Submitted:

22 March 2024

Posted:

25 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Weldability

3. Technics for Joining of Vehicle Components Made of Al Alloy

3.1. Various Kinds of Welding Process

3.1.1. Conventional Welding

3.1.2. Friction Stir Welding

3.1.3. Resistance Spot Welding

3.1.4. Gas Metal Arc Welding GMAW

3.1.5. Cold Metal Transfer Welding

3.1.6. Collision Welding

3.1.7. Magnetic Pulse Welding

3.1.8. Laser Welding

3.2. Problems during Welding Process

3.3. Al Alloys for Welding

| Group of aluminium alloys | Main alloy components | Durability | Weldability |

|---|---|---|---|

| 2XXX | Al – Cu | High | Low |

| 5XXX | Al – Mg | Increased | High |

| 6XXX | Al – Si – Mg | Increased | High |

| 7XXX | Al – Zn | High | Low |

3.3.1. Similar Al Alloys

3.3.2. Dissimilar Al Alloys

4. Features of Al Welded Joints and Phenomena Occurred Therein

4.1. TIG and MIG Welding Methods

4.2. Cold Metal Transfer CMT Welding Method

4.3. Laser Welding

4.4. Laser-MIG Hybrid Welding

4.5. The Laser -MIG Hybrid Welding Seems to be Particularly Useful for Some Al Alloys of 5xxx Series. Such a Technique Is Under Continuous Development Laser Mirror Imagewelding and Laser Impact Welding

4.6. Electron Beam Welding

4.7. Resistance Spot Welding RSW

4.8. Friction Welding

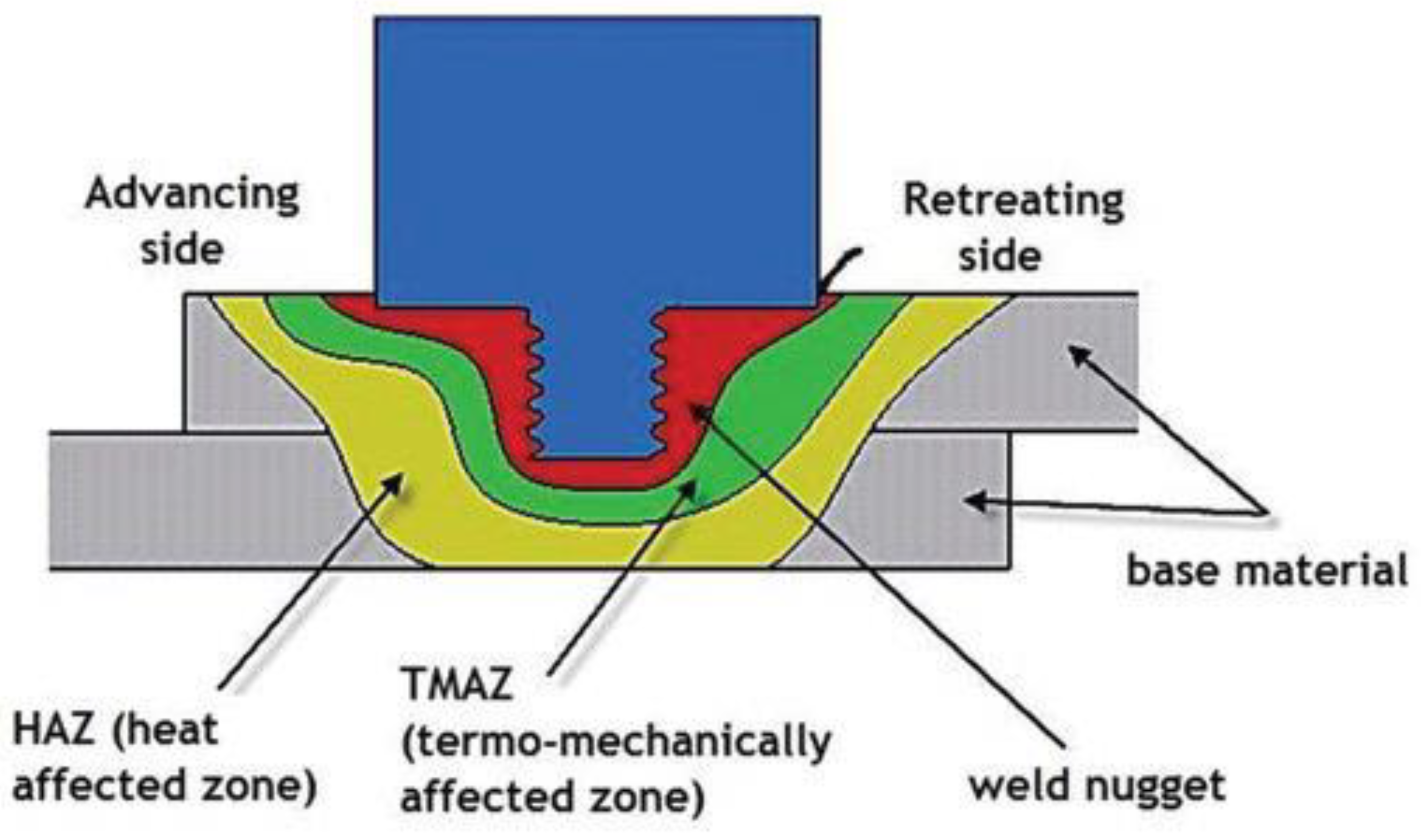

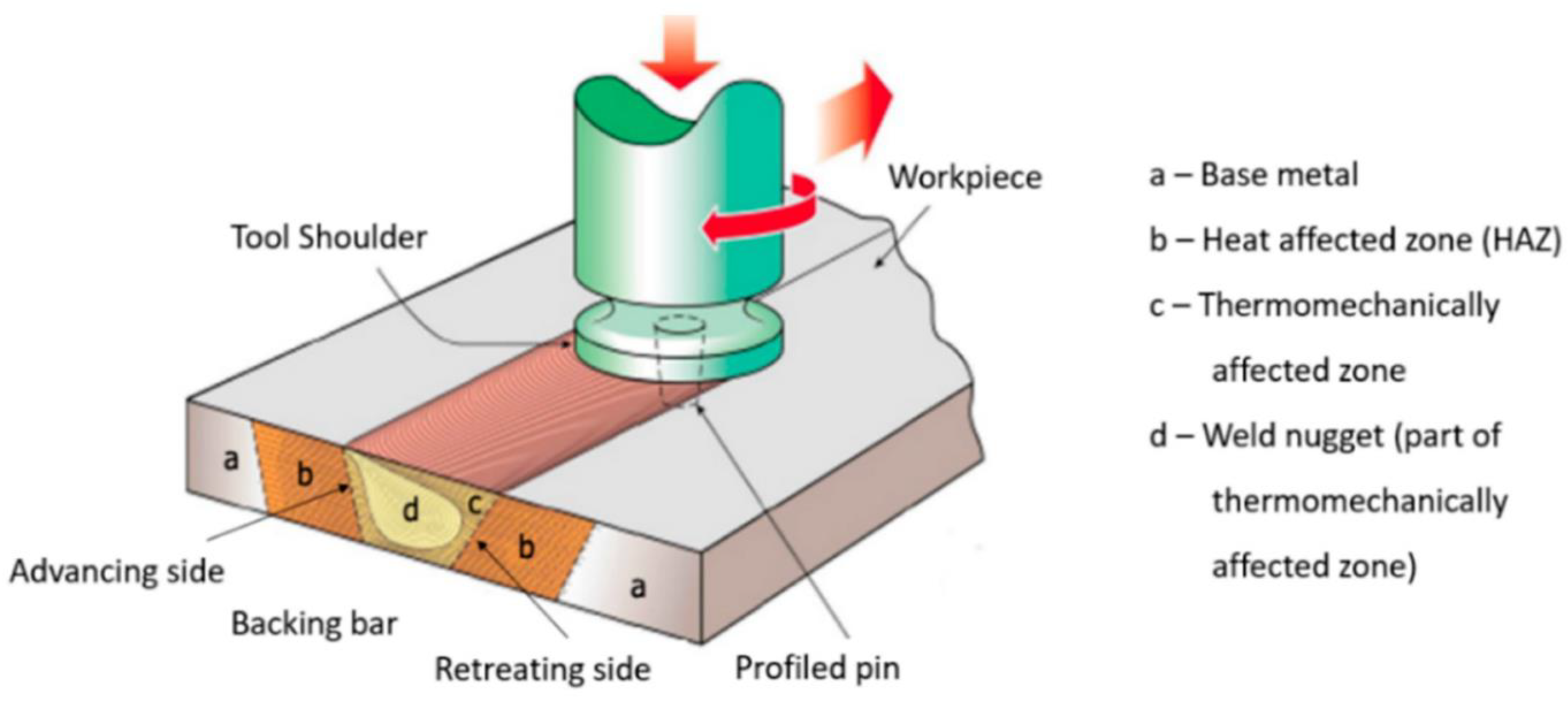

4.8.1. Friction Stir Welding

4.8.1.1. Positioning of Alloy

| Refs. | Alloy Combinations | Thick (mm) | Alloy Positioning | ||

|---|---|---|---|---|---|

| Configuration | AS | RS | |||

| 262 | Butt | 2024-T351/5083-H112 | 6.35 | 2024 | 5083 |

| 262 | Butt | 7075-T651/2024-T351 | 6.35 | 7075 | 2024 |

| 264 | Butt | 7075-T651/2024-T351 | 6 | Both | Both |

| 265 | Butt | 7075-T651/5083-H111 | 6 | Both | Both |

| 265 | Butt | 5052/AlMg2Si | 8 | Al- Mg2Si | 5052 |

| 270 | Butt | 2024-T351 /6061-T6 | 6 | 2024 | 6061 |

| 271 | Butt | 6061-T6/6351T6 | 6.35 | Both | Both |

| 272,328 | Butt | 6082-T6/7075-T6 | 10 | 7075 | 6082 |

| 273 | Butt | 6061-T651and 5A06-H112 | 5 | 6061 | 5A06 |

| 274 | Butt | 6101-T6/6351-T6 | 12 | 6101 | 6351 |

| 275 | Butt | 2024-T3/6063-T6 | 8 | 2024 | 6063 |

| 276 | Butt | 2219-T87/2195-T8 | 7.2 | Both | Both |

| 277 | Butt | 2017A-T451/cast AlSi9Mg | 6 | 2017A | AlSi9Mg |

| 280 | Butt | 5083-H111/6082-T6 | 5 | 6082NR | 5083NR |

| 144 | Butt | 5083-H111/6351-T6 | 6 | 6351 | 5083 |

| 144 | Butt | 5083-H111/6351 | 6 | 6351 | 5083 |

| 282 | Butt | 2024-T6/7075-T6 | 5 | 2024 | 7075 |

| 283,284 | Butt | Al-Mg-Si/Al-Zn-Mg | 15 | Both | Both |

| 286 | Butt | UFG 1050/6061-T6 | 2 | Both | Both |

| 287 | Butt | 2024-T3/2198-T3 | 3.18 | 2198 | 2024 |

| 288,289 | Butt | 6061-T6/7050-T7451 | 5 | 7050 | 6061 |

| 290 | Butt | 5086-O/6061-T6 | 6 | 6061 | 5086 |

| 291 | Butt | 2050-T4/6061-T651 | 20 | Both | Both |

| 292 | Butt | 5083-O/6082-T6 | NR(~7) | 5083 | 6082 |

| 293 | Butt | A319/A413 cast | 10 | A413 | A319 |

| 294 | Butt | 7075-O/6061-O 7075-T6/6061-T6 |

3.17 | 6061 | 7075 |

| 295 | Butt | 6061-T6/7075-T6 | 4.6 | Both | Both |

| 297 | Butt | 5083-O/6061-T6 | 6 | 6061 | 5083 |

| 302,303 | Butt | A356/6061-T6 | 3 | 6061 | A356 |

| 304 | Butt | 2219-T87/5083-H321 | 6 | 2219 | 5083 |

| 305 | Butt | 6061 cast/6061 rolled | 6 | Both | Both |

| 306 | Butt | 6351-T6/5083-H111 | 6 | 6351 | 5083 |

| 127 | Butt | 5052-H34/5023-T4 | ~1.5 | 5052 | 5023 |

| 307 | Butt | 5052-H34/5023-T4 | 1.5 & 1.6 | Both | Both |

| 308 | Butt | 7050-T7451/2024-T351 | 25.4 | 2024 | 7050 |

| 260 | Butt | 2024-T351/6056-T4 | 4 | 2024 | 6056 |

| 261 | Butt | cast A 356/6061 | 4 | Both | Both |

| 57 | Butt | 2017-T351 | 5 | Both | Both |

| 309 | Butt | 1050-H24 | 5 | Both | Both |

| 310 | Butt | 2017A-T451/AlSi9Mg | 6 | 2017A | AlSi9Mg |

| 311 | Butt | 2017A | 6 | Both | Both |

| 312 | Butt | 7003-T4/7046-T4 | 3 | 7003 | 7046 |

| 314 | Butt | 6013-T4/7003 | 2.8 | Both | Both |

| 313 | Butt | 6013-T6 | 5 | Both | Both |

| 316 | Butt | 6061-T6 | 9.5 | Both | Both |

| 317 | Butt | 6061-T6/7075-T6 | 6 | 6061 | 7075 |

| 279 | Underwater Butt |

6061-T6/7075-T6 | 5 | 6061 | 7075 |

| 46,268, 326 | Butt NA Butt |

2017A-T451/ 7075-T651 |

6 | Both | Both |

| 298,299 | NA Butt | 6351-T6/5083-H111 | 6 | 6351 | 5083 |

| 300,301 | NA Butt | 2014-T6/6061-T6 | 4.7 | Both | Both |

| 278 | NA | 5083-H12/6061-T6 | 1.5 | 6061 | 5083 |

| 285 | NA | 2024-T3/6061-T6 | 4.8 | 2024 | 6061 |

| 281 | NA | 5052/6061 | 1, 1.5 | 6061 | 5052 |

| 266 | NA | 2024-T4/7075-T6 | 4 | 2024 | 7075 |

| 267 | NA | 6351-T6/5083-H111 | 6 | 6351 | 5083 |

| 315 | Lap | 6111-T4/5023-T4 | 1 | Both | Both |

| 296 | Lap | 2024-T3/7075-T6 | 5 | Both | Both |

| 47 | Lap | 6111-T4/5023-T4 | 1 | Both | Both |

| 61 | Lap | 7075-T6/2024-T3 7075-upper; 2024-lower |

3 | 2024 | 7075 |

4.8.1.2. Tool Rotation and Welding Speeds

| Refs | Alloy Combinations | Thick | Rotation Speed | Welding Speed | Plunge depth | Tool tilt angle | Downward force |

|---|---|---|---|---|---|---|---|

| [mm] | [rpm] | [mm/min] | [mm] | [°] | [kN] | ||

| 262 | 2024-T351/5083-H112 | 6.35 | 600 | 150 | |||

| 262 | 7075-T651/2024-T351 | 6.35 | 600 | 150 | |||

| 264 | 7075-T651/2024-T351 | 6 | 900 | 150 | |||

| 61 | 7075-T6/2024-T3 Lap joint: 7075-upper; 2024-lower |

3 | 600 | 30, 60, 90, 120 | 0.2 | 2.5 | |

| 265 | 7075-T651/5083-H111 | 6 | 280,355, 450, 560 | 140 | 26.4 | ||

| 266 | 2024-T4/7075-T6 | 4 | 1140 | 32 | |||

| 267 | 6351-T6/5083-H111 | 6 | 800,1000 1200 | 45, 60, 75 | |||

| 46,265 326 | 2017A-T451/7075-T651 | 6 | 355 | 112 | 1.5 | 32.8 | |

| 327 | 5083-O/6063-T6 | 6 | 900 | 60 | |||

| 269 | 5052andAlMg2Si | 8 | 1000 | 80 | 2.5 | ||

| 270 | 2024-T351/6061-T6 | 6 | 800 | 31.5 | 2 | ||

| 271 | 6061-T6/6351-T6 | 6.35 | 600,900, 1200 | 30, 60, 90 | |||

| 272,328 | 6082-T6/7075-T6 | 10 | 950, 1000 | 80, 100 | |||

| 273 | 6061-T651/5A06-H112 | 5 | 600, 900, 1200 | 100, 150 | 4.7 | 2 | |

| 274 | 6101-T6/6351-T6 | 12 | 900,1100, 1300 | 16 | |||

| 275 | 2024-T3/6063-T6 | 8 | 900,1120 1400 | 125, 160, 200 | 2.5 | ||

| 276 | 2219-T87/2195-T8 | 7.2 | 400, 600, 800 | 120, 180, 240, 300 | |||

| 277 | 2017A-T451/cast AlSi9Mg | 6 | 355 | 112 | |||

| 278 | 5083-H12/6061-T6 | 1.5 | 700,1800 2500 | 25, 30, 212.5, 400 | |||

| 279 | 6061-T6/7075-T6 | 5 | 1000, 1375, 1750, 2125, 2500 | 50, 125, 200, 275, 350 | 0.2 | 3 | |

| 280 | 5083-H111/6082-T6 | 5 | 400,500, 630, 800 | 40, 50, 63, 80 | 2 | ||

| 144 | 5083-H111/6351-T6 | 6 | 800-1200 | 45-85 | 1 | 15 | |

| 281 | 5052/6061 | 1, 1.5 | 1500 | 63, 98 | |||

| 282 | 2024-T6/ 7075-T6 |

5 | 1200 | 12 | 8 | ||

| 283,284 | Al-Mg-Si/Al-Zn-Mg | 15 | 800 | 180 | 0.2 | 2.5 | |

| 285 | 2024-T3/6061-T6 | 4.8 | 500, 650, 840 | 45, 65 | 2 | ||

| 286 | UFG 1050/6061-T6 | 2 | 800 | 400, 600, 800, 1000 | 3 | 8 | |

| 329 | 2024-T6/ 6061-T6 |

4 | 1000 | 500 | 2.5 | ||

| 288,289 | 6061-T6/7050-T7451 | 5 | 270, 340, 310 | 114 | |||

| 47 | 6111-T4/5023-T4 Lap joint |

1 | 1500 1000 |

100 700 |

|||

| 290 | 5086-O/6061-T6 | 6 | 1100 | 22 | 1 | 12 | |

| 291 | 2050-T4/6061-T651 | 20 | 150, 300, 300 | 101, 203, 406 | |||

| 292 | 5083-O/6082-T6 | NR(~7) | 400 | 400 | |||

| 293 | A319/ A413 cast |

10 | 630, 800, 1000 | 20, 40, 63 | 1 | 3 | |

| 294 | 7075-O/6061-O 7075-T6/6061-T6 |

3.17 | 1000 1500 |

150 400 |

|||

| 295 | 6061-T6/7075-T6 | 4.6 | 700-1450 | 100 | |||

| 296 | 2024-T3/7075-T6 Lap joint |

5 | 1500 | 50, 150, 225, 300 | 0.2 | 2.5 | |

| 297 | 5083-O/6061-T6 | 6 | 600, 750, 900 | 20, 40 | |||

| 298 | 6351-T6/5083-H111 | 6 | 950 | 36, 63, 90 | |||

| 300 | 2014-T6/6061-T6 | 4.7 | 500, 1500 | 90 | |||

| 299 | 6351-T6/5083-H111 | 6 | 600-1300 | 36-90 | 9.8, 12.25, 14.7, 17.18, 19.6 | ||

| 302 | A356/6061-T6 | 3 | 1000 | 70-240 | 3 | ||

| 330 | 2198-T351/7075-T6 Lap joint |

3 & 1.9 | 830 | 40 | 2 | ||

| 304 | 2219-T87/5083-H321 | 6 | 400-800 | 15-60 | |||

| 305 | 6061 cast/6061 rolled | 6 | 800,1000 1200, 1400 | 50 | 8 | ||

| 306 | 6351-T6/5083-H111 | 6 | 600, 950, 1300 | 60 | 0 | 8 | |

| 127 | 5052-H34/5023-T4 | ~1.5 | 1500 | 100-700 | 3 | ||

| 303 | A356/6061-T6 | 3 | 1000, 1400 | 80, 240 | |||

| 307 | 5052-H34/5023-T4 | 1.5 & 1.6 | 1000, 1500 | 100, 200, 300, 400 | 3 | ||

| 308 | 7050-T7451/2024-T351 | 25.4 | NA | 50.8 | |||

| 332 | 5182-O/5754-O 5182-O/6022-T4 5754-O/6022-T4 |

~2 | 500, 1000, 1500 | 130, 240, 400 | |||

| 333 | 6061-T6/2024-T3 | 12.7 | 151-914 | 57-330 | |||

| 260 | 2024-T351/6056-T4 | 4 | 500-1200 | 150-400 | |||

| 261 | cast A 356/wrought 6061 | 4 | 1600 | 78-267 | 3 | ||

| 312 | 7003-T4/7046-T4 | 3 | 2000 | 400 | 0.3 | 2.5 | |

| 321 | 2219-T6/5083-H116 | 5 | 400, 800, 1200, 1600, 2000 | 30, 210, 390, 570, 750 | |||

| 335 | 6063/5083 | 6 | 600,800, 1000 | 40 | 4 | ||

| 336 | 2618-T87/5086-H321 | 6 | 450,600, 750, 850 | 15, 35, 50, 65 | |||

| 337 | 2014-T6 | 3 | 1070, 1520, 2140 | 40, 80, 112 | |||

| 338 | 3003-H12 | 3 | 1070, 1520, 2140 | 40, 80, 112, 160, 224 | |||

| 339 | 3003-O | 3 | 1070, 1520, 2140 | 40, 80, 112 | |||

| 340 | 2024-T4 | 4 | 350 | 210 | |||

| 341 | 2024-T4 | 3 | 300-1300 | 40-145 | 2.7, 2.9 | 6 | |

| 342 | 2024-T351 | 6 | 750 | 73, 116, 150 | |||

| 343 | 2014-T6 | 8 | 300-800 | 50-300 | |||

| 17 | 2014 | NA | 931 | 41 | |||

| 344 | 2014-T6 | 5 | 900 | 40 | 2.5 | 5 | |

| 57 | 2017-T351 | 5 | 1500 | 25-600 | 3 | ||

| 309 | 1050-H24 | 5 | 600-2000 | 100-800 | 3 | ||

| 310 | 2017A-T451 /AlSi9Mg |

6 | 560 | 1120 | 1.5 | ||

| 311 | 2017A | 6 | 355, 900 | 280 | 1.5 | ||

| 346 | 3003-H14 | 3 | 1500 | 80 | |||

| 347 | 3003 | 2 | 1000, 1500, 2000 | 200, 300, 400 | |||

| 348 | 3003-H24 | 3 | 500,800, 1000 | 50, 80 | |||

| 313 | 6013-T6 | 5 | 500, 630, 800 | 50 | |||

| 322 | 5754-H111/7075-T651 | 5 | 1000, 1250 | 80, 100, 125 | |||

| 349 | 3003-H17 | 5 | 2000 | 1500, 3000 | 0.2 | ||

| 350 | 3003 | 5 | 663,800, 1000, 1200, 1336 | 20, 40, 70, 100, 120 | 0.65, 1, 1.5, 2, 2.35 | ||

| 351 | 3004 | 5 | 95-600 | 115-925 | |||

| 352 | 5083-H111/7020-T651 | 5 | 400,800, 1200 | 100, 200, 300 | |||

| 353 | 5454-O | 1, 1.4 | 500-2500 | 100 | |||

| 354 | AA1100 | 5 | 562,700, 800,900, 1037 | 40.54, 75, 100, 125, 159.5 | 3.62, 5, 6, 7, 8.38 | ||

| 355 | 7003-T4/6060-T4 | 4.5 | 1000 | 40, 120, 240 | |||

| 315 | 6111-T4/5023-T4 | 1 | 1000, 1250, 1500 | 100, 300, 500, 700 | |||

| 356 | 6181-T4 | 1, 2 | 1300, 1600, 2000 | 800, 1000, 1125, 1500 | 1.5, 3 | 4.5, 5.5 | |

| 357 | 6061-T6 | 1 | 11000 | 200-500 | 0.05 | ||

| 316 | 6061-T6 | 9.5 | 1000 | 90 | |||

| 317 | 6061-T6/7075-T6 | 6 | 765 | 31.5 | 2 |

4.8.1.3. Tool Geometry

| Refs. | Alloy Combinations | Thick (mm) | Tool profile (-) | Shoulder diameter | Pin diameter/ length/ taper angle |

Tool material hardness | |

|---|---|---|---|---|---|---|---|

| Shoulder | Pin | [mm] | [mm]/ [mm]/ [°] | [HRC] | |||

| 264 | 7075-T651/2024-T351 | 6 | concave | conical threaded and with flute radius (0, 2, 3, 6, and ∞mm)) | 18 | 6/5.7 | AISI H13 |

| 61 | 7075-T6/ 2024-T3 Lap joint: 7075-upper; 2024-lower |

3 | concentric-circles- flute |

tapered | 13.5 | 6/3,4,5/16.7 | |

| 265 | 7075-T651/5083-H111 | 6 | spiral (convex scrolled) | triflute, tapered with a thread |

24 | 10/5.8; 10 (6 on tip)/5.8 |

HS 6-5-2 |

| 267 | 6351-T6/ 5083-H111 |

6 | partial impeller, full impeller, flat grove | cylindrical or conical with and without threads | |||

| 46 268,, 326 | 2017A-T451/7075-T651 | 6 | scrolled | tapered threaded | 24 | 6-4.5/5.7 | HS 6-5-2 |

| 327 | 5083-O/6063- T6 |

6 | 18 | 5 | |||

| 269 | 5052/Al-Mg2Si | 8 | concave | conical | 18 | 6-4/5.7 | H13 steel |

| 270 | 2024-T351/6061-T6 | 6 | conical with 4° cavity | square frustum | 18 | 7-3.5/5.9 | H13 steel |

| 271 | 6061-T6/ 6351-T6 |

6.35 | cylindrical scrolled | cylindrical | 14 | 4/5 | molybdenum M42/ HRC 63 |

| 273 | 6061-T651/5A06-H112 | 5 | cylindrical | conical | 16 | 5-4.2/4.6 | |

| 275 | 2024-T3/ 6063-T6 |

8 | conical triangular | D5 steel/60 | |||

| 276 | 2219-T87/2195-T8 | 7.2 | spiral | 16 | H13 steel | ||

| 277 | 2017A-T451/cast AlSi9Mg | 6 | scrolled | tapered threaded | 24 | 6-4.5/5.7 | HS 6-5-2 |

| 278 | 5083-H12/ 6061-T6 |

1.5 | 10-14 | 2-4 | |||

| 279 | 6061-T6/ 7075-T6 |

5 | conic threated | 15 | 5/4.7/5° | 2344 steel/52 | |

| 280 | 5083-H111/6082-T6 | 5 | triangular, pentagonal | 20 | 5-6 | DIN EN 1.7131 steel | |

| 144 | 5083-H111/6351-T6 | 6 | straight square | 18 | 6/5.6 | ||

| 282 | 2024-T6/ 7075-T6 |

5 | flat | smooth cylindrical | 15-16 | 3-8/4.7 | high carbon steel |

| 283 284 | Al-Mg-Si/Al-Zn-Mg | 15 | 35 | 20-12/14.5 | |||

| 285 | 2024-T3/ 6061-T6 |

4.8 | concaved | tapered threaded | 20 | 4 | |

| 286 | UFG 1050/6061-T6 | 2 | concave | thread | 12 | 4/1.8 | steel |

| 329 | 2024-T6/ 6061-T6 |

4 | concentric circles | conical thread, deep groove thread, conical cam thread | 18 | 7-5/3.7 | |

| 288289 | 6061-T6/7050-T7451 | 5 | cylindrical threaded | 18 | 10 | ||

| 47 | 6111-T4/ 5023-T4 Lap joint |

1 | threaded | 8 | 3/1.45 | ||

| 290 | 5086-O/ 6061-T6 | 6 | straight cylindrical, threaded cylindrical, tapered cylindrical | 18 | 6-5/5.7 | steel HSS | |

| 291 | 2050-T4/ 6061-T651 |

20 | single scroll | conical threaded | 25.4 | 15.9/12.7/8° | steel H13 |

| 292 | 5083-O/ 6082-T6 |

NR(~7) | scroll | triflute | 25 | 8/6.4 | |

| 293 | A319/A413 cast | 10 | conical threated | 26 | 10-6/9 | steel H13 | |

| 294 | 7075-O/ 6061-O 7075-T6/ 6061-T6 |

3.17 | concave | cylindrical threaded | 15 | 4/3 | steel H13/52 |

| 295 | 6061-T6/ 7075-T6 |

4.6 | concave | conical threaded | 15 | 7-5.2/4.7 | steel H13 |

| 296 | 2024-T3/ 7075-T6 Lap joint |

5 | concave | cylindrical threaded | 15 | 6-4/6 | steel H13/52 |

| 300 | 2014-T6/ 6061-T6 |

4.7 | scrolled | cylindrical threaded | 15 | 5/4.4 | |

| 299 | 6351-T6/ 5083-H111 |

6 | with concentric circular slots | straight square, tapered square, straight hexagon, straight octagon, tapered octagon without draft | 18 | 6/5.6 | high carbon high chromium steel |

| 302 | A356/6061-T6 | 3 | concave | cylindrical | 15 | 5/2.6 | high speed steel |

| 330 | 2198-T351/7075-T6 Lap joint |

3 and 1.9 | flat | conical | 15.5 | max 4/3.1 | |

| 304 | 2219-T87/5083-H321 | 6 | straight cylinder, tapered cylinder, cylindrical threaded tapered threaded | 9, 12, 15, 18 | 6/5.7 | Steel H13/50-55 VHN | |

| 305 | 6061 cast/6061 rolled | 6 | with concentric circular slots | hexagonal | 19.2 | 6/5.8 | HCHCr steel/ 62 |

| 306 | 6351-T6/5083-H111 | 6 | flat | straight square, straight hexagon, straight octagon, tapered square, tapered octagon | 18 | 6/5.7 | High carbon high chromium steel/63 HRC |

| 127 | 5052-H34/ 5023-T4 |

~1.5 | cylindrical threaded | 12 | 3.8/1.45 | ||

| 303 | A356/6061-T6 | 3 | cylindrical | 15 | 5/2.6 | HSS steel | |

| 307 | 5052-H34/ 5023-T4 |

1.5 & 1.6 | cylindrical threaded | 8 | 3/1.45 | ||

| 308 | 7050-T7451/2024-T351 | 25.4 | threaded | ||||

| 332 | 5182-O/ 5754-O 5182-O/ 6022-T4 5754-O/ 6022-T4 |

~2 | concave | cylindrical threaded | 10.2 | 3.18/1.95 | H13 steel |

| 333 | 6061-T6/ 2024-T3 |

12.7 | threaded | ||||

| 260 | 2024-T351/6056-T4 | 4 | concave | cylindrical threaded | 15 | 5 | |

| 261 | cast A356/ wrought 6061 |

4 | screw-like | ||||

| 57 | 2017-T351 | 5 | 15 | 6/4.7 | |||

| 309 | 1050-H24 | 5 | 15 | 6/4.7 | |||

| 26 | 2017A-T451/AlSi9Mg | 6 | cylindrical threaded | 22 | 8 | ||

| 311 | 2017A | 6 | 25 | 8 | |||

| 357 | 6061-T6 | 1 | flat | quadrangular prism, quadrangular frustum pyramid, frustum | 7 | 2-1.5/0.9 | |

| 335 | 6063/5083 | 6 | Straight cylindrical | 20 | 5/5 | steel HSS | |

| 356 | 6181-T4 | 1, 2 | concave, scroll | cylindrical and threaded | 13 | 5, 6.5, 7 | |

| 336 | 2618-T87/5086-H321 | 6 | Straight cylinder, tapered cylinder, cylindrical threaded tapered threaded | 24, 30, 33, 36 | 12/5.7 | steel H13 | |

| 340 | 2024-T4 | 4 | triflute with round bottom pin, triflat with round bottom pin, triflute with flat bottom pin, triflat with flat bottom pin | high speed steel SW7M |

|||

| 341 | 2024-T4 | 3 | cylindrical, concave | tapered unthreaded, tapered threaded |

20 | 6/3 | |

| 344 | 2014-T6 | 5 | straight cylindrical, tapered cylindrical | 18 | 6/4.8 | stainless steel | |

| 365 | 7075-T6 | 1, 0.8 | concave | cylindrical threaded | 10 | 4/1.2 | Schilling 10S4ZGO/54-56 |

| 347 | 3003 | 2 | flat | conical | 19.5 | 6.8-5/1.7 | X210Cr12 steel |

| 349 | 3003-H17 | 5 | conical threated | 16 | 6/4.7/2.5° | ||

| 350 | 3003 | 5 | concave | square | 18 | 6/4.75 | steel H13/45 |

| 351 | 3004 | 5 | flat | cylindrical threated tapered threated | 21 | 10/4.5/10° | |

| 354 | 1100 | 5 | 7.86, 12, 15, 18, 22.13 | 2.6, 4, 5, 6, 7.37 | high carbon steel 33, 40, 45, 50, 56 HRC |

||

| 316 | 6061-T6 | 9.5 | flat | composite (cylindrical shaft and cylindrical |

25.4 | 11/9(3) | H13 steel |

| 317 | 6061-T67075-T6 | 6 | flat | cylindrical | 21 | 6/6 | |

4.8.1.4. Microstructure Evolution

4.8.1.5. Mechanical Properties Hardness

4.8.1.6. Reinforcement of Weldment

4.8.2. Friction Stir Spot Welding

| Refs | Joint | Thickness | Rotational speed | Welding speed | Welding time | Plunge depth | Tool |

|---|---|---|---|---|---|---|---|

| [mm] | [rpm] | [mm/min] | [s] | [mm] | |||

| 405 | EN AW 5005 | 1.5 | 1500/2000 | 5/10 | Cylindrical Shoulder diameter 10/shoulder length 50/ Cylindrical Pin diameter 4mm/Pin height 2.2/2.6 mm/ AISI 1050 steel 52 HRC | ||

| 407 | EN AW 5005 | 1.5 | 1500/2000 | 5/10 | Cylindrical Shoulder diameter 10/shoulder length 50/ Cylindrical Pin diameter 4mm/Pin height 2.2/2.6 mm/ AISI 1050 steel 52 HRC | ||

| 393 | 1100 | 3 | 760/1065/1445/ 2000 | 40-64/28-40/23-57/32-40 | Cylindrical shoulder diameter 10/shoulder length 55/tapered pin min diameter 3, pin length 2/5/ tilt angle 10/ HSS material | ||

| 394 | 1100 | 5 | 1100-1500 | 20-60 | 0.1-0.5 | cylindrical shoulder diameter of 21 mm/square pin width 7 mm/ pin length of 4.5 mm / tool steel | |

| 395 | 1200 | 3 | Cylindrical pin with groove, and tapered pin/ H13-Tool Steel 56 HRC | ||||

| 410 | 2024 up/7075 bottom | 5 | 1500/2000/2500 | 20/40/60 | 3/3.3/3.6 | Cylindrical shoulder diameter 16 mm/ shoulder length 50 mm/ cylindrical pin diameter 4 mm/ pin length 2.5 mm | |

| 411 | 6063 | 1 | 1220/660/380 | Cylindrical shoulder diameter 12 mm/pin length 1.7 mm/ Pin Circular/Square/Triangular |

|||

| 412 | 6061-T6 | 2 | 1200/1400/1600/1800 | 10/15/20/25 | Cylindrical Shoulder Diameter 12/ Threaded Pin Diameter M5/ Pin Length 2.85/ H13 tool steel |

4.9. Gas Metal Arc Welding GMAW

4.10. Magnetic Pulse Welding MPW

4.11. Vaporizing Foil Actuator Welding VFAW

5. Summary

- -

- the absorption and subsequent entrapment of the ambient gases during welding;

- -

- the existing gas content in the base material;

- -

- the entrapment of gas bubbles due to the imperfect collapse of the keyhole during keyhole welding [443].

Author Contributions

Funding

Conflicts of Interest

References

- Dzikuć, M.; Adamczyk, J.; Piwowar, A. Problems associated with the emissions limitations from road transport in the Lubuskie Province (Poland). Atmospheric Environ. 2017, 160, 1–8, . [CrossRef]

- Lyu, P.; Wang, P.; Liu, Y.; Wang, Y. Review of the studies on emission evaluation approaches for operating vehicles. J. Traffic Transp. Eng. English Ed. 2021, 8, 493–509, . [CrossRef]

- Angnunavuri, P.N.; Kuranchie, F.A.; Attiogbe, F.; Nerquaye-Tetteh, E.N. The potential of integrating vehicular emissions policy into Ghana’s transport policy for sustainable urban mobility. SN Appl. Sci. 2019, 1, 1201, . [CrossRef]

- Correia, G.N.; Batista, T.P.; Marques, S.S.; Silva, C.M. How car material life-cycle emissions are considered in environmental rating methodologies? Suggestion of expedite models and discussion. Renew. Sustain. Energy Rev. 2014, 38, 20–35, . [CrossRef]

- Serrenho, A.C.; Norman, J.B.; Allwood, J.M. The impact of reducing car weight on global emissions: the future fleet in Great Britain. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2017, 375, 20160364, . [CrossRef]

- Neuer Audi Space Frame mit hohen Anteilen an Aluminium und CKF/New Audi Space Frame with increased content of aluminium and CFK. Audi. 2015, Aluminiumkarosserien/Aluminium car bodies, Vol. 3.

- Anwar, M.; Cahyono, S.I.; Wijang, W.R.; Diharjo, K. Application of Carbon Fiber-Based Composite for Electric Vehicle. Adv. Mater. Res. 2014, 896, 574–577, . [CrossRef]

- Ahmad, H.; A Markina, A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Series: Mater. Sci. Eng. 2020, 971, 032011, . [CrossRef]

- Harrison, N.R.; Luckey, S.G. Hot Stamping of a B-Pillar Outer from High Strength Aluminum Sheet AA7075. SAE Int. J. Mater. Manuf. 2014, 7, 567–573, . [CrossRef]

- Kutsuna, M.; Kitamura, S.; Shibata, K.; Sakamoto, H.; Tsushima, K. Improvement of the Joint Performance in Laser Welding of Aluminium Alloys. Weld. World 2006, 50, 22–27, . [CrossRef]

- AlShaer, A.W., Li, L. and Mistry, A. Effect of filler wire properties on porosity formation in laser welding of AC-170PX aluminium alloy for light-weight automotive component manufacture. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture. 2015, Vol. 231, 6, pp. 1-13. [CrossRef]

- Arun, N., Cijo, M. and Joby, J. Influence of Gas Tungsten Arc welding parameters in Aluminium 5083 alloy. Inter. J. Eng. Sci. Inno. Technol. 2013, Vol. 2, 5, pp. 269-277.

- Kumar, A.; Sundarrajan, S. Optimization of pulsed TIG welding process parameters on mechanical properties of AA 5456 Aluminum alloy weldments. Mater. Des. 2009, 30, 1288–1297, . [CrossRef]

- SZCZUCKA-LASOTA, B.; Węgrzyn, T.; Jurek, A. ALUMINUM ALLOY WELDING IN AUTOMOTIVE INDUSTRY. Transp. Probl. 2020, 15, 67–78, . [CrossRef]

- Red-Bag. Joint quality factor (joint efficiency coefficient). PCC User Manual version 4.4.x. Calculation. [Online] 10 January 2024. https://redbag.com/pcc/doc/calculations/jointqualityfactor.html].

- Cheng, J.; Song, G.; Zhang, X.; Liu, C.; Liu, L. Review of Techniques for Improvement of Softening Behavior of Age-Hardening Aluminum Alloy Welded Joints. Materials 2021, 14, 5804, . [CrossRef]

- Torzewski, J., Łazińska, M., Grzelak, K., Szachogłuchowicz, I. and Mierzyński, J. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded Joint AA7020/AA5083 with Different Joining Parameters. Materials. 2022, Vol. 15, 5, p. 1910. [CrossRef]

- Fracture Toughness Behaviour of FSW Joints on Aluminium Alloys. von Strombeck, A., dos Santos, J.F., Torster, F., Laureano, P., Kogak, M. Threadhill P.L. (Ed.): First International Symposium on Friction Stir Welding - Proceedings, June 14-16, 1999, in Thousands Oaks, CA, USA. Cambridge, UK: The Welding Institute Ltd, 1999. CD-ROM;

- Experimental Investigation on Tensile Test Properties of EB Welded Joints of Aluminum 6061-T6 Alloy for Plate-type Fuel Assembly Fabrication. Kim, S.S., Kang, D.H., Jeong, Y.J., Park, J.M. Transactions of the Korean Nuclear Society Spring Meeting Jeju, Korea, May 23-24, 2019].

- Lippold, J.C. Welding Metallurgy and Weldability. s.l. : John Wiley & Sons, Inc., 2015.

- Wojdat, T.; Kustroń, P.; Jaśkiewicz, K.; Pabian, J. Study of Corrosion, Structural, and Mechanical Properties of EN AW-6082 and EN AW-7075 Welded Joints. Materials 2021, 14, 4349, . [CrossRef]

- Lee, J.; Park, S.-Y.; Choi, B.-H. Evaluation of Fatigue Characteristics of Aluminum Alloys and Mechanical Components Using Extreme Value Statistics and C-Specimens. Metals 2021, 11, 1915, . [CrossRef]

- Li, H.; Gao, J.; Li, Q. Fatigue of Friction Stir Welded Aluminum Alloy Joints: A Review. Appl. Sci. 2018, 8, 2626, . [CrossRef]

- Bahaideen, F.B.; Saleem, A.M.; M.T, K.H.; Ripin, Z.M.; Ahmad, Z.A.; Samad, Z.; Badarulzman, N.A. Fatigue Behaviour of Aluminum Alloy at Elevated Temperature. Mod. Appl. Sci. 2009, 3, p52, . [CrossRef]

- Azadi, M.; Aroo, H. Creep properties and failure mechanisms of aluminum alloy and aluminum matrix silicon oxide nano-composite under working conditions in engine pistons. Mater. Res. Express 2019, 6, 115020, . [CrossRef]

- Chen, P. Fan, X., Yang, Q., Zhang, Z., Jia, Z. and Liu, Q. Creep behavior and microstructural evolution of 8030 aluminum alloys compressed at intermediate temperature. Journal of Materials Research and Technology. 2021, Vol. 12, pp. 1755-1761. [CrossRef]

- Li, Z. & Fu, Xue-Song & Chang, Z.-L & Zhou, Wen & Chen, Guo-Qing. Creep behavior and forecast of welded joint for 2219T87 aluminum alloy at room temperature. Zhongguo Youse Jinshu Xuebao/Chinese Journal of Nonferrous Metals. 2014, Vol. 24, 9, pp. 2235-2242.

- Fourmeau, M.; Børvik, T.; Benallal, A.; Hopperstad, O. Anisotropic failure modes of high-strength aluminium alloy under various stress states. Int. J. Plast. 2013, 48, 34–53, . [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Ren, X.; Nyhus, B.; Eriksson, M. Laser Beam and Laser-Arc Hybrid Welding of Aluminium Alloys. Metals 2021, 11, 1150, . [CrossRef]

- Petrie, E.M. Adhesive Bonding of Aluminum Alloys. Met. Finish. 2007, 105, 49–56, . [CrossRef]

- Li, Y.-D.; Zhao, P.-Z.; Feng, Y.-J.; Cao, H.-L. Influence of anodic oxide film structure on adhesive bonding performance of 5754 aluminum alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1836–1841, . [CrossRef]

- Lathabai, S. 20 - Joining of aluminium and its alloys. [book auth.] R. (Ed.) Lumley. Metals and Surface Engineering, Fundamentals of Aluminium Metallurgy. s.l. : Woodhead Publishing, 2011, pp. 607-654.

- He, X. A review of finite element analysis of adhesively bonded joints. Int. J. Adhes. Adhes. 2011, 31, 248–264, . [CrossRef]

- Barnes, T.; Pashby, I. Joining techniques for aluminium spaceframes used in automobiles: Part II — adhesive bonding and mechanical fasteners. J. Am. Acad. Dermatol. 2000, 99, 72–79, . [CrossRef]

- Groche, P., Wohletz, S., Brenneis, M., Pabst, C. and Resch, F. Joining by forming - A review on joint mechanisms, applications and future trends. J. Mater. Process. Technol. 2014, Vol. 214, 10, pp. 1972-1994.

- Kim, D.C., Park, H.J., Hwang, I.S. and Kang, M.J. Resistance spot welding of aluminum alloy sheet 5J32 using SCR type and inverter type power supplies. Archives of Materials Science and Engineering. 2009, Vol. 38, 1, pp. 55-60.

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: an overview. J. Am. Acad. Dermatol. 1996, 59, 257–267, . [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology - An overview. Def. Technol. 2018, 14, 28–44, . [CrossRef]

- Lakshman Singh, Rajeshwar Singh, Naveen Kumar Singh, Davinder Singh, Pargat Singh. An Evaluation of TIG Welding Parametric Influence on Tensile Strength of 5083 Aluminum Alloy. International Journal of Mechanical, Industrial Science and Engineering. 2013, Vol. 7, 11, pp. 795-798.

- Liu, Y.; Wang, W.; Xie, J.; Sun, S.; Wang, L.; Qian, Y.; Meng, Y.; Wei, Y. Microstructure and mechanical properties of aluminum 5083 weldments by gas tungsten arc and gas metal arc welding. Mater. Sci. Eng. A 2012, 549, 7–13, . [CrossRef]

- Wadelton, F. Aluminum 7005-6061 custom frames. Bicycle fabrication. [Online] www.frankthewelder.com.

- How To Advice and Tips for Welders of All Experience Levels. [Online] 10 January 2024. https://www.weldinghandbook.com/types-of-welding/\.

- Haboudou, A.; Peyre, P.; Vannes, A.; Peix, G. Reduction of porosity content generated during Nd:YAG laser welding of A356 and AA5083 aluminium alloys. Mater. Sci. Eng. A 2003, 363, 40–52, . [CrossRef]

- Peng, Z.; Yang, S.; Wang, Z.; Gao, Z. Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy. Materials 2022, 15, 4698, . [CrossRef]

- Grujicic, M.; Arakere, G.; Pandurangan, B.; Hariharan, A.; Yen, C.-F.; Cheeseman, B.A. Development of a Robust and Cost-Effective Friction Stir Welding Process for Use in Advanced Military Vehicles. J. Mater. Eng. Perform. 2010, 20, 11–23, . [CrossRef]

- Hamilton, C.; Dymek, S.; Kopyściański, M.; Węglowska, A.; Pietras, A. Numerically Based Phase Transformation Maps for Dissimilar Aluminum Alloys Joined by Friction Stir-Welding. Metals 2018, 8, 324, . [CrossRef]

- Yoon, T.-J.; Yun, J.-G.; Kang, C.-Y. Formation mechanism of typical onion ring structures and void defects in friction stir lap welded dissimilar aluminum alloys. Mater. Des. 2016, 90, 568–578, . [CrossRef]

- Mishra, R.S. and Ma, Z.Y. Friction stir welding and processing. Materials Science and Engineering: R: Reports. 2005, Vol. 50, 1-2, pp. 1-78. [CrossRef]

- Mishra, R.S.; Komarasamy, M. Friction Stir Welding of High Strength 7XXX Aluminum Alloys; Elsevier BV: Amsterdam, NX, Netherlands, 2016; ISBN: 9780128094655.

- Mishra, R.S.; Sidhar, H. Friction Stir Welding of 2XXX Aluminum Alloys Including Al-Li Alloys; Elsevier BV: Amsterdam, NX, Netherlands, 2017; ISBN: .

- Uday, M.B.; Ahmad Fauzi, M.N.; Zuhailawati, H.; Ismail, A.B. Advances in friction welding process: a review. Sci. Technol. Weld. Join. 2010, 15, 534–558, . [CrossRef]

- Threadgill, P.L., Leonard, A.J., Shercliff, H.R. and Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, Vol. 54, 2, pp. 49-93. [CrossRef]

- Kumar, N.; Yuan, W.; Mishra, R.S. Friction Stir Welding of Dissimilar Alloys and Materials; Elsevier BV: Amsterdam, NX, Netherlands, 2015; ISBN: 9780128024188.

- DebRoy, T.; Bhadeshia, H.K.D.H. Friction stir welding of dissimilar alloys – a perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270, . [CrossRef]

- Murr, L.E. A Review of FSW Research on Dissimilar Metal and Alloy Systems. J. Mater. Eng. Perform. 2010, 19, 1071–1089, . [CrossRef]

- Chen, Y.; Liu, H.; Feng, J. Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater. Sci. Eng. A 2006, 420, 21–25, . [CrossRef]

- Liu, H.J., Fujii, H., Maeda, M. and Nogi, K. Tensile properties and fracture locations of friction stir welded joints of 2017-T351 aluminum alloy. J Mater Process Technol. 2003, Vol. 142, 3, pp. 692-696. [CrossRef]

- Meng, X.; Xu, Z.; Huang, Y.; Xie, Y.; Wang, Y.; Wan, L.; Lv, Z.; Cao, J. Interface characteristic and tensile property of friction stir lap welding of dissimilar aircraft 2060-T8 and 2099-T83 Al–Li alloys. Int. J. Adv. Manuf. Technol. 2017, 94, 1253–1261, . [CrossRef]

- Costa, M.I., Verdera, D., Leitão, C. and Rodrigues, D.M. Dissimilar friction stir lap welding of AA 5754-H22/AA 6082-T6 aluminium alloys: influence of material properties and tool geometry on weld strength. Mater Des. 2015, Vol. 87, pp. 721-731. [CrossRef]

- Kallee, S.W Industrial applications of friction stir welding. [book auth.] D. Lohwasser and Z. (Eds.) Chen. Welding and Other Joining Technologies, Friction Stir Welding. s.l. : Woodhead Publishing, 2010, pp. 118-163.

- Ge, Z.; Gao, S.; Ji, S.; Yan, D. Effect of pin length and welding speed on lap joint quality of friction stir welded dissimilar aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 98, 1461–1469, . [CrossRef]

- Khan, N.Z.; Khan, Z.A.; Siddiquee, A.N. Effect of Shoulder Diameter to Pin Diameter (D/d) Ratio on Tensile Strength of Friction Stir Welded 6063 Aluminium Alloy. Mater. Today: Proc. 2015, 2, 1450–1457, . [CrossRef]

- Vimalraj, C.; Kah, P. Experimental Review on Friction Stir Welding of Aluminium Alloys with Nanoparticles. Metals 2021, 11, 390, . [CrossRef]

- Burek, R.; Wydrzyński, D.; Sęp, J.; Więckowski, W. The effect of tool wear on the quality of lap joints between 7075 t6 aluminum alloy sheet metal created with the FSW method. Eksploat. i Niezawodn. - Maint. Reliab. 2018, 20, 100–106, . [CrossRef]

- Brown, B.M. A comparison of AC and DC resistance welding of automotive steels. Welding Journal. 1987, Vol. 66, 1, pp. 18-23.

- Guo, H.; Hu, J.; Tsai, H.L. Three-Dimensional Modeling of Gas Metal Arc Welding of Aluminum Alloys. J. Manuf. Sci. Eng. 2010, 132, 021011, . [CrossRef]

- Furukawa, K. New CMT arc welding process – welding of steel to aluminium dissimilar metals and welding of super-thin aluminium sheets. Weld. Int. 2006, 20, 440–445, . [CrossRef]

- Chinnasamy, R.; Chelladurai, S.J.S.; Sonar, T. Investigation on Microstructure and Tensile Properties of High-Strength AA2014 Aluminium Alloy Welds Joined by Pulsed CMT Welding Process. Adv. Mater. Sci. Eng. 2021, 2021, 1–8, . [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585, . [CrossRef]

- Pickin, C.; Williams, S.; Lunt, M. Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Am. Acad. Dermatol. 2011, 211, 496–502, . [CrossRef]

- Kah, P.; Suoranta, R.; Martikainen, J. Advanced gas metal arc welding processes. Int. J. Adv. Manuf. Technol. 2012, 67, 655–674, . [CrossRef]

- Schierl, A. The CMT-process - a revolution in welding technology. Weld World. 2005, Vol. 49, 9, p. 38.

- Gullino, A.; Matteis, P.; D’aiuto, F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals 2019, 9, 315, . [CrossRef]

- Dutra, J.C.; e Silva, R.H.G.; Marques, C. Melting and welding power characteristics of MIG–CMT versus conventional MIG for aluminium 5183. Weld. Int. 2013, 29, 181–186, . [CrossRef]

- Zhang, Y. Investigation of magnetic pulse welding on lap joint of similar and dissimilar materials. PhD Thesis. s.l. : The Ohio State University, 2010.

- Bellmann, J.; Lueg-Althoff, J.; Niessen, B.; Böhme, M.; Schumacher, E.; Beyer, E.; Leyens, C.; Tekkaya, A.E.; Groche, P.; Wagner, M.F.-X.; et al. Particle Ejection by Jetting and Related Effects in Impact Welding Processes. Metals 2020, 10, 1108, . [CrossRef]

- Niessen, B., Schumacher, E., Lueg-Althoff, J., Bellmann, J., Böhme, M., Böhm, S., Tekkaya, A.E., Beyer, E., Leyens, C. and Wagner, M.F.-X. Interface Formation during Collision Welding of Aluminum. Metals 2020, Vol. 10, p. 1202. [CrossRef]

- Wang, H.; Wang, Y. High-Velocity Impact Welding Process: A Review. Metals 2019, 9, 144, . [CrossRef]

- Schumacher, E.; Rebensdorf, A.; Böhm, S. Influence of the jet velocity on the weld quality of magnetic pulse welded dissimilar sheet joints of aluminum and steel. Mater. und Werkst. 2019, 50, 965–973, . [CrossRef]

- Carpenter, S.H. and Wittman, R.H. Explosion Welding. Ann. Rev. Mater. Sci. 1975, Vol. 5, pp. 177–199. [CrossRef]

- Deribas, A.A.; Zakharenko, I.D. Surface effects with oblique collisions between metallic plates. Combust. Explos. Shock. Waves 1974, 10, 358–367, . [CrossRef]

- Patra, S.; Arora, K.S.; Shome, M.; Bysakh, S. Interface characteristics and performance of magnetic pulse welded copper-Steel tubes. J. Am. Acad. Dermatol. 2017, 245, 278–286, . [CrossRef]

- Zhang, Y.; Babu, S.S.; Prothe, C.; Blakely, M.; Kwasegroch, J.; LaHa, M.; Daehn, G.S. Application of high velocity impact welding at varied different length scales. J. Am. Acad. Dermatol. 2011, 211, 944–952, . [CrossRef]

- Kapil, A.; Sharma, A. Magnetic pulse welding: an efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 100, 35–58, . [CrossRef]

- Jassim, A. Comparison of magnetic pulse welding with other welding methods. J. Energy Power Eng. 2011, Vol. 5, pp. 1173–1178.

- Aizawa, T., Kashani, M. and Okagawa, K. Application of Magnetic Pulse Welding for Aluminum Alloys and SPCC Steel Sheet Joints. Welding Journal. 2007, Vol. 86, pp. 119-124.

- Qi, N.; Wang, L.; Zhao, Y.; Tian, S.; Zhan, X. The tensile properties of 2219 aluminum alloy plate butt joint welded by novel laser mirror welding. Opt. Laser Technol. 2021, 149, 107796, . [CrossRef]

- Theron, M., Burger, H.P., Van Rooyen, C. and lvanchev, L.H. Laser welding of A357 aluminium alloy. International Congress on Applications of Lasers & Electro-Optics. 2008, Vol. P112. [CrossRef]

- Peterson, W., Pakalnins, E. and Carpenter, J.A. Longlife electrodes for resistance spot welding of aluminium sheet alloys and coated high strength steel sheet. FY Progress Report. 2004, pp. 237-244.

- Boomer, D.R., Hunter, J.A. and Castle, D.R. A new approach for robust high productivity resistance spot welding of aluminium. SAE Transactions. 2003, Vol. 112, pp. 280-292.

- Spinella, D.J., Brockenbrough, J.R. and Fridy, J.M. Trends in aluminium resistance spot welding for the auto industry. Welding Journal. 2005, Vol. 84, 1, pp. 34-40.

- Bamberg, P.; Seewald, R.; Schiebahn, A.; Reisgen, U.; Precoma, N.; Epperlein, M. Improvement of the resistance spot welding of Al-Mg-Si alloys by using cladding technology: An optical and mechanical characterization study. J. Adv. Join. Process. 2022, 5, 100090, . [CrossRef]

- Indira Rani, M. and Marpu, R.N. Effect of Pulsed Current TIG Welding Parameters on Mechanical Properties of J-Joint Strength of AA6351. The International Journal of Engineering and Science (IJES). 2012, Vol. 1, 1, pp. 1-5.

- Howard, R.D. Industrial Heating. Aluminum Heat Treatment Processes, Applications and Equipment. [Online] 1 February 2007. https://www.industrialheating.com/articles/87310-aluminum-heat-treatment-processes-applications-and-equipment.

- Spira, N. Aluminum in Cars: Aluminum Alloys for Car Bodies. Kloeckner Metals. [Online] 07 July 2021. https://www.kloecknermetals.com/blog/aluminum-in-cars.

- EngineersEdge. Aluminium plate,Aluminium Cast and Wrough Engineering Specifications. [Online] 15 March 2023. https://www.engineersedge.com/aluminum_plate.htm.

- Davis, J.R. Aluminum and Aluminum Alloys. Cleveland : ASM International, 1993.

- Bamberg, P.; Gintrowski, G.; Liang, Z.; Schiebahn, A.; Reisgen, U.; Precoma, N.; Geffers, C. Development of a new approach to resistance spot weld AW-7075 aluminum alloys for structural applications: an experimental study – Part 1. J. Mater. Res. Technol. 2021, 15, 5569–5581, . [CrossRef]

- Elrefaey, A. Effectiveness of cold metal transfer process for welding 7075 aluminium alloys. Sci. Technol. Weld. Join. 2015, 20, 280–285, . [CrossRef]

- Kumar, N.P.; Vendan, S.A.; Shanmugam, N.S. Investigations on the parametric effects of cold metal transfer process on the microstructural aspects in AA6061. J. Alloy. Compd. 2016, 658, 255–264, . [CrossRef]

- Zhang, C.; Li, G.; Gao, M.; Yan, J.; Zeng, X.Y. Microstructure and process characterization of laser-cold metal transfer hybrid welding of AA6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2013, 68, 1253–1260, . [CrossRef]

- Ahmad, R.; Bakar, M. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AA6061 joints welded by the gas metal arc welding cold metal transfer method. Mater. Des. 2011, 32, 5120–5126, . [CrossRef]

- Benoit, A.; Paillard, P.; Baudin, T.; Klosek, V.; Mottin, J.-B. Comparison of four arc welding processes used for aluminium alloy cladding. Sci. Technol. Weld. Join. 2015, 20, 75–81, . [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2014, 76, 1593–1606, . [CrossRef]

- Rajeev, G.P.; Kamaraj, M.; Bakshi, S.R. Al-Si-Mn Alloy Coating on Aluminum Substrate Using Cold Metal Transfer (CMT) Welding Technique. JOM 2014, 66, 1061–1067, . [CrossRef]

- Luijendijk, T. Welding of dissimilar aluminium alloys. Journal of Materials Processing Technology. 2000, Vol. 103, 1, pp. 29-35. [CrossRef]

- Kaba, L.; Djeghlal, M.E.; Ouallam, S.; Kahla, S. Dissimilar welding of aluminum alloys 2024 T3 and 7075 T6 by TIG process with double tungsten electrodes. Int. J. Adv. Manuf. Technol. 2021, 118, 937–948, . [CrossRef]

- Jweeg, M.J.; Resan, K.K.; A Abbod, E.; Al-Waily, M. Dissimilar Aluminium Alloys Welding by Friction Stir Processing and Reverse Rotation Friction Stir Processing. IOP Conf. Series: Mater. Sci. Eng. 2018, 454, 012059, . [CrossRef]

- Friedman, P.A.; Kridli, G.T. Microstructural and Mechanical Investigation of Aluminum Tailor-Welded Blanks. J. Mater. Eng. Perform. 2000, 9, 541–551, . [CrossRef]

- Prediction of Strain Distribution in Aluminium Tailor Welded Blanks for Different Welding Techniques. Buste, A., Lalbin, X. and Worswick, M.J. [ed.] M. Bouchard and A. (Eds.) Faucher. Montreal : Canadian Institute of Mining, Metallurgy, and Petroleum, 1999. Proc. Int. Symp. on Light Metals . pp. 485-500. [CrossRef]

- Davies, R.W.; Grant, G.J.; Khaleel, M.A.; Smith, M.T.; Oliver, H.E. Forming-limit diagrams of aluminum tailor-welded blank weld material. Met. Mater. Trans. A 2001, 32, 275–283, . [CrossRef]

- Pickering, E., Glagola, M., Ramage, R., and Taylor, G. Production and Performance of High Speed GTA Welded Aluminum Tailored Blanks. SAE Technical Paper. 1995, p. 950722.

- Gungor, B.; Kaluc, E.; Taban, E.; SIK ŞŞ, A. Mechanical and microstructural properties of robotic Cold Metal Transfer (CMT) welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 54, 207–211, . [CrossRef]

- Totten, G.E. and Mackenzie, S. Handbook of aluminum. vol 1. Physical metallurgy and processes. Marcel Dekker Inc. : s.n., 2003. pp. 66-73. Vol. 1.

- Mathers, G. The welding of aluminium and its alloys . Cambridge : Woodhead Publishing Limited, 2002.

- Elrefaey, A.; Ross, N.G. Microstructure and Mechanical Properties of Cold Metal Transfer Welding Similar and Dissimilar Aluminum Alloys. Acta Met. Sin. (English Lett. 2015, 28, 715–724, . [CrossRef]

- Boşneag, A.; A Constantin, M.; Niţu, E.; Iordache, M. Friction Stir Welding of three dissimilar aluminium alloy used in aeronautics industry. IOP Conf. Series: Mater. Sci. Eng. 2017, 252, 012041, . [CrossRef]

- Sharma, S. and Upadhyay, V. Friction Stir Welding of Dissimilar Aluminum Alloys AA5086 and AA7039. J. Phys.: Conf. Ser. 2019, Vol. 1240, p. 012160. [CrossRef]

- Pourabbas, M.; Abdollah-Zadeh, A.; Sarvari, M.; Pouranvari, M.; Miresmaeili, R. Investigation of structural and mechanical properties of magnetic pulse welded dissimilar aluminum alloys. J. Manuf. Process. 2018, 37, 292–304, . [CrossRef]

- Meng, Z., Wang, X., Guo, W., Hu, Z., Vivek, A., Hua, L. and Daehn, G.S. Joining Performance and Microstructure of the 2024/7075 Aluminium Alloys Welded Joints by Vaporizing Foil Actuator Welding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2019, Vol. 34, pp. 368-372. [CrossRef]

- Kou, S. The Partially Melted Zone. Welding Metallurgy. 2. New-Jersey : A John Wiley & Sons, Inc., Publication, 2002, 3, pp. 304-328.

- Huang, C. and Kou, S. Liquation Mechanisms in Multi-Component Aluminum Alloys During Welding. Welding Journal. 2002, Vol. 81, 10, pp. 211s-222s.

- Huang, C. and Kou, S. Liquation cracking in partial-penetration aluminum welds: Effect of penetration oscillation and backfilling. Welding Journal. 2003, Vol. 82, pp. 184s-194s.

- Huang, C. and Kou, S. Liquation Cracking in Full-Penetration Al-Mg-Si Welds. Welding Journal. 2004, Vol. 83, pp. 111s-122s.

- Song, S.-W.; Lee, S.-H.; Kim, B.-C.; Yoon, T.-J.; Kim, N.-K.; Kim, I.-B.; Kang, C.-Y. Liquation Cracking of Dissimilar Aluminum Alloys during Friction Stir Welding. Mater. Trans. 2011, 52, 254–257, . [CrossRef]

- Cornacchia, G. and Cecchel, S. Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison. Metals. 2020, Vol. 10, 4, p. 441. [CrossRef]

- Dalle Donne, C., Braun, R., Staniek, G., Jung, A. and Kaysser, W.A. Mikrostrukturelle, mechanische und korrosive Eigenschaften reibrührgeschweißter Stumpfnähte in Aluminiumlegierungen. Materialwissenschaft und Werkstofftechnik./Materials Science & Engineering Technology. 1998, Vol. 29, 10, pp. 609-617. [CrossRef]

- Hassan, K.A.A.; Prangnell, P.B.; Norman, A.F.; Price, D.A.; Williams, S.W. Effect of welding parameters on nugget zone microstructure and properties in high strength aluminium alloy friction stir welds. Sci. Technol. Weld. Join. 2003, 8, 257–268, . [CrossRef]

- Wang, P., Chen, K., Jiang, H., Chen, S. and Hu, G. Microstructures and properties of TIG welded joint of 7003 aluminum alloy. Materials Science and Engineering of Powder Metallurgy. 2016, Vol. 2016, 6, pp. 832-839.

- An Experimental Investigation of the Heat Affected Zone (HAZ) Properties of AA6060 and AA7046 Following Different Heat Treatment Schedules. Alisibramulisi, A., Myhr, O., Lademo, O.-G. and Larsen, P. Yokohama: The Japan Institute of Light Metals, 2010. Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan. pp. 994-999.

- Haryadi, G.D.; Kim, S.J. Influences of post weld heat treatment on fatigue crack growth behavior of TIG welding of 6013 T4 aluminum alloy joint (Part 1. Fatigue crack growth across the weld metal). J. Mech. Sci. Technol. 2011, 25, 2161–2170, . [CrossRef]

- Hou, B., Zhao, Y., Zhou, C., Xie, M. and Hu, Z. Research on Welding Properties of Al-Mg Alloy Welding Wire Containing In. Material Sciences. 2019, Vol. 9, 3, pp. 189-195.

- Shanavas, S.; Dhas, J.R. Weldability of AA 5052 H32 aluminium alloy by TIG welding and FSW process – A comparative study. IOP Conf. Series: Mater. Sci. Eng. 2017, 247, 012016, . [CrossRef]

- Vijay Mohan Shetty, V.M., Vattem, R.K. and Musku, S. Optimization and Evaluation of Ageing Parameters on Mechanical Properties of AA 6061AND AA 5154 Welded Joints using Taguchi Method. International Journal of Engineering Sciences & Researches Technology. 2018, Vol. 7, 5, pp. 64-72.

- Zhu, G.; Wang, S.; Zhang, M.; Yang, X.; Liu, W.; Wang, G. Application of laser cleaning in postwelding treatment of aluminum alloy. Appl. Opt. 2020, 59, 10967–10972, . [CrossRef]

- Mossman, M.M. and Lippold, J.C. Weldability Testing of Dissimilar Combinations of 5000- and 6000-Series Aluminum Alloys. Welding Journal. 2002, Vol. September, pp. 188s-194s.

- European aluminium. Joining - Arc Welding, the Aluminium Automotive Manual. [Online] 2015. [Cited: 18 February 2020.] https://www.european-aluminium.eu/media/1518/3-arc-welding_2015_new.pdf.

- Peter, I.; Rosso, M. Study of 7075 Aluminium Alloy Joints. Sci. Bull. Valahia Univ. - Mater. Mech. 2017, 15, 7–11, . [CrossRef]

- Kang, M.; Kim, C. A Review of Joining Processes for High Strength 7xxx Series Aluminum Alloys. J. Weld. Join. 2017, 35, 79–88, . [CrossRef]

- Niu, L.-Q., Li, X.-Y., Zhang, L., Liang, X.-B. and Li, M. Correlation Between Microstructure and Mechanical Properties of 2219-T8 Aluminum Alloy Joints by VPTIG Welding[J]. Acta Metallurgica Sinica (English Letters). 2017, Vol. 30, 5, pp. 438-446. [CrossRef]

- Kwon, Y.; Weckman, D.C. Analytical thermal model of conduction mode double sided arc welding. Sci. Technol. Weld. Join. 2008, 13, 539–549, . [CrossRef]

- Nyrkova, L.; E.O. Paton Electric Welding Institute NAS of Ukraine; Labur, T.; Shevtsov, E.; Nazarenko, O.; Dorofeev, A.; Osadchuk, S.; Yavorska, M.; Poklyatsky, A.; Fedorchuk, V.; et al. Complex of properties of 2219 alloy weld joint in T62 state under modeling operating conditions. 2022, 28, 14–29, . [CrossRef]

- Su, D.; Zhang, J.; Wang, B. The microstructure and weldability in welded joints for AA 5356 aluminum alloy after adding modified trace amounts of Sc and Zr. J. Manuf. Process. 2020, 57, 488–498, . [CrossRef]

- Palanivel, R., Laubscher, R.F., Dinaharan, I. and Murugan, N. Developing a Friction-StirWeldingWindow for Joining the Dissimilar Aluminum Alloys AA6351 and AA5083. Mater. Technol. 2017, Vol. 51, 1, pp. 5-9.

- Kumar, A.; Sundarrajan, S. Optimization of pulsed TIG welding process parameters on mechanical properties of AA 5456 Aluminum alloy weldments. Mater. Des. 2009, 30, 1288–1297, . [CrossRef]

- Singh, A.K., Dey, V. and Rai, R.N. Techniques to improve weld penetration in TIG welding (A review). Materials Today: Proceedings 2017, Vol. 4, 2, A, pp. 1252-1259. [CrossRef]

- Chen, Q.; Lin, S.; Yang, C.; Fan, C.; Ge, H. Grain fragmentation in ultrasonic-assisted TIG weld of pure aluminum. Ultrason. Sonochemistry 2017, 39, 403–413, . [CrossRef]

- Gupta, Y., Tanwar, A. and Gupta, R. Investigation of Microstructure and Mechanical Properties of TIG and MIG Welding Using Aluminium Alloy. IOSR Journal of Mechanical and Civil Engineering 2016, Vol. 13, 5, pp. 121-126.

- Zhang, Y.M.; Pan, C.; Male, A.T. Improved microstructure and properties of 6061 aluminum alloy weldments using a double-sided arc welding process. Met. Mater. Trans. A 2000, 31, 2537–2543, . [CrossRef]

- Squillace, A.; De Fenzo, A.; Giorleo, G.; Bellucci, F. A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA 2024-T3 butt joints. J. Am. Acad. Dermatol. 2004, 152, 97–105, . [CrossRef]

- Wang, X.; Wang, K.; Shen, Y.; Hu, K. Comparison of fatigue property between friction stir and TIG welds. J. Univ. Sci. Technol. Beijing, Miner. Met. Mater. 2008, 15, 280–284, . [CrossRef]

- Cabello M., Ruckert G., Huneau S. B. and Marya S. Comparison of TIG welded and friction stir welded Al–4.5Mg–0.26Sc alloy, Journal of Materials Processing Technology 2008, Vol. 197, 1-3, pp. 337-343. [CrossRef]

- Zhao J., Jiang F., Jian H., Wen K., Jiang L. and Chen X. Comparative investigation of tungsten inert gas and friction stir welding characteristics of Al–Mg–Sc alloy plates. Materials & Design 2010, Vol. 31, 1, pp. 306-311. [CrossRef]

- Malarvizhia S. and Balasubramanian V. Effects of welding processes and post-weld aging treatment on fatigue behavior of AA2219 aluminium alloy joints. Journal of Materials Engineering and Performance 2011, Vol. 20, 3, pp. 359-367. [CrossRef]

- Zhen H., Yong P., Zhi Y. and Xue L. Comparison of FSW and TIG welded joints in Al-Mg-Mn-Sc-Zr alloy plates. Transactions of Nonferrous Metals Society of China 2011, Vol. 21, pp. 1685-1691. [CrossRef]

- Anjaneya Prasad B. and Prasanna P. Experimental Comparison of the MIG and Friction Stir Welding Processes for AA 6061(AlMgSiCu) Aluminium Alloy. International Journal of Mining, Metallurgy & Mechanical Engineering 2013, Vol. 1, pp. 137-140.

- Jannet, S., Mathews, P.K. and Raja, R. Comparative investigation of Friction stir welding & Fusion welding of 6061T-6 & 5083-0 Aluminium Alloys based on mechanical properties & microstructure. Journal of Achievements in Materials & Manufacturing Engg. 2013, Vol. 61, pp. 181-186.

- Sasidharan, B., Narayanan, K.P. and Prakash. R.S. Tensile & Microstructural characteristics of DCSP TIG welded & Friction stir welded AA2219 Aluminum Alloy. International Journal of Design & Manufacturing Technology 2014, Vol. 5, pp. 121-129.

- Ashwani Kumar, Shakti Singh Gautam and Alok Kumar. Heat input & joint efficiency of three welding processes TIG, MIG & FSW using AA6061. International Journal of Mechanical Engg. & Robotic Research 2014, Vol. 1, pp. 89-94.

- Navyashree, S. and Sivaramakrishna, V. Experimental Investigation of Friction Stir Welding and TIG Welding for Al-6082. International Journal of Innovative Research in Science, Engg. & Technology 2015, Vol. 4, pp. 5292-5298.

- Vimalraj, C., Kah, P., Mvola, B. and Martikainen, J. Effect of nanomaterial addition using gmaw and gtaw processes. Rev. Adv. Mater. Sci. 2016, Vol. 44, pp. 370–382.

- Kumar, A. and Milton, M.S. A Comparison of Welding Techniques of Aluminium Alloys. A Literature Review. International Journal of Scientific Research in Science, Engineering and Technology 2016, Vol. 2, 3, pp. 172-175.

- Singh, S.; Kumar, V.; Kumar, S.; Kumar, A. Variant of MIG welding of similar and dissimilar metals: A review. Mater. Today: Proc. 2021, 56, 3550–3555, . [CrossRef]

- Nie, F.; Dong, H.; Chen, S.; Li, P.; Wang, L.; Zhao, Z.; Li, X.; Zhang, H. Microstructure and Mechanical Properties of Pulse MIG Welded 6061/A356 Aluminum Alloy Dissimilar Butt Joints. J. Mater. Sci. Technol. 2018, 34, 551–560, . [CrossRef]

- Warinsiriruk, E.; Greebmalai, J.; Sangsuriyun, M. Effect of Double Pulse MIG Welding on Porosity Formation on Aluminium 5083 Fillet Joint. MATEC Web Conf. 2019, 269, 01002, . [CrossRef]

- Bai, Y.; Gao, H.-M.; Qiu, L. Droplet transition for plasma-MIG welding on aluminium alloys. Trans. Nonferrous Met. Soc. China 2010, 20, 2234–2239, . [CrossRef]

- Liu, J.; Zhu, H.; Li, Z.; Cui, W.; Shi, Y. Effect of ultrasonic power on porosity, microstructure, mechanical properties of the aluminum alloy joint by ultrasonic assisted laser-MIG hybrid welding. Opt. Laser Technol. 2019, 119, 105619, . [CrossRef]

- Chen, C.; Fan, C.; Lin, S.; Cai, X.; Zhou, L.; Ye, S.; Yang, C. Effect of ultrasonic pattern on weld appearance and droplet transfer in ultrasonic assisted MIG welding process. J. Manuf. Process. 2018, 35, 368–372, . [CrossRef]

- Wojdat, T., Kustroń, P., Jaskiewicz, K., Zwierzchowski, M. and Margielewska, A. Numerical modelling of welding of car body sheets made of selected aluminum alloys. Arch. Metall. Mater. 2019, Vol. 64, 4, pp. 1403-1409. [CrossRef]

- Pfeifer, T. and Rykała, J. Welding EN AW7075 Aluminium Alloy Sheets—Low-energy Versus Pulsed Current. Inst. Weld. Bull. Gliwice. 2014, Vol. 5, pp. 137-144.

- The CMT process a revolution in welding technology. Bruckner, J., Wagner, J. and Arenholz, E. San Francisco : s.n., 2005. Proceedings of the International Light Metals Technology Conference 2005, San Francisco, CA, USA. pp. 275-284.

- Pfeifer, T. and Stano, S. Modern methods of weldbrazing in the aspect of quality and properties of joints. Weld. Technol. Rev. 2016, Vol. 9, pp. 95-102.

- Talalaev, R.; Veinthal, R.; Laansoo, A.; Sarkans, M. Cold metal transfer (CMT) welding of thin sheet metal products. Estonian J. Eng. 2012, 18, 243, . [CrossRef]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852, . [CrossRef]

- Dutra, J.C.; e Silva, R.H.G.; Savi, B.M.; Marques, C.; Alarcon, O.E. Metallurgical characterization of the 5083H116 aluminum alloy welded with the cold metal transfer process and two different wire-electrodes (5183 and 5087). Weld. World 2015, 59, 797–807, . [CrossRef]

- Shu, F.Y., Tian, Z., Lu, Y.H., He, W.X., Lu, F.Y., Lin, J.J., Zhao, H.Y. and Xu, B.S. Prediction of vulnerable zones based on residual stress and microstructure in cmt welded aluminium alloy joint. Trans Nonferrous Met. Soc China. 2015, Vol. 25, 8, pp. 2701-2707. [CrossRef]

- Shu, F.Y., Lu, Y.H., Liu, Y.X., Xu, F.J., Sun, Z., He, P. and Xu, B.S. FEM modeling of softened base metal in narrow-gap joint by CMT+Pmix welding procedure. Trans Nonferrous Met. Soc China. 2014, Vol. 24, 6, pp. 1830-1835. [CrossRef]

- Kotsikos, G.; Robinson, M.; Zangani, D.; Roberts, J. Investigation of the weld unzipping failure mode during collisions of welded aluminium rail vehicles. Proc. Inst. Mech. Eng. Part F: J. Rail Rapid Transit 2008, 222, 59–68, . [CrossRef]

- Improving the Crashworthiness of Aluminium Rail Vehicles. Zangani, D., Robinson, M. and Kotsikos, G. [ed.] S., Rodopoulos, C. Pantelakis. s.l. : Springer, Dordrecht, 2009. Engineering Against Fracture. [CrossRef]

- Gay, R., Robinson, M. and Zangani, D. Crashworthiness of Joints in Aluminium Rail Vehicles. [Online] 2022. https://trimis.ec.europa.eu/sites/default/files/project/documents/20091125_164508_79987_ALJOIN%20overview%20paper.pdf.

- Zhao, Y.; Chen, F.; Cao, S.; Chen, C.; Xie, R. Effect of CMT Welding Heat Input on Microstructure and Properties of 2A14 Aluminum Alloy Joint. Metals 2022, 12, 2100, . [CrossRef]

- Shanker, H.; Wattal, R. Comparative study of microstructural and mechanical properties of robotic CMT and GMAW welded 7475-T7351 aluminium alloy joints. Mater. Today Commun. 2023, 37, . [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Gou, J. Macrostructure, microstructure and wear performance of Al alloy cladding fabricated by CMT technique. Eng. Res. Express 2020, 2, 015026, . [CrossRef]

- Yang, G.; Guan, K.; Zou, L.; Sun, Y.; Yang, X. Weld Defect Detection of a CMT Arc-Welded Aluminum Alloy Sheet Based on Arc Sound Signal Processing. Appl. Sci. 2023, 13, 5152, . [CrossRef]

- Srinivasan, D.; Sevvel, P.; Solomon, I.J.; Tanushkumaar, P. A review on Cold Metal Transfer (CMT) technology of welding. Mater. Today: Proc. 2022, 64, 108–115, . [CrossRef]

- Zhang, H.; Feng, J.; He, P.; Zhang, B.; Chen, J.; Wang, L. The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater. Sci. Eng. A 2009, 499, 111–113, . [CrossRef]

- Shang, J.; Wang, K.; Zhou, Q.; Zhang, D.; Huang, J.; Li, G. Microstructure characteristics and mechanical properties of cold metal transfer welding Mg/Al dissimilar metals. Mater. Des. 2012, 34, 559–565, . [CrossRef]

- Cao, R.; Wen, B.; Chen, J.; Wang, P.-C. Cold Metal Transfer joining of magnesium AZ31B-to-aluminum A6061-T6. Mater. Sci. Eng. A 2013, 560, 256–266, . [CrossRef]

- Singh, I.J.; Murtaza, Q.; Kumar, P. A comprehensive review on effect of cold metal transfer welding parameters on dissimilar and similar metal welding. J. Eng. Res. 2023, . [CrossRef]

- Gierth, M.; Henckell, P.; Ali, Y.; Scholl, J.; Bergmann, J.P. Wire Arc Additive Manufacturing (WAAM) of Aluminum Alloy AlMg5Mn with Energy-Reduced Gas Metal Arc Welding (GMAW). Materials 2020, 13, 2671, . [CrossRef]

- Bergmann, J.P.; Bielenin, M.; Feustel, T. Aluminum welding by combining a diode laser with a pulsed Nd:YAG laser. Weld. World 2015, 59, 307–315, . [CrossRef]

- Park, Y.W.; Rhee, S. Process modeling and parameter optimization using neural network and genetic algorithms for aluminum laser welding automation. Int. J. Adv. Manuf. Technol. 2007, 37, 1014–1021, . [CrossRef]

- Influence of Alloy and Solidification Parameters on Grain Refinement in Aluminum Weld Metal due to Inoculation. Schempp, P., Tang, Z., Cross, C., Pittner, A., Seefeld, T. and Rethmeier, M. Chicago : s.n., 2012. ASM Proceedings of the 9th International Conference: Trends in Welding Research June 4–8, 2012, Chicago, Illinois, USA. pp. 98-107.

- Zhao, H.; DebRoy, T. Macroporosity free aluminum alloy weldments through numerical simulation of keyhole mode laser welding. J. Appl. Phys. 2003, 93, 10089–10096, . [CrossRef]

- Pastor, M., Zhao, H., Martukanitz, R.P. and Debroy, T. Porosity, underfill and magnesium lose during continuous wave Nd: YAG laser welding of thin plates of aluminum alloys 5182 and 5754 78: 207-s. Welding Journal. 1999, Vol. 78, 6, pp. 207s-216s.

- Sheikhi, M.; Ghaini, F.M.; Assadi, H. Prediction of solidification cracking in pulsed laser welding of 2024 aluminum alloy. Acta Mater. 2015, 82, 491–502, . [CrossRef]

- Yi, H., Jian, H. and Pulin, N. Microstructures and Textures of 6016 and 5182 Aluminum Laser Welded Joints. Chinese Journal of Lasers. 2019, Vol. 46, 4, p. 0402003.

- Sánchez-Amaya, J.; Delgado, T.; González-Rovira, L.; Botana, F. Laser welding of aluminium alloys 5083 and 6082 under conduction regime. Appl. Surf. Sci. 2009, 255, 9512–9521, . [CrossRef]

- Strengthening mechanism in laser-welded 2219 aluminium alloy under the cooperative effects of aging treatment and pulsed electromagnetic loadings. Mater. Sci. Eng. A 2018, Vol. 714, pp. 124–139. [CrossRef]

- Wang, Z.; Oliveira, J.; Zeng, Z.; Bu, X.; Peng, B.; Shao, X. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2018, 111, 58–65, . [CrossRef]

- Peng, G.; Li, L.; Wang, J.; Xia, H.; Meng, S.; Gong, J. Effect of subatmospheric pressures on weld formation and mechanical properties during disk laser welding of 5A06 aluminium alloy. J. Am. Acad. Dermatol. 2019, 277, 116457, . [CrossRef]

- Braun, R. Nd:YAG laser butt welding of AA6013 using silicon and magnesium containing filler powders. Mater. Sci. Eng. A 2006, 426, 250–262, . [CrossRef]

- Zhang, L., Li, X., Nie, Z., Huang, H. and Sun, J. Microstructure and mechanical properties of a new Al–Zn–Mg–Cu alloy joints welded by laser beam. Mater. Des. 2015, Vol. 83, pp. 451–458. [CrossRef]

- Enz, J.; Khomenko, V.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Single-sided laser beam welding of a dissimilar AA2024–AA7050 T-joint. Mater. Des. 2015, 76, 110–116, . [CrossRef]

- Viscusi, A.; Leitão, C.; Rodrigues, D.; Scherillo, F.; Squillace, A.; Carrino, L. Laser beam welded joints of dissimilar heat treatable aluminium alloys. J. Am. Acad. Dermatol. 2016, 236, 48–55, . [CrossRef]

- Enz, J.; Kumar, M.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Mechanical properties of laser beam welded similar and dissimilar aluminum alloys. J. Manuf. Process. 2017, 29, 272–280, . [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Salminen, A.; Unt, A. Fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J. Mater. Process. Technol. 2016, 233, 107–114, . [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Ren, X.; Nyhus, B.; Eriksson, M. Laser Beam and Laser-Arc Hybrid Welding of Aluminium Alloys. Metals 2021, 11, 1150, . [CrossRef]

- Shibata, K.; Sakamoto, H.; Iwase, T. Laser-MIG Hybrid Welding of Aluminium Alloys. Weld. World 2006, 50, 28–34, . [CrossRef]

- Han, X.; Yang, Z.; Ma, Y.; Shi, C.; Xin, Z. Porosity distribution and mechanical response of laser-MIG hybrid butt welded 6082-T6 aluminum alloy joint. Opt. Laser Technol. 2020, 132, 106511, . [CrossRef]

- Katayama, S.; Uchiumi, S.; Mizutani, M.; Wang, J.; Fujii, K. Penetration and porosity prevention mechanism in YAG laser-MIG hybrid welding. Weld. Int. 2007, 21, 25–31, . [CrossRef]

- Yan, J.; Zeng, X.; Gao, M.; Lai, J.; Lin, T. Effect of welding wires on microstructure and mechanical properties of 2A12 aluminum alloy in CO2 laser-MIG hybrid welding. Appl. Surf. Sci. 2009, 255, 7307–7313, . [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Davies, C.; Dear, J. Effect of filler metal feed rate and composition on microstructure and mechanical properties of fibre laser welded AA 2024-T3. J. Manuf. Process. 2017, 25, 26–36, . [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Dear, J.; Davies, C. The effect of Ar and He shielding gas on fibre laser weld shape and microstructure in AA 2024-T3. J. Manuf. Process. 2017, 29, 62–73, . [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Dear, J.; Davies, C. Optimisation of process parameters and weld shape of high power Yb-fibre laser welded 2024-T3 aluminium alloy. J. Manuf. Process. 2018, 34, 70–85, . [CrossRef]

- Yan, S.; Nie, Y.; Zhu, Z.; Chen, H.; Gou, G.; Yu, J.; Wang, G. Characteristics of microstructure and fatigue resistance of hybrid fiber laser-MIG welded Al–Mg alloy joints. Appl. Surf. Sci. 2014, 298, 12–18, . [CrossRef]

- Huang, L.; Wu, D.; Hua, X.; Liu, S.; Jiang, Z.; Li, F.; Wang, H.; Shi, S. Effect of the welding direction on the microstructural characterization in fiber laser-GMAW hybrid welding of 5083 aluminum alloy. J. Manuf. Process. 2018, 31, 514–522, . [CrossRef]

- Leo, P.; D'Ostuni, S.; Casalino, G. Hybrid welding of AA5754 annealed alloy: Role of post weld heat treatment on microstructure and mechanical properties. Mater. Des. 2016, 90, 777–786, . [CrossRef]

- Yan, S.; Chen, H.; Zhu, Z.; Gou, G. Hybrid laser-Metal Inert Gas welding of Al–Mg–Si alloy joints: Microstructure and mechanical properties. Mater. Des. 2014, 61, 160–167, . [CrossRef]

- Zhang, C.; Gao, M.; Jiang, M.; Zeng, X. Effect of Weld Characteristic on Mechanical Strength of Laser-Arc Hybrid-Welded Al-Mg-Si-Mn Aluminum Alloy. Met. Mater. Trans. A 2016, 47, 5438–5449, . [CrossRef]

- Yan, S.; Xing, B.; Zhou, H.; Xiao, Y.; Qin, Q.-H.; Chen, H. Effect of filling materials on the microstructure and properties of hybrid laser welded Al-Mg-Si alloys joints. Mater. Charact. 2018, 144, 205–218, . [CrossRef]

- Wang, H.; Liu, X.; Liu, L. Research on Laser-TIG Hybrid Welding of 6061-T6 Aluminum Alloys Joint and Post Heat Treatment. Metals 2020, 10, 130, . [CrossRef]

- Hu, B.; Richardson, I. Microstructure and mechanical properties of AA7075(T6) hybrid laser/GMA welds. Mater. Sci. Eng. A 2007, 459, 94–100, . [CrossRef]

- Ola, O.; Doern, F. Fusion weldability studies in aerospace AA7075-T651 using high-power continuous wave laser beam techniques. Mater. Des. 2015, 77, 50–58, . [CrossRef]

- Allen, C.; Verhaeghe, G.; Hilton, P.; Heason, C.P.; Prangnell, P.B. Laser and Hybrid Laser-MIG Welding of 6.35 and 12.7mm Thick Aluminium Aerospace Alloy. Mater. Sci. Forum 2006, 519-521, 1139–1144, . [CrossRef]

- Korzhyk, V., Khaskin, V., Grinyuk, A.A., Shcheretskyi, V., Oleinychenko, T. and Babych, O. Hybrid Laser-MIG Welding of Aluminum Alloys Al-Mg-Mn, Al-Cu-Mg and Al-Mg-Li Systems. Environment Technology Resources Proceedings of III International Scientific and Practical Conference Chicago, USA 1-3 September 2021, pp. 125-132 .

- Nathish, .P.V., Naveen Ram kumar M., Raghul Raaj, K. and Omprakasam, S. Hybrid Laser Beam Welding of Aluminium Alloys. International Research Journal of Engineering and Technology 2017, Vol. 4, 11, pp. 520-524.

- Daehn, G.S. and Lippold, J.C. Low-Temperature Spot Impact Welding Driven without Contact. U.S. Patent No. PCT/US09/36499, 27 December 2011.

- Zhao, Y.; Lei, Z.; Chen, Y.; Tao, W. A comparative study of laser-arc double-sided welding and double-sided arc welding of 6mm 5A06 aluminium alloy. Mater. Des. 2011, 32, 2165–2171, . [CrossRef]

- Han, B., Chen, Y.B., Wang, T., Lei, Z.L., Li, H., Guo, S., and Li, P. Nano-indentation investigation on the local softening of equiaxed zone in 2060–T8/2099-T83 aluminum-lithium alloys T-joints welded by double-sided laser beam welding. J. Alloy Compd. 2018, Vol. 756, pp. 145-162. [CrossRef]

- Chen, X., Lei, Z., Chen, Y., Han, B., Jiang, M., Tian, Z., Bi, J. and Lin, S. Nano-indentation and in-situ investigations of double-sided laser beam welded 2060–T8/2099-T83 Al-Li alloys T-joints. Mat. Sci Eng A-Struct. 2019, Vol. 756, pp. 291-301. [CrossRef]

- Sadeh, S., Gleason, G.H. Hatamleh, M.I., Sunny, S.F., Yu, H., Malik, A.S. and Qian, D. Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model. Metals 2019, Vol. 9, p. 1196. [CrossRef]

- Wang, X.; Gu, C.; Zheng, Y.; Shen, Z.; Liu, H. Laser shock welding of aluminum/aluminum and aluminum/copper plates. Mater. Des. 2014, 56, 26–30, . [CrossRef]

- Peyre, P., Berthe, L. and Fabbro, R. Laser shock processing of materials: Basics mechanisms and applications. In Proceedings of the 65th Laser Materials Processing Conference, Tokyo, Japan, 2–5 December 2005; pp. 95–109.

- Wang, X.; Gu, Y.; Qiu, T.; Ma, Y.; Zhang, D.; Liu, H. An experimental and numerical study of laser impact spot welding. Mater. Des. 2015, 65, 1143–1152, . [CrossRef]

- Çam, G.; Ventzke, V.; Dos Santos, J.; Koçak, M.; Jennequin, G.; Gonthier-Maurin, P. Characterisation of electron beam welded aluminium alloys. Sci. Technol. Weld. Join. 1999, 4, 317–323, . [CrossRef]

- Fujii, H., Umakoshi, H., Aoki, Y. and Nogi, K. Bubble formationin aluminium alloy during electron beam welding. Journal of Materials Processing Technology 2004, Vol. 155-156, 1-3, pp. 1252–1255. [CrossRef]

- Elseddig, Z.A., Sobih, M., Almazy, Kh. and Sallam, M. Experimental investigation of electron beam welding of AA1350aluminum alloy. in Proceedings of the in 14th International Conference on Applied Mechanics and Mechanical Engineering, Cairo, Egypt, 2010.

- Sobih, M., Elseddig, Z., Almazy, K., Youssef, A. and Sallam, M. Optimization of EBW parameters for 2219 al-alloy using greyrelation method. Advanced Materials Research 2012, Vol. 591-593, pp. 507-514. [CrossRef]

- Sobih, M.; Elseddig, Z.; Almazy, K.; Sallam, M. Experimental Evaluation and Characterization of Electron Beam Welding of 2219 AL-Alloy. Indian J. Mater. Sci. 2016, 2016, 1–6, . [CrossRef]

- Saha, D.C.; Park, Y.-D. A Review on Al-Al/Al-Steel Resistance Spot Welding Technologies for Light Weight Vehicles. J. Weld. Join. 2011, 29, 35–40, . [CrossRef]

- Auhl, J.R. and Patrick, E.P. A fresh look at resistance spot welding of aluminium automotive components. SAE Technical Paper. 1994, p. 940160.

- Rönnhult, T.; Rilby, U.; Olefjord, I. The surface state and weldability of aluminium alloys. Mater. Sci. Eng. 1980, 42, 329–336, . [CrossRef]

- Li, Z., Hao, C., ZHANG, J. and Zhang, H. Effects of Sheet Surface Conditions on Electrode Life in Resistance Welding Aluminum. Welding journal. 2007, Vol. 86, 4, pp. 81s-89s.

- Newton, C., Thornton, M., Keay, B., Sheasby, P. and Boomer, D. How to Weld Bond Aluminium with Structural Adhesives. SAE Technical Paper. 1997, p. 970018.

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [CrossRef]

- Shah, U.; Liu, X. Effect of ultrasonic energy on the spot weldability of aluminum alloy AA6061. Mater. Des. 2020, 192, 108690, . [CrossRef]

- Qi, L.; Zhang, Q.; Ma, Y.; Xu, Y.; Han, X.; Li, Y. A comparative study on mechanical performance of traditional and magnetically assisted resistance spot welds of A7N01 aluminum alloy. J. Manuf. Process. 2021, 66, 133–144, . [CrossRef]

- Metal Suppliers Online. Aluminum 7178 aluminum - material property data sheet. [Online] https://www.suppliersonline.com/propertypages/7178.asp.

- Davis, J.R. Aluminum and Aluminum Alloys - Chapter. Alloying: Understanding the Basics. Materials Park, Ohio : ASM International, 2001, pp. 351-416.

- Fracchia, E.; Gobber, F.; Rosso, M. About weldability and welding of Al alloys: case study and problem solving. J. Achiev. Mater. Manuf. Eng. 2017, 2, 67–74, . [CrossRef]

- Matokhnyuk, L.E.; Byalonovich, A.V.; Gopkalo, E.E.; Vorob’ev, E.V.; Karaush, D.P.; Malyshko, V.I. Fatigue Resistance of 2219 Aluminum Alloy and its Welded Joints. Strength Mater. 2019, 51, 860–867, . [CrossRef]

- Manladan, S.M.; Yusof, F.; Ramesh, S.; Fadzil, M.; Luo, Z.; Ao, S. A review on resistance spot welding of aluminum alloys. Int. J. Adv. Manuf. Technol. 2016, 90, 605–634, . [CrossRef]

- Evaluation of Joint Performance of 5056 Aluminum Friction Welded Joints By Heat Input And Burn-Off Quantity. Ochi, H., Sawai, T., Yamamoto, Y., Ogawa, K. and Suga, Y. Seatle, Washington, USA : s.n., 2000. Paper presented at the Tenth International Offshore and Polar Engineering Conference Seattle, Washington, USA, May 2000.

- Manjhi, S.K.; Das, A.; Prasad, S.B. Review on joining of aluminum alloy by solid-state welding technique. Mater. Today: Proc. 2020, 26, 1255–1261, . [CrossRef]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction Stir Welding of Dissimilar Aluminum Alloy Combinations: State-of-the-Art. Metals 2019, 9, 270, . [CrossRef]

- Barbini, A., Carstensen, J. and Dos Santos, J. Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar ButtWeld Obtained by Friction Stir Welding. Metals. 2018, Vol. 8, 4, p. 202. [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of welding parameters on mechanical and microstructural properties of dissimilar AA6082–AA2024 joints produced by friction stir welding. Mater. Des. 2009, 30, 609–616, . [CrossRef]

- Friction stir welding of dissimilar alloys for aircraft. Presented at the 5th International Symposium on Friction Stir Welding, Metz, France, 2004. Gérard, H. and Ehrström, J.C. 2004. Proceedings of International Friction Stirr Welding Symposium, Metz, France, 14–16 September 2004.

- Amancio-Filho, S.; Sheikhi, S.; dos Santos, J.; Bolfarini, C. Preliminary study on the microstructure and mechanical properties of dissimilar friction stir welds in aircraft aluminium alloys 2024-T351 and 6056-T4. J. Am. Acad. Dermatol. 2008, 206, 132–142, . [CrossRef]

- Lee, W.-B.; Yeon, Y.-M.; Jung, S.-B. The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials. Scr. Mater. 2003, 49, 423–428, . [CrossRef]

- Niu, P.; Li, W.; Chen, D. Strain hardening behavior and mechanisms of friction stir welded dissimilar joints of aluminum alloys. Mater. Lett. 2018, 231, 68–71, . [CrossRef]

- Niu, P.; Li, W.; Li, N.; Xu, Y.; Chen, D. Exfoliation corrosion of friction stir welded dissimilar 2024-to-7075 aluminum alloys. Mater. Charact. 2018, 147, 93–100, . [CrossRef]

- Hasan, M.M.; Ishak, M.; Rejab, M.R.M. Effect of pin tool flute radius on the material flow and tensile properties of dissimilar friction stir welded aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 98, 2747–2758, . [CrossRef]

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779, . [CrossRef]

- Safarbali, B.; Shamanian, M.; Eslami, A. Effect of post-weld heat treatment on joint properties of dissimilar friction stir welded 2024-T4 and 7075-T6 aluminum alloys. Trans. Nonferrous Met. Soc. China 2018, 28, 1287–1297, . [CrossRef]

- Palanivel, R.; Laubscher, R.; Vigneshwaran, S.; Dinaharan, I. Prediction and optimization of the mechanical properties of dissimilar friction stir welding of aluminum alloys using design of experiments. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2016, 232, 1384–1394, . [CrossRef]

- Hamilton, C.; Dymek, S.; Dryzek, E.; Kopyściański, M.; Pietras, A.; Węglowska, A.; Wróbel, M. Application of positron lifetime annihilation spectroscopy for characterization of friction stir welded dissimilar aluminum alloys. Mater. Charact. 2017, 132, 431–436, . [CrossRef]

- Huang, B.W.; Qin, Q.D.; Zhang, D.H.; Wu, Y.J.; Su, X.D. Microstructure and Mechanical Properties of Dissimilar Joints of Al-Mg2Si and 5052 Aluminum Alloy by Friction Stir Welding. J. Mater. Eng. Perform. 2018, 27, 1898–1907, . [CrossRef]

- Moradi, M.M.; Aval, H.J.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Microstructure and texture evolution of friction stir welded dissimilar aluminum alloys: AA2024 and AA6061. J. Manuf. Process. 2018, 32, 1–10, . [CrossRef]

- Prasanth, R.S.S.; Raj, K.H. Determination of Optimal Process Parameters of Friction Stir Welding to Join Dissimilar Aluminum Alloys Using Artificial Bee Colony Algorithm. Trans. Indian Inst. Met. 2017, 71, 453–462, . [CrossRef]

- Azeez, S.; Akinlabi, E. Effect of processing parameters on microhardness and microstructure of a double-sided dissimilar friction stir welded aa6082-t6 and aa7075-t6 aluminum alloy. Mater. Today: Proc. 2018, 5, 18315–18324, . [CrossRef]

- Peng, G.; Ma, Y.; Hu, J.; Jiang, W.; Huan, Y.; Chen, Z.; Zhang, T. Nanoindentation Hardness Distribution and Strain Field and Fracture Evolution in Dissimilar Friction Stir-Welded AA 6061-AA 5A06 Aluminum Alloy Joints. Adv. Mater. Sci. Eng. 2018, 2018, 1–11, . [CrossRef]

- Das, U.; Toppo, V. Effect of Tool Rotational Speed on Temperature and Impact Strength of Friction Stir Welded Joint of Two Dissimilar Aluminum Alloys. Mater. Today: Proc. 2018, 5, 6170–6175, . [CrossRef]

- Sarsilmaz, F. Relationship between micro-structure and mechanical properties of dissimilar aluminum alloy plates by friction stir welding. Therm. Sci. 2018, 22, 55–66, . [CrossRef]

- No, K.; Yoo, J.-T.; Yoon, J.-H.; Lee, H.-S. Effect of Process Parameters on Friction Stir Welds on AA2219-AA2195 Dissimilar Aluminum Alloys. Korean J. Mater. Res. 2017, 27, 331–338, . [CrossRef]

- Kopyściański, M.; Dymek, S.; Hamilton, C.; Węglowska, A.; Pietras, A.; Szczepanek, M.; Wojnarowska, M. Microstructure of Friction Stir Welded Dissimilar Wrought 2017A and Cast AlSi9Mg Aluminum Alloys. Acta Phys. Pol. A 2017, 131, 1390–1394, . [CrossRef]

- Ghaffarpour, M.; Kazemi, M.; Sefat, M.J.M.; Aziz, A.; Dehghani, K. Evaluation of dissimilar joints properties of 5083-H12 and 6061-T6 aluminum alloys produced by tungsten inert gas and friction stir welding. Proc. Inst. Mech. Eng. Part L: J. Mater. Des. Appl. 2015, 231, 297–308, . [CrossRef]

- Bijanrostami, K.; Barenji, R.V.; Hashemipour, M. Effect of Traverse and Rotational Speeds on the Tensile Behavior of the Underwater Dissimilar Friction Stir Welded Aluminum Alloys. J. Mater. Eng. Perform. 2017, 26, 909–920, . [CrossRef]

- Kasman, S.; Kahraman, F.; Emiralioğlu, A.; Kahraman, H. A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding. Metals 2016, 7, 6, . [CrossRef]

- Doley, J.K.; Kore, S.D. A Study on Friction Stir Welding of Dissimilar Thin Sheets of Aluminum Alloys AA 5052–AA 6061. J. Manuf. Sci. Eng. 2016, 138, 114502, . [CrossRef]

- Saravanan, V.; Rajakumar, S.; Banerjee, N.; Amuthakkannan, R. Effect of shoulder diameter to pin diameter ratio on microstructure and mechanical properties of dissimilar friction stir welded AA2024-T6 and AA7075-T6 aluminum alloy joints. Int. J. Adv. Manuf. Technol. 2016, 87, 3637–3645, . [CrossRef]

- Yan, Z., Liu, X. and Fang, H. Effect of Sheet Configuration on Microstructure and Mechanical Behaviors of Dissimilar Al–Mg–Si/Al–Zn–Mg Aluminum Alloys Friction Stir Welding Joints. J. Mater. Sci. Technol. 2016, 32, 1378–1385. 2016, Vol. 32, 12, pp. 1378-1385. [CrossRef]