Submitted:

25 March 2024

Posted:

26 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Design bio-composed pultruded bar for profiles for the frame of façade system modules.

- Validate with mechanical simulations the bio-composed pultruded profile for the frame of façade system modules.

- Define alternative materials and components to support introduction of eco-friendly solutions replacing conventional ones in prefabricated façade system in particular for insulation and tightness system.

- Design a bio composites-based curtain wall façade systems based on technical and normative requirement for real case applicability in line with the current building envelope standard for curtain wall façade solution. The design should support the development of multiple façade module typologies with different building envelope targets: (1) “vision façade module; (2) opaque façade module; (3) window/opaque façade module.

- Validate with mechanical, thermal and acoustic simulations the bio-based façade system modules to demonstrate the compliance with normative.

- Identify testing activities to be conducted in manufacturing and lab environments to validate feasibility of manufacturability and integrability of components in façade system modules.

2. Materials and Methods

- Analysis for selection of biobased and alternative components for façade system module – bio-based and less environmental impactful alternative technologies are identified for their potential to meet façade design objectives and minimize carbon footprint. In particular, components with the most significant environmental impact, such as frame profiles, insulation, and tightness system are evaluated.

- Identification of façade requirements – requirements to design the façade for real market application are defined. The requirements are identified based on the normative standards in curtain wall façade and real case studies application adopted as validation simulation for European application.

- Façade System Design – an iterative design process is implemented to refine the façade system configuration to guarantee components integration, off-site production principles and reduced on-site activities.

- Façade system design validation – iterative process to simulate façade behavior to identify mechanical, thermal and acoustic behavior. This phase is a desk validation of the façade design and its components before the manufacturing.

- Previously research façades developed in OSIRYS project [33] to use its outcomes as starting point for the investigation of the bio-composite profiles for façades and the development of an industrialized solution for market integration, and RenoZEB project [34,35] to use its outcomes as starting point for the investigation of the adoption of membranes and tapes alternative to metal sheets within curtain wall façade market.

- Real case demo-buildings are adopted, one in Jyväskylä, Finland, and one in Bordeaux, France, to define some pilot cases for façade requirements identification in two climate conditions [36].

-

Software adopted for simulations:

- o

- Mechanical simulations with AUTODESK INVENTOR PROFESSIONAL 2020.

- o

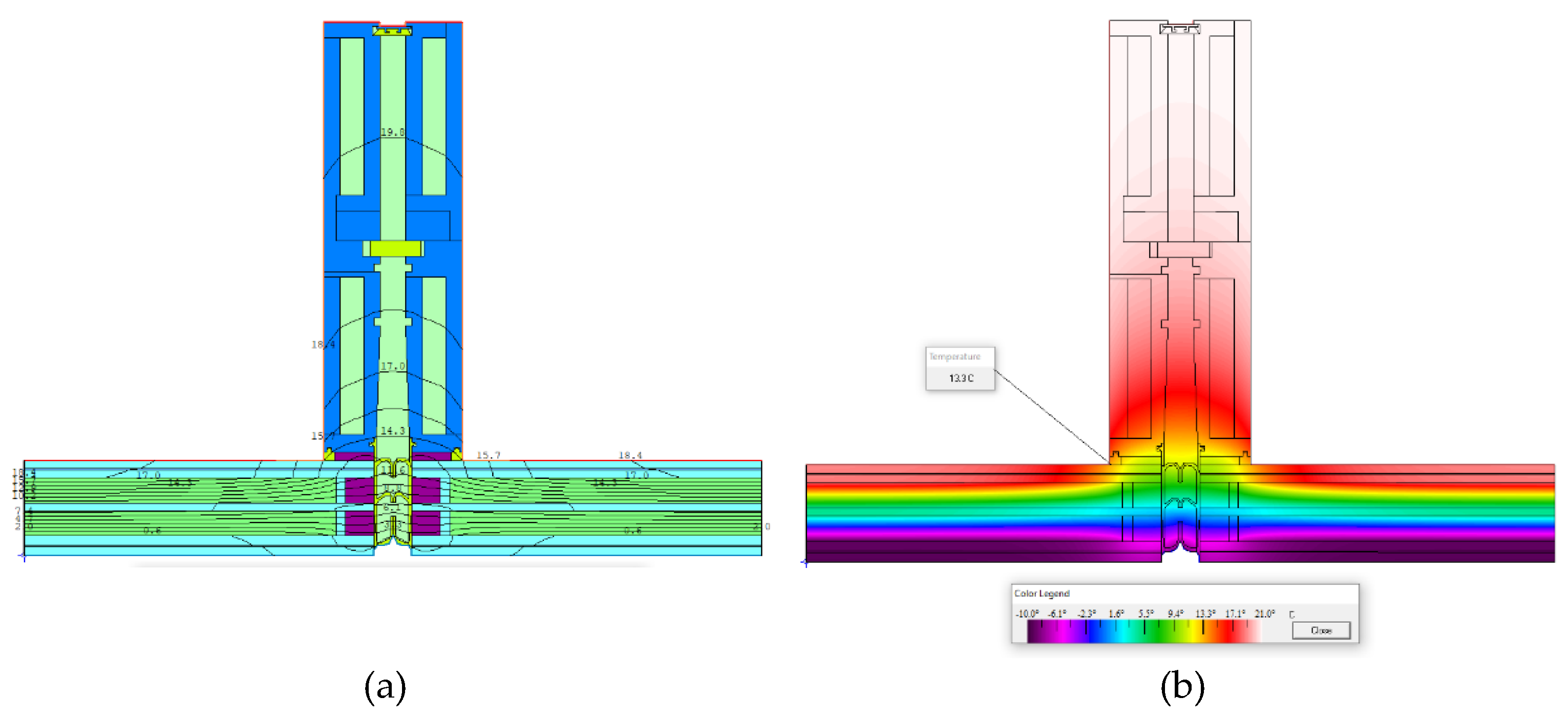

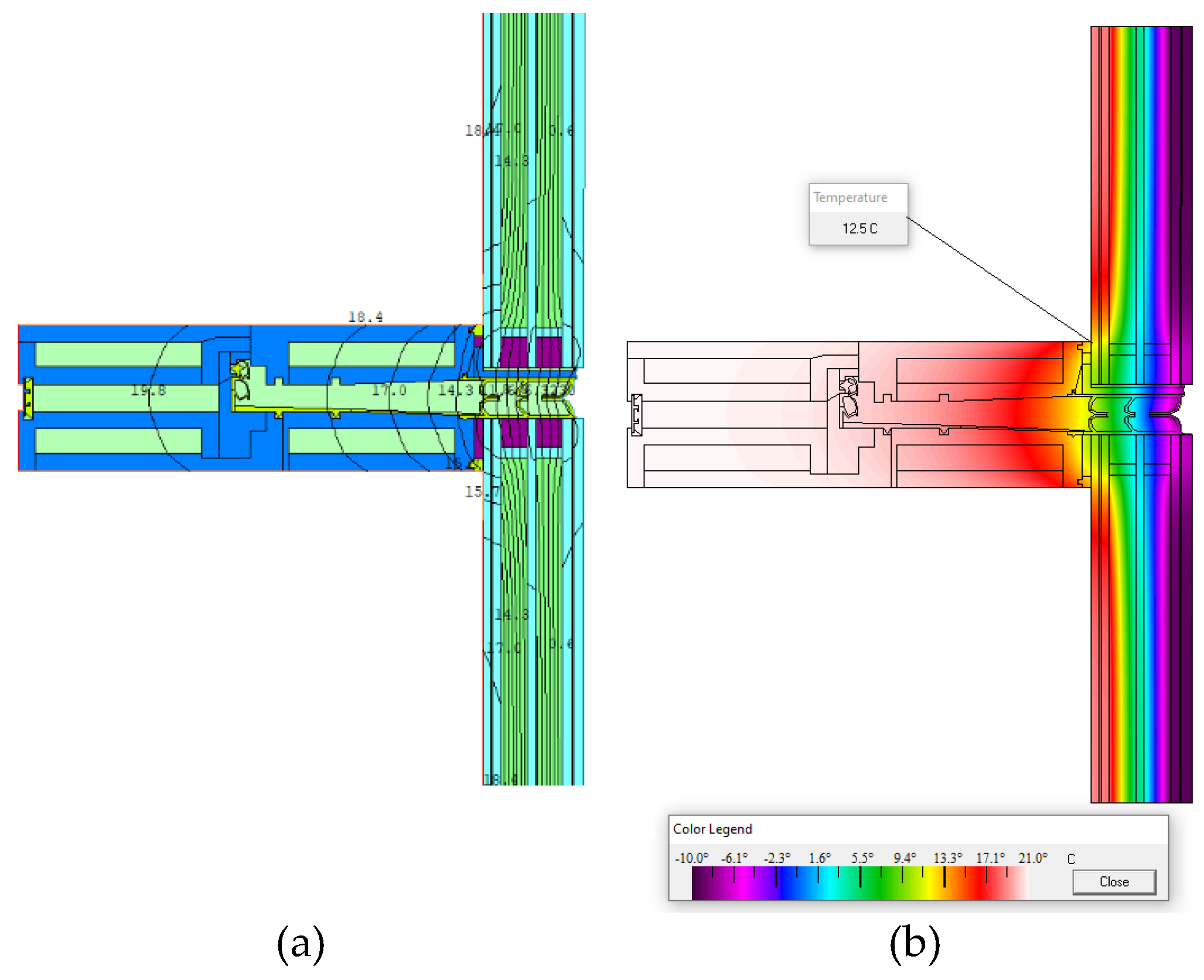

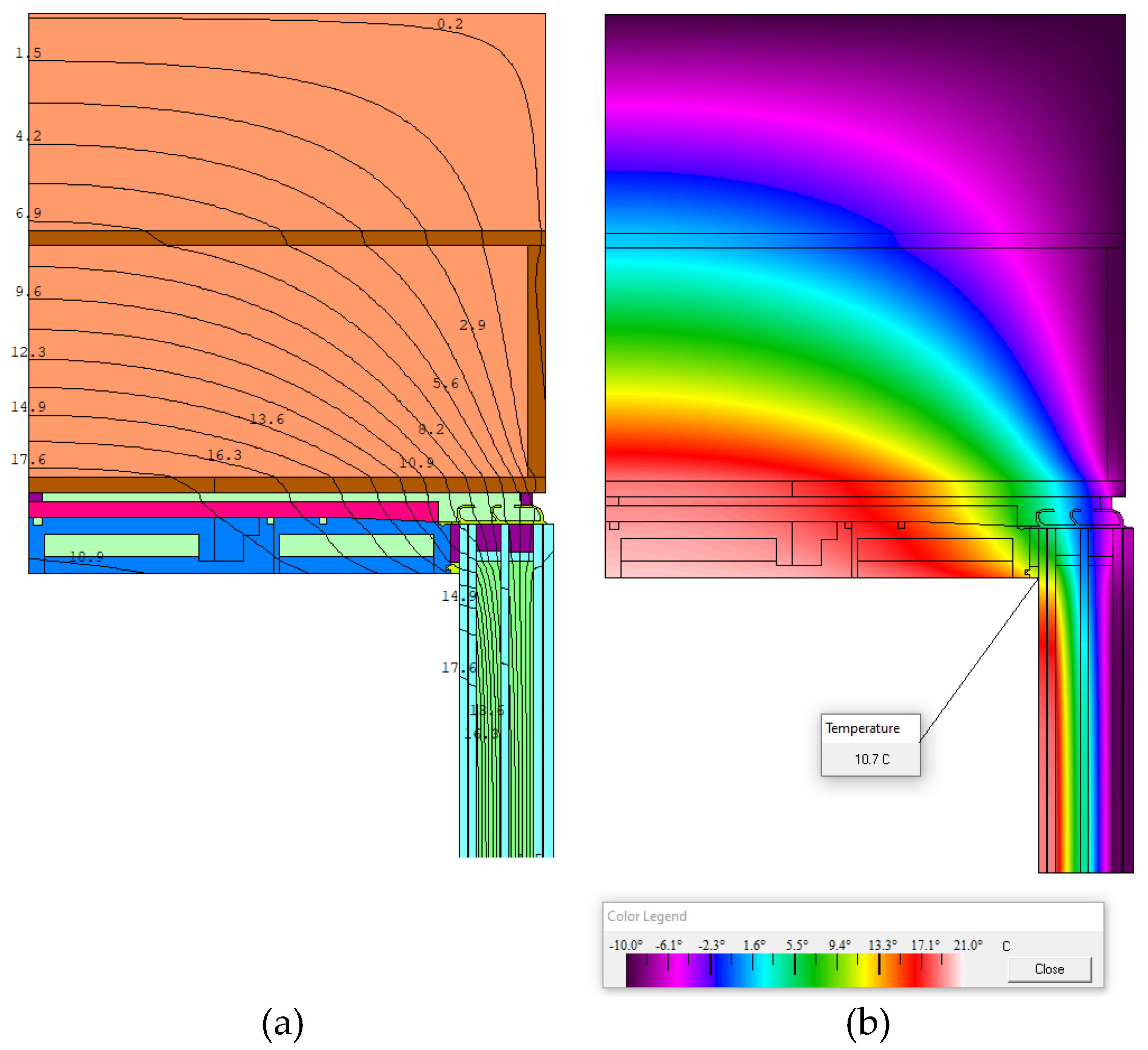

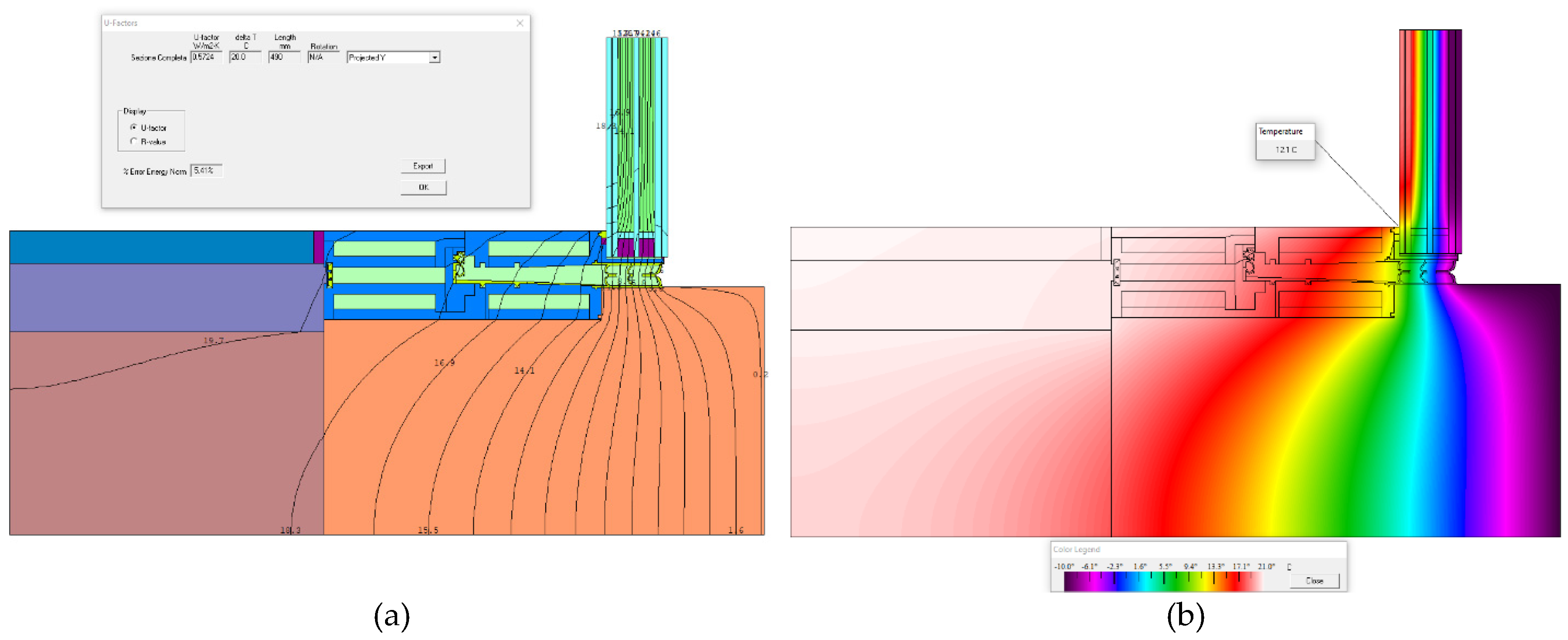

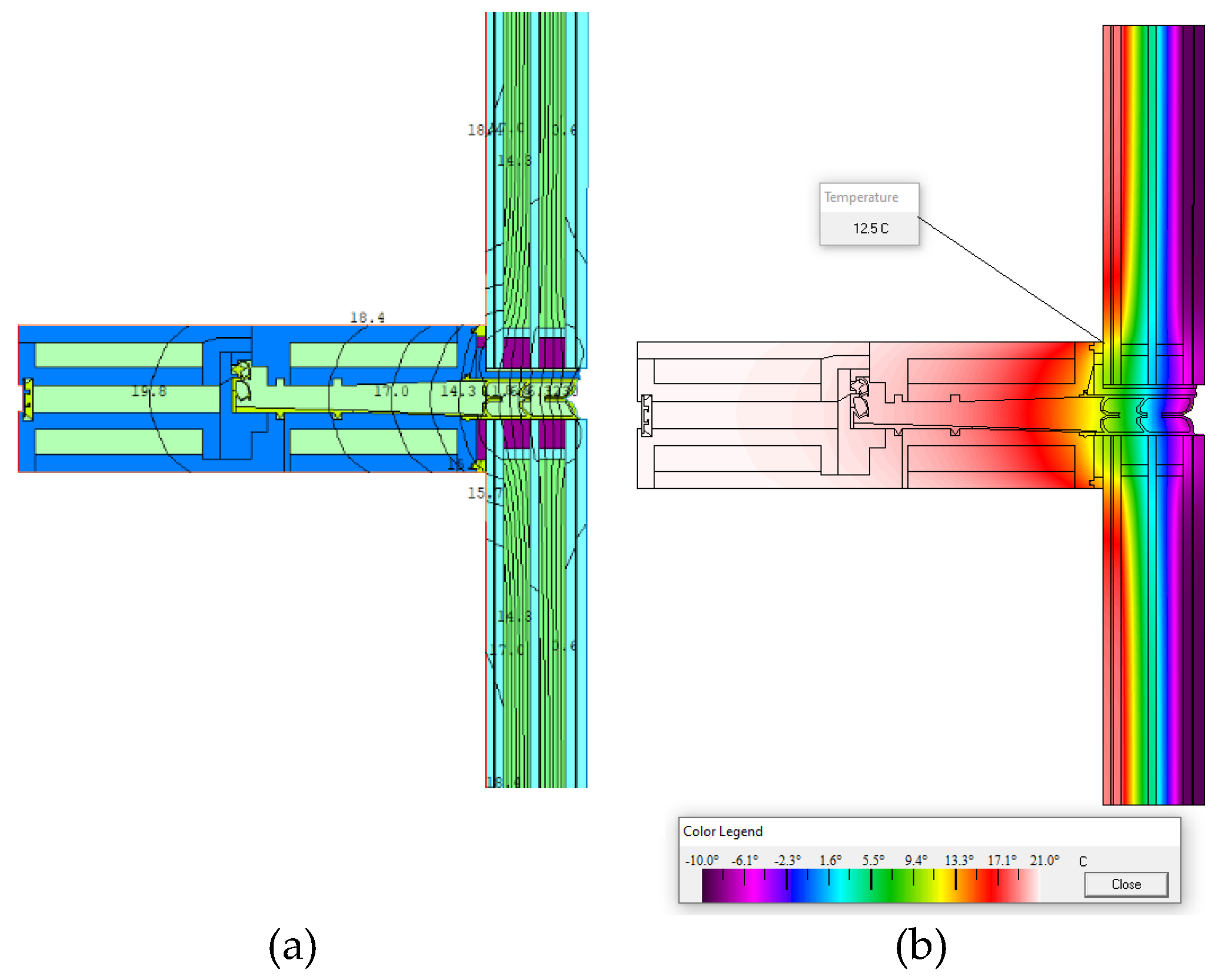

- Thermal simulation with THERM 7.7, following the conventions in EN ISO 10211 [39] and conductivity values as reported in Table 22 reference to Appendix A

- o

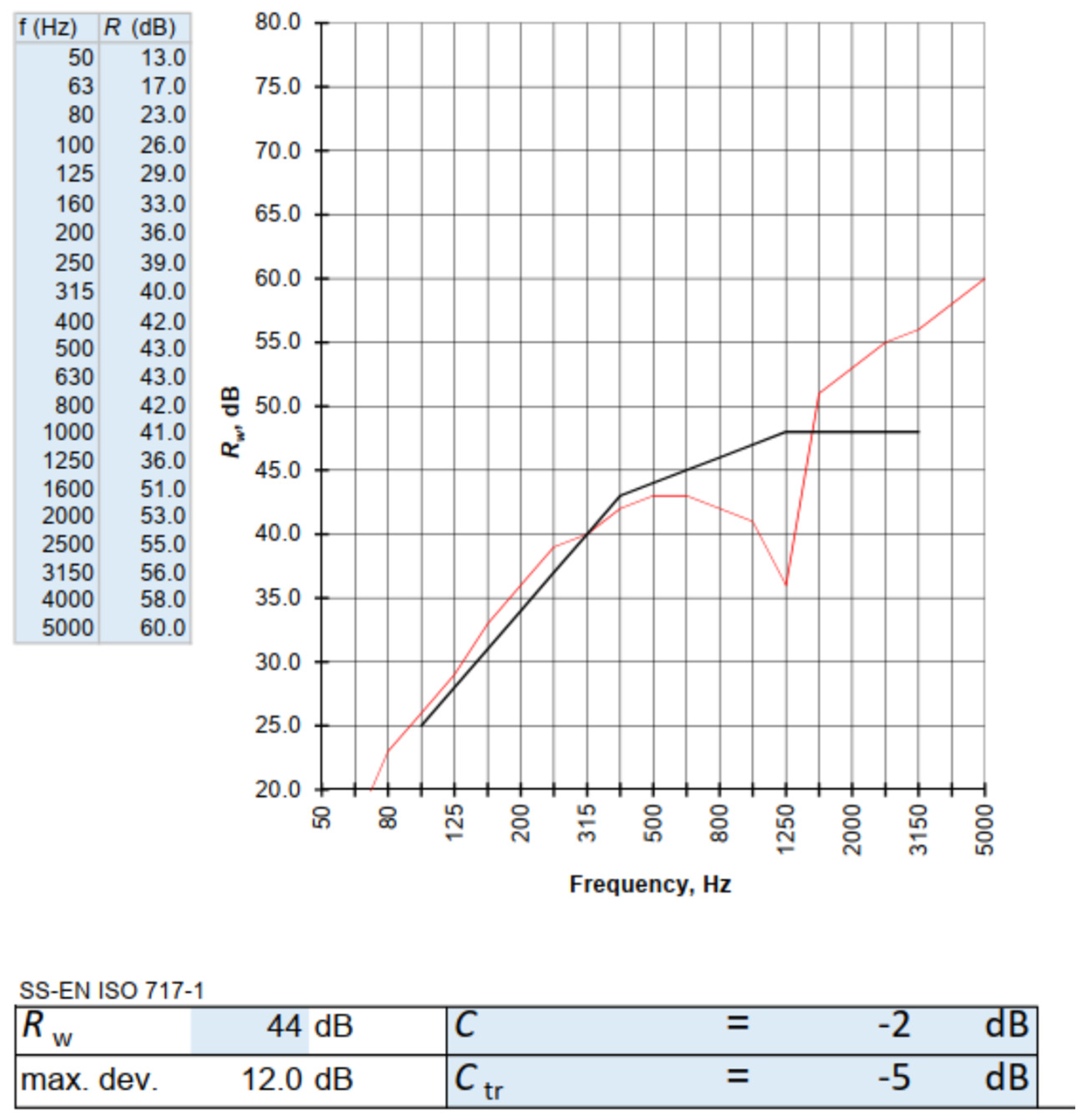

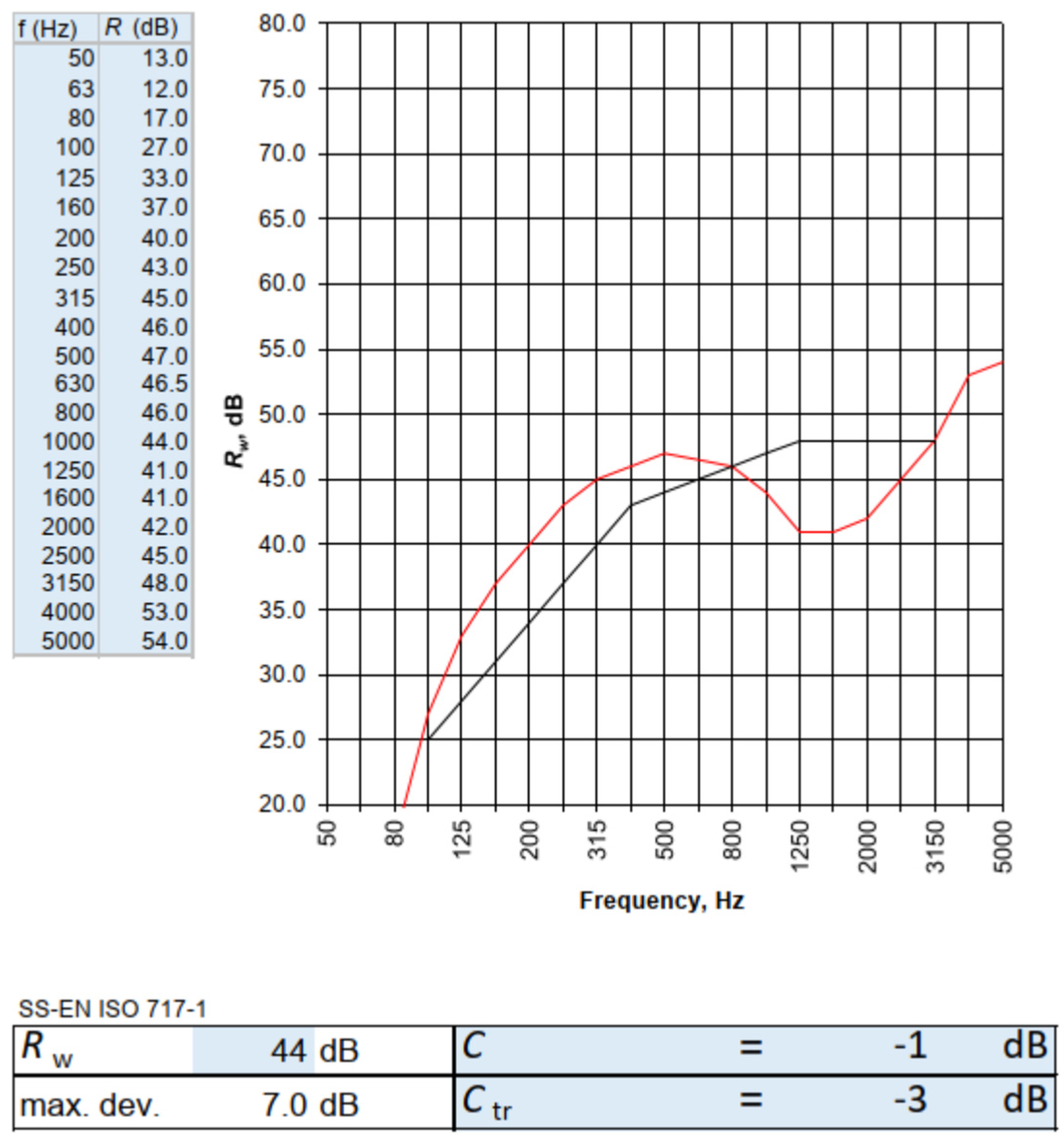

- Acoustic simulation based on EN 717-1 [40]

3. Results

3.1. Bio-Based and Alternative Components for Façade System Module

- Frame profile – the conventional on-market curtain wall façade adopts aluminium profile, with a European average of 36% of recycled content and an embodied carbon of about 44.03 kgCO2eq/ml, while the bio-composite pultruded profile has 26.80 kgCO2eq/ml of embodied carbon.

- Insulation – the conventional on-market curtain wall façade adopts rock wool with an average A1-A5 GWP from EPDs of about 45.00 kgCO2eq/m3 while the wood fiber insulation used in Basajaun has a A1-A5 GWP of 1.63 kgCO2eq/m3 (biogenic carbon = 261.00 kgCO2eq/m3) certified by an EPD [43]. Insulation panels that guarantee the same thermal resistance have been compared.

- Tightness layer and stiffness layer – the conventional on-market curtain wall façade adopts silicones, sealants and aluminum sheets with an estimated embodied carbon of about 37.74 average kgCO2eq/m2 for opaque façade module, while the membranes, tapes and plywood implemented have an estimated embodied carbon of about 5.41 kgCO2eq/m2 of opaque façade module (biogenic carbon = 15.10 average kgCO2eq/m2).

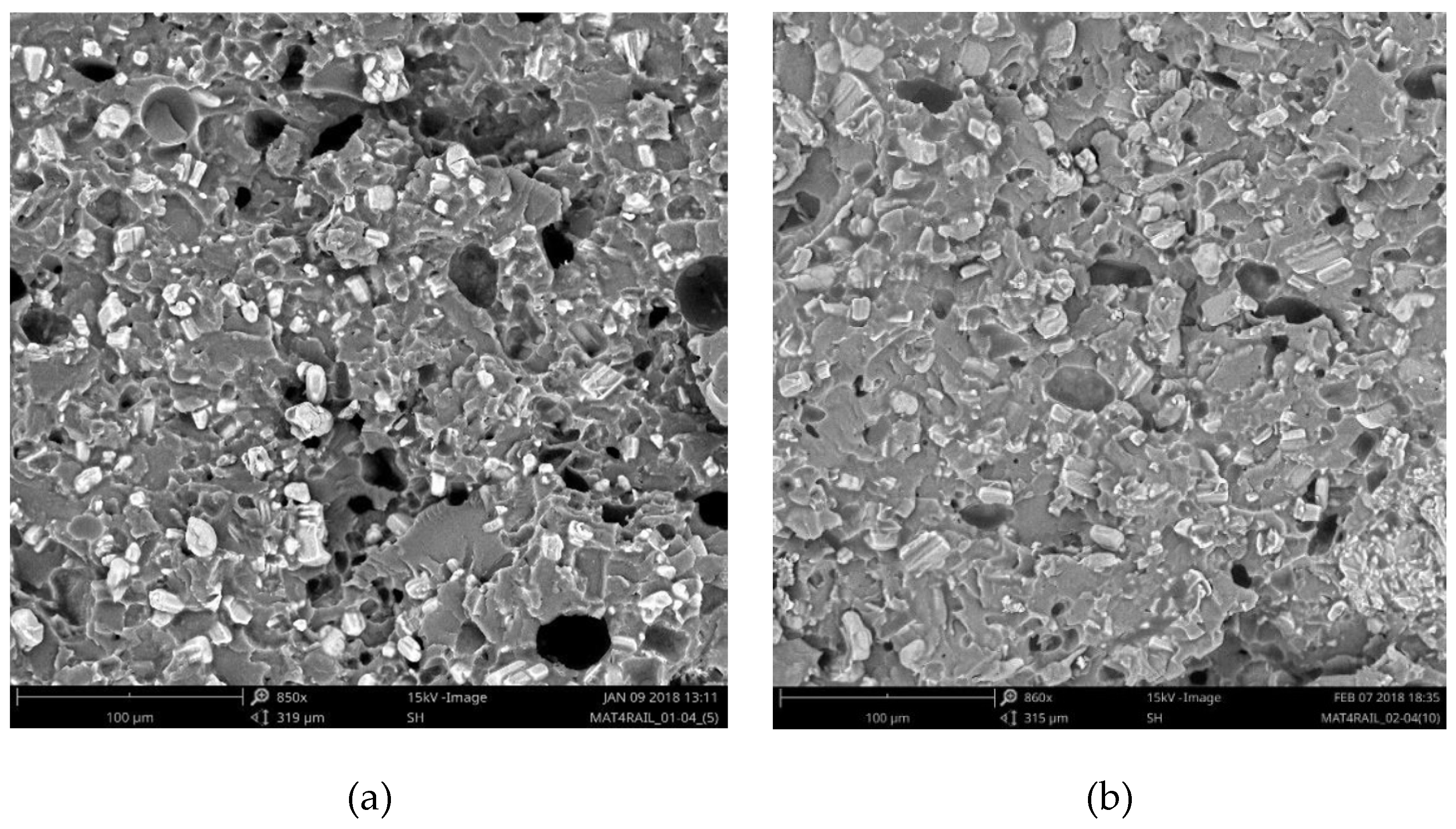

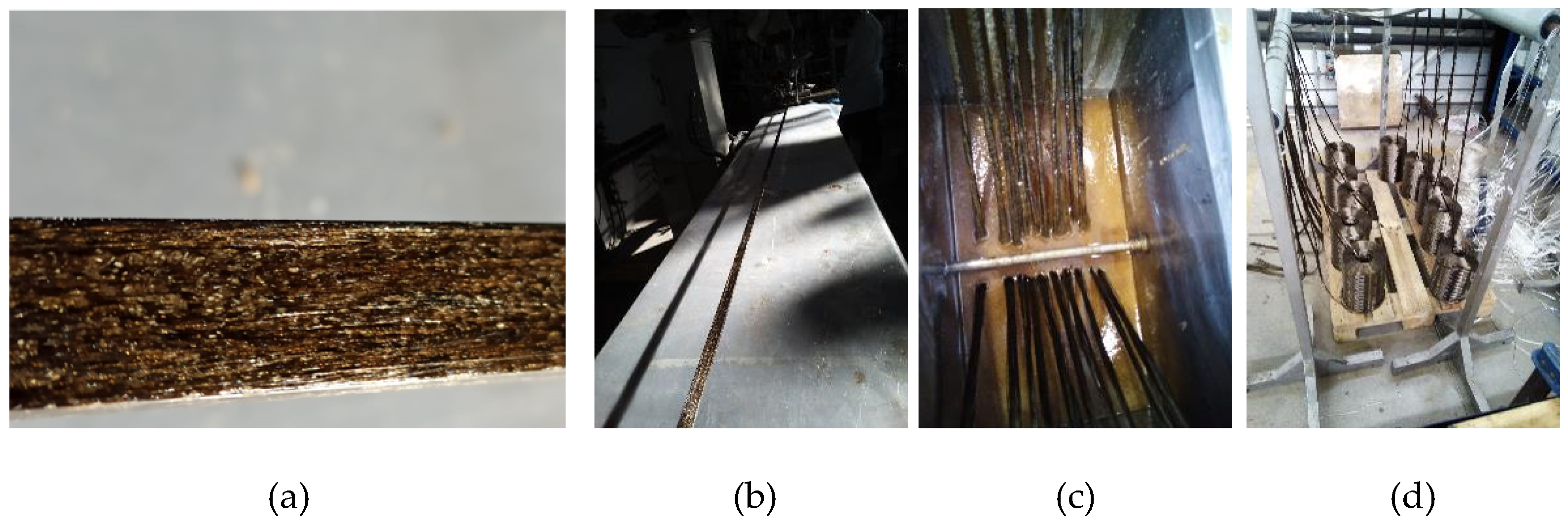

3.1.1. Bio-Composite Frame Profiles

- -

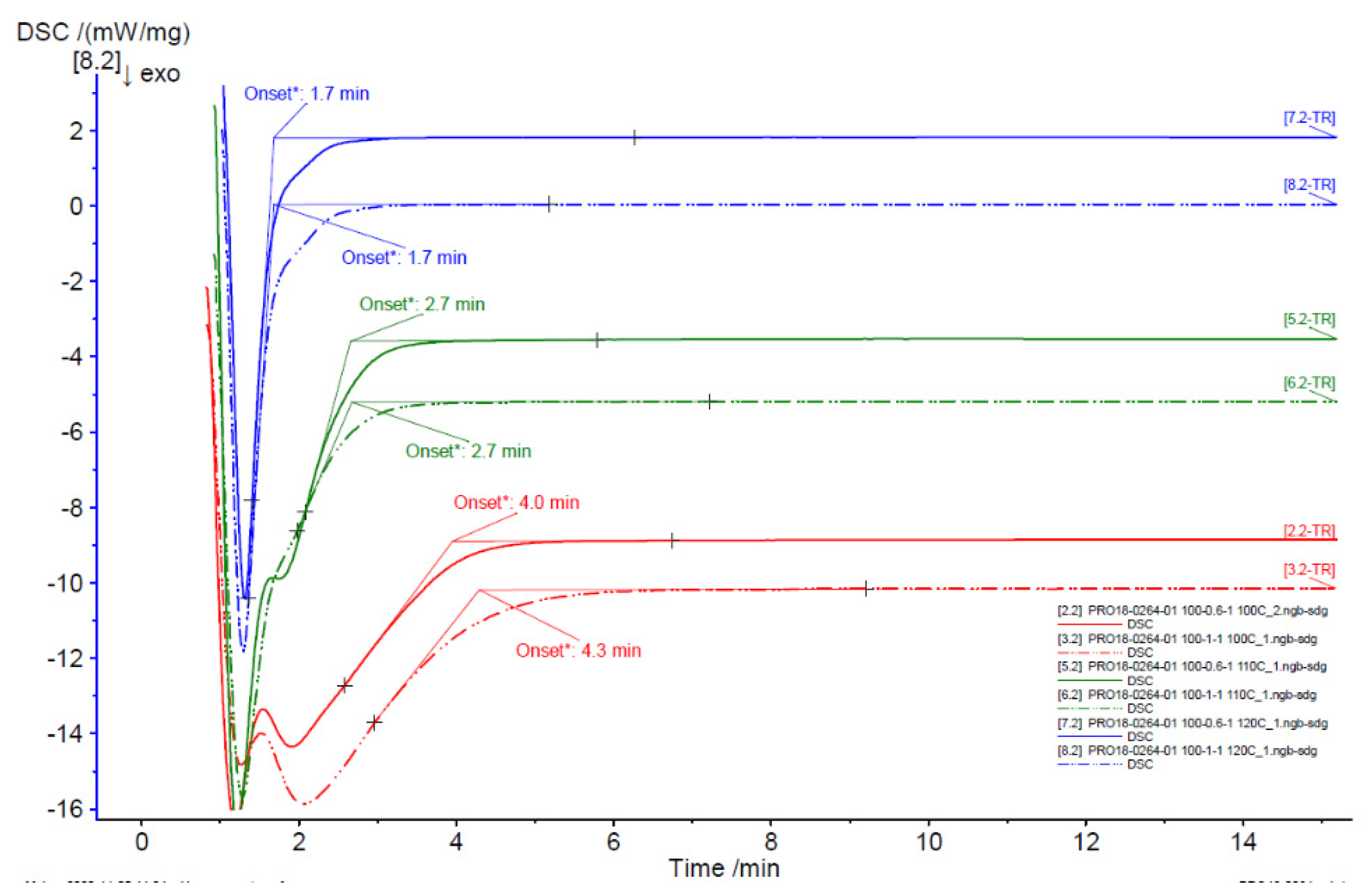

- Selection and evaluation of bio-based polyester

- -

- Resin selection and preparation

- -

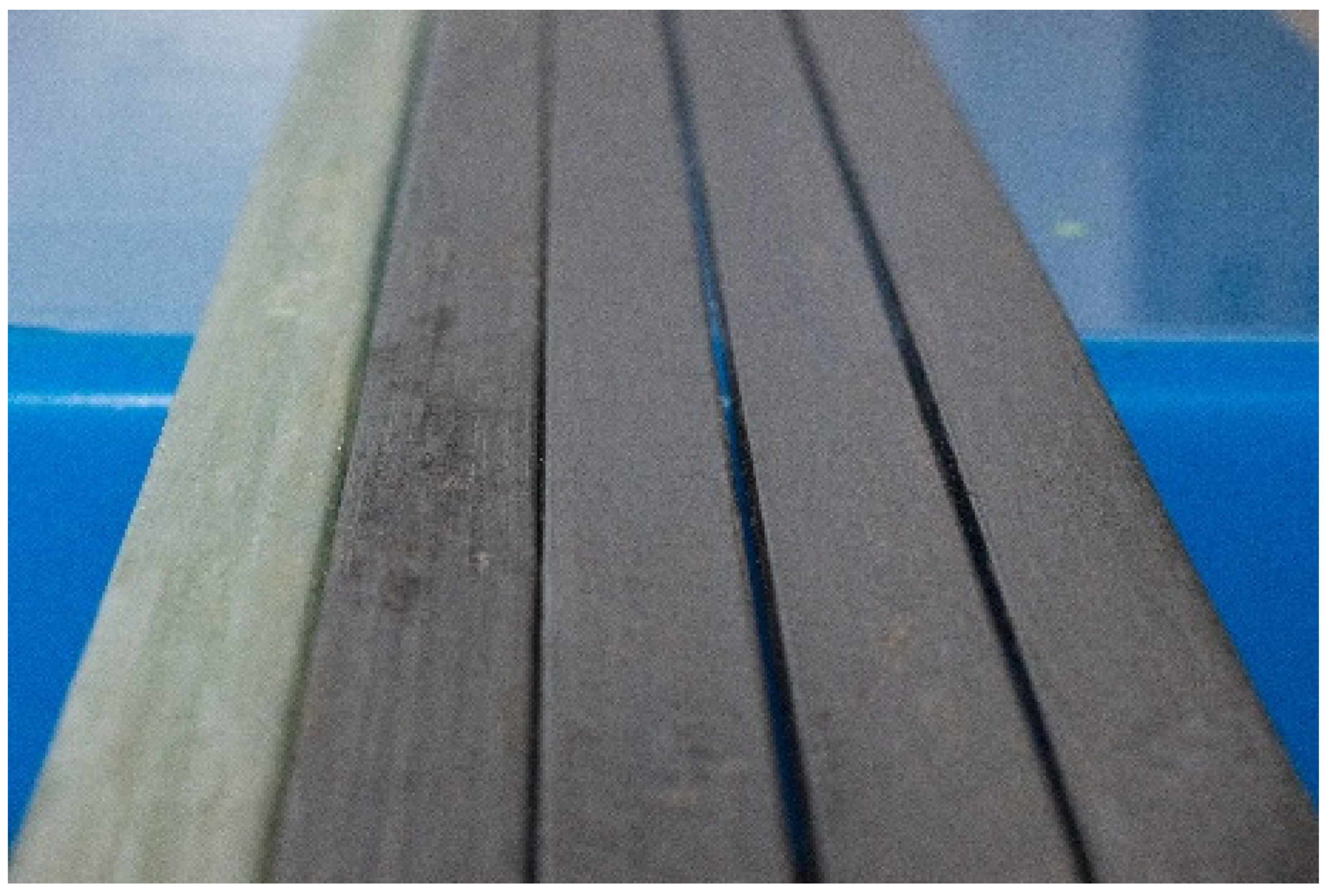

- Preparation of fibers

- -

- Pultrusion trials

- -

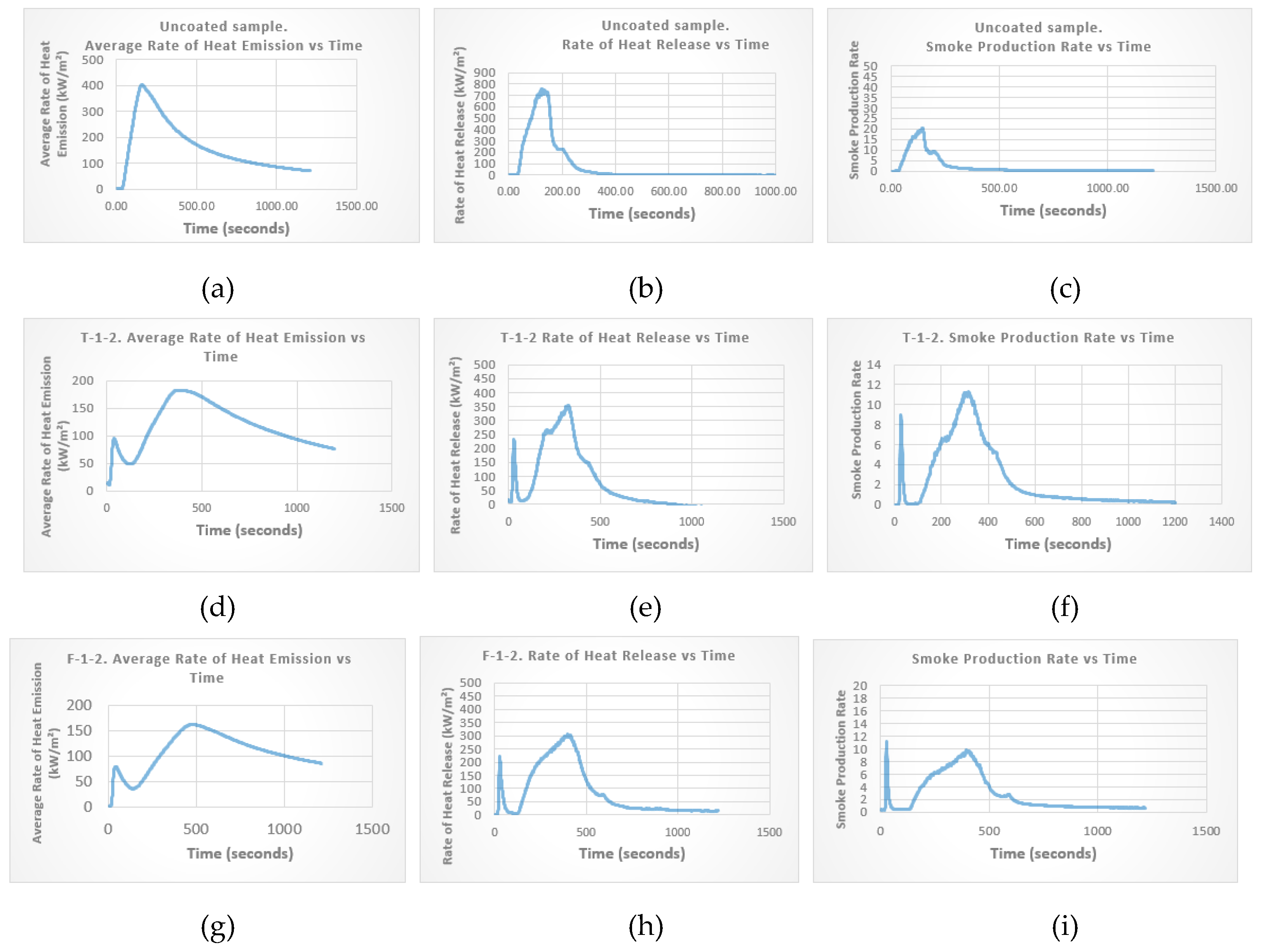

- First flame retardancy tests

- -

- Mechanical characterization profiles obtained.

- -

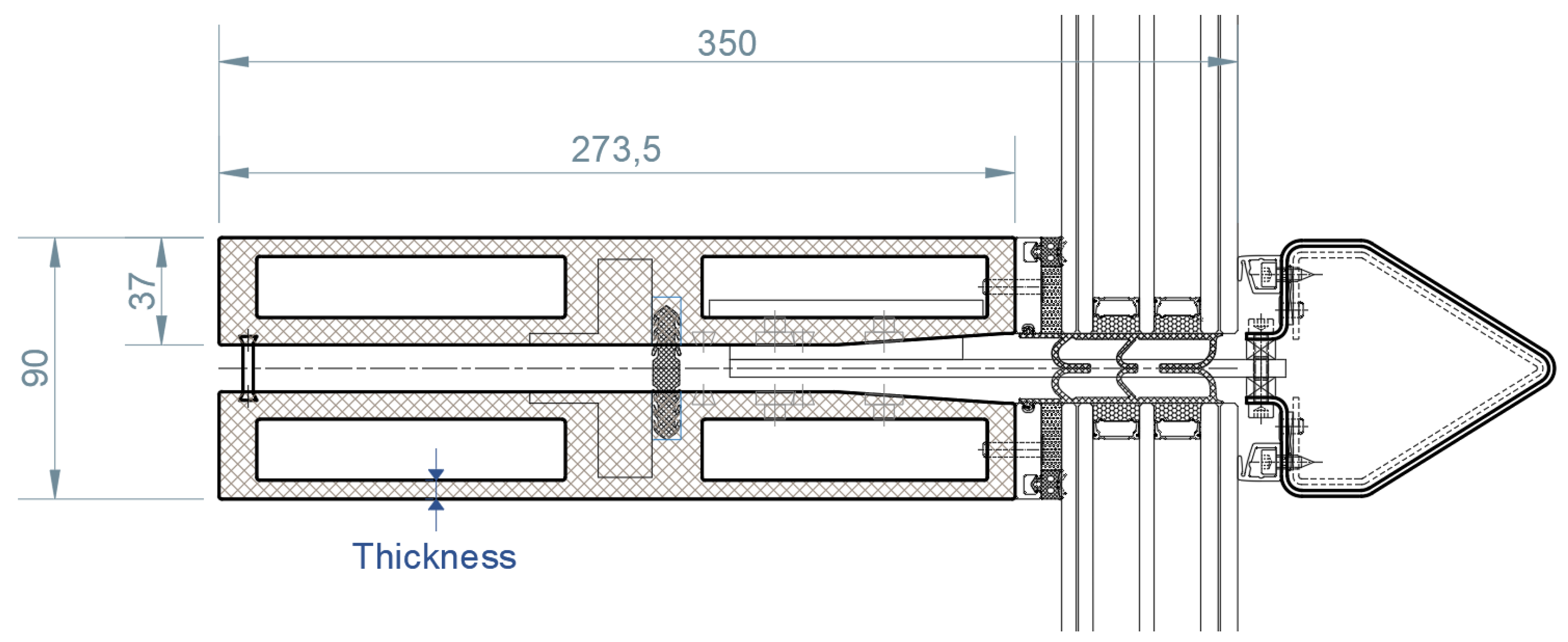

- Bio-composite profile for façade system design

- The catalyst was mixed with resin.

- Hardener and liquid components were added to this mixture.

- Once the mixtures were prepared, they were stirred with the help of a high-speed mixer.

- -

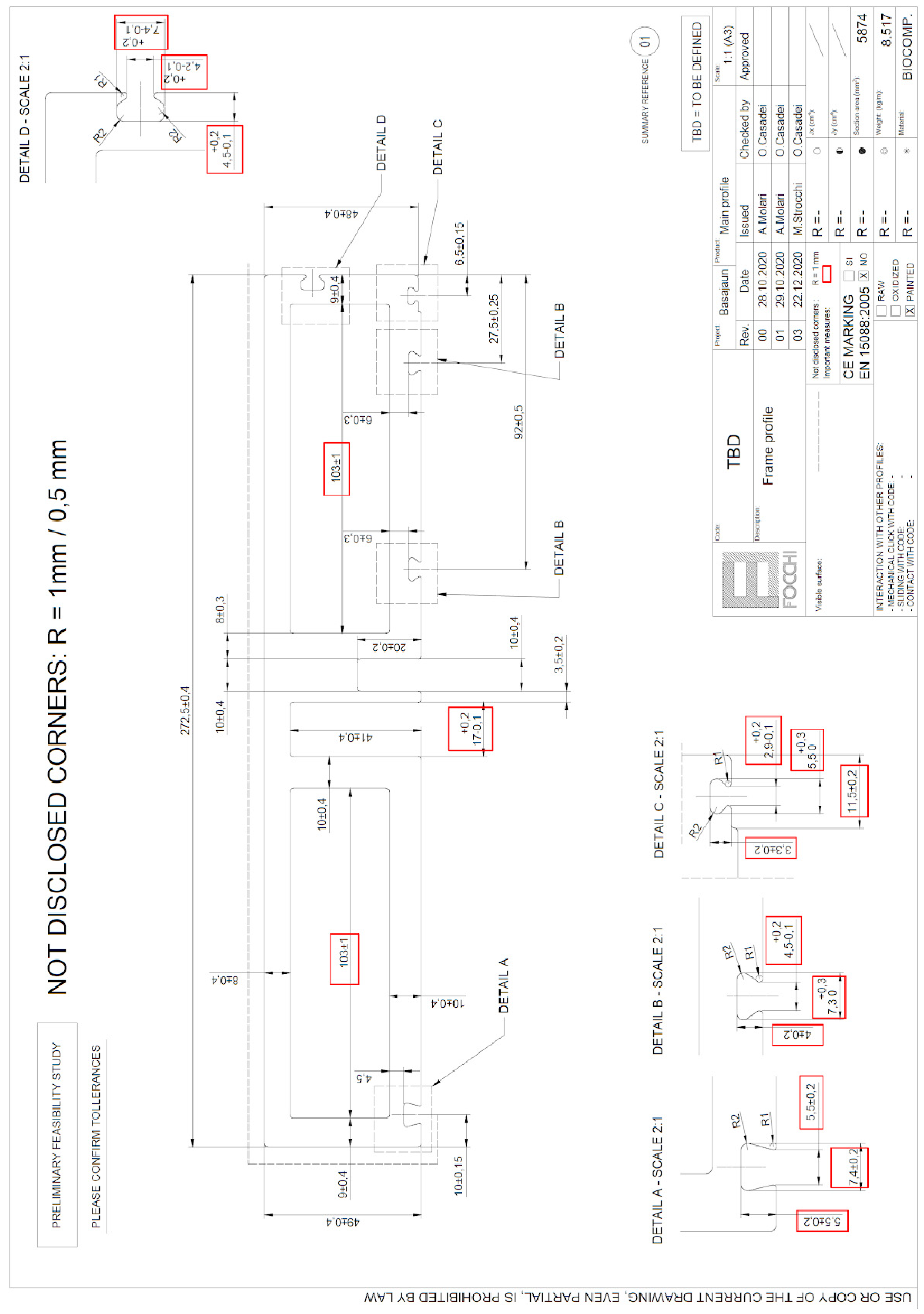

- simple shape – pultrusion process needs simpler shape than other manufacturing process (e.g., extrusion typical manufacturing process for aluminium profile) and this request for profile standard thickness, absence of notches for fixing (specific corner connectors are needed).

- -

- mould cost – to keep control of cost and avoid to manufacture moulds of big dimension for each profile (mullion, male transom, female transom) with higher cost impact, the three profiles should be designed as a single shape with a smaller profile for the male transom. This is particularly relevant in the case of customize building project less in the case of an industrialized façade in which case the mould costs are depreciated on more amount of square meters.

| Bio-composite manufacturing components | Bio-composite profile requirements | Basajaun profile design |

| Pultrusion activity | Maximum length of the profile is 4 mt | Maximum façade height 4 around mt |

| Low tolerance during the pultrusion | Simple and reduced activities for cutting and machining | |

| Sharp or rounded corner for the bio-composite profile | ||

| Thickness and dimensions | ||

| Moulds | High time consuming for the mould creations | Unique mould for multiple profiles and accessories for transoms and connection |

| Cost for mould manufacturing | ||

| Simple shape of the mould is required | Feasibility of the mould geometry needs to be checked | |

| Impossibility to manufacture notches | ||

| Bio-composite material | Low UV resistance to be protected by façade components | |

| Test compatibility with silicones and sealants |

3.1.2. Wood-Based Insulation

3.1.3. Alternatives Seals and Gaskets

3.2. Façade System Modules Requirements

- -

- simple shape - pultrusion process needs simpler shape than other manufacturing process (e.g., extrusion typical manufacturing process for aluminum profile) and this request for profile standard thickness, absence of notches for fixing (specific corner connectors are needed).

- -

- mould cost - for budget issue within the Basajaun project, it is not possible to manufacture moulds of big dimension for each profile (mullion, male transom, female transom), the three profiles should be designed as a single shape with a smaller profile for the male transom.

| Biocomposite manufacturing components | Biocomposite profile requirements | Basajaun profile design |

| Pultrusion activity | Maximum length of the profile is 4 mt | Maximum façade height of about 4 m |

| Low tolerance during the pultrusion | Simple and reduced activities for cutting and machining | |

| Sharp or rounded corner for the biocomposite profile | ||

| Thickness and dimensions | ||

| Moulds | High time consuming for the mould creations | Unique mould – for budget issue – for multiple profiles and accessories for transoms and connection |

| Expensive mould creating | ||

| Simple shape of the mould is required | Feasibility of the mould geometry needs to be checked | |

| Impossibility to manufacture notches | ||

| Biocomposite material | Low UV resistance to be protected by façade components | |

| Test compatibility with silicones and sealants |

| Requirement | Vision Module Façade System |

Opaque and Window Module Façade |

Basajaun Façade System Design |

|---|---|---|---|

| Airborne sound insulation |

Sound insulation R’w ≥ 30 dB. SFS-EN ISO 717-1. | Acoustic reduction index RA = 31 | RA=31 Acoustic test to be conducted |

| Thermal transmittance |

U Value of wall/façade: ≤ 0,17 W/m²K U value of window: ≤ 1,0 W/m²K |

U Value of opaque: = 0,20 W/m²K U Value window: ≤1,3 W/m²K U Value door: ≤ 0,80 W/m²K |

Simulation with EN ISO 10077-2:2019 |

| Air permeability | The air permeability rate (q50) of a building envelope may be a maximum of 4.0 m3/(h m2). | Air permeability < 0.4 m3(h/.m2) |

Air permeability: < 0.4 m3(h/.m2) Test under 13830 to be conducted |

| Validation | Test conducted | |

| Thermal Behavior (EN13788) | EN 9869: 2014 EN 15026:2007 |

Simulation |

| Heat bridges and condensation risks | Simulation | |

| Acoustic insulation | EN 717-1:2020 | Simulation |

3.3. Bio-Based Façade Systems

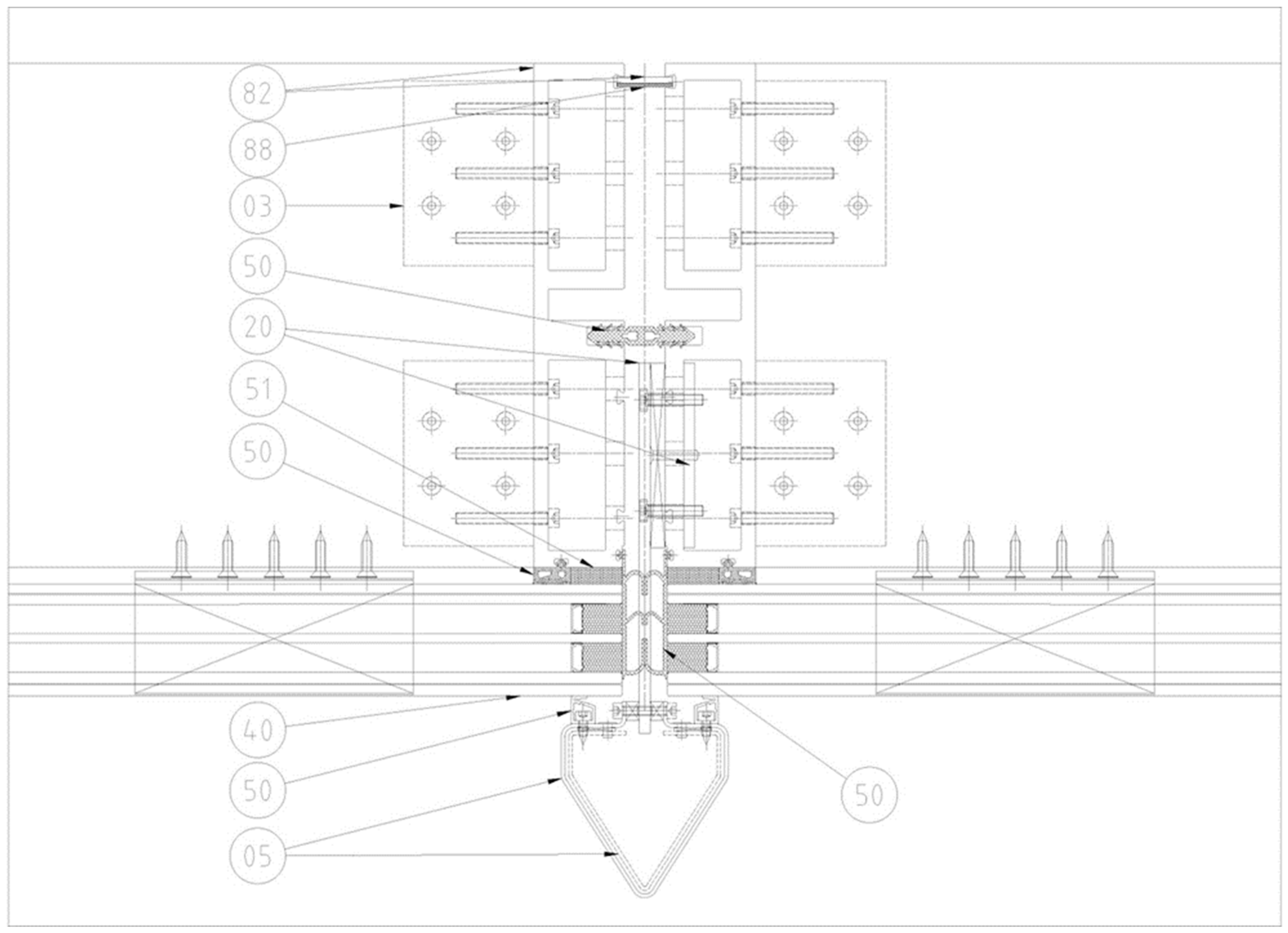

3.3.1. Vision Façade System

| Figure Code | Layer | Objectives | Characteristics |

| 03 | Aluminium bracket mill finish | To connect the transoms to the mullions | Structural part |

| 05 | Aluminium sheet | External finishing | - |

| 20 | Stainless steel sheet AISI316 | To connect the external fin to the frame | Structural part |

| 20 | Stainless steel sheet AISI316 | Internal support | Structural part |

| 40 | GL-1 TGU | - | Triple glass unit |

| 50 | EPDM gasket | Second water barrier | - |

| 50 | EPDM gasket | Glass support | - |

| 50 | EPDM gasket | First water barrier | - |

| 50 | EPDM gasket | Finishing gasket | - |

| 51 | Structural silicone black colour | To join the glass to the frame | Structural part 9mmx27mm |

| 82 | Biocomposite profile- Internal key | To join two units | Thickness 3,5 mm |

| 82 | Biocomposite profile- Mullions | To bead the unit load and connect it with the structural slab | Thickness 8/10 mm |

| 88 | Foam rubber | To not vibrate the internal key | - |

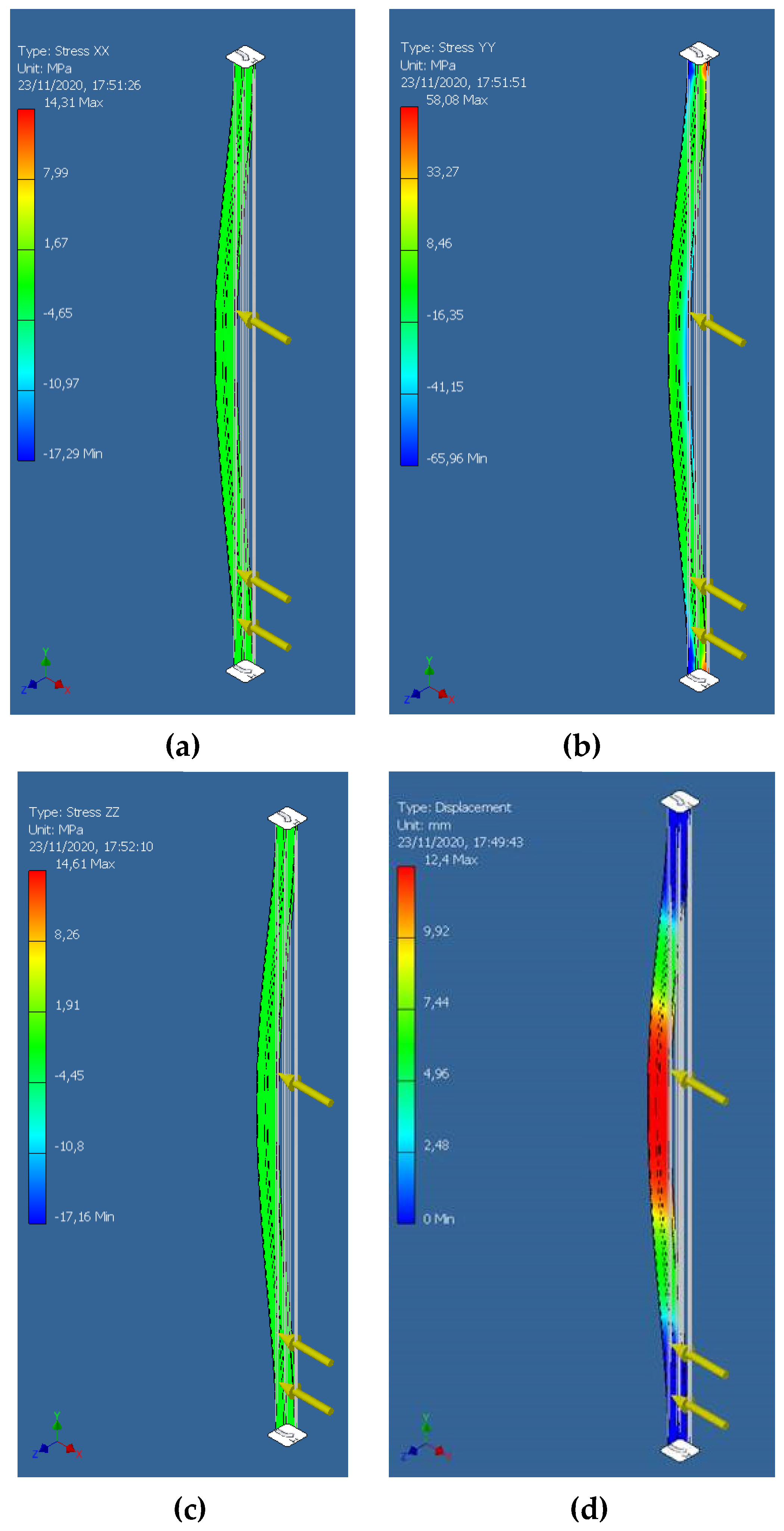

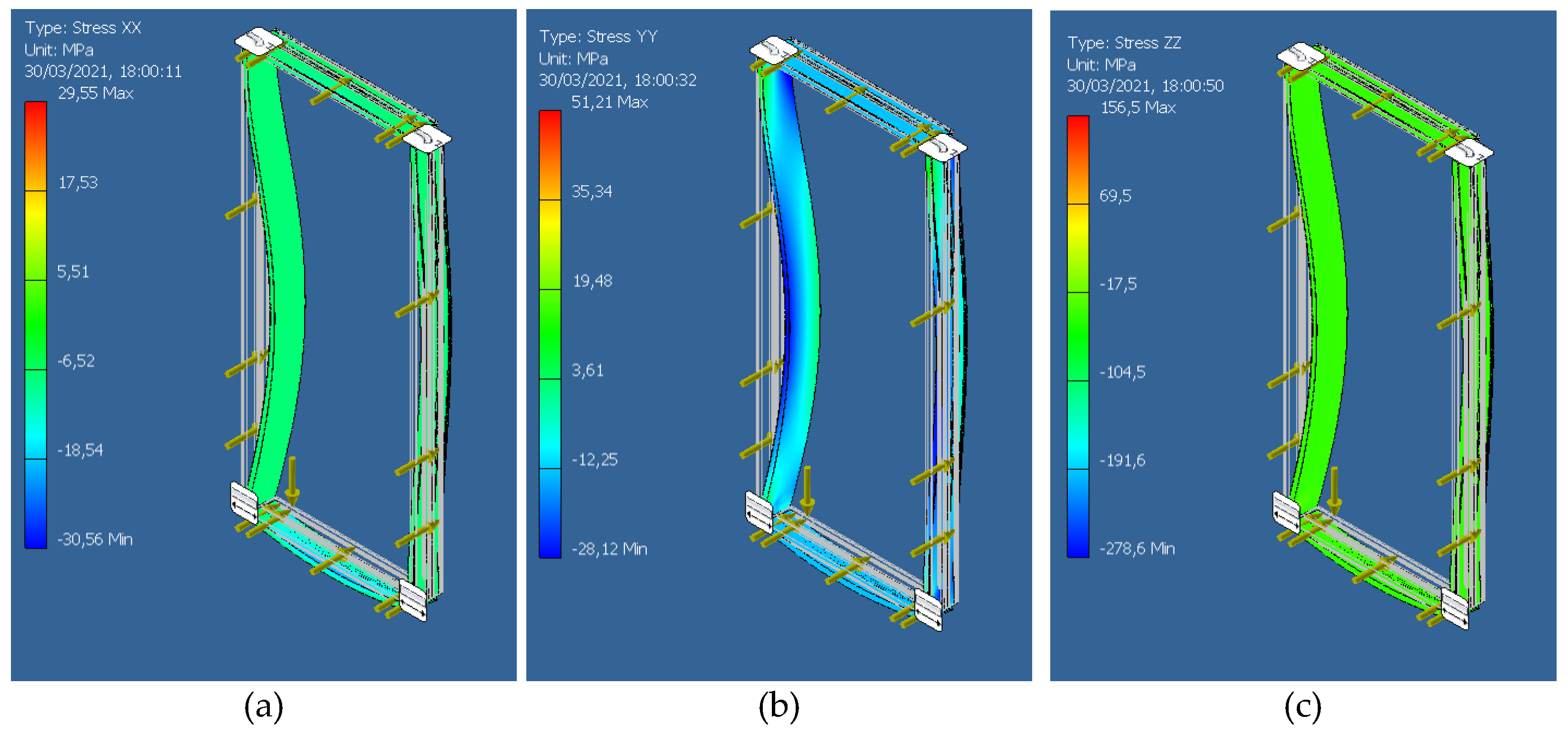

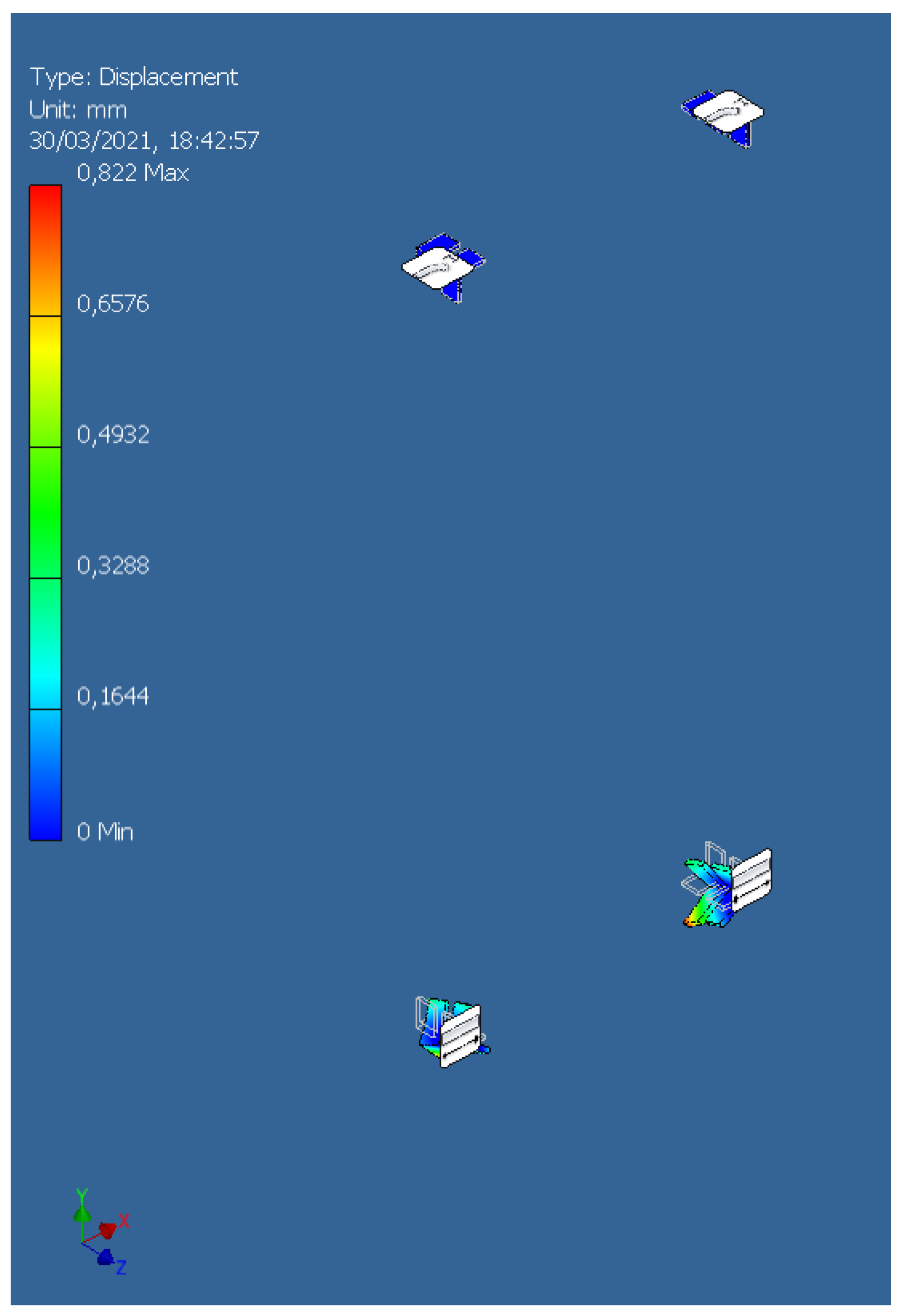

- Glass weight: 25KN/m3 x 0,029 m x 1,56 m x 3,85 m / 2 supports = 2,18 KN at l/10 ends of the bottom transom.

- Façade wind load (suction): - 3,5 KN/m2. The wind load is uniformly distributed in the entire glass surface.

- The value of the linear live load is 1,0 kN/m at 1,20 m height from bottom edge.

- ULS1 (Ultimate State Limit): 1,35 Self-weight Load + Wind Load (Suction) x 1,5 + Horizontal live load x 1,5 x 0,7.

- ULS2 (Ultimate State Limit): 1,35 Self-weight Load + Wind Load (Suction) x 1,5 x 0,6 + Horizontal live load x 1,5

- SLS1 (Serviceability limit state): Self-weight Load + Wind Load (Suction) + Horizontal live load x 0,7.

- SLS2 (Serviceability limit state): Self-weight Load + Wind Load (Suction) x 0,6 + Horizontal live load.

-

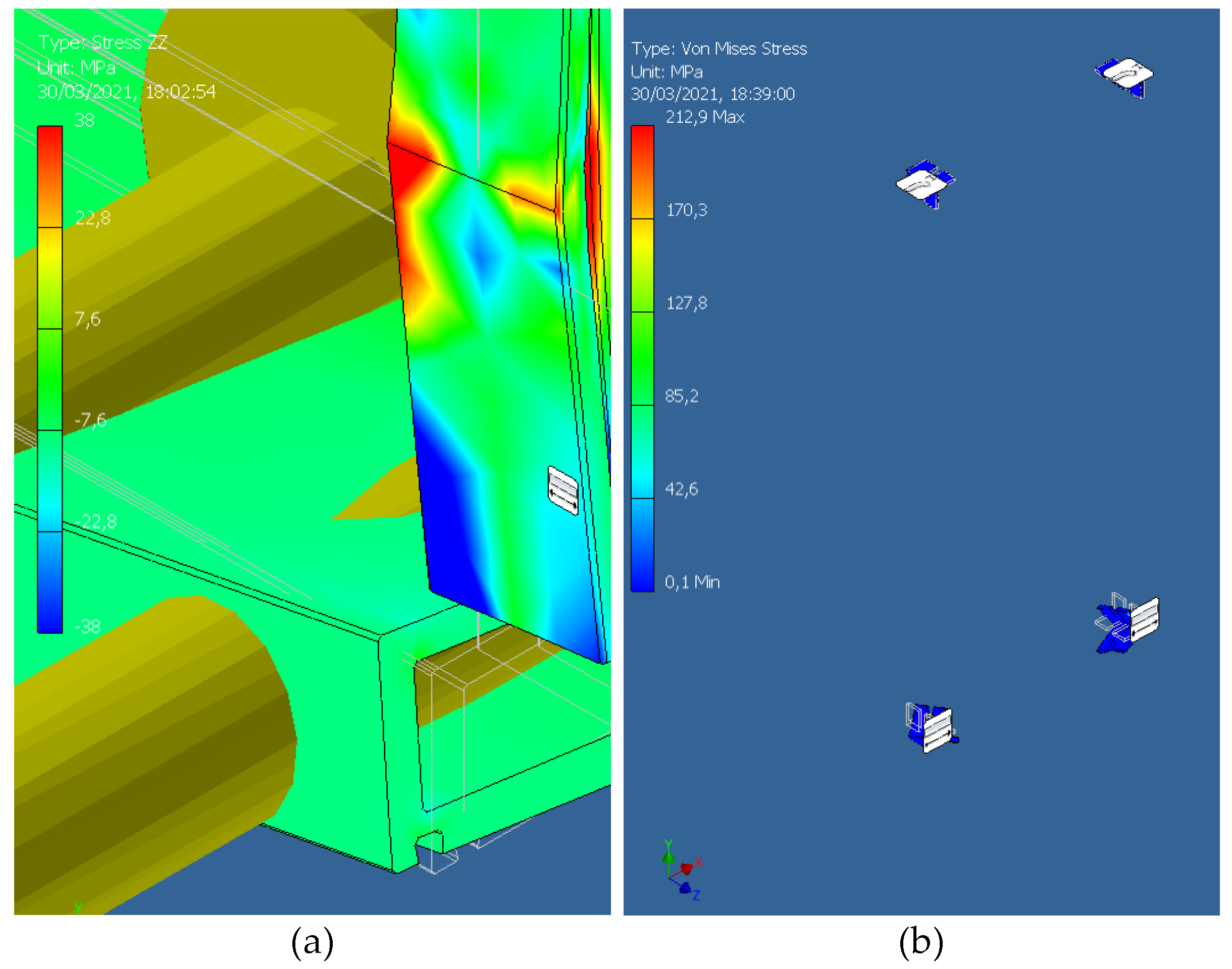

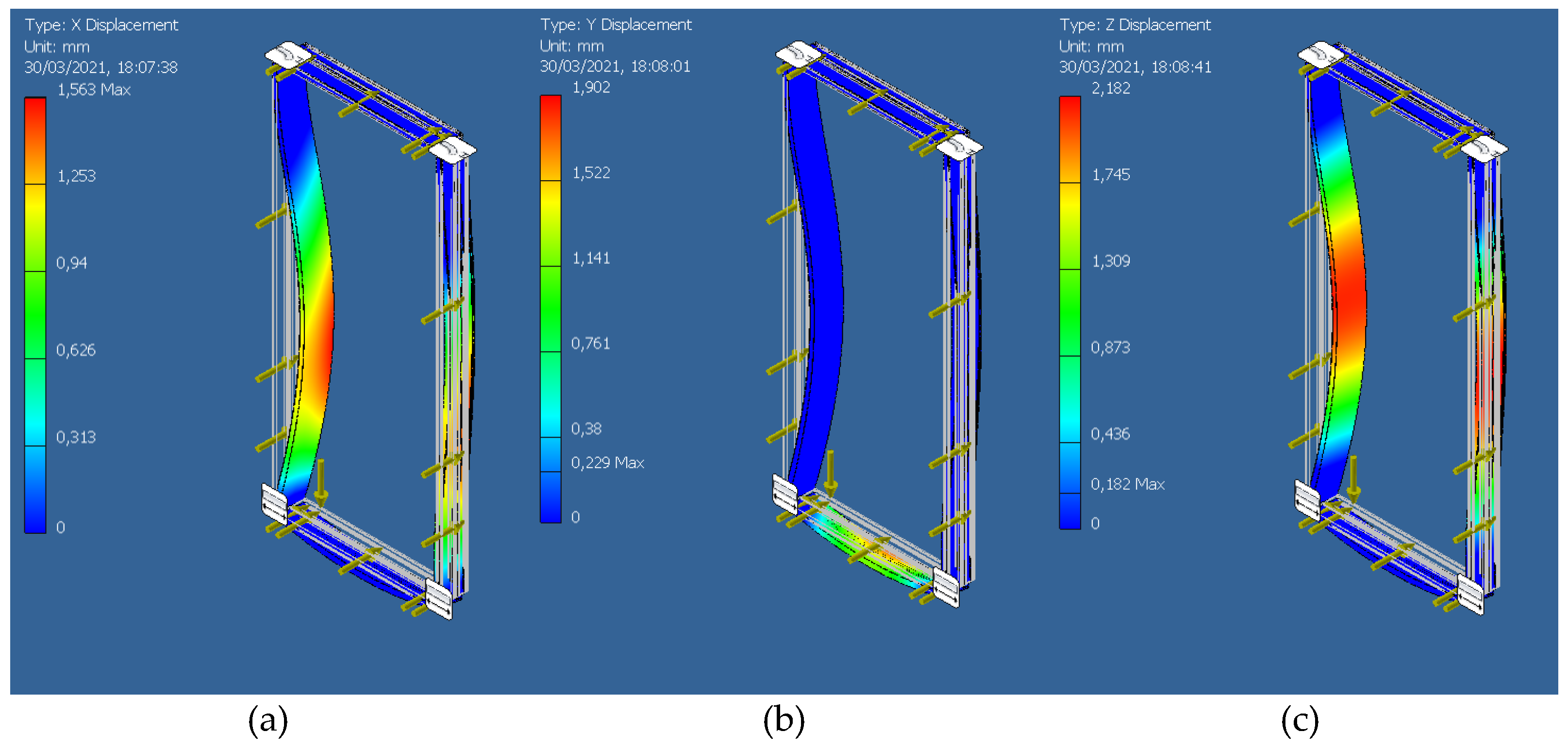

the perimeter structure stress analysis requested are:

- o

- Stress XX - Permissible Stress: 38 MPa;

- o

- Stress YY - Permissible Stress: 125 MPa.

- o

- Stress ZZ - Permissible Stress: 38 MPa.

- o

- X Deflection - Max. Deformation < 3850 / 300 + 5 = 17,83 mm.

- o

- Y Deflection - Max. Deformation < 1560 / 500 = 3,12 mm.

- o

- Z Deflection - Max. Deformation < 3850 / 300 + 5 = 17,83 mm.

-

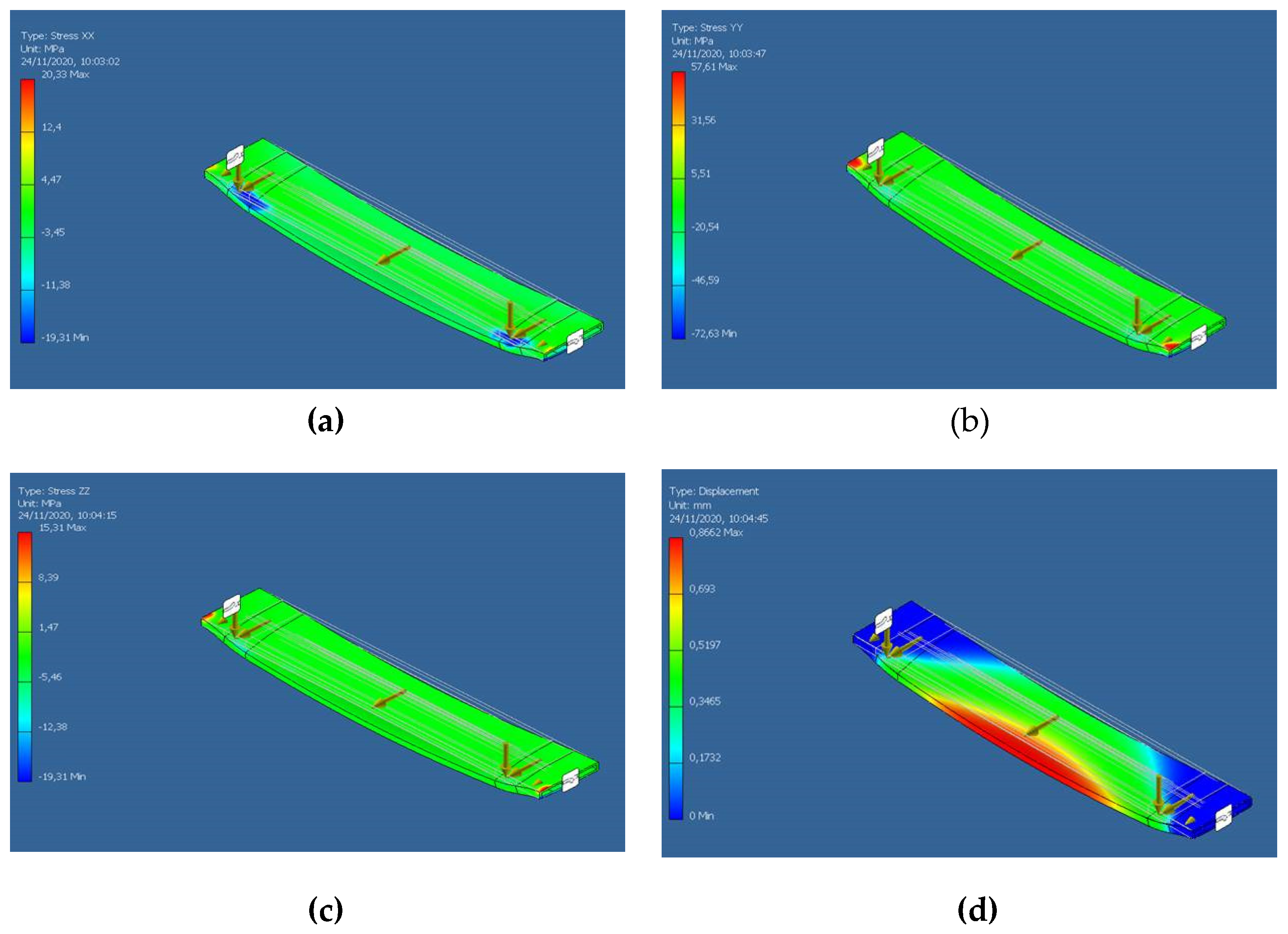

the cross-member connection stress analysis requested is:

- o

- Stress - Permissible Stress: 227 MPa (250/1,1) Aluminium 6082 T6.

- o

- X Deflection - Max. Deformation < 1 mm

| Node | Lenght m |

Area m2 |

UTJ W/m2K |

UTJ x A W/K |

| Node 1 | 0.9 | 2.498 | 2.253 | 5.630 |

| Node 2 | 0.9 | 0.614 | 2.331 | 1.431 |

| Node 3 | 0.36 | 2.525 | 0.556 | 1.404 |

| Node 4 | 0.30 | 2.304 | 0.521 | 1.201 |

| Node 5 | 0.24 | 2.732 | 0.852 | 2.328 |

| Glass | 44.894 | 0.650 | 29.181 |

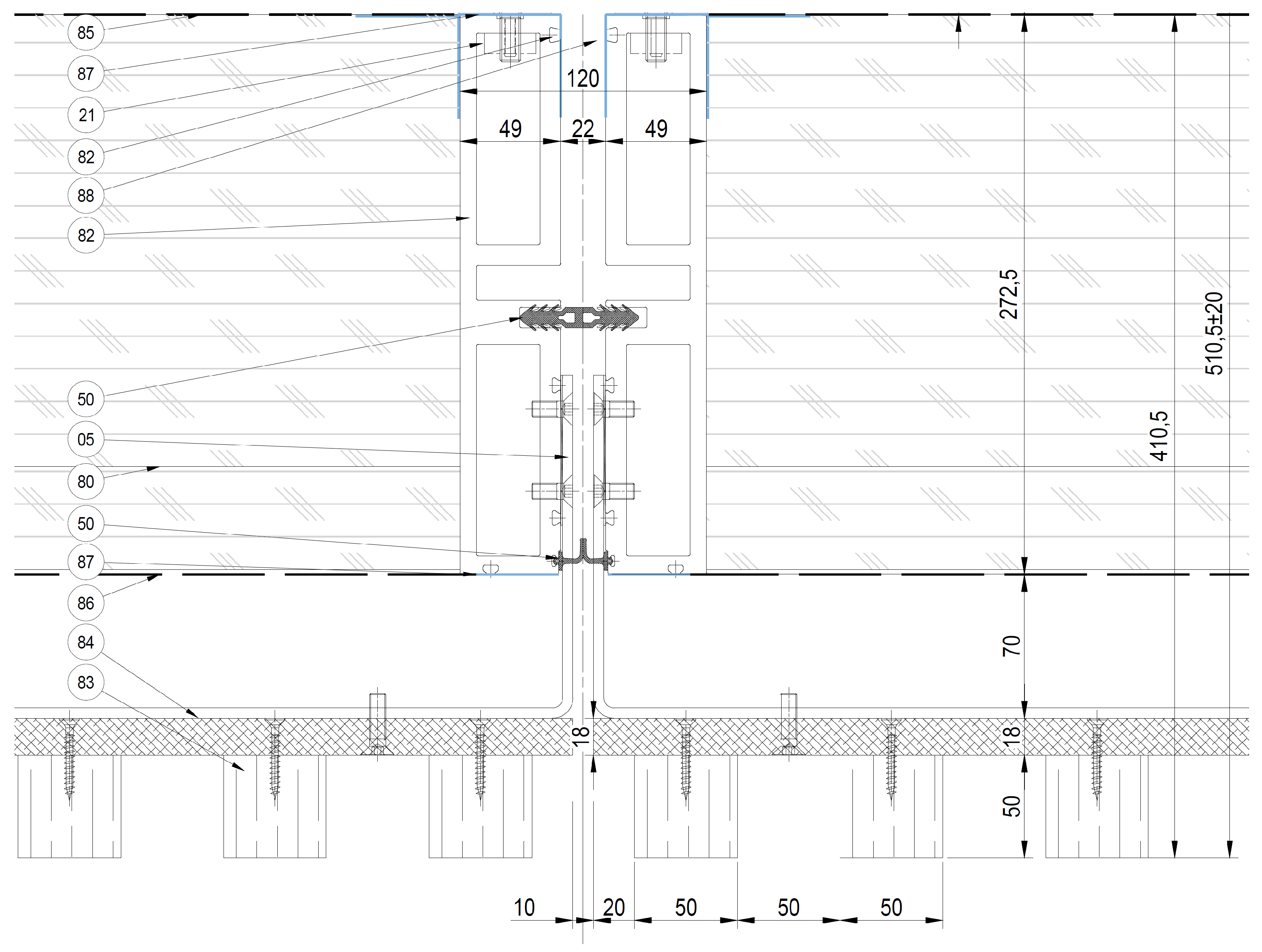

3.3.2. Opaque Module Façade System

| Figure Code | Layer | Objectives | Characteristics |

|---|---|---|---|

| 05 | Stainless steel sheet AISI 316 | To connect the external cladding to the frame | Structural part |

| 21 | Stainless steel accessory | To connect anchor to profile | Structural part |

| 32 | Galvanized steel bracket | - | - |

| 50 | EPDM gasket | Second water barrier | - |

| 50 | EPDM gasket | First water barrier | - |

| 80 | Insulated panel - fiber wood | Insulation | 0,036 W/m2K transmittance |

| 82 | Biocomposite profile- Mullions | To bead the unit load and connect it with the structural slab | To bead the unit load and connect it with the structural slab |

| 83 | Wooden Lamellas | External finishing | Reaction to fire class B1,s0-d0 |

| 84 | Plywood | Internal plywood for false wall | Reaction to fire class B1,s0-d0 |

| 85 | Internal membrane | Vapor barrier | Reaction to fire class A2,s1-d0 |

| 86 | External membrane | Water barrier, wind load resistance | Reaction to fire class A2,s1-d0 |

| 87 | Tape bioadhesive | to stick the membrane to the frame | - |

| 88 | Foam rubber | To not vibrate the internal key | - |

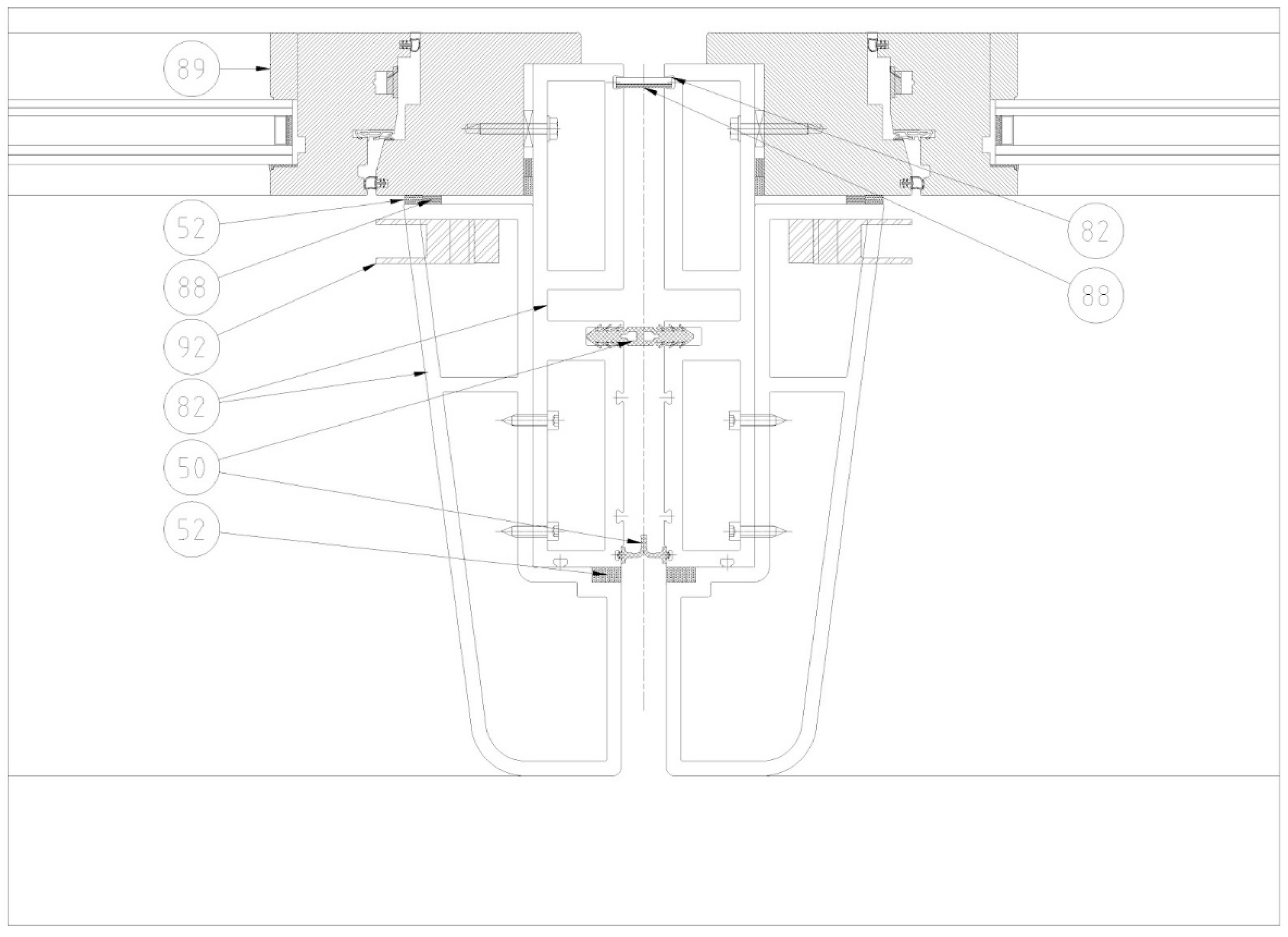

3.3.3. Window/Door Module Façade System

| Code | Layer | Objectives | Characteristics |

|---|---|---|---|

| 9 | Openable | Natural ventilation | - |

| 50 | EPDM gasket | Second water barrier | - |

| 50 | EPDM gasket | First water barrier | - |

| 52 | Water seal silicone black color | To join the external frame to the internal frame | - |

| 52 | Water seal silicone black color | To join the openable to the frame | - |

| 82 | Biocomposite profile-Internal key | To join two units | Thickness 3,5 mm |

| 82 | Biocomposite profile-Mullions | To bead the unit load and connect it with the structural slab | Thickness 8/10 mm |

| 82 | Biocomposite profile-External frame | To cover the biocomposite profile - esthetical aim | - |

| 88 | Foam rubber | To not vibrate the internal key | - |

| 88 | Foam rubber | To not drop the silicone | - |

| 92 | Roller shutter | to guarantee shading elements | - |

4. Discussion

- The development and design of bio-composite pultruded bars for façade system module frames are feasible but require specific considerations for façade designers. The pultrusion process has different tolerances compared to aluminum extrusion, which must be factored into profile design. Notably, larger curvature radiius necessitate simpler gasket designs. The caskets grooves must be carefully designed and validated during initial bar pultrusion activities, which will be part of the overall validation process for façade bar manufacturing.

- The mechanical simulation for the façade’s bar demonstrates its feasibility for a load stress façade module system as the vision. However, the required load capacity of the frame necessitates bars with larger dimensions than extruded aluminum profiles, with limitation on bar lengths. Indeed, to avoid bar with weight > 25 kg, the bar is available with a length of maximum 4 m, long enough for the pilot cases define for the façade, but a limitation for higher façade module. The bar weight has consequences for the overall dimensions of the façade system module and the load capacity of the bar itself, impacting façade manufacturing activities, particularly during cutting and machining processes.

- The curtain wall façade system’s components are well-established, but alternative components with lower environmental impacts can be integrated into facade systems. In addition to bio-based profiles, membranes and tapes for tightness systems have emerged as alternatives to metal sheets and sealant systems in facade design. Membranes offer valuable alternatives due to their Class A fire reaction, vapor barrier, water resistance, and wind load capability. However, final validation requires tests such as adhesion testing between tapes/membranes systems and bio-based profiles, as well as EN13830 testing. Despite achieving the required thermal transmittance, using a 70 mm insulation internal wall raises concerns about adopting wood fiber insulation in curtain wall facades. To maintain the same thermal resistance, wider facades must be designed, impacting system size. Further investigation is needed for market applications, particularly in markets like the UK, where only Class A insulation is permitted. This limitation, especially following recent tragic fire events in multistorey buildings, warrants further discussion.

- Design a bio composites-based curtain wall façade systems based on technical and normative requirement for real case applicability in line with the current building envelope standard for curtain wall façade solution is demonstrated for multiple façade system typologies also adopting the same profile. The overall system design appears in line with the requirements of the pilot references. Indeed, based on mechanical, thermal, and acoustic simulations the bio-based façade system modules demonstrate the compliance with normative.

- Despite the positive design validation, some specific tests should be conducted to confirm the adoption of the bio-based profile between sealants adopted in façade manufacturing and installation and bio-composite profile. For the vision façade module, the ambitious is to use structural silicone in direct contact to the bio-composite profile. This opportunity needs to investigate the adhesion behavior of the bio-composite profile with structural silicone and other sealants to be used in façade manufacturing (vision façade module) and in the installation stage (tightness sealing for curtain wall façade).

5. Conclusions

- Enhancing the proportion of biobased components in the profiles, with a specific emphasis on the resin content, to contribute to a more sustainable and environmentally friendly product.

- Conducting specific prototyping and tests validation to demonstrate how the bio-based façade system achieved the normative standards based on established procedures.

- Validate the Basajaun façade system design to demonstrate its applicability in pilot buildings with the development of the pilot detail design to investigate consequence on real case design for manufacturing.

- Validate in production line the façade manufacturing process, to demonstrate the feasibility and cost-effectiveness of the tapes/membrane system replacing metal sheet and sealant as well as to understand the critical aspect for the cutting and machining of pultruded profiles with basalt fibers and their movement operations due to higher weight than usual aluminum profile.

- Investigate the cost of bio-based facade modules and understand their competitiveness compared to conventional curtain wall facade systems and determine any potential premium pricing for their adoption.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Material | Thermal conductivity | Source |

|---|---|---|

| Woodfibre insulation | 0.038 W/mK | Manufacturer |

| Plywood, timber | 0.13 W/mK | EN ISO 10456 |

| Gypsum plasterboard | 0.25 W/mK | EN ISO 10456 |

| Biocomposite | 0.35 W/mK | Assumed |

| EPDM gasket | 0.25 W/mK | EN ISO 10456 |

| Internal seal | 0.35 W/mK | EN ISO 10456 |

| Air cavity (unventilated) | Geometry-dependent | EN ISO 10211 |

| 1 | From date of manufacture |

| 2 | Curing schedule 24hours @ 20ºC then 3 hours at 80ºC |

References

- H.-O. Pörtner, D.C. Roberts, E.S. Poloczanska, K. Mintenbeck, M. Tignor,; A. Alegría, M. Craig, S. Langsdorf, S. Löschke, V. Möller, A. Okem. IPCC, 2022: Summary for Policymakers. In Climate Change 2022: Impacts, Adaptation and Vulnerability; Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; pp. 3–33. [Google Scholar]

- Adams, M.; Burrows, V.; Richardson, S.; Drinkwater, J.; Gamboa, C.; Collin, C.; Ostenfeld Riemann, L.; Porteron, S.; Qvist Secher, A. Bringing Embodied Carbon Upfront: Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon; World Green Building Council, Toronto, Ontario, 2019.

- Ratiarisoa, R.; Magniont, C.; Ginestet, S.; Oms, C.; Escadeillas, G. Assessment of Distilled Lavender Stalks as Bioaggregate for Building Materials: Hygrothermal Properties, Mechanical Performance and Chemical Interactions with Mineral Pozzolanic Binder. Constr. Build. Mater. 2016, 124, 801–815. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.; Suchart, S.; Jyotishkumar, P. Renewable and Sustainable Biobased Materials: An Assessment on Biofibers, Biofilms, Biopolymers and Biocomposites. J. Clean. Prod. 2020, 258. [Google Scholar] [CrossRef]

- Jones, D.; Ormondroyd, G.O.; Curling, S.F.; Popescu, C.-M.; Popescu, M.-C. 2 - Chemical Compositions of Natural Fibres. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing, 2017; pp. 23–58 ISBN 978-0-08-100411-1.

- Leszczyszyn, E.; Heräjärvi, H.; Verkasalo, E.; Garcia-Jaca, J.; Araya-Letelier, G.; Lanvin, J.-D.; Bidzińska, G.; Augustyniak-Wysocka, D.; Kies, U.; Calvillo, A.; et al. The Future of Wood Construction: Opportunities and Barriers Based on Surveys in Europe and Chile. Sustainability 2022, 14, 4358. [Google Scholar] [CrossRef]

- Carcassi, O.B.; Paoletti, I.; Malighetti, L.E. Reasoned Catalogue of Biogenic Products in Europe. An Anticipatory Vision between Technical Potentials and Availability. TECHNE - J. Technol. Archit. Environ. 2021; 63–70. [Google Scholar] [CrossRef]

- Pimponi, D.; Porcari, A.; Airi – Associazione Italiana per la Ricerca Industriale Circular Economy in The Building and Construction Sector in Italy: Towards Sustainable Production and Consumption; Mapping of Key Enabling Technologies Innovation Eco-Systems; 2020.

- Fernández Fortunato, E.; Jiménez-Sáez, F.; Hontoria, E. Can Industry Counteract the Ecological Crisis? An Approach for the Development of a New Circular Bioeconomic Model Based on Biocomposite Materials. Sustainability 2023, 15, 3382. [Google Scholar] [CrossRef]

- Kutnik, M.; Suttie, E.; Brischke, C. 10 - Durability, Efficacy and Performance of Bio-Based Construction Materials: Standardisation Background and Systems of Evaluation and Authorisation for the European Market. In Performance of Bio-based Building Materials; Jones, D., Brischke, C., Eds.; Woodhead Publishing, 2017; pp. 593–610 ISBN 978-0-08-100982-6.

- Winandy, J.E.; Morrell, J.J. Improving the Utility, Performance, and Durability of Wood- and Bio-Based Composites. Ann. For. Sci. 2017, 74, 1–11. [Google Scholar] [CrossRef]

- Pokharel, A.; Falua, K.J.; Babaei-Ghazvini, A.; Acharya, B. Biobased Polymer Composites: A Review. J. Compos. Sci. 2022, 6, 255. [Google Scholar] [CrossRef]

- Haraguchi, K. Biocomposites. In Encyclopedia of Polymeric Nanomaterials; Kobayashi, S., Müllen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–8. ISBN 978-3-642-36199-9. [Google Scholar]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Sunthonrvarabhas, J.; Sriroth, K.; Kim, H.-J. Polysaccharide Bio-Based Composites: Nanofiber Fabrication and Application. In Bio-Based Composites for High-Performance Materials; CRC Press, 2014 ISBN 978-0-429-15616-8.

- Zechmeister, C.; Gil Pérez, M.; Dambrosio, N.; Knippers, J.; Menges, A. Extension of Computational Co-Design Methods for Modular, Prefabricated Composite Building Components Using Bio-Based Material Systems. Sustainability 2023, 15, 12189. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Biomaterials for Building Skins. In Bio-based Building Skin; Sandak, A., Sandak, J., Brzezicki, M., Kutnar, A., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer: Singapore, 2019; pp. 27–64. ISBN 9789811337475. [Google Scholar]

- Fernando, D.; Navaratnam, S.; Rajeev, P.; Sanjayan, J. Study of Technological Advancement and Challenges of Façade System for Sustainable Building: Current Design Practice. Sustainability 2023, 15, 14319. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Designing Building Skins with Biomaterials. In Bio-based Building Skin; Sandak, A., Sandak, J., Brzezicki, M., Kutnar, A., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer: Singapore, 2019; pp. 65–97. ISBN 9789811337475. [Google Scholar]

- EN 13830:2015; Curtain Walling - Product Standard. European Committee For Standardization: Brussels, Belgium, 2015.

- ISO 10077-2:2017; Thermal Performance of Windows, Doors and Shutters — Calculation of Thermal Transmittance — Part 2: Numerical Method for Frames. ISO: Geneva, Switzerland, 2017.

- Juaristi, M.; Sebastiani, I.; Avesani, S. Timber-Based Façades with Different Connections and Claddings: Assessing Materials’ Reusability, Water Use and Global Warming Potential. J. Facade Des. Eng. 2022, 10, 71–86. [Google Scholar] [CrossRef]

- Li, Y.; Chen, L. Investigation of European Modular Façade System Utilizing Renewable Energy. Int. J. Low-Carbon Technol. 2022; 17, 279–299. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of Modularity to the Circular Economy: A Systematic Review of Literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Roxas, C.L.C.; Bautista, C.R.; Dela Cruz, O.G.; Dela Cruz, R.L.C.; De Pedro, J.P.Q.; Dungca, J.R.; Lejano, B.A.; Ongpeng, J.M.C. Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry: Challenges, Trends and Developments. Buildings 2023, 13, 1164. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A Quantitative and Qualitative Evaluation of the Sustainability of Industrialised Building Systems: A Bibliographic Review and Analysis of Case Studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar] [CrossRef]

- Savoja, G. Experimentation of Composites Materials Reinforced with Vegetable Fibres for the Construction Sector. TECHNE - J. Technol. Archit. Environ. 2018; 16, 317–324. [Google Scholar] [CrossRef]

- Arregi, B.; Garay-Martinez, R.; Astudillo, J.; García, M.; Ramos, J.C. Experimental and Numerical Thermal Performance Assessment of a Multi-Layer Building Envelope Component Made of Biocomposite Materials. Energy Build. 2020, 214, 109846. [Google Scholar] [CrossRef]

- Astudillo, J.; González, M.G.; Sacristán, J.; Uranga, N.; Leivo, M.; Mueller, M.; Roig, I.; Langer, S.; Gemignani, G.; Vilkki, M.; et al. New Biocomposites for Innovative Construction Facades and Interior Partitions. J. Facade Des. Eng. 2018, 6, 065–083. [Google Scholar] [CrossRef]

- Circular Economy Principles for the Design of Buildings - EEB Response to Survey - EEB - The European Environmental Bureau.

- European Parliament and Council. Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) (Recast) (Text with EEA Relevance); European Union: Brussels, Belgium, 2010. [Google Scholar]

- BASAJAUN - Building A SustainAble Joint between rurAl and UrbaN Areas Through Circular And Innovative Wood Construction Value Chains | BASAJAUN Project | Fact Sheet | H2020. Available online: https://cordis.europa.eu/project/id/862942/it (accessed on 11 January 2024).

- FOREST BASED COMPOSITES FOR FAÇADES AND INTERIOR PARTITIONS TO IMPROVE INDOOR AIR QUALITY IN NEW BUILDS AND RESTORATION | OSIRYS Project | Fact Sheet | FP7. Available online: https://cordis.europa.eu/project/id/609067 (accessed on 11 January 2024).

- Pracucci et al. - 2021 - Prefabricated Plug-and-Play Unitized Façade System.Pdf.

- Pracucci et al. - 2021 - An Analytical Approach for the Selection of Techno.Pdf.

- Objectives and Impacts. Basajaun-Horizoneu.

- BS EN 13830 2015.

- EN 14019:2016 - Curtain Walling - Impact Resistance - Performance Requirements. Available online: https://standards.iteh.ai/catalog/standards/cen/1bfe4fa0-6bf4-4ae7-b2a2-0a87ced89e0d/en-14019-2016 (accessed on 12 February 2024).

- 14:00-17:00 ISO 10211:2017. Available online: https://www.iso.org/standard/65710.html (accessed on 12 February 2024).

- ISO 717-1:2020(En), Acoustics — Rating of Sound Insulation in Buildings and of Building Elements — Part 1: Airborne Sound Insulation. Available online: https://www.iso.org/obp/ui/#iso:std:iso:717:-1:ed-4:v1:en (accessed on 12 February 2024).

- CWCT Embodied Carbon Committee Sustainability Guide 01: An Introduction to Sustainability in Façades; Centre for Window and Cladding Technology: The Studio, Entry Hill, Bath, BA2 5LY, 2021; pp. 1–62.

- Morganti, L.; Vandi, L.; Astudillo Larraz, J.; García-Jaca, J.; Navarro Muedra, A.; Pracucci, A. A1–A5 Embodied Carbon Assessment to Evaluate Bio-Based Components in Façade System Modules. Sustainability 2024, 16, 1190. [Google Scholar] [CrossRef]

- Pavatex Sa PAVAFLEX Flexible Woodfibre Insulation Material (EPD) 2014.

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Chen, X. Time-Variant Simulation of Multi-Material Thermal Pultrusion. Appl. Compos. Mater. 2011, 18, 283–296. [Google Scholar] [CrossRef]

- Jeswani, A.; Roux, J. Modeling of Processing for Slot and Discrete Port Tapered Resin Injection Pultrusion. J. Thermophys. Heat Transf. - J THERMOPHYS HEAT Transf. 2008; 22, 749–757. [Google Scholar] [CrossRef]

- EPD International Library. International EPD System, Stockholm, Sweden. Available online: https://environdec.com/home (accessed on 13 February 2024).

| Liquid resin properties | Units | Specifications |

| Viscosity (cone & plate @ 25ºC) | dPa.s | 3.9 -4.7 |

| Specific Gravity (25ºC) | 1.08 | |

| Volatile Content | % | 35-40 |

| Acid Value | mg KOH/g | 16-20 |

| Stability¥1 when stored in accordance with recommended limits | months | 9 |

| Geltime at 25 °C (1% Catalyst M & 1% Accelerator G) | minutes | 9 to 12 |

| Cast resin properties | Units | Specification |

| Barcol Hardness (Model GYZJ 934-1) | 36 | |

| Deflection Temperature under load †2 (1.80 MPa) | ºC | 72 |

| Tensile Modulus | GPa | 2.7 |

| Tensile stress | MPa | 88 |

| Tensile Elongation at break | % | 4.8 |

| Flexural Modulus | GPa | 2.6 |

| Flexural stress | MPa | 54 |

| Basalt Fibers Properties | Units | Specification |

| Single filament diameters:( ± 1) acc. ISO 137 – 1975 | [μm] | 13 to 17 |

| Density: | [g/m³] | 2,6 to 2,8 |

| Linear density acc. ISO 1889:1987 | [tex] | 4800 ± 5% |

| Specific tensile strength: acc. DIN ISO EN 10618 | [cN/tex] | 104,6 ± 5% |

| E-Modul acc. DIN ISO EN 10618 | [GPa] | 84,2 ± 5 % |

| Linear expansion coeff. | [x¹⁰⁻⁷/K] | 6 |

| Moisture content: | less than 0,1 % | |

| Size content | [% ] | 1,0 ± 0,1 |

| Weight of the coil | [kg] | 5 to 10 |

| Stability at tension (20C°) | [%] | 100 |

| Stability at tension (200C°) | [%] | 95 |

| Stability at tension (400C°) | [%] | 82 |

| Thermal limit application | [ºC] | 440 |

| Vitrification temperature | [ºC] | 1050 |

| Description | Rovings | Mat or Fabric | Fiber | ||||||

| Tex (gr/km) | No. Threads or layers | Gramagge (g/m2) | Effective Width (m) | Weight (g/m) | Density (g/cm3) | Volume (cm3/m) | Fraction V. Local | Occupied Section (cm2) | |

| Roving (basalt fiber) | 4800 | 20 | 96 | 2.65 | 36.23 | 0.55 | 0.66 | ||

| Total | 96 | 36.23 | 0.66 | ||||||

| Percentage of mold filling: occupied section/mold section x 100 | Total | 87.82 | |||||||

| Description | Rovings | Mat or Fabric | Fiber | ||||||

| Tex (gr/km) | No. Threads or layers | Gramagge (g/m2) | Effective Width (m) | Weight (g/m) | Density (g/cm3) | Volume (cm3/m) | Fraction V. Local | Occupied Section (cm2) | |

| Fabric (Glass Fiber) |

2 | 500 | 0.1 | 100 | 2.55 | 39.22 | 0.28 | 500 | |

| Roving (Basalt Fiber) |

4800 | 80 | 384 | 2.55 | 150.59 | 0.55 | 2.74 | ||

| Total | 384 | 150.59 | 4.14 | ||||||

| Percentage of mold filling: occupied section/mold section x 100 | Total | 51.73 | |||||||

| Flammability rating UL 94 | |||

| V-0 | V-1 | V-2 | |

| Burning time after flame application (s) | ≤ 10 | ≤ 30 | ≤ 30 |

| Total burning time (s) (10 flame applications) | ≤ 50 | ≤ 250 | ≤ 250 |

| Burning and afterglow times of specimen after second flame application (s) | ≤ 30 | ≤ 60 | ≤ 60 |

| Dripping of burning specimens (ignition of cotton batting) | No | No | Yes |

| Specimens completely burned | No | No | No |

| Description | Classification UL94 |

| Bio-based resin Only resin | Not classifiable |

| Bio-based resin+FR 1 20% | V2 |

| Bio-based resin+FR 1 30% | V0 |

| Bio-based resin+FR 1 40% | V0 |

| Bio-based resin+FR 2 30% | Not classifiable |

| Bio-based resin+FR 2 40% | Not classifiable |

| Bio-based resin+FR 2 50% | Not classifiable |

| Bio-based resin+FR 1 20%+ FR 2 40% | V2 |

| Sample | E | SD | R | SD | %R | SD | Poisson Ratio | SD | Apparent ILSS | SD | Break mode |

| MPa | MPa | % | µ | MPa | |||||||

| Resin with glass fibre cured (2h 70ºC) | 38400 | 1920 | 584 | 2.7 | 1.44 | 0.14 | 0.25 | 0.04 | |||

| Resin with basalt fibres with cured cycle (2 h 70ºC) | 39200 | 1500 | 431 | 73 | 1.11 | 0.16 | 0.07 | 0.06 | 10.7 | 0.8 | simple shear |

| Resin with basalt fibres without cured cycle (20 rovings) | 38600 | 852 | 378 | 9 | 1.01 | 0.03 | 0.16 | 0.25 | 10.5 | 0.6 | simple shear |

| Resin with basalt fibres and wood particles without cured cycle (13 rovings) | 26700 | 837 | 426 | 1.6 | 1.6 | 0.08 | 0.24 | 0.14 | |||

| OMIKRON sample (Longitudinal direction) |

30500 [ANM3] |

244 | 453 | 26,1 | 1,5 | 0,1 | -0.04 | 0,05 | |||

| Bio-based resin (Only Resin) |

1870 | 410 | 45.5 | 8.6 | 2.6 | 0.7 | 0.22 | 0.21 | |||

| Bio-based resin (Only Resin) + FR 1 20% |

2160 | 270 | 25.9 | 2.7 | 1.5 | 0.2 | 0.26 | 0.32 | |||

| Bio-based resin (Only resin) + FR 1 30% |

2060 | 319 | 22.1 | 1.3 | 1.6 | 0.4 | 0.35 | 0.14 | |||

| Bio-based resin (Only resin) + FR 1 40% |

2380 | 730 | 18.1 | 1.1 | 0.96 | 0.2 | 0.23 | 0.33 | |||

| Bio-based resin (Only resin) + FR 2 30% |

2750 | 1130 | 13.7 | 3.4 | 0.4 | 0.06 | -0.12 | 0.28 | |||

| Bio-based resin (Only resin) + FR 2 40% |

3000 | 1020 | 17.1 | 2.7 | 0.51 | 0.03 | 0.22 | 0.06 | |||

| Bio-based resin (Only resin) + FR 2 50% |

4160 | 1100 | 20 | 1.6 | 0.43 | 0.01 | 0.74 | 0.17 | |||

| Bio-based resin + FR 1 20% + FR 2 40% | 3550 | 128 | 19.3 | 1.5 | 0.55 | 0.07 | 0.72 | 0.25 | |||

| Test | Flexural Modulus | SD | Flexural strength | SD | Deflection at flexural strength | SD |

| MPa | MPa | % | ||||

| Flexural properties according EN ISO 14125 | 32100 | 792 | 572 | 26 | 6,9 | 0,4 |

| Flexural properties Longitudinal Direction (non-standardized tests) | 18800 | 1580 | 409 | 35 | 2,0 | 0,4 |

| Flexural properties Cross Direction (non-standardized tests) | 8790 | 985 | 125 | 4 | 1,6 | 0,2 |

| Maximum wind load = 2.00 kN/m2 | |

| Loads: | |

| WL = 2 KN/m2 x 0,79 m x 7,65 m = | 12.1 kN |

| WLult= 1.5 x 12.1 = | 18.13 kN |

| E = 1 kN/m x 0.79 m = | 0.79 kN |

| Eult= 1.05 x 0.79 kN = | 0.83 kN |

| E2 = 1 kN/m x 0.79 m x 0.7 = | 0.553 kN |

| Maximum wind load = 2.00 kN/m2 | |

| Loads: | |

| WL=2 KN/m2 x 0,79 m x 1,58 m = | 2.5 KN |

| WLult= 1,5 x 2,5 = | 3.75 KN |

| DL= 25KN/m3 x 0,027 m x 7,65 m x 1,58 m / 2 Blocks = | 4.1 KN |

| DLult= 1,35 x 4,1 = | 5.51 KN |

| Wood fiber insulation used in Basajuan |

Average Rock Wool products from supplier A | Average Rock Wool products from supplier B | |

|---|---|---|---|

| Gross density (EN 1602) | 55.00 kg/m3 | 72.33 kg/m3 | 80.00 kg/m3 |

| Thermal conductivity (EN 13171) | 0.038 W/(mK) | 0.034 W/(mK) | 0.035 W/(mK) |

| Fire classification (EN 13501-1) | Class E | Euroclass A1 | Euroclass A1 |

| Water vapour resistance | 5 (EN 12667) | Not specified | 1 (EN 12086) |

| Reflective fire reaction vapor barrier screen used in Basajuan |

Example of an average sheet as conventional per façade module type A | Example of an average sheet as conventional per façade module type B | |

|---|---|---|---|

| Material | Aluminium - PE-Glass fiber | PET | PUR.PP |

| Fire classification (EN 13501-1) | Class A2-s1,d0 | B-s1,d0 | Class E |

| UV resistance | ✔ | ✔ | ✔ |

| Water impermeability | Class W1 | Class W1 | Class W1 |

| Water vapor transmission (Sd) [m] | 0.08 | 0.02 | 0.14 |

| Tensile strength [N/5 cm] | 3000/3200 | 250/210 | 210/205 |

| Thermal conductivity [W/(m*k)] | 0.0007 | 0.17 | 0.22 |

| Vapor resistance factor [μ] | 185 | 40 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).