.

Combined Effect of Soil Thermal Conductivity, Borehole Size and Shank Spacing

In this subsection, combined impact of soil thermal conductivity, borehole size (diameter) and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for different cases of grout thermal conductivity (minimum, k

g = 0.5 W/m∙K; average, k

g = 1.5 W/m∙K and maximum, k

g = 2.2 W/m∙K) and borehole depth (shallow borehole depth, H = 50 m; average borehole depth, H = 100 m and deep borehole depth, H = 300 m). The simulation result generated under this subsection has different cases (listed in

Table 3 under column D) and presented in

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25 and

Figure 26). This case is important as a quick reference for the design of the BHE with a given borehole depth and grout thermal conductivity, and desired to be installed at the ground with known (experimentally determined) value of thermal conductivity. Specifically, the results presented in

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25 and

Figure 26 provide an important information on how to select the BHE that provides the highest heat transfer among the BHE design options (sBHE and dBHE with small, medium and large borehole size and each of them have the corresponding minimum, average and maximum shank spacing) for a given soil thermal conductivity, borehole depth (H = 50 m, H = 100 m and H = 300 m) and grout thermal conductivity (k

g = 0.5 W/m∙K (minimum); 1.5 W/m∙K (average) and 2.2 W/m∙K (maximum)). An important BHE design information can be read/obtained from these simulation results. For example, if a BHE (with shallow/deep borehole depth and with a given grout thermal conductivity) that can transfer highest heat transfer is required to be installed at the ground with a certain thermal conductivity, reference information suitable for the design of such BHE configuration can be obtained from results presented in

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25 and

Figure 26.

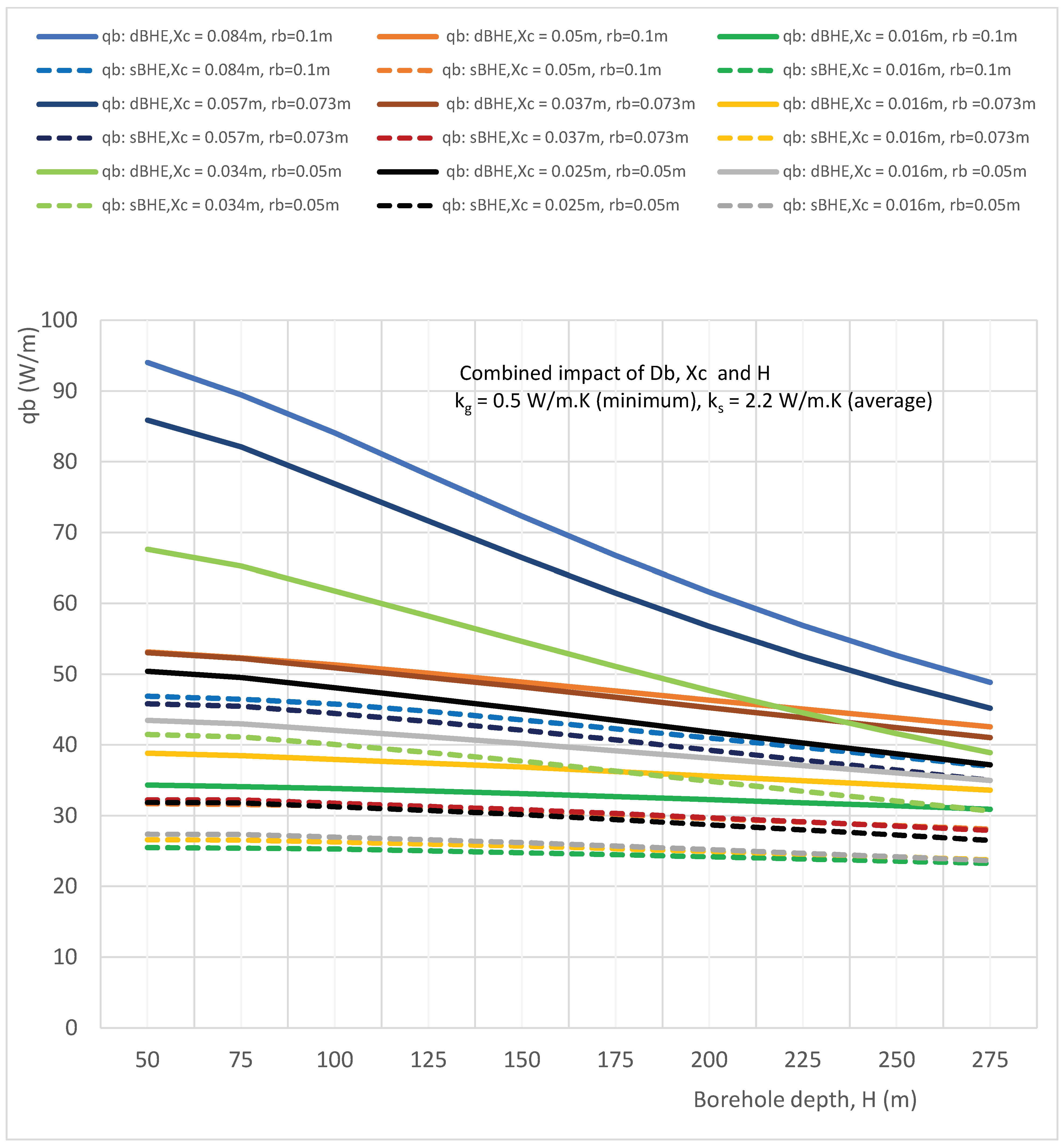

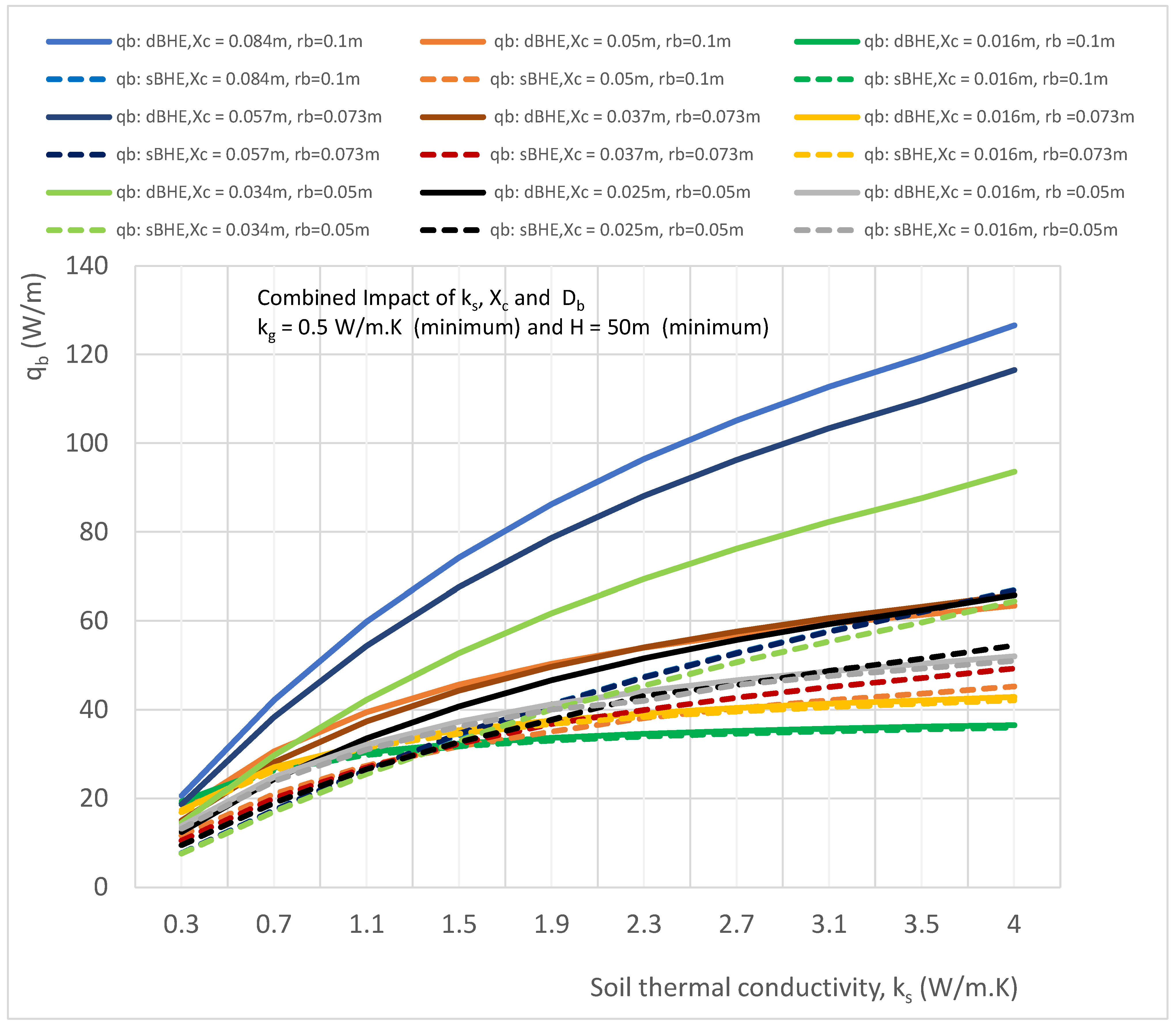

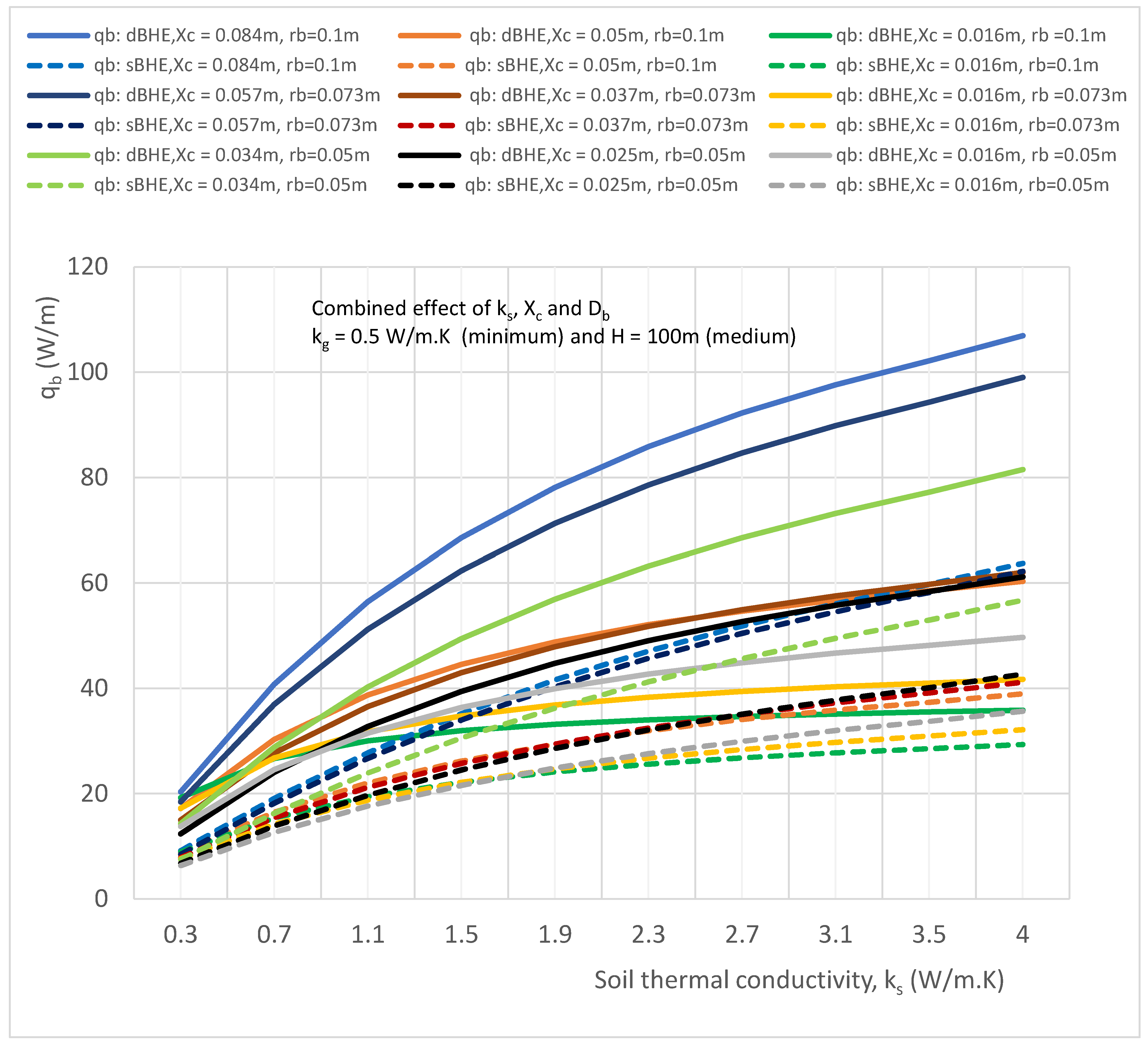

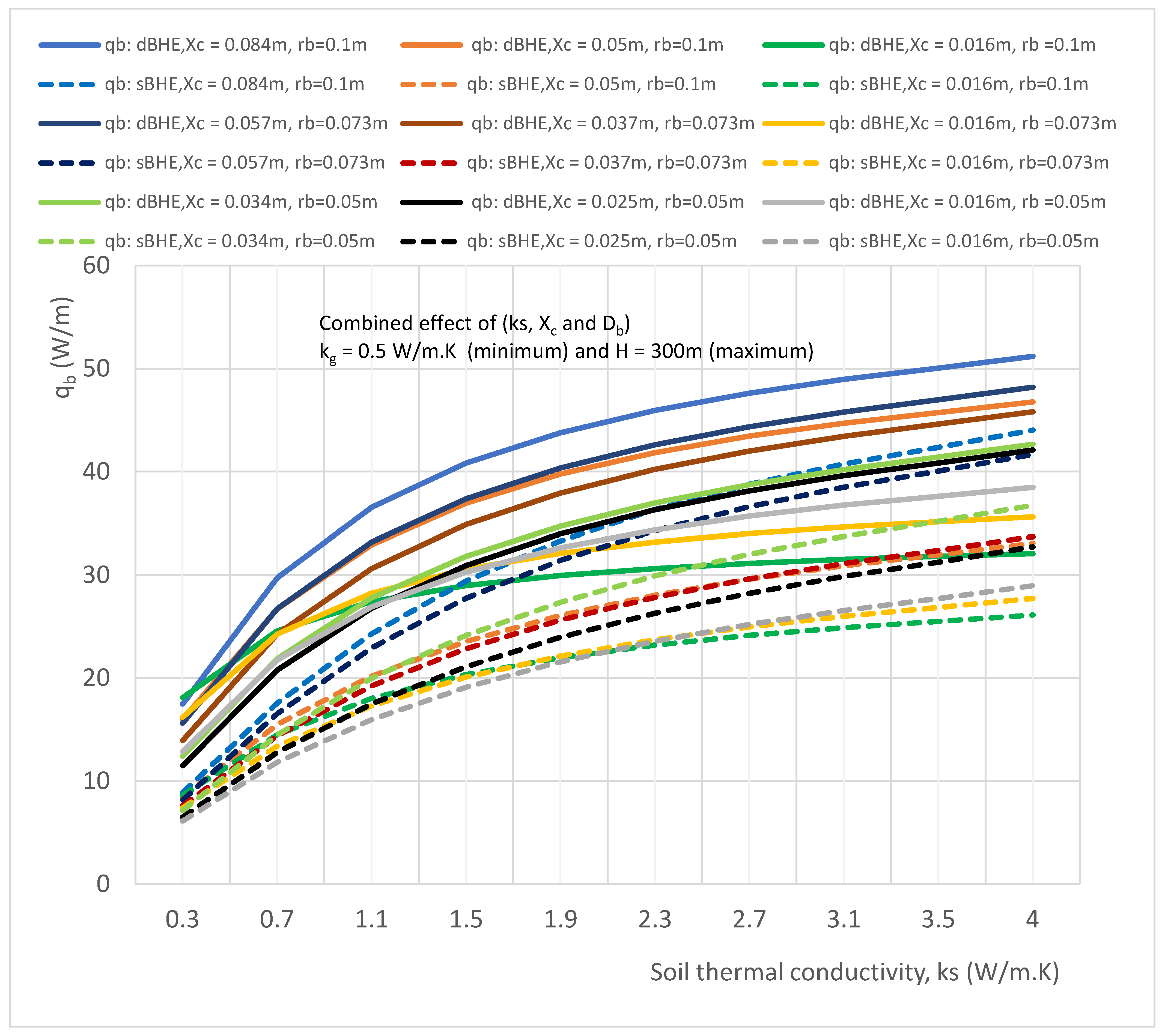

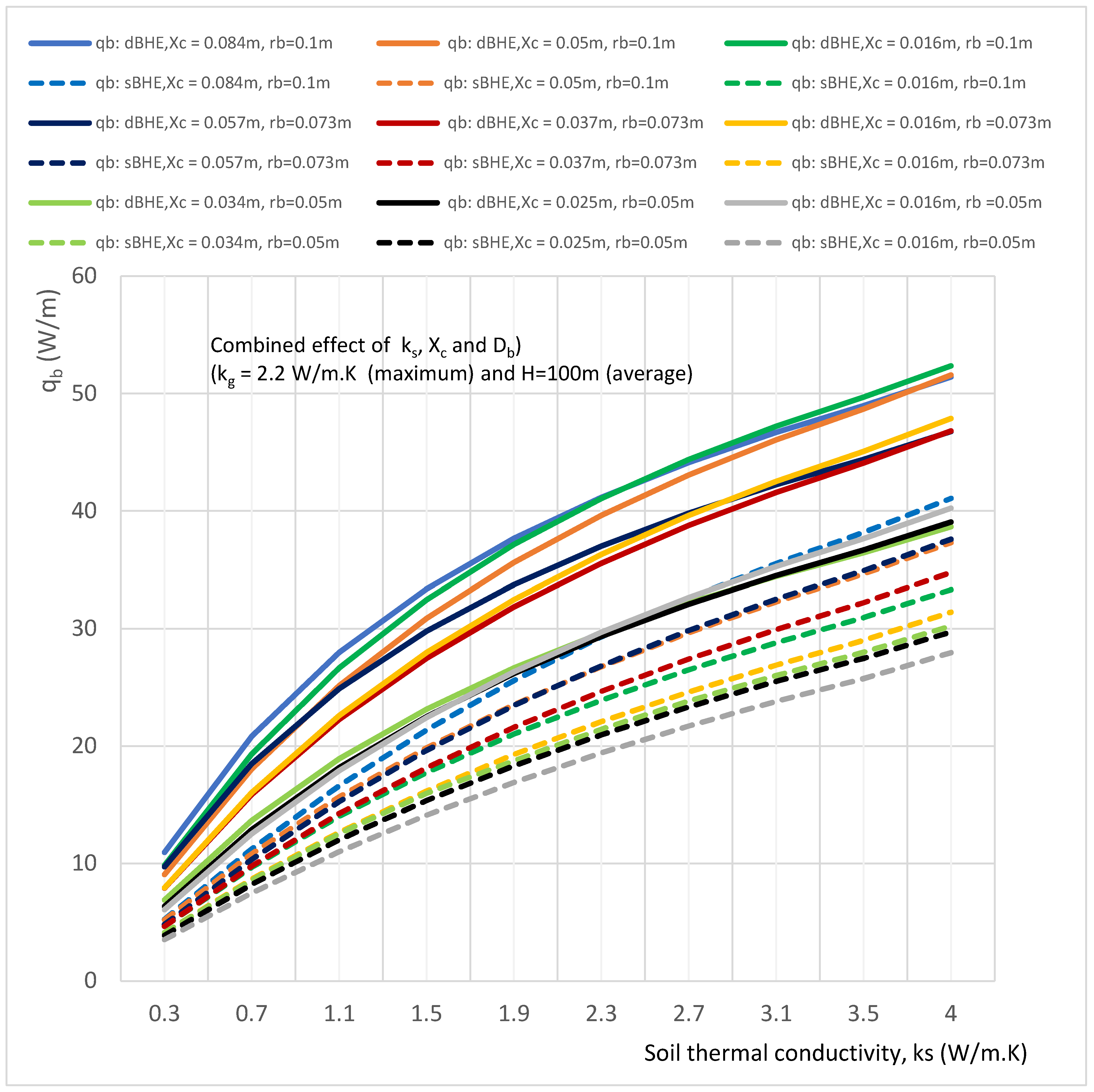

The results presented in

Figure 21,

Figure 22 and

Figure 23 indicate the combined impact of soil thermal conductivity, borehole size and shank spacing on heat transfer rate in both sBHE and dBHE filled by the grout with minimum thermal conductivity (k

g = 0.5 W/m∙K) combined with shallow borehole depth (H = 50 m), average borehole depth (H = 100 m) and deep borehole depth (H = 300 m) respectively. Valuable BHE design information can be obtained from these simulation results. For instance,

Figure 21,

Figure 22 and

Figure 23 show that dBHE with large borehole size (r

b = 0.1 m) and maximum shank spacing (X

c = 0.084 m) provides the highest heat transfer for the whole range of soil of thermal conductivity considered in this study (0.3 to 4 W/m∙K). Then, it is followed by the dBHEs with medium and small borehole size each with the corresponding maximum shank spacing. In addition,

Figure 30 and

Figure 31 show that in the ground with high soil thermal conductivity (higher than 3.5 W/m∙K), sBHE with large borehole size (r

b = 0.1 m) and maximum shank spacing (X

c = 0.084 m) provides more heat transfer than even dBHE with medium size (r

b = 0.073 m) and maximum shank spacing as well as dBHE with small borehole size (r

b = 0.05 m) and maximum shank spacing (X

c = 0.034 m). However, for low ground thermal conductivity (lower than 3.5 W/m∙K), dBHE provides more heat transfer than the corresponding sBHE. Furthermore,

Figure 21,

Figure 22 and

Figure 23 show that increasing shank spacing has more impact on heat transfer of dBHE than the corresponding sBHE, and this impact on heat transfer becomes higher for the ground with high soil thermal conductivity. The results depicted in

Figure 21,

Figure 22 and

Figure 23 show that the impact of increasing borehole size and shank spacing is less effective for sBHE (as compared to the corresponding dBHE) specially for the case of the BHE with deep borehole depth (H = 300 m) shown in

Figure 23. Moreover, comparison among

Figure 21,

Figure 22 and

Figure 23 shows that case 1 (depicted in

Figure 21) provides the highest transfer than the second and third case (presented in

Figure 21 and

Figure 23 or listed under column D of

Table 3)

Figure 21.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with shallow borehole depth (H = 50 m).

Figure 21.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with shallow borehole depth (H = 50 m).

Figure 22.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with average borehole depth (H = 100 m).

Figure 22.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with average borehole depth (H = 100 m).

Figure 23.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with high borehole depth (H = 300 m).

Figure 23.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of minimum grout thermal conductivity (kg = 0.5 W/m∙K) with high borehole depth (H = 300 m).

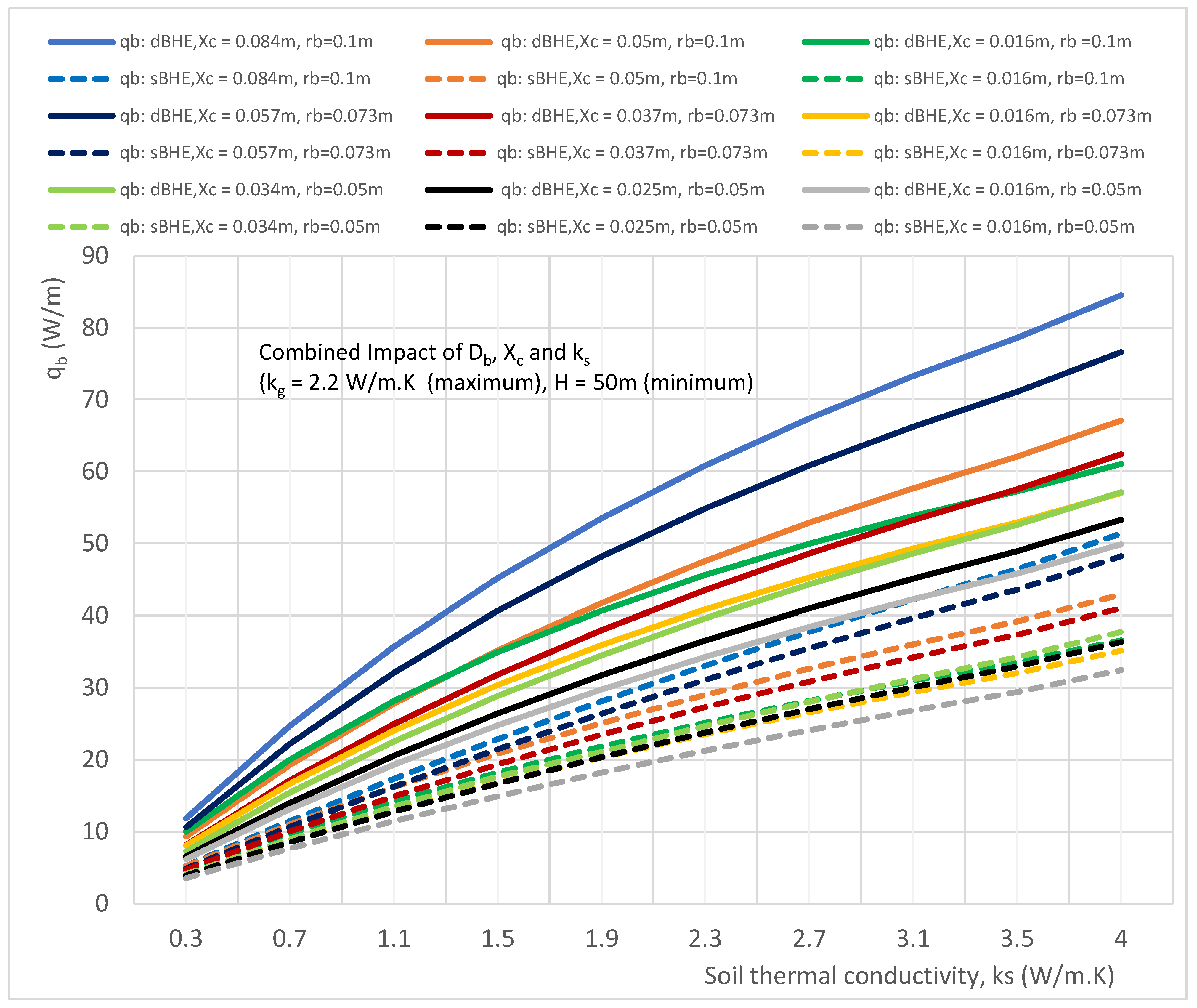

The results presented in

Figure 24,

Figure 25 and

Figure 26 illustrates the combined impact of soil thermal conductivity, borehole size and shank spacing on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of grout with maximum thermal conductivity (k

g = 2.2 W/m∙K) borehole with shallow borehole depth (H = 50 m), average borehole depth (H = 100 m) and deep borehole depth (H = 300 m) respectively. The simulation results reveal that the heat transfer per unit borehole depth for these cases (with maximum grout thermal conductivity) indicated in

Figure 24,

Figure 25 and

Figure 26 are the lowest as compared to the corresponding heat transfer values obtained for the remaining cases considered

Table 3 under column D. The reduction in heat transfer of the BHE of these cases could be due to the thermal short-circuit associated with grout with high/maximum thermal conductivity. The impact of this thermal interference between the legs of the BHE becomes more amplified in BHE with deep borehole depth as presented in

Figure 26, and hence, the heat transfer per unit borehole depth is further reduced and become the lowest as compared to all other cases considered under column D of

Table 3 (

Figure 24,

Figure 25 and

Figure 26).

Figure 24.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with shallow borehole depth (H = 50 m).

Figure 24.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with shallow borehole depth (H = 50 m).

Figure 25.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with medium borehole depth (H = 100 m).

Figure 25.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with medium borehole depth (H = 100 m).

Figure 26.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with deep borehole depth (H = 300 m).

Figure 26.

Combined effect of soil thermal conductivity, shank spacing and borehole size on heat transfer rate per unit borehole depth in sBHE and dBHE for the case of maximum grout thermal conductivity (kg = 2.2 W/m∙K) with deep borehole depth (H = 300 m).