Submitted:

19 March 2024

Posted:

22 March 2024

You are already at the latest version

Abstract

Keywords:

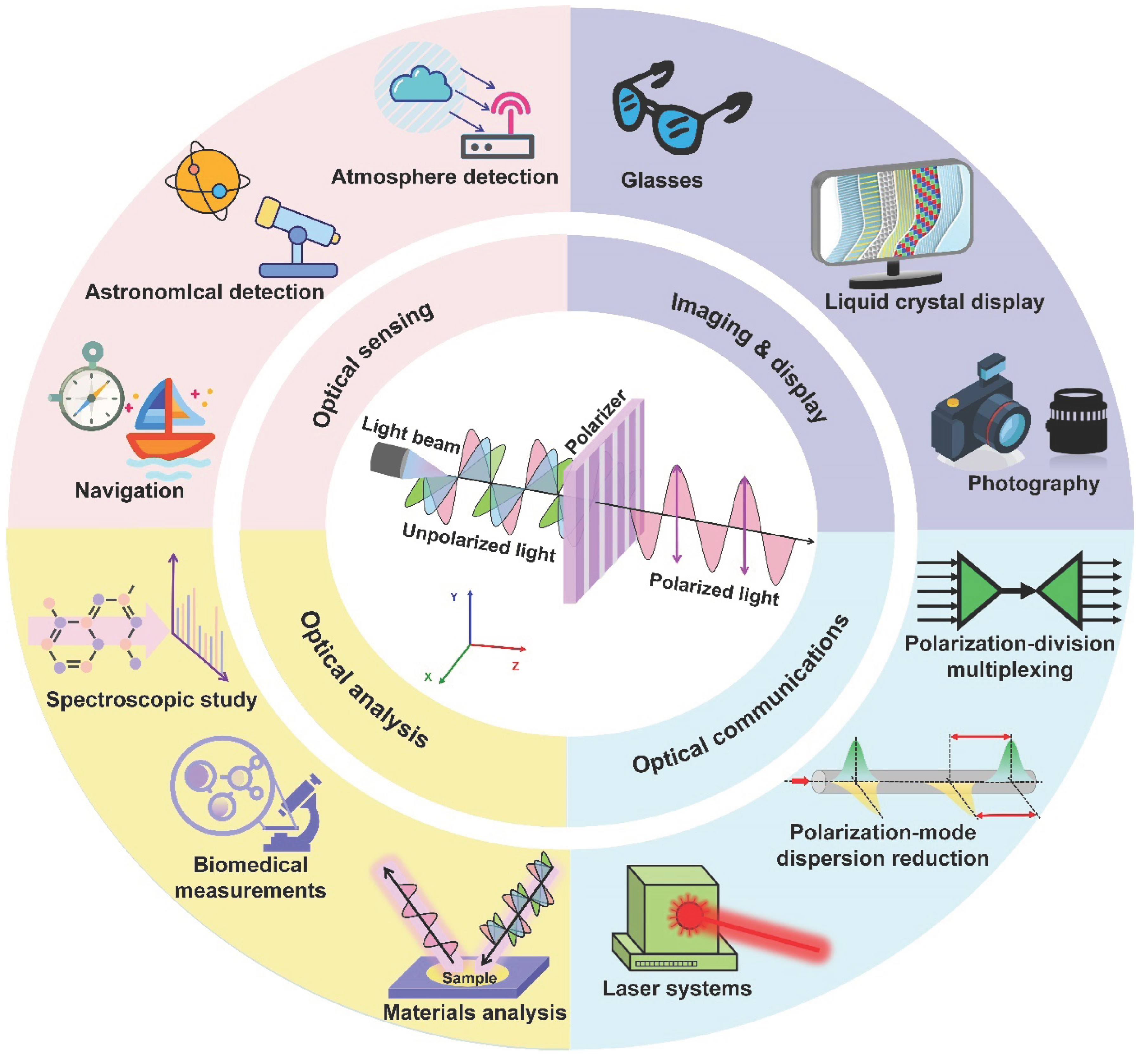

Introduction

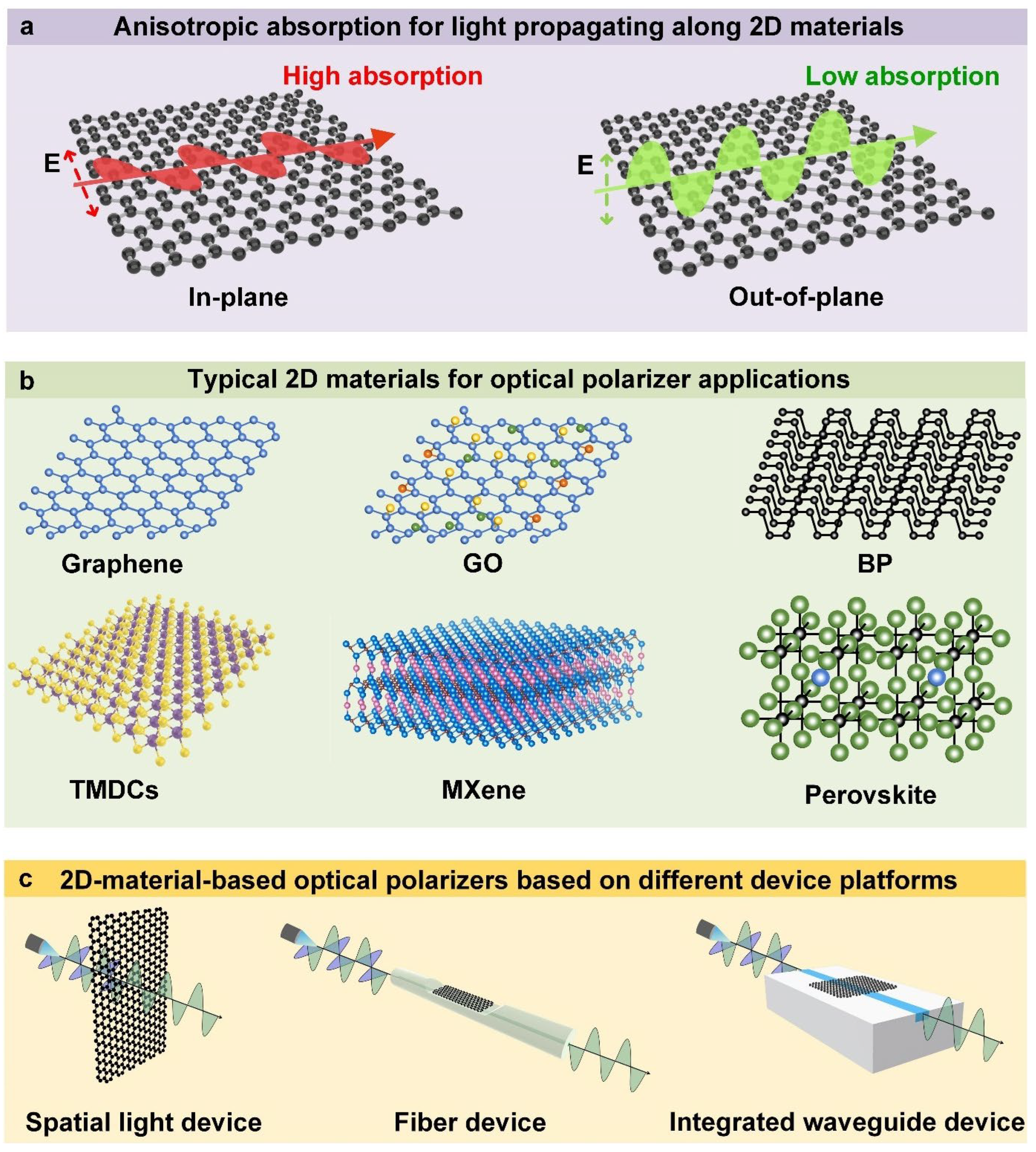

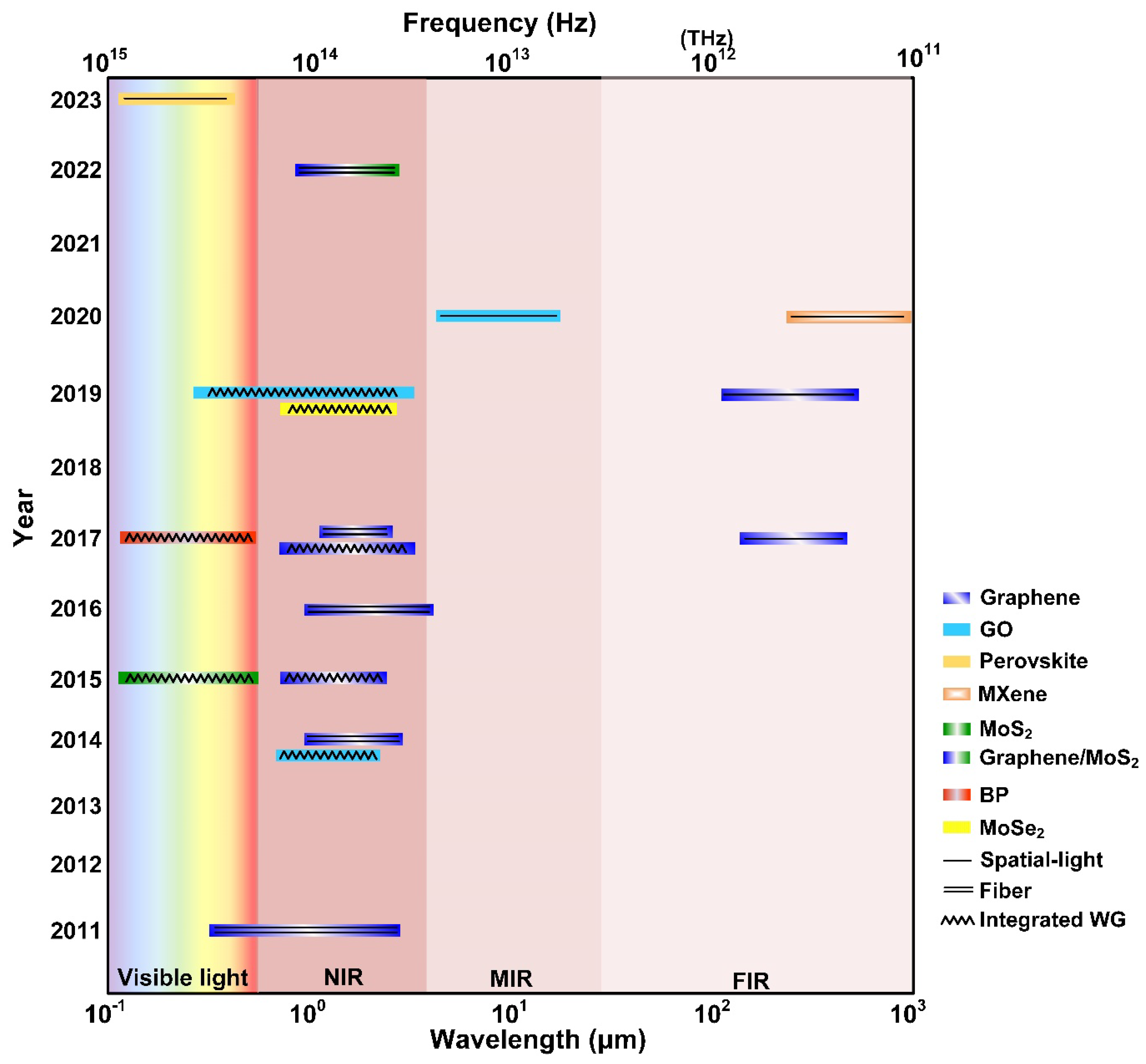

Properties of 2D Materials for Optical Polarizers

Graphene

Graphene Oxide

Transition Metal Dichalcogenides

Black Phosphorus

MXene

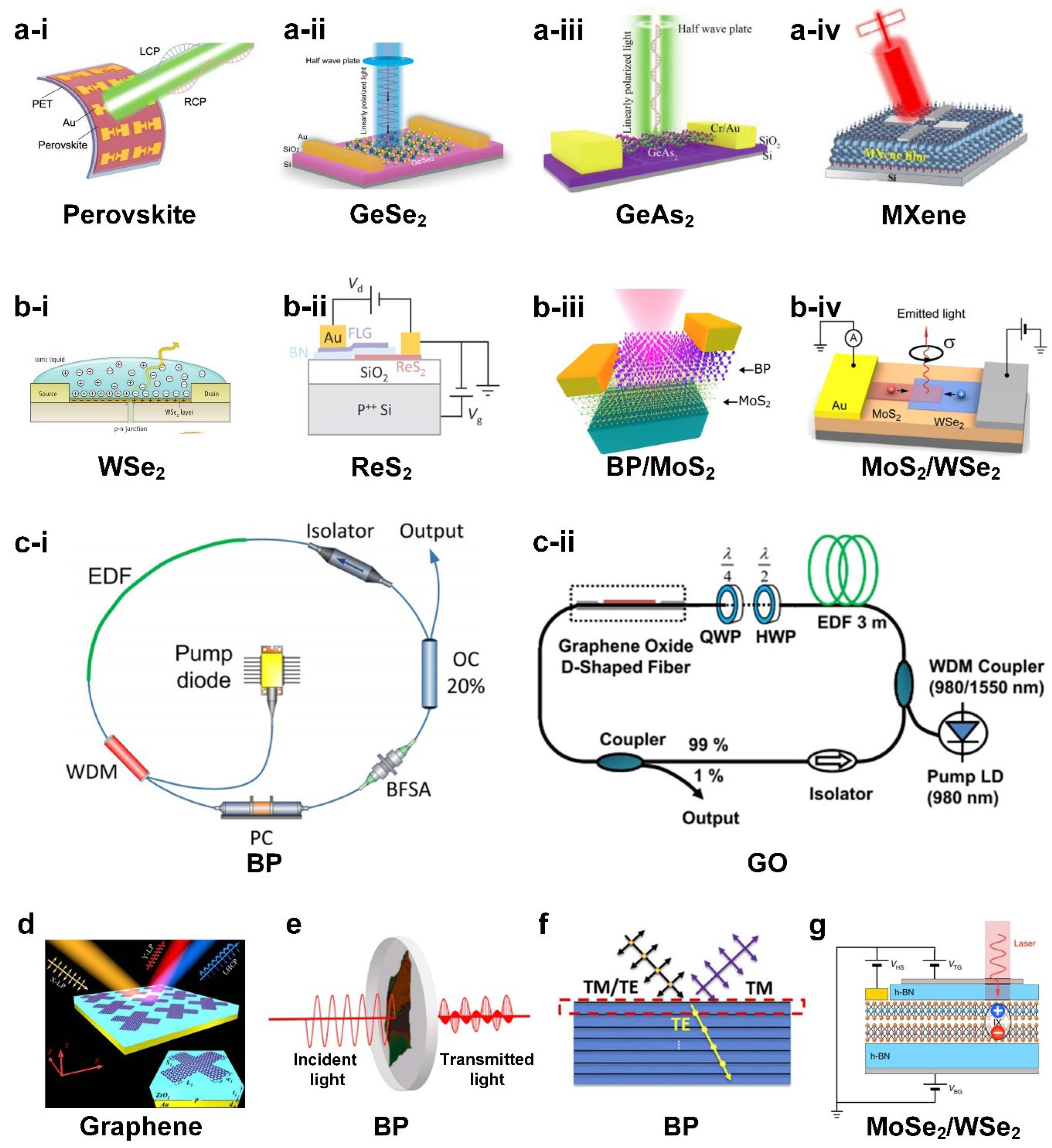

Perovskites

Van der Waals Heterostructures

2D-Material-Based Optical Polarizers in Different Device Platforms

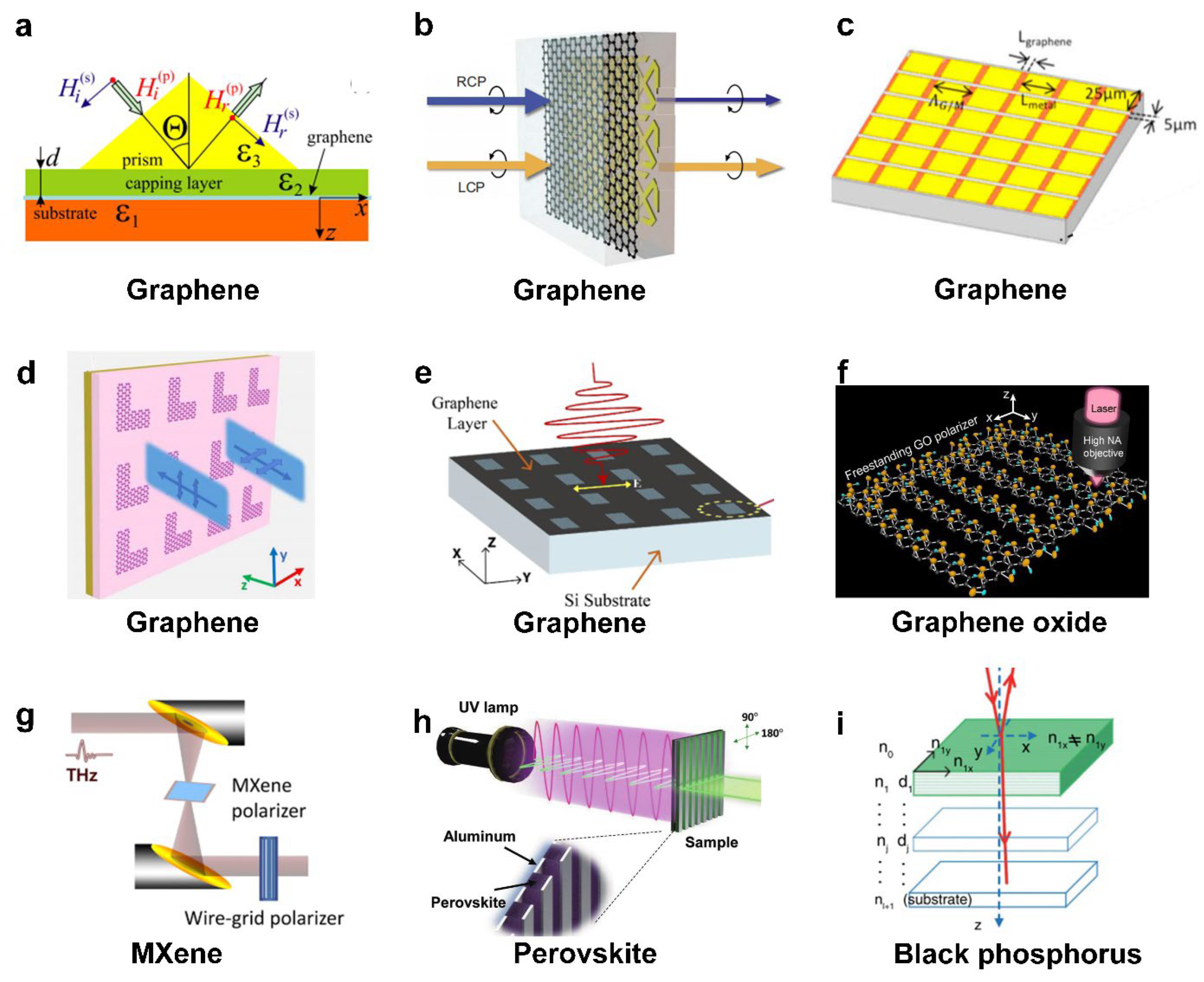

Spatial-Light Devices

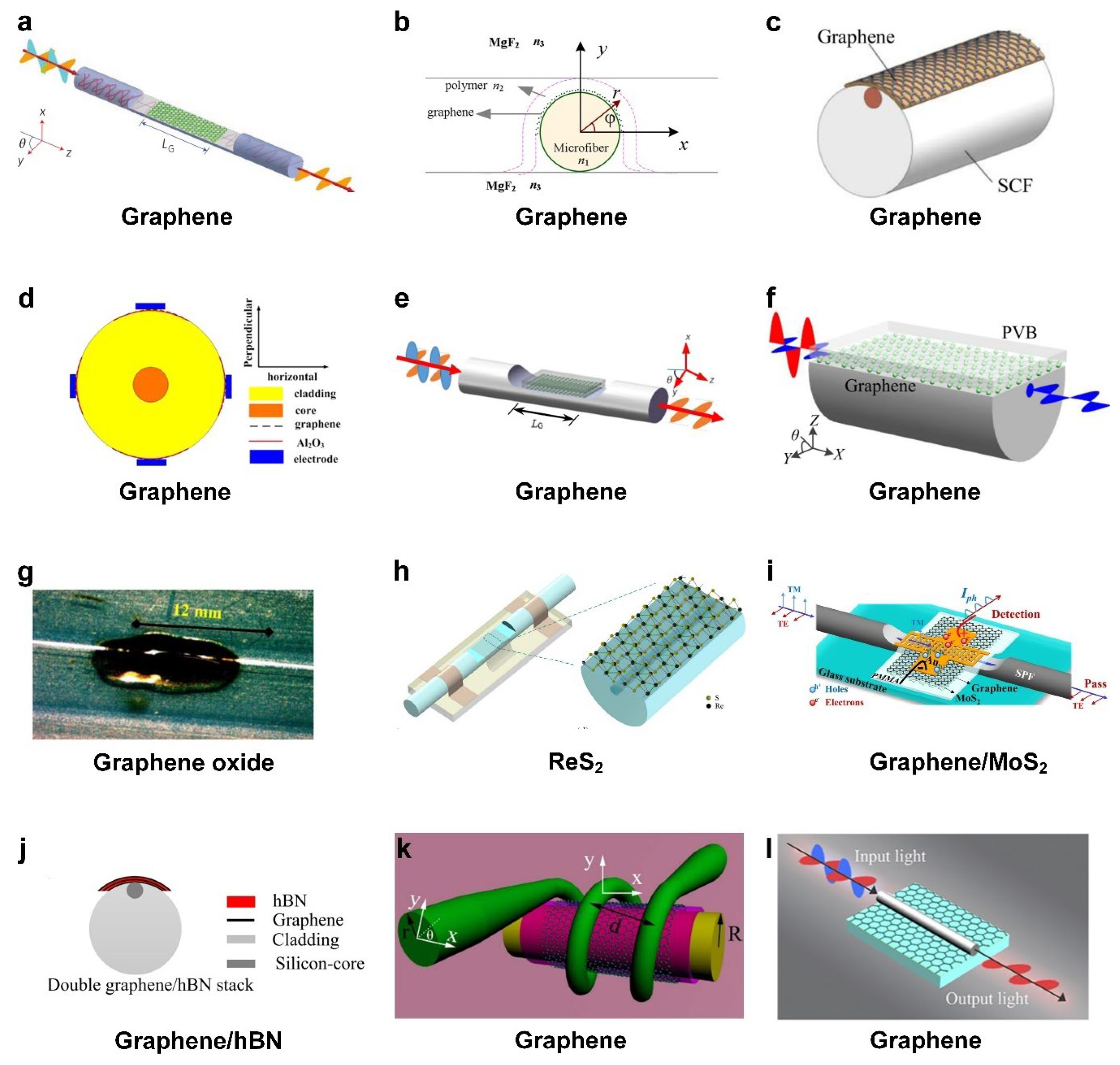

Fiber Devices

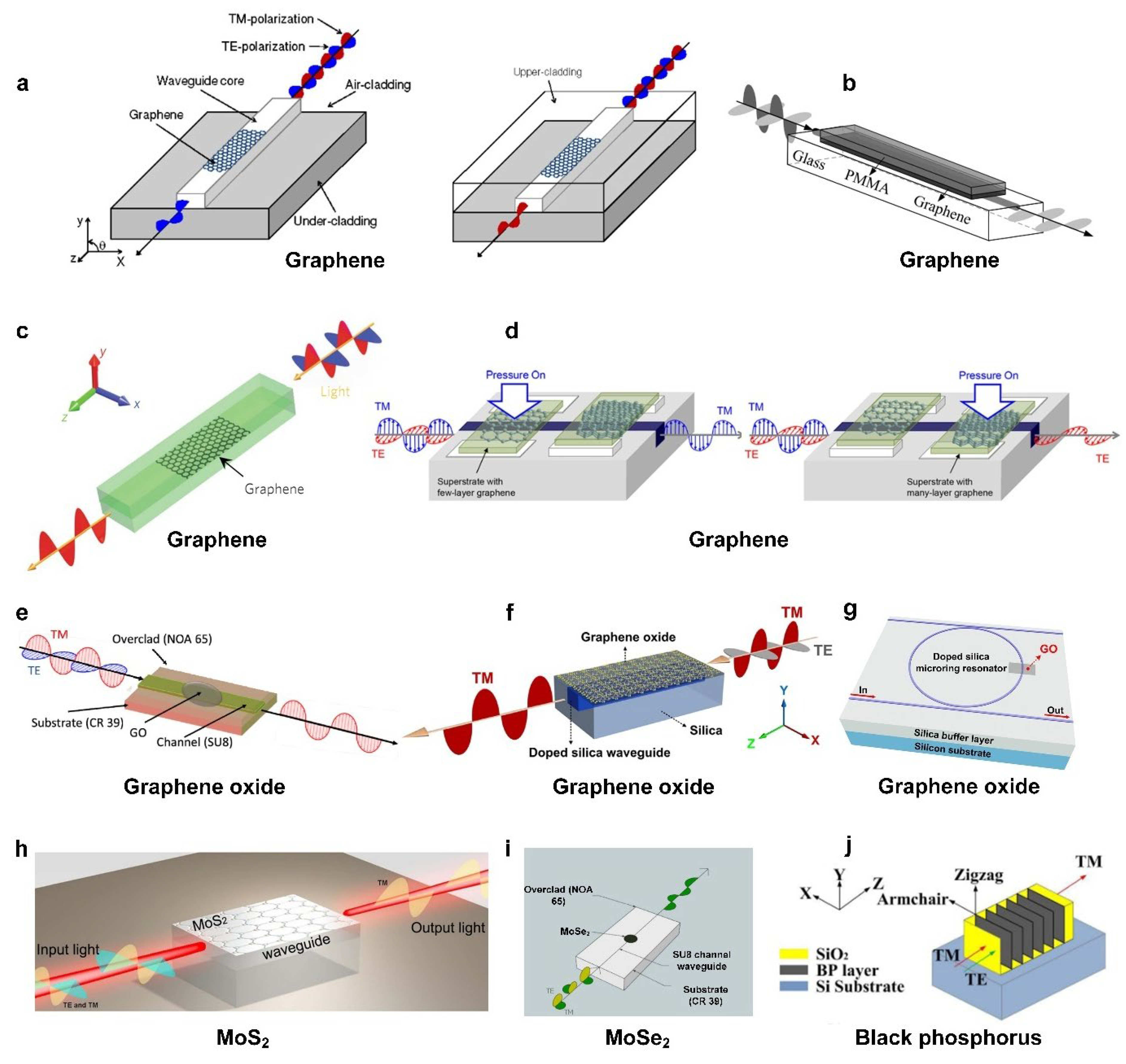

Integrated Waveguide Devices

Challenges and Perspectives

Conclusion

Conflicts of Interest

References

- Yan, Y.; Xie, G.; Lavery, M.P.J.; Huang, H.; Ahmed, N.; Bao, C.; Ren, Y.; Cao, Y.; Li, L.; Zhao, Z. High-capacity millimetre-wave communications with orbital angular momentum multiplexing. Nat. Commun. 2014, 5, 4876. [Google Scholar] [CrossRef] [PubMed]

- Dai, D.; Liu, L.; Gao, S.; Xu, D.; He, S. Polarization management for silicon photonic integrated circuits. Laser Photon- Rev. 2012, 7, 303–328. [Google Scholar] [CrossRef]

- Chu, J.; Zhao, K.; Zhang, Q.; Wang, T. Construction and performance test of a novel polarization sensor for navigation. Sensors Actuators A: Phys. 2008, 148, 75–82. [Google Scholar] [CrossRef]

- Thilak, V.; Voelz, D.G.; Creusere, C.D. Polarization-based index of refraction and reflection angle estimation for remote sensing applications. Appl. Opt. 2007, 46, 7527–7536. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-T.; Lin, H.-Y.; Tsai, C.-H. Designs of broadband and wide-view patterned polarizers for stereoscopic 3D displays. Opt. Express 2010, 18, 27079–27094. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Park, J.-D.; Lee, K.-D. Fabrication of a nano-wire grid polarizer for brightness enhancement in liquid crystal display. Nanotechnology 2006, 17, 4436–4438. [Google Scholar] [CrossRef]

- Cho, Y.T. Fabrication of wire grid polarizer for spectroscopy application: From ultraviolet to terahertz. Appl. Spectrosc. Rev. 2017, 53, 224–245. [Google Scholar] [CrossRef]

- He, C.; He, H.; Chang, J.; Chen, B.; Ma, H.; Booth, M.J. Polarisation optics for biomedical and clinical applications: a review. Light. Sci. Appl. 2021, 10, 1–20. [Google Scholar] [CrossRef]

- Han, Y.; Li, G. Coherent optical communication using polarization multiple-input-multiple-output. Opt. Express 2005, 13, 7527–7534. [Google Scholar] [CrossRef]

- Zhang, Z.; Gan, J.; Yang, T.; Wu, Y.; Li, Q.; Xu, S.; Yang, Z. All-fiber mode-locked laser based on microfiber polarizer. Opt. Lett. 2015, 40, 784–787. [Google Scholar] [CrossRef]

- Li, Z.; Xu, B.; Liang, D.; Pan, A. Polarization-Dependent Optical Properties and Optoelectronic Devices of 2D Materials. Research 2020, 2020. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Ke, C.; Tang, W.; Liu, M.; Huang, F.; Wu, Y.; Wu, Z.; Kang, J. Review of Anisotropic 2D Materials: Controlled Growth, Optical Anisotropy Modulation, and Photonic Applications. Laser Photon- Rev. 2021, 15, 2100322. [Google Scholar] [CrossRef]

- Akkanen, S.M.; Fernandez, H.A.; Sun, Z. Optical Modification of 2D Materials: Methods and Applications. Adv. Mater. 2022, 34, 2110152. [Google Scholar] [CrossRef] [PubMed]

- Xia, F.; Wang, H.; Xiao, D.; Dubey, M.; Ramasubramaniam, A. Two-dimensional material nanophotonics. Nat. Photon- 2014, 8, 899–907. [Google Scholar] [CrossRef]

- Autere, A. , et al., Nonlinear Optics with 2D Layered Materials. Adv Mater, 2018. 30(24): p. e1705963.

- Bao, Q.; Zhang, H.; Wang, B.; Ni, Z.; Lim, C.H.Y.X.C.; Wang, Y.Y.; Tang, D.Y.D.; Loh, K. Broadband graphene polarizer. Nat. Photon- 2011, 5, 411–415. [Google Scholar] [CrossRef]

- Kim, J.T.; Choi, C.-G. Graphene-based polymer waveguide polarizer. Opt. Express 2012, 20, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Kou, J.-L.; Chen, J.-H.; Chen, Y.; Xu, F.; Lu, Y.-Q. Platform for enhanced light–graphene interaction length and miniaturizing fiber stereo devices. Optica 2014, 1, 307–310. [Google Scholar] [CrossRef]

- Kim, T.-T.; Oh, S.S.; Kim, H.-D.; Park, H.S.; Hess, O.; Min, B.; Zhang, S. Electrical access to critical coupling of circularly polarized waves in graphene chiral metamaterials. Sci. Adv. 2017, 3, e1701377–1701377. [Google Scholar] [CrossRef]

- Lin, H.; Song, Y.; Huang, Y.; Kita, D.; Deckoff-Jones, S.; Wang, K.; Li, L.; Li, J.; Zheng, H.; Luo, Z.; et al. Chalcogenide glass-on-graphene photonics. Nat. Photonics 2017, 11, 798–805. [Google Scholar] [CrossRef]

- Kim, J.T.; Choi, H. Polarization Control in Graphene-Based Polymer Waveguide Polarizer. Laser Photon- Rev. 2018, 12. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K. and K.S. Novoselov, The rise of graphene. Nature materials, 2007. 6(3): p. 183-191.

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308–1308. [Google Scholar] [CrossRef] [PubMed]

- Meng, K.; Park, S.J.; Li, L.H.; Bacon, D.R.; Chen, L.; Chae, K.; Park, J.Y.; Burnett, A.D.; Linfield, E.H.; Davies, A.G.; et al. Tunable broadband terahertz polarizer using graphene-metal hybrid metasurface. Opt. Express 2019, 27, 33768–33778. [Google Scholar] [CrossRef] [PubMed]

- Sarker, D.; Nakti, P.P.; Tahmid, I.; Mamun, A.Z.; Zubair, A. Terahertz polarizer based on tunable surface plasmon in graphene nanoribbon. Opt. Express 2021, 29, 42713–42725. [Google Scholar] [CrossRef]

- Phare, C.T.; Lee, Y.-H.D.; Cardenas, J.; Lipson, M. Graphene electro-optic modulator with 30 GHz bandwidth. Nat. Photonics 2015, 9, 511–514. [Google Scholar] [CrossRef]

- Liu, M.; Yin, X.; Ulin-Avila, E.; Geng, B.; Zentgraf, T.; Ju, L.; Wang, F.; Zhang, X. A graphene-based broadband optical modulator. Nature 2011, 474, 64–67. [Google Scholar] [CrossRef] [PubMed]

- Yao, B.; Huang, S.-W.; Liu, Y.; Vinod, A.K.; Choi, C.; Hoff, M.; Li, Y.; Yu, M.; Feng, Z.; Kwong, D.-L.; et al. Gate-tunable frequency combs in graphene–nitride microresonators. Nature 2018, 558, 410–414. [Google Scholar] [CrossRef] [PubMed]

- Loh, K.P.; Bao, Q.; Eda, G.; Chhowalla, M. Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010, 2, 1015–1024. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, J.; Xu, X.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; Moss, D.J. Invited Article: Enhanced four-wave mixing in waveguides integrated with graphene oxide. APL Photon- 2018, 3, 120803. [Google Scholar] [CrossRef]

- Wu, J. , et al., Graphene oxide for photonics, electronics and optoelectronics. Nat Rev Chem, 2023. 7(3): p. 162-183.

- Wu, J.; Yang, Y.; Qu, Y.; Xu, X.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; Moss, D.J. Graphene Oxide Waveguide and Micro-Ring Resonator Polarizers. Laser Photon- Rev. 2019, 13, 1900056. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Jia, L.; Qu, Y.; Yang, Y.; Jia, B.; Moss, D.J. Graphene Oxide for Nonlinear Integrated Photonics. Laser Photon- Rev. 2023, 17. [Google Scholar] [CrossRef]

- Wu, J.; Jia, L.; Zhang, Y.; Qu, Y.; Jia, B.; Moss, D.J. Graphene Oxide for Integrated Photonics and Flat Optics. Adv. Mater. 2020, 33, e2006415. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X. , et al., In situ third-order non-linear responses during laser reduction of graphene oxide thin films towards on-chip non-linear photonic devices. Adv Mater, 2014. 26(17): p. 2699-703.

- Yang, Y.; Lin, H.; Zhang, B.Y.; Zhang, Y.; Zheng, X.; Yu, A.; Hong, M.; Jia, B. Graphene-Based Multilayered Metamaterials with Phototunable Architecture for on-Chip Photonic Devices. ACS Photon- 2019, 6, 1033–1040. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Moein, T.; Jia, B.; Moss, D.J. Enhanced Kerr Nonlinearity and Nonlinear Figure of Merit in Silicon Nanowires Integrated with 2D Graphene Oxide Films. ACS Appl. Mater. Interfaces 2020, 12, 33094–33103. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Wu, J.; Yang, Y.; Zhang, Y.; Liang, Y.; El Dirani, H.; Crochemore, R.; Demongodin, P.; Sciancalepore, C.; Grillet, C.; et al. Enhanced Four-Wave Mixing in Silicon Nitride Waveguides Integrated with 2D Layered Graphene Oxide Films. Adv. Opt. Mater. 2020, 8. [Google Scholar] [CrossRef]

- Tian, H.; Chin, M.L.; Najmaei, S.; Guo, Q.; Xia, F.; Wang, H.; Dubey, M. Optoelectronic devices based on two-dimensional transition metal dichalcogenides. Nano Res. 2016, 9, 1543–1560. [Google Scholar] [CrossRef]

- Tan, T.; Jiang, X.; Wang, C.; Yao, B.; Zhang, H. 2D Material Optoelectronics for Information Functional Device Applications: Status and Challenges. Adv. Sci. 2020, 7, 2000058. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, N.; Park, J.; Hwang, J.Y.; Choi, W. Growth of Large-Scale and Thickness-Modulated MoS2 Nanosheets. ACS Appl. Mater. Interfaces 2014, 6, 21215–21222. [Google Scholar] [CrossRef]

- You, J.; Luo, Y.; Yang, J.; Zhang, J.; Yin, K.; Wei, K.; Zheng, X.; Jiang, T. Hybrid/Integrated Silicon Photonics Based on 2D Materials in Optical Communication Nanosystems. Laser Photon- Rev. 2020, 14. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, G.H.; Cho, J.; Amani, M.; Mastandrea, J.P.; Groschner, C.K.; Lien, D.-H.; Zhao, Y.; Ager, J.W.; Scott, M.C.; et al. Synthetic WSe 2 monolayers with high photoluminescence quantum yield. Sci. Adv. 2019, 5, eaau4728. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; Xiao, D.; Shan, J. Light–valley interactions in 2D semiconductors. Nat. Photon- 2018, 12, 451–460. [Google Scholar] [CrossRef]

- Zeng, H.; Dai, J.; Yao, W.; Xiao, D.; Cui, X. Valley polarization in MoS2 monolayers by optical pumping. Nat. Nanotechnol. 2012, 7, 490–493. [Google Scholar] [CrossRef] [PubMed]

- Liang, Q. , et al., High-performance, room temperature, ultra-broadband photodetectors based on air-stable PdSe2. Advanced Materials, 2019. 31(24): p. 1807609.

- Zhang, E.; Wang, P.; Li, Z.; Wang, H.; Song, C.; Huang, C.; Chen, Z.-G.; Yang, L.; Zhang, K.; Lu, S.; et al. Tunable Ambipolar Polarization-Sensitive Photodetectors Based on High-Anisotropy ReSe2 Nanosheets. ACS Nano 2016, 10, 8067–8077. [Google Scholar] [CrossRef] [PubMed]

- Pi, L. , et al., Recent progress on 2D noble-transition-metal dichalcogenides. Advanced Functional Materials, 2019. 29(51): p. 1904932.

- Qiao, J.; Kong, X.; Hu, Z.-X.; Yang, F.; Ji, W. High-mobility transport anisotropy and linear dichroism in few-layer black phosphorus. Nat. Commun. 2014, 5, 4475. [Google Scholar] [CrossRef]

- Autere, A. , et al., Nonlinear optics with 2D layered materials. Advanced Materials, 2018. 30(24): p. 1705963.

- Yuan, H.; Liu, X.; Afshinmanesh, F.; Li, W.; Xu, G.; Sun, J.; Lian, B.; Curto, A.G.; Ye, G.; Hikita, Y.; et al. Polarization-sensitive broadband photodetector using a black phosphorus vertical p–n junction. Nat. Nanotechnol. 2015, 10, 707–713. [Google Scholar] [CrossRef]

- Youngblood, N.; Peng, R.; Nemilentsau, A.; Low, T.; Li, M. Layer-Tunable Third-Harmonic Generation in Multilayer Black Phosphorus. ACS Photon- 2016, 4, 8–14. [Google Scholar] [CrossRef]

- Yang, T.; Abdelwahab, I.; Lin, H.; Bao, Y.; Tan, S.J.R.; Fraser, S.; Loh, K.P.; Jia, B. Anisotropic Third-Order Nonlinearity in Pristine and Lithium Hydride Intercalated Black Phosphorus. ACS Photon- 2018, 5, 4969–4977. [Google Scholar] [CrossRef]

- Li, L.; Kim, J.; Jin, C.; Ye, G.J.; Qiu, D.Y.; da Jornada, F.H.; Shi, Z.; Chen, L.; Zhang, Z.; Yang, F.; et al. Direct observation of the layer-dependent electronic structure in phosphorene. Nat. Nanotechnol. 2016, 12, 21–25. [Google Scholar] [CrossRef]

- Guo, Q.; Pospischil, A.; Bhuiyan, M.; Jiang, H.; Tian, H.; Farmer, D.; Deng, B.; Li, C.; Han, S.-J.; Wang, H.; et al. Black Phosphorus Mid-Infrared Photodetectors with High Gain. Nano Lett. 2016, 16, 4648–4655. [Google Scholar] [CrossRef]

- Island, J.; A Steele, G.; van der Zant, H.S.J.; Castellanos-Gomez, A. Environmental instability of few-layer black phosphorus. 2D Mater. 2015, 2. [Google Scholar] [CrossRef]

- Lu, J.; Wu, J.; Carvalho, A.; Ziletti, A.; Liu, H.; Tan, J.; Chen, Y.; Neto, A.H.C.; Özyilmaz, B.; Sow, C.H. Bandgap Engineering of Phosphorene by Laser Oxidation toward Functional 2D Materials. ACS Nano 2015, 9, 10411–10421. [Google Scholar] [CrossRef] [PubMed]

- Abate, Y.; Akinwande, D.; Gamage, S.; Wang, H.; Snure, M.; Poudel, N.; Cronin, S.B. Recent Progress on Stability and Passivation of Black Phosphorus. Adv. Mater. 2018, 30, e1704749. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X. , et al., Broadband nonlinear photonics in few-layer MXene Ti3C2Tx (T= F, O, or OH). Laser & Photonics Reviews, 2018. 12(2): p. 1700229.

- Zhang, B. , et al., Self-Assembled Hydrophobic/Hydrophilic Porphyrin-Ti3C2T x MXene Janus Membrane for Dual-Functional Enabled Photothermal Desalination. ACS Applied Materials & Interfaces, 2021. 13(3): p. 3762-3770.

- Fu, B. , et al., MXenes: Synthesis, Optical Properties, and Applications in Ultrafast Photonics. Small, 2021. 17(11): p. e2006054.

- Shen, J.; Liu, G.; Ji, Y.; Liu, Q.; Cheng, L.; Guan, K.; Zhang, M.; Liu, G.; Xiong, J.; Yang, J.; et al. 2D MXene Nanofilms with Tunable Gas Transport Channels. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Liu, B.; Qian, L.; Zhao, Y.; Zhang, Y.; Liu, F.; Zhang, Y.; Xie, Y.; Shi, W. A polarization-sensitive, self-powered, broadband and fast Ti3C2Tx MXene photodetector from visible to near-infrared driven by photogalvanic effects. Front. Phys. 2022, 17, 1–7. [Google Scholar] [CrossRef]

- Li, G. , et al., Terahertz Polarizers Based on 2D Ti3C2Tz MXene: Spin Cast from Aqueous Suspensions. Advanced Photonics Research, 2020. 1(2): p. 2000084.

- Jiang, Q.; Lei, Y.; Liang, H.; Xi, K.; Xia, C.; Alshareef, H.N. Review of MXene electrochemical microsupercapacitors. Energy Storage Mater. 2020, 27, 78–95. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Nguyen, D.M.T.; Tran, D.L.; Le, H.K.; Vo, D.-V.N.; Lam, S.S.; Varma, R.S.; Shokouhimehr, M.; Nguyen, C.C.; Van Le, Q. MXenes: Applications in electrocatalytic, photocatalytic hydrogen evolution reaction and CO2 reduction. Mol. Catal. 2020, 486, 110850. [Google Scholar] [CrossRef]

- Grancini, G.; Nazeeruddin, M.K. Dimensional tailoring of hybrid perovskites for photovoltaics. Nat. Rev. Mater. 2018, 4, 4–22. [Google Scholar] [CrossRef]

- Hou, J.; Li, W.; Zhang, H.; Sidhik, S.; Fletcher, J.; Metcalf, I.; Anantharaman, S.B.; Shuai, X.; Mishra, A.; Blancon, J.-C.; et al. Synthesis of 2D perovskite crystals via progressive transformation of quantum well thickness. Nat. Synth. 2023, 3, 265–275. [Google Scholar] [CrossRef]

- Rong, Y.; Hu, Y.; Mei, A.; Tan, H.; Saidaminov, M.I.; Seok, S.I.; McGehee, M.D.; Sargent, E.H.; Han, H. Challenges for commercializing perovskite solar cells. Science 2018, 361, eaat8235. [Google Scholar] [CrossRef]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Li, J.; Ma, J.; Cheng, X.; Liu, Z.; Chen, Y.; Li, D. Anisotropy of Excitons in Two-Dimensional Perovskite Crystals. ACS Nano 2020, 14, 2156–2161. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, Y.; Gao, W.; Song, L.; Ran, C.; Chen, Y.; Huang, W. Polarization-Sensitive Halide Perovskites for Polarized Luminescence and Detection: Recent Advances and Perspectives. Adv. Mater. 2021, 33, 2003615. [Google Scholar] [CrossRef] [PubMed]

- Park, Y. , et al., Sub-30 nm 2D Perovskites Patterns via Block Copolymer Guided Self-Assembly for Color Conversion Optical Polarizer. Small, 2023. 19(47): p. e2300568.

- Liu, Y.; Weiss, N.O.; Duan, X.; Cheng, H.-C.; Huang, Y.; Duan, X. Van der Waals heterostructures and devices. Nat. Rev. Mater. 2016, 1, 16042. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, Z.; Zhang, H.; Lin, K.-T.; Wen, X.; Liang, Y.; Fu, Y.; Lau, A.K.T.; Ma, T.; Qiu, C.-W.; et al. Engineering van der Waals Materials for Advanced Metaphotonics. Chem. Rev. 2022, 122, 15204–15355. [Google Scholar] [CrossRef]

- Zhuo, L.; Li, D.; Chen, W.; Zhang, Y.; Zhang, W.; Lin, Z.; Zheng, H.; Zhu, W.; Zhong, Y.; Tang, J.; et al. High performance multifunction-in-one optoelectronic device by integrating graphene/MoS2 heterostructures on side-polished fiber. Nanophotonics 2022, 11, 1137–1147. [Google Scholar] [CrossRef]

- Kang, J.; Yun, H.; Jang, H.; Kim, J.; Park, J.H.; Lee, J. Solution-Processed Aluminum Nanogratings for Wire Grid Polarizers. Adv. Opt. Mater. 2018, 6, 1800205. [Google Scholar] [CrossRef]

- Jung, M.; Noh, Y.; Suh, D.; Ahn, S. Flexible and Thermally Stable Optical Polarizers Based on Highly Aligned Carbon Nanotube Sheets for the Visible Spectral Range. Adv. Mater. Technol. 2018, 3. [Google Scholar] [CrossRef]

- Shahsafi, A.; Salman, J.; Perez, B.E.R.; Xiao, Y.; Wan, C.; Kats, M.A. Infrared Polarizer Based on Direct Coupling to Surface Plasmon Polaritons. Nano Lett. 2020, 20, 8483–8486. [Google Scholar] [CrossRef]

- Yin, S.; Qi, J. Metagrating-enabled Brewster’s angle for arbitrary polarized electromagnetic waves and its manipulation. Opt. Express 2019, 27, 18113–18122. [Google Scholar] [CrossRef]

- Bludov, Y.V.; Vasilevskiy, M.I.; Peres, N.M.R. Tunable graphene-based polarizer. J. Appl. Phys. 2012, 112, 084320. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Zhang, C.; Shao, L.; Zhu, W. Dynamic manipulation of microwave polarization based on anisotropic graphene meta-device. npj 2D Mater. Appl. 2022, 6, 1–9. [Google Scholar] [CrossRef]

- Zhang, C.; Long, C.; Yin, S.; Song, R.G.; Zhang, B.H.; Zhang, J.W.; He, D.P.; Cheng, Q. Graphene-based anisotropic polarization meta-filter. Mater. Des. 2021, 206, 109768. [Google Scholar] [CrossRef]

- Lee, S. , et al., Metamaterials for Enhanced Optical Responses and their Application to Active Control of Terahertz Waves. Advanced Materials, 2020. 32(35): p. 2000250.

- Guo, T.; Argyropoulos, C. Broadband polarizers based on graphene metasurfaces. Opt. Lett. 2016, 41, 5592–5595. [Google Scholar] [CrossRef] [PubMed]

- Anjali; Varshney, R. K.; Kumar, S. Actively tunable graphene ribbon based multi-band THz polarizer with a high extinction ratio. J. Opt. Soc. Am. B 2023, 40, 1688–1695. [Google Scholar] [CrossRef]

- Zheng, X.; Xu, B.; Li, S.; Lin, H.; Qiu, L.; Li, D.; Jia, B. Free-standing graphene oxide mid-infrared polarizers. Nanoscale 2020, 12, 11480–11488. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Hu, C.; Huo, S.; Sun, Z.; Fan, S.; Liu, J.; Hu, X. Wavelength tunable polarizer based on layered black phosphorus on Si/SiO2 substrate. Opt. Lett. 2018, 43, 1255–1258. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Lin, J.; Sun, W.; Tan, Z.; Liu, R.; Wang, Z. Polarization Selectivity of the Thin-Metal-Film Plasmon-Assisted Fiber-Optic Polarizer. ACS Appl. Mater. Interfaces 2020, 12, 32189–32196. [Google Scholar] [CrossRef] [PubMed]

- Rahnama, A.; Dadalyan, T.; Aghdami, K.M.; Galstian, T.; Herman, P.R. In-Fiber Switchable Polarization Filter Based on Liquid Crystal Filled Hollow-Filament Bragg Gratings. Adv. Opt. Mater. 2021, 9, 2100054. [Google Scholar] [CrossRef]

- Wang, X. , et al., Low-Loss Broadband Transverse Electric Pass Hybrid Plasmonic Fiber Polarizers Using Metallic Nanomaterials. ACS Applied Materials & Interfaces, 2021. 13(12): p. 14718-14727.

- Fan, Y. , et al., Broadband Vis–NIR Circular Polarizer with Cascaded Aluminum Wire-Grid. Advanced Materials Technologies, 2023. 8(7).

- He, X.; Zhang, X.; Zhang, H.; Xu, M. Graphene Covered on Microfiber Exhibiting Polarization and Polarization-dependent Saturable Absorption. IEEE J. Sel. Top. Quantum Electron. 2013, 20, 55–61. [Google Scholar] [CrossRef]

- Guan, C.; Li, S.; Shen, Y.; Yuan, T.; Yang, J.; Yuan, L. Graphene-Coated Surface Core Fiber Polarizer. J. Light. Technol. 2015, 33, 349–353. [Google Scholar] [CrossRef]

- Zhou, F.; Du, W. A graphene-based all-fiber TE/TM switchable polarizer. J. Opt. 2018, 20, 035401. [Google Scholar] [CrossRef]

- Chu, R.; Guan, C.; Yang, J.; Zhu, Z.; Li, P.; Shi, J.; Tian, P.; Yuan, L.; Brambilla, G. High extinction ratio D-shaped fiber polarizers coated by a double graphene/PMMA stack. Opt. Express 2017, 25, 13278–13285. [Google Scholar] [CrossRef]

- Zhang, H.; Healy, N.; Shen, L.; Huang, C.C.; Aspiotis, N.; Hewak, D.W.; Peacock, A.C. Graphene-Based Fiber Polarizer With PVB-Enhanced Light Interaction. J. Light. Technol. 2016, 34, 3563–3567. [Google Scholar] [CrossRef]

- Ahmad, H.; Rahman, M.T.; Faruki, M.J.; Azzuhri, S.R.; Ismail, M.F.; Shah, N.M.S.; Razak, M.Z.A. Graphene oxide (GO)-based wideband optical polarizer using a non-adiabatic microfiber. J. Mod. Opt. 2016, 64, 439–444. [Google Scholar] [CrossRef]

- Cui, Y.; Lu, F.; Liu, X. Nonlinear Saturable and Polarization-induced Absorption of Rhenium Disulfide. Sci. Rep. 2017, 7, 40080. [Google Scholar] [CrossRef]

- He, X., A. Hu, and X. Guo, In-Fiber Graphene-hBN Polarizer With Enhanced Performance and Bandwidth. IEEE Photonics Journal, 2019. 11(6): p. 1-8.

- Yang, M.; Xiong, L.; Li, Q.; Cheng, S.; Ye, Y.; Liu, Z.; Hu, W.; Guo, D. van der Waals forces enhanced light–graphene interaction in optical microfiber polarizer. AIP Adv. 2022, 12, 045027. [Google Scholar] [CrossRef]

- Bloemer, M.; Haus, J. Broadband waveguide polarizers based on the anisotropic optical constants of nanocomposite films. J. Light. Technol. 1996, 14, 1534–1540. [Google Scholar] [CrossRef]

- Schablitsky, S.; Yu, Z.; Wu, W.; Chou, S.Y.; Krauss, P.R.; Renstrom, P.J.; Wang, J.J.; Liu, F.; Deng, X.; Liu, X.; et al. Fabrication of a new broadband waveguide polarizer with a double-layer 190 nm period metal-gratings using nanoimprint lithography. J. Vac. Sci. Technol. B: Microelectron. Nanometer Struct. 1999, 17, 2957–2960. [Google Scholar] [CrossRef]

- Pei, C.; Yang, L.; Wang, G.; Wang, Y.; Jiang, X.; Hao, Y.; Li, Y.; Yang, J. Broadband Graphene/Glass Hybrid Waveguide Polarizer. IEEE Photon- Technol. Lett. 2015, 27, 927–930. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J. Ultrabroadband Compact Graphene–Silicon TM-Pass Polarizer. IEEE Photon- J. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, T.; Chen, L.; Li, X. Ultra-compact TE-pass polarizer with graphene multilayer embedded in a silicon slot waveguide. Opt. Lett. 2015, 40, 1733–1736. [Google Scholar] [CrossRef] [PubMed]

- Hao, R.; Du, W.; Li, E.-P.; Chen, H.-S. Graphene Assisted TE/TM-Independent Polarizer Based on Mach–Zehnder Interferometer. IEEE Photon- Technol. Lett. 2015, 27, 1112–1115. [Google Scholar] [CrossRef]

- Lim, W.H.; Yap, Y.K.; Chong, W.Y.; Pua, C.H.; Huang, N.M.; De La Rue, R.M.; Ahmad, H. Graphene oxide-based waveguide polariser: From thin film to quasi-bulk. Opt. Express 2014, 22, 11090–11098. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; He, R.; Cheng, C.; Wang, D.; Chen, Y.; Chen, F. Polarization-dependent optical absorption of MoS2 for refractive index sensing. Sci. Rep. 2014, 4, 7523. [Google Scholar] [CrossRef] [PubMed]

- Sathiyan, S. , et al., Evolution of the Polarizing Effect of $\text {MoS} _ {2} $. IEEE Photonics Journal, 2015. 7(6): p. 1-10.

- Berahim, N.; Amiri, I.; Anwar, T.; Azzuhri, S.; Nasir, M.M.; Zakaria, R.; Chong, W.; Lai, C.; Lee, S.; Ahmad, H.; et al. Polarizing effect of MoSe2-coated optical waveguides. Results Phys. 2018, 12, 7–11. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, J. Polarization-Independent Black-Phosphorus Polarizer in Visible Regime. IEEE Photon- Technol. Lett. 2017, 29, 1923–1926. [Google Scholar] [CrossRef]

- Gramotnev, D.K.; Bozhevolnyi, S.I. Plasmonics beyond the diffraction limit. Nat. Photonics 2010, 4, 83–91. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.-Y.; Li, B.; Chen, H.-Z.; Wang, Y.-L.; Dai, L.; Oulton, R.F.; Ma, R.-M. Unusual scaling laws for plasmonic nanolasers beyond the diffraction limit. Nat. Commun. 2017, 8, 1–8. [Google Scholar] [CrossRef]

- Miao, J.; Cai, L.; Zhang, S.; Nah, J.; Yeom, J.; Wang, C. Air-Stable Humidity Sensor Using Few-Layer Black Phosphorus. ACS Appl. Mater. Interfaces 2017, 9, 10019–10026. [Google Scholar] [CrossRef]

- Illarionov, Y.Y.; Knobloch, T.; Jech, M.; Lanza, M.; Akinwande, D.; Vexler, M.I.; Mueller, T.; Lemme, M.C.; Fiori, G.; Schwierz, F.; et al. Insulators for 2D nanoelectronics: the gap to bridge. Nat. Commun. 2020, 11, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Jia, J.; Jang, S.K.; Lai, S.; Xu, J.; Choi, Y.J.; Park, J.-H.; Lee, S. Plasma-Treated Thickness-Controlled Two-Dimensional Black Phosphorus and Its Electronic Transport Properties. ACS Nano 2015, 9, 8729–8736. [Google Scholar] [CrossRef]

- Cao, G.; Lin, H.; Fraser, S.; Zheng, X.; Del Rosal, B.; Gan, Z.; Wei, S.; Gan, X.; Jia, B. Resilient Graphene Ultrathin Flat Lens in Aerospace, Chemical, and Biological Harsh Environments. ACS Appl. Mater. Interfaces 2019, 11, 20298–20303. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.S. , et al., 2D Materials Decorated with Ultrathin and Porous Graphene Oxide for High Stability and Selective Surface Activity. Adv Mater, 2020. 32(36): p. e2002723.

- Khaliji, K.; Martín-Moreno, L.; Avouris, P.; Oh, S.-H.; Low, T. Twisted Two-Dimensional Material Stacks for Polarization Optics. Phys. Rev. Lett. 2022, 128, 193902. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, Y.; Zhu, R.; Xu, H.; Wu, C.; Chen, J.; Ma, Y.; Liu, Y.; Chen, Y.; Watanabe, K.; et al. Twisted black phosphorus–based van der Waals stacks for fiber-integrated polarimeters. Sci. Adv. 2022, 8, eabo0375. [Google Scholar] [CrossRef]

- Tong, L.; Duan, X.; Song, L.; Liu, T.; Ye, L.; Huang, X.; Wang, P.; Sun, Y.; He, X.; Zhang, L.; et al. Artificial control of in-plane anisotropic photoelectricity in monolayer MoS2. Appl. Mater. Today 2019, 15, 203–211. [Google Scholar] [CrossRef]

- Sherrott, M.C.; Whitney, W.S.; Jariwala, D.; Biswas, S.; Went, C.M.; Wong, J.; Rossman, G.R.; Atwater, H.A. Anisotropic Quantum Well Electro-Optics in Few-Layer Black Phosphorus. Nano Lett. 2018, 19, 269–276. [Google Scholar] [CrossRef]

- Freitag, M.; Low, T.; Zhu, W.; Yan, H.; Xia, F.; Avouris, P. Photocurrent in graphene harnessed by tunable intrinsic plasmons. Nat. Commun. 2013, 4, 1951. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Weiss, N.O.; Duan, X.; Cheng, H.-C.; Huang, Y.; Duan, X. Van der Waals heterostructures and devices. Nat. Rev. Mater. 2016, 1, 16042. [Google Scholar] [CrossRef]

- Huang, L.; Dong, B.; Guo, X.; Chang, Y.; Chen, N.; Huang, X.; Liao, W.; Zhu, C.; Wang, H.; Lee, C.; et al. Waveguide-Integrated Black Phosphorus Photodetector for Mid-Infrared Applications. ACS Nano 2018, 13, 913–921. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, X.; Xiao, S.; Hu, H.; Frandsen, L.H.; Mortensen, N.A.; Yvind, K. Effective Electro-Optical Modulation with High Extinction Ratio by a Graphene–Silicon Microring Resonator. Nano Lett. 2015, 15, 4393–4400. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Ren, W.; Xu, H.; Jin, L.; Wang, Z.; Ma, T.; Ma, L.-P.; Zhang, Z.; Fu, Q.; Peng, L.-M.; et al. Repeated growth and bubbling transfer of graphene with millimetre-size single-crystal grains using platinum. Nat. Commun. 2012, 3, 699. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B.; Ahn, B.Y.; Gao, T.Z.; Lewis, J.A.; Hersam, M.C. Rapid and Versatile Photonic Annealing of Graphene Inks for Flexible Printed Electronics. Adv. Mater. 2015, 27, 6683–6688. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, R.; Wu, J.; Jiang, X.; Cao, P.; Hu, X.; Pan, T.; Qiu, C.; Yang, J.; Song, Y.; et al. Bottom-up Fabrication of Graphene on Silicon/Silica Substrate via a Facile Soft-hard Template Approach. Sci. Rep. 2015, 5, 13480. [Google Scholar] [CrossRef] [PubMed]

- Qu, Q.; Qian, F.; Yang, S.; Gao, T.; Liu, W.; Shao, J.; Zheng, H. Layer-by-Layer Polyelectrolyte Assisted Growth of 2D Ultrathin MoS2 Nanosheets on Various 1D Carbons for Superior Li-Storage. ACS Appl. Mater. Interfaces 2016, 8, 1398–1405. [Google Scholar] [CrossRef]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Ye, Y.; Gan, L.; Dai, L.; Dai, Y.; Guo, X.; Meng, H.; Yu, B.; Shi, Z.; Shang, K.; Qin, G. A simple and scalable graphene patterning method and its application in CdSe nanobelt/graphene Schottky junction solar cells. Nanoscale 2011, 3, 1477–1481. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C. (.; McKeon, L.; Kremer, M.P.; Park, S.-H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C..; McEvoy, N.; Nerl, H.C.; et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 2019, 10, 1–9. [Google Scholar] [CrossRef]

- Luo, W.; Cai, W.; Xiang, Y.; Wu, W.; Shi, B.; Jiang, X.; Zhang, N.; Ren, M.; Zhang, X.; Xu, J. In-Plane Electrical Connectivity and Near-Field Concentration of Isolated Graphene Resonators Realized by Ion Beams. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Kelly, A.G.; Hallam, T.; Backes, C.; Harvey, A.; Esmaeily, A.S.; Godwin, I.; Coelho, J.; Nicolosi, V.; Lauth, J.; Kulkarni, A.; et al. All-printed thin-film transistors from networks of liquid-exfoliated nanosheets. Science 2017, 356, 69–73. [Google Scholar] [CrossRef]

- Stanford, M.G. , et al., Tungsten Diselenide Patterning and Nanoribbon Formation by Gas-Assisted Focused-Helium-Ion-Beam-Induced Etching. Small Methods, 2017. 1(4): p. 1600060.

- Wang, L.; Xue, Y.; Cui, M.; Huang, Y.; Xu, H.; Qin, C.; Yang, J.; Dai, H.; Yuan, M. A Chiral Reduced-Dimension Perovskite for an Efficient Flexible Circularly Polarized Light Photodetector. Angew. Chem. Int. Ed. 2020, 59, 6442–6450. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, S.-C.; Yang, W.; Li, Z.; Wang, Y.; Wang, X.; Zhang, S.; Zhang, Y.; Long, M.; Zhang, G.; et al. Air-Stable In-Plane Anisotropic GeSe2 for Highly Polarization-Sensitive Photodetection in Short Wave Region. J. Am. Chem. Soc. 2018, 140, 4150–4156. [Google Scholar] [CrossRef]

- Li, L. , et al., Highly In-Plane Anisotropic 2D GeAs(2) for Polarization-Sensitive Photodetection. Adv Mater, 2018. 30(50): p. e1804541.

- Zaumseil, J. Electronic Control of Circularly Polarized Light Emission. Science 2014, 344, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. , et al., Polarized Light-Emitting Diodes Based on Anisotropic Excitons in Few-Layer ReS(2). Adv Mater, 2020. 32(32): p. e2001890.

- Wang, J.; Rousseau, A.; Yang, M.; Low, T.; Francoeur, S.; Kéna-Cohen, S. Mid-infrared Polarized Emission from Black Phosphorus Light-Emitting Diodes. Nano Lett. 2020, 20, 3651–3655. [Google Scholar] [CrossRef]

- Sanchez, O.L.; Ovchinnikov, D.; Misra, S.; Allain, A.; Kis, A. Valley Polarization by Spin Injection in a Light-Emitting van der Waals Heterojunction. Nano Lett. 2016, 16, 5792–5797. [Google Scholar] [CrossRef]

- Sotor, J.; Sobon, G.; Macherzynski, W.; Paletko, P.; Abramski, K.M. Black phosphorus saturable absorber for ultrashort pulse generation. Appl. Phys. Lett. 2015, 107, 051108. [Google Scholar] [CrossRef]

- Koo, J.; Debnath, P.; Song, Y.-W.; Lee, J.H. AQ-switched, mode-locked fiber laser using a graphene oxide-based polarization sensitive saturable absorber. Laser Phys. Lett. 2013, 10. [Google Scholar] [CrossRef]

- Zhang, R.; You, B.; Wang, S.; Han, K.; Shen, X.; Wang, W. Broadband and switchable terahertz polarization converter based on graphene metasurfaces. Opt. Express 2021, 29, 24804–24815. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Jussila, H.; Autere, A.; Komsa, H.-P.; Ye, G.; Chen, X.; Hasan, T.; Sun, Z. Optical Waveplates Based on Birefringence of Anisotropic Two-Dimensional Layered Materials. ACS Photon- 2017, 4, 3023–3030. [Google Scholar] [CrossRef]

- Dong, D.; Liu, Y.; Fei, Y.; Fan, Y.; Li, J.; Fu, Y. Polarization beam splitter based on extremely anisotropic black phosphorus ribbons. Opt. Express 2020, 28, 8371–8383. [Google Scholar] [CrossRef]

- Ciarrocchi, A.; Unuchek, D.; Avsar, A.; Watanabe, K.; Taniguchi, T.; Kis, A. Polarization switching and electrical control of interlayer excitons in two-dimensional van der Waals heterostructures. Nat. Photon- 2018, 13, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Zhang, Y.; Xu, X.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; et al. 2D Layered Graphene Oxide Films Integrated with Micro-Ring Resonators for Enhanced Nonlinear Optics. Small 2020, 16, 1906563. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Yang, Y.; Qu, Y.; Xu, X.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; Moss, D.J. Graphene Oxide Waveguide and Micro-Ring Resonator Polarizers. Laser Photon- Rev. 2019, 13, 1900056. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Moein, T.; Jia, B.; Moss, D.J. Enhanced Kerr Nonlinearity and Nonlinear Figure of Merit in Silicon Nanowires Integrated with 2D Graphene Oxide Films. ACS Appl. Mater. Interfaces 2020, 12, 33094–33103. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Wu, J.; Yang, Y.; Zhang, Y.; Liang, Y.; El Dirani, H.; Crochemore, R.; Demongodin, P.; Sciancalepore, C.; Grillet, C.; et al. Enhanced Four-Wave Mixing in Silicon Nitride Waveguides Integrated with 2D Layered Graphene Oxide Films. Adv. Opt. Mater. 2020, 8. [Google Scholar] [CrossRef]

- Jia, L.; Cui, D.; Wu, J.; Feng, H.; Yang, Y.; Yang, T.; Qu, Y.; Du, Y.; Hao, W.; Jia, B.; et al. Highly nonlinear BiOBr nanoflakes for hybrid integrated photonics. APL Photon- 2019, 4, 090802. [Google Scholar] [CrossRef]

- Yuning Zhang, Jiayang Wu, Yang Qu, Yunyi Yang, Linnan Jia, Baohua Jia, and David J. Moss, “Enhanced supercontinuum generated in SiN waveguides coated with GO films”, Advanced Materials Technologies Vol. 8 (1) 2201796 (2023).

- Zhang, Y.; Wu, J.; Jia, L.; Qu, Y.; Yang, Y.; Jia, B.; Moss, D.J. Graphene Oxide for Nonlinear Integrated Photonics. Laser Photon- Rev. 2023, 17. [Google Scholar] [CrossRef]

- Wu, J.; Lin, H.; Moss, D.J.; Loh, K.P.; Jia, B. Graphene oxide for photonics, electronics and optoelectronics. Nat. Rev. Chem. 2023, 7, 162–183. [Google Scholar] [CrossRef]

- Qu, Y.; Yang, Y.; Wu, J.; Zhang, Y.; Jia, L.; El Dirani, H.; Crochemore, R.; Sciancalepore, C.; Demongodin, P.; Grillet, C.; et al. Photo-Thermal Tuning of Graphene Oxide Coated Integrated Optical Waveguides. Micromachines 2022, 13, 1194. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Yang, Y.; Qu, Y.; El Dirani, H.; Crochemore, R.; Sciancalepore, C.; Demongodin, P.; Grillet, C.; Monat, C.; et al. Enhanced self-phase modulation in silicon nitride waveguides integrated with 2D graphene oxide films. IEEE J. Sel. Top. Quantum Electron. 2022, PP, 1–1. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Jia, B.; Moss, D.J. Enhanced Spectral Broadening of Femtosecond Optical Pulses in Silicon Nanowires Integrated with 2D Graphene Oxide Films. Micromachines 2022, 13, 756. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.; Wu, J.; Zhang, Y.; Qu, Y.; Jia, B.; Chen, Z.; Moss, D.J. Fabrication Technologies for the On-Chip Integration of 2D Materials. Small Methods 2022, 6, 2101435. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wu, J.; Qu, Y.; Jia, L.; Jia, B.; Moss, D.J. Design and Optimization of Four-Wave Mixing in Microring Resonators Integrated With 2D Graphene Oxide Films. J. Light. Technol. 2021, 39, 6553–6562. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Qu, Y.; Jia, L.; Jia, B.; Moss, D.J. Optimizing the Kerr Nonlinear Optical Performance of Silicon Waveguides Integrated With 2D Graphene Oxide Films. J. Light. Technol. 2021, 39, 4671–4683. [Google Scholar] [CrossRef]

- Qu, Y.; Wu, J.; Zhang, Y.; Jia, L.; Liang, Y.; Jia, B.; Moss, D.J. Analysis of Four-Wave Mixing in Silicon Nitride Waveguides Integrated With 2D Layered Graphene Oxide Films. J. Light. Technol. 2021, 39, 2902–2910. [Google Scholar] [CrossRef]

- Wu, J.; Jia, L.; Zhang, Y.; Qu, Y.; Jia, B.; Moss, D.J. Graphene Oxide for Integrated Photonics and Flat Optics. Adv. Mater. 2020, 33, e2006415. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Qu, Y.; Yang, Y.; Jia, L.; Jia, B.; Moss, D.J. Graphene oxide for enhanced optical nonlinear performance in CMOS compatible integrated devices. 2D Photonic Materials and Devices IV. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE;

- Qu, Y.; Wu, J.; Yang, Y.; Zhang, Y.; Liang, Y.; El Dirani, H.; Crochemore, R.; Demongodin, P.; Sciancalepore, C.; Grillet, C.; et al. Enhanced Four-Wave Mixing in Silicon Nitride Waveguides Integrated with 2D Layered Graphene Oxide Films. Adv. Opt. Mater. 2020, 8. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Moein, T.; Jia, B.; Moss, D.J. Enhanced Kerr Nonlinearity and Nonlinear Figure of Merit in Silicon Nanowires Integrated with 2D Graphene Oxide Films. ACS Appl. Mater. Interfaces 2020, 12, 33094–33103. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Qu, Y.; Jia, L.; Zhang, Y.; Xu, X.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; et al. 2D Layered Graphene Oxide Films Integrated with Micro-Ring Resonators for Enhanced Nonlinear Optics. Small 2020, 16, 1906563. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Zhang, Y.; Qu, Y.; Xu, X.; Jia, L.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; et al. Integrated polarizers based on graphene oxide in waveguides and ring resonators. 2D Photonic Materials and Devices III. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; p. 112820U.

- Wu, J.; Yang, Y.; Qu, Y.; Xu, X.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; Moss, D.J. Graphene Oxide Waveguide and Micro-Ring Resonator Polarizers. Laser Photon- Rev. 2019, 13, 1900056. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, J.; Xu, X.; Liang, Y.; Chu, S.T.; Little, B.E.; Morandotti, R.; Jia, B.; Moss, D.J. Invited Article: Enhanced four-wave mixing in waveguides integrated with graphene oxide. APL Photon- 2018, 3, 120803. [Google Scholar] [CrossRef]

- Jia, L.; Wu, J.; Zhang, Y.; Qu, Y.; Jia, B.; Moss, D.J. Third-Order Optical Nonlinearities of 2D Materials at Telecommunications Wavelengths. Micromachines 2023, 14, 307. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.; Cui, D.; Wu, J.; Feng, H.; Yang, Y.; Yang, T.; Qu, Y.; Du, Y.; Hao, W.; Jia, B.; et al. Highly nonlinear BiOBr nanoflakes for hybrid integrated photonics. APL Photon- 2019, 4, 090802. [Google Scholar] [CrossRef]

- Jia, L.; Wu, J.; Yang, T.; Jia, B.; Moss, D.J. Large Third-Order Optical Kerr Nonlinearity in Nanometer-Thick PdSe2 2D Dichalcogenide Films: Implications for Nonlinear Photonic Devices. ACS Appl. Nano Mater. 2020, 3, 6876–6883. [Google Scholar] [CrossRef]

- Ghahramani, E.; Moss, D.J.; Sipe, J.E. Full-band-structure calculation of first-, second-, and third-harmonic optical response coefficients of ZnSe, ZnTe, and CdTe. Phys. Rev. B 1991, 43, 9700–9710. [Google Scholar] [CrossRef] [PubMed]

- Pasquazi, A.; Peccianti, M.; Park, Y.; Little, B.E.; Chu, S.T.; Morandotti, R.; Azaña, J.; Moss, D.J. Sub-picosecond phase-sensitive optical pulse characterization on a chip. Nat. Photon- 2011, 5, 618–623. [Google Scholar] [CrossRef]

- Grillet, C.; Smith, C.L.C.; Freeman, D.; Madden, S.; Luther-Davies, B.; Magi, E.C.; Moss, D.J.; Eggleton, B.J. Efficient coupling to chalcogenide glass photonic crystal waveguides via silica optical fiber nanowires. Opt. Express 2006, 14, 1070–1078. [Google Scholar] [CrossRef] [PubMed]

- S Tomljenovic-Hanic, MJ Steel, CM de Sterke, DJ Moss, “High-Q cavities in photosensitive photonic crystals” Optics Letters vol. 32 (5), 542-544 (2007).

- E Ghahramani, DJ Moss, JE Sipe, “Second-harmonic generation in odd-period, strained, (Si(Ge/Si superlattices and at Si/Ge interfaces”, Physical Review Letters vol. 64 (23), 2815 (1990).

- et al. , “On-Chip ultra-fast 1st and 2nd order CMOS compatible all-optical integration”, Optics Express vol. 19 (23), 23153-23161 (2011).

- Ta'Eed, V.G.; Fu, L.; Pelusi, M.; Rochette, M.; Littler, I.C.M.; Moss, D.J.; Eggleton, B.J. Error free all optical wavelength conversion in highly nonlinear As-Se chalcogenide glass fiber. Opt. Express 2006, 14, 10371–10376. [Google Scholar] [CrossRef]

- Rochette, M.; Fu, L.; Ta'Eed, V.; Moss, D.; Eggleton, B. 2R optical regeneration: an all-optical solution for BER improvement. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 736–744. [Google Scholar] [CrossRef]

- Vo, T.D.; Corcoran, B.; Schroder, J.; Pelusi, M.D.; Xu, D.-X.; Densmore, A.; Ma, R.; Janz, S.; Moss, D.J.; Eggleton, B.J. Silicon-Chip-Based Real-Time Dispersion Monitoring for 640 Gbit/s DPSK Signals. J. Light. Technol. 2011, 29, 1790–1796. [Google Scholar] [CrossRef]

- C Monat, C Grillet, B Corcoran, DJ Moss, BJ Eggleton, TP White,..., et al., “Investigation of phase matching for third-harmonic generation in silicon slow light photonic crystal waveguides using Fourier optics”, Optics Express vol. 18 (7), 6831-6840 (2010).

- L Carletti, P Ma, Y Yu, B Luther-Davies, D Hudson, C Monat,...., et al., “Nonlinear optical response of low loss silicon germanium waveguides in the mid-infrared”, Optics Express vol. 23 (7), 8261-8271 (2015).

- Bao, C.; Xuan, Y.; Jaramillo-Villegas, J.A.; Leaird, D.E.; Qi, M.; Weiner, A.M. Direct soliton generation in microresonators. Opt. Lett. 2017, 42, 2519–2522. [Google Scholar] [CrossRef]

- M.Ferrera et al., “CMOS compatible integrated all-optical RF spectrum analyzer”, Optics Express, vol. 22, no. 18, 21488 - 21498 (2014).

- Kues, M.; Reimer, C.; Wetzel, B.; Roztocki, P.; Little, B.E.; Chu, S.T.; Hansson, T.; Viktorov, E.A.; Moss, D.J.; Morandotti, R. Passively mode-locked laser with an ultra-narrow spectral width. Nat. Photon- 2017, 11, 159–162. [Google Scholar] [CrossRef]

- M.Ferrera et al.“On-Chip ultra-fast 1st and 2nd order CMOS compatible all-optical integration”, Opt. Express, vol. 19, (23)pp. 23153-23161 (2011).

- Duchesne, D.; Peccianti, M.; Lamont, M.R.E.; Ferrera, M.; Razzari, L.; Légaré, F.; Morandotti, R.; Chu, S.; Little, B.E.; Moss, D.J. Supercontinuum generation in a high index doped silica glass spiral waveguide. Opt. Express 2010, 18, 923–930. [Google Scholar] [CrossRef]

- Bao, H.; Olivieri, L.; Rowley, M.; Chu, S.T.; Little, B.E.; Morandotti, R.; Moss, D.J.; Gongora, J.S.T.; Peccianti, M.; Pasquazi, A. Turing patterns in a fiber laser with a nested microresonator: Robust and controllable microcomb generation. Phys. Rev. Res. 2020, 2, 023395. [Google Scholar] [CrossRef]

- Ferrera, M.; Park, Y.; Razzari, L.; Little, B.E.; Chu, S.T.; Morandotti, R.; Moss, D.J.; Azaña, J. On-chip CMOS-compatible all-optical integrator. Nat. Commun. 2010, 1, 29–5. [Google Scholar] [CrossRef]

- Pasquazi, et al., “All-optical wavelength conversion in an integrated ring resonator,” Optics Express, vol. 18, no. 4, pp. 3858-3863, 2010.

- Pasquazi, Y. Park, J. Azana, et al., “Efficient wavelength conversion and net parametric gain via Four Wave Mixing in a high index doped silica waveguide,” Optics Express, vol. 18, no. 8, pp. 7634-7641, 2010.

- Peccianti, M.; Ferrera, M.; Razzari, L.; Morandotti, R.; Little, B.E.; Chu, S.T.; Moss, D.J. Subpicosecond optical pulse compression via an integrated nonlinear chirper. Opt. Express 2010, 18, 7625–7633. [Google Scholar] [CrossRef]

- M. Ferrera et al., “Low Power CW Parametric Mixing in a Low Dispersion High Index Doped Silica Glass Micro-Ring Resonator with Q-factor > 1 Million”, Optics Express, vol.17, no. 16, pp. 14098–14103 (2009).

- M. Peccianti, et al., “Demonstration of an ultrafast nonlinear microcavity modelocked laser”, Nature Communications, vol. 3, pp. 765, 2012.

- Pasquazi, et al., “Self-locked optical parametric oscillation in a CMOS compatible microring resonator: a route to robust optical frequency comb generation on a chip,” Optics Express, vol. 21, no. 11, pp. 1333.

- Pasquazi, et al., “Stable, dual mode, high repetition rate mode-locked laser based on a microring resonator,” Optics Express, vol. 20, no. 24, pp. 27355-27362, 2012.

- Pasquazi, A.; Peccianti, M.; Razzari, L.; Moss, D.J.; Coen, S.; Erkintalo, M.; Chembo, Y.K.; Hansson, T.; Wabnitz, S.; Del’haye, P.; et al. Micro-combs: A novel generation of optical sources. Phys. Rep. 2017, 729, 1–81. [Google Scholar] [CrossRef]

- Razzari, L.; Duchesne, D.; Ferrera, M.; Morandotti, R.; Chu, S.; Little, B.E.; Moss, D.J. CMOS-compatible integrated optical hyper-parametric oscillator. Nat. Photon- 2009, 4, 41–45. [Google Scholar] [CrossRef]

- Ferrera, M.; Razzari, L.; Duchesne, D.; Morandotti, R.; Yang, Z.; Liscidini, M.; Sipe, J.E.; Chu, S.; Little, B.E.; Moss, D.J. Low-power continuous-wave nonlinear optics in doped silica glass integrated waveguide structures. Nat. Photon- 2008, 2, 737–740. [Google Scholar] [CrossRef]

- Moss, D.; Morandotti, R.; Gaeta, A.L.; Lipson, M. New CMOS-compatible platforms based on silicon nitride and Hydex for nonlinear optics. Nat. Photonics 2013, 7, 597–607. [Google Scholar] [CrossRef]

- Sun, Y. et al. Applications of optical microcombs. Advances in Optics and Photonics Vol. 15, 86 (2023).

- Bao, H.; Cooper, A.; Rowley, M.; Di Lauro, L.; Gongora, J.S.T.; Chu, S.T.; Little, B.E.; Oppo, G.-L.; Morandotti, R.; Moss, D.J.; et al. Laser cavity-soliton microcombs. Nat. Photon- 2019, 13, 384–389. [Google Scholar] [CrossRef]

- Cutrona, A.; Rowley, M.; Das, D.; Olivieri, L.; Peters, L.; Chu, S.T.; Little, B.E.; Morandotti, R.; Moss, D.J.; Gongora, J.S.T.; et al. High parametric efficiency in laser cavity-soliton microcombs. Opt. Express 2022, 30, 39816–39825. [Google Scholar] [CrossRef]

- M.Rowley, P. M.Rowley, P.Hanzard, A.Cutrona, H.Bao, S.Chu, B.Little, R.Morandotti, D. J. Moss, G. Oppo, J. Gongora, M. Peccianti and A. Pasquazi, “Self-emergence of robust solitons in a micro-cavity”, Nature vol. 608 (7922) 303–309 (2022).

- Cutrona, A.; Cecconi, V.; Hanzard, P.H.; Rowley, M.; Das, D.; Cooper, A.; Peters, L.; Olivieri, L.; Wetzel, B.; Morandotti, R.; et al. Nonlocal bonding of a soliton and a blue-detuned state in a microcomb laser. Commun. Phys. 2023, 6, 1–10. [Google Scholar] [CrossRef]

- Cutrona, A.; Rowley, M.; Bendahmane, A.; Cecconi, V.; Peters, L.; Olivieri, L.; Little, B.E.; Chu, S.T.; Stivala, S.; Morandotti, R.; et al. Stability of laser cavity-solitons for metrological applications. Appl. Phys. Lett. 2023, 122, 121104. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Shoeiby, M.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Reconfigurable broadband microwave photonic intensity differentiator based on an integrated optical frequency comb source. APL Photon- 2017, 2. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Nguyen, T.G.; Moein, T.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Photonic microwave true time delays for phased array antennas using a 49 GHz FSR integrated optical micro-comb source [Invited]. Photon- Res. 2018, 6, B30–B36. [Google Scholar] [CrossRef]

- Xu, X.; Tan, M.; Wu, J.; Morandotti, R.; Mitchell, A.; Moss, D.J. Microcomb-Based Photonic RF Signal Processing. IEEE Photon- Technol. Lett. 2019, 31, 1854–1857. [Google Scholar] [CrossRef]

- Xu, et al., “Advanced adaptive photonic RF filters with 80 taps based on an integrated optical micro-comb source,” Journal of Lightwave Technology, vol. 37, no. 4, pp. 1288-1295 (2019).

- Xu, X.; Tan, M.; Wu, J.; Boes, A.; Corcoran, B.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. Photonic RF and Microwave Integrator Based on a Transversal Filter With Soliton Crystal Microcombs. IEEE Trans. Circuits Syst. II: Express Briefs 2020, 67, 3582–3586. [Google Scholar] [CrossRef]

- Xu, X.; Tan, M.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. High performance RF filters via bandwidth scaling with Kerr micro-combs. APL Photon- 2019, 4, 026102. [Google Scholar] [CrossRef]

- Tan, M.; Mitchell, A.; Moss, D.J.; Xu, X.; Corcoran, B.; Wu, J.; Boes, A.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; et al. Microwave and RF Photonic Fractional Hilbert Transformer Based on a 50 GHz Kerr Micro-Comb. J. Light. Technol. 2019, 37, 6097–6104. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Corcoran, B.; Wu, J.; Boes, A.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. RF and Microwave Fractional Differentiator Based on Photonics. IEEE Trans. Circuits Syst. II: Express Briefs 2020, 67, 2767–2771. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Boes, A.; Corcoran, B.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. Photonic RF Arbitrary Waveform Generator Based on a Soliton Crystal Micro-Comb Source. J. Light. Technol. 2020, 38, 6221–6226. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Morandotti, R.; Mitchell, A.; Moss, D.J. RF and microwave photonic temporal signal processing with Kerr micro-combs. Adv. Physics: X 2020, 6. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Nguyen, T.G.; Shoeiby, M.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Advanced RF and microwave functions based on an integrated optical frequency comb source. Opt. Express 2018, 26, 2569–2583. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Boes, A.; Corcoran, B.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Lowery, A.J.; Morandotti, R.; et al. Highly Versatile Broadband RF Photonic Fractional Hilbert Transformer Based on a Kerr Soliton Crystal Microcomb. J. Light. Technol. 2021, 39, 7581–7587. [Google Scholar] [CrossRef]

- Wu, J. et al. RF Photonics: An Optical Microcombs’ Perspective. IEEE Journal of Selected Topics in Quantum Electronics Vol. 24, 6101020, 1-20 (2018).

- Nguyen, T.G.; Shoeiby, M.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Integrated frequency comb source based Hilbert transformer for wideband microwave photonic phase analysis. Opt. Express 2015, 23, 22087–22097. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Broadband RF Channelizer Based on an Integrated Optical Frequency Kerr Comb Source. J. Light. Technol. 2018, 36, 4519–4526. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Jia, L.; Tan, M.; Nguyen, T.G.; Chu, S.T.; E Little, B.; Morandotti, R.; Mitchell, A.; Moss, D.J. Continuously tunable orthogonally polarized RF optical single sideband generator based on micro-ring resonators. J. Opt. 2018, 20, 115701. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Tan, M.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Orthogonally Polarized RF Optical Single Sideband Generation and Dual-Channel Equalization Based on an Integrated Microring Resonator. J. Light. Technol. 2018, 36, 4808–4818. [Google Scholar] [CrossRef]

- Xu, X.; Tan, M.; Wu, J.; Boes, A.; Corcoran, B.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. Photonic RF Phase-Encoded Signal Generation With a Microcomb Source. J. Light. Technol. 2020, 38, 1722–1727. [Google Scholar] [CrossRef]

- Xu, X.; Wu, J.; Tan, M.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Broadband Microwave Frequency Conversion Based on an Integrated Optical Micro-Comb Source. J. Light. Technol. 2019, 38, 332–338. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Morandotti, R.; Mitchell, A.; Moss, D.J. Photonic RF and microwave filters based on 49 GHz and 200 GHz Kerr microcombs. Opt. Commun. 2020, 465, 125563. [Google Scholar] [CrossRef]

- Xu, X.; Tan, M.; Wu, J.; Boes, A.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Broadband Photonic RF Channelizer With 92 Channels Based on a Soliton Crystal Microcomb. J. Light. Technol. 2020, 38, 5116–5121. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Mitchell, A.; Morandotti, R.; Moss, D.J. Orthogonally polarized RF optical single sideband generation with integrated ring resonators. J. Semicond. 2021, 42. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Photonic radio frequency channelizers based on Kerr optical micro-combs. J. Semicond. 2021, 42. [Google Scholar] [CrossRef]

- Corcoran, et al., “Ultra-dense optical data transmission over standard fiber with a single chip source”, Nature Communications, vol. 11, Article:2568, 2020.

- Xu, X.; Tan, M.; Corcoran, B.; Wu, J.; Nguyen, T.G.; Boes, A.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. Photonic Perceptron Based on a Kerr Microcomb for High-Speed, Scalable, Optical Neural Networks. Laser Photon- Rev. 2020, 14. [Google Scholar] [CrossRef]

- Xu, X.; Tan, M.; Corcoran, B.; Wu, J.; Boes, A.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Hicks, D.G.; Morandotti, R.; et al. 11 TOPS photonic convolutional accelerator for optical neural networks. Nature 2021, 589, 44–51. [Google Scholar] [CrossRef]

- Xu, X.; Han, W.; Tan, M.; Sun, Y.; Li, Y.; Wu, J.; Morandotti, R.; Mitchell, A.; Xu, K.; Moss, D.J. Neuromorphic Computing Based on Wavelength-Division Multiplexing. IEEE J. Sel. Top. Quantum Electron. 2022, 29, 1–12. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, J.; Tan, M.; Xu, X.; Li, Y.; Morandotti, R.; Mitchell, A.; Moss, D.J. Applications of optical microcombs. Adv. Opt. Photon- 2023, 15, 86–175. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, X.; Tan, M.; Sun, Y.; Li, Y.; Wu, J.; Morandotti, R.; Mitchell, A.; Xu, K.; Moss, D.J. Photonic multiplexing techniques for neuromorphic computing. Nanophotonics 2022, 12, 795–817. [Google Scholar] [CrossRef]

- Prayoonyong, C.; Boes, A.; Xu, X.; Tan, M.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J.; Corcoran, B. Frequency comb distillation for optical superchannel transmission. J. Light. Technol. 2021, 39, 1–1. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Corcoran, B.; Boes, A.; Nguyen, T.G.; Chu, S.T.; E Little, B.; Morandotti, R.; Mitchell, A.; et al. Integral order photonic RF signal processors based on a soliton crystal micro-comb source. J. Opt. 2021, 23, 125701. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, J.; Li, Y.; Xu, X.; Ren, G.; Tan, M.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; et al. Optimizing the Accuracy of Microcomb-Based Microwave Photonic Transversal Signal Processors. J. Light. Technol. 2023, 41, 7223–7237. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Boes, A.; Corcoran, B.; Nguyen, T.G.; Chu, S.T.; Little, B.E.; Morandotti, R.; Wu, J.; Mitchell, A.; et al. Photonic signal processor based on a Kerr microcomb for real-time video image processing. Commun. Eng. 2023, 2, 1–13. [Google Scholar] [CrossRef]

- Tan, M.; Xu, X.; Wu, J.; Morandotti, R.; Mitchell, A.; Moss, D.J. Photonic RF and microwave filters based on 49 GHz and 200 GHz Kerr microcombs. Opt. Commun. 2020, 465, 125563. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, J.; Li, Y.; Tan, M.; Xu, X.; Chu, S.T.; Little, B.E.; Morandotti, R.; Mitchell, A.; Moss, D.J. Quantifying the Accuracy of Microcomb-Based Photonic RF Transversal Signal Processors. IEEE J. Sel. Top. Quantum Electron. 2023, 29, 1–17. [Google Scholar] [CrossRef]

- Kues, M.; Reimer, C.; Lukens, J.M.; Munro, W.J.; Weiner, A.M.; Moss, D.J.; Morandotti, R. Quantum optical microcombs. Nat. Photon- 2019, 13, 170–179. [Google Scholar] [CrossRef]

- Reimer, L. Caspani, M. Clerici, et al., “Integrated frequency comb source of heralded single photons,” Optics Express, vol. 22, no. 6, pp. 6535-6546, 2014.

- Reimer, C.; Kues, M.; Caspani, L.; Wetzel, B.; Roztocki, P.; Clerici, M.; Jestin, Y.; Ferrera, M.; Peccianti, M.; Pasquazi, A.; et al. Cross-polarized photon-pair generation and bi-chromatically pumped optical parametric oscillation on a chip. Nat. Commun. 2015, 6, 8236. [Google Scholar] [CrossRef]

- Caspani, L.; Reimer, C.; Kues, M.; Roztocki, P.; Clerici, M.; Wetzel, B.; Jestin, Y.; Ferrera, M.; Peccianti, M.; Pasquazi, A.; et al. Multifrequency sources of quantum correlated photon pairs on-chip: a path toward integrated Quantum Frequency Combs. Nanophotonics 2016, 5, 351–362. [Google Scholar] [CrossRef]

- Reimer, C.; Kues, M.; Roztocki, P.; Wetzel, B.; Grazioso, F.; Little, B.E.; Chu, S.T.; Johnston, T.; Bromberg, Y.; Caspani, L.; et al. Generation of multiphoton entangled quantum states by means of integrated frequency combs. Science 2016, 351, 1176–1180. [Google Scholar] [CrossRef]

- Kues, M.; Reimer, C.; Roztocki, P.; Cortés, L.R.; Sciara, S.; Wetzel, B.; Zhang, Y.; Cino, A.; Chu, S.T.; Little, B.E.; et al. On-chip generation of high-dimensional entangled quantum states and their coherent control. Nature 2017, 546, 622–626. [Google Scholar] [CrossRef]

- Roztocki, P.; Kues, M.; Reimer, C.; Wetzel, B.; Sciara, S.; Zhang, Y.; Cino, A.; Little, B.E.; Chu, S.T.; Moss, D.J.; et al. Practical system for the generation of pulsed quantum frequency combs. Opt. Express 2017, 25, 18940–18949. [Google Scholar] [CrossRef]

- Zhang, Y.; Kues, M.; Roztocki, P.; Reimer, C.; Fischer, B.; MacLellan, B.; Bisianov, A.; Peschel, U.; Little, B.E.; Chu, S.T.; et al. Induced Photon Correlations Through the Overlap of Two Four-Wave Mixing Processes in Integrated Cavities. Laser Photon- Rev. 2020, 14. [Google Scholar] [CrossRef]

- Reimer, C.; Sciara, S.; Roztocki, P.; Islam, M.; Cortés, L.R.; Zhang, Y.; Fischer, B.; Loranger, S.; Kashyap, R.; Cino, A.; et al. High-dimensional one-way quantum processing implemented on d-level cluster states. Nat. Phys. 2018, 15, 148–153. [Google Scholar] [CrossRef]

- P.Roztocki et al., “Complex quantum state generation and coherent control based on integrated frequency combs”, Journal of Lightwave Technology vol. 37 (2) 338-347 (2019).

- Sciara, S.; Roztocki, P.; Rimoldi, C.; Chemnitz, M.; Fischer, B.; Cortes, L.R.; Munro, W.J.; Moss, D.J.; Caspani, L.; Reimer, C.; et al. Generation and Processing of Complex Photon States With Quantum Frequency Combs. IEEE Photon- Technol. Lett. 2019, 31, 1862–1865. [Google Scholar] [CrossRef]

- Sciara, S.; Roztocki, P.; Fischer, B.; Reimer, C.; Cortés, L.R.; Munro, W.J.; Moss, D.J.; Cino, A.C.; Caspani, L.; Kues, M.; et al. Scalable and effective multi-level entangled photon states: a promising tool to boost quantum technologies. Nanophotonics 2021, 10, 4447–4465. [Google Scholar] [CrossRef]

- Caspani, L.; Reimer, C.; Kues, M.; Roztocki, P.; Clerici, M.; Wetzel, B.; Jestin, Y.; Ferrera, M.; Peccianti, M.; Pasquazi, A.; et al. Multifrequency sources of quantum correlated photon pairs on-chip: a path toward integrated Quantum Frequency Combs. Nanophotonics 2016, 5, 351–362. [Google Scholar] [CrossRef]

- Arianfard, H.; Juodkazis, S.; Moss, D.J.; Wu, J. Sagnac interference in integrated photonics. Appl. Phys. Rev. 2023, 10, 011309. [Google Scholar] [CrossRef]

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. Optical Analogs of Rabi Splitting in Integrated Waveguide-Coupled Resonators. Adv. Phys. Res. 2023, 2. [Google Scholar] [CrossRef]

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. Spectral shaping based on optical waveguides with advanced Sagnac loop reflectors. Integrated Optics: Devices, Materials, and Technologies XXVI. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE;

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. Spectral Shaping Based on Coupled Sagnac Loop Reflectors Formed by a Self-Coupled Wire Waveguide. IEEE Photon- Technol. Lett. 2021, 33, 680–683. [Google Scholar] [CrossRef]

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. Three Waveguide Coupled Sagnac Loop Reflectors for Advanced Spectral Engineering. J. Light. Technol. 2021, 39, 3478–3487. [Google Scholar] [CrossRef]

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. Advanced Multi-Functional Integrated Photonic Filters Based on Coupled Sagnac Loop Reflectors. J. Light. Technol. 2021, 39, 1400–1408. [Google Scholar] [CrossRef]

- Arianfard, H.; Wu, J.; Juodkazis, S.; Moss, D.J. High performance optical filters based on advanced coupled Sagnac loop waveguide reflector structures. Silicon Photonics XVI. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; p. 1169107.

- Wu, J.; Moein, T.; Xu, X.; Moss, D.J. Advanced photonic filters based on cascaded Sagnac loop reflector resonators in silicon-on-insulator nanowires. APL Photon- 2018, 3, 046102. [Google Scholar] [CrossRef]

- Wu, J.; Moein, T.; Xu, X.; Ren, G.; Mitchell, A.; Moss, D.J. Micro-ring resonator quality factor enhancement via an integrated Fabry-Perot cavity. APL Photon- 2017, 2. [Google Scholar] [CrossRef]

- Monro, T.M.; Moss, D.; Bazylenko, M.; de Sterke, C.M.; Poladian, L. Observation of Self-Trapping of Light in a Self-Written Channel in a Photosensitive Glass. Phys. Rev. Lett. 1998, 80, 4072–4075. [Google Scholar] [CrossRef]

- MD Pelusi, F Luan, E Magi, MRE Lamont, DJ Moss, BJ Eggleton,... et al., “High bit rate all-optical signal processing in a fiber photonic wire”, Optics Express vol. 16 (15), 11506-11512 (2008).

- M Shokooh-Saremi, VG Ta’Eed, NJ Baker, ICM Littler, DJ Moss,... et al., “High-performance Bragg gratings in chalcogenide rib waveguides written with a modified Sagnac interferometer”, JOSA B vol. 23 (7), 1323-1331 (2006).

- MRE Lamont, VG Ta’eed, MAF Roelens, DJ Moss, BJ Eggleton, DY Choi,... et al., “Error-free wavelength conversion via cross-phase modulation in 5cm of As2S3 chalcogenide glass rib waveguide”, Electronics Letters vol. 43 (17), 945-947 (2007).

- M Ferrera, Y Park, L Razzari, BE Little, ST Chu, R Morandotti, DJ Moss,... et al., “All-optical 1st and 2nd order integration on a chip”, Optics Express vol. 19 (23), 23153-23161 (2011).

- C Grillet, C Monat, CLC Smith, BJ Eggleton, DJ Moss, S Frédérick,... et al., “Nanowire coupling to photonic crystal nanocavities for single photon sources”, Optics Express vol. 15 (3), 1267-1276 (2007).

- VG Ta’Eed, MRE Lamont, DJ Moss, BJ Eggleton, DY Choi, S Madden,... et al., “All optical wavelength conversion via cross phase modulation in chalcogenide glass rib waveguides”, Optics Express vol. 14 (23), 11242-11247 (2006).

| Materials | Platforms | Thickness | PER (dB) | OBW (µm) | IL (dB) | Ref. |

| Graphene | Spatial-light | Monolayer | ‒ a | ~188 – 500 | ‒ a | [20] |

| Graphene | Spatial-light | Monolayer | ~10 | ~120 – 600 | ‒ a | [26] |

| BP | Spatial-light | ~96 nm | ~9 | ‒ a | ‒ a | [90] |

| GO | Spatial-light | ~1000 nm | ~20 | ~2 – 14 | ‒ a | [89] |

| MXene | Spatial-light | ~30 nm | ~6 | ~150 – 1000 | <2.0 | [66] |

| Perovskite | Spatial-light | ~40 nm | ‒ a | ~0.20 – 0.60 | ‒ a | [75] |

| Graphene | Fiber | Monolayer | ~27 | ~0.50 – 1.63 | ~5.0 | [17] |

| Graphene | Fiber | ~1.0 nm | ~16 | ~1.20 – 1.65 | ‒ a | [19] |

| Graphene | Fiber | Monolayer | ~38 | ~1.43 – 2.00 | ~1.0 | [99] |

| Graphene | Fiber | 2 layers | ~44 | ~1.56 – 1.63 | >5.0 | [98] |

| Graphene | Fiber | Monolayer | ~31 | ‒ a | ‒ a | [103] |

| Graphene/MoS2 | Fiber | Monolayer | ~19 | ~0.98 – 1.62 | <10.5 | [78] |

| GO | Fiber | ~24000 nm | ~36 | ~1.30 – 1.60 | ~2.2 | [100] |

| ReS2 | Fiber | Monolayer | ‒ a | ‒ a | <4.4 | [101] |

| Graphene | Polymer WG | ‒ a | ~19 | ‒ a | ~26.0 | [18] |

| Graphene | Glass WG | ‒ a | ~27 | ~1.23 – 1.61 | ~9.0 | [106] |

| Graphene | Chalcogenide glass-on-graphene WG | Monolayer | ~23 | ~0.94 – 1.60 | ~0.8 | [21] |

| Graphene | Polymer WG | > or < 10 nm b | ~6 | ‒ a | ~9.0 | [22] |

| GO | Polymer WG | ~2000 nm | ~40 | ~1.53 – 1.63 | ~6.5 | [110] |

| GO | Doped silica WG | ~2 – 200 nm | ~54 | ~0.63 – 1.60 | ~7.5 | [34] |

| MoS2 | Nd:YAG waveguide | ~6.5 nm | ~3 | ‒ a | ~0.4 | [111] |

| MoS2 | Polymer WG | ~2.5 nm | ~12.6 | ~0.65 – 0.98 | <10 | [112] |

| BP | Metamaterial WG | ~0.5 nm | ~30 | ~0.50 – 0.80 | ~0.3 | [114] |

| MoSe2 | Polymer WG | ~24000 nm | ~14 | ~0.98 – 1.55 | ‒ a | [113] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).