Submitted:

14 March 2024

Posted:

15 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- In order to solve the problem of fault diagnosis of CNC machine feed system under variable speed conditions, a fault diagnosis method based on multi monitoring signals, multi domain feature extraction and DoubleEnsemble-LightGBM integrated learning model is proposed. The experimental results show that this method achieves better diagnosis effect than Xgboost and other advanced integrated learning models;

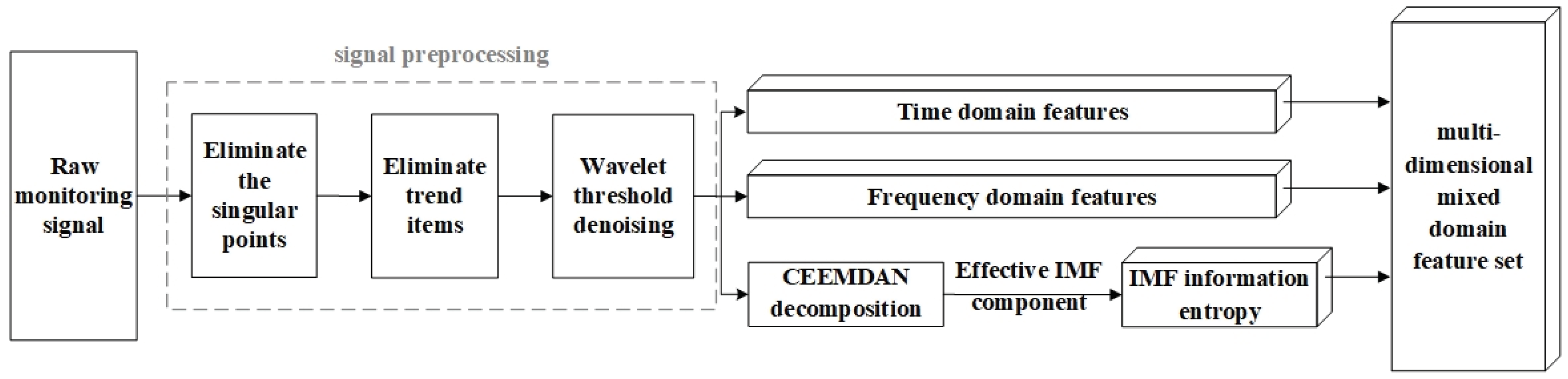

- A variety of monitoring signals including vibration signal, noise signal and current signal are collected. The monitoring signals are preprocessed by singularity elimination, trend item elimination, Wavelet threshold denoising, and then the time-domain, frequency-domain feature indexes and IMF information entropy of the monitroring signals are extracted. Finally, the multi-dimensional mixed domain feature set is constructed;

- Based on the LightGBM model, the DoubleEnsemble-LightGBM fault diagnosis model is constructed by introducing the sample reweighting mechanism based on learning trajectory and the feature selection mechanism based on shuffling technology, which realizes the intelligent fault diagnosis of CNC machine feed system.

2. Relevant Theories

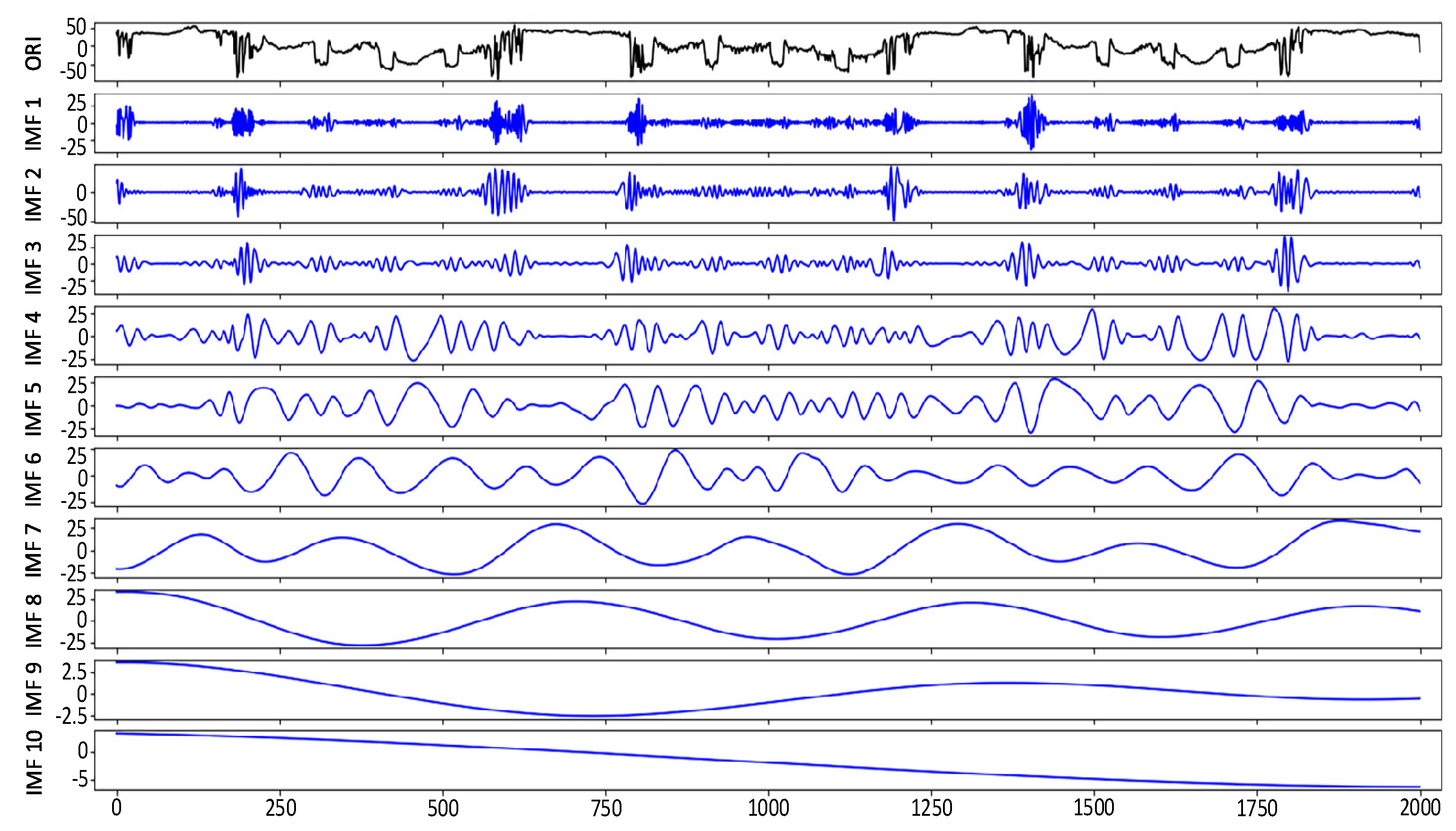

2.1. CEEMDAN Decomposition and IMF Information Entropy

2.1.1. CEEMDAN Decomposition

2.1.2. False Modal Component Rejection

2.1.3. Calculation of IMF Information Entropy

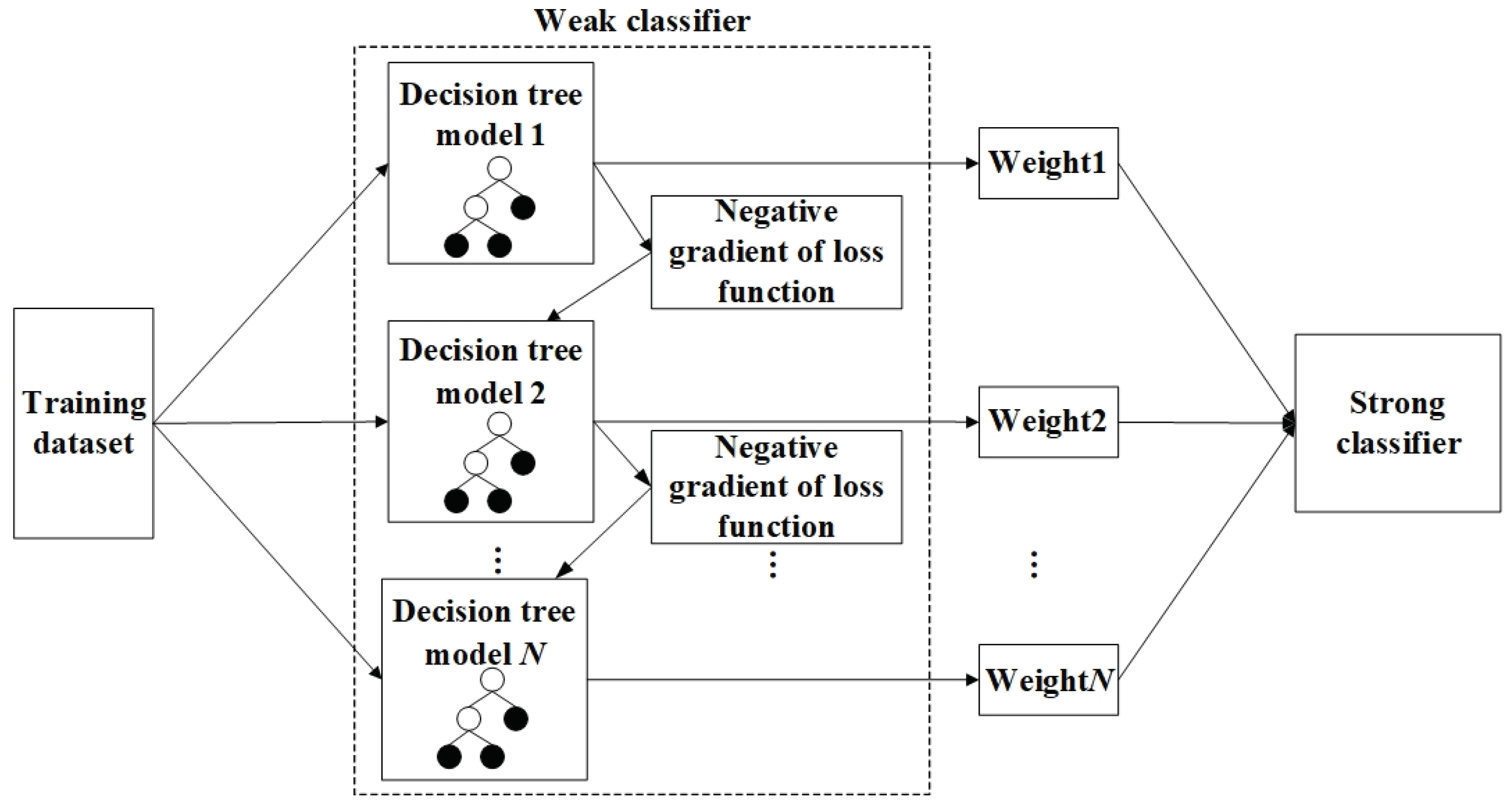

2.2. LightGBM Algorithm

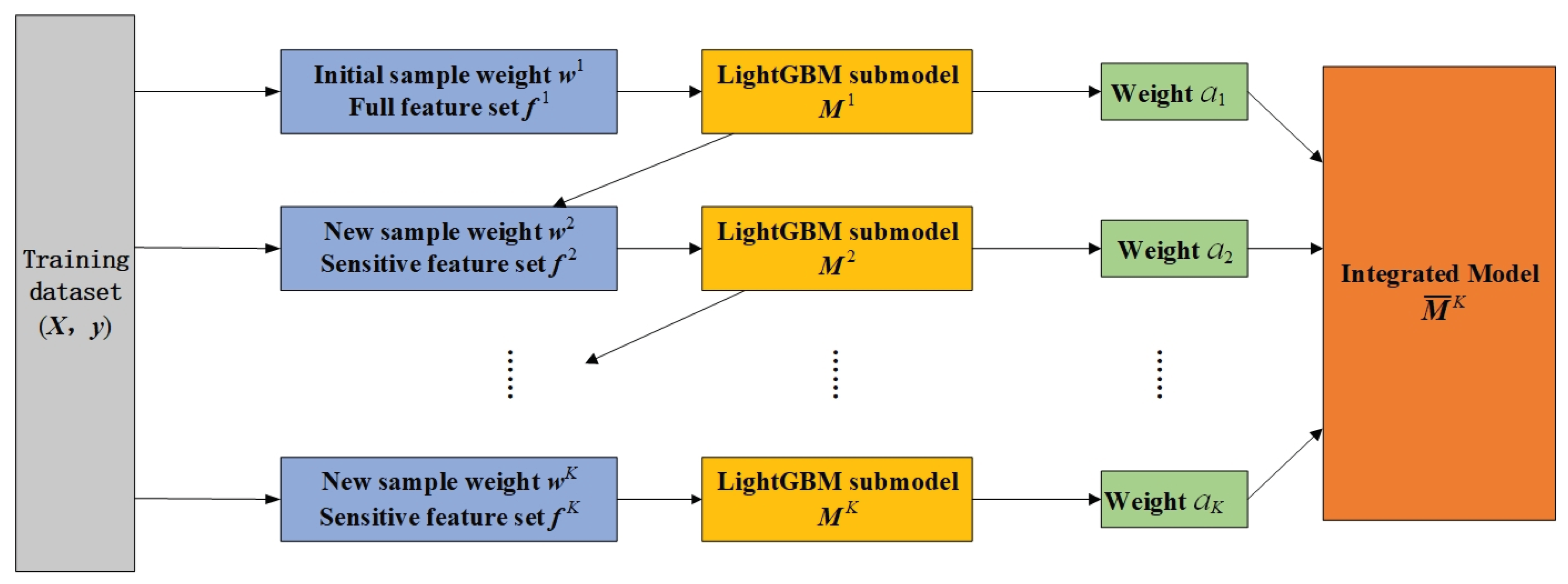

2.3. DoubleEnsemble Algorithm

3. Model: Multi-Domain Feature and DoubleEnsemble-LightGBM

4. Experimental Results

4.1. Data Set Description

4.1.1. University of Ottawa Variable Speed Bearing Failure Open Data Set

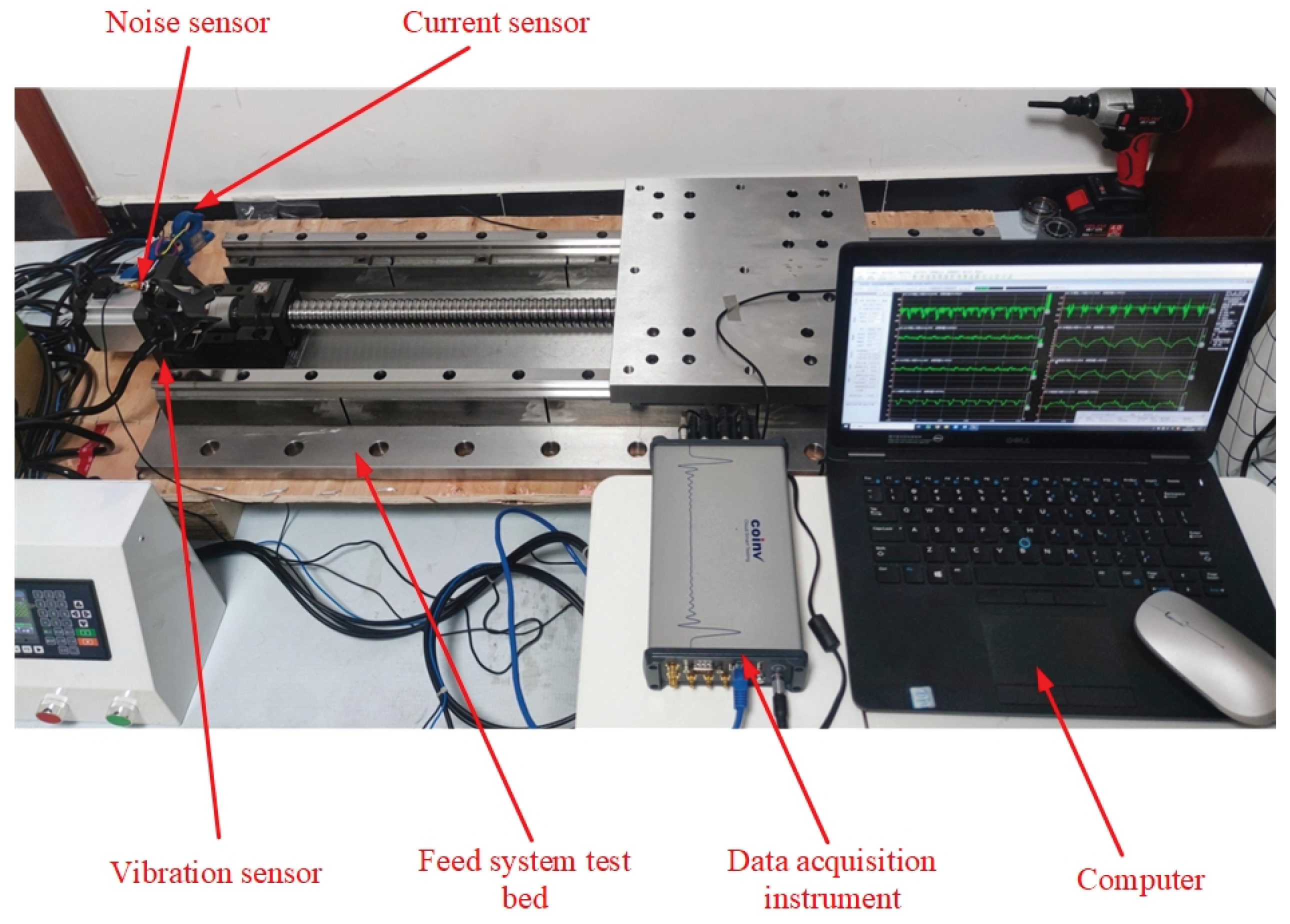

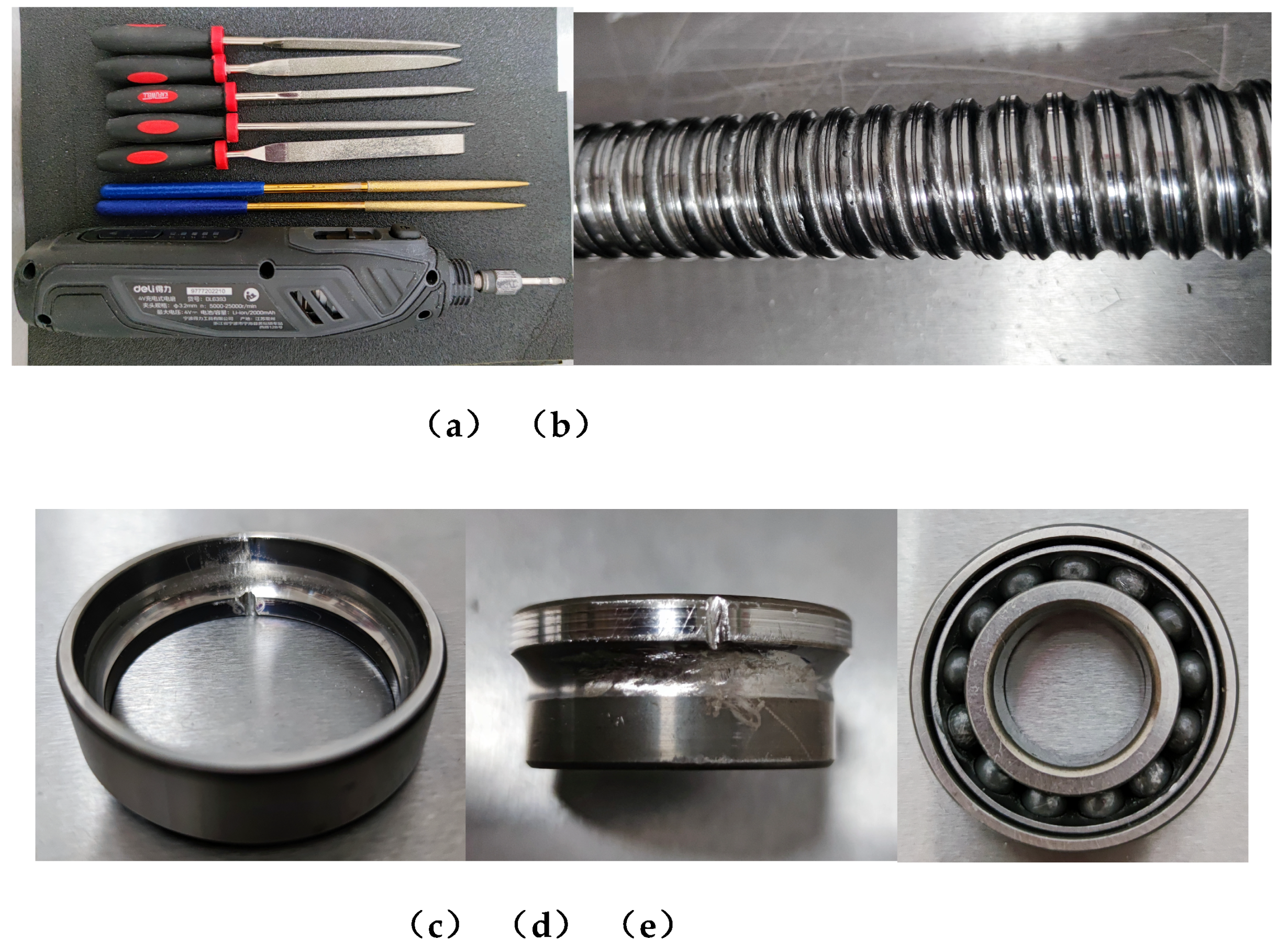

4.1.2. Dataset of Feed System Test Bench

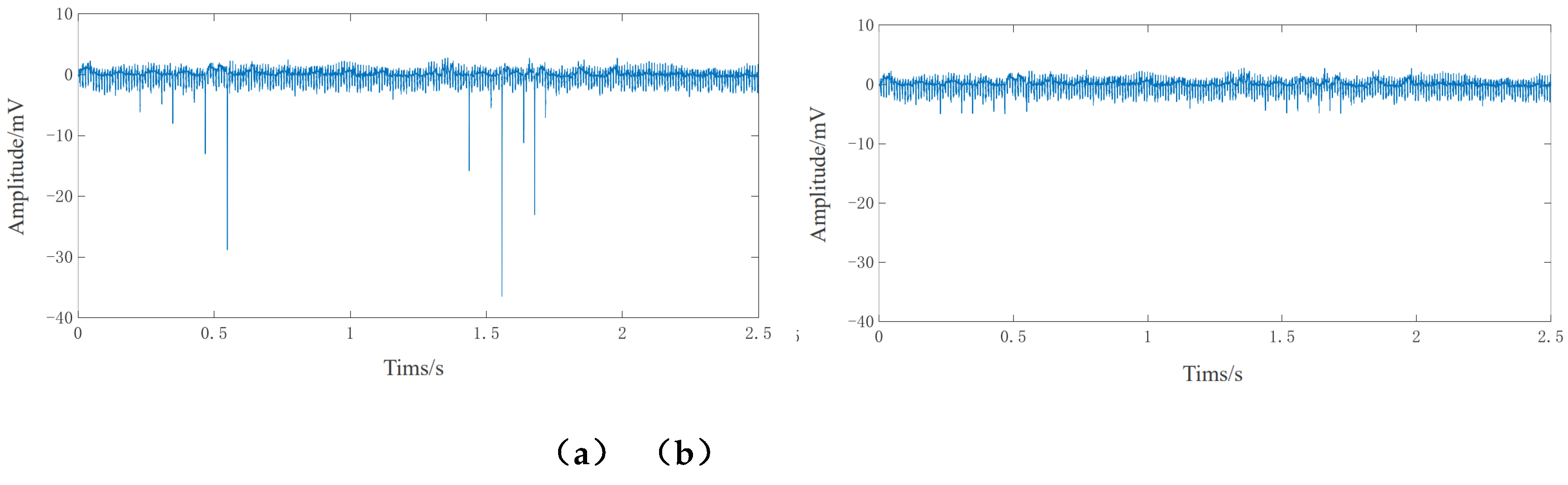

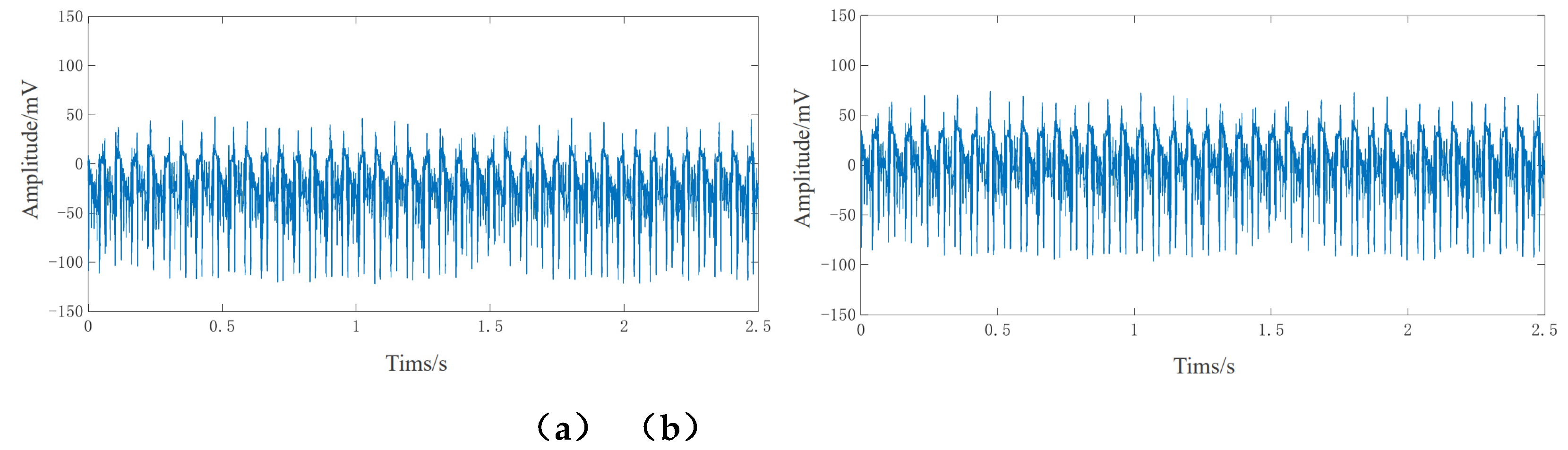

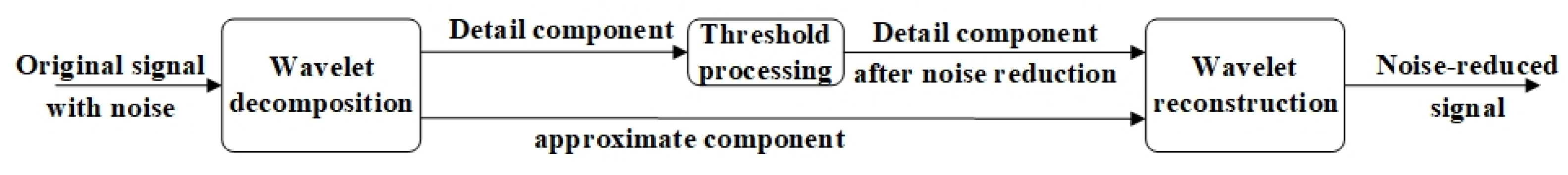

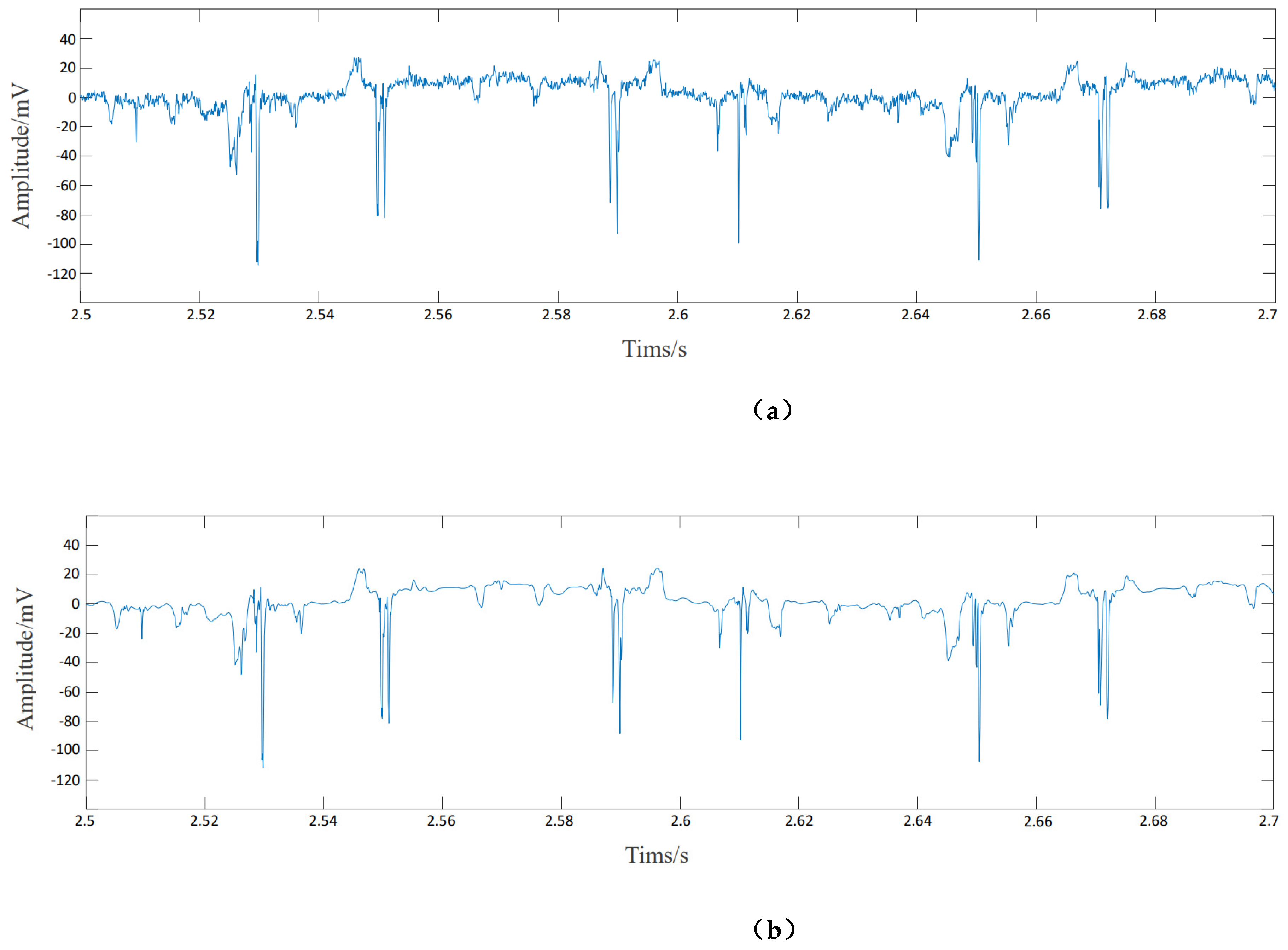

4.2. Signal Preprocessing

4.3. Signal Feature Extraction

4.4. Experimental Environment, Hyper-Parameter Setting and Model Evaluation Index

4.5. Analysis of Experimental Results

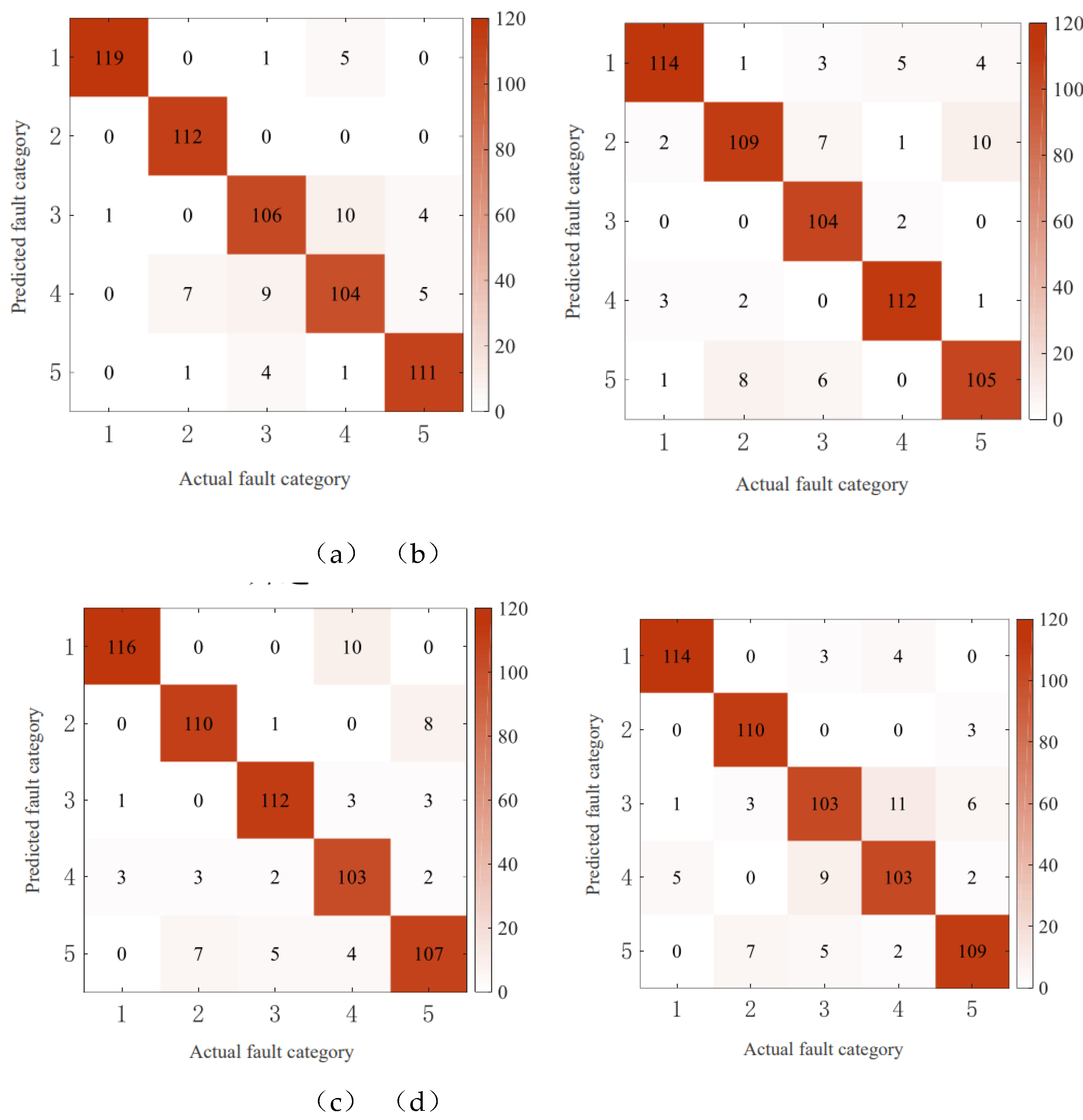

4.5.1. Analysis of Experimental Results of Public Data Set

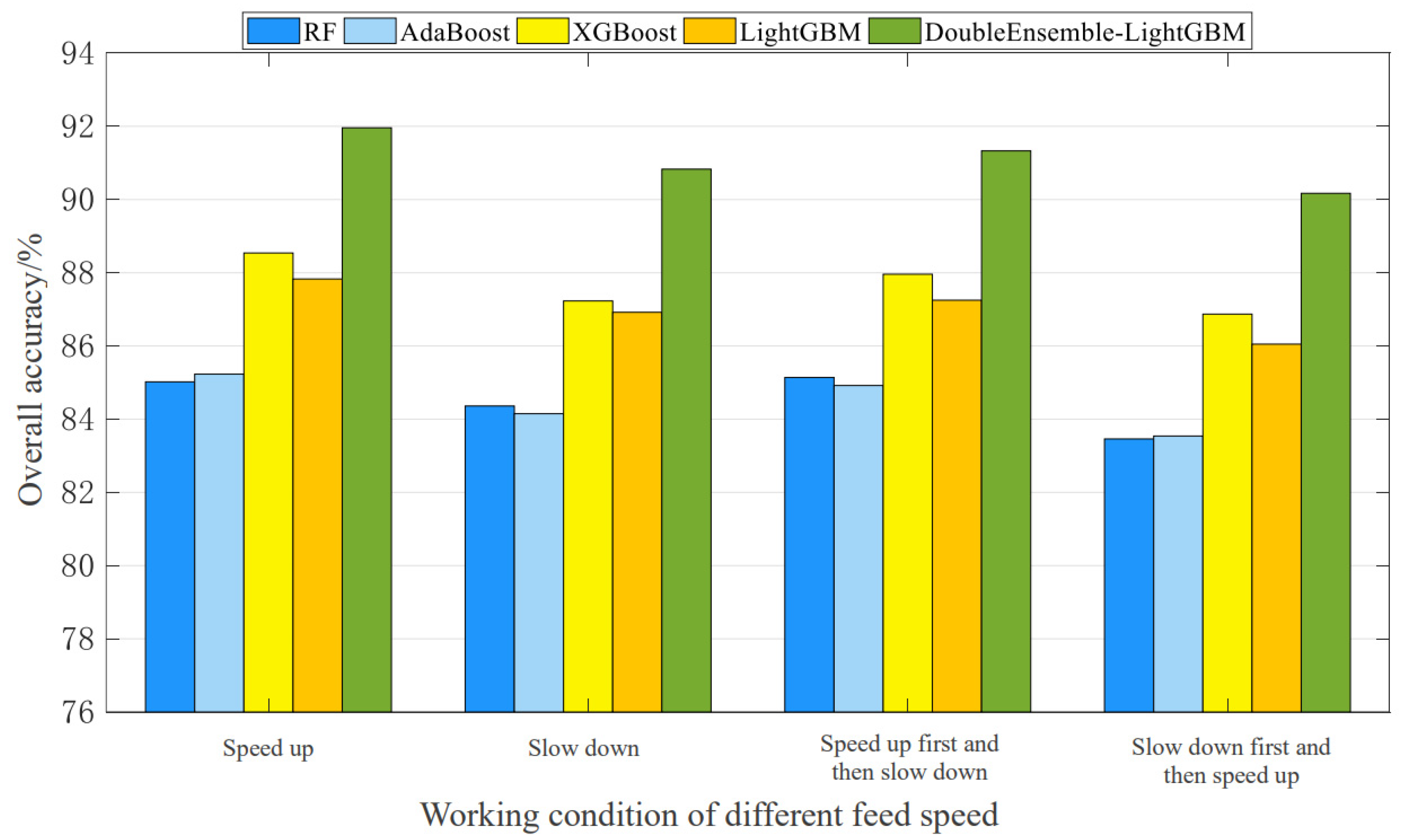

4.5.2. Analysis of Experimental Results of Feed System Test Bench Data Set

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li Shan. Research on complex fault diagnosis of CNC machine tool feed system based on multi-source information fusion [D]. Qingdao University of Technology, 2016.

- Michael, G.; Peng, J.; Marinov, M.B.; et al. Research on fault diagnosis expert system of cnc machine tool based on expert knowledge[C]//2021 International Scientific Conference Electronics (ET). IEEE, 2021: 1-4. IEEE,.

- Wang, J. Error analysis and fault diagnosis of CNC machine tools under artificial intelligence technology[C]// Journal of Physics: Conference Series. IOP Publishing, 2021, 1881, 022085. [Google Scholar]

- Polat, K. The fault diagnosis based on deep long short-term memory model from the vibration signals in the computer numerical control machines. Journal of the Institute of Electronics and Computer 2020, 2, 72–92. [Google Scholar] [CrossRef]

- Shan, P.; Lv, H.; Yu, L.; et al. A multisensor data fusion method for ball screw fault diagnosis based on convolutional neural network with selected channels. IEEE Sensors Journal 2020, 20, 7896–7905. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, S.; Wang, J.; et al. General normalized sparse filtering: A novel unsupervised learning method for rotating machinery fault diagnosis. Mechanical Systems and Signal Processing 2019, 124, 596–612. [Google Scholar] [CrossRef]

- Chen, J.; Huang, R.; Zhao, K.; et al. Multiscale convolutional neural network with feature alignment for bearing fault diagnosis. IEEE Transactions on Instrumentation and Measurement 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Azamfar, M.; Li, X.; Lee, J. Intelligent ball screw fault diagnosis using a deep domain adaptation methodology. Mechanism and Machine Theory 2020, 151, 103932. [Google Scholar] [CrossRef]

- Pandhare, V.; Li, X.; Miller, M.; et al. Intelligent diagnostics for ball screw fault through indirect sensing using deep domain adaptation. IEEE Transactions on Instrumentation and Measurement 2020, 70, 1–11. [Google Scholar] [CrossRef]

- Jin, G.; Zhu, T.; Akram, M.W.; et al. An adaptive anti-noise neural network for bearing fault diagnosis under noise and varying load conditions. IEEE Access 2020, 8, 74793–74807. [Google Scholar]

- H, Darpe A K. Coupled bending-torsional vibration analysis of rotor with rub and crack. Journal of Sound and Vibration 2009, 326, 740–752. [Google Scholar] [CrossRef]

- Abbasion, S.; Rafsanjani, A.; Farshidianfar, A.; et al. Rolling bearing element bearings mufti-fault classification based on the wavelet denoising and support vector machine. Mechanical Systems and Signal Processing 2007, 21, 2933–2945. [Google Scholar]

- Lei Y G, He Z J, Zi Yanyang. Application of a novel hybrid intelligent method to compound fault diagnosis of locomotive roller bearings. ASME Transactions on Journal of Vibration and Acoustics 2008, 130, 1–6. [Google Scholar]

- Delgado, M.; Garcia, A.; Ortega, J.A.; et al. Multidimensional intelligent diagnosis system based on support vector machine classifier[C]//2011 IEEE International Symposium on Industrial Electronics. IEEE, 2011: 2124-2131.

- Yang, S. An experiment of state estimation for predictive maintenance using Kalman filter on a DC motor. Reliability engineering & system safety 2002, 75, 103–111. [Google Scholar]

- Wang, P.; Xiong, H.; He, H. Bearing fault diagnosis under various conditions using an incremental learning-based multi-task shared classifier. Knowledge-Based Systems 2023, 266, 110395. [Google Scholar]

- Li, J.; Liu, Y.; Li, Q. Intelligent fault diagnosis of rolling bearings under imbalanced data conditions using attention-based deep learning method. Measurement 2022, 189, 110500. [Google Scholar]

- Xu, Z.; Li, C.; Yang, Y. Fault diagnosis of rolling bearings using an improved multi-scale convolutional neural network with feature attention mechanism. ISA Transactions 2021, 110, 379–393. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, L.; Gao, H.; et al. Instance-based ensemble deep transfer learning network: A new intelligent degradation recognition method and its application on ball screw. Mechanical Systems and Signal Processing 2020, 140, 106681. [Google Scholar]

- Azamfar, M.; Li, X.; Lee, J. Intelligent ball screw fault diagnosis using a deep domain adaptation methodology. Mechanism and Machine Theory 2020, 151, 103932. [Google Scholar]

- Wu, H.; Li, J.; Zhang, Q.; et al. Intelligent fault diagnosis of rolling bearings under varying operating conditions based on domain-adversarial neural network and attention mechanism. ISA Transactions 2022, 130, 477–489. [Google Scholar] [CrossRef]

- Huang, M.; Yin, J.; Yan, S.; et al. A fault diagnosis method of bearings based on deep transfer learning. Simulation Modelling Practice and Theory 2023, 122, 102659. [Google Scholar] [CrossRef]

- Shanshan, S.; Shuqing, Z.; Wei, D.; et al. A new hybrid method for bearing fault diagnosis based on CEEMDAN and ACPSO-BP neural network. Journal of Mechanical Science and Technology 2023, 37, 5597–5606. [Google Scholar]

- Ayenu-Prah, A.; Attoh-Okine, N. A criterion for selecting relevant intrinsic mode functions in empirical mode decomposition. Advances in Adaptive Data Analysis 2010, 2, 1–24. [Google Scholar]

- Ke, G.; Meng, Q.; Finley, T.; et al. LightGBM: A highly efficient gradient boosting decision tree[C]//Proceedings of the 31st International Conference on Neural Information Processing Systems, 2017: 3149-3157.

- Wei, D.; Qing, C.; Yuzhan, D.; et al. Fault Diagnosis Method of Intelligent Substation Protection System Based on Gradient Boosting Decision Tree. Applied Sciences 2022, 12, 8989–8989. [Google Scholar]

- Daying, Q.; Wei, F.; Gabriel, D.; et al. A Novel Double Ensemble Algorithm for the Classification of Multi-Class Imbalanced Hyperspectral Data. Remote Sensing 2022, 14, 3765–3765. [Google Scholar]

- Zhu Jiwei. Health evaluation of feed system in machining center [D]. Jilin University, 2022.

- Jared, N.; RR, H.; Andrew, G.; et al. Lightning forecast from chaotic and incomplete time series using wavelet de-noising and spatiotemporal kriging. Journal of Defense Analytics and Logistics 2023, 7, 90–102. [Google Scholar]

- R,S. S S.Classification of yoga, meditation, combined yoga–meditation EEG signals using L-SVM, KNN, and MLP classifiers. Soft Computing 2024, 28, 4607–4619. [Google Scholar] [CrossRef]

- Fei, C.; Liyao, Z.; Wenshen, L.; et al. A fault diagnosis method of rotating machinery based on improved multiscale attention entropy and random forests. Nonlinear Dynamics 2023, 112, 1191–1220. [Google Scholar]

- Jiahui, J.; Yuqing, L.; Chaozheng, X.; et al. Research on Motor Bearing Fault Diagnosis Based on the AdaBoost Algorithm and the Ensemble Learning with Bayesian Optimization in the Industrial Internet of Things. Security and Communication Networks 2022, 2022. [Google Scholar]

- Zhiguo, L.; Lijun, Z.; Xizhe, W. A Novel Intelligent Method for Fault Diagnosis of Steam Turbines Based on T-SNE and XGBoost. Algorithms 2023, 16, 98–98. [Google Scholar]

| Algorithm: Double Ensemble |

| 1: Input: Training data (X, y), number of sub-models K, and sub-model weights |

| 2: Set the initial sample weights = (1, ······, 1) |

| 3: Select initial feature set = [F] |

| 4:for k=1 to K : |

| 5: ← Train sub-model (X, y, ,) |

| 6: Retrieve the loss curve of the sub-model and the loss of the current integrated model |

| 7: Update sample weights based on sample reweighting technique ← SR (, ,K) |

| 8: Update feature set based on feature selection technique ← FS (, X, y) |

| 9: Return: Integrated model |

| Label | Category | Number of training set samples | Number of test set samples |

| 1 | Health | 480 | 120 |

| 2 | Bearing inner ring failure | 480 | 120 |

| 3 | Bearing ball failure | 480 | 120 |

| 4 | Bearing outer ring failure | 480 | 120 |

| 5 | Bearing compound failure | 480 | 120 |

| Device name | Equipment model | Device parameters |

| Data acquisition instrument | INV3062C | Sampling frequency range: 0.4~ 216 kHz; resolution: 24 bits; number of channels: 8 |

| Three-direction vibration sensor | INV9832 | Frequency range: 1-10 kHz; sensitivity: 100 mV/G; |

| Noise sensor | INV9206 | Frequency range: 20 Hz ~ 20 kHz; sensitivity: 50 mV/Pa |

| Hall current sensor | CHK-100R1 | Frequency range: from 0 to 20 kHz |

| Type of fault | Number of samples | ||

| Condition 1 | Condition 2 | Condition 3 | |

| Health | 600 | 600 | 600 |

| bearing inner ring fault | 600 | 600 | 600 |

| bearing outer ring fault | 600 | 600 | 600 |

| bearing ball fault | 600 | 600 | 600 |

| Worn lead screw | 600 | 600 | 600 |

| screw bending | 600 | 600 | 600 |

| screw wear and bearing inner ring composite fault | 600 | 600 | 600 |

| screw wear and bearing outer ring composite fault | 600 | 600 | 600 |

| screw wear and bearing ball composite fault | 600 | 600 | 600 |

| Dimensional characteristic index | Calculation formula | Dimensionless characteristic index | Calculation formula |

| Maximum value | Peak factor | ||

| Peak value | Pulse factor | ||

| Average amplitude | Waveform factor | ||

| Absolute mean | Margin factor | ||

| Square root magnitude | Kurtosis | ||

| Variance | |||

| Root mean square value | Skewness |

| Frequency domain characteristic index | Calculation formula |

| Center of gravity frequency | |

| Mean square frequency | |

| Frequency variance |

| IMF1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | IMF8 | IMF9 | IMF10 |

| 0.150 | 0.239 | 0.200 | 0.286 | 0.185 | 0.220 | 0.611 | 0.684 | 0.132 | 0.009 |

| Predictive failure category (label) | Actual fault category (label) | ||||

| 1 | 2 | 3 | N | ||

| 1 | |||||

| 2 | |||||

| 3 | |||||

| N | |||||

| Speed change | Individual accuracy Ii/% | Overall accuracy T /% |

||||

| I1 | I2 | I3 | I4 | I5 | ||

| Speed up | 99.17 | 93.33 | 88.33 | 86.67 | 92.50 | 92.00 |

| Slow down | 95.00 | 90.83 | 86.67 | 93.33 | 87.50 | 90.67 |

| First up, then down. | 96.67 | 91.67 | 93.33 | 85.83 | 89.17 | 91.33 |

| First down, then up. | 95.00 | 91.67 | 85.83 | 85.83 | 90.83 | 89.83 |

| Average value | 96.46 | 91.88 | 88.54 | 87.92 | 90.00 | 90.96 |

| Comparison model | Overall accuracy T/% | Average Overall Accuracy/% | |||

| Speed up | Slow down | First up, then down. | First down, then up. | ||

| RF | 85.02 | 84.36 | 85.14 | 83.46 | 84.50 |

| AdaBoost | 85.23 | 84.15 | 84.92 | 83.54 | 84.46 |

| XGBoost | 88.54 | 87.23 | 87.96 | 86.87 | 87.65 |

| LightGBM | 87.83 | 86.92 | 87.25 | 86.05 | 87.01 |

| DoubleEnsemble-LightGBM | 91.96 | 90.83 | 91.33 | 90.17 | 91.07 |

| Label | Category | Number of training set samples | Number of test set samples |

| 1 | Health | 480 | 120 |

| 2 | Bearing inner ring failure | 480 | 120 |

| 3 | Bearing ball failure | 480 | 120 |

| 4 | Bearing outer ring failure | 480 | 120 |

| 5 | Worn lead screw | 480 | 120 |

| 6 | screw bending | 480 | 120 |

| 7 | Worn lead screw and bearing inner ring complex fault | 480 | 120 |

| 8 | Worn lead screw and bearing ball complex fault | 480 | 120 |

| 9 | Worn lead screw and bearing outer ring complex fault | 480 | 120 |

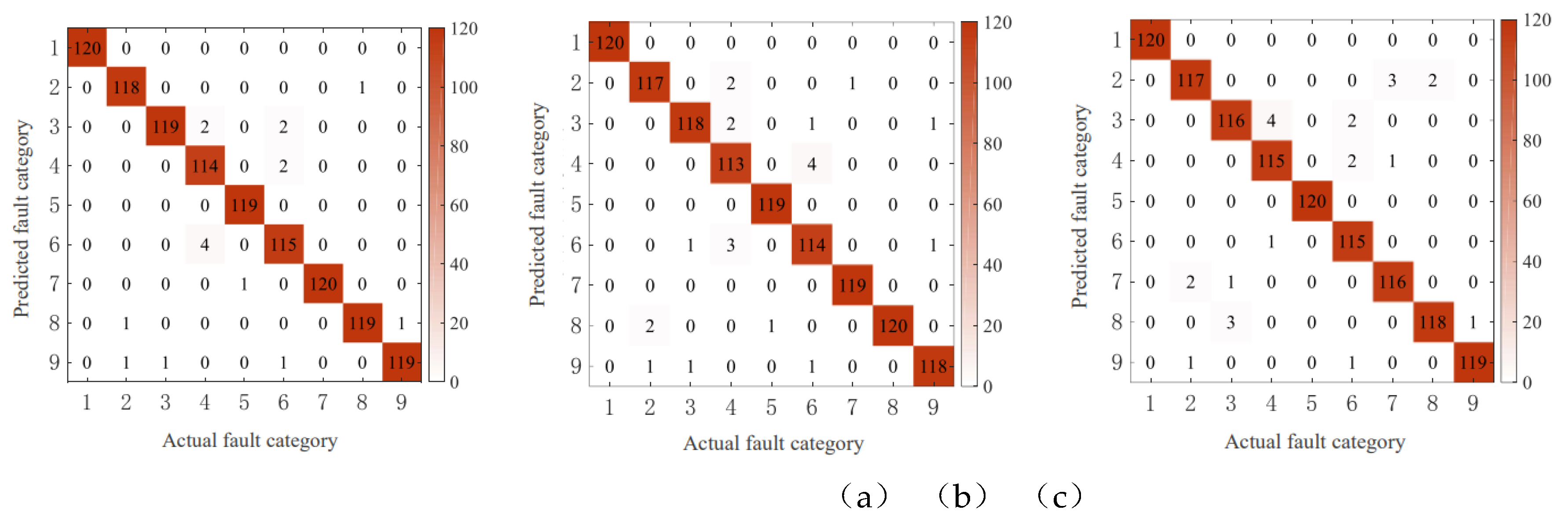

| Working condition | Individual accuracy Ii/% | Overall accuracy T /% |

||||||||

| I1 | I2 | I3 | I4 | I5 | I6 | I7 | I8 | I9 | ||

| 1 | 100 | 98.33 | 99.17 | 95.00 | 99.17 | 95.83 | 100 | 99.17 | 99.17 | 98.43 |

| 2 | 100 | 97.50 | 98.33 | 94.17 | 99.17 | 95.00 | 99.17 | 100 | 98.33 | 97.96 |

| 3 | 100 | 97.50 | 96.67 | 95.83 | 100 | 95.83 | 96.67 | 98.33 | 99.17 | 97.78 |

| Average value | 100 | 97.78 | 98.06 | 95.00 | 99.45 | 95.55 | 98.61 | 99.17 | 98.89 | 98.06 |

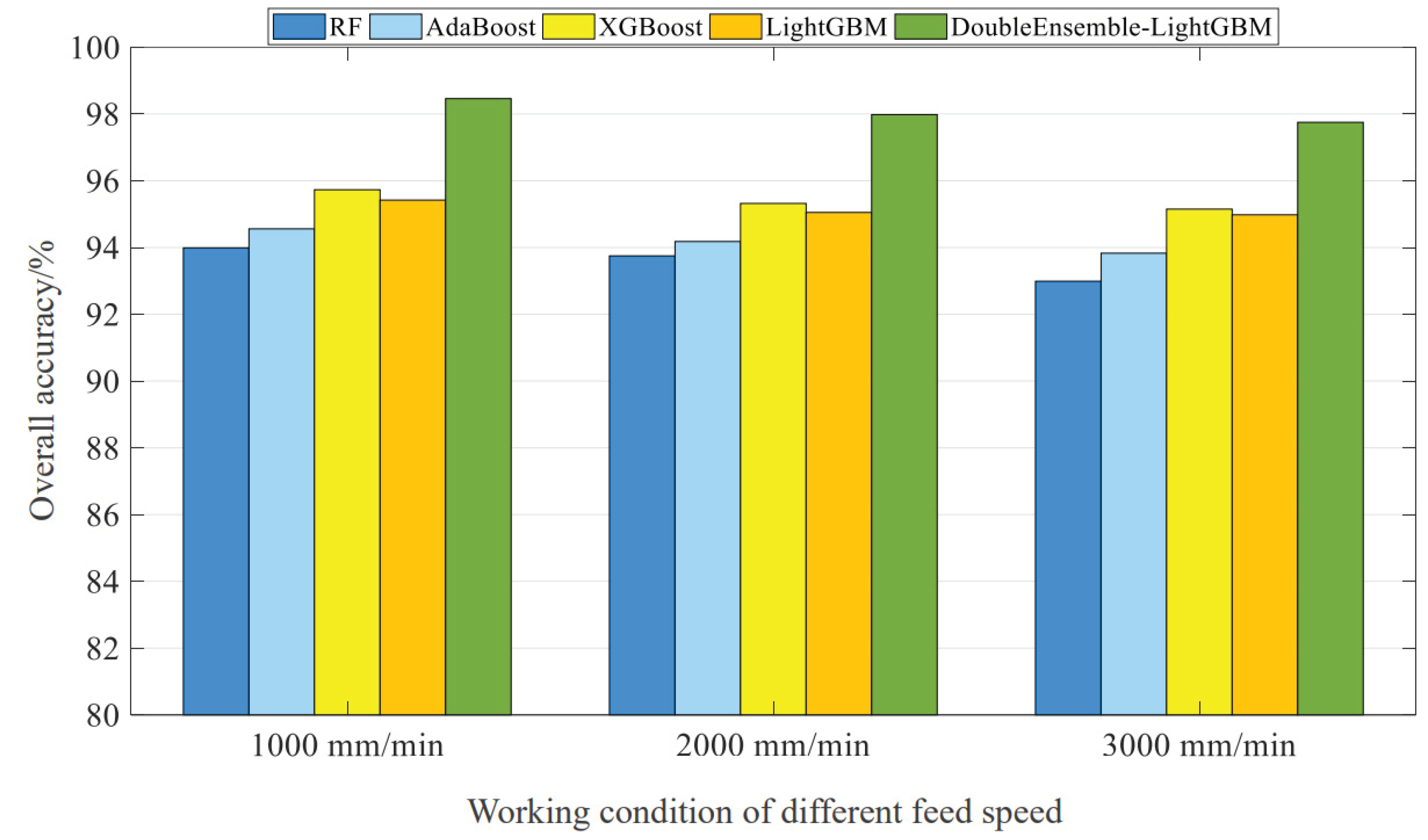

| Comparison model | Overall accuracy T/% | Average Overall Accuracy/% | ||

| Condition 1 | Condition 2 | Condition 3 | ||

| RF | 93.99 | 93.75 | 92.99 | 93.58 |

| AdaBoost | 94.56 | 94.18 | 93.83 | 94.19 |

| XGBoost | 95.73 | 95.32 | 95.15 | 95.4 |

| LightGBM | 95.42 | 95.05 | 94.98 | 95.15 |

| DoubleEnsemble-LightGBM | 98.46 | 97.98 | 97.75 | 98.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).