1. Introduction

The proportional-integral-derivative (PID) controllers are the most significant control components used in numerous industrial processes [

1]. It is estimated that PID controllers are utilized in over 90% of all dynamical control systems [

2]. With its three-term functionality involving proportional, integral, and derivative actions, the PID controller handles the treatment of transient and steady-state responses and adjusts the level of system stability, which are effective solutions for a wide range of real-world control problems [

3]. It also offers simplicity, robustness, wide applicability, and simple parameter tuning. Consequently, the prevalence of PID control has increased considerably.

Literature review reveals that the PID controller implementation includes a wide variety of designs based on the use of different active elements [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17]. In [

4], voltage-feedback operational amplifiers (OAs) are extensively used to implement conventional voltage-mode (VM) PID controllers. The realized controller, however, requires a significant number of active and passive components. Its response time is also limited by the constant gain bandwidth product and low slew rate of the OA. To overcome these limitations, some current-mode (CM) active components, such as operational transconductance amplifier (OTA), current differencing buffered amplifier (CDBA), operational transresistance amplifier (OTRA), second-generation current conveyor (CCII), voltage differencing current conveyor (VDCC), and current-feedback operational amplifier (CFOA), are suggested for PID controller implementations. The OTA-based PID controller in [

5] uses two grounded capacitors and eight OTAs. It supplies the output voltage signal at the high-impedance terminal, which is incompatible with cascading in VM. The PID controller designed with CDBAs requires four active and ten passive components, and lacks high input impedance [

6]. In [

7], the VM PID controller circuit is constructed with two OTRAs, four floating resistors, and three floating capacitors, but it does not have both high input and low output impedances. Based on CCIIs, the PID controller circuits are proposed in [

8,

9,

10]. The works of [

8,

9] present two distinct configurations for VM and CM operations, while [

10] only discusses CM operation. However, none of the CCII-based VM PID designs have low output impedance, and neither of the CM PID designs have low input impedance. As described in [

11], a single VDCC-based VM PID controller circuit with a single input and two output terminals is realized with four resistors and two capacitors. It can simultaneously implement non-inverting and inverting control signals. However, the configuration does not fully utilize the differential input property of the VDCC because one of the differential inputs is not employed. This could be the result of input noise injection. Also, a recent VM PID controller using a single active component was reported in [

12], but its limitations are the same to those in [

11]. Three DDCCs and five passive elements are used in the construction of VM PID controllers [

13]. At the inputs of all DDCCs, the high input impedance and capability of arithmetic operations are not fully utilized. Some earlier works do not exhibit high-input and low-output impedances for VM [

14,

15], or low-input and high-output impedances for CM [

16]. In addition, all of the proposed PID controllers in [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16] are capable of operating in either VM or CM. In real-world process control applications, mixed-signal processing PID controllers are required to interact between CM and VM circuits. To satisfy this requirement, the trans-admittance-mode (TAM) and trans-impedance-mode (TIM) PID controller circuits are also used to interface between CM and VM units without any distortion. Only one of those controllers suggests a transconductor-capacitor-based mixed-mode PID design [

17]. The active blocks used in the design are not commercially available. Note that implementing the controller with commercially available elements is advantageous from both a practical and a simplicity aspect.

This work describes a mixed-mode PID controller circuit that utilizes three CFOAs as active components in addition to four resistors and two capacitors as passive components. In a single topology, the proposed controller can implement mixed-mode PID control responses, i.e., VM, CM, TAM, and TIM.

Table 1 provides a detailed comparison between the proposed circuit and earlier PID controllers [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17].

2. Proposed Mixed-Mode PID Controller Configuration

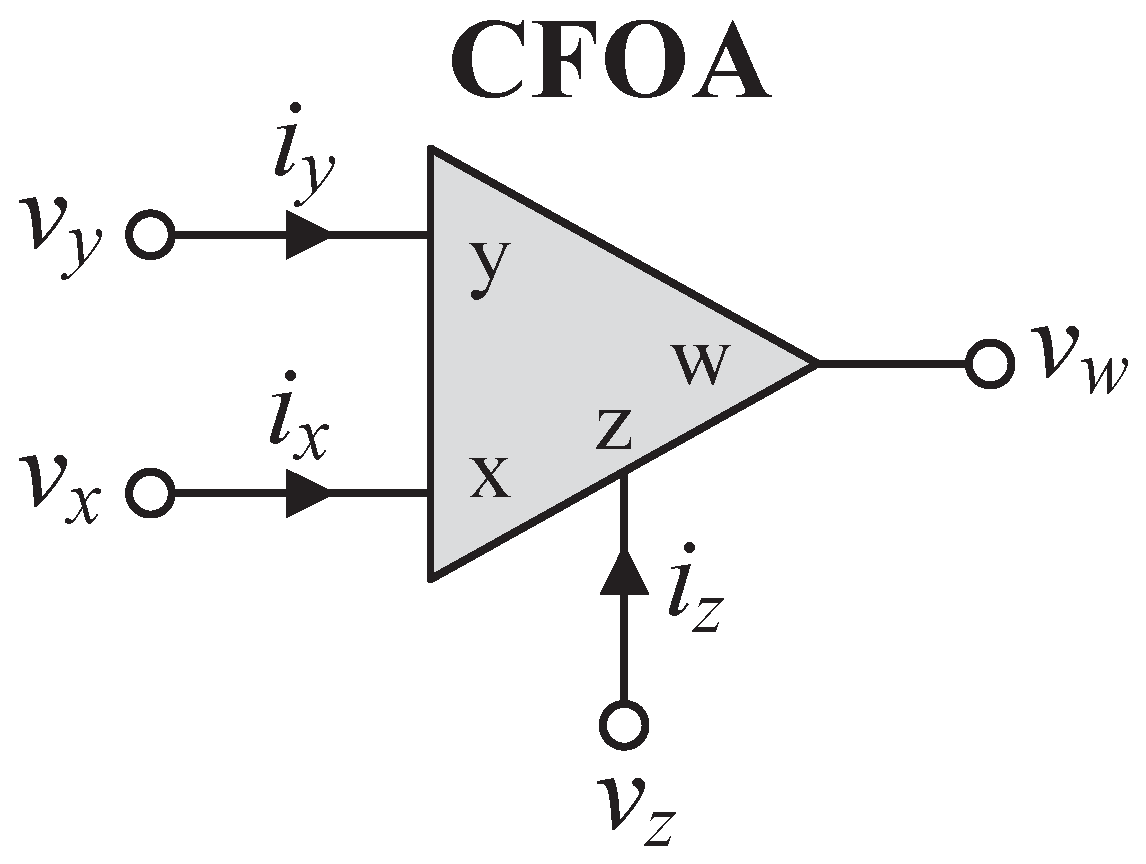

The CFOA is a four-terminal active device represented symbolically in

Figure 1. Its ideal characteristic is defined by

iy = 0,

vx =

vy,

iz =

ix, and

vw =

vz. In addition, the characteristics of the CFOA with non-ideal transfer gains can be defined by the following terminal relations:

where

β = (1 -

εβ),

α = (1 -

εα), and

γ = (1 -

εγ). Further,

εβ (|

εβ| << 1) is the input-voltage tracking error,

εα (|

εα| << 1) is the input-current tracking error, and

εγ (|

εγ| << 1) is the output-voltage tracking error. All of the parameters

β,

α, and

γ should ideally equal one.

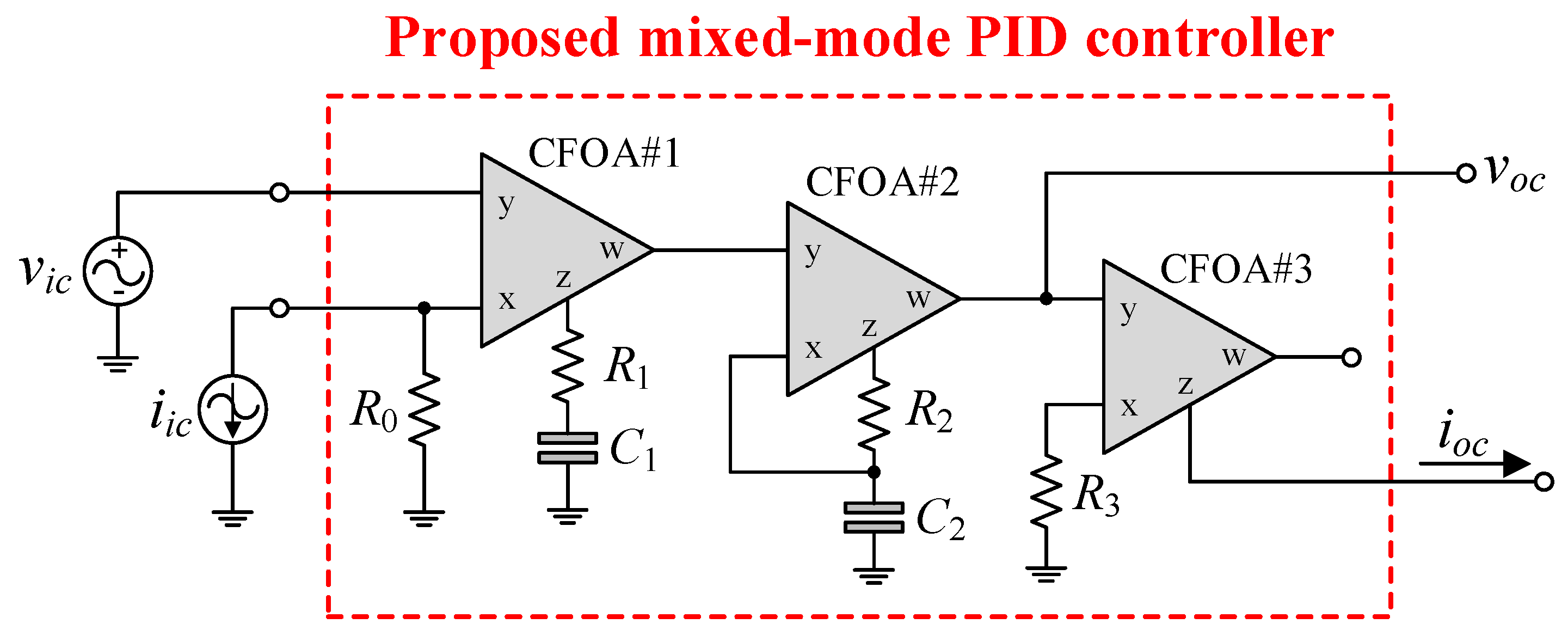

Figure 2 depicts the configuration of the proposed mixed-mode PID controller, which consists of two input terminals (

vic and

iic), and two output terminals (

voc and

ioc). For the VM signal, the circuit provides high input and low output impedance, while for the CM signal, it provides low input and high output impedance. By appropriately employing the relevant input signals via

vic and

iic, the proposed PID controller can realize all four possible modes of operation, VM, TIM, CM, and TAM, in a single topology. Consequently, it is a mixed-mode PID controller.

The general transfer function of the PID controller can be expressed as:

where the parameters

KP,

KI and

KD are the proportional gain, integral gain, and derivative gain of the controller, respectively.

2.1. VM and TAM Operations

From

Figure 2, if

iic = 0, one can derive the following generalized transfer function for VM:

Comparing Equation (3) to Equation (2), the important gain coefficients of the proposed VM PID controller are obtained as follows:

and

In Equation (4), the parameters

KPV,

KIV and

KDV are the gains

KP,

KI, and

KD for VM, respectively.

Similarly, the transfer function of the proposed TAM PID controller is also obtained as:

where

and

Since the primary objective of this communication is to design an analog PID controller with all four modes of operation in a single configuration, orthogonal adjustment of the control gain parameters KPV(Y), KIV(Y), and KDV(Y) derived from Equations (4) and (6) is not anticipated. However, independent tuning of KIV(Y) and KDV(Y) is possible via R0 and C2, respectively, by adjusting R0, R1, C1, and C2 simultaneously in order that R1/R0 and C2/C1 remain constant.

2.2. CM and TIM Operations

Furthermore, by applying

iin while connecting

vic to ground (

vic = 0), the proposed circuit in

Figure 2 can be used for CM PID control. As a consequence, the realized transfer function of the CM PID controller is

For

R0 =

R3, the gain parameters

KPI,

KII, and

KDI of the CM PID controller in Equation (7) are the exact same as

KPV,

KIV, and

KDV in Equation (4).

It is also observed that the transfer function of the proposed TIM PID controller is found as:

where

and

According to Equations (4), (6), and (9), it can be observed that the relative element sensitivities of the control coefficients are low, in that their values are all less than unity, as given below:

and

3. Non-Ideality Effects of CFOA Parasitic Gains

In practice, the CFOA may take into account the non-ideal transfer gains

β,

α, and

γ. According to Equation (1), when

β ≠

α ≠

γ ≠ 1, the following are the practical gain parameters of the proposed PID controller in

Figure 2.

For VM operation, the control parameters

KPV,

KIV, and

KDV are nonideally obtained as:

and

where the multiplication coefficients

βi,

αi, and

γi (

i = 1, 2, 3) denote the non-ideal gains

β,

α, and

γ of the

i-th CFOA, respectively.

For TAM operation, the non-ideal control parameters

KPY,

KIY, and

KDY can be expressed as:

and

For CM and TIM operations, the non-ideal control parameters can be determined, respectively, as follows:

and

According to Equations (15)-(18), the gain parameters of the proposed PID controller differ slightly owing to the non-ideal transfer gains βi, αi, and γi. Inspecting these equations implies that all sensitivities of the PID control coefficients with respect to non-ideal transfer gains of the CFOA are not greater than unity in absolute value.

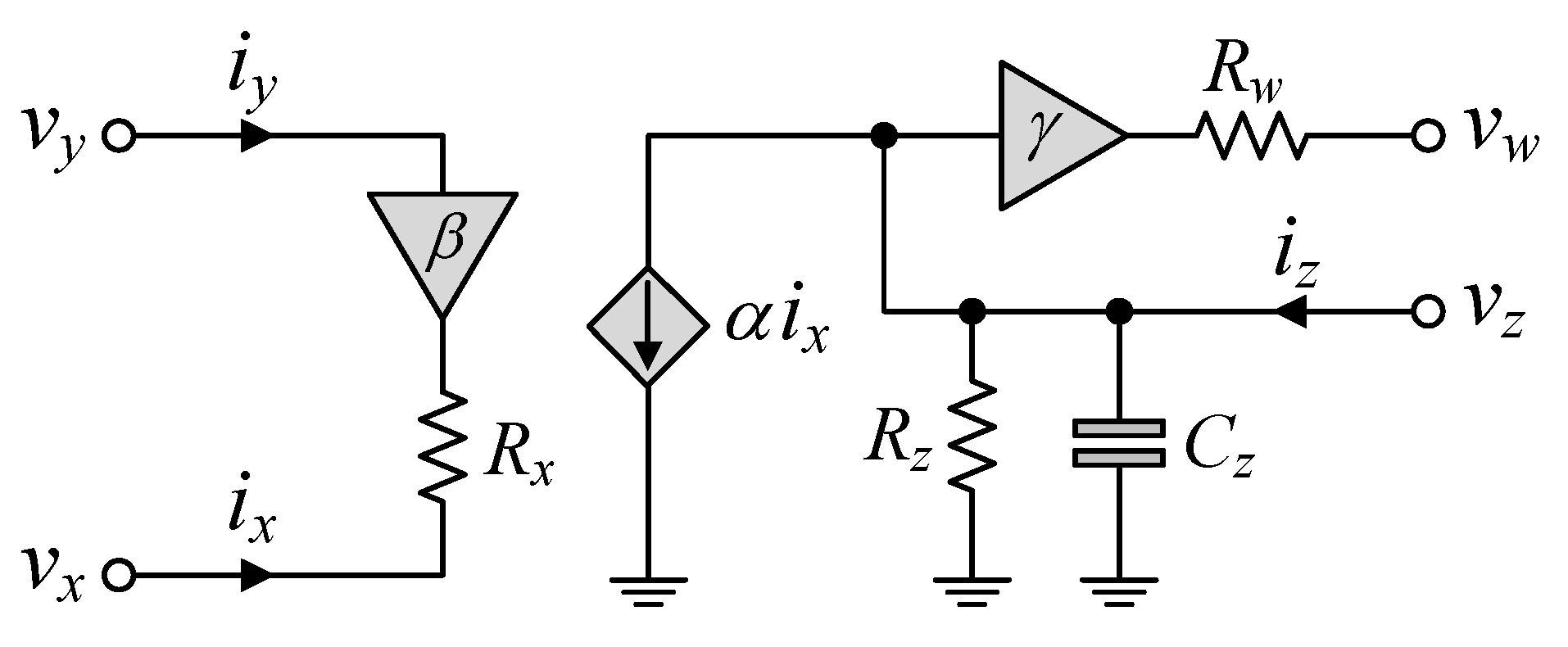

4. Non-Ideality Effects of CFOA Parasitic Impedances

Figure 3 shows the non-ideal behavior model of the practical CFOA, including the typical parasitic impedances. In accordance with this model,

Rx and

Rw are the low-level parasitic resistances,

Rz is the high-level parasitic resistance, and

Cz is the parasitic capacitance, associated with the corresponding terminals. For example, the parasitic element values for the commercially available integrated circuit (IC) AD844 CFOA are as follows:

Rx = 50 Ω,

Rw = 15 Ω,

Rz = 3 MΩ, and

Cz = 4.5 pF [

18].

Considering the dominant parasitic effects of the CFOA on the performance of the proposed mixed-mode PID controller in

Figure 2, the following additional assumptions can be defined under the conditions that

β ≅

α ≅

γ ≅ 1:

and

It is important to note that, in practice, the impact of the parasitic resistances

Rx1 and

Rx3 is negligible due to the fact that

R0 >>

Rx1 and

R3 >>

Rx3. The expression in Equation (19) can be rewritten as:

When the parasitic capacitance

Cz1 is minimal, the operating frequency is limited to the following range:

Additionally, from Equation (21), if

Rz1 is negligible, the range of applicable frequency is as follows:

For instance, if the commercially available IC AD844 CFOA is employed with

R1 = 5 kΩ, and

C1 = 1 nF, the useful operating frequencies found from Equations (22) and (23) are around

f1 ≅ 53 Hz, and

f2 ≅ 7.07 MHz.

Assuming that

R2 >>

Rx2, Equation (20) can be rearranged as:

In the same manner, the practical frequency range in this case is limited to

By utilizing R2 = 5 kΩ, Rz2 = 3 MΩ, and Cz2 = 4.5 pF, it is possible to determine the frequency location of f3 ≅ 7.07 MHz.

By combining Equations (22), (23), and (25), the proposed mixed-mode PID controller shown in

Figure 2 can be effectively utilized over the following frequency range:

5. Functional Simulation and Discussion

In order to validate the theoretical analysis presented in the previous section, the proposed mixed-mode PID controller circuit depicted

Figure 2 was investigated using PSPICE program with model parameters of the commercial CFOA IC-type AD844 available from Analog Devices company [

18]. All the AD844 ICs were biased with symmetrical power supplies of ±9 V. The passive components for the controller were set as:

R0 = 1 kΩ,

R1 =

R2 =

R3 = 5 kΩ, and

C1 =

C2 = 1 nF. For the specified component values, the controller parameters were calculated as follows:

KPV = 7.5, KIV = 1 Ms-1, and KDV = 12.5 μs for VM;

KPY = 1.5 m, KIY = 200 s-1, and KDY = 2.5 ns for TAM;

KPI = 1.5, KII = 0.2 Ms-1, and KDI = 2.5 μs for CM;

KPZ = 7.5 k, KIZ = 1 Gs-1, and KDZ = 12.5 ms for TIM.

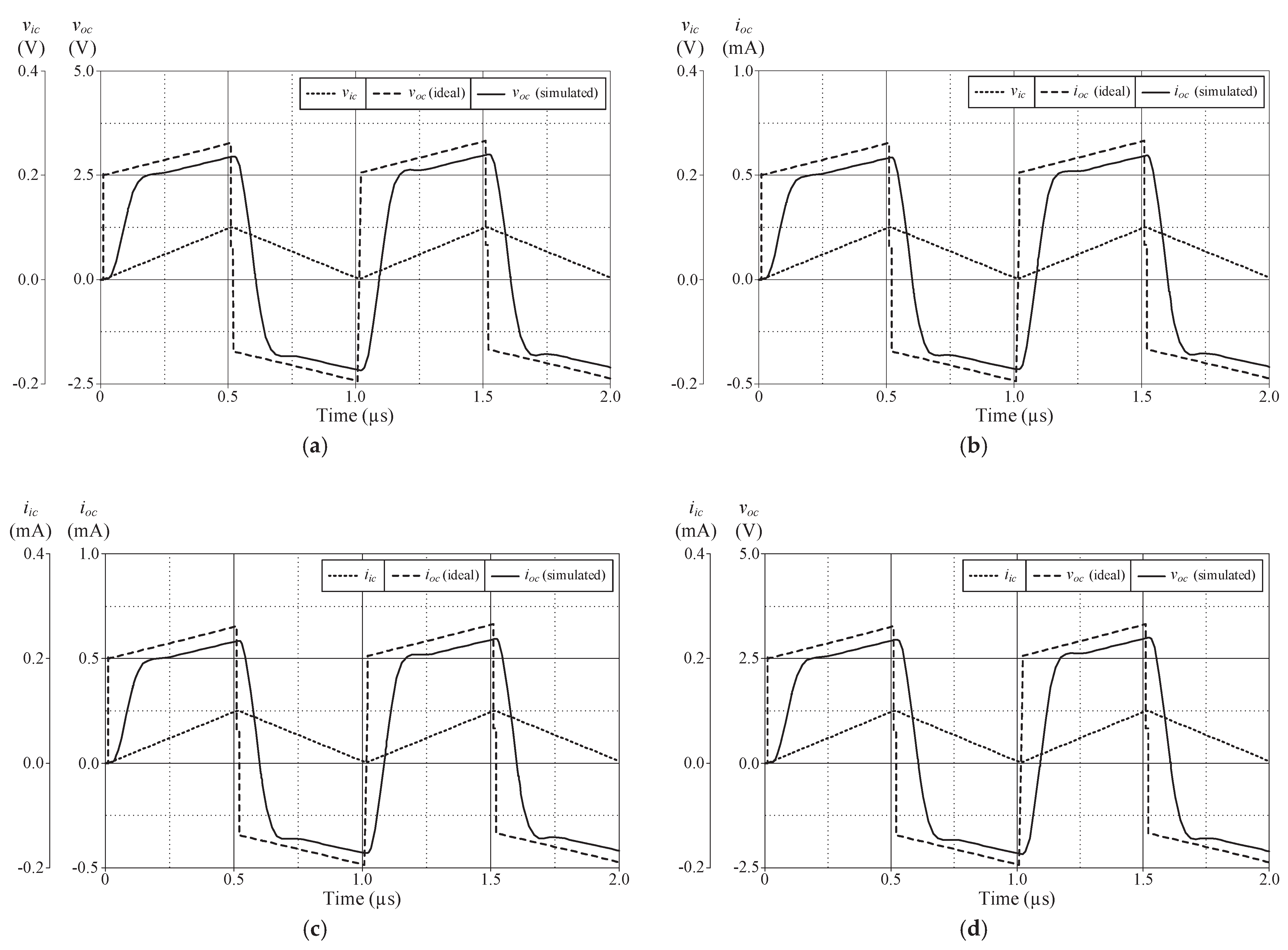

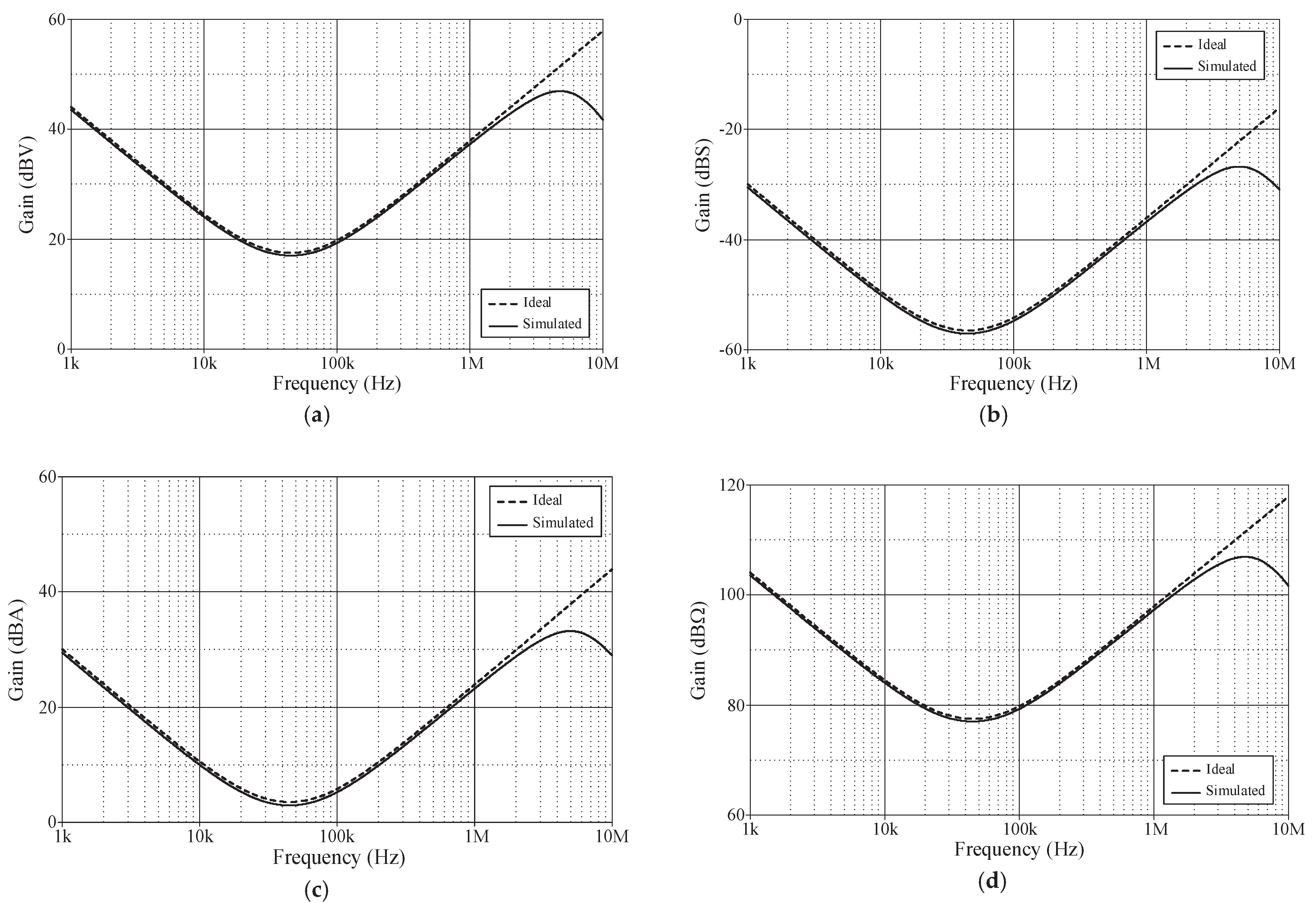

Figure 4 illustrates the time-domain simulation responses of the VM, TAM, CM and TIM PID controllers in comparison to the ideal responses. As shown in

Figure 4, the controller was applied with a 100-mV triangular input signal with a frequency of 1 MHz.

Figure 5 additionally illustrates the ideal and simulated frequency-domain characteristics of the proposed mixed-mode PID controller with the exact same components. It is evident from these responses that the gain-frequency limitation of the controller occurs predominantly at more than 5 MHz. This phenomenon can be attributed to the dominant pole frequencies of parasitic impedances, as expected in the previous section. The total power consumption of the controller is approximately 0.348 W.

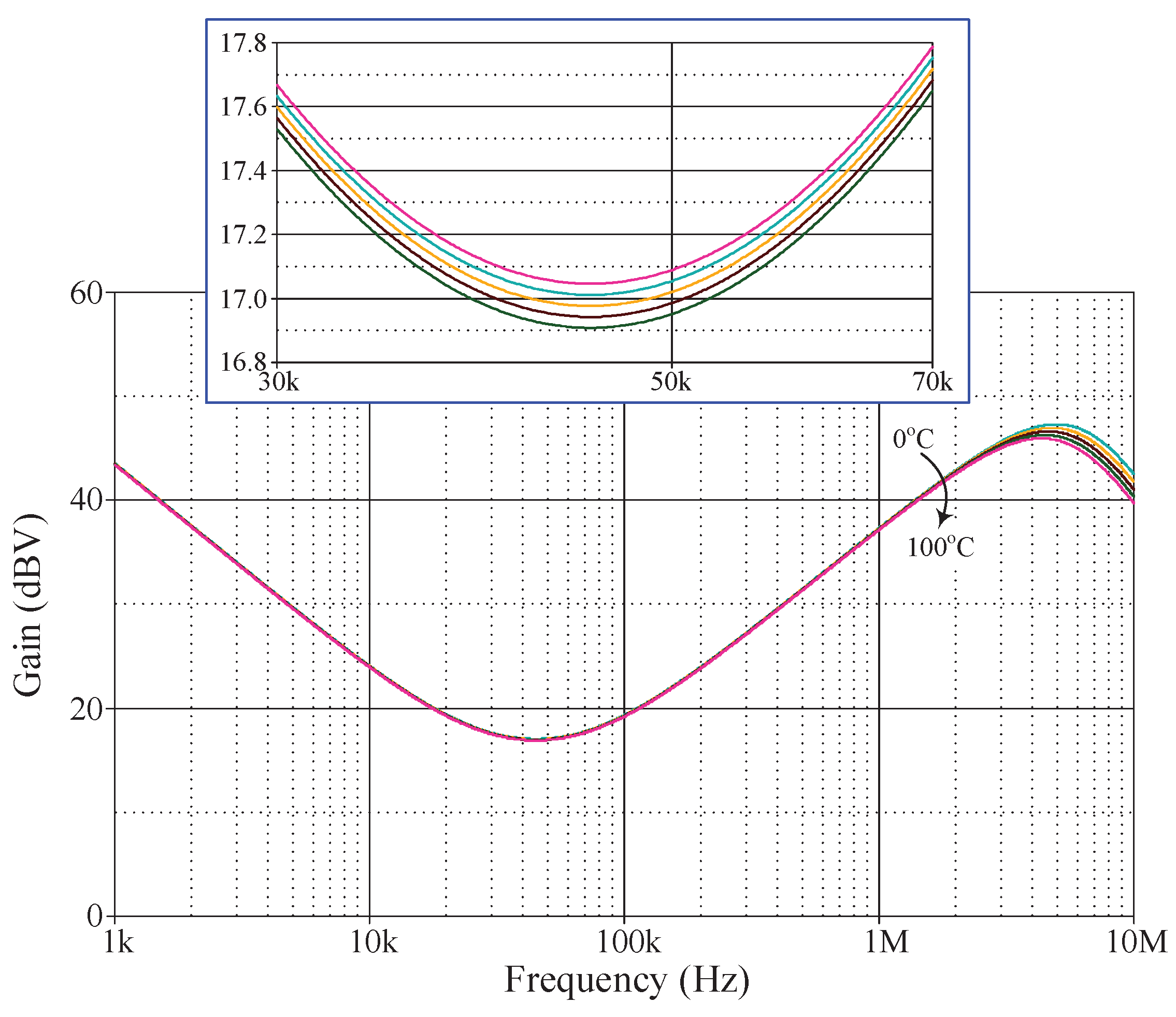

A further analysis was conducted on the gain response variation in the proposed VM PID controller with respect to ambient temperature. The temperature analysis was performed at the following temperatures:

T = 0°C, 25°C, 50°C, 75°C, and 100°C. The simulation results of the analysis of ambient temperature are illustrated in

Figure 6, while

Table 2 provides the controller gain values for various temperatures. Based on the data given in

Table 2, the controller gain change with respect to temperature variation (ΔdBV/Δ

T) is determined to be 0.137%, 0.138%, and 0.179% at

f = 10 kHz, 100 kHz, and 1 MHz, respectively.

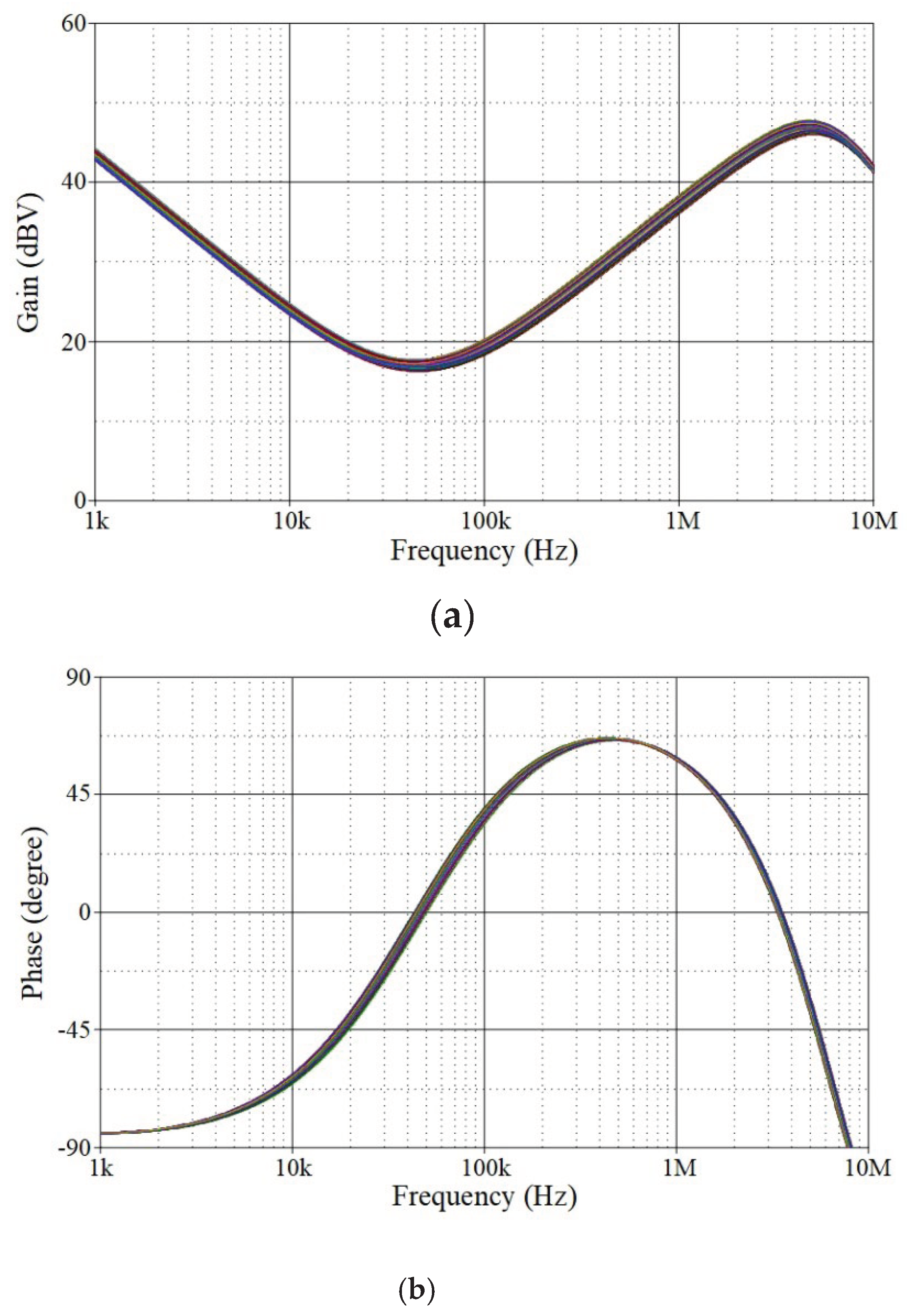

Additionally, Monte Carlo statistical analysis has been performed to demonstrate the robustness of the proposed controller. The analysis was conducted using 200 simulation runs in which the resistor and capacitor values were subject to a 5% Gaussian deviation. The Monte Carlo analysis results are shown in

Figure 7. The results indicate that a change in the passive component has no significant effect on the phase or gain responses of the controller.

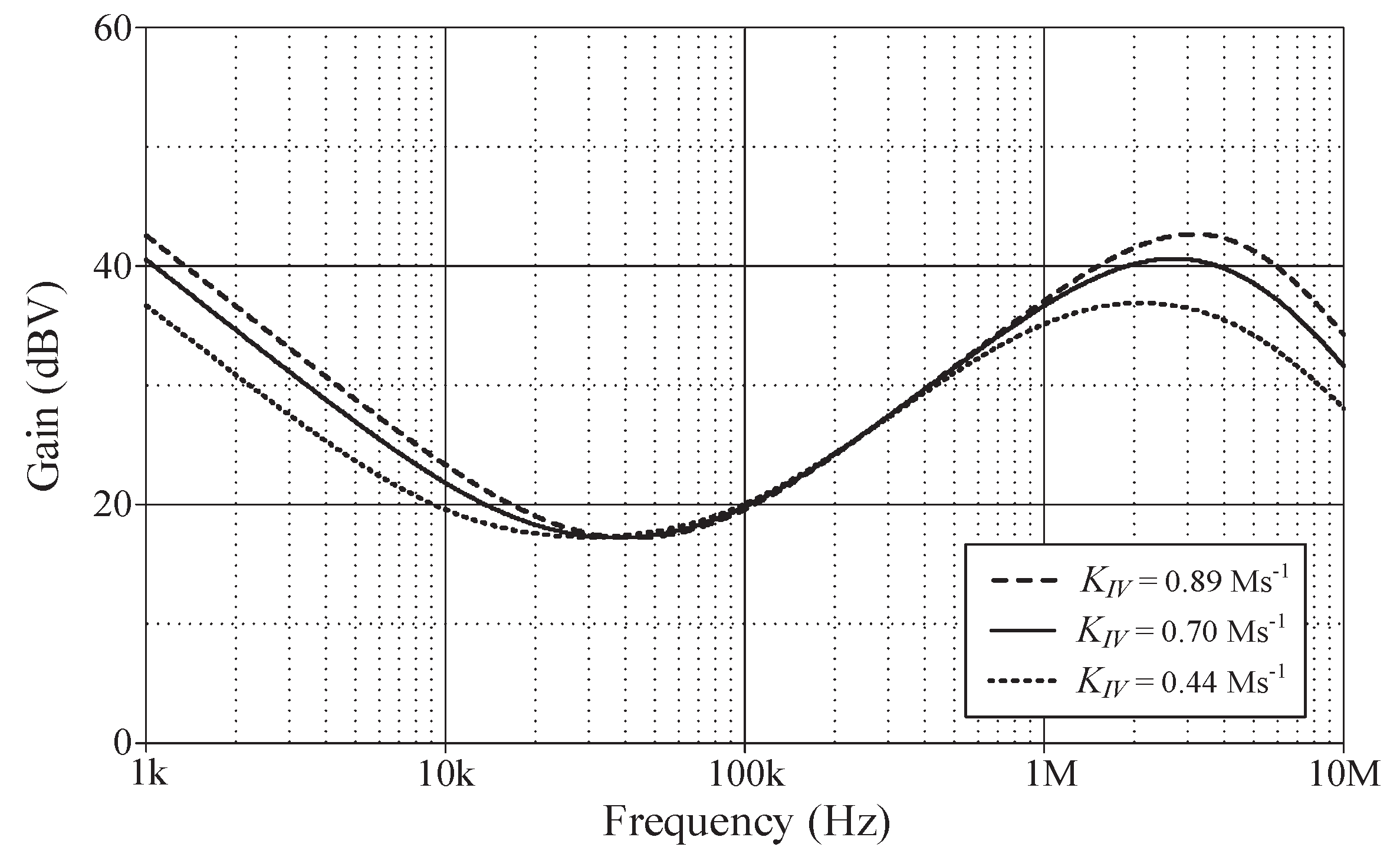

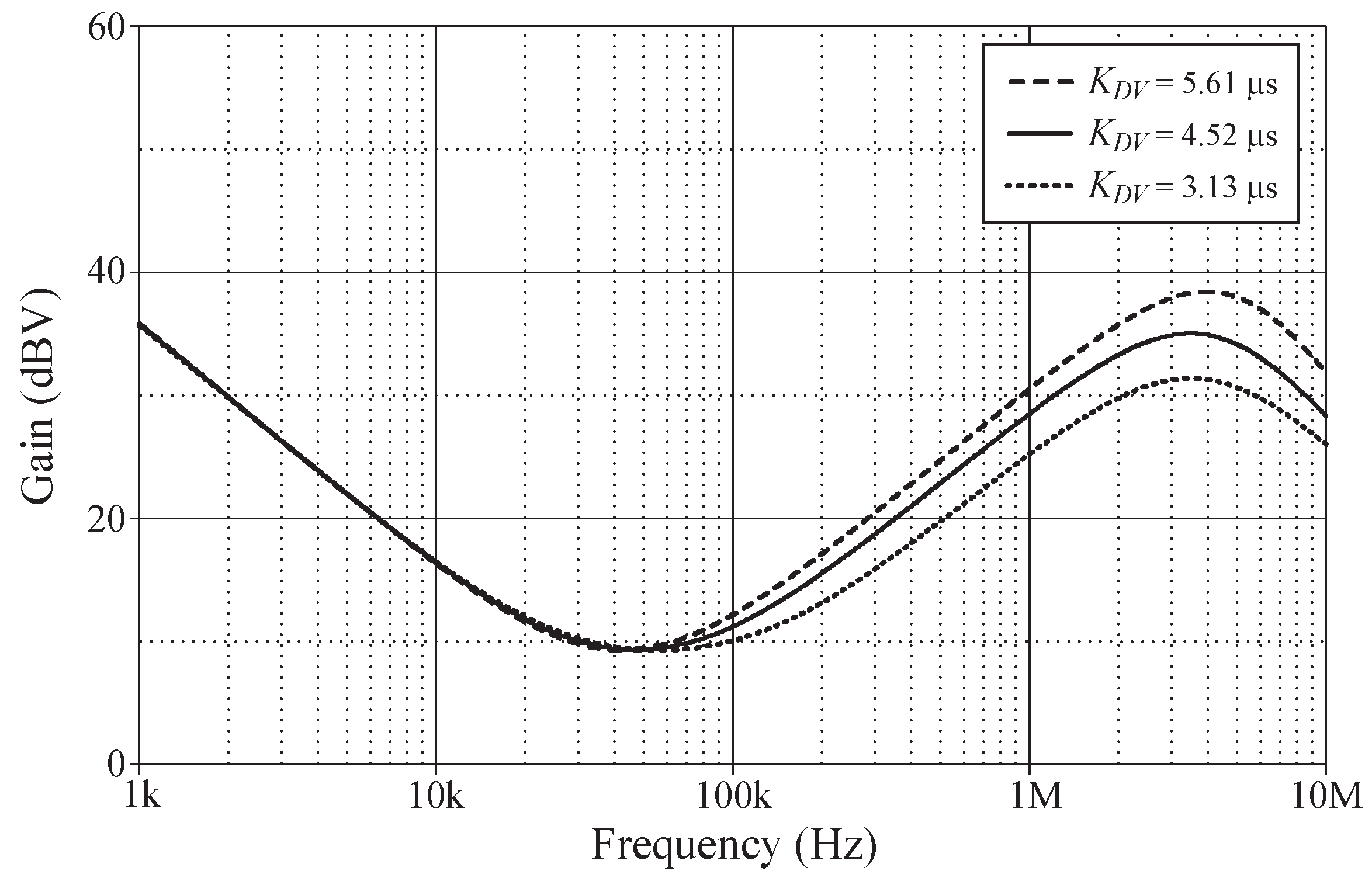

In order to evaluate of the tuning performance, the simulations have been carried out by varying the coefficients

KPV,

KIV and

KDV of the VM controller. For our first tuning example, the values of various controller components for the variation in controller coefficient

KPV, while holding

KIV and

KDV constant, are given in

Table 3. As evident in

Figure 8, the parameter

KPV influences the entire operational range as it appears from the gain response of the controller. The variations in the

KIV and

KDV values resulting from the use of different component values are also provided in

Table 4 and

Table 5. For the specified set parameters, the gain responses of the VM PID controller with tuning

KIV and

KDV are illustrated in

Figure 9 and

Figure 10, respectively.

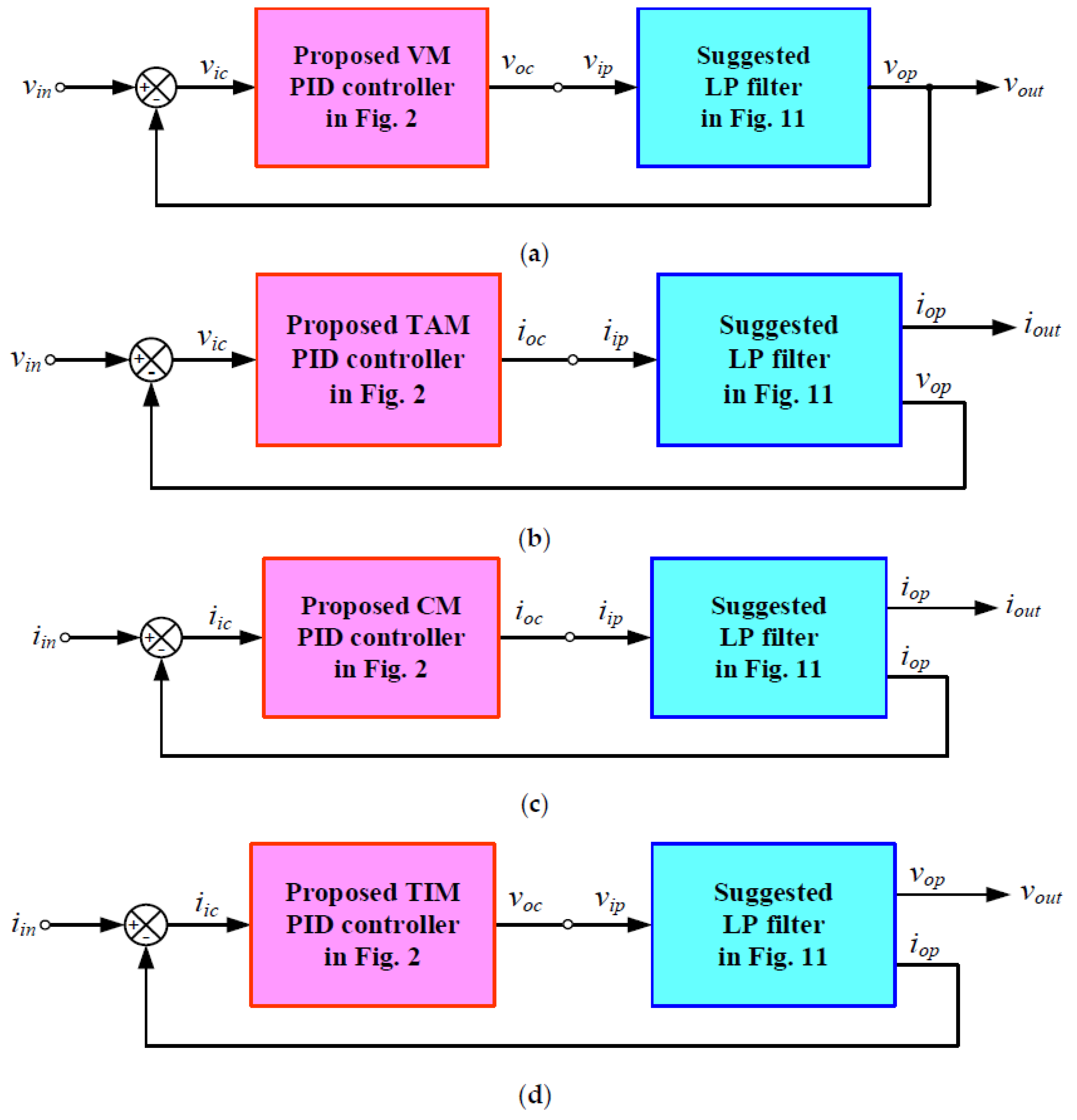

6. Performance Verification with Closed-Loop Control Implementation

In order to assess the effectiveness of the proposed mixed-mode PID controller in

Figure 2, the mixed-mode second-order lowpass (LP) filter depicted in

Figure 11 is suggested as a plant for implementing a closed-loop control system. The suggested LP filter can be realized for all four-mode LP filters with the following transfer functions:

where

From Equations (27)-(31), the natural angular frequency (

ωn) and the quality factor (

Q) for the filter are respectively obtained as:

and

The implemented closed-loop systems, as depicted in

Figure 12, utilize the mixed-mode PID controller proposed in

Figure 2 and the filter plant suggested in

Figure 11. The configurations depicted in

Figure 12a–d were constructed for the performance assessment of VM, TAM, CM, and TIM controllers, correspondingly. The component values for the filters are as follows:

Rp0 =

Rp1 =

Rp2 =

Rp3 = 1 kΩ and

Cp1 =

Cp2 = 1 nF; thus,

fn = 159 kHz and

Q = 0.5 are obtained. All implemented controllers utilized

R1 =

R3 = 5 kΩ and

C1 =

C2 = 200 pF.

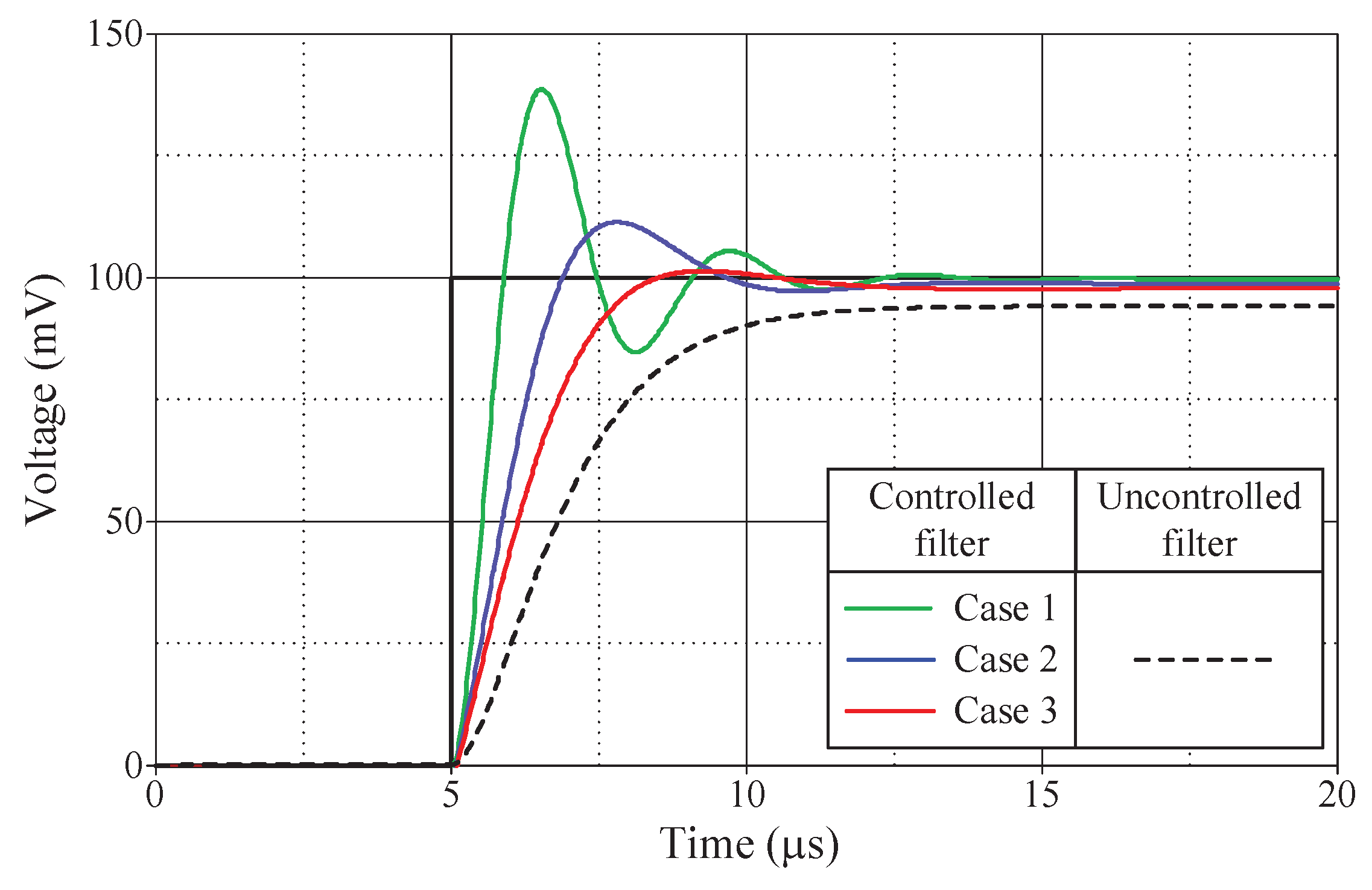

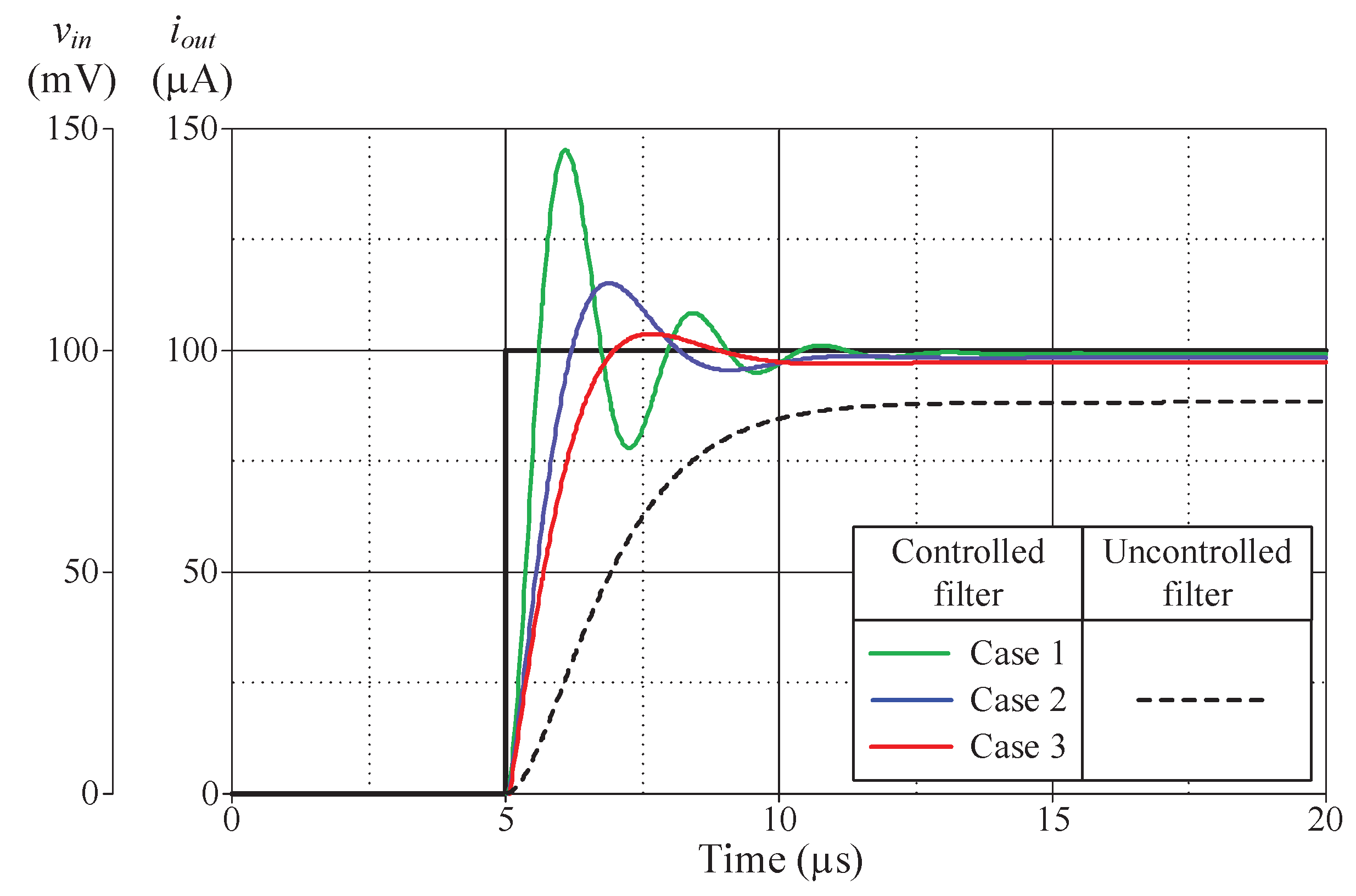

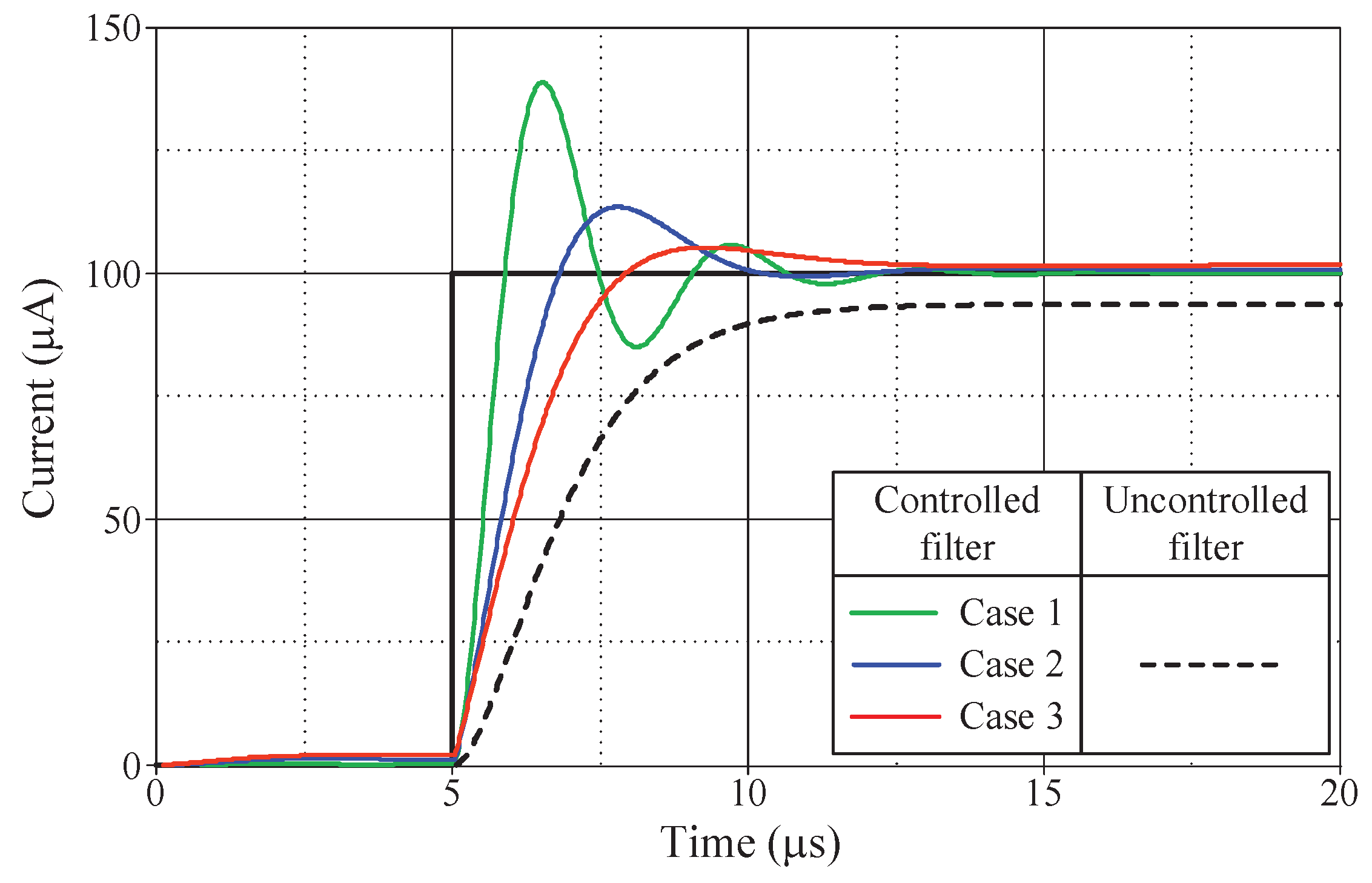

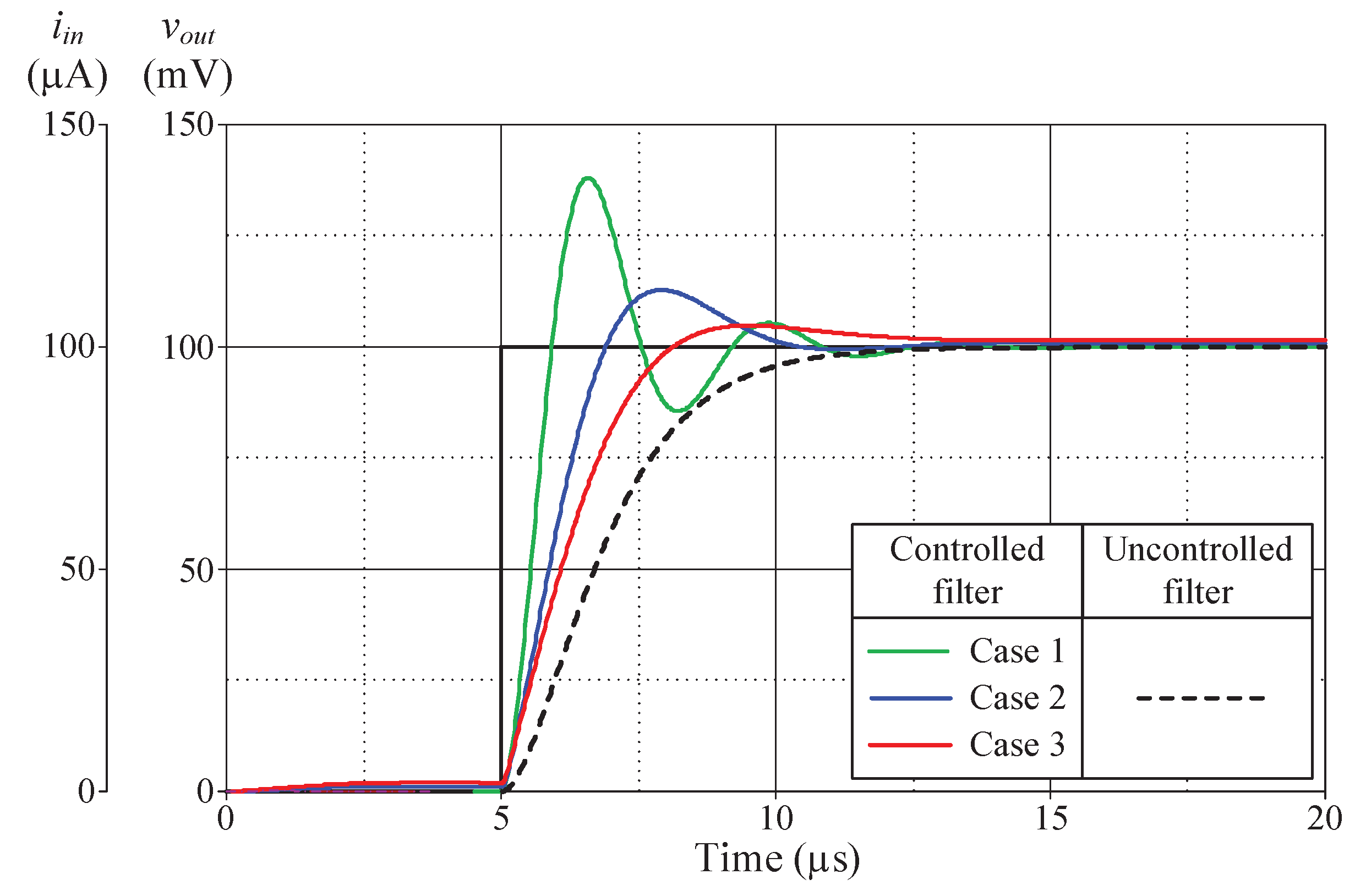

Figure 13,

Figure 14,

Figure 15 and

Figure 16 illustrate the step responses of the uncontrolled filter and PID-controlled filter systems for

Figure 12a–d, respectively. The controller parameters employed to evaluate the step response, along with the characteristics derived from the responses for each of the four modes, are also documented in

Table 6,

Table 7,

Table 8 and

Table 9. It is evident from the tables that the proposed PID controllers improve the time response of the closed-loop control filter systems, particular for

td,

tr,

tp, and

ts. Additionally, the controlled filters enter the steady-state faster than the uncontrolled filters, and track the step-input with a reduced stead-state error.

7. Conclusions

This work presents the tunable mixed-mode PID controller implemented with commercially available integrated circuits (ICs), the current-feedback operational amplifiers (CFOAs). The presented PID controller circuit employs three CFOAs, four resistors, and two capacitors. All four operational mode PID controllers, namely VM, TAM, CM, and TIM, can be performed with a single proposed circuit topology. The important parameters of the proposed PID controllers, namely, KP, KI, and KD, are modifiable as desired. Since the proposed controller is designed using only off-the-shelf ICs together with some passive components, it has advantages in terms of practicality and simplicity. Analyses of non-ideal transfer gain and parasitic effects on the controller performance have also been examined in detail. In addition, to evaluate the practical applicability of the proposed mixed-mode PID controller, the mixed-mode second-order lowpass filter is designed to be a testing plant for a mixed-mode closed-loop control system. A simulation study demonstrates the performance of the circuits.

Author Contributions

Conceptualization, N.R., J.S., and W.T.; methodology, N.R., J.S., T.P., and W.T.; software, N.R. and J.S.; validation, N.R., J.S., T.P., and W.T.; formal analysis, N.R., J.S. and W.T.; investigation, N.R., J.S., T.P., and W.T.; resources, N.R., J.S., T.P., and W.T.; data curation, N.R., J.S., and W.T.; writing—original draft preparation, N.R., J.S., and W.T.; writing—review and editing, T.P. and W.T.; visualization, N.R., J.S., and W.T.; supervision, T.P. and W.T.; project administration, T.P. and W.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by King Mongkut’s Institute of Technology Ladkrabang [2567-02-01-067].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the results presented in this work are available on request from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Michael, A. J.; Mohammad, H. M. PID Control New Identification and Design Methods, Springer, Berlin, 2005.

- Astrom, K. J.; Hagglund, T. The future of PID control. Control Eng. Practice. 2001, 9, 1163–1175. [Google Scholar] [CrossRef]

- Astrom, K. J.; Hagglund, T. PID Controllers: Theory, Design and Tuning, 2nd ed.; Instrument Society of America: Research Triangle Park, USA, 1995. [Google Scholar]

- Franco, S. Design with operational amplifiers and analog integrated circuits, 3rd ed.; McGraw-Hill: Boston, 2002. [Google Scholar]

- Erdal, C.; Toker, A.; Acar, C. OTA-based proportional-integral-derivative (PID) controller and calculating optimum parameter tolerances. Turk. J. Elec. Engin. 2001, 9, 189–198. [Google Scholar]

- Keskin, A. U. Design of PID controller circuit employing CDBAs. Int. J. Electr. Eng. Educ. 2006, 43, 48–56. [Google Scholar] [CrossRef]

- Pandey, R.; Pandey, N.; Chitranshi, S.; Paul, S. K. Operational transresistance amplifier based PID controller. Adv. Electr. Electron. Eng. 2015, 13, 171–181. [Google Scholar] [CrossRef]

- Yuce, E.; Tokat, S.; Minaei, S.; Cicekoglu, O. Low-component-count insensitive current-mode and voltage-mode PID, PI and PD controllers. Frequenz 2006, 60, 65–69. [Google Scholar] [CrossRef]

- Yuce, E.; Tokat, S.; Kizilkaya, A.; Cicekoglu, O. CCII-based PID controllers employing grounded passive components. AEU - Int. J. Electron. Commun. 2006, 60, 399–403. [Google Scholar] [CrossRef]

- Yuce, E.; Minaei, S. New CCII-based versatile structure for realizing PID controllers and instrumentation amplifier. Microelectron. J. 2010, 41, 311–316. [Google Scholar] [CrossRef]

- Ozer, E.; Kacar, F. Design of voltage-mode PID controller using a single voltage differencing current conveyor (VDCC). Analog Integr. Circuits Signal Process. 2021, 109, 11–27. [Google Scholar] [CrossRef]

- Shrivastava, P.; Surendra, S.; Ranjan, R. K.; Shrivastav, A.; Priyadarshini, B. PI, PD and PID controllers using single DVCCTA. Iran. J. Sci. Technol. Trans. Electr. Eng. 2019, 43, 673–685. [Google Scholar] [CrossRef]

- Yuce, E.; Alpaslan, H. DDCC+ based voltage-mode PID controller employing only grounded passive components. Indian J. Eng. Mater. Sci. 2016, 23, 120–128. [Google Scholar]

- Tangsrirat, W. Voltage-mode analog PID controller using a single z-copy current follower transconductance amplifier (ZC-CFTA). Informacije MIDEM 2015, 45, 175–179. [Google Scholar]

- Mongkolwai, P.; Tangsrirat, W.; Suesut, T. Novel voltage-Mode PID controller using a single CCTA and all grounded passive components. Informacije MIDEM 2022, 52, 169–179. [Google Scholar] [CrossRef]

- Taskıran, Z. G. Ç.; Sedef, H.; Anday, F. A new PID controller circuit design using CFOAs. Circuits, Syst. Signal Process. 2021, 40, 1166–1182. [Google Scholar] [CrossRef]

- Silaruam, V.; Lorsawatsiri, A.; Wongtaychatham, C. Novel resistorless mixed-mode PID controller with improved low-frequency performance. Radioengineering 2013, 22, 932–940. [Google Scholar]

- Analog Devices, AD844: 60 MHz, 2000 V/μs, Monolithic op amp with Quad Low Noise. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/AD844.pdf (accessed on 29 June 2022).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).