1. Introduction

Globally, biomass serves as a significant energy source, with over 90% of biomass energy generated through direct combustion methods such as wood-fired heating plants and wood pellet burners [

1]. The global energy-related CO2 emissions rose to 33 billion metric tons in 2021 from 20.5 billion metric tons in 1990, highlighting the urgent need for the world to shift towards cleaner renewable energy sources [

2]. In 2020, the total primary energy supply was 585 EJ globally, with fossil fuels accounting for 80% (coal 27%, oil 29%, and gas 24%), nuclear power contributing 29.2 EJ, 5%, and renewable energy technologies such as solar, wind, hydro, biomass, and geothermal accounting for 15%. According to International Energy Agency - Bioenergy, especially modern biofuels account for the largest renewable energy source constituting 55% of renewable energy and over 6% of the global energy supply [

3]. Despite fossil fuels currently dominating the global energy supply, there has been a paradigm shift towards promoting and using renewable energy technologies, playing a pivotal role in mitigating climate change, improving human health, and decarbonizing energy systems [

4].

Nepal, primarily an agricultural country, heavily relies on traditional biomass [

5], with 77% of the country’s energy consumption coming from sources like cattle dung, wood fuel, and agricultural residues [

6]. The estimated supply potential of agricultural residues in Nepal was 26 million tons in 2021, producing about 442 million GJ of energy, highlighting the potential for transitioning towards modern biofuels. In 2022, Nepal's total energy consumption reached 640PJ, with traditional sources accounting for 64.17% and fuelwood dominating at 58.53% of total fuel consumption. With abundant agricultural residues and significant forest cover encompassing 45% of its territory, Nepal is well-positioned for the production and utilization of modern biofuels [

7]. However, properly identifying biomass in terms of its energy properties, managing it efficiently, and utilizing it effectively poses significant challenges. Therefore, research on characterizing Nepal's biomass for rapid and reliable evaluation of its energy properties non-destructively is of utmost importance and constitutes a national priority research domain.

Near Infrared Spectroscopy (NIRS) has broad multidisciplinary applications in quality control, quality assurance, and real-time screening across various fields, including energy, agriculture, agri-food, medicine, polymer, chemical production, cosmetics, and water quality analysis [

8,

9,

10]. NIRS utilizes the near-infrared light spectrum to analyze molecular information in samples of various states, shapes, and thicknesses by measuring absorption bands resulting from overtones and combination excitation [

11], making it valuable for assessing compounds and their concentrations. It offers a wide range of benefits over conventional destructive techniques as it provides accurate qualitative and quantitative results in under a minute non-destructively, without using any chemicals. This makes it an eco-friendly and non-contact analysis technique.

Biomass effectively absorbs near infrared radiation within the NIR range of 3598 to 12489 cm

−1 [

12,

13]. Therefore, in the energy sector, the combination of NIRS with chemometrics is particularly useful for predicting and evaluating biomass energy properties, including HHV, proximate analysis parameters (moisture content, volatile matter, fixed carbon, ash content), and ultimate analysis parameters (carbon, hydrogen, sulfur, oxygen, and nitrogen). These parameters are vital components in the design and analysis of any bioenergy system [

14]. Shrestha,

et al. studied the effect of combined non-wood and wood spectra of biomass chips for the rapid prediction of ultimate analysis parameters using FT-NIRS [

15]. Elena,

et al. monitored the qualitative properties of commercialized pellets to rapidly assess whether they were made of virgin or chemically treated wood using FT-NIRS [

16]. Fumin,

et al. developed a model combining partial least squares and artificial neural networks to estimate sugarcane stalk bending strength and flexural rigidity via FT-NIR spectrum calibration [

17]. Cristiano,

et al. predicted the lignin content of tropical Amazon woods using FT-NIRS [

18]. Livia,

et al. studied the potential of FT-NIRS for predicting cellulose nanofibril quality in commercial bleached kraft pulp of Eucalyptus [

19]. Shrestha,

et a

l. developed the PLSR model combined with chip and ground biomass FT-NIR spectra for the evaluation of proximate analysis parameters as an alternative to a thermogravimetric analyzer [

20]. Phoomwarin,

et al. enhanced the evaluation of sugarcane energy content for energy cane varieties selection purposes in breeding programs using FT-NIRS [

21]. Shrestha,

et al. conducted a comprehensive assessment of biomass properties for energy usage using FT-NIRS and spectral multi-preprocessing techniques [

12]. All the research mentioned above highlights the potential of FT-NIRS for the rapid and non-destructive evaluation of different biomass properties. Therefore, in this study, we have proved a partial least square regression (PLSR) based model developed for the rapid non-destructive prediction of the HHV of biomass for energy usage in industry.

The research output of this study will be applicable to various stakeholders. This includes biomass traders who trade biomass based on volume or weight rather than its actual energy content, engineers and researchers involved in the design and development of different bio-based technologies, particularly in combustion via combined heat and power systems, industries reliant on biomass for the production of quality biomass pellets and briquettes, and policymakers seeking accurate forecasts of biomass energy, mainly from fast-growing trees and agricultural residues.

2. Materials and Methods

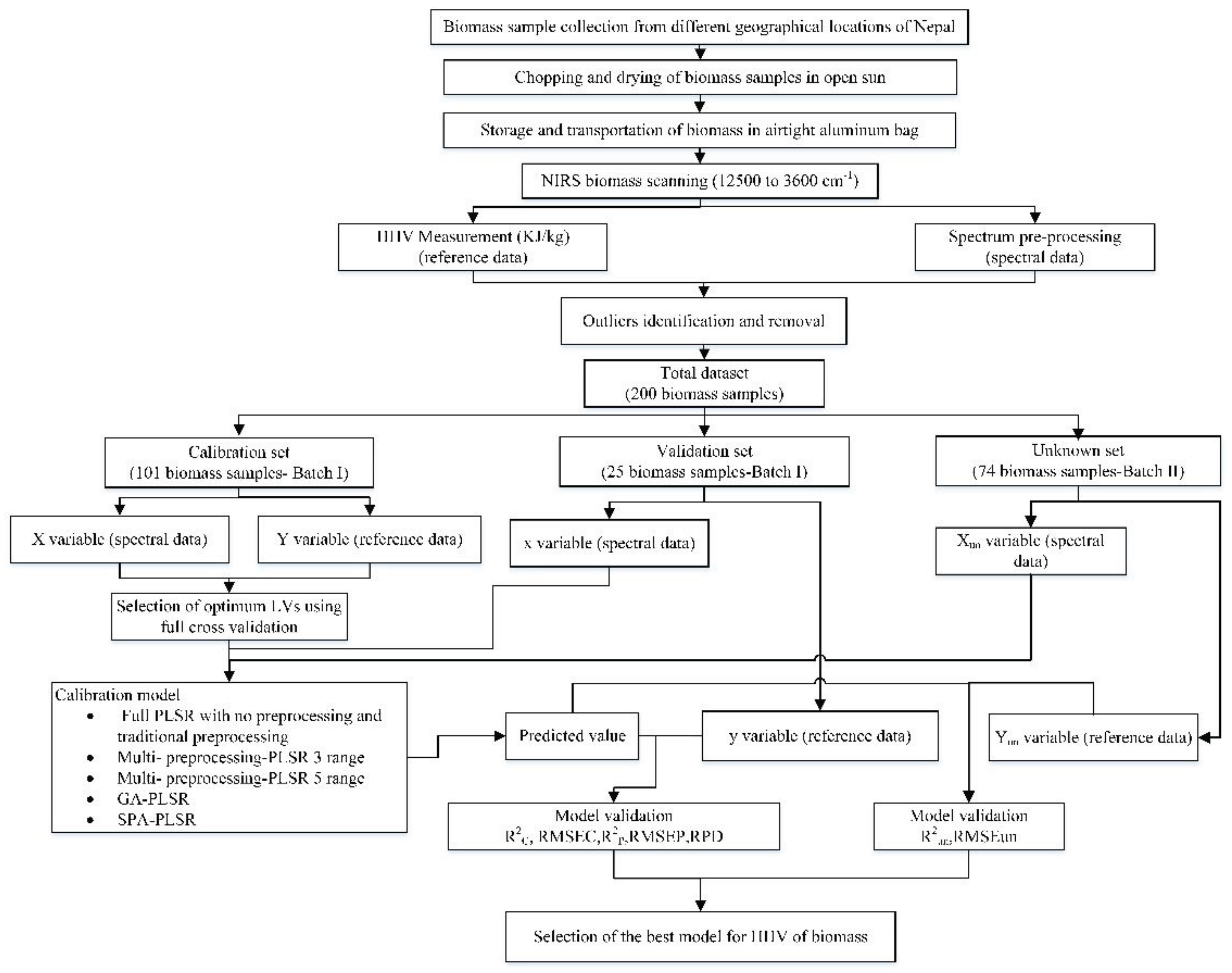

Figure 1 illustrates the overall research methodology for the rapid and non-destructive evaluation of the HHV of biomass collected from various locations in Nepal, employing a combination of NIRS with PLSR-based models.

2.1. Sample Collection

Figure 2 shows the geographical location of Nepal, district-wise, from which biomass samples were collected. The biomass samples include five varieties each of fast-growing trees:

Alnus nepalensis, Pinus roxburghii, Bambusa vulgaris, Bombax ceiba, and

Eucalyptus camaldulensis and of agricultural residues

: Zea mays (cob),

Zea mays (shell),

Zea mays (stover),

Oryza sativa, and

Saccharum officinarum. The biomass samples were collected in two batches. In the first batch (I) a total of 126 biomass samples were collected in January to February 2021, which were used for developing the calibration model. The second batch (II) includes 74 biomass samples that were collected in January 2022, which were used as an unknown sample set to prove the performance of the model to be used in biomass industries. All the samples were manually chopped into pieces smaller than 30 mm by 15 mm, and then dried in the open sun. They were stored in airtight aluminum bags to prevent the exchange of air and moisture. The bags were only opened during FT-NIRS scanning of specific biomass.

2.2. FT-NIRS Sample Scanning

Biomass samples from both batches (I and II) were scanned across the full NIR wavenumber range (3598−12489 cm

−1) using an FT-NIR spectrometer (MPA, Bruker, Ettlingen, Germany) in diffuse reflectance with a sphere macro sample rotating setup, while maintaining consistent laboratory conditions, i.e., air conditioning at a temperature of 25±2°C [

15].

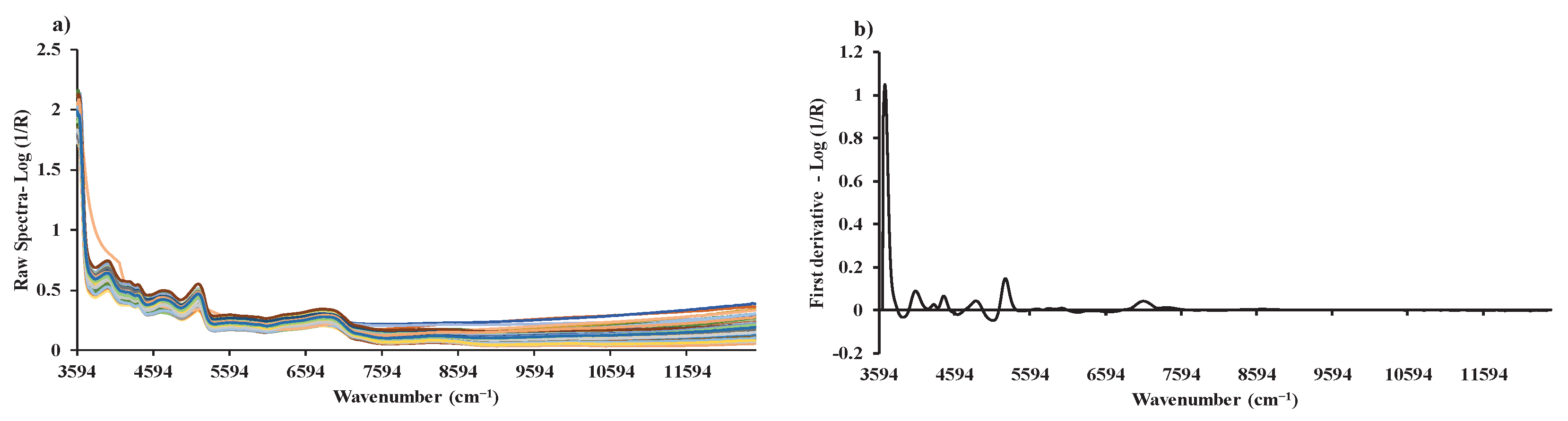

Figure 3 displays the raw spectra obtained after scanning biomass samples of fast-growing trees and agricultural residues used in this research. The biomass located at the bottom of the scanning cup was collected and immediately subjected to the evaluation of HHV using a bomb calorimeter.

2.3. Higher Heating Value (Reference Data)

Approximately 0.5 ± 0.2 g of biomass was collected from the bottom of the FT-NIR spectrometer scanning cup. The biomass was manually compressed using a laboratory-scale pelletizer to form biomass tablets, which were then weighted using an electronic balance (Mettler Toledo JS1203C). The HHV was determined using an automatic bomb calorimeter (IKA C 200, Staufen, Baden-Württemberg, Germany) employing the isoperibol method [

12].

2.4. Spectral Preprocessing

The raw spectra obtained from the FT-NIR spectrometer mainly contains baseline shifts and noise, attributed to instrument artifacts, light scattering, and variations in moisture and temperature. Therefore, in this study, the raw spectra were preprocessed using ten different techniques, including constant offset, SNV, MSC, first derivative, second derivative, vector normalization, min-max normalization, mean centering, first derivative + vector normalization, and first derivative + MSC. Additionally, the raw spectra were pretreated using multi-preprocessing techniques with 3-range and 5-range methods proposed by Shrestha et al [

12,

15]. Following the preprocessing of the raw spectra, PLSR-based models were developed.

2.5. PLSR Based Model Development

Before model development, outliers from the reference data were identified using equation (1).

Where,

represents the measured value of sample i, while

and SD denote the average and standard deviation, respectively, of the measured values across all samples [

12,

15,

20]

If equation (1) is satisfied, the sample is considered an outlier, and both the reference value and spectral data of that specific sample are excluded from the dataset.

Based on the available dataset, after removing outliers, the total dataset is divided into a calibration set (80%) and a validation set (20%) manually where the calibration set comprises the maximum and minimum HHV values of biomass samples to ensure the model’s capability in predictions of prediction set. Full-PLSR models were developed using raw spectra and ten different preprocessing methods. Similarly, SPA-PLSR and GA-PLSR selected NIR bands based models were also developed using raw spectra and ten different preprocessing methods. Additionally, PLSR models based on multi-preprocessing 3-range and 5-range techniques were developed. The performance of the models was evaluated based on R2C, RMSEC, R2P, RMSEP, RPD, and bias values. The best-performing models were selected based on a comparison between higher R2C, R2P, and RPD values and lower RMSEC and RMSEP values. Furthermore, best performing models were validated using the unknown sample set. The performance of the model based on unknown sample set was proved in terms of R2UN, RMSEUN, and RPDUN.

Then updating model was developed by combining the samples in calibration set, validation set and unknown set and made the model using the best pretreated method spectra and the best PLSR algorithm selected in previous procedure. The updating model was validated by leave one out cross validation. The performance of the updating model based on cross validation was reported in terms of R2CV, RMSECV, and RPDCV.

The interpretation of R

2 in the calibration set, validation set, and unknown sample set is conducted according to the guidelines established by Williams,

et al. [

22], while RPD values for the respective sets were assessed based on the guidelines provided by Zornoza,

et al. [

23].

All PLSR based modeling was carried out using the built-in MATLAB R2020b code (MathWorks, USA).

3. Results

Table 1 shows the descriptive statistics of samples in calibration set, validation set and unknown set.

As explained in section 2.5, outliers for reference data were calculated using equation (1) before model development. Out of the 126 biomass samples collected from the first batch, 4 samples were identified as outliers and subsequently removed from the total dataset to develop PLSR-based models for evaluating the HHV.

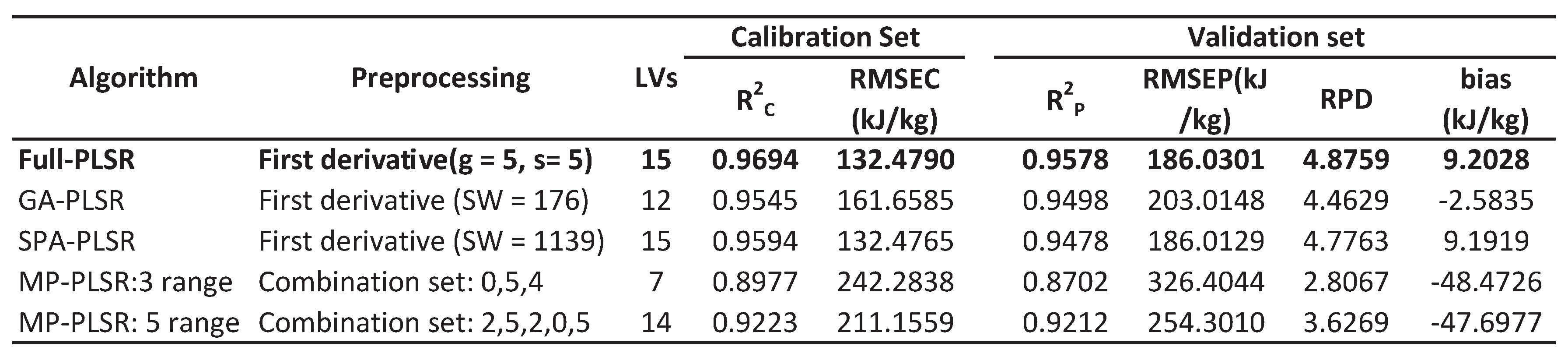

Table 2 shows best performing models obtained from Full-PLSR, GA-PLSR, SPA-PLSR, MP-PLSR: 3 range, and MP-PLSR: 5 range methods. Out of the five different PLSR-based models, Full-PLSR with the first derivative, having a segment and gap of 5 each, and number of latent variable (LVs) of 15 demonstrates the best performance with an R

2C of 0.9694, RMSEC of 132.4790 kJ/kg, R

2P of 0.9578, RMSEP of 186.0301 kJ/kg, RPD of 4.8759 and bias of 9.2028 kJ/kg. The accuracy of Full-PLSR improved by 6.77% with spectral preprocessing using the first derivative compared to that of Full-PLSR using raw spectra.

Table 2.

Results of the PLSR-based model for the HHV (kJ/kg) of biomass, with best performing model highlighted in bold.

Table 2.

Results of the PLSR-based model for the HHV (kJ/kg) of biomass, with best performing model highlighted in bold.

The model's performance on the validation set, assessed following guidelines by Williams,

et al. [

22] for R

2P and Zornoza,

et al. [

23] for RPD, indicates that the selected model, Full-PLSR with preprocessing from the first derivate, can be applied in various applications, including quality assurance, and demonstrates excellent prediction capabilities.

Similarly, 74 biomass samples collected from the second batch were scanned in an FT-NIR spectrometer under the same laboratory conditions, and their HHV was evaluated. These samples were used as an unknown sample set. The performance of the unknown sample set was evaluated in terms of R

2UN, RMSEUN, RPD

UN, and BiasUN, resulting in values of 0.8089, 360.8845 kJ/kg, 2.44, and -131.4356 kJ/kg, respectively. The model's performance is comparatively lower for the unknown sample set compared to the validation set. This discrepancy could stem from differences in biomass characteristics, environmental conditions during sample collection, and variations in sample preparation. Also, seasonal variations in plant growth may influence the chemical composition of the biomass, thereby affecting its HHV. Based on the performance of the unknown sample set, following Williams,

et al. [

22] and Zornoza,

et al. [

23] the model can make approximate quantitative predictions for screening and other appropriate calibrations.

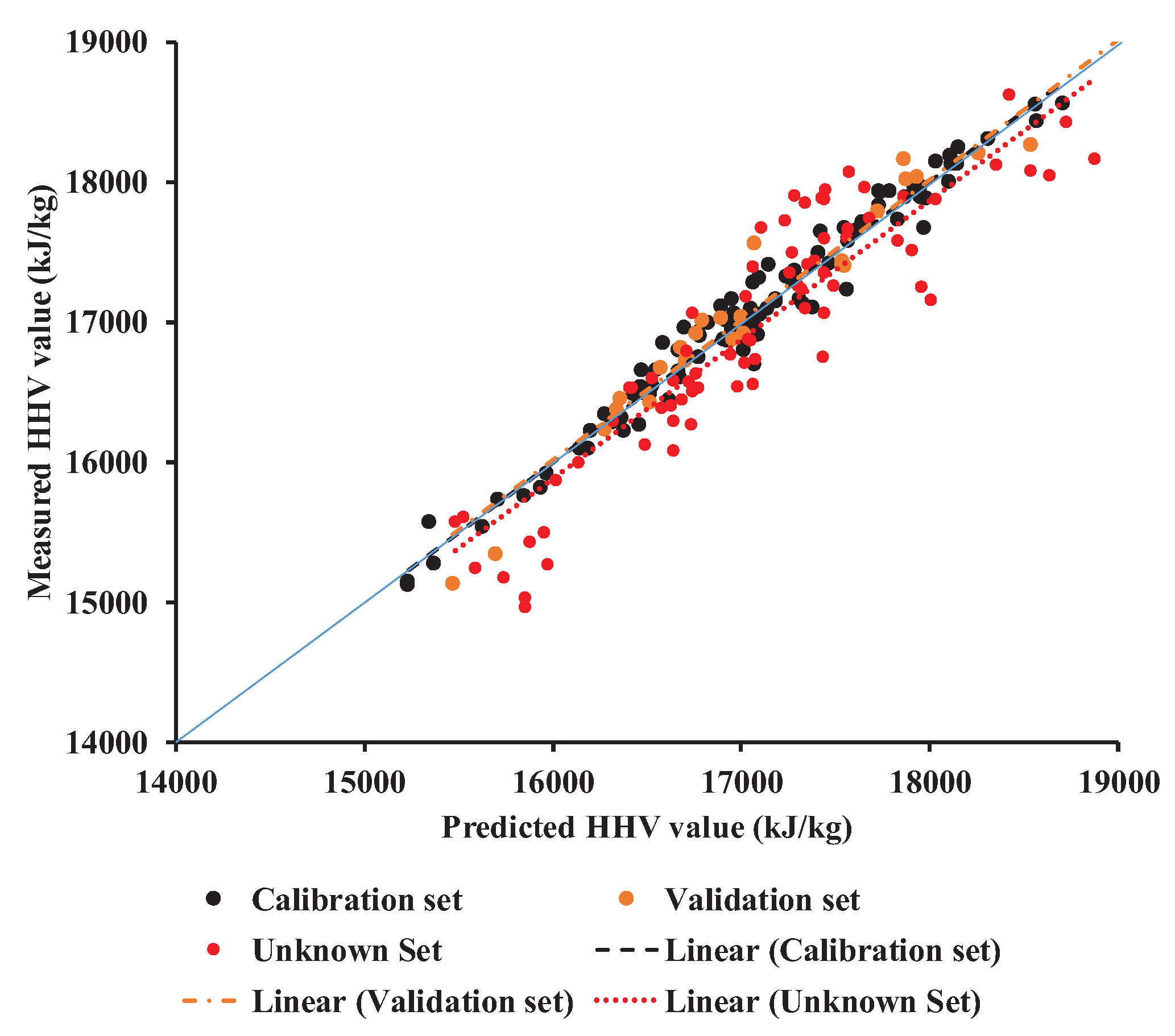

Figure 4 displays the measured and predicted values of calibration, validation, and unknown samples for the Higher Heating Value (HHV) of biomass obtained using Full-PLSR. In the figure, the trend lines for the calibration and validation sets overlap, indicating similar predictability. However, the trend line for the unknown sample set shows an offset compared to the trend lines for the calibration set and the validation set, as well as the 45-degree target line. This offset raises concerns about the model's performance with the unknown sample set. Therefore, by existing NIRS protocol, the unknown set and validation set have to be input into updating model to be used in future for higher robustness of the model specifically.

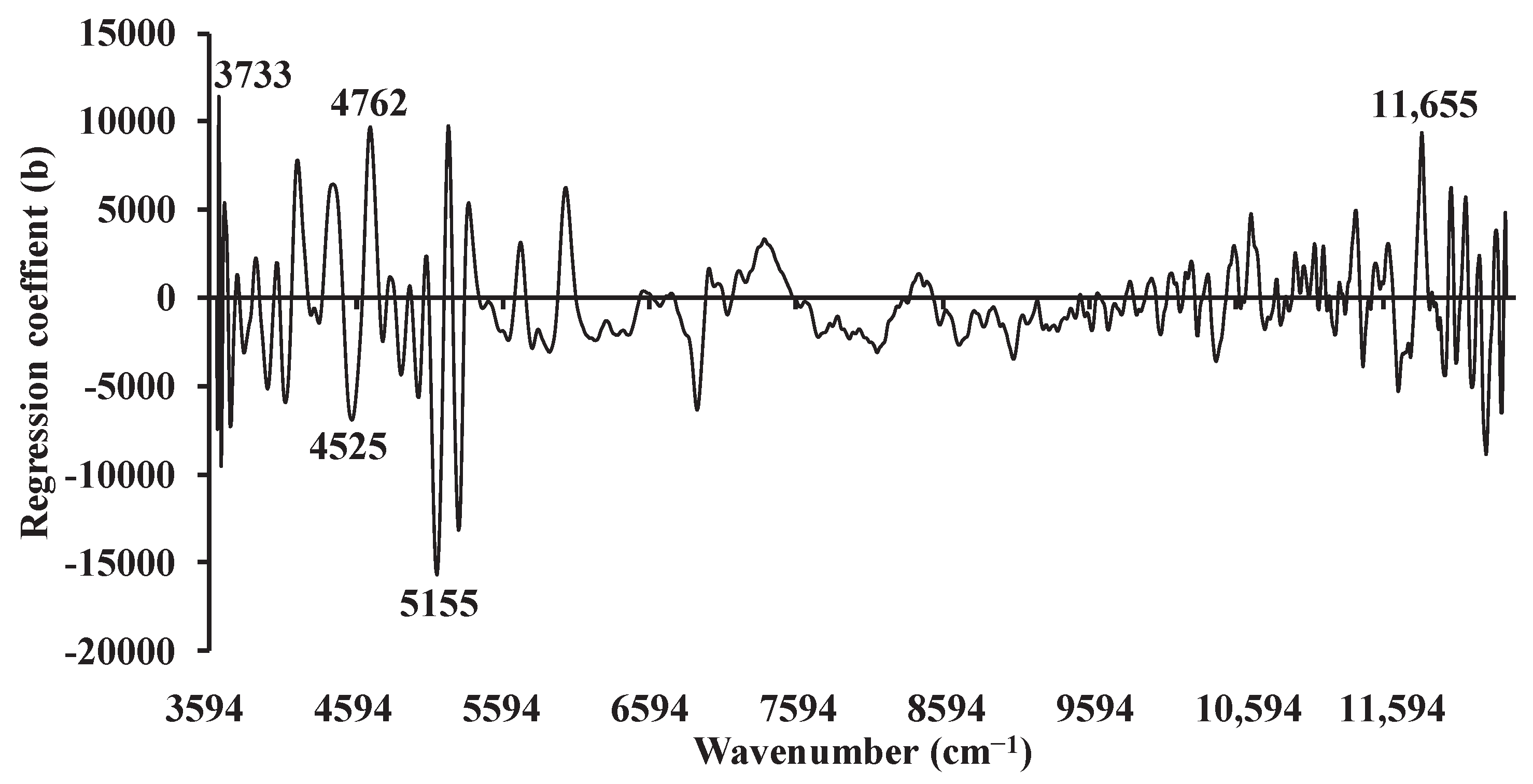

Figure 5 shows the regression coefficient plot for HHV (kJ/kg) of the biomass, which is obtained from the first derivative preprocessing Full-PLSR model. The significant peaks were observed at wavenumbers 3733, 4525, 4762, 5155 and 11655 cm

−1 which might have significant influence in the performance of the model. Interpreted by Workman and Weyer [

24]: the positive peak at 3733 cm

−1 corresponds to the functional group of C−H aromatic with material types as C−H aryl. Similarly, the negative peak at 4525 cm

−1 corresponds to the spectral-structure of the second overtone of fundamental stretching band of N-H for NH3 in water, and functional group of N-H ammonia in water. The peaks at 4762 cm

−1 are associated with spectra structure of combination of O-H bending and C-O stretching with material type as polysaccharides. The peaks at 5122 cm

−1 are associated with combination of O-H stretching and HOH bending with material type as a water. The peak at 11655 cm

−1 corresponds to the third overtone of fundamental stretching band of C-H with material type as hydrocarbons, aromatic. These findings provide valuable insights into the spectral features contributing to the prediction of HHV in biomass.

Table 3 shows the performance of updating model created by using every sample spectra in full wavenumber range of calibration set, validation set and unknown set pretreated by first derivative (g = 5, s = 5) and corresponding HHV and subjecting to PLSR. The result shows that when the LVs was 15 as same as the selected model of the best performance, the R

2CV was 0.95 and RMSECV and SECV was very closed to each other. Therfore, the average error or bias was very closed to zero. R

2CV of 0.95 and RPD

CV was 4.6 indicating that the model was excellent for any application including HHV of biomass quantification. This is proved for the updating model can be the base model for practical implementing in biomass industries.

4. Discussion

Two general classes of spectrometers including wavelength-dispersive and Fourier transform (FT), where the former, the wavelength selector only passes selected, narrow wavelength windows that can reach detector at a time [

25]. By FT principle, an interferometer (mostly Michelson interferometer is employed) enables a simultaneous incidence of all wavelengths on the detector and spectrum is obtained through Fourier transform [

25]. The FTIR spectrometers have the well-known advantages of the approach: "Fellgett advantage”: Multiplex operation, i.e. all wavelengths are captured simultaneously, resulting in short scan times; "Jacquinot advantage”: High optical throughput as no slits limit the aperture, resulting in a good signal-to-noise ratio (SNR); “Connes advantage”: Linearity of the wavelength scale can easily be calibrated, e.g. using a reference laser [

26].

The NIR spectra obtained by FT-NIR spectrometer with full wavenumber range of 12500-4000 cm

-1 combined with PLSR for HHV of biomass prediction model development is shown in some researches, for example, rice husk [

27], ground sorghum biomass [

28], wood sawdust from

Eucalyptus benthamii Maiden & Cambage,

Eucalyptus dunnii Maiden and

Eucalyptus saligna Sm [

29], ground bamboo [

30], bamboo wood chip [

31], biomass made up of needles, twigs, branches, bark and wood of

Pinus taeda (loblolly pine) [

32], ground biomass of fast growing trees and agricultural residue [

33], and ground cassava rhizome [

34] in which the R

2P were 0.79, 0.96, 0.98, 0.92, 0.84, 0.34, 0.96, and 0.90, respectively. As expected, the homogeneous of ground biomass models provide better R

2P due to less noise in scattering. Although ground sample described a better performance, the operation in the power plant was found to be inconvenient due to sample preparation costs and labour required for the necessary preparation of ground samples [

31].

However, in case of our result of model performance for wood chip biomass of fast growing trees and agricultural residue show better R

2P of 0.96 and R

2UN of 0.81 which indicating outperform of the model to bamboo wood chip model (R

2P of 0.84) which contained only one specie. It was noticed for model for biomass made up of needles, twigs, branches, bark and wood of

Pinus taeda (loblolly pine) [

32] which provided very low R

2P indicating the cause and effect must be researched which, for example, might be due to heterogeneous sample while scanning, though same specie when other models mentioned before were scanned on more homogeneous with smaller particle size of same specie. The FTIR spectra (4000-650 cm

−1) of whole tree, wood and bark, slash (i.e., limbs and foliage), and clean wood chips in ground form of several loblolly pine plantations combined with PLSR provided R

2P by cross validation of 0.64 [

35], though not well but very better than, by NIR spectroscopy (R

2P of 0.34) [

30] obviously. By 400-750 nm visible spectra of

Eucalyptus sawdust obtained by spectrophotometer, PLSR model provided R

2P of 0.985 [

29] and by 10000-4000 cm

−1 FT-NIR spectra of the same sample, PLSR model provided better R

2P of 0.9779 [

29]. There was very few reports on combined different species of biomass in one model like we did. Additionally without any other reports, our updating PLSR model for HHV of wood chip of fast growing trees and agricultural residue was proved for capability to implement for biomass industrial use.

5. Conclusions

The rapid non-destructive modeling created by FT-NIR sensor confirmed its phenomenon in biomass energy prediction in this work. It is proved that wood chip Nepali biomass prediction model developed for evaluation of HHV of the biomass is ready to be installed in the biomass industry for updating in the industrial environment by developing the robust model combining the calibration, validation, and unknown sets. This finding is not only useful to biomass industry but for other various stakeholders including biomass traders, engineers and researchers involved in the design and development of energy system, for example, in combustion via combined heat and power systems, and renewable energy policymakers.

Author Contributions

B.S.: conceptualization, methodology, software, formal analysis, investigation, resources, data curation, visualization, writing the original draft, writing—review and editing. T.P.: software, formal analysis. Z.S.: investigation. J.P.: conceptualization, methodology, software, formal analysis, data curation, writing—review and editing, supervision. P.S.: conceptualization, methodology, data curation, writing the original draft, writing—review and editing, validation, supervision, project administration, funding acquisition. B.P.S.: conceptualization, methodology, writing—review and editing, project administration, and supervision. P.P.: conceptualization, methodology, writing—review and editing, and supervision. H.A.: writing the original draft, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by King Mongkut’s Institute of Technology Ladkrabang (KMITL), Thailand through KMITL doctoral scholarship KDS 2020/52 and The APC was partially funded by the School of Engineering, KMITL, Bangkok, Thailand.

Data Availability Statement

The data will be made available upon request from the corresponding author.

Acknowledgments

The authors would like to express their sincere gratitude to the Near-Infrared Spectroscopy Research Center for Agricultural Products and Food, the Department of Agricultural Engineering, School of Engineering at King Mongkut’s Institute of Technology, Ladkrabang, Bangkok, Thailand, for their generous research funding support provided through the KMITL doctoral scholarship (KDS 2020/052).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- El-Sayed, S.A.; Mostafa, M.E.; Khass, T.M.; Noseir, E.H.; Ismail, M.A. Combustion and mass loss behavior and characteristics of a single biomass pellet positioning at different orientations in a fixed bed reactor. Biomass Conversion and Biorefinery 2023, 1–21. [Google Scholar] [CrossRef]

- IEA. CO2 Emissions—Global Energy Review 2021—Analysis—IEA. 2021.

- IEA. Bioenergy - Tracking Clean Energy Progress 2023. Available online: https://www.iea.org/energy-system/renewables/bioenergy (accessed on 1 February 2024).

- Share of global primary energy consumption by source, 2022. Available online: https://ourworldindata.org/grapher/global-primary-energy-share-inc-biomass?time=1800 (accessed on 1 February 2024).

- Poudyal, R.; Regmi, S. Review on Future of Biomass Energy: A Case of Nepal. Engineering for Environment 2023, 63. [Google Scholar]

- Bhattarai, B. The Industrialization of forest-based bioenergy production in Nepal and its impacts on women and other forest-dependent people; NAFAN, Nepal: 2019.

- Kafle, S.; Parajuli, R.; Adhikari, K.; Euh, S.H.; Oh, K.C.; Choi, Y.S.; Kim, D.H. Forest-based biomass supply potential and economics for the pellet production in Nepal. International Journal of Green Energy 2018, 15, 1–7. [Google Scholar] [CrossRef]

- Dos Santos, C.A.T.; Lopo, M.; Páscoa, R.N.; Lopes, J.A. A review on the applications of portable near-infrared spectrometers in the agro-food industry. Applied spectroscopy 2013, 67, 1215–1233. [Google Scholar] [CrossRef]

- Ferrari, M.; Quaresima, V. A brief review on the history of human functional near-infrared spectroscopy (fNIRS) development and fields of application. Neuroimage 2012, 63, 921–935. [Google Scholar] [CrossRef]

- Mancini, M.; Mazzoni, L.; Gagliardi, F.; Balducci, F.; Duca, D.; Toscano, G.; Mezzetti, B.; Capocasa, F. Application of the non-destructive NIR technique for the evaluation of strawberry fruits quality parameters. Foods 2020, 9, 441. [Google Scholar] [CrossRef]

- Beć, K.B.; Grabska, J.; Huck, C.W. Near-infrared spectroscopy in bio-applications. Molecules 2020, 25, 2948. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P. Comprehensive Assessment of Biomass Properties for Energy Usage Using Near-Infrared Spectroscopy and Spectral Multi-Preprocessing Techniques. Energies 2023, 16, 5351. [Google Scholar] [CrossRef]

- Adnan, A.; Horsten, D.V.; Pawelzik, E.; Morlein, A.D. Rapid Prediction of Moisture Content in Intact Green Coffee Beans Using Near Infrared Spectroscopy. Foods 2017, 6. [Google Scholar] [CrossRef]

- Kocer, A. Prediction of the higher heating values of biomass using machine learning methods based on proximate and ultimate analysis. Journal of Mechanical Science and Technology 2024, 38, 1569–1574. [Google Scholar] [CrossRef]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P.; Funke, A. Effect of Combined Non-Wood and Wood Spectra of Biomass Chips on Rapid Prediction of Ultimate Analysis Parameters Using near Infrared Spectroscopy. Energies 2024, 17, 439. [Google Scholar] [CrossRef]

- Leoni, E.; Gasperini, T.; Di Marzio, N.; Picchio, R.; Toscano, G.; Duca, D. Application of Near Infrared Spectroscopy for the Detection of Chemically Treated Pellets Unsuitable for Combustion. Energies 2024, 17, 825. [Google Scholar] [CrossRef]

- Ma, F.; Wang, M.; Yan, N.; Adnan, M.; Jiang, F.; Hu, Q.; He, G.; Shen, Y.; Wan, Y.; Yang, Y. A fast and efficient phenotyping method to estimate sugarcane stalk bending properties using near-infrared spectroscopy. European Journal of Agronomy 2024, 154, 127107. [Google Scholar] [CrossRef]

- Nascimento, C.S.d.; Cruz, I.d.A.; Araújo, R.D.d.; Soares, J.C.R.; Eugenio da Silva, C.; Nascimento, C.C.d.; Santos, J.d.; Higuchi, N. A rapid and nondestructive method for the prediction of lignin content in tropical Amazon woods using FT-NIR spectroscopy. Journal of the Indian Academy of Wood Science 2024, 1-12. [Google Scholar] [CrossRef]

- Costa, L.R.; Dos Santos, A.d.A.; Dias, M.C.; Silva, L.E.; Wood, D.F.; Williams, T.G.; Hein, P.R.G.; Tonoli, G.H.D. Potential of NIR spectroscopy for predicting cellulose nanofibril quality in commercial bleached Kraft pulp of Eucalyptus. Carbohydrate Polymers 2024, 329, 121802. [Google Scholar] [CrossRef]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P.; Pornchaloempong, P.; Funke, A. NIR Spectroscopy as an Alternative to Thermogravimetric Analyzer for Biomass Proximate Analysis: Comparison of Chip and Ground Biomass Models. Energies 2024, 17, 800. [Google Scholar] [CrossRef]

- Phoomwarin, K.; Posom, J.; Saengprachatanarug, K.; Phuphaphud, A. Enhancing of the rapid evaluation of sugarcane energy content for energy cane varieties selection purposes in breeding program using Near-Infrared spectroscopy (NIRS). Engineering & Applied Science Research 2024, 51. [Google Scholar]

- Williams, P.; Manley, M.; Antoniszyn, J. Near infrared technology: getting the best out of light; African Sun Media: 2019.

- Zornoza, R.; Guerrero, C.; Mataix-Solera, J.; Scow, K.M.; Arcenegui, V.; Mataix-Beneyto, J. Near infrared spectroscopy for determination of various physical, chemical and biochemical properties in Mediterranean soils. Soil Biology and Biochemistry 2008, 40, 1923–1930. [Google Scholar] [CrossRef] [PubMed]

- Workman, J.; Weyer, L. Practical guide to interpretive near-infrared spectroscopy; CRC Press: Boca Raton, 2007. [Google Scholar]

- Huck, C.W. New Trend in Instrumentation of NIR Spectroscopy—Miniaturization. In Near-Infrared Spectroscopy: Theory, Spectral Analysis, Instrumentation, and Applications, Yukihiro Ozaki, C.H., Satoru Tsuchikawa, Søren Balling Engelsen, Ed.; Springer: Singapore, 2020; pp. 193–210. [Google Scholar]

- Grüger, H. MOEMS and MEMS - Technology, Benefits & Uses. In Portable Spectroscopy and Spectrometry, Richard Crocombe, P.L., Brooke Kammrath, Ed.; John Wiley & Sons, Inc: 2021; pp. 89-113.

- Nakawajana, N.; Posom, J.; Paeoui, J. The prediction of higher heating value, lower heating value and ash content of rice husk using FT-NIR spectroscopy. Engineering Journal 2018, 22, 45–56. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, L.; Brady, M.; Xu, F.; Yu, J.; Wang, D. Fast analysis of high heating value and elemental compositions of sorghum biomass using near-infrared spectroscopy. Energy 2017, 118, 1353–1360. [Google Scholar] [CrossRef]

- Gmach, F.; Jacobowski, L.; Júnior, E.A.B.; Lengowski, E.C.; Oliveira, R.S.; Silva, D.A.d.; Nisgoski, S.; Viana, L.C.; Stangerlin, D.M. Performance of visible and Near-infrared spectroscopy to predict the energetic properties of wood. Maderas. Maderas Ciencia y tecnologí 2023, 26. [Google Scholar] [CrossRef]

- Posom, J.; Sirisomboon, P. Evaluation of the higher heating value, volatile matter, fixed carbon and ash content of ground bamboo using near infrared spectroscopy. Journal of Near Infrared Spectroscopy 2017, 25. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Funke, A.; Posom, J. Improvement of proximate data and calorific value assessment of bamboo through near infrared wood chips acquisition. Renewable Energy 2020, 147, 1921–1931. [Google Scholar] [CrossRef]

- Acquah, G.E.; Via, B.K.; Fasina, O.O.; Eckhardt, L.G. Non-destructive prediction of the properties of forest biomass for chemical and bioenergy applications using near infrared spectroscopy. Journal of Near Infrared Spectroscopy 2015, 23. [Google Scholar] [CrossRef]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P. Comprehensive assessment of biomass properties for energy usage using near-infrared spectroscopy and spectral multi-preprocessing techniques. Energies 2023, 16, 5351. [Google Scholar] [CrossRef]

- Nakawajana, N.; Posom, J. Comparison of analytical ability of pls and svm algorithm in estimation of moisture content, higher heating value, and lower heating value of cassava rhizome ground using FT-NIR spectroscopy. In Proceedings of the The 12th TSAE International Conference, Hard Rock Hotel Pattaya, Chonburi, Thailand, 2019., 14-15 March 2019. [Google Scholar]

- Acquah, G.E.; Via, B.V.; Fasina, O.O.; Eckhardt, L.G. Rapid quantitative analysis of forest biomass using fourier transform infrared spectroscopy and partial least squares regression. Journal of Analytical Methods in Chemistry 2016, 2016, 1–10. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).