1. Introduction

Bioenergy can be defined as all energy forms associated with photosynthesis (BNDES, 2008; Gupta et al., 2013), including biomass, known and used since the Paleolithic era (2,500,000 years – 10,000 years B.C.) for cooking, heating, and lighting (Guo et al., 2015; Wrangham, 2010). Burning wood was sufficient to produce heat and light until the Industrial Revolution (1760 A.C.) when fossil energy sources (i.e., oil, mineral coal, and natural gas) reached 80-84% of the total world supply (Goldemberg, 2007; Rapier, 2019). However, these non-renewable energy sources are scarce, with estimations lasting 41 years (oil), 64 years (natural gas), and 155 years (coal) (British Petroleum, 2006). This scenario raised the need for new matrices and the conversion of biomass to electricity (gasification and pyrolysis) and liquid fuels (bioethanol, biodiesel, and bio-oil from pyrolysis) (Karp & Shield, 2008).

The annual biomass storage is 3 to 4 times the current global energy demand, representing a sustainable substitute for oil derivatives (Guo et al., 2015). Energy crops will be responsible for 30% of the energy required worldwide by 2050 (Guo et al., 2015). Therefore, these crops must have high yield, low energy consumption, high content of compounds of interest (starch, sugars, and lipids), few polluting chemicals, and low nutritional requirements (McKendry, 2002).

In this context, the Brazilian sugarcane bioethanol production system is the most efficient (De Souza et al., 2014a; Goldemberg, 2007). Brazil is the largest sugarcane producer (accounts for 43% of the sugarcane production worldwide - (FAO, 2021), with 642.7 million tons (2019/2020 harvest), generating 34 billion liters of ethanol (2019/2020 harvest) (CONAB, 2020)). India, China, and Thailand occupy the 2nd, 3rd, and 4th positions in the sugarcane production rank, respectively. Here, we review the history of sugarcane and ethanol production in Brazil towards the scientific, technological, industrial, and environmental advances from the beginning of the 20th century, along with a bibliometrics evaluation of the contribution of Brazilian universities in this process.

2. History of Ethanol Production from Sugarcane

Sugarcane's first description dates to 500 B.C. by Indian manuscripts (Leão, 2002), but only in 1793 it was classified as Saccharum by Linnaeus (Bakker, 1999). The relatively high sugar accumulation had globally spread the interest in sugarcane. The sugarcane route started in China, entered the Middle East, was introduced to Egypt and Greece by Arabs, arrived in the Roman Empire through Sicily, and reached the Americas (Leão, 2002). Initially, sugarcane was used for medical purposes by the Indians and Chinese as a natural juice and sweet syrup. Later, sugarcane syrup began to be used as a sweetener in beverages. Portugal and Spain dominated sugar technology with plantations in the Atlantic Islands and Central and South America. The cachaça, a kind of run, was developed in Brazil by enslaved people through cane juice fermentation, followed by distillation, becoming popular in 1776 (Leão, 2002).

Alcohol as fuel was tested in 1826 by the American Samuel Morey in an internal combustion engine combined with turpentine to operate a boat (Guo et al., 2015). The German Nicolaus August Otto developed another engine that worked with a mixture of ethanol and gasoline, and Henry Ford built tractors that could run only on ethanol (Songstad, 2009). The capacity and sustainability of alcohol were defended by many scientists when gasoline took over the market in the 1910s (Guo et al., 2015). In 1917, Alexander Graham Bell highlighted the abundance of raw plant materials that could be used for producing ethanol. In 1918, an article in Scientific American showed the efficiency of a fuel consisting of 25% gasoline, 25% benzol, and 50% alcohol, proposing it as a solution to the high consumption of oil reserves (Songstad, 2009).

In Brazil, the infrastructure for alcohol production for the automotive and other industry sectors was discussed and planned at the First National Congress on the Industrial Applications of Alcohol in 1903 (CGEE, 2009; Moreira & Goldemberg, 1999). In 1920, the Experimental Station of Fuels and Minerals (Estação Experimental de Combustíveis e Minérios), which later became the National Institute of Technology (Instituto Nacional de Tecnologia - INT), was created to test alcohol-powered vehicles (called alcohol-motor), and in 1931, 5% anhydrous ethanol was added to gasoline to reduce oil use (Castro & Schwartzman, 2008; CGEE, 2009).

Henry Ford developed the flexible-fuel technology for cars in the United States of America (USA) in 1908, and General Motors commercially launched it in 1992 (Moraes & Bacchi, 2015). Those engines worked with gasoline or E85 (ethanol with 15% gasoline) (Nigro, 2010) but not with pure ethanol. Brazil pioneered the selling of ethanol-powered vehicles, developing a large fleet of flex-fuel cars, and the government has increasingly added ethanol to gasoline for several decades, reaching 27% to minimize carbon emissions into the atmosphere (Leão, 2002). Only in 2003 did other countries regularly add ethanol to gasoline, but at lower proportions (5-10%) (He et al., 2016).

3. Foundation of the Institutions and the First Investments in Sugarcane Agriculture in Brazil

Started in 1500 with the arrival of the Portuguese in Brazil, sugarcane plants became to be cultivated mainly in the northeastern region at the beginning and lasted up to the 20th century. The emperor Dom Pedro II ordered the creation of several agricultural institutes [Instituto Imperial Bahiano de Agricultura (1859), Instituto de Pernambuco (1859), Instituto de Sergipe (1859), Instituto Fluminense (1860), and Instituto do Rio Grande do Sul (1861)] across the country to boost national products and promote sugarcane productivity (Rodrigues, 1987). Despite the extensive cultivation system in fertile, deforested areas, the need for technological incentives and information on Brazilian soil management were the main limitations of sugar market demand back then (Reifschneider FJB, 2010). Sugar was Brazil's first and only commodity produced for over 300 years (Rodrigues, 1987).

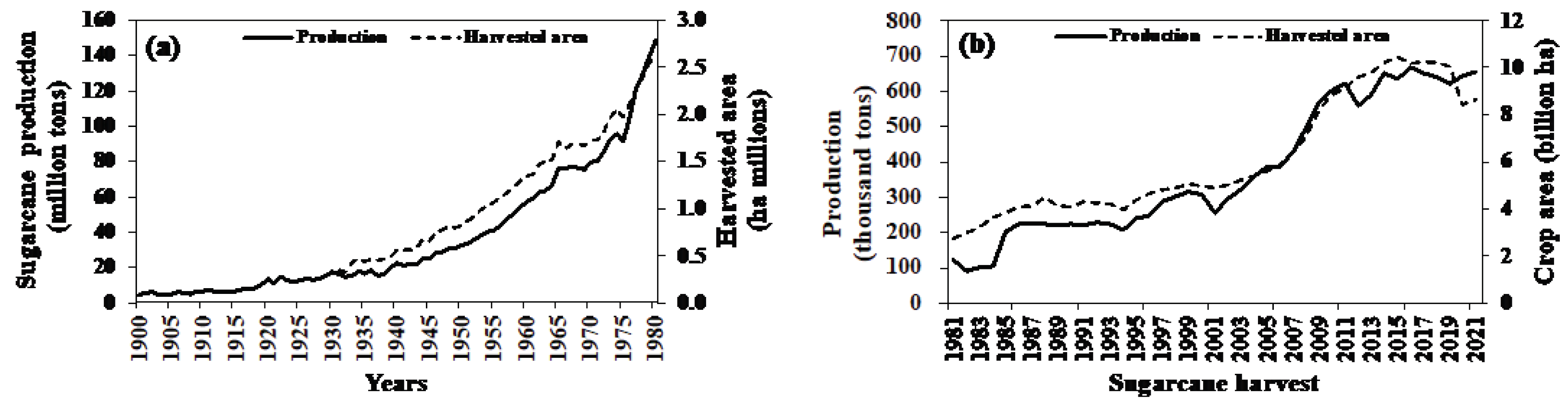

Brazil's sugarcane production and planted area significantly increased from 1900 to 1980 (

Figure 1A). At the beginning of the 20th century, central mills still produced sugar for subsistence and/or exportation (Ramos, 2007). Frequent export drops, along with external market competition (beet sugar) and World War II, demanded sugarcane industrialization and the internal maintenance of the Brazilian economy. The sugar industry has adapted to produce anhydrous alcohol, aiming its addition to gasoline. After the 1950s, the sugarcane planted area and production increased almost linearly, reaching an area approximately five times greater than at the beginning of the century (

Figure 1A).

The regulation, commercialization, technology, and database of sugarcane, sugar, and alcohol production were achieved with the leadership of governmental institutions. Studies on sugarcane began in 1892 with Franz W. Dafert, who tested 42 varieties of

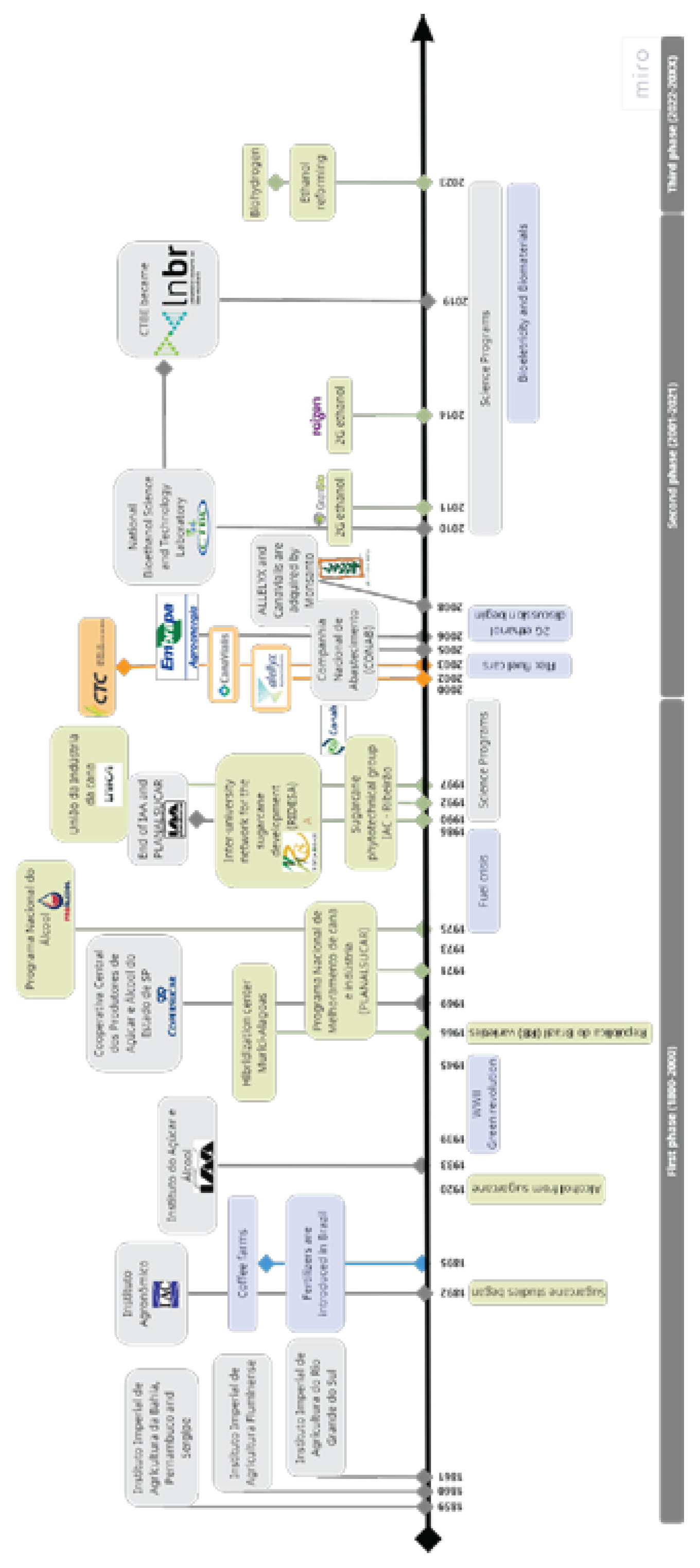

Saccharum officinarum under two cultivation conditions at the Agronomic Institute of Campinas (IAC, Brazilian acronym) (IAC, 2021). The gummosis and the mosaic virus spread throughout the sugarcane fields, reducing production and alerting about the necessity of breeding and more appropriate cultivating systems (

Figure 2).

4. The First Phase of Brazilian Investments in Science and Technology in the Sugarcane Sector: An Analysis from 1969 to 2000

Although government investments in sugarcane have been obvious since the 1500s, science and technology displayed a transition phase during the 1930s onwards, with science (mainly breeding) being developed by government-funded institutions. We artificially set the beginning of the first phase of investment in science, technology, and financing of the sugarcane sector in 1969 because this is the year in which we detected the first record of a scientific publication in the scientific databank we used in this review.

The investment in the production of ethanol from sugarcane in Brazil can be dated back to 1933 when the Institute of Alcohol and Sugar (

Instituto de Álcool e Açúcar -IAA) was founded with the intervention of the State to regulate sugarcane activity that lasted until the mid-1980s (Lima, 1992). IAA was responsible for establishing sugarcane production quotas for mills and suppliers, managing the price of raw materials and products (sugar and alcohol), and the export rules. In 1966, this institute and the productive sector of Alagoas created a hybridization station in

Serra do Ouro (Murici, Alagoas), where the first Brazilian sugarcane varieties called RB (referring to

República do Brasil) were developed (Cursi et al., 2022). At first, genetic breeding prioritized the genotypes introduced from other countries such as India, Java, and the USA (IAC, 2021). In 1971, IAA started the National Sugarcane Breeding Program (

Programa Nacional de Melhoramento da Cana de Açúcar - PLANALSUCAR), fundamental for the implementation of the National Alcohol Program (

Programa Nacional do Álcool - PROÁLCOOL) in 1975 (

Figure 2).

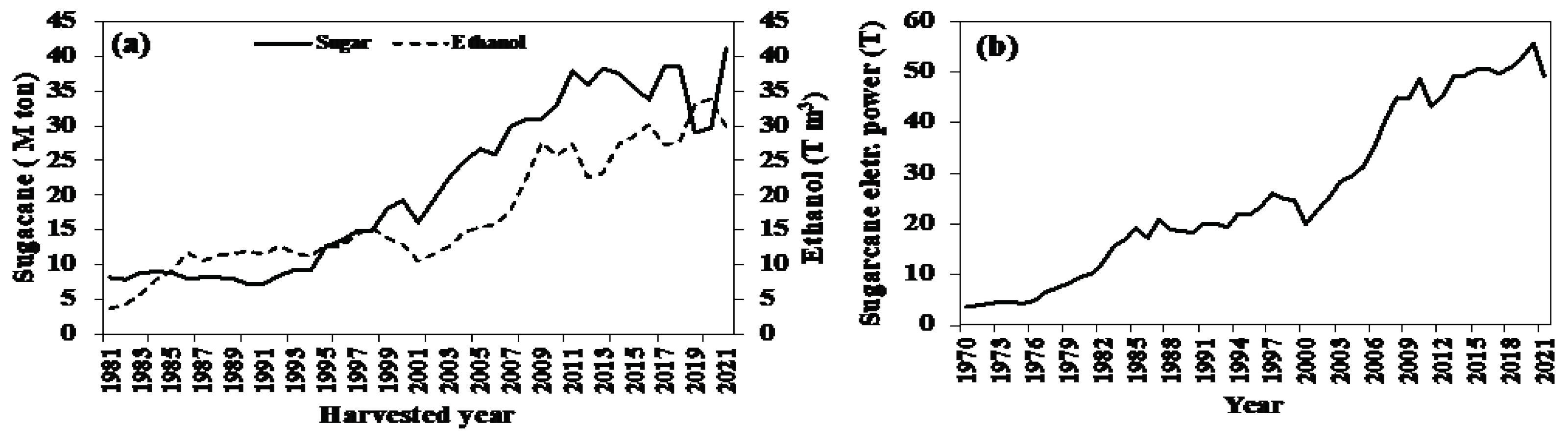

The PRO-ÁLCOOL Program boosted the sugar and alcohol industry and fuel ethanol (hydrated) as a principal energy matrix in the country (

Figure 1) to compete with the oil fuel. The Brazilian dependence on oil as a primary energy source grew from 13.2% in 1940 to 41.7% in 1977 (Pimentel, 1980). This program increased sugarcane production, expanding the planted areas with qualified technical support to generate more efficient hybrids with a high sugar content and disease resistance (Pimentel, 1980). Moreover, thanks to PRO-ÁLCOOL, new yeast strains were selected, the fermentation processes were optimized (continuous, semi-continuous, and discontinuous), and other biomasses were studied (e.g., cassava, babassu, and sorghum), which contributed to increased productivity of fermentation (Pimentel, 1980). The effectiveness of PRÓ-ÁLCOOL allowed car sales powered exclusively by alcohol in 1978. As a result of the second oil crisis (1979), the Brazilian government decided to invest in ethanol as fuel. However, the Brazilian strategy did not count on reducing oil prices, and ethanol production did not meet the internal demand. At the same time, an increased demand in the market for sugar shifted the industrial production, decreasing even more ethanol production (Leão, 2002).

In 1990, the IAA/PLANALSUCAR was closed by the government. Its entire physical structure, human resources, and technologies were transferred to Federal Universities: The Federal Universities of Alagoas, Mato Grosso, Paraná, Piauí, Sergipe, São Carlos (in São Paulo State), Viçosa (in Minas Gerais State), Goiânia (in Goiás State), and the Federal Rural Universities of Pernambuco and Rio de Janeiro, (Cursi et al., 2022). This change created the Interuniversity Network for the Development of the Sugarcane Industry (RIDESA for the Brazilian acronym) (

Figure 2), which decentralized the sugar and ethanol sector. In São Paulo State, the Phytotechnical Group of Sugarcane was created in 1992 in Ribeirão Preto, and the Sugar Cane Program was launched by the Agronomic Institute of Campinas (IAC) in 1994, integrating research in genetics, physiology, phytopathology, entomology, pedology, fertility, and climatology. Until today, the IAC’s sugarcane program has generated and disseminated knowledge on sugarcane to researchers, companies, industry, and farmers (IAC, 2021).

The Cooperative of Sugar and Alcohol Producers of the State of São Paulo (

Cooperativa Central dos Produtores de Açúcar e Álcool do Estado de São Paulo Central - COPERSUCAR) was created in 1969 together with its research center in Piracicaba, State of São Paulo. COPERSUCAR had an Experimental Station in Camamu, in the State of Bahia, which developed hybrid sugarcane varieties (named SP varieties) suitable for the climatic conditions of this region (

Figure 2). In the 1970s, the IAC signed an agreement with COPERSUCAR, which enabled the introduction of 678 genotypes from several countries in Camamu (IAC, 2021). COPERSUCAR became extinct in 2003, and all the genetic resources generated were acquired by its substitute, the Sugarcane Technology Center (

Centro de Tecnologia Canavieira - CTC), which became the leading Brazilian sugarcane breeding company with its then-named CTC varieties (Cursi et al., 2022).

All these programs were essential for the generation of new technologies and varieties, as well as sugarcane development and data collection, which improved the production sector (

Figure 1). Since 1980, the database Sugar Cane Industry Union (

União da Indústria da Cana de Açúcar - UNICA) started to gather data on sugarcane production and the total sugarcane planted area (

Figure 1). In 2005, a federal institution named

Companhia Nacional de Abastecimento - (CONAB) was founded and started monitoring agricultural development in Brazil (

Figure 2). CONAB compiles data on agricultural production by state and region (

Figure 1C). The average sugarcane production increased from 50 to 90 tons per hectare with breeding programs and investment in science and technology for crop productivity (Pimentel, 1980).

From 1980 to 1998, juice extraction increased by 6% (from 90 to 96%) and fermentation yield by 7% (from 84% to 91%) (CGEE, 2009), while the planted area and sugarcane production doubled (

Figure 1B). Ethanol production increased from 664,000 m

3 (1977 harvest year) to 3.7 million m

3 (1981 harvest year). The financing of new distilleries also contributed to the growth of the sugar and alcohol industry, reaching 11.5 million m

3 in 1985 (

Figure 3A). In that same period, in which production was breaking records, the increase in oil prices (second oil crisis - 1979) led to a new market for vehicles powered only by alcohol (Furtado et al., 2011). The government has provided tax incentives, controlled alcohol prices, and directed companies to create the necessary systems for storing, transporting, and distributing hydrous alcohol to cars. Together, these actions led to a rapid expansion of alcohol-powered vehicles, representing 90% of fleet renewal in the 1980s (Furtado et al., 2011). However, the crisis caused by the shortage of alcohol and the closure of IAA (in 1990) marked the end of the government incentive program (

Figure 2), reflected in the ratio between sugar and ethanol production from 1994 to 2000 (

Figure 3A). Sugar production increased five times while ethanol production was maintained at 12 million m

3 annually (Furtado & Scandiffio, 2006). Ethanol production declined and started to recover only from 2008 onwards. Even so, sugar accounted for most of the production until the 2019 harvest, which had a balanced production between the two main sugarcane products.

5. The Second Phase of Brazilian Investments in Science and Technology in the Sugarcane Sector: An Analysis from 2001 to 2021

The PRO-ÁLCOOL and the creation of several research institutes have boosted sugar and ethanol production, although basic knowledge about sugarcane biology and development hampered biotechnological manipulation for more productive and stress-resistant varieties (Matsuoka et al., 2009; Buckeridge, 2010; Hotta et al., 2010; Arruda, 2011).

At the end of the 1990s, the São Paulo Research Foundation (

Fundação de Amparo à Pesquisa do Estado de São Paulo - FAPESP) joined efforts with CTC to develop sugarcane research (Arruda, 2001), especially in genomics. The SUCEST (SUgarCane Expressed Sequence Tags) program identified genes associated with agronomic traits, sugar yield, cell wall, and resistance to biotic and abiotic stresses (

Figure 2) (Lima et al., 2001; Vettore et al., 2003). This program and several others marked the beginning of studies on sugarcane molecular biology and bioinformatics (

Figure 2). They allowed the foundation of the plant genomics companies Alellyx Applied Genomics (2002) and CanaVialis (2003) (Bernardes et al., 2013). Although Alellyx has developed technology with several crops (citrus, eucalyptus, grapes, and soybeans), most of the budget was directed to developing transgenic sugarcane (Reinach, 2008). As an alternative to genetic transformation, CanaVialis has improved sugarcane varieties using classic breeding and provided consultancy services to farmers. In 2008, both companies were bought by Monsanto (

Figure 2). BASF, Syngenta, and DuPont established their respective research centers to develop new sugarcane varieties and crop technologies (Arruda, 2011), leading to pre-sprouted seedlings, sugarcane "seed," and precision agriculture after one decade.

In 2003, the flex-fuel technology that uses an electronic injection controlled by sensors to detect ethanol and gasoline permitted the choice between those fuels to run vehicles (Watanabe et al., 2020). After the launch of flex-fuel vehicles in Brazil, the sale levels of ethanol fuel cars increased by 90% (Matsuoka et al., 2009) which, consequently, increased ethanol production from 10 billion m

3 in 2001 to over 30 billion m3 in 2019 (

Figure 3A).

To achieve the global demand for ethanol with the growing number of cars and the need for renewable fuels, second-generation technologies (2G) emerged. 2G ethanol converts agroindustrial lignocellulosic residues into fermentable sugars by cell wall hydrolysis, followed by yeast fermentation and distillation. In Brazil, 2G ethanol is produced from sugarcane bagasse and straw (Hotta et al., 2010; Soccol et al., 2010; Buckeridge & De Souza, 2014). This second green energy revolution became necessary in Brazil in 2006. Once again, researchers needed the scientific and technical knowledge to support a new industrial demand (De Souza et al., 2014b). Research and development on 2G ethanol focused on sequencing the sugarcane genome, developing sugarcane genetic transformation protocols, characterizing the architecture of the sugarcane cell wall, discovering and understanding the action of enzymes on polysaccharides, and developing biomass pretreatments and processes to ferment pentoses (five-carbon sugars).

To face these major challenges, the FAPESP Bioenergy Research Program (BIOEN), the National Institute of Science and Technology of Bioethanol (INCT of Bioethanol), the Brazilian Bioethanol Science and Technology Laboratory (CTBE), and the Center for Biological and Industrial Processes for Biofuels (CeProBio) were created. Among the Brazilian research funding agencies, the following stood out: the Financier of Studies and Projects (FINEP) and the National Council for Scientific and Technological Development (CNPq), both linked to the Ministry of Science, Technology and Information, and FAPESP liked to the São Paulo State Government (Cursi et al., 2022).

To ensure the renewable sources in the national energy balance, new programs and institutes were created, such as the

Embrapa AgroEnergia, the National Program for the Production and Use of Biodiesel (

Programa Nacional de Produção e Uso de Biodiesel - PNPB), the National Agroenergy Plan (

Programa Nacional de Agroenergia - PNA), and the National Bioethanol Science and Technology Laboratory (

Laboratório Nacional de Ciência e Tecnologia do Bioetanol - CTBE) to fully use biomass from different crops in the energy production chain (EMBRAPA, 2023). CTBE was created by the Center for Management and Strategic Studies (CGEE) for exploratory research by the Interdisciplinary Center for Energy Planning (NIPE/UNICAMP) to identify the limiting factors of ethanol production. CTBE aimed to assess the impact of new agricultural and industrial technologies on ethanol production and the environment, society, economy, and logistics shifts in the sector (

Figure 2). Later, CTBE was renamed the Brazilian Biorenewables National Laboratory (LNBR), being added to the other technology centers of the National Center for Research in Energy and Materials (CNPEM) complex (LNBIO, 2023).

The company Granbio was founded in 2011 to develop sugarcane varieties with low-production cost, high biomass, and energy efficiency that can be cultivated in restricted areas to avoid competition between biofuel feedstock and food production (Dos Santos et al., 2016; Grassi & Pereira, 2019). Those sugarcane varieties are called energy cane, of which 11 were registered in Brazil under the name of Vertix. Raízen, another company formed by the joint venture between Shell and Cosan, operates most of Brazil's sugar, ethanol, and energy-producing systems. Raízen also operates a 2G ethanol industrial manufacturing; others are under construction. Besides that, sugarcane straw and bagasse can be burned for bioelectricity co-generation (

Figure 3B).

As a result of these incentives and investment in research, the activities for industrial biotechnology and green chemistry were expanded in Brazil (EMBRAPA, 2023). Ongoing studies focus on breeding sugarcane to improve the control of pests in agriculture and face the challenges of global warming. In 2021, the Brazilian Ministry of Agriculture, Livestock, and Supply (MAPA, 2023) registered 214 new sugarcane varieties (68 RB, 38 CTC, 37 SP, 33 IAC, and 38 other varieties).

The energy balance of the Brazilian ethanol production chain has changed. Before PROÁLCOOL, the energy balance was negative, but the fossil fuel was replaced in the sugarcane mills, and the energy surplus from bagasse was sold to the energy grid (Martinelli & Filoso, 2008). As a result, Brazilian bioethanol has lower production costs, becoming competitive with other fuels, and has the advantage of reducing ~ 80% of GHG emissions (Walter et al., 2018). A new phase is currently being implemented with a partnership between Shell and the University of São Paulo involving the Research Center of Green House Gas Innovation (RCGI) and the INCT do Bioethanol. For the first time in the world, an ethanol reforming unit for the production of green hydrogen is underway (Geraque, 2022).

6. The Production of Scientific Knowledge in the Sugar-Energy Sector: A Bibliometrics Analysis of Phases 1 and 2

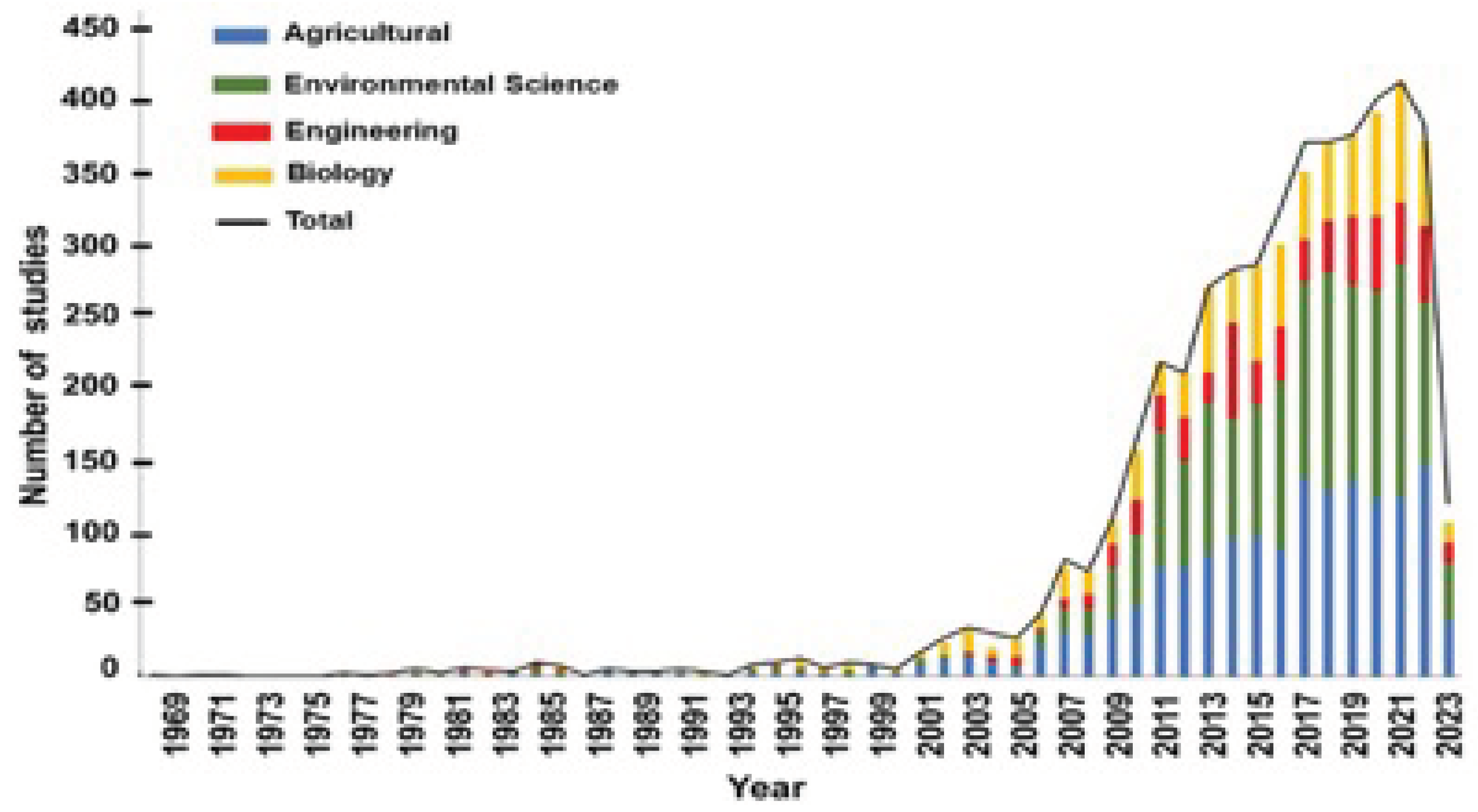

The quality and number of articles and documents published on bioenergy were performed in a bibliometric search in the Scopus/Elsevier database to evaluate scientific research production. Bibliometrics is a statistical methodology used to evaluate and quantify the number and tendency of growth of a specific subject (in our case, bioenergy research) in the literature (Zupic e Čater, 2014).

The bibliometrics in sugarcane and ethanol science revealed the count of journal publications by country and the thematic categories for the research area. These analyses were performed in March 2023, using the following keywords: sugarcane AND (ethanol OR bioethanol OR bioenergy OR alcohol) of documents published between 1900 and 2023. We recovered 4,523 articles from 103 countries (

Supplementary Table S1), with the first publication in 1969 entitled “Products of arginine catabolism in growing cells of sugarcane" (Nickell & Maretzki, 1969). The number of publications remained constant between 1969 and 2000 and increased exponentially from 2005 onwards. The most productive year was 2021, with 402 articles (

Figure 4). Analyzing those articles by area, the agriculture and environmental sciences counted for 70% of the publications (1550 and 1599 articles, respectively) (

Figure 4), whereas biology counted for 18% (830 papers) and engineering 12% (544 papers) (

Figure 4).

The first historical phase with PRO-ÁLCOOL and several research groups being created increased published works after 1975 (

Figure 4). Before this time, most of the research was carried out directly by industry and private sectors, which reduced the ability to estimate knowledge produced during this period. The lower speed of pre-2000 publication processing may be related to the lower number of publications that preceded and the increase afterward. The new technologies, equipment, and computer systems accelerated the publishing process, which led to a vertiginous increase in the rate of knowledge spread through scientific journals (Lawrence, 2001).

Citation numbers are another parameter that can indicate research visibility and preference by the research community in a given period. The most cited article was "Biofuels from microalgae - A review of technologies for production, processing, and extractions of biofuels and co-products," with 5,893 citations (Brennan & Owende, 2010). In Brazil, “Ethanol for a Sustainable Energy Future” (Goldemberg, 2007), addressing ethanol from Brazilian sugarcane as an energy commodity fully competitive with gasoline, received a high number of citations (1,640).

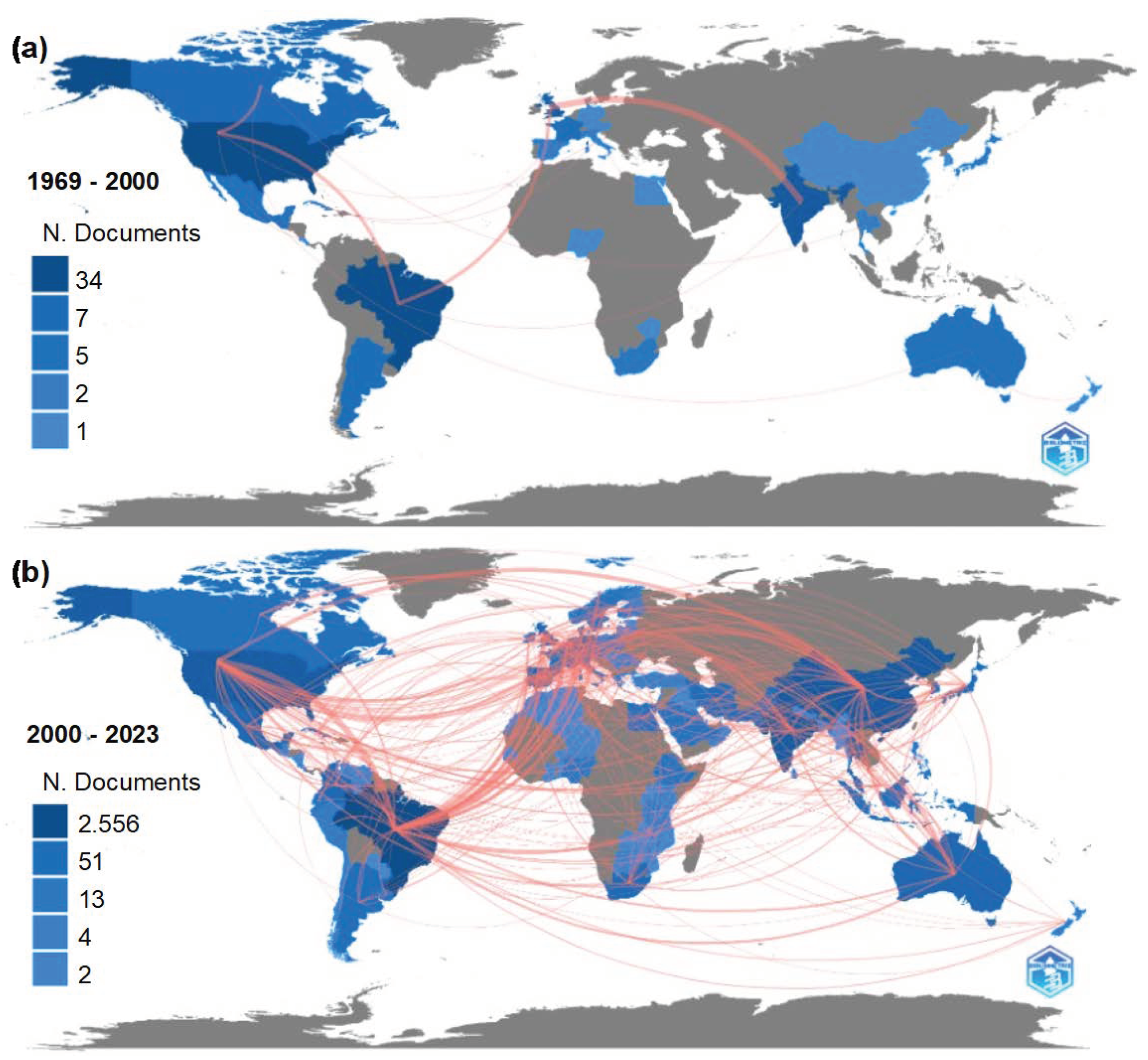

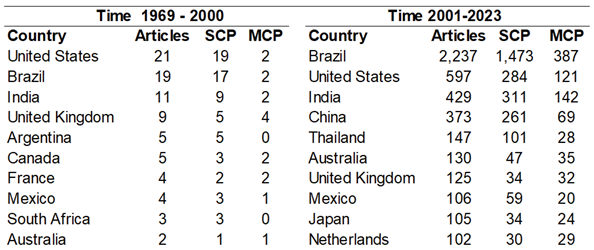

The increase in the number of publications in the last two decades appears to be related to the connections among research groups (

Figure 5). This data can be parameterized with bibliometric analysis, which shows the number of authors, publication types, collaborators, and scientific contributions to bioenergy and sugarcane ethanol advancement. In the first phase of sugarcane science and technology development (1969-2000), the countries that contributed most to disseminating scientific knowledge were the USA, Brazil, India, the UK, Argentina, Canada, France, Mexico, South Africa, and Australia (

Table 1 and

Figure 5). As mentioned above, the second phase (2001-2021) increased research productivity, the internationalization of Brazilian research, and collaborations (

Table 1 and

Figure 5). During this time, Brazil led the publications, followed by the USA, India, China, Thailand, Australia, the UK, Mexico, Japan, and the Netherlands (

Table 1).

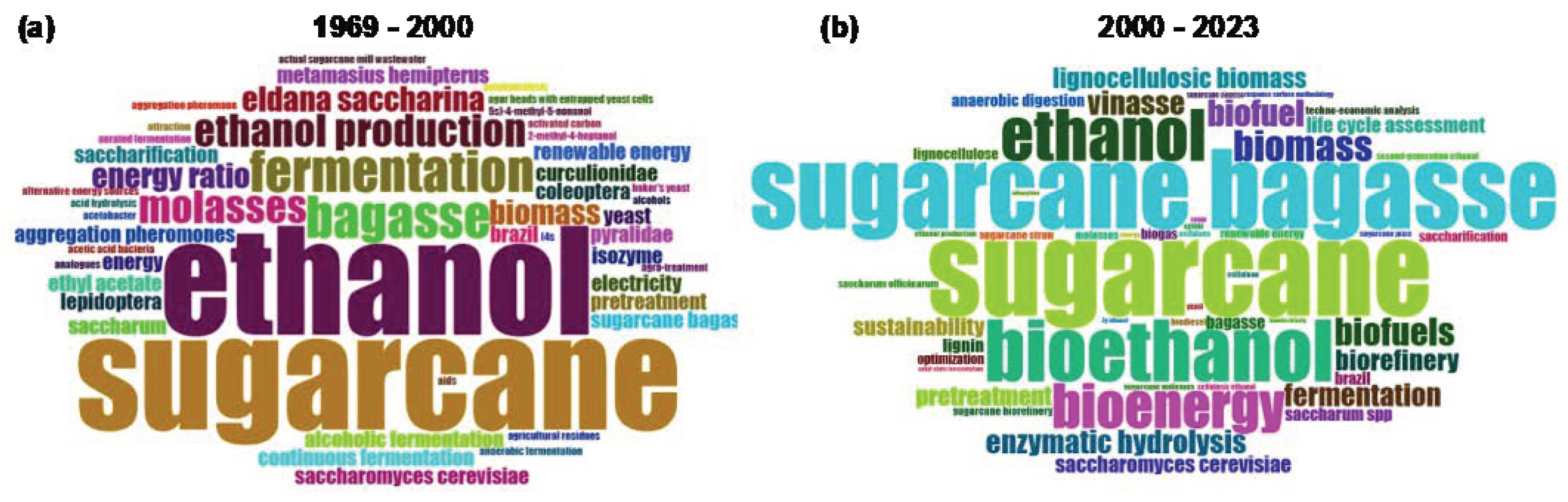

Co-word analysis is an effective tool for analyzing hot topics and search trends by title, keywords, and abstract from published work, and therefore, important for content analysis (Zupic & Čater, 2015). Using the “bibliometrix” package from R (R Core Team, 2022), a network with the 50 most frequent keywords was constructed to explore the data recovered. The terms studied over the two phases showed that changes in scientific research could be analyzed by word frequency in keywords (

Figure 6). Sugarcane, ethanol, bagasse, and molasses were the most used keywords from 1969 to 2000. However, fermentation processes, yeast names, and crop pests were also highlighted (

Figure 6A), suggesting the focus on 1G bioethanol (sucrose fermentation). These keywords shifted from 2001-2023 when bioethanol, bioenergy, and biofuel were highlighted along with biomass pretreatment processes (lignocellulose biomass, pretreatment, biorefinery, and enzymatic hydrolysis) (

Figure 6B) focusing on 2G ethanol. The bio prefix added to the most frequently used terms indicates that research on sugarcane ethanol has been associated with the evolution of socio-environmental ethics, incorporating the ideas of sustainability of the latter decade (Buckeridge et al., 2019).

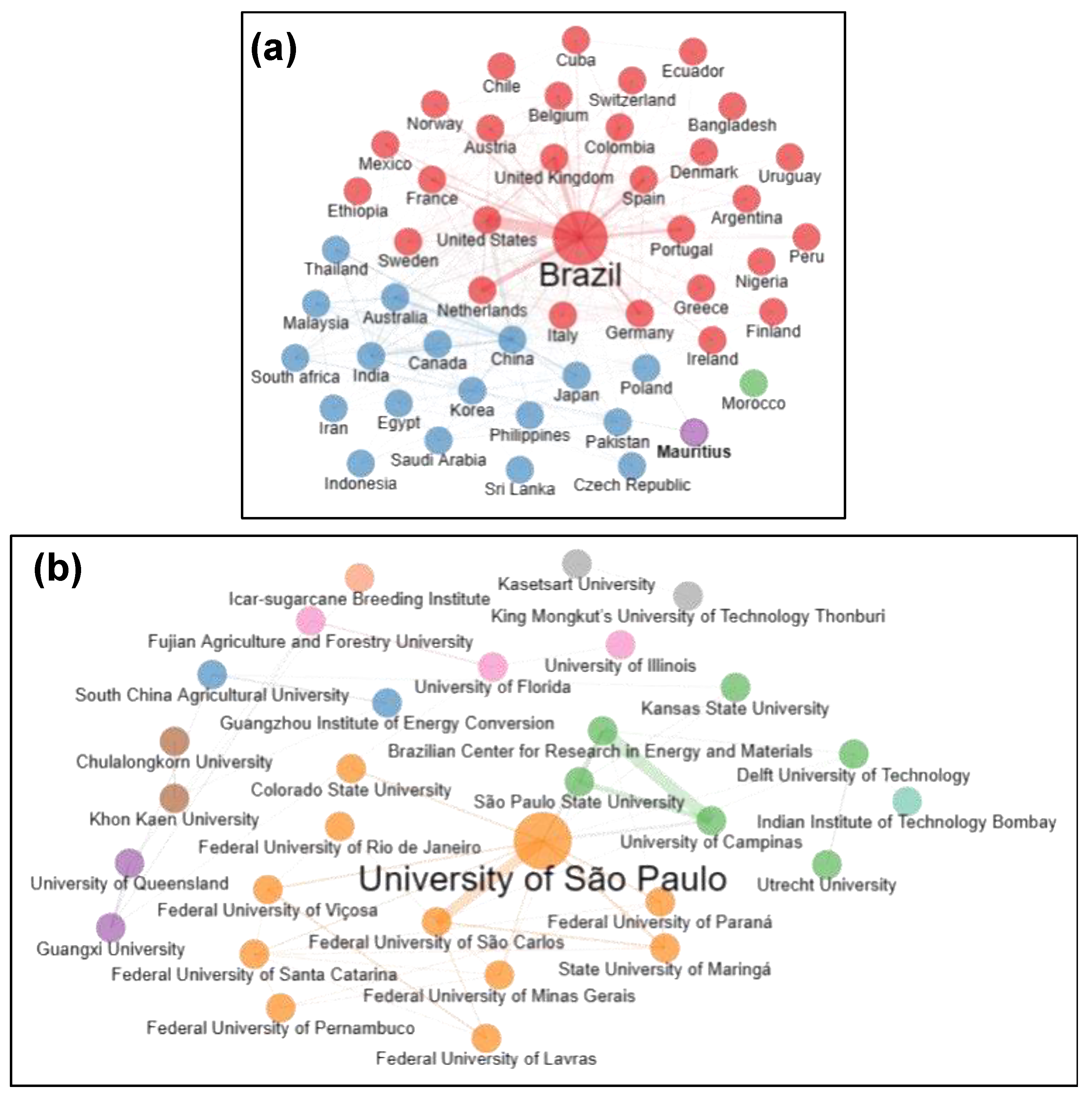

Brazil has become the largest sugarcane producer due to advances in policies that invest in the science and technology of agriculture and refineries (Creutzig et al., 2015; IRENA, 2020) (

Figure 1). The country consolidates leadership in sugarcane and ethanol production, as seen in

Figure 7. Network research in sugarcane bioethanol shows 49 countries that contributed to the scientific advancement in this area (

Figure 7A). Brazil has been collaborating mainly with the USA and European countries (

Table 1 and

Figure 5 and

Figure 7). Despite governmental investment in science and technology, which became a benchmark in sugarcane production (Zhang & Govindaraju, 2018), China only appeared after the 2000s in fourth place in the list of countries with the most publications (

Table 1).

The internationalization programs in Brazil funded by CNPq and FAPESP have stimulated collaboration with the USA, UK, the Netherlands, Colombia, Spanish, Portugal, and Germany (

Figure 7A). China and India had a collaboration network with Canada, Japan, Thailand, and Australia but lacked stronger collaborations with Brazil. The interaction between world institutes and universities highlights Brazil, especially the University of São Paulo (USP) (712 articles), University of Campinas (UNICAMP) (416), São Paulo State University – (UNESP) (296), Federal University of São Carlos (UFSCAR) (213), and Brazilian Center for Research in Energy and Materials (149). The University of São Paulo had the highest number of articles and interactions with other central nodes, having the Federal University of São Carlos (part of RIDESA) in its subnet. The State of São Paulo had research funding advantages that developed agriculture, accounts for 55% of the Brazilian sugarcane-cultivated areas, and produces 48.5% of the country's ethanol (CONAB, 2020; Rudorff et al., 2010).

7. Future of Brazilian Ethanol and Climate Change

As the global temperature is likely to increase above 1.5 ºC in the following decades, CO2 emissions must reach net zero, and greenhouse gas emissions must be more effective (IPCC, 2018, 2021). To achieve these goals, the Intergovernmental Panel on Climate Change (IPCC) reported that governments must comply with the Paris Agreement (IPCC, 2018, 2021), and the world has been discussing how to capture, use, and store carbon. Bioenergy with Carbon Capture and Storage (BECCS) is a technology that may help achieve negative carbon emissions via plant photosynthesis (Köberle, 2019). The biomass accumulated is converted into liquid or solid fuel that will be burned, and the CO2 produced in the industrial process can captured and stored underground. Thus, sugarcane and the advantages of ethanol reappear as sustainable promises. The capture of the carbon released by the ethanol production chain could benefit from BECCS to reach negative carbon emissions. Programs such as RenovaBio have directed industries and agribusiness towards negative emissions and the circular economy of ethanol. These new sustainability-related approaches can already characterize a third phase of ethanol science and technology.

Other ethanol production systems rely on sugar beet (Europe) or corn (the USA), but the Brazilian sugarcane system is the most efficient. The production of 1L of corn ethanol requires nine times more energy than 1L of sugarcane ethanol (Macedo, 2007). As mentioned above, Brazil has a successful history in sugarcane science, technology, and development (

Figure 2) and its derivative products' logistics, manufacture, and commercialization (sugar, bioethanol, and bioelectricity). This was possible with the engagement of the public and private sectors, along with universities and research institutes.

The generation of bioethanol from vinasse residues is a promising practice that could reduce the environmental impact of ethanol production. Vinasse is a by-product of alcohol production that contains high concentrations of organic matter, nutrients, and pollutant potential. This by-product can be anaerobically digested to produce biogas (a mixture of methane, carbon dioxide, and hydrogen sulfide), used as electrical and thermal energy or as fuel. The residue of the biogas production could be used as a fermentation substrate for ethanol production (Szymanski et al., 2010). This approach aggregates value to residues and reduces the emission of greenhouse gases and the consumption of raw materials (Nakashima & de Oliveira Junior, 2020). The circular economy in industrial processes contributes to climate change mitigation and sustainable development, with social benefits.

Sugarcane is at the forefront with a promising market that can be expanded worldwide. Investing in 2G ethanol and higher sugarcane productivity are paths followed by Brazil to increase world energy production to supply domestic and international markets. To make 2G ethanol profitable, research and development are still needed. Most sugarcane straw is still left in the field, and much of the bagasse is burned for bioelectricity. Using these biomasses to generate additional ethanol is more efficient in energy but still expensive.

Brazil's third bioethanol phase begins with ethanol steam reforming to generate green hydrogen sustainably (Kumar et al., 2022). Electric and hybrid cars, buses, and trucks are perspectives for the near future energy derived from BECCS, fueling transportation with negative carbon emissions.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on

Preprints.org. Table S1. Countries involved in the scientific production of sugarcane and the number of retrieved documents.

Author Contributions

AG and JSF performed a data review. JSF performed bibliometrics. AG, JSF, DP, prepared a draft. AG and MSB idealized the research. MSB led the research group and edited and produced the final version of the manuscript. All authors approved the final version of the manuscript.

Funding

Please add: This research was funded by the Instituto Nacional de Ciência e Tecnologia do bioethanol – INCT do Bioethanol (FAPESP 2014/50884-5 and CNPq 465319/2014-9) and Centro de Pesquisa e Inovação de Gased de Efeito Estufa – RCGI/Shell/FUSP 371055 (RCGI - FAPESP/Shell 2020/15230-5). AG (FAPESP 2019/13936-0) and JSF (FAPESP 2022/14886-0) are grateful for the fellowships.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Arruda, P. Sugarcane transcriptome: A landmark in plant genomics in the tropics. Genet. Mol. Biol. 2001, 24. [Google Scholar] [CrossRef]

- Arruda, P. Perspective of the Sugarcane Industry in Brazil. Trop. Plant Biol. 2011, 4, 3–8. [Google Scholar] [CrossRef]

- Bakker, H. Sugar Cane Cultivation and Management Kluwer. Academic/Plenum Publishers. Chapter 1 - The Origins of Sugar Cane, 1999; 1–2.

- Bernardes, R.C.; Varela, C.A.; Consoni, F.L.; Sacramento, E.S. Ensaio sobre as virtudes do capital de risco corporativo para projetos de alta tecnologia no setor agrícola: a trajetória inovadora da Alellyx Applied Genomics e da CanaVialis. Revista de Administração. [CrossRef]

- BNDES, C. Sugarcane-based bioethanol: energy for sustainable development. BNDES and CGEE Coordination – Rio de Janeiro: BNDES, 2008.

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- British Petroleum. Statistical Review of World Energy. 2006. Available online: www.Bp.Com/Liveassets/Bp_internet/Globalbp/Globalbp_uk_english/Publications/Energy_reviews_2006/STAGING/Local_assets/Downloads/Spreadsheets/Statistical_review_full_report_workbook_2006.Xls.

- Buckeridge, M. S., S. W. D., D. S. A. P. As rotas para o etanol celulósico no Brasil. In: Luís Augusto Barbosa Cortez. (Org.). Bioetanol Da Cana-de-Açúcar: P&D Para Produtividade e Sustentabilidade. São Paulo: Editora Edgard Blucher, 2010; 365–380.

- Buckeridge, M.S.; de Souza, A.P. Breaking the “Glycomic Code” of Cell Wall Polysaccharides May Improve Second-Generation Bioenergy Production from Biomass. BioEnergy Res. 2014, 7, 1065–1073. [Google Scholar] [CrossRef]

- Buckeridge, M.S.; Grandis, A.; Tavares, E.Q.P. Disassembling the Glycomic Code of Sugarcane Cell Walls to Improve Second-Generation Bioethanol Production. In Bioethanol Production from Food Crops 2019; (pp. 31–43). Elsevier. [CrossRef]

- Castro, M.H.M.; Schwartzman, S. Tecnologia para a indústria a história do Instituto Nacional de Tecnologia. Centro Edelstein. 2008. [CrossRef]

- CGEE. Relatório Final do Contrato de Gestão. 2009. Https://Www.Cgee.Org.Br/Documents/10182/37920/Rel-Cg-2009.Pdf.

- CONAB. Companhia Nacional de Abastecimento. 2020. https://www.Conab.Gov.Br.

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and climate change mitigation: an assessment. GCB Bioenergy 2014, 7, 916–944. [Google Scholar] [CrossRef]

- Cursi, D.E.; Hoffmann, H.P.; Barbosa, G.V.S.; Bressiani, J.A.; Gazaffi, R.; Chapola, R.G.; Junior, A.R.F.; Balsalobre, T.W.A.; Diniz, C.A.; Santos, J.M.; et al. History and Current Status of Sugarcane Breeding, Germplasm Development and Molecular Genetics in Brazil. Sugar Tech 2021, 24, 112–133. [Google Scholar] [CrossRef]

- de Souza, A.P.; Grandis, A.; Leite, D.C.C.; Buckeridge, M.S. Sugarcane as a Bioenergy Source: History, Performance, and Perspectives for Second-Generation Bioethanol. BioEnergy Res. 2013, 7, 24–35. [Google Scholar] [CrossRef]

- de Souza, A.P.; Grandis, A.; Leite, D.C.C.; Buckeridge, M.S. Sugarcane as a Bioenergy Source: History, Performance, and Perspectives for Second-Generation Bioethanol. BioEnergy Res. 2014, 7, 24–35. [Google Scholar] [CrossRef]

- dos Santos, L.; de Barros Grassi, M.C.; Gallardo, J.C.M.; Pirolla, R.; Calderón, L.L.; De Carvalho-Netto, O.V.; Parreiras, L.; Camargo, E.L.O.; Drezza, A.L.; Missawa, S.K.; et al. Second-Generation Ethanol: The Need is Becoming a Reality. Ind. Biotechnol. 2016, 12, 40–57. [Google Scholar] [CrossRef]

- EMBRAPA. História.Empresa Brasileira de Pesquisa Agropecuária 2023. Https://Www.Embrapa.Br/Agroenergia/Historia.

- FAOSTAT Food Balance Sheets. 2020. Available online: http://www.fao.org/faostat/en/#data/FBS (accessed on 24 April 2020).

- Furtado, A.; Scandiffio, M. The Ethanol Promise in Brazil. Scientific American, Special Edition Brazil, 2006, 53.

- Furtado, A.T.; Scandiffio, M.I.G.; Cortez, L.A.B. The Brazilian sugarcane innovation system. Energy Policy 2011, 39, 156–166. [Google Scholar] [CrossRef]

- Goldemberg, J. Ethanol for a Sustainable Energy Future. Science 2007, 315, 808–810. [Google Scholar] [CrossRef] [PubMed]

- Grassi, M.; Pereira, G. Energy-cane and RenovaBio: Brazilian vectors to boost the development of Biofuels. Ind. Crop. Prod. 2018, 129, 201–205. [Google Scholar] [CrossRef]

- Guo, B.; Dai, S.; Wang, R.; Guo, J.; Ding, Y.; Xu, Y. Combined effects of elevated CO2 and Cd-contaminated soil on the growth, gas exchange, antioxidant defense, and Cd accumulation of poplars and willows. Environ. Exp. Bot. 2015, 115, 1–10. [Google Scholar] [CrossRef]

- Gupta, V.K.; Tuohy, M.G.; Kubicek, C.P.; Saddler, J.; Xu, F. Bioenergy Research: Advances and Applications; Elsevier BV: Amsterdam, NX, Netherlands, 2014; ISBN 9780444595614. [Google Scholar]

- He, L.-Y.; Hou, L.-Q.; Lin, H.; Du, S.-F. Biofuels or hybrid vehicles? A scenario perspective in China. Energy Sources, Part B: Econ. Planning, Policy 2016, 11, 443–449. [Google Scholar] [CrossRef]

- Hotta, C.T.; Lembke, C.G.; Domingues, D.S.; Ochoa, E.A.; Cruz, G.M.Q.; Melotto-Passarin, D.M.; Marconi, T.G.; Santos, M.O.; Mollinari, M.; Margarido, G.R.A.; et al. The Biotechnology Roadmap for Sugarcane Improvement. Trop. Plant Biol. 2010, 3, 75–87. [Google Scholar] [CrossRef]

- IAC. BRASIL/Açúcar. Rio de Janeiro: MIC/IAC 2021. Https://Www.Iac.Sp.Gov.Br/Areasdepesquisa/Cana/Centrocana.Php?Pg=historicocana.

- IPCC. Intergovernmental Panel on Climate Changes. Special report: Global Warming of 1.5oC. 2018. Https://Www.Ipcc.Ch/Sr15/.

- IPCC, 2021. Summary for Policymakers. In Climate Change 2021 – The Physical Science Basis (pp. 3–32). Cambridge University Press. [CrossRef]

- IRENA. Recycle Bioenergy. Circular Carbon Economy report 05—the United Arab Emirates: The International Renewable Energy Agency (IRENA). 2020. Https://Www.Irena.Org/Publications/2020/Sep/Recycle-Bioenergy.

- Karp, A.; Shield, I. Bioenergy from plants and the sustainable yield challenge. New Phytol. 2008, 179, 15–32. [Google Scholar] [CrossRef] [PubMed]

- Köberle, A.C. The Value of BECCS in IAMs: a Review. Curr. Sustain. Energy Rep. 2019, 6, 107–115. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, A.; Pal, A. Overview of hydrogen production from biogas reforming: Technological advancement. Int. J. Hydrogen Energy 2022, 47, 34831–34855. [Google Scholar] [CrossRef]

- Lawrence, S. Free online availability substantially increases a paper's impact. Nature 2001, 411, 521–521. [Google Scholar] [CrossRef]

- Leão, R. M. Álcool, energia verde. Iqual, 2002, 255.

- Lima, D.; Santos, H.; Tiné, M.; Molle, F.; Buckeridge, M. Patterns of expression of cell wall related genes in sugarcane. Genet. Mol. Biol. 2001, 24, 191–198. [Google Scholar] [CrossRef]

- Lima, J. A intervenção governamental no setor açucareiro: ênfase à problemática do subsídio de equalização [Tese de Doutorado]. Universidade de São Paulo. 1992.

- LNBIO. National Laboratories: Brazilian Synchrotron Light Laboratory. 2023. https://Lnbr.Cnpem.Br/Overview/.

- Macedo, I. Situação atual e perspectivas do etanol. Estudos Avançados, São Paulo 2007, 21, 157–165. [Google Scholar] [CrossRef]

- MAPA. Ministério de Agricultura Pecuária e Abastecimento do Brasil. 2023. https://Sistemasweb.Agricultura.Gov.Br/.

- Martinelli, L.A.; Filoso, S. Expansion Of Sugarcane Ethanol Production In Brazil: Environmental And Social Challenges. Ecol. Appl. 2008, 18, 885–898. [Google Scholar] [CrossRef]

- Matsuoka, S.; Ferro, J.; Arruda, P. The Brazilian experience of sugarcane ethanol industry. Vitr. Cell. Dev. Biol. - Plant 2009, 45, 372–381. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Moraes, M.; Bacchi, M. Etanol: do início às fases atuais de produção. Revista de Política Agrícola. 2015. Https://Seer.Sede.Embrapa.Br/Index.Php/RPA/Article/View/950.

- Moreira, J.R.; Goldemberg, J. The alcohol program. Energy Policy 1999, 27, 229–245. [Google Scholar] [CrossRef]

- Nakashima, S.d.O., Jr. Comparative exergy assessment of vinasse disposal alternatives: Concentration, anaerobic digestion and fertirrigation. Renew. Energy 2019, 147, 1969–1978. [Google Scholar] [CrossRef]

- Nickell, L.G.; Maretzki, A. Growth of Suspension Cultures of Sugarcane Cells in Chemically Defined Media. Physiol. Plant. 1969, 22, 117–125. [Google Scholar] [CrossRef]

- Nigro, F., S. A. O etanol como combustível. In: Sousa, E. L. L. de; Macedo, I. de C. (Org.). Etanol e Bioeletricidade: A Cana-de-Açúcar No Futuro Da Matriz Energética. São Paulo: Luc Projetos de Comunicação 2010, 6, 154–189.

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Pimentel, L. S. The Brazilian Ethanol Program. Biotechnology and Bioengineering, John Wiley & Sons, Inc, 1980; 22, 1989–2012.

- R Core Team. R Foundation for Statistical Computing. 2022.

- Ramos, P. Os mercados mundiais de açúcar e a evolução da agroindústria canavieira do Brasil entre 1930 e 1980: do açúcar ao álcool para o mercado interno. Econ. Apl. 2007, 11. [Google Scholar] [CrossRef]

- Rapier, R. Fossil fuels still supply 84 percent of world energy - and other eye openers from BP’s Annual Review. 2019. https://www.forbes.com/sites/rrapier/2020/06/20/bp-review-new-highs-in-global-nergy-consumption-and-carbon-emissions-in-2019/?sh=61a41b4966a1.

- Reifschneider FJB, H. G. R. C. A. U. and F. R. Novos ângulos da história da agricultura no Brasil. Embrapa Informação Tecnológica, Brasília, 2010; 112.

- Reinach, F. Impactos da genômica na agricultura brasileira. Revista de Pesquisa Fapesp, São Paulo, www.revistapesquisa2.Fapesp.Br/Pdf/Revolucao_genomica/Reinach.Pdf, 2008; 48.

- Rodrigues, C.M. Gênese e evolução da pesquisa agropecuária no Brasil: da instalação da Corte Portuguesa ao início da República. Cadernos de Ciência & Tecnologia 1987, 4, 21–38. [Google Scholar]

- Rudorff, B.F.T.; Aguiar, D.A.; Silva, W.F.; Sugawara, L.M.; Adami, M.; Moreira, M.A. Studies on the Rapid Expansion of Sugarcane for Ethanol Production in São Paulo State (Brazil) Using Landsat Data. Remote. Sens. 2010, 2, 1057–1076. [Google Scholar] [CrossRef]

- Soccol, C.R.; Vandenberghe, L.P.d.S.; Medeiros, A.B.P.; Karp, S.G.; Buckeridge, M.; Ramos, L.P.; Pitarelo, A.P.; Ferreira-Leitão, V.; Gottschalk, L.M.F.; Ferrara, M.A.; et al. Bioethanol from lignocelluloses: Status and perspectives in Brazil. Bioresour. Technol. 2010, 101, 4820–4825. [Google Scholar] [CrossRef] [PubMed]

- Songstad, D. D., L. P., C. J. , G. W. , H. S. , N. R. Historical Perspective of Biofuels: Learning from the Past to Rediscover the Future. In Vitro Cellular & Developmental Biology, 2054.

- Szymanski, M.S.E.; Balbinot, R.; Schirme, W.N. Anaerobic digestion of vinasse: energy use of biogas and obtaining carbon credits - case study. 2010. https://www.Uel.Br/Revistas/Uel/Index. 7596. [Google Scholar]

- Vettore, A.L.; da Silva, F.R.; Kemper, E.L.; Souza, G.M.; da Silva, A.M.; Ferro, M.I.T.; Henrique-Silva, F.; Giglioti, A.; Lemos, M.V.; Coutinho, L.L.; et al. Analysis and Functional Annotation of an Expressed Sequence Tag Collection for Tropical Crop Sugarcane. Genome Res. 2003, 13, 2725–2735. [Google Scholar] [CrossRef] [PubMed]

- Walter, A.; Dolzan, P.; Quilodran, O.; Gracia, J.; Da Silva, C.; Piacente, F. Sustainability Analysis of the Brazilian Ethanol. 2018. http://www.globalbioenergy.org/uploads/media/0811_unicamp_- a_sustainability_analysis_of_the brazilian_ethanol.pdf.

- Watanabe, M.D.; Morais, E.R.; Cardoso, T.F.; Chagas, M.F.; Junqueira, T.L.; Carvalho, D.J.; Bonomi, A. Process simulation of renewable electricity from sugarcane straw: Techno-economic assessment of retrofit scenarios in Brazil. J. Clean. Prod. 2020, 254, 120081. [Google Scholar] [CrossRef]

- Wrangham, R. Pegando Fogo: Por que cozinhas nos tornou humanos. Editora Zahar, Rio de Janeiro, 2010, 226.

- Zhang, M.; Govindaraju, M. Sugarcane Production in China. In Sugarcane - Technology and Research. InTech. 2018. [CrossRef]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).