Submitted:

18 March 2024

Posted:

19 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

3. Experiments of Fingerprint Backup

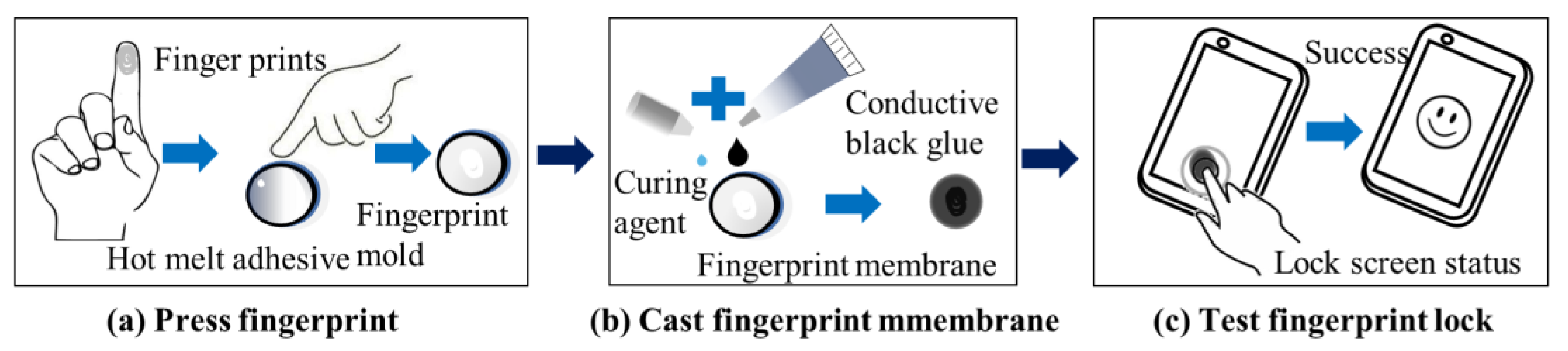

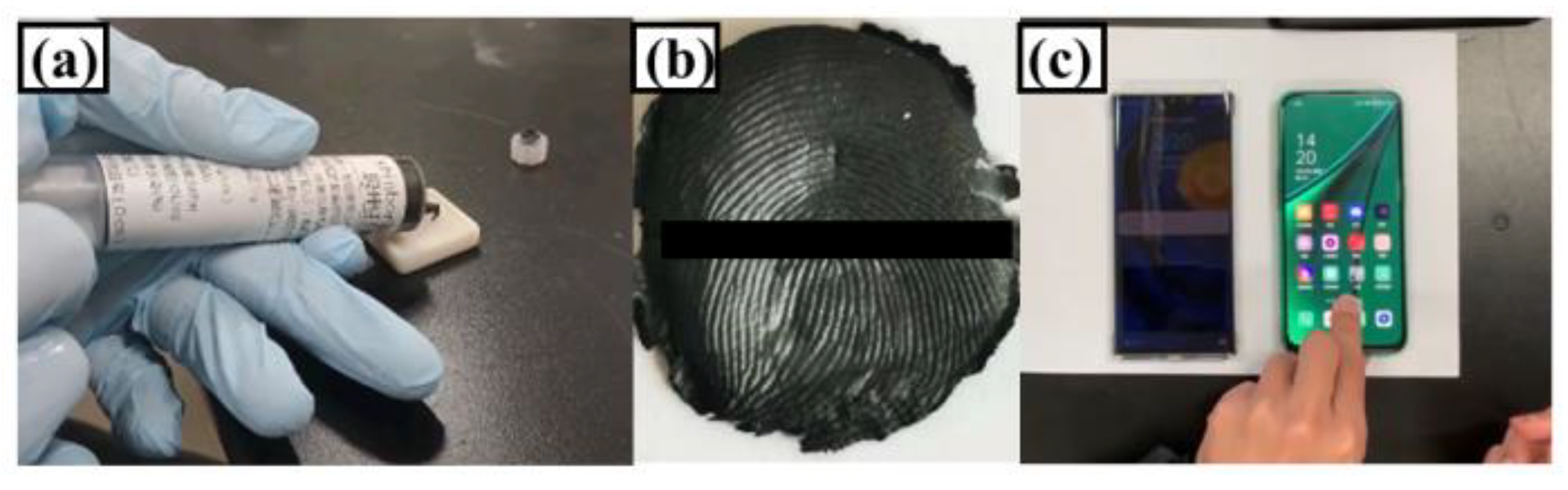

3.1. Fingerprint Backup Experiment Using Fingerprint Impression Technology

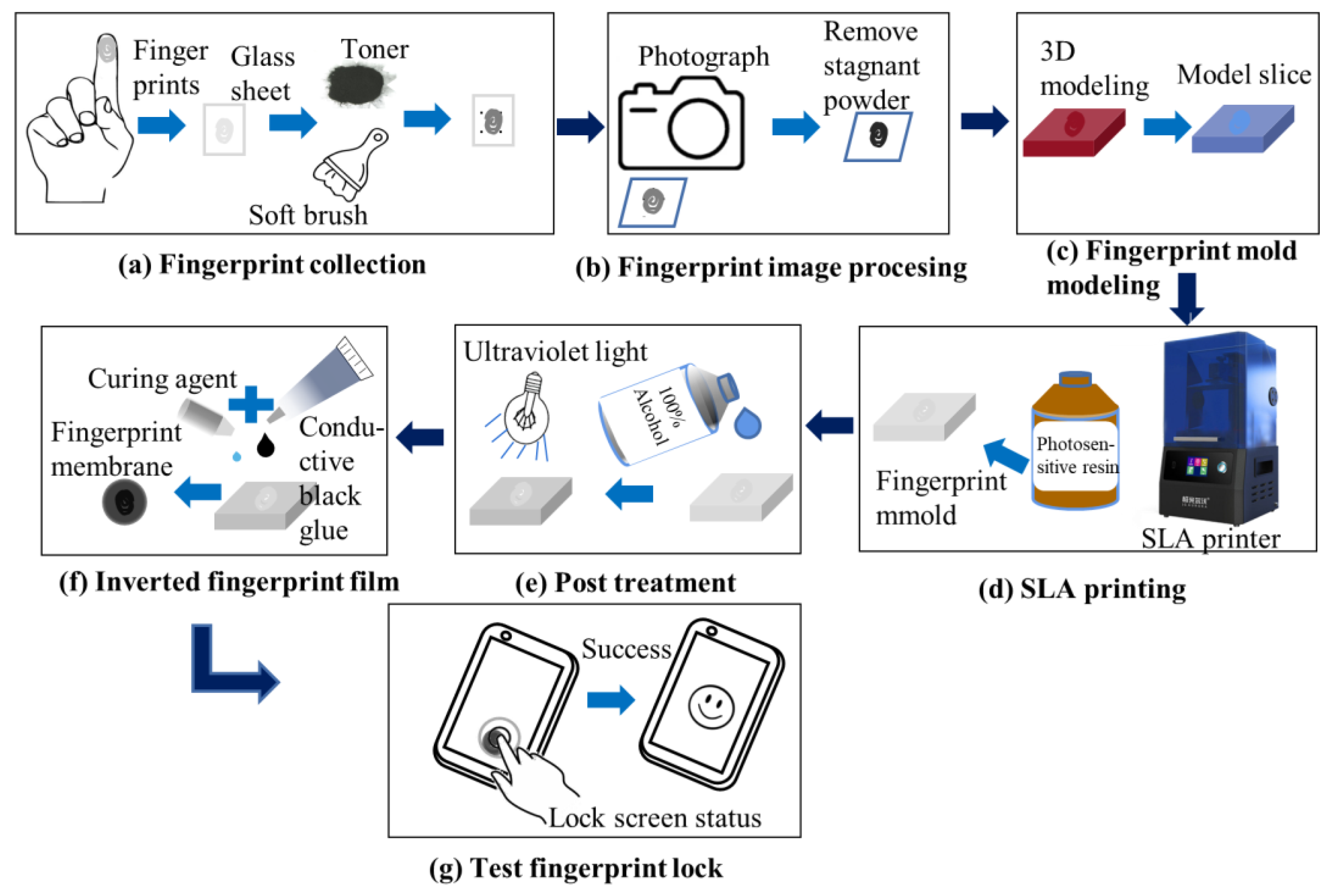

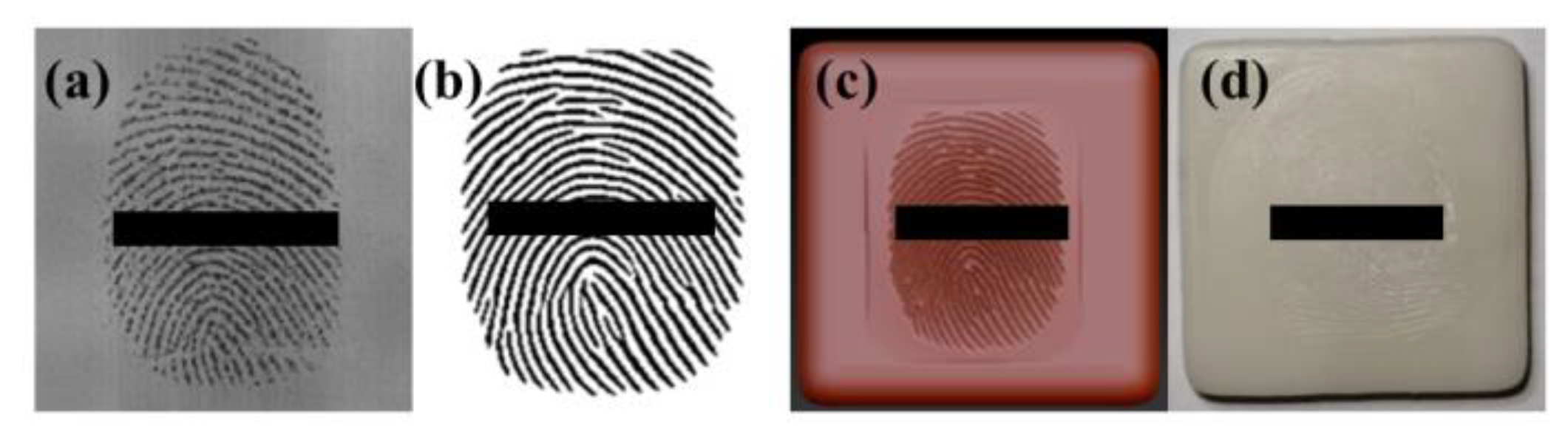

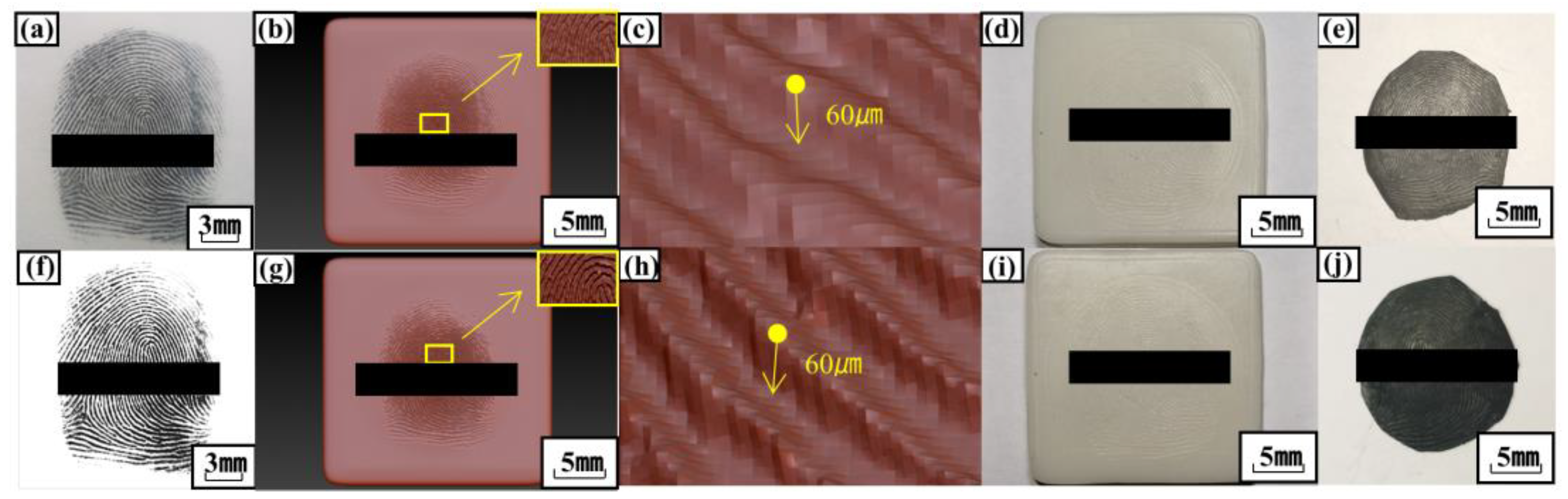

3.2. Fingerprint Backup Experiment Using SLA Printing

3.3. Unlocking Test Experiment

4. Results and Discussion

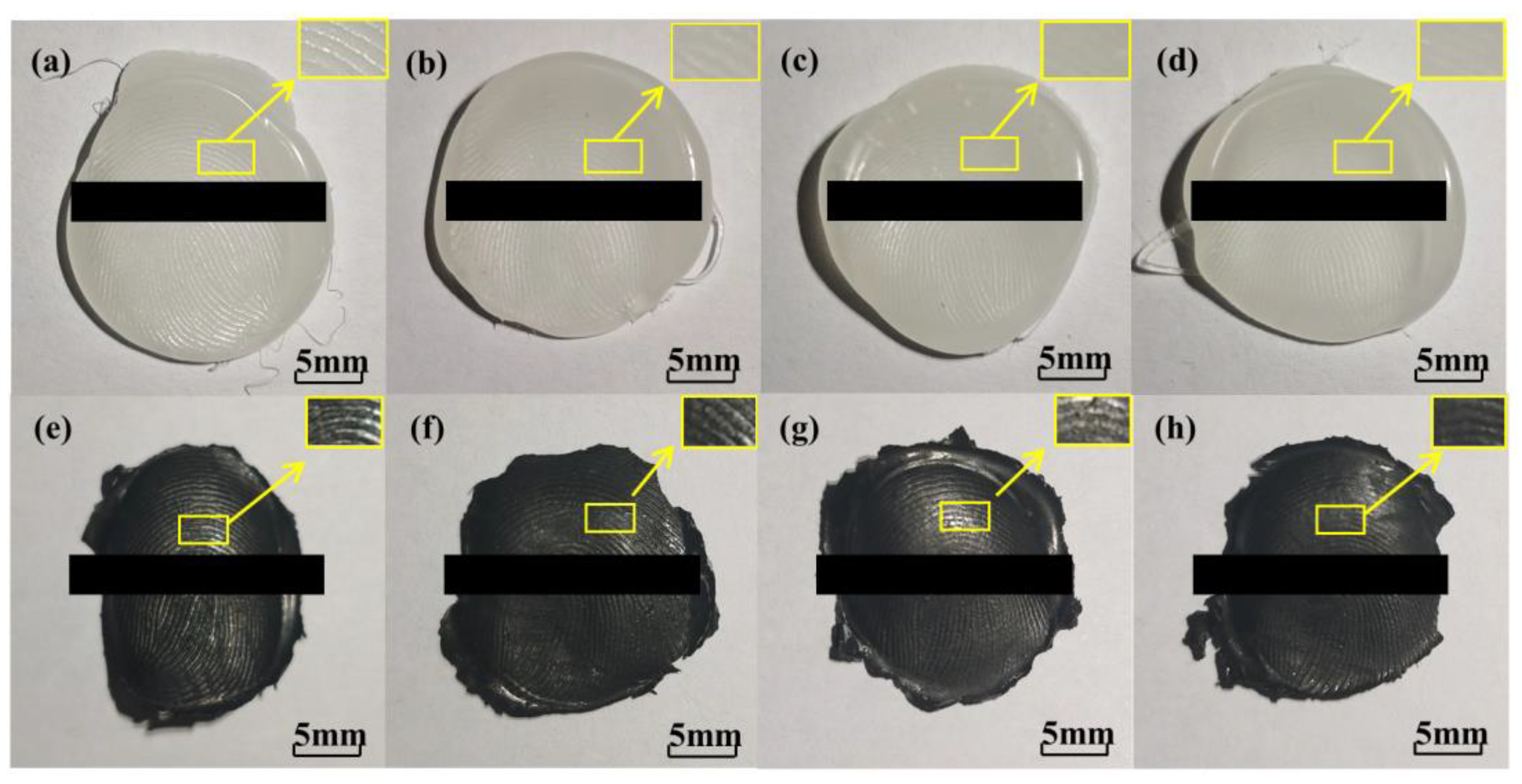

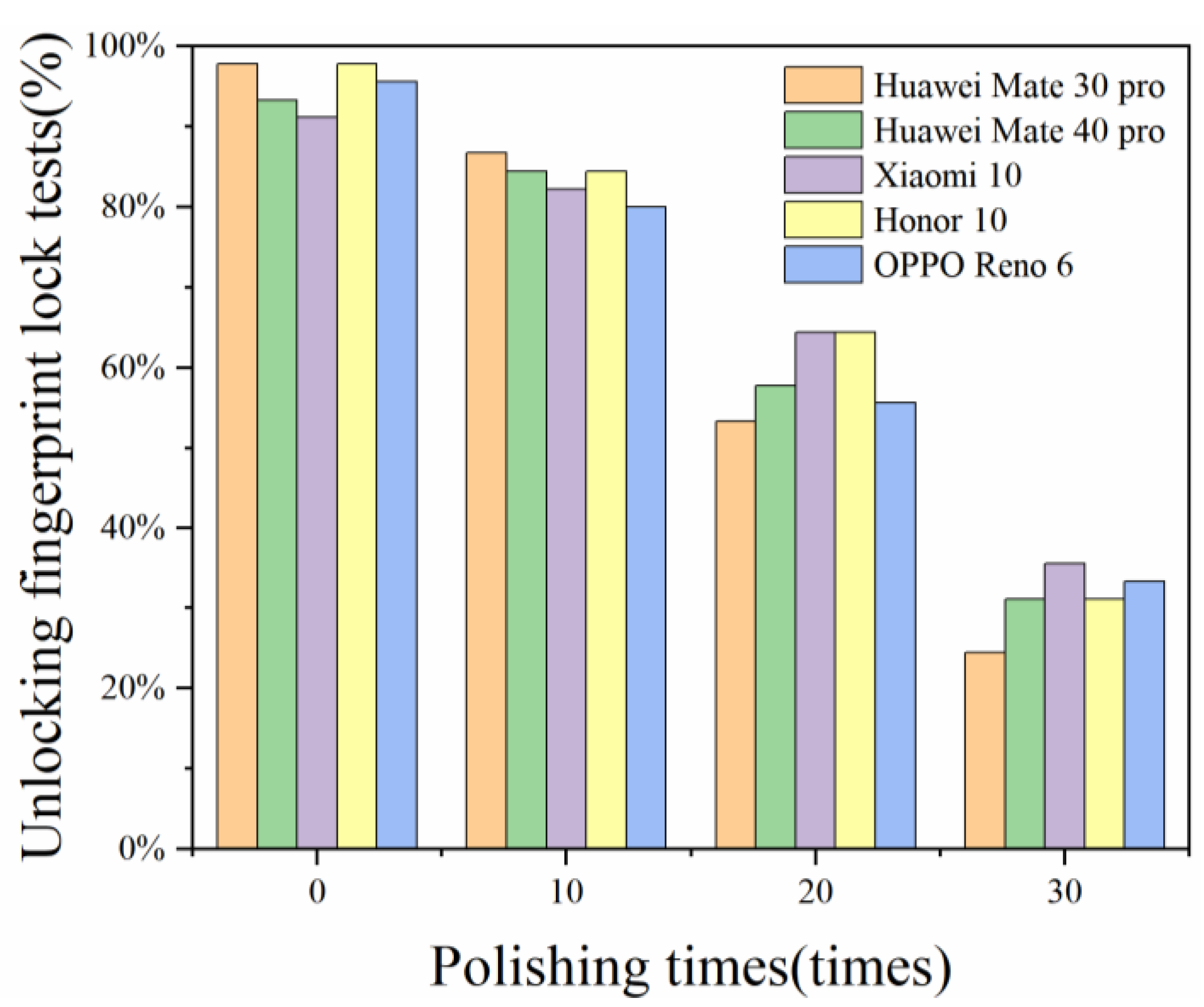

4.1. Impact of Finger Wear on the Unlocking Capability of Fingerprint Membranes Produced by Fingerprint Impression

4.2. Impact of Finger Wear on the Unlocking Capability of Fingerprint Membranes Produced by SLA Printing

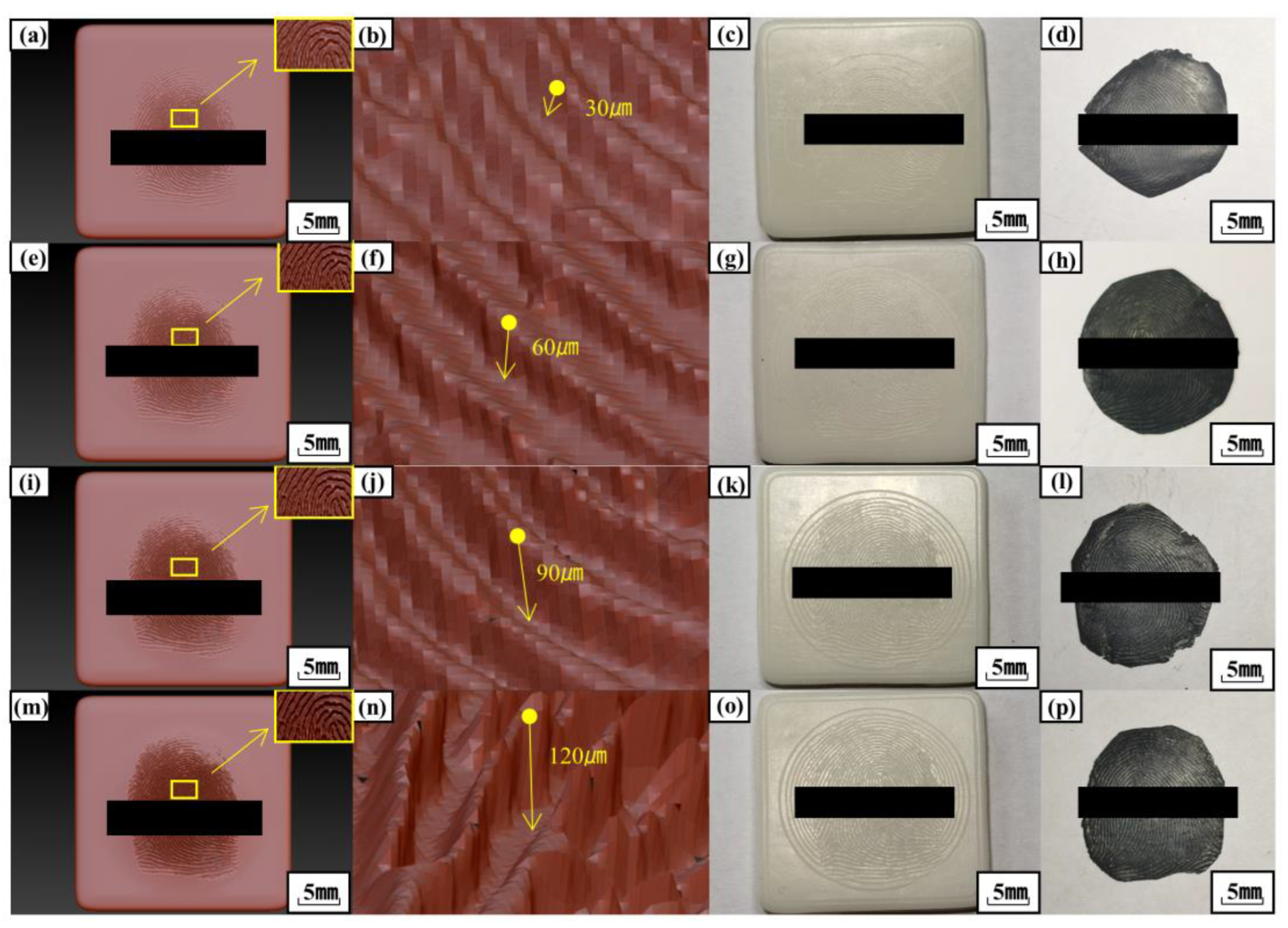

4.2.1. Impact of Fingerprint Image Processing on the Unlocking Effect of Fingerprint Film

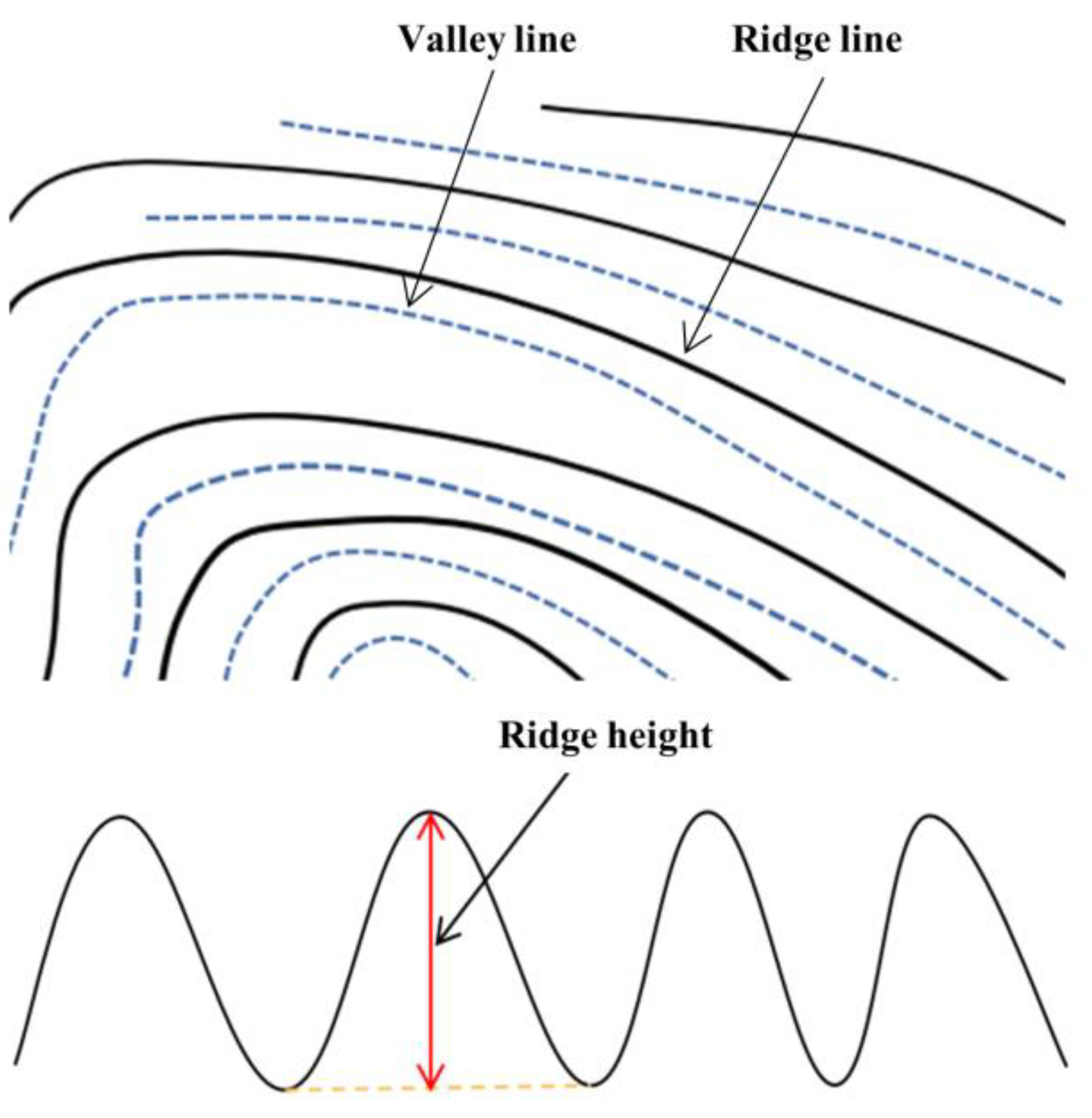

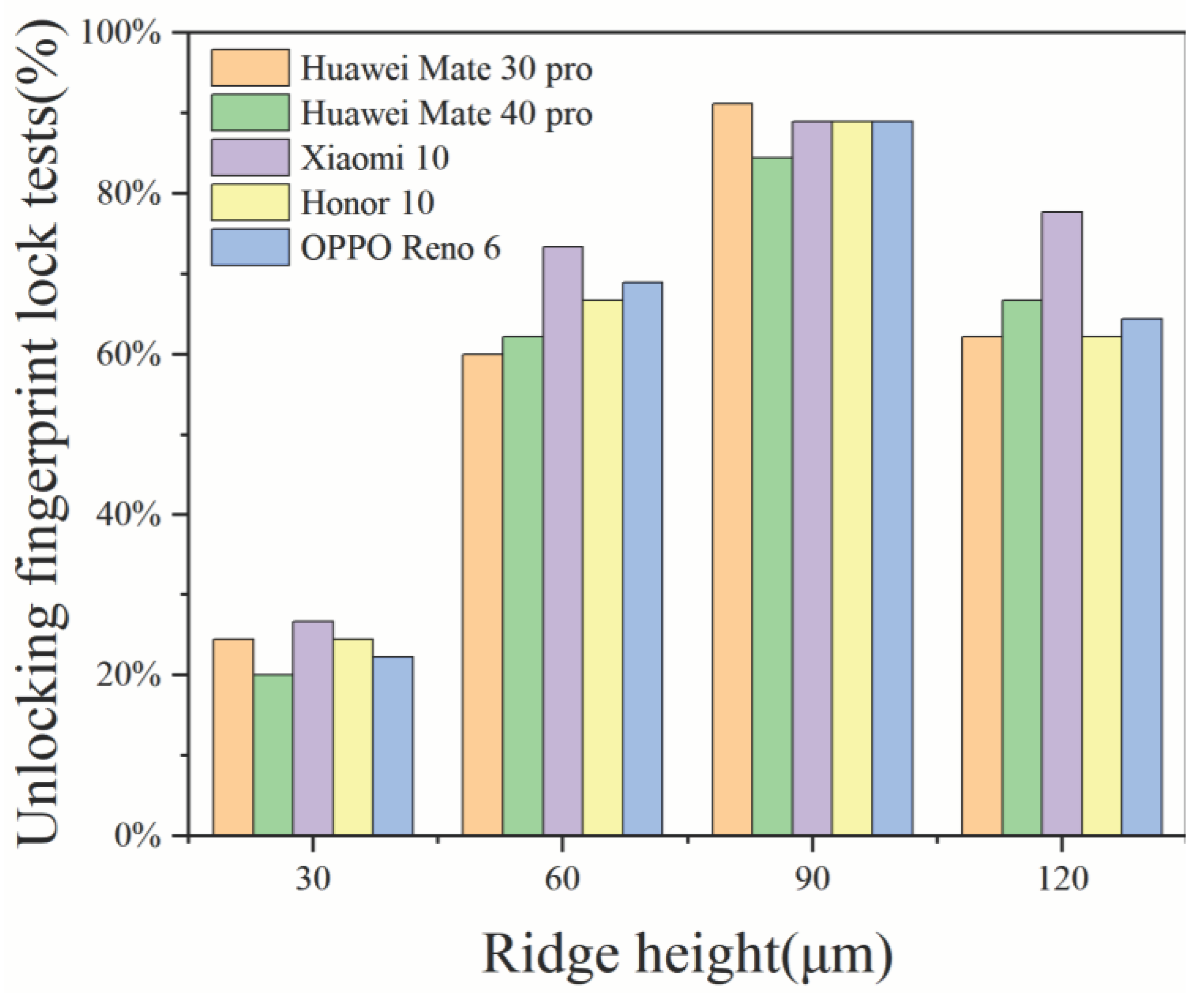

4.2.2. Influence of Different Ridge Heights on the Unlocking Effect of Fingerprint film

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Ma, R.; Zhang, M. Recent Progress in Visualization and Analysis of Fingerprint Level 3 Features. ChemistryOpen 2022, 11, e202200091. [Google Scholar] [CrossRef]

- Li, J. , Glover, J. D., Zhang, H., Peng, M., Tan, J., Mallick, C.B., Hou, D., Yang, Y., Wu, S., Liu, Y., et al.Limb Development Genes Underlie Variation in Human Fingerprint Patterns. Cell 2022, 185, 95–112. [Google Scholar]

- Rivalderia, N.; Gutierrez-Redomero, E.; Alonso-Rodriguez, C.; Dipierri, J.E.; Martin, L.M. Study of Fingerprints in Argentina Population for Application in Personal Identification. Sci Justice 2017, 57, 199–208. [Google Scholar] [CrossRef]

- Wang, C.N.; Wang, J.W.; Lin, M.H.; Chang, Y.L.; Kuo, C.M. Optical Methods in Fingerprint Imaging for Medical and Personality Applications. Sensors (Basel) 2017, 17, 2418. [Google Scholar] [CrossRef]

- Abbasi, S.; Ayyoubzadeh, S.M. The Role of Hand Fingerprints on Predisposition of Cancer Development. Heliyon. 2023, 9, e14074. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Ma, W.; Xiao, X. The Recognition of Sweat Latent Fingerprints with Green-Emitting Carbon Dots. Nanomaterials (Basel). 2018, 8, 612. [Google Scholar] [CrossRef] [PubMed]

- Van Dam, A.; Van Beek, F.T.; Aalders, M.C.; Van Leeuwen, T.G.; Lambrechts, S.A. Techniques That Acquire Donor Profiling Information from Fingermarks - a Review. Sci Justice. 2016, 56, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Baldini, G.; Steri, G. A Survey of Techniques for the Identification of Mobile Phones Using the Physical Fingerprints of the Built-in Components. IEEE Communications Surveys & Tutorials. 2017, 19, 1761–1789. [Google Scholar]

- Monson, K.L.; Roberts, M.A.; Knorr, K.B.; Ali, S.; Meagher, S.B.; Biggs, K.; Blume, P.; Brandelli, D.; Marzioli, A.; Reneau, R.; et al. The Permanence of Friction Ridge Skin and Persistence of Friction Ridge Skin and Impressions: A Comprehensive Review and New Results. Forensic Sci Int. 2019, 297, 111–131. [Google Scholar] [CrossRef]

- Bossen, A.; Lehmann, R.; Meier, C. Internal Fingerprint Identification with Optical Coherence Tomography. IPTL. 2010, 22, 507–509. [Google Scholar] [CrossRef]

- Chugh, T.; Jain, A.K. Fingerprint Spoof Detector Generalization. IEEE Transactions on Information Forensics and Security. 2021, 16, 42–55. [Google Scholar] [CrossRef]

- Chen, X.; Feng, X.; Li, Y.; Duan, R.; Wang, L.; Li, Y.; Xuan, M.; Tan, Q.; Dong, X. An Image Unmixing and Stitching Deep Learning Algorithm for in-Screen Fingerprint Recognition Application. Electronics. 2023, 12, 3768. [Google Scholar] [CrossRef]

- Seo, W.; Pi, J.E.; Cho, S.H.; Kang, S.Y.; Ahn, S.D.; Hwang, C.S.; Jeon, H.S.; Kim, J.U.; Lee, M. Transparent Fingerprint Sensor System for Large Flat Panel Display. Sensors (Basel) 2018, 18, 293. [Google Scholar] [CrossRef]

- Jin, X.; Fan, X.; Liu, Z.; Kuang, Z.; Yang, J. Sensitivity and Crosstalk Study of the Zero Gap Microlens Used in 3. 2μm Active Pixel Image Sensors. MiEng. 2010, 87, 631–634. [Google Scholar]

- Tang, H.-Y.; Lu, Y.; Jiang, X.; Ng, E.J.; Tsai, J.M.; Horsley, D.A.; Boser, B.E. 3-D Ultrasonic Fingerprint Sensor-on-a-Chip. IJSSC. 2016, 51, 2522–2533. [Google Scholar] [CrossRef]

- Iula, A. Ultrasound Systems for Biometric Recognition. Sensors (Basel). 2019, 19, 2317. [Google Scholar] [CrossRef] [PubMed]

- Makar, A.B.; Mcmartin, K.E.; Palese, M.; Tephly, T.R. Formate Assay in Body Fluids: Application in Methanol Poisoning. Biochem. Med. 1975, 13, 117–126. [Google Scholar] [CrossRef]

- Kauba, C.; Sollinger, D.; Kirchgasser, S.; Weissenfeld, A.; Fernandez Dominguez, G.; Strobl, B.; Uhl, A. Towards Using Police Officers’ Business Smartphones for Contactless Fingerprint Acquisition and Enabling Fingerprint Comparison against Contact-Based Datasets. Sensors (Basel). 2021, 21, 2248. [Google Scholar] [CrossRef]

- Xie, H.; Zhou, Z. Research on Fingerprint Film Cracking Technology Based on Mobile Phone Fingerprint Lock. China Public Security (Academic Edition). 2017, 126-131.

- Engelsma, J.J.; Arora, S.S.; Jain, A.K.; Paulter, N.G. Universal 3d Wearable Fingerprint Targets: Advancing Fingerprint Reader Evaluations. IEEE Transactions on Information Forensics and Security. 2018, 13, 1564–1578. [Google Scholar] [CrossRef]

- Maro, E.A.; Kovalchuk, M. 2018.

- Arora, S.S.; Cao, K.; Jain, A.K.; Paulter, N.G. Design and Fabrication of 3d Fingerprint Targets. IEEE Transactions on Information Forensics and Security. 2016, 11, 2284–2297. [Google Scholar] [CrossRef]

- Lefkowitz, R.J. Identification of Adenylate Cyclase-Coupled Beta-Adrenergic Receptors with Radiolabeled Beta-Adrenergic Antagonists. Biochem Pharmacol. 1975, 24, 1651–1658. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, T.; Matsumoto, H.; Yamada, K.; Hoshino, S. Impact of Artificial "Gummy" Fingers on Fingerprint Systems. Proceedings of Spie the International Society for Optical Engineering. 2002, 26, 275–289. [Google Scholar]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3d Printing. Polymers (Basel). 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

| Huawei Mate 30 pro | Huawei Mate 40 pro | Xiaomi 10 | Honor 10 | OPPO Reno 6 | |

|---|---|---|---|---|---|

| Untreated fingerprint images | 20.0% | 28.9% | 22.2% | 24.4% | 26.7% |

| Processed fingerprint images | 60.0% | 62.2% | 73.3% | 66.7% | 68.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).